Abstract

Fruit pomace is a highly valuable byproduct from a nutritional standpoint. The aim of this study was to determine the physicochemical and sensory properties of wheat bread enriched with freeze-dried and powdered chokeberry pomace in amounts of 1, 2, 3, 4, 5, and 6% relative to the flour weight. The influence of pomace addition on the physical properties of the wheat dough was analyzed, and the physicochemical properties and consumer acceptance of the chokeberry-pomace-enriched bread were determined. Based on the obtained research results, it was shown that the addition of pomace increased the water absorption of the flour but caused a decrease in stability and weakening of the dough, resulting in increased softening. Consequently, the volume of the bread decreased, and the crumb hardness increased. Furthermore, the addition of pomace significantly reduced the brightness and yellowness of the bread crumbs, while making them more red. Importantly, compared to the control bread, the pomace-enriched bread was characterized by higher contents of minerals, dietary fiber, phenolic compounds, and higher antioxidant activity. Sensory evaluation showed that the addition of freeze-dried chokeberry pomace to wheat bread should not exceed 3% in relation to the weight of the flour used. Additionally, a 3% addition of chokeberry pomace increased the dietary fiber content by 80.9%, ash content by 2.6%, fat content by 26.5%, and total phenolics content by 272%. It decreased the protein content by 1.2%, and reduced the carbohydrate content by 4% compared to the control sample.

1. Introduction

Bread is one of the basic food products consumed widely in many regions of the world. In Europe, wheat bread is particularly popular, most often produced from low-extraction white flour. The advantages of such bread are a crunchy crust, soft, fluffy, and light-colored crumbs, and easy digestibility [1]. However, white wheat bread is characterized by a relatively low nutritional value, containing a high amount of carbohydrates and little dietary fiber, mineral components, vitamins, or other bioactive compounds, regular consumption of which is an essential element of preventive healthcare [2,3].

In recent years, a popular trend has been to enrich the recipe of food with additional ingredients to obtain a product with functional properties [4]. Bread, due to its frequent consumption, provides a good food matrix for introducing various recipe additives, such as oily plant seeds [5], flour from other types of grains or pseudocereals [6,7,8], flour from legume seeds [9,10], spices, herbs [11,12,13,14], and dried vegetable and fruit extracts [15,16], as well as waste products from the processing of plant raw materials, such as bran, brewer’s spent grain, or pomace [17,18,19]. It should be emphasized that waste products can be particularly valuable recipe ingredients for bread, as they are often characterized by a much higher content of valuable nutritional components than the raw materials from which they were processed [20]. The use of waste products is in line with the EU’s policy on waste-free food production and is one of the elements of the circular economy strategy [21].

A plant with exceptional chemical composition of its fruit is the black chokeberry (Aronia melanocarpa (Michx.) Elliott), a perennial deciduous shrub from the Roseaceae family. This plant comes from North America and is characterized by low soil requirements and high frost and disease resistance, and is currently widely cultivated in the northern and eastern parts of Europe. Aronia fruits are spherical in shape and are gathered in clusters. When ripe, they have a dark pomegranate to black color, are covered with a waxy coating, and are slightly shiny [22]. The dry matter content in aronia fruits is 17.9–26.0% [22,23], including 13.7–15.1% carbohydrates, 4.8–6.3% dietary fiber, 0.7% protein, and 0.2% fat [24]. Aronia fruits are characterized by an exceptionally high content of active substances that have a beneficial effect on the body, which is why they are called a superfruit or superberry [23]. These compounds include polyphenols, including anthocyanins, flavonoids, tannins, and phenolic acids. The total content of polyphenols in aronia fruits is 2000–8000 mg per 100 g of dry matter, including about 500 mg of anthocyanins [22,25]. The most important compounds from the group of anthocyanins are cyanidin glycosides (3-O-galactoside, 3-O-arabinoside, 3-O-xyloside, and 3-O-glucoside) [25]. Aronia fruits are also rich in phenolic acids, mainly chlorogenic and neochlorogenic acid [23]. They also contain flavonoid glycosides, with quercetin 3-O-galactoside and quercetin 3-O-glucoside being the most prevalent. Tannins are also included in the phenolic compounds, with a content of approximately 0.4% [22]. Together with organic acids, they contribute to the tart taste of the fruits. In addition, aronia fruits are a source of vitamins, especially vitamin C, as well as vitamins E, K, B1, B2, B3, B5, B6, and folic acid [24], and macro- and microelements, including magnesium, potassium, calcium, iron, iodine, molybdenum, and manganese [24,26,27].

Ripe aronia berries are characterized by a tart and bitter taste, and therefore are rarely consumed in their unprocessed form as a dessert fruit. They are widely used in processing as a raw material for the production of juices, jams, preserves, beverages, wines, liqueurs, and infusions, as well as fruit teas and jellies, and for obtaining food extracts and dyes [23,28]. During the processing of the berries, waste is produced in the form of pomace. Mayer-Miebach et al. [23] have shown that pomace has a much greater antioxidant activity than the fruit or juice.

The aim of this study was to determine the effect of lyophilized pomace on the properties of dough and the quality of wheat flour bread, as well as to determine the maximum level of this additive acceptable to consumers.

2. Materials and Methods

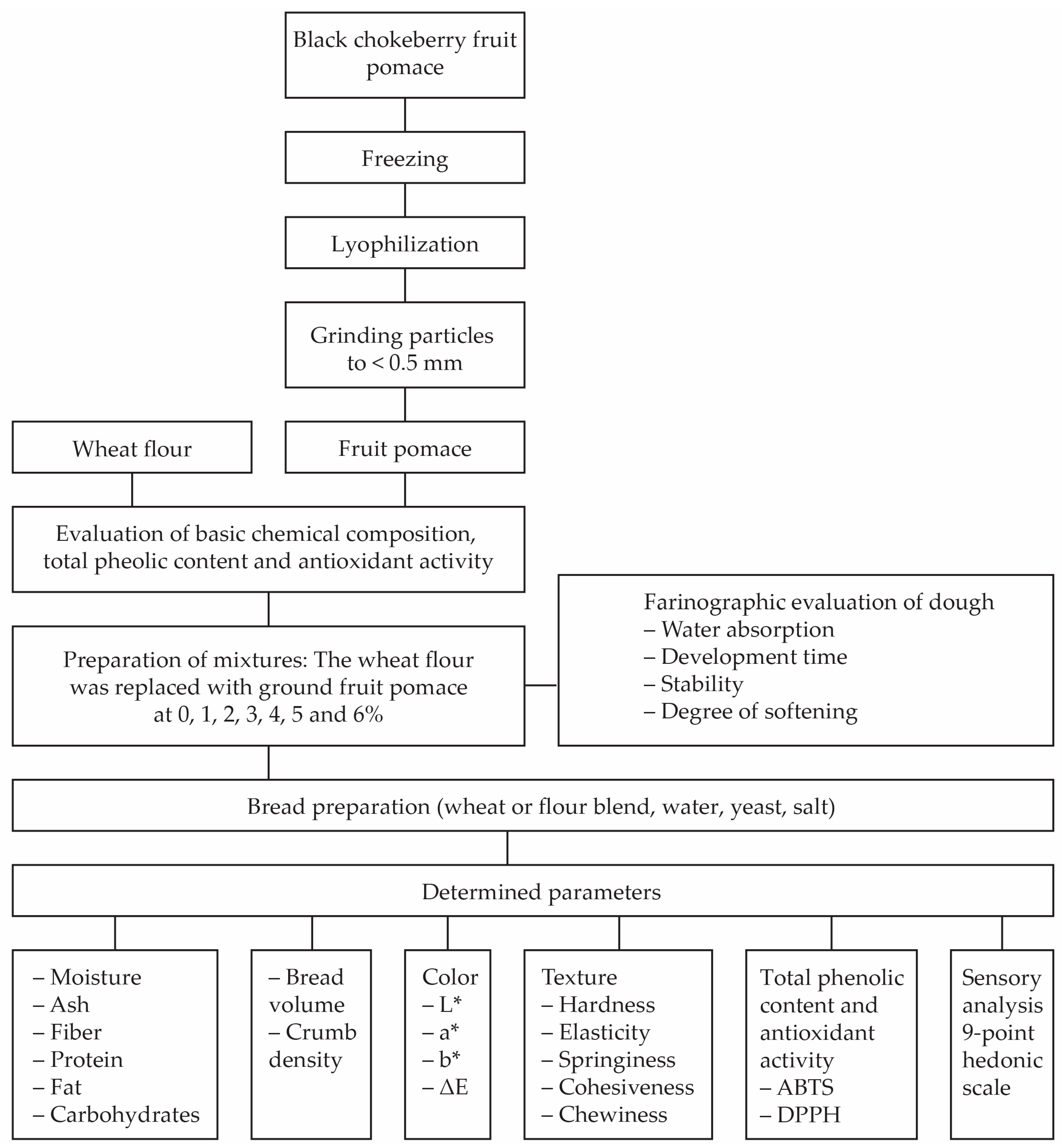

The scope of the conducted research is schematically presented in Figure 1.

Figure 1.

Graphic diagram of conducted research.

2.1. Materials

The following chemical reagents were used for the research: sodium salicylate, gallic acid, ferrozine (3-(2-pyridyl)-5,6-bis-(4-phenyl-sulfonic acid)-1,2,4-triazone), and ABTS (2,2′-azino-bis-(3-ethylbenzothiazoline-6-sulfonic acid)) in analytical purity. All reagents were purchased from Sigma-Aldrich (Poznań, Poland).

For the preparation of the bread dough, the following ingredients were used: commercial bread wheat flour type 750 (Polskie Młyny S.A., Warsaw, Poland), fresh pressed yeast (Lesaffre Polska S.A., Wołczyn, Poland), table salt (Cenos Sp. z o.o., Września, Poland), and freeze-dried pomace from black chokeberries. The pomace used in the study was a waste product obtained during laboratory juice extraction. Immediately after extraction, the pomace was frozen at −25 °C and then subjected to freeze-drying using an Alpha 1–4 LSC Plus freeze-dryer with shelf heating (Martin Christ Gefriertrocknungsanlagen GmbH, Osterode am Harz, Germany). The shelf temperature was set at 20 °C, the condenser temperature at −56 °C, and the pressure at 0.1 kPa. After drying, the pomace was vacuum-sealed in foil pouches. Prior to analysis, the pomace was ground to particles below 0.5 mm using an analytical mill A11 (IKA Works GmbH & Co., Staufen im Breisgau, Germany).

2.2. Basic Composition of Raw Materials and Bread

The basic composition of the raw materials (wheat flour, freeze-dried pomace from black chokeberries), as well as the bread samples, was determined using AACC methods [29]. Moisture content was determined using the gravimetric drying method (Method 44-15.02) using a SUP-65 W drying oven (Wamed, Warsaw, Poland). Total ash content was determined with the incineration method (Method 08-01.01) using an FCF S muffle furnace (Czylok, Jastrzębie Zdrój, Poland). Total dietary fiber content (Method 32-05.01) was determined using a Fibertec 2010 apparatus (Foss, Hillerod, Denmark). Total protein content was determined with the Kjeldahl method (Method 46-11.02) using a Kjeltec 8200 apparatus (Foss, Hillerod, Denmark). Total fat content was determined with the Soxhlet method (Method 30.10.01) using a Soxtec Labtec Line ST 243 apparatus with a Cu 2046 Control Unit Controller (Foss, Hillerod, Denmark). Carbohydrate content was calculated as the difference between 100 and the sum of the other components (water, ash, protein, fat, and fiber).

2.3. Properties of Flour and Dough

In wheat flour, the yield and quality of wet gluten were determined using the mechanical method (Method 38.12) on the Glutomatic 2200 device (Perten Instruments, Stockholm, Sweden), and the falling number was determined using the Hagberg–Perten method (Method 56-81B) on the Falling Number 1400 device (Perten Instrument, Stockholm, Sweden). The water absorption of the flour and the rheological properties of the dough were also evaluated using the Farinograph-E model 810114 (Brabender GmbH & Co. KG, Duisburg, Germany) according to AACC Method 54-21 [29]. Prior to the analysis, mixtures were prepared in which wheat flour was replaced with lyophilized pomace from black chokeberries in amounts of 1, 2, 3, 4, 5, and 6% relative to the flour weight. The control sample consisted of dough made from wheat flour. The water absorption of the flour mixtures was determined based on the amount of water added from a burette needed to achieve a dough consistency of 500 FU, and the rheological properties of the dough (development time, stability time, degree of softening after 12 min of mixing) were determined from the normal curve graph using the Farinograph v.5 computer program.

2.4. Baking Procedure

Bread dough was prepared using the direct method according to the methodology provided by Cacak-Pietrzak et al. [3]. The basic recipe for the bread dough (control sample (CP)) included 500 g of wheat flour, 15.0 g of fresh compressed yeast, 7.5 g of salt, and water in the amount necessary to achieve a dough consistency of 350 FU. This consistency is especially preferred for the process of bread production in molds [3]. The amount of water added was calculated based on the determined farinographic water absorption. Wheat flour was replaced with pomace from black chokeberries in the following amounts: 1, 2, 3, 4, 5, and 6% (CP1, CP2, CP3, CP4, CP5, and CP6, respectively) relative to the flour weight. The dough ingredients were mixed in an SP-800A mixer (Spar Food Machinery, Taichung, Taiwan) for 4 min at speed level 2. The dough was fermented in a fermentation chamber D-32 (Sveba Dahlen, Fristad, Sweden) for 90 min, with punching performed after 60 min for 1 min. After fermentation, the dough was divided into 250 g portions, shaped by hand, placed in molds, and subjected to proofing for 40 min in the fermentation chamber. Baking took place in the D-32 oven (Sveba Dahlen, Fristad, Sweden) at a temperature of 230 °C for 30 min. After baking, bread samples were removed from the molds, cooled, and then packed in polyethylene bags and stored for 24 h at a temperature of 20–22 °C.

2.5. Basic Properties of Bread

After 24 h of baking, the bread loaves were weighed, the bread yield was calculated, and the loaf volume and crumb density were determined. The loaf volume was measured using a 3D scanner (NextEngine, West Los Angeles, CA, USA) with computer software (MeshlLab 2016, ISTI-CNR Research Center, Rome, Italy) following the methodology described by Romankiewicz et al. [5], and then converted to 100 g of bread. The crumb density of the bread was determined according to the methodology provided by Belyaev et al. [30]. The procedure involved cutting cubes of known volume from the middle part of the crumb, weighing them, and calculating the crumb density.

2.6. Bread Texture

Texture profile analysis of the bread crumbs was conducted using a texture analyzer TA.XT2i (Stable Microsystem, Surrey, UK). The measurement was performed according to the methodology described by Armero and Collar [31]. Cylindrical samples (diameter 30 mm) were cut from bread slices with a thickness of 20 mm and subjected to compression using a probe with a diameter of 25 mm. The sample penetration was set at 40%, with a 45-second pause between the first and second compression, and a probe speed of 1 mm s−1. From the obtained curve, the following parameters were determined: hardness, elasticity, springiness, cohesiveness, and chewiness of the crumbs.

2.7. Color Coordinates

The color coordinates of the bread samples were determined using the reflective method in the CIE-Lab* color space, where L* represents lightness, a* indicates redness (+)/greenness (−), and b* indicates yellowness (+)/blueness (−). Measurements were performed using a CR-200 colorimeter (Konica Minolta, Osaka, Japan). From the average values of the Lab* color components, the absolute color difference (ΔE*) between the bread made from wheat flour (control sample) and the bread with the addition of freeze-dried black chokeberry pomace was calculated using the formula provided by Różyło et al. [32].

2.8. The Content of Total Phenolic and Antioxidant Activity

The total polyphenol content (TPC) and antioxidant activity (AA) were determined in the raw materials (wheat flour, freeze-dried black chokeberry pomace) as well as in the bread. The ability to scavenge DPPH free radicals and ABTS•+ cation radicals was assessed.

2.8.1. Extract Preparation for TPC and AA Evaluation

The extracts of the bread samples were prepared according to the methodology described by Gawlik-Dziki et al. [33]. Samples weighing 1 ± 0.0001 g were weighed on an analytical balance and extracted with 25 cm3 of PBS buffer (pH = 7.4) at room temperature for 60 min. The mixture was then centrifuged, and the supernatant was separated. The extraction process was repeated three times, and the supernatants were combined and stored in a dark place at a temperature of −20 °C.

2.8.2. Total Phenolic Content

The total polyphenol content was determined using the Folin–Ciocalteu spectrophotometric method, following the methodology described by Singleton and Rossi [34]. For the analysis, 0.5 mL of the buffer extract was taken, and 0.5 mL of distilled water, 2 mL of Folin reagent (diluted 1:5 with water), and 2 mL of a 10% Na2CO3 solution were added. The mixture was thoroughly mixed and left to stand for 60 min. The absorbance of the solution was measured using a UV Mini 1240 spectrophotometer (Shimadzu, Kyoto, Japan) at a wavelength of 720 nm against a blank sample (PBS buffer). The total polyphenol content was expressed in milligrams of gallic acid equivalents (mg GAE) per gram of dry matter (DM).

2.8.3. The Ability to Scavenge DPPH Free Radicals

The ability to scavenge DPPH free radicals was determined using a spectrophotometric method according to the methodology described by Brand-Williams et al. [35]. For the analysis, 0.01 mL of the buffer extract was taken, and 0.25 mL of an ethanol solution of DPPH was added. After thorough mixing, the mixture was left to stand for 15 min. The absorbance of the solution was measured using a microplate spectrophotometer (BioTek, Santa Clara, CA, USA) at a wavelength of 725 nm. The ability to scavenge DPPH free radicals was expressed as EC50, which represents the concentration at which the DPPH radicals were reduced by 50%.

2.8.4. The Ability to Scavenge ABTS•+ Cation Radicals

The ability to scavenge ABTS•+ cation radicals was determined using a spectrophotometric method according to the methodology described by Re et al. [36]. For the analysis, 0.04 mL of the buffer extract and 1.8 mL of the ABTS•+ radical were taken. After 5 min, the absorbance of the solution was measured using a UV Mini 1240 spectrophotometer (Shimadzu, Kyoto, Japan) at a wavelength of 734 nm. The ability to scavenge ABTS•+ cation radicals was expressed as EC50, which represents the concentration at which the ABTS•+ radicals were reduced by 50%.

2.9. Sensory Evaluation of Bread

The sensory evaluation of the bread was conducted according to the methodology provided by Garcia-Gómez et al. [37], 24 h after baking. The evaluation panel consisted of 46 assessors (employees and students of Warsaw University of Life Sciences) aged 21–56. The bread samples were assessed on a 9-point hedonic scale, where 1 represented very undesirable and 9 represented very desirable. The evaluation took into account the following quality attributes of the bread: loaf appearance, crust appearance, crumb properties, taste and aroma, and overall acceptability.

2.10. Statistical Analysis

All measurements were performed in a minimum of three parallel repetitions. Statistical analysis of the obtained results was conducted using Statistica 13.3 software (TIBCO Software, Palo Alto, CA, USA). Analysis of variance (ANOVA) was performed, and homogeneous groups were determined using Tukey’s test. Additionally, the Pearson’s correlation coefficients between variables were determined. All statistical tests were performed with a significance level of α set at 0.05.

3. Results and Discussion

3.1. Physical Properties of Dough

The physical properties of dough measured by the farinograph can help to adjust the bread recipe and consequently allow for the optimization of bread production [38]. Addition of CP into wheat dough resulted in a linear increase in water absorption of flour from 59.07% for the control sample to 60.97% for dough with 6% of CP flour (Table 1). This means that the dough can hold more water, which can affect the bread yield and texture. A strong and positive linear relation was found between the level of wheat flour replacement with CP and flour water absorption (r = 0.982, p = 0.001). Higher water absorption of enriched flour probably results from the high content of fiber in pomace. Similar effects on wheat flour water absorption were observed by others authors after the addition of powders rich in fiber [1,39]. Interestingly, incorporation of AP into wheat flour had no significant influence on the development time but significantly decreased the stability of dough during mixing. These parameters can vary depending on the type of flour and used additives [14]. Typically, higher values of these parameters result in a stronger gluten structure and a firmer dough, while a shorter development time and stability result in a weaker gluten structure and a softer dough [2]. The stability of the dough decreased linearly (r = −0.951, p = 0.001) from 5.83 (CD) to 2.13 min (CDP6). It indicated that AP considerably weakened the gluten structure. It was also confirmed by the linear increase in degree of dough softening with the increase in percentage of CP in wheat flour. The control dough was characterized by an approximately twofold lower degree of softening compared with the AP6 dough sample. A strong and positive correlation was found between this parameter and the level of CP in dough (r = 0.965, p = 0.001). Degree of softening is an important indicator of the quality of the flour. A high degree of softening indicates that the flour is weak and has poor gluten-forming ability, which can result in a low volume and dense crumbs. On the other hand, lower values of this parameter indicate that the flour has strong gluten-forming ability, which usually indicates a well-risen bread with a good crumb structure.

Table 1.

Physical properties of control dough and dough enriched with chokeberry powder.

3.2. Basic Properties of Bread Samples

The addition of CP into wheat flour resulted in a linear decrease in baking loss (r = −0.971, p = 0.001). This loss decreased from 13.6% (C) to 10.7% (CP6) (Table 2). Baking loss refers to the reduction in weight that occurs during the baking process, primarily caused by the loss of water but also due to the evaporation of volatile substances such as carbon dioxide, alcohol, and volatile acids. This loss of weight can affect the texture, taste, and appearance of the final product, which is why it is important to understand the factors that contribute to baking loss and take steps to minimize it [40]. The decrease in baking loss with the increased percentage of CP in the bread recipe could have resulted from the higher water holding capacity of the CP. Similar results were obtained by other authors when potato flour was incorporated into wheat bread [41]. Importantly, CP increased the yield of bread from 137.8 to 144.1%. This is because CP is high in dietary fiber, which has the ability to absorb water and hold it in the bread dough during processing, leading to better dough consistency and less water loss during baking. On the other hand, bread volume decreased and, as a result, the density of the bread increased with the higher percentage of CP (r = −0.989, p = 0.001 and 0.988, p = 0.001, respectively). These changes usually have a negative influence on bread texture, leading to a more compact and harder crumbs [9].

Table 2.

Basic properties of control and enriched bread samples.

3.3. Crumb Texture

The increase in the proportion of CP in the bread recipe resulted in a significant increase in the bread’s crumb hardness. This trend was observed after both 24 and 72 h of bread storage. However, storage itself had a relatively minor impact on this parameter. The crumb hardness of the bread changed from 7.77 to 21.36 N and from 8.43 to 22.54 N after one and three days of storage, respectively (Table 3). It should be noted that the addition of 6% CP caused an approximately threefold increase in this parameter compared to the control bread. These changes are attributed to a decrease in volume and an increase in crumb density due to the addition of CP, resulting in a more compact and harder crumbs. Enriching the bread had a similar effect on the chewiness of the crumbs. CP influenced the increase in these parameter, primarily due to the increase in crumb hardness. On the other hand, bread storage generally did not have a significant impact on gumminess or chewiness. However, the elasticity and cohesiveness of the crumbs decreased under the influence of CP, although the differences between the means were mostly insignificant. The highest values of these parameters were obtained for the control bread. After 72 h of storage, both the control and enriched bread showed significantly lower elasticity and cohesiveness compared to the values after 24 h since baking. The replacement of wheat flour with 6% CP addition, similar to storage, did not have a significant impact on the crumb springiness. Several authors have suggested that partial substitution of wheat flour with powdered fruits and other plant additives weakens the dough structure, resulting in decreased volume due to reduced carbon dioxide retention during dough fermentation [42], which consequently negatively affects the bread texture, particularly in terms of crumb hardness [3].

Table 3.

Texture parameters of control and enriched bread samples.

3.4. Color Coordinates

The color of food products is a crucial determinant of consumer acceptability, including for bread. The lightness values (L*) were the highest for the control sample, while those for bread enriched with 5 and 6% CP were the lowest and not significantly different from each other. Specifically, the L* value ranged from 72.00 for the control sample to 37.53 for the bread enriched with 6% CP (Table 4). The color of the bread gradually became darker with increasing levels of fruit supplementation, and the brightness was influenced by the extent of enrichment. Petković et al. [43] reported a significant decrease in bread brightness only at 10% chokeberry fruit powder supplementation, while concentrations of 1, 2.5, and 5% CP did not cause a significant change, compared to the control. The discrepancies in the results could potentially be attributed to variations in amount of used additive. Specifically, in the cited study, the fruits were subjected to convection drying, while in this research, freeze-dried CP was used. Furthermore, the addition of chokeberry led to a significant increase in redness (a*), which was dependent on the concentration of the additive. The sample containing 6% CP had the highest a* value, while the control sample had the lowest, with values of 12.74 and 1.92, respectively. In general, the decline in b* values was associated with the concentration of CP. However, there were no significant differences in b* values between breads enriched with 4 and 5% additive or between those enriched with 5 and 6% additive. Therefore, changes in yellowness were more evident at lower (1–3%) enrichment levels. The control and bread enriched with 6% CP exhibited the highest and lowest b* values, respectively, with values of 16.83 and 0.97. In another study by Petković et al. [43], it was observed that the b* value of bread decreased with the addition of powdered chokeberry fruit. However, the significant reduction was only observed at higher substitution levels (10% for powder dried at 50, 60, and 70 °C, and 5% for powder dried at 70 °C), indicating that the incorporation of freeze-dried chokeberry pomace in our study had a greater effect on the change in yellowness than the addition of convection-dried chokeberry fruits. The total color difference (ΔE) ranged from 15.22 to 37.88 for the control and the bread enriched with 5% CP, respectively. This demonstrates that the incorporation of CP into bread had a strong influence on the color of enriched bread. The red pigment fraction, composed of cyanidin derivatives, is mainly responsible for these color changes [44].

Table 4.

Results of colorimetric measurements of control and enriched bread samples.

3.5. Basic Chemical Composition of Raw Materials and Bread

CP enriched the bread in terms of mineral, TDF, and fat content. In particular, TDF content increased almost threefold, from 3.56 (C) to 9.27% (CP6), whereas fat and ash content changed from 1.81 (C) to 2.56% (CP6) and from 0.928 (C) to 0.974% (CP6), respectively (Table 5). Conversely, increasing the percentage of CP in the bread tends to decrease the protein and carbohydrate content. However, the differences in protein content between the samples were small, and the addition of up to 3% CP was not statistically influential on this component. The correlation analysis revealed significant linear relations (p < 0.05) between pomace content in bread and ash, TDF, fat, protein, and carbohydrate content (r = 0.998; 0.972; 0.998, −0.975 and −0.998, respectively). Bread enriched with chokeberry pomace can be a valuable source of fiber and minerals. CP is an especially rich source of such macroelements (K, Ca, Mg and Na) and microelements (B, Cr, Cu, Fe, Mn, Ni, Se, Sr and Zn) [27]. Moreover, CP is a also abundant in insoluble dietary fiber, which makes up 76% of its total fiber content. It also contains about 20% of high molecular weight soluble fraction and 4% low molecular weight soluble fiber fraction [45].

Table 5.

Basic composition [% DM] of raw materials and bread samples.

3.6. Phenolics Content and Antioxidant Capacity

Chokeberry pomace is known to be abundant in phenolic compounds, especially anthocyanins, which have antioxidant properties and may provide various health benefits [46]. The content of TPC and AA of raw materials and enriched breads is presented in Table 6. CP contained the highest phenolics content with the strongest antioxidant activity. Most phenolic compounds are primarily found in the fruit skin. As a result, a considerable amount of these compounds are retained in the CP even after the extraction of juice from the fruit [47]. Kapci et al. [48] found about 63 mg GAE g DM−1 of TPC in chokeberry pomace. This effect was visible in the enrichment of bread. With the addition of 1% CP, the TPC doubled; with 6% addition, it was about 4.5 times higher compared to the control sample (Table 6). The relationship between the percentage of CP and TPC in bread samples was linear (r = 0.987, p = 0.001). Consequently, antioxidant capacity of enriched bread increased (decrease in EC50 index). Both ABTS and DPPH antiradical activity increased with the percentage of CP in the bread recipe. However, the relations were non-linear, and the highest decrease in EC50 was observed when wheat flour was replaced with 1% of CP from 552.47 to 202.33 mg DM mL−1 and from 194.37 to 115.89 mg DM mL−1, for ABTS and DPPH, respectively. Other authors also found that CP significantly increased TPC and antioxidant capacity of shortbread cookies [49].

Table 6.

Phenolics content and antioxidant capacity of raw materials, control, and enriched bread samples.

3.7. Sensory Evaluation Results

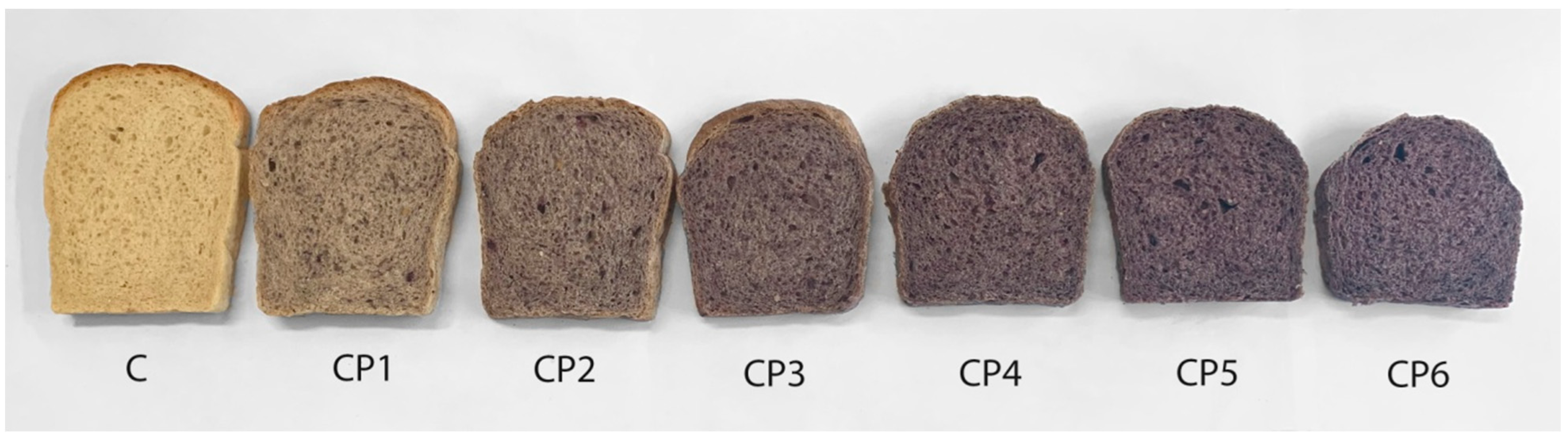

The acceptance of food products by consumers is a very important element of their presence on the market. The final acceptability of bread depends on both the type and quality of the raw materials used, as well as the applied technological process. When evaluating the overall appearance of a loaf, consumers paid attention to the degree of its rising and shape, as well as the appearance of the crust surface. The picture of the control and enriched bread is presented in Figure 2. The addition of CP caused the crust color to become darker and gradually take on a purple hue. The control sample and bread with the addition of 1 to 4% pomace were characterized by a shiny crust, while the crust of bread with 5 and 6% CP addition was matte, with visible cracks and unevenness on its surface. The highest scores for appearance acceptability were given by evaluators to the control bread, which had the most uniform shape, was the best risen, and had no visible mechanical damage. The addition of CP caused the bread loaves to have a lower degree of rising and an irregular shape. The appearance of bread with more than 3% CP was generally not accepted by consumers, and all attempts with a higher content of this addition received a rating below 5 points on a 9-point hedonic scale (Table 7). Five points on the hedonic scale (neither like or dislike) can be considered as the threshold of consumer acceptability for a product [50]. However, it is worth remembering that the threshold of acceptability may vary depending on the context, product, or target group. The final assessment of consumer satisfaction depends on various factors such as expectations, preferences, and individual experiences. The taste and aroma of the control bread were rated the highest. The introduction of CP into the bread recipe up to 2% allowed for the production of products with good acceptability according to these indicators. A higher addition of CP was poorly accepted by consumers. Panelists found that, as the pomace content in the bread recipe increased, its taste became too acidic and tart, and the smell was unique. When evaluating the bread texture, evaluators observed that the crumbs were more compact and hard above 3% CP addition. As a result, all breads above this enrichment level were already unacceptable to consumers. In summary, the overall acceptability rating showed that the addition of dried and powdered pomace to wheat bread should not be higher than 3% relative to the amount of flour used. Many authors have shown that replacement of wheat flour with different powdered and dried plant materials in wheat bread production should not exceed a few percentage points [3,51], whereas, in the case of others cereal products such pasta or cookies, this level can be higher [52,53]. The main reason for this is the unfavorable effect of the plant additives used on the volume of bread. These additives weaken the structure of the gluten network, and as a result, the bread loses its ability to retain carbon dioxide, which often leads not only to a decrease in volume but also to deformation of the shape of the loaves.

Figure 2.

Picture of control and CP-enriched bread samples: C—control bread, CP1, CP2, CP3, CP4, CP5, CP6—bread enriched with 1, 2, 3, 4, 5, and 6% of chokeberry powder.

Table 7.

Results of sensory evaluation of control and enriched bread samples.

4. Conclusions

The addition of powdered chokeberry pomace to wheat flour resulted in a deterioration in the bread’s quality. There was a decrease in volume and an increase in crumb hardness. Additionally, a decrease in consumer acceptance of the enriched bread was observed, especially when the wheat flour was replaced with pomace in a proportion higher than 3%. On the other hand, the chokeberry pomace enriched the bread with dietary fiber, minerals, and phenolic compounds, and increased its antioxidant activity. Notably, the total phenolic content in the CP3 bread increased by about threefold compared to the control bread. Future studies should focus on the possibility of improving the sensory characteristics of bread enriched with chokeberry pomace by testing different types of wheat flour, dough fermentation methods, and raw material selection in order to enhance its consumer acceptability at higher levels of pomace inclusion in the bread recipe.

Author Contributions

Conceptualization: G.C.-P. and D.D.; methodology: G.C.-P., D.D., U.G.-D., N.P-N. and S.K.; software: U.G.-D. and S.K.; validation: G.C.-P. and D.D.; formal analysis: G.C.-P., N.P.-N. and A.K.; investigation: G.C.-P., D.D., U.G.-D., N.P.-N. and S.S.; resources: G.C.-P. and D.D., data curation: G.C.-P. and D.D.; writing—original draft preparation: G.C.-P., D.D. and A.K.; writing—review and editing: G.C.-P., D.D. and A.K.; visualization: G.C.-P. and S.S.; supervision: D.D.; project administration: G.C.-P.; funding acquisition: G.C.-P., D.D. and S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

Research for this publication was conducted using research equipment purchased as part of the “Food and Nutrition Centre—modernisation of the WULS campus to create a Food and Nutrition Research and Development Centre (CZi Z)” co-financed by the European Union from the European Regional Development Fund under the Regional Operational Programme of the Mazowieckie Voivodeship for 2014–2020 (Project No. RPMA.01.01.00-14-8276/17).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Conte, P.; Fadda, C.; Piga, A.; Collar, C. Techno-functional and nutritional performance of commercial breads available in Europe. Food Sci. Technol. Int. 2016, 22, 621–633. [Google Scholar] [CrossRef] [PubMed]

- Capurso, A.; Capurso, C. The mediterranean way: Why elderly people should eat whole wheat sourdough bread—A little known component of the mediterranean diet and healthy food for elderly adults. Aging Clin. Exp. Res. 2020, 32, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Cacak-Pietrzak, G.; Dziki, D.; Gawlik-Dziki, U.; Sułek, A.; Wójcik, M.; Krajewska, A. Dandelion flowers as an additive to wheat bread: Physical properties of dough and bread quality. Appl. Sci. 2023, 13, 477. [Google Scholar] [CrossRef]

- Pilipović, K.; Jurišić Grubešić, R.; Dolenec, P.; Kučić, N.; Juretić, L.; Mršić-Pelčić, J. Plant-Based Antioxidants for Prevention and Treatment of Neurodegenerative Diseases: Phytotherapeutic Potential of Laurus nobilis, Aronia melanocarpa, and Celastrol. Antioxidants 2023, 12, 746. [Google Scholar] [CrossRef] [PubMed]

- Romankiewicz, D.; Hassoon, W.H.; Cacak-Pietrzak, G.; Sobczyk, M.; Wirkowska-Wojdyła, M.; Ceglińska, A.; Dziki, D. The effect of chia seeds (Salvia hispanica L.) addition on quality and nutritional value of wheat bread. J. Food Qual. 2017, 2017, 7352631. [Google Scholar] [CrossRef]

- Sluková, M.; Levková, J.; Michalcová, A.; Horáčková, Š.; Skřivan, P. Effect of the dough mixing process on the quality of wheat and buckwheat proteins. Czech J. Food Sci. 2017, 35, 522–531. [Google Scholar] [CrossRef]

- Cao, H.; Gao, F.; Shen, H.; Su, Q.; Guan, X.; Sun, Z.; Yu, Z. Influence of partial substitution of wheat flour with sprouted oat flours on physicochemical and textural characteristics of wheat bread. J. Cereal Sci. 2023, 110, 103649. [Google Scholar] [CrossRef]

- Cotovanu, I.; Ungureanuluga, M.; Mironeasa, S. Investigation of quinoa seeds fractions and their application in wheat bread production. Plants 2021, 10, 2150. [Google Scholar] [CrossRef] [PubMed]

- Yamsaengsung, R.; Schoenlechner, R.; Berghofer, E. The effects of chickpea on the functional properties of white and whole wheat bread. Int. J. Food Sci. Technol. 2010, 45, 610–620. [Google Scholar] [CrossRef]

- Bojňanská, T.; Musilová, J.; Vollmannová, A. Effects of Adding Legume Flours on the rheological and breadmaking properties of dough. Foods 2021, 10, 1087. [Google Scholar] [CrossRef] [PubMed]

- Dziki, D.; Cacak-Pietrzak, G.; Hassonn, W.H.; Gawlik-Dziki, U.; Sułek, A.; Różyło, R.; Suger, D. The fruit of sumac (Rhus coriaria L.) as a functional additive and salt replacement to wheat bread. LWT Food Sci. Technol. 2021, 136, 110346. [Google Scholar] [CrossRef]

- Dziki, D.; Cacak-Pietrzak, G.; Gawlik-Dziki, U.; Sułek, A.; Kocira, S.; Biernacka, B. Effect of Moldavian dragonhead (Dracocephalum moldavica L.) leaves on the baking properties of wheat flour and quality of bread. CyTA—J. Food 2019, 17, 536–543. [Google Scholar] [CrossRef]

- Wójcik, M.; Różyło, R.; Łysiak, G.; Kulig, R.; Cacak-Pietrzak, G. Textural and sensory properties of wheat bread fortified with nettle (Urtica dioica L.) produced by scalded flour method. J. Food Process. Preserv. 2021, 45, e15851. [Google Scholar] [CrossRef]

- Cacak-Pietrzak, G.; Dziki, D.; Gawlik-Dziki, U.; Sułek, A.; Kalisz, S.; Sujka, K. Effect of the addition of dried dandelion roots (Taraxacum officinale F.H. Wigg.) on wheat dough and bread properties. Molecules 2021, 26, 7564. [Google Scholar] [CrossRef] [PubMed]

- Korus, A.; Witczak, M.; Korus, J.; Juszczak, L. Dough rheological properties and characteristics of wheat bread with the addition of lyophilized kale (Brassica oleracea L. var. sabellica) powder. Appl. Sci. 2023, 13, 29. [Google Scholar] [CrossRef]

- Czubaszek, A.; Czaja, A.; Sokół-Letowska, A.; Kolniak-Ostek, J.; Kucharska, A. Changes in antioxidant properties and amounts of bioactive compounds during simulated in vitro digestion of wheat bread enriched with plant extracts. Molecules 2021, 26, 6292. [Google Scholar] [CrossRef]

- Baiano, A.; la Gatta, B.; Rutigliano, M.; Fiore, A. Functional bread produced in a circular economy perspective: The use of brewers’ spent grain. Foods 2023, 12, 834. [Google Scholar] [CrossRef]

- Valková, V.; Ďúranová, H.; Havrlentová, M.; Ivanišová, E.; Mezey, J.; Tóthová, Z.; Gabríny, L.; Kačániová, M. Selected physico-chemical, nutritional, antioxidant and sensory properties of wheat bread supplemented with apple pomace powder as a by-product from juice production. Plants 2022, 11, 1256. [Google Scholar] [CrossRef]

- Czubaszek, A.; Wojciechowicz-Budzisz, A.; Spychaj, R.; Kawa-Rygielska, J. Effect of added brewer’s spent grain on the baking value of flour and the quality of wheat bread. Molecules 2022, 27, 1624. [Google Scholar] [CrossRef]

- Granucci, N.; Harris, P.J.; Villas-Boas, S.G. Chemical Compositions of Fruit and Vegetable Pomaces from the Beverage Industries. Waste Biomass Valor. 2023, early access. [Google Scholar] [CrossRef]

- European Commision. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment: Updated Bioeconomy Strategy; Publications Office of the European Union: Brussels, Belgium, 2018. [Google Scholar]

- Ochmian, I.; Grajkowski, J.; Smolik, M. Comparsion of some morphological features, quality and chemical content of four cultivars of chokeberry fruits (Aronia melanocarpa). Not. Bot. Horti. Agrobot. 2012, 40, 253–260. [Google Scholar] [CrossRef]

- Mayer-Miebach, E.; Adamiuk, M.; Behsnilian, D. Stability of chokeberry bioactive polyphenols during juice processing and stabilization of a polyphenol-rich material from the by-product. Agriculture 2012, 2, 244–258. [Google Scholar] [CrossRef]

- Tanaka, T.; Tanaka, A. Chemical components and characteristics of black chokeberry. J. Jpn. Soc. Food Sci. Technol. 2001, 8, 606–610. [Google Scholar] [CrossRef]

- Samoticha, A.J.; Wojdyło, A.; Lech, K. The influence of different the drying methods on chemical composition and antioxidant activity in chokeberries. LWT—Food Sci. Technol. 2016, 66, 484–489. [Google Scholar] [CrossRef]

- Pavlović, A.N.; Brcanović, J.M.; Veljković, J.N.; Mitić, S.S.; Tošić, S.B.; Kalićanin, B.M.; Kostić, D.A.; Dordević, M.S.; Velimirović, D.S. Characterization of commercially available products of aronia according to their metal content. Fruits 2015, 70, 385–393. [Google Scholar] [CrossRef]

- Kaličanin, B.; Velimirović, D.; Nešić, I. A study on mineral composition of Aronia melanocarpa as a functional food with potential therapeutic properties. J. Food Nutr. Res. 2022, 61, 53–60. [Google Scholar]

- Kitryte, V.; Kraujaliene, V.; Sulniute, V.; Pukalskas, A.; Rimantas Venskutonis, P. Chokeberry pomace valorization into foodingredients by enzyme-assisted extraction: Process optimization and product characterization. Food Bioprod. Process. 2017, 105, 36–50. [Google Scholar] [CrossRef]

- AACC. American Association of Cereal Chemistry Approved Methods, 11th ed.; AACC: Greensboro, NC, USA, 2009. [Google Scholar]

- Belyaev, A.G.; Kovaleva, A.E.; Pyanikova, E.A. The influence of fireweed powder on the quality of wheat bread. Proc. Vor. State Univ. Eng. Technol. 2019, 80, 254–258. [Google Scholar] [CrossRef]

- Almero, E.; Collar, C. Texture properties of formulated wheat doughs: Relationship with dough and bread technological quality. Z. Lebensm. Forsch. A 1997, 204, 136–145. [Google Scholar] [CrossRef]

- Różyło, R.; Wójcik, M.; Dziki, D.; Biernacka, B.; Cacak-Pietrzak, G.; Gawłowski, S.; Zdybel, A. Freeze-dried elderberry and chokeberry as natural colorants for gluten-free wafer sheets. Int. Agrophys. 2018, 33, 217–225. [Google Scholar] [CrossRef]

- Gawlik-Dziki, U.; Kaszuba, K.; Piwowarczyk, K.; Świeca, M.; Dziki, D.; Czyż, J. Onion skin—Raw material for the production of suplement that enhances the health beneficial properties of wheat bread. Food Res. Int. 2015, 73, 97–106. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J. Colorimetry of total phenolics with phosphomolybdic. Am. J. Enol. Vitic. 1965, 6, 144–158. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT—Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef] [PubMed]

- García-Gómez, B.; Fernández-Canto, N.; Vázquez-Odériz, M.L.; Quiroga-García, M.; Muñoz-Ferreiro, N.; Romero-Rodríguez, M.Á. Sensory descriptive analysis and hedonic consumer test for Galician type breads. Food Control 2022, 134, 108765. [Google Scholar] [CrossRef]

- Biel, W.; Jaroszewska, A.; Stankowski, S.; Sobolewska, M.; Kępińska-Pacelik, J. Comparison of yield, chemical composition and farinograph properties of common and ancient wheat grains. Eur. Food Res. Technol. 2021, 247, 1525–1538. [Google Scholar] [CrossRef]

- Sudha, M.L.; Vetrimani, R.; Leelavathi, K. Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem. 2007, 100, 1365–1370. [Google Scholar] [CrossRef]

- Jaskulska, I.; Jaskulski, D.; Gałȩzewski, L.; Knapowski, T.; Kozera, W.; Wacławowicz, R. Mineral composition and baking value of the winter wheat grain under varied environmental and agronomic conditions. J. Chem. 2018, 2018, 5013825. [Google Scholar] [CrossRef]

- Kotoki, D.; Deka, S.C. Baking loss of bread with special emphasis on increasing water holding capacity. J. Food Sci. Technol. 2010, 47, 128–131. [Google Scholar] [CrossRef]

- Seguchi, B.M.; Tabara, A.; Fukawa, I.; Ono, H.; Kumashiro, C.; Yoshino, Y.; Kusunose, C.; Yamane, C. Effects of size of cellulose granules on dough rheology, microscopy, and breadmaking properties. J. Food Sci. 2007, 72, E79–E84. [Google Scholar] [CrossRef]

- Petković, M.; Filipović, V.; Filipović, J.; Đurović, I.; Miletić, N.; Radovanović, J. Chemical, antioxidative, and sensory characteristics of wheat bread partially substituted with black chokeberry (Aronia melanocarpa L.) powder. J. Food Process. Preserv. 2021, 45, e15027. [Google Scholar] [CrossRef]

- Matsumoto, M.; Hara, H.; Chiji, H.; Kasai, T. Gastroprotective effect of red pigments in black chokeberry fruit (Aronia melanocarpa Elliot) on acute gastric hemorrhagic lesions in rats. J. Agric. Food Chem. 2004, 52, 2226–2229. [Google Scholar] [CrossRef]

- Schmid, V.; Steck, J.; Mayer-Miebach, E.; Behsnilian, D.; Bunzel, M.; Karbstein, H.P.; Emin, M.A. Extrusion processing of pure chokeberry (Aronia melanocarpa) pomace: Impact on dietary fiber profile and bioactive compounds. Foods 2021, 10, 518. [Google Scholar] [CrossRef] [PubMed]

- Woźniak, L.; Marszalek, K.; Skapska, S.; Jedrzejczak, R. The application of supercritical carbon dioxide and ethanol for the extraction of phenolic compounds from chokeberry pomace. Appl. Sci. 2017, 7, 322. [Google Scholar] [CrossRef]

- Sójka, M.; Kołodziejczyk, K.; Milala, J. Polyphenolic and basic chemical composition of black chokeberry industrial by-products. Ind. Crops Prod. 2013, 51, 77–86. [Google Scholar] [CrossRef]

- Kapci, B.; Neradová, E.; Čížková, H.; Voldřich, M.; Rajchl, A.; Capanoglu, E. Investigating the antioxidant potential of chokeberry (Aronia melanocarpa) products. J. Food Nutr. Res. 2013, 52, 219–229. [Google Scholar]

- Raczkowska, E.; Nowicka, P.; Wojdyło, A.; Styczyńska, M.; Lazar, Z. chokeberry pomace as a component shaping the content of bioactive compounds and nutritional, health-promoting (anti-diabetic and antioxidant) and sensory properties of shortcrust pastries sweetened with sucrose and erythritol. Antioxidants 2022, 11, 190. [Google Scholar] [CrossRef]

- Wichchukit, S.; O’Mahony, M. The 9-point hedonic scale and hedonic ranking in food science: Some reappraisals and alternatives. J. Sci. Food Agric. 2015, 95, 2167–2178. [Google Scholar] [CrossRef]

- Betoret, E.; Rosell, C.M. Enrichment of bread with fruits and vegetables: Trends and strategies to increase functionality. Cereal Chem. 2020, 97, 9–19. [Google Scholar] [CrossRef]

- Dziki, D. Current trends in enrichment of wheat pasta: Quality, nutritional value and antioxidant properties. Processes 2021, 9, 1280. [Google Scholar] [CrossRef]

- das Chagas, E.G.L.; Vanin, F.M.; dos Santos Garcia, V.A.; Yoshida, C.M.P.; de Carvalho, R.A. Enrichment of antioxidants compounds in cookies produced with camu-camu (Myrciaria dubia) coproducts powders. LWT—Food Sci. Technol. 2021, 137, 110472. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).