Understanding the Mechanism of Strong Mining Tremors near the Goaf Area of Longwall Mining: A Case Study

Abstract

1. Introduction

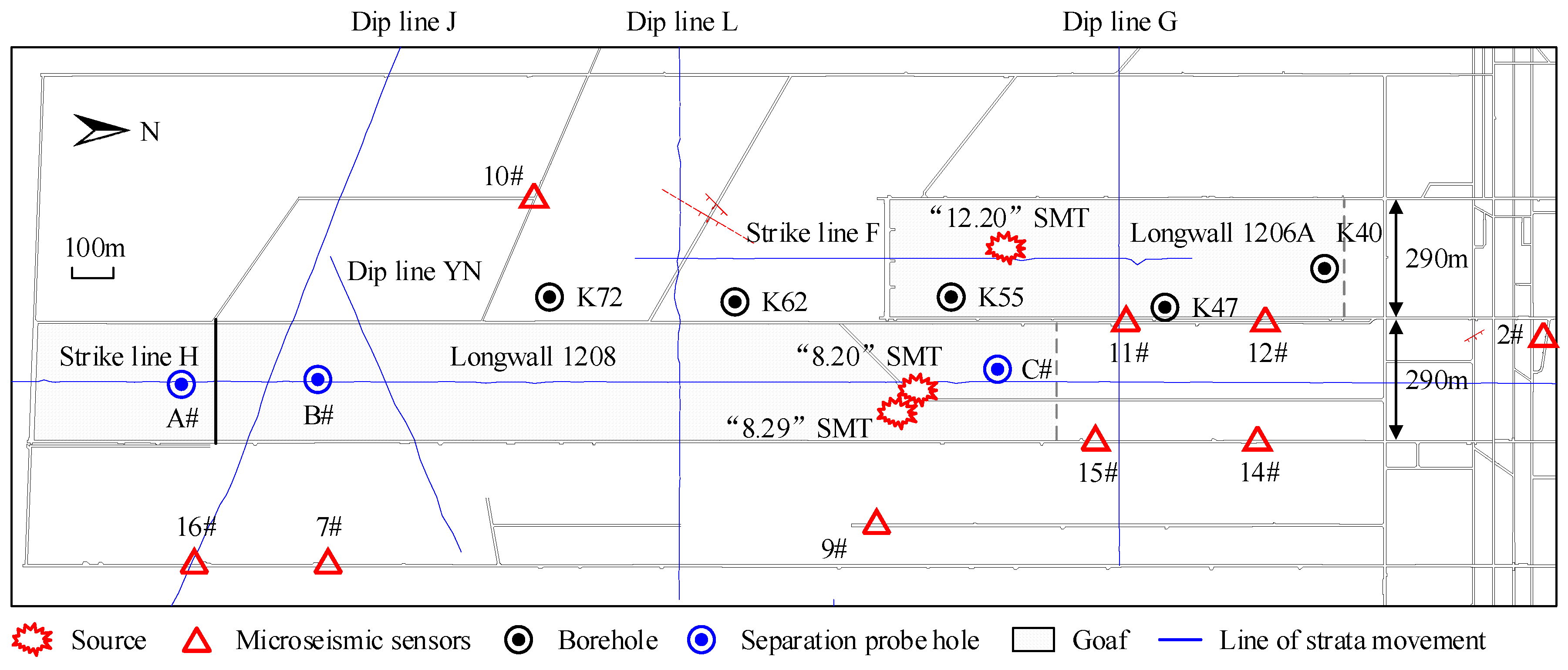

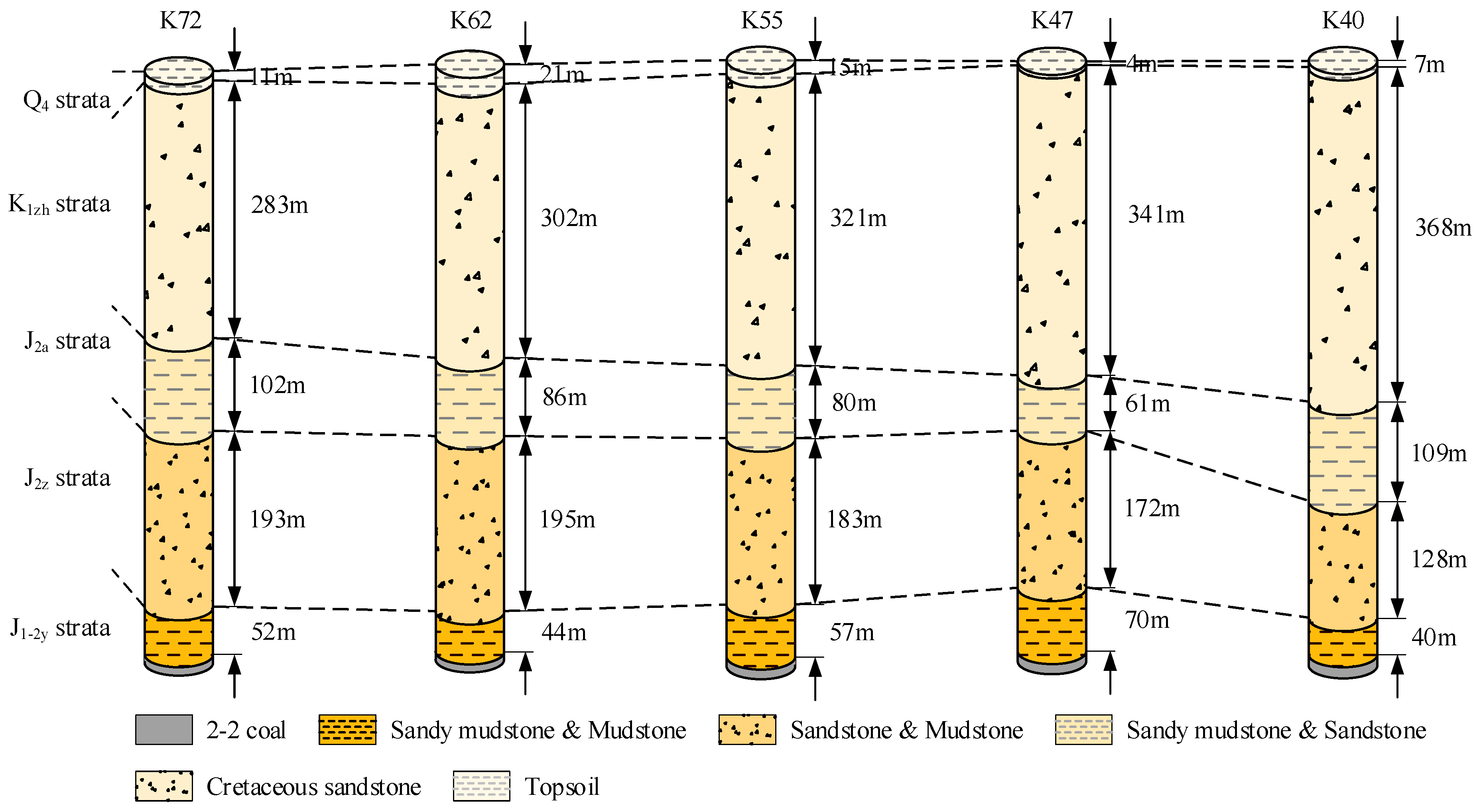

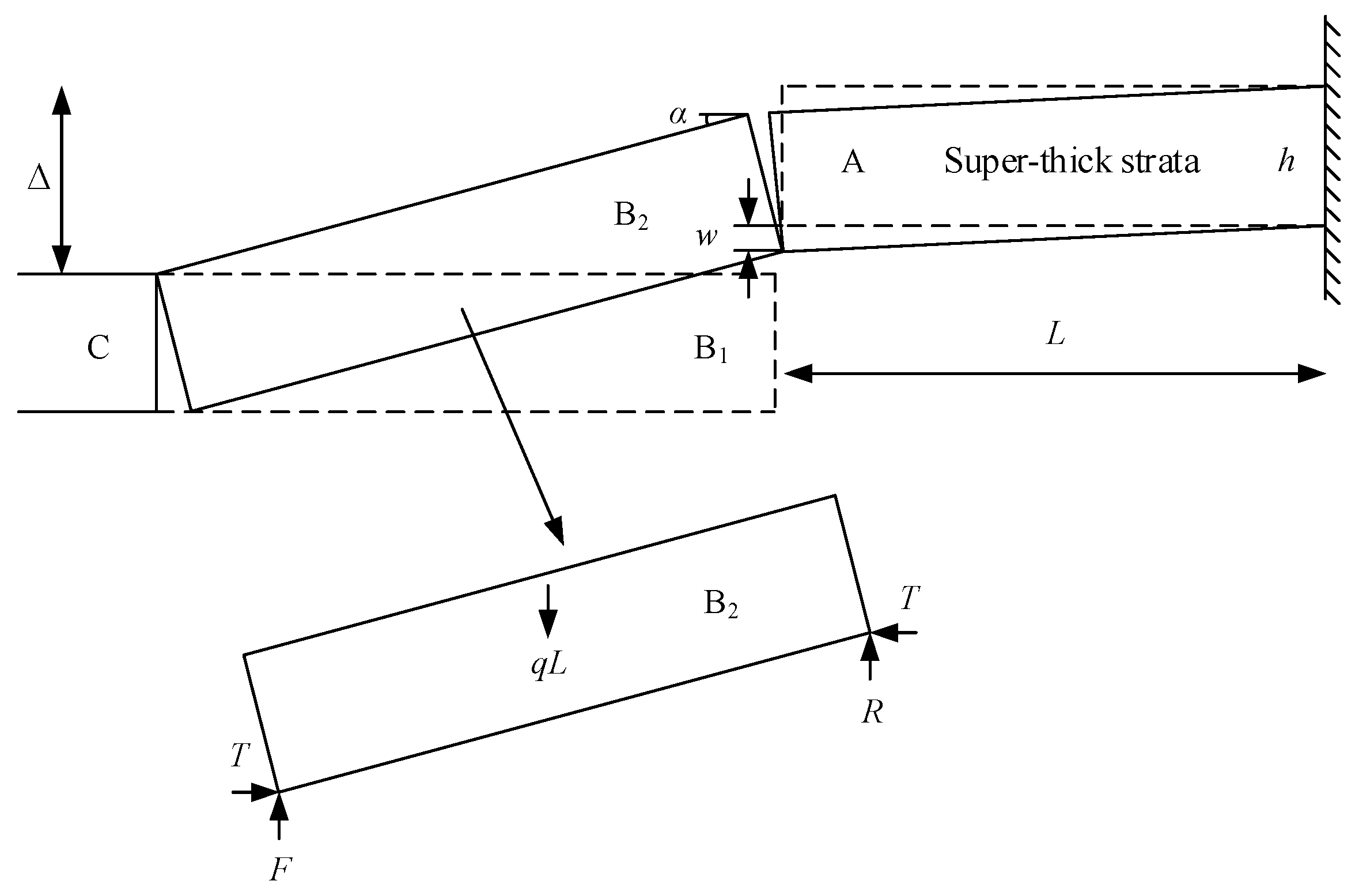

2. Geological Setting and Data

2.1. Formation and Mining Condition

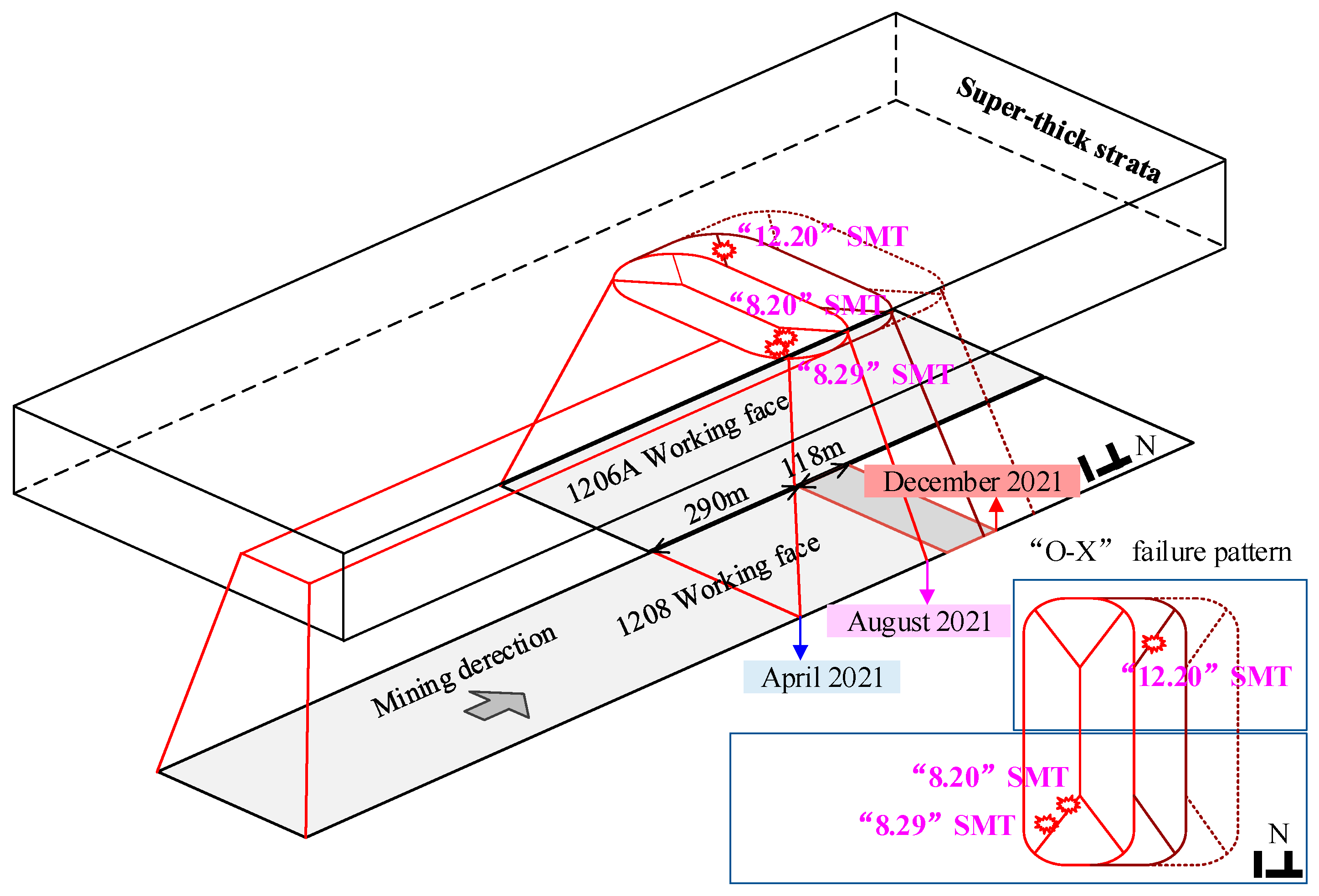

2.2. Characteristics of Mining Tremors

2.2.1. Spatial Distribution of Mining Tremors

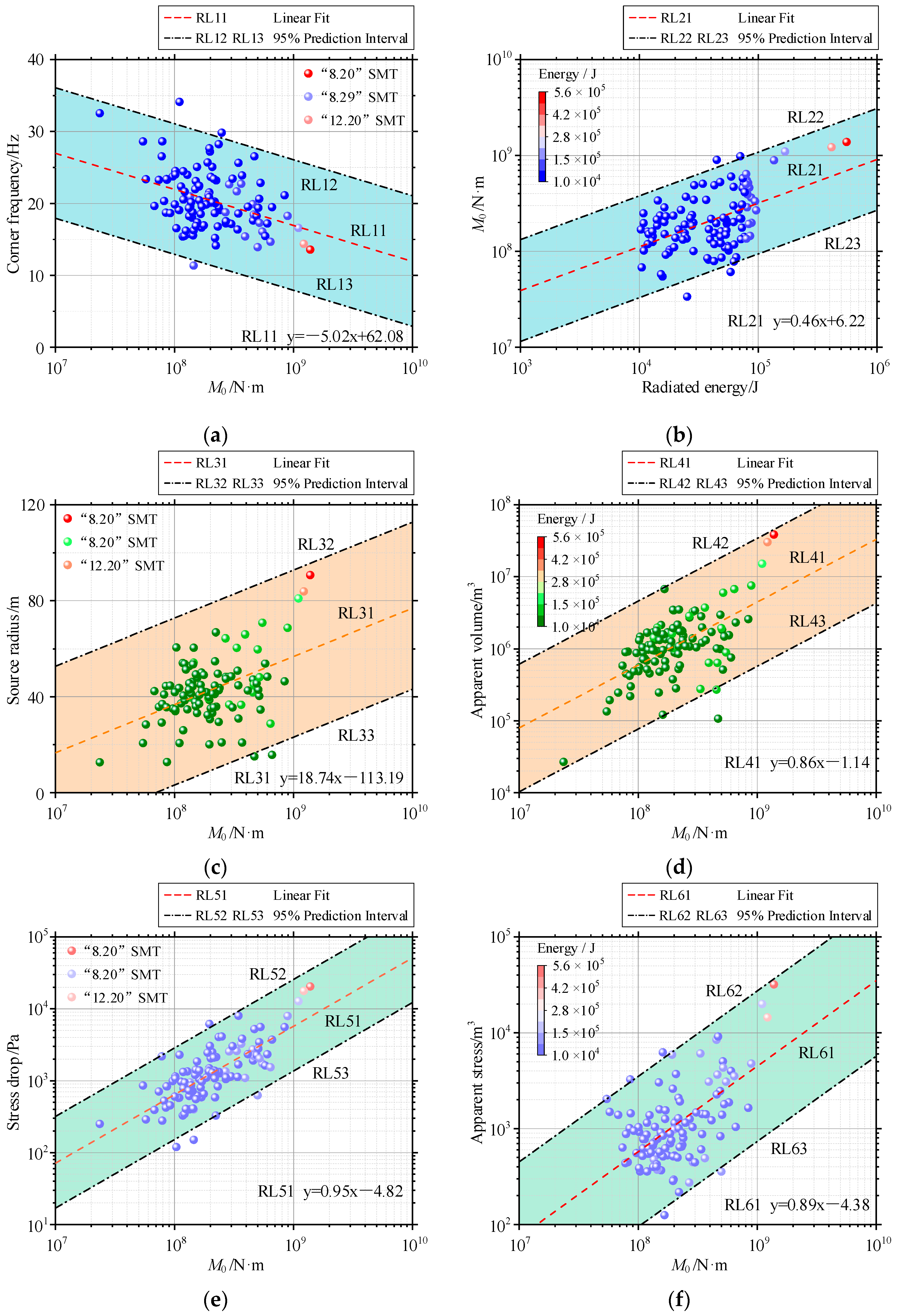

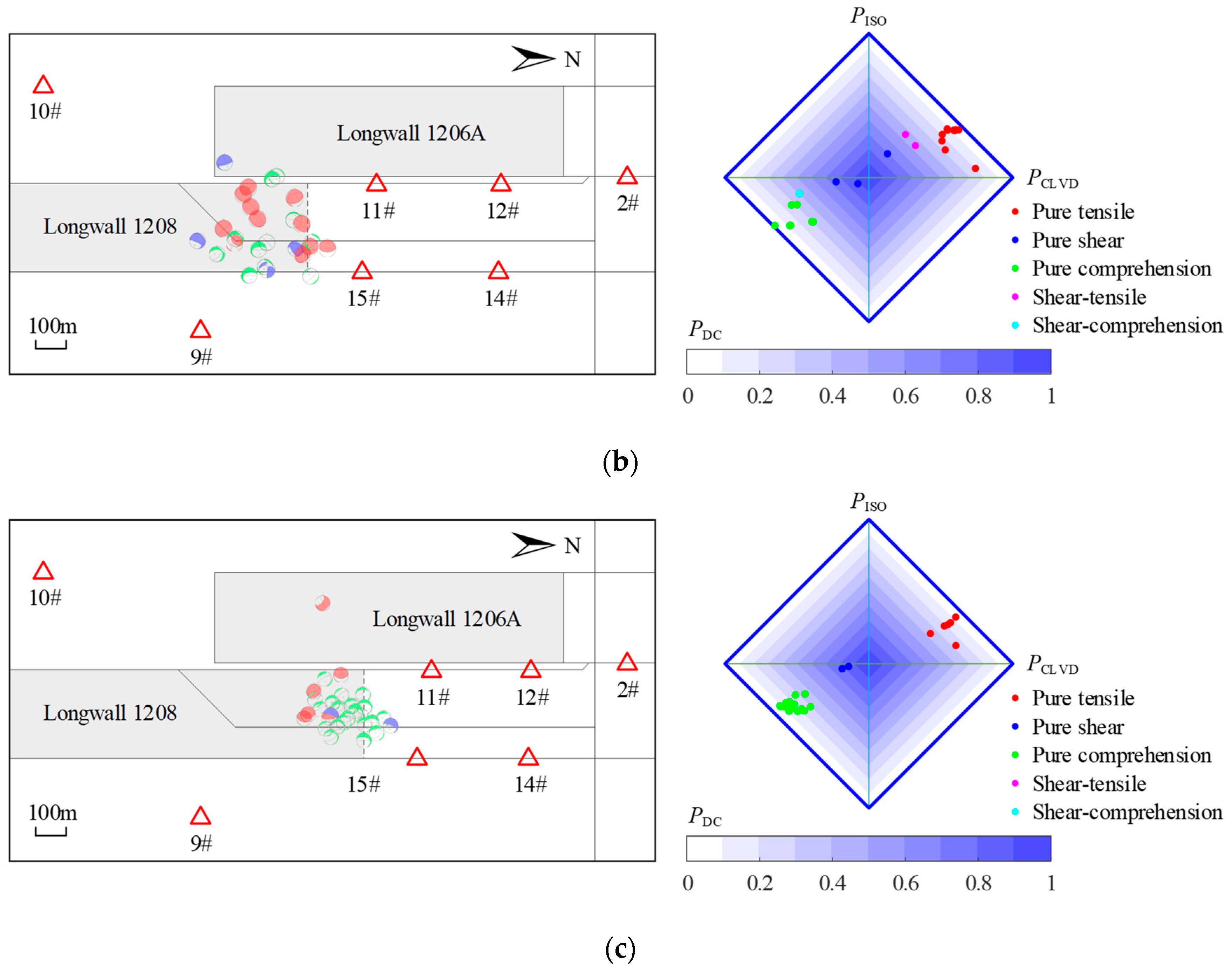

2.2.2. Distribution Features of Source Mechanical Parameters

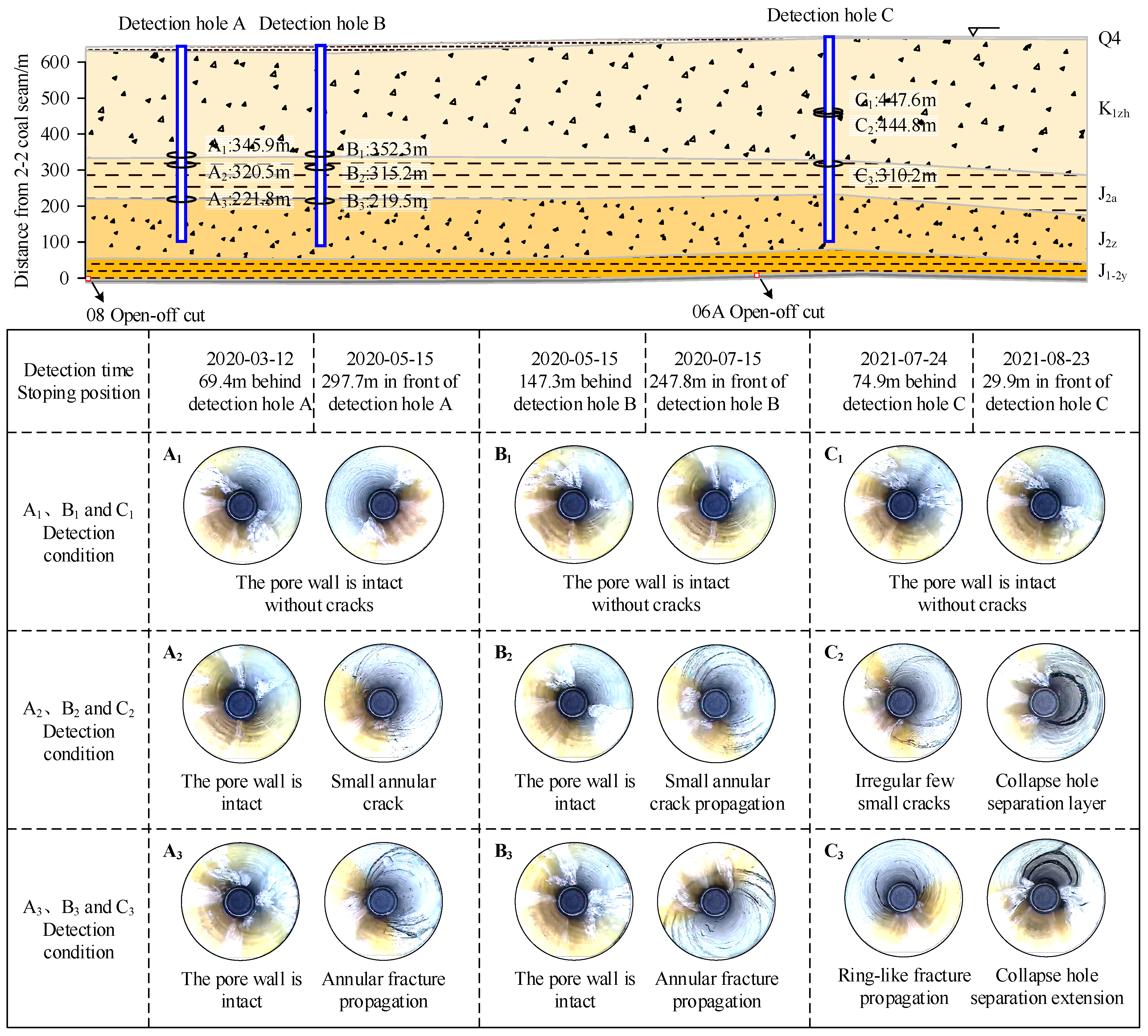

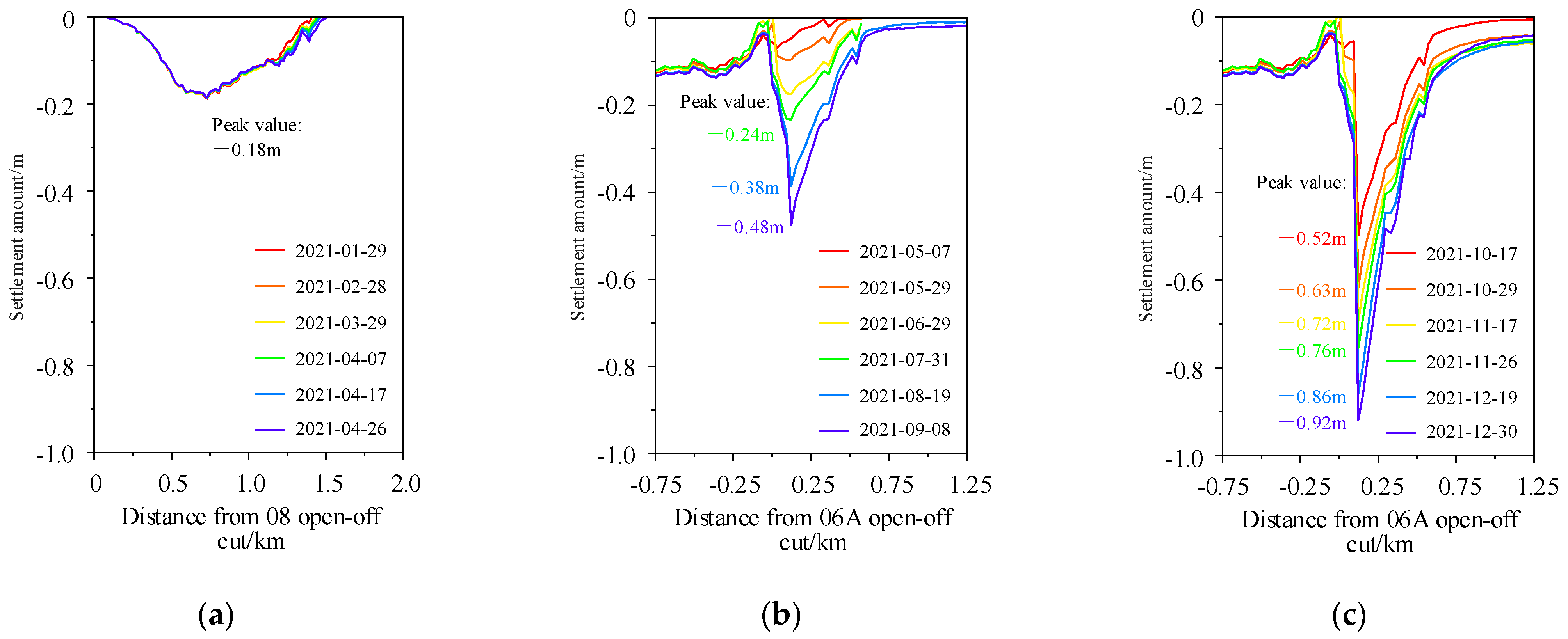

3. Law of Strata Fracture Movement

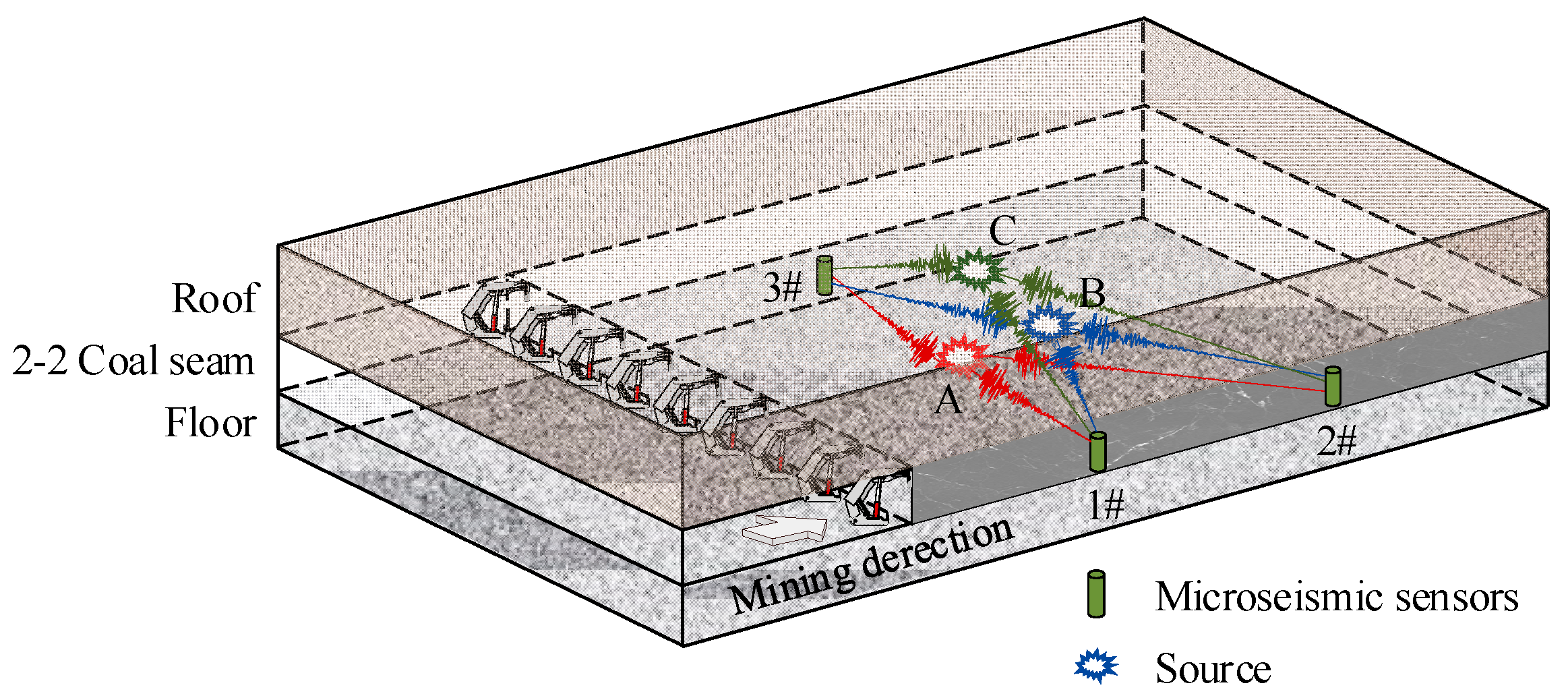

3.1. Observation of Strata Separation

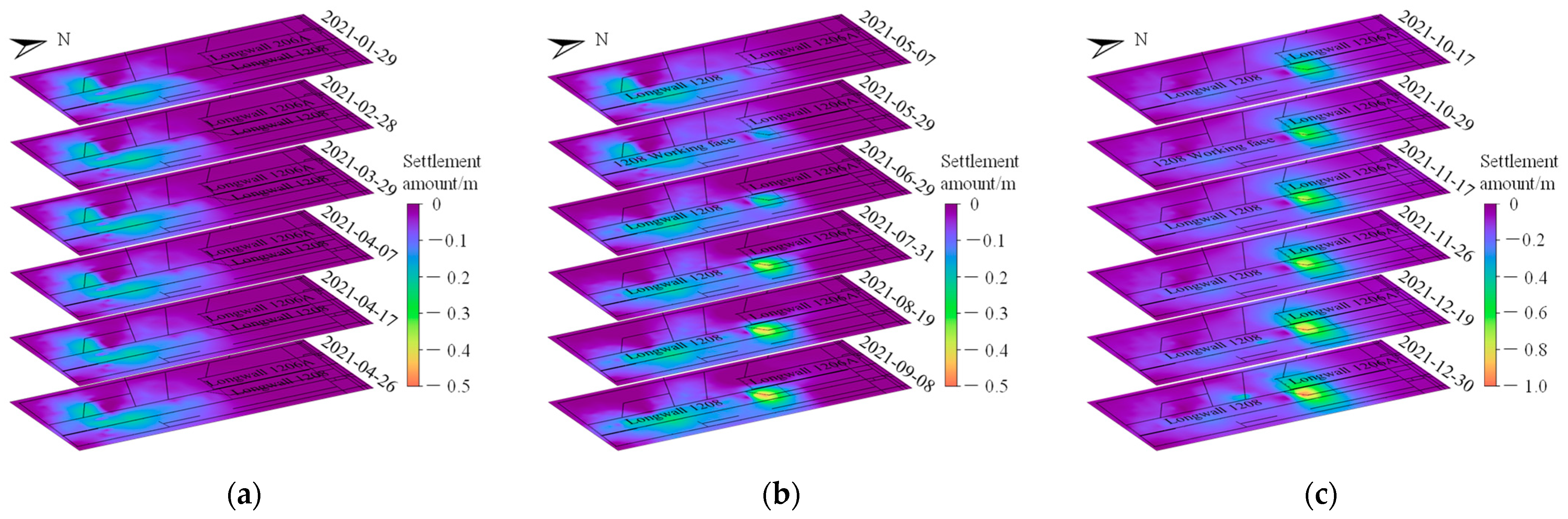

3.2. Monitoring of Strata Deformation

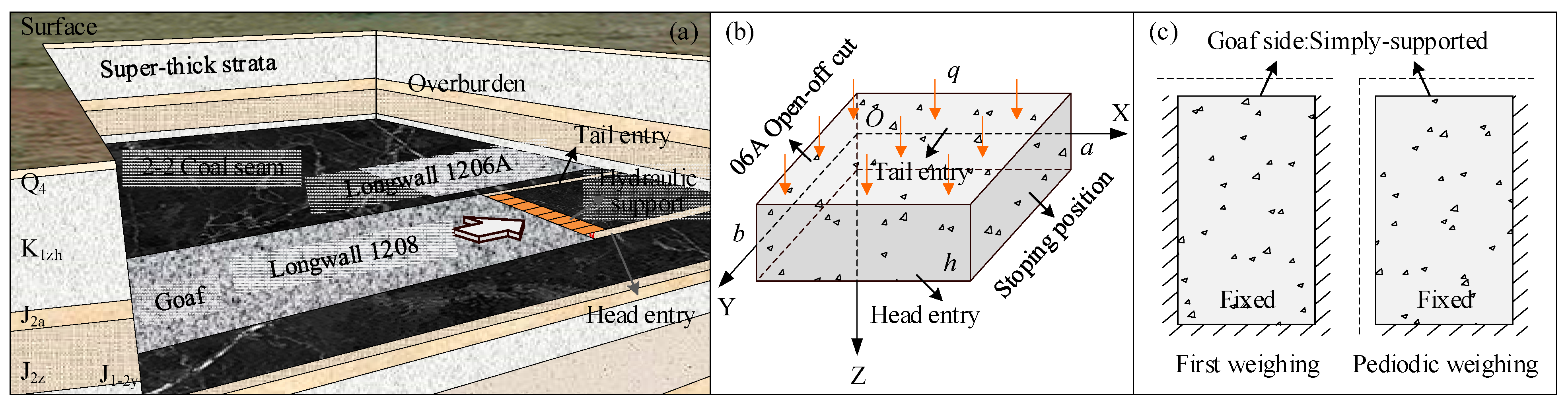

3.3. Theoretical Analysis of Strata Fracture Movement

4. Rupture Mechanism of Strong Mining Tremors

4.1. Relative Moment Tensor Inversion

4.1.1. Principle of Inversion

4.1.2. Condition of Inversion

4.2. Identification of Source Rupture Type

4.3. Rupture Mechanism of Strong Mining Tremors

- (1)

- For the “8.20” SMT, the PISO, PCLVD, and PDC were 6.37%, 74.02%, and 19.61%, respectively. The source rupture type is pure tensile failure, indicating that the “8.20” SMT was induced by the tensile failure of the super-thick strata.

- (2)

- For the “8.29” SMT, the PISO = −2.87%, PCLVD = −22.86%, and PDC = 74.27%. The source rupture type of this SMT is shear fracture. It can be inferred that the “8.29” SMT is related to the slip and dislocation of the super-thick strata. It is worth noting that the disturbance caused by the “8.20” SMT is the key factor causing the dislocation of the super-thick strata.

- (3)

- Similar to the “8.20” SMT, the PISO, PCLVD and PDC of the “12.20” SMT were 12.62%, 60.44% and 26.94%, respectively, which was again induced by the tensile failure of the super-thick strata.

| Name | PISO/% | PCLVD/% | PDC/% | Source Rupture Type | Beach Ball |

|---|---|---|---|---|---|

| “8.20” SMT | 6.37 | 74.02 | 19.61 | Tensile failure |  |

| “8.29” SMT | −2.87 | −22.86 | 74.27 | Shear failure |  |

| “12.20” SMT | 12.62 | 60.44 | 26.94 | Tensile failure |  |

5. Discussion

5.1. Comparison of SMTs with Mine Tremors and Earthquakes

5.2. Occurrence Mechanism of Strong Mining Tremors

- (1)

- The Jurassic Yan’an formation strata collapsed before the “8.20” SMT, the strata of Jurassic Anding and Zhiluo formation strata formed unstable rock blocks after fracturing, and the mutual movement and rotational extrusion of the blocks induced shear and compression fracture mining tremors, respectively. The super-thick strata did not break, but constantly deformed and accumulated elastic energy, resulting in an increase in surface settlement.

- (2)

- As LW 1208 continued to advance, cracks in the super-thick strata continued to expand and develop, and the initial tensile fracture of super-thick strata induced the “8.20” SMT.

- (3)

- After the occurrence of the “8.20” SMT, the super-thick strata was in a state of instability. Meanwhile, the disturbance of the SMT made the super-thick strata slip and mismove, which induced the “8.29” shear fracture SMT.

- (4)

- Mining continued at LW 1208, and cracks developed in the upper thick overburdened area within the mining area of LW 1206A. Further expansion of the cracks led to the tensile failure of the super-thick strata, and eventually induced the “12.20” SMT.

6. Conclusions

- (1)

- The SMTs induced by the fracture of super-thick strata are more likely to cause ground shaking. The SMTs are all located in the super-thick strata behind the goaf, which is relatively close to the ground. The apparent volume distribution is more than 107 m3, and the stress drop and apparent stress at the source are more than 104 Pa, which is one to three orders of magnitude higher than other mining tremors.

- (2)

- The SMTs were mainly caused by the movement of fractures in the super-thick strata. When solid coal mining was conducted, the surface subsidence was relatively small, and there were no fractures in the super-thick strata, thus SMTs did not occur. However, during goaf mining, there were two “stepped” increases in maximum surface subsidence, and fractures began to appear in the super-thick strata, leading to the occurrence of SMTs.

- (3)

- Theoretical calculations show that, during goaf mining, when LW 1208 advances by about 307 m, the super-thick strata will experience initial fracture. Then, when LW 1208 continues to advance approximately 118 m, there will be another fracture of the super-thick strata—a periodic fracture. This is the main reason for triggering the “8.20” and “12.20” SMT events. Moreover, after the super-thick strata are fractured, unstable structural adjustments can easily induce SMTs, such as the “8.29” SMT.

- (4)

- The strata below the super-thick strata gradually break upwards. Once the super-thick strata reach their fracture limit, it produces initial and periodic fractures in the form of tensional rupture, which can trigger SMT. Similarly, after tensional rupture occurs in the super-thick strata, the structural adjustment of the ruptured super-thick strata can produce shear failures that trigger SMTs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Milczarek, W. Investigation of post inducted seismic deformation of the 2016 MW 4.2 Tarnovek Poland mining tremor based on DInSAR and SBAS method. Acta Geodyn. Geomater. 2019, 16, 183–193. [Google Scholar] [CrossRef]

- Bai, J.; Zhao, J.; Ren, Z.; Li, W.; Wang, K.; Li, X. Paleogeographic and sedimentary evolution of Meso–Neoproterozoic strata in the Ordos Basin, western North China Craton. J. Pet. Sci. Eng. 2022, 215, 110600. [Google Scholar] [CrossRef]

- Rudziński, Ł.; Mirek, K.; Mirek, J. Rapid ground deformation corresponding to a mining-induced seismic event followed by a massive collapse. Nat. Hazards 2019, 96, 461–471. [Google Scholar] [CrossRef]

- Wu, K.; Zou, J.; Jiao, Y.-Y.; Zhang, X.; Wang, C. Focal Mechanism of Strong Ground Seismicity Induced by Deep Coal Mining. Rock Mech. Rock Eng. 2022, 56, 779–795. [Google Scholar] [CrossRef]

- Lu, C.-P.; Liu, G.-J.; Liu, Y.; Zhang, N.; Xue, J.-H.; Zhang, L. Microseismic multi-parameter characteristics of rockburst hazard induced by hard roof fall and high stress concentration. Int. J. Rock Mech. Min. Sci. 2015, 76, 18–32. [Google Scholar] [CrossRef]

- Huang, B.; Liu, J.; Zhang, Q. The reasonable breaking location of overhanging hard roof for directional hydraulic fracturing to control strong strata behaviors of gob-side entry. Int. J. Rock Mech. Min. Sci. 2018, 103, 1–11. [Google Scholar] [CrossRef]

- Liu, J.; Liu, C.; Yao, Q.; Si, G. The position of hydraulic fracturing to initiate vertical fractures in hard hanging roof for stress relief. Int. J. Rock Mech. Min. Sci. 2020, 132, 104328. [Google Scholar] [CrossRef]

- Xu, C.; Fu, Q.; Cui, X.; Wang, K.; Zhao, Y.; Cai, Y. Apparent-Depth Effects of the Dynamic Failure of Thick Hard Rock Strata on the Underlying Coal Mass During Underground Mining. Rock Mech. Rock Eng. 2019, 52, 1565–1576. [Google Scholar] [CrossRef]

- Zhang, X.; Gong, P.; Wang, K.; Li, J.; Jiang, Y. Characteristic and Mechanism of Roof Fracture Ahead of the Face in an LTCC Panel When Passing an Abandoned Roadway: A Case Study from the Shenghua Coal Mine, China. Rock Mech. Rock Eng. 2019, 52, 2775–2788. [Google Scholar] [CrossRef]

- Xie, H.; Gao, M.; Zhang, R.; Peng, G.; Wang, W.; Li, A. Study on the Mechanical Properties and Mechanical Response of Coal Mining at 1000 m or Deeper. Rock Mech. Rock Eng. 2019, 52, 1475–1490. [Google Scholar] [CrossRef]

- Guo, P.; Yuan, Y.; Ye, K.; Sun, D. Fracturing mechanisms and deformation characteristics of rock surrounding the gate during gob-side entry retention through roof pre-fracturing. Int. J. Rock Mech. Min. Sci. 2021, 148, 104927. [Google Scholar] [CrossRef]

- Lu, C.-P.; Dou, L.-M.; Zhang, N.; Xue, J.-H.; Wang, X.-N.; Liu, H.; Zhang, J.-W. Microseismic frequency-spectrum evolutionary rule of rockburst triggered by roof fall. Int. J. Rock Mech. Min. Sci. 2013, 64, 6–16. [Google Scholar] [CrossRef]

- Konicek, P.; Waclawik, P. Stress changes and seismicity monitoring of hard coal longwall mining in high rockburst risk areas. Tunn. Undergr. Space Technol. 2018, 81, 237–251. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, G.; Liu, C.; Li, S.; Xue, J.; Cheng, R.; Wang, X.; Zeng, X. Prediction of rockbursts in a typical island working face of a coal mine through microseismic monitoring technology. Tunn. Undergr. Space Technol. 2021, 113, 103972. [Google Scholar] [CrossRef]

- Sazid, M.; Ahmed, H.A. Stability Analysis of Shallow Depth Tunnel in Weak Rock Mass: 3D Numerical Modeling Approach. J. City Dev. 2019, 1, 18–22. [Google Scholar]

- Sazid, M. Effect of Underground Blasting on Surface Slope Stability: A Numerical Approach. Am. J. Min. Metall. 2023, 4, 32–36. [Google Scholar]

- Wang, F.; Kaunda, R. Assessment of rockburst hazard by quantifying the consequence with plastic strain work and released energy in numerical models. Int. J. Min. Sci. Technol. 2019, 29, 93–97. [Google Scholar] [CrossRef]

- Dou, L.; Sun, Z.; Li, X.; Liu, Q.; Gong, S.; Wang, C. Detection and targeted control of regional stress field for coal burst prevention. Geohazard Mech. 2023, 1, 69–76. [Google Scholar] [CrossRef]

- Yang, J.; Chen, W.; Tan, X.; Yang, D. Analytical estimation of stress distribution in interbedded layers and its implication to rockburst in strong layer. Tunn. Undergr. Space Technol. 2018, 81, 289–295. [Google Scholar] [CrossRef]

- He, J.; Dou, L.; Gong, S.; Li, J.; Ma, Z. Rock burst assessment and prediction by dynamic and static stress analysis based on micro-seismic monitoring. Int. J. Rock Mech. Min. Sci. 2017, 93, 46–53. [Google Scholar] [CrossRef]

- Laguillo, M.; Segarra, P.; Sanchidrián, J.A.; Beitia, F. A novel borehole surveying system for underground mining: Design and performance assessment. Measurement 2022, 194, 111021. [Google Scholar] [CrossRef]

- Chen, F.; Cao, A.Y.; Liang, Z.Z.; Liu, Y.Q. A Coal Burst Risk Assessment Model of Seismic Events Based on Multiple Seismic Source Parameters: A Case Study of the Huating Coal Mine, Gansu Province, China. Nat. Resour. Res. 2021, 30, 4515–4532. [Google Scholar] [CrossRef]

- Yang, S.; Song, G.; Kong, D. An evaluation of longwall face stability in thick coal seams through a basic understanding of shield–strata interaction. J. Geophys. Eng. 2019, 16, 125–135. [Google Scholar] [CrossRef]

- Yang, S.; Wang, J.; Li, L. Deformation and fracture characteristics of key strata based on the medium thick plate theory. J. China Coal Soc. 2020, 45, 2718–2727. [Google Scholar] [CrossRef]

- Reissner, E. Reflections on the Theory of Elastic Plates. Appl. Mech. Rev. 1985, 38, 1453–1464. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, K.; Jiang, J.; Ji, S.; Pan, R. The fracture and rockburst laws of high-position hard and extremely thick red beds. J. Min. Saf. Eng. 2016, 33, 1116–1122. [Google Scholar] [CrossRef]

- Li, Z.-L.; Dou, L.-M.; Cai, W.; Wang, G.-F.; Ding, Y.-L.; Kong, Y. Mechanical Analysis of Static Stress within Fault-Pillars Based on a Voussoir Beam Structure. Rock Mech. Rock Eng. 2016, 49, 1097–1105. [Google Scholar] [CrossRef]

- Mendecki, M.J.; Wojtecki, Ł.; Zuberek, W.M. Case Studies of Seismic Energy Release Ahead of Underground Coal Mining before Strong Tremors. Pure Appl. Geophys. 2019, 176, 3487–3508. [Google Scholar] [CrossRef]

- Yamada, T.; Mori, J.J.; Ide, S.; Abercrombie, R.E.; Kawakata, H.; Nakatani, M.; Iio, Y.; Ogasawara, H. Stress drops and radiated seismic energies of microearthquakes in a South African gold mine. J. Geophys. Res. Solid Earth 2007, 112. [Google Scholar] [CrossRef]

- Song, C.-H.; Lu, C.-P.; Zhang, X.-F.; Wang, C.; Xie, H.-D.; Yan, X.-Y.; Yang, H.-W. Moment Tensor Inversion and Stress Evolution of Coal Pillar Failure Mechanism. Rock Mech. Rock Eng. 2022, 55, 2371–2383. [Google Scholar] [CrossRef]

- Dahm, T. Relative moment tensor inversion based on ray theory: Theory and synthetic tests. Geophys. J. Int. 1996, 124, 245–257. [Google Scholar] [CrossRef]

- Aki, K.; Richards, P.G. Quantitative seismology-theory and methods. Freeman 1980, 1, 116–119. [Google Scholar]

- Cao, A.; Chen, F.; Liu, Y.; Dou, L.; Wang, C.; Yang, X.; Bai, X.; Song, S. Response characteristics of rupture mechanism and source parameters of mining tremors in frequent coal burst area. J. China Coal Soc. 2022, 47, 722–733. [Google Scholar] [CrossRef]

- Ohtsu, M. Acoustic Emission Theory for Moment Tensor Analysis. Res. Nondestruct. Eval. 1995, 6, 169–184. [Google Scholar] [CrossRef]

- Yu, C.; Vavryčuk, V.; Adamová, P.; Bohnhoff, M. Moment Tensors of Induced Microearthquakes in The Geysers Geothermal Reservoir from Broadband Seismic Recordings: Implications for Faulting Regime, Stress Tensor, and Fluid Pressure. J. Geophys. Res. Solid Earth 2018, 123, 8748–8766. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, T.; Zhang, P.; Xu, H.; Wang, S. Inversion of seepage channels based on mining-induced microseismic data. Int. J. Rock Mech. Min. Sci. 2020, 126, 104180. [Google Scholar] [CrossRef]

- Ren, Y.; Vavryčuk, V.; Wu, S.; Gao, Y. Accurate moment tensor inversion of acoustic emissions and its application to Brazilian splitting test. Int. J. Rock Mech. Min. Sci. 2021, 141, 104707. [Google Scholar] [CrossRef]

- Gibowicz, S.; Harjes, H.; Schäfer, M. Source parameter of seismic events at Heinrich Robert Mine, Ruhr Basin, Federal Republic of Germany: Evidence for non double-couple events. Bull. Seismol. Soc. Am. 1990, 80, 88–109. [Google Scholar]

- Vavryčuk, V. Moment tensor decompositions revisited. J. Seismol. 2015, 19, 231–252. [Google Scholar] [CrossRef]

- Chen, D.; Martin Mai, P. Automatic identification model of micro-earthquakes and blasting events in Laohutai coal mine based on the measurement of source parameter difference. Measurement 2021, 184, 109883. [Google Scholar] [CrossRef]

- Calderoni, G.; Rovelli, A.; Di Giovambattista, R. Stress Drop, Apparent Stress, and Radiation Efficiency of Clustered Earthquakes in the Nucleation Volume of the 6 April 2009, Mw 6.1 L’Aquila Earthquake. J. Geophys. Res. Solid Earth 2019, 124, 10360–10375. [Google Scholar] [CrossRef]

- Ye, L.; Lay, T.; Kanamori, H.; Rivera, L. Rupture characteristics of major and great (Mw ≥ 7.0) megathrust earthquakes from 1990 to 2015: 1. Source parameter scaling relationships. J. Geophys. Res. Solid Earth 2016, 121, 826–844. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, A.; Gupta, S.C.; Mittal, H.; Kumar, R. Source parameters and fmax in Kameng region of Arunachal Lesser Himalaya. J. Asian Earth Sci. 2013, 70–71, 35–44. [Google Scholar] [CrossRef]

- Franceschina, G.; Gentili, S.; Bressan, G. Source parameters scaling of the 2004 Kobarid (Western Slovenia) seismic sequence. Phys. Earth Planet. Inter. 2013, 222, 58–75. [Google Scholar] [CrossRef]

- Bressan, G.; Kravanja, S.; Franceschina, G. Source parameters and stress release of seismic sequences occurred in the Friuli-Venezia Giulia region (Northeastern Italy) and in Western Slovenia. Phys. Earth Planet. Inter. 2007, 160, 192–214. [Google Scholar] [CrossRef]

| Time of Occurrence | Panel Position | Source Location | Energy/J | Magnitude | Field Survey Condition |

|---|---|---|---|---|---|

| 20 August 2021 17:41:51 | 289.9 m in front of 06A open-off cut | 218 m behind the panel position of LW 1208 and 179.8 m behind the tail entry. | 5.56 × 105 | 2.40 | (1) There was no obvious vibration in the underground and no deformation in the roadway; (2) The ground shook slightly, and building facilities on the ground are normal; (3) No loss of personnel or property. |

| 29 August 2021 00:41:41 | Same as above (stoppage of LW 1208) | 264.6 m behind the panel position of LW 1208, and 57.2 m behind the head entry. | 1.69 × 105 | 2.80 | |

| 20 December 2021 17:03:15 | 398.2 m in front of 06A open-off cut | 70.3 m behind the panel position of LW 1208, and 165.5 m to the west of the head entry. | 2.92 × 105 | 2.60 |

| Detection Hole Name | Detection Position Name | Distance from 2-2 Coal Seam/m | Stratigraphic Name | Detection Date | Spatial Relationship with Mining Location |

|---|---|---|---|---|---|

| A | A1 | 345.9 | K1zh | 12 March 2020 15 May 2020 | 69.4 m behind detection hole A 297.7 m in front of detection hole A |

| A2 | 320.5 | J2a | |||

| A3 | 221.8 | J2z | |||

| B | B1 | 352.3 | K1zh | 15 May 2020 15 July 2020 | 147.3 m behind detection hole B 247.8 m in front of detection hole B |

| B2 | 315.2 | J2a | |||

| B3 | 219.5 | J2z | |||

| C | C1 | 447.6 | K1zh | 24 July 2021 23 August 2021 | 74.9 m behind detection hole C 29.9 m in front of detection hole C |

| C2 | 444.8 | K1zh | |||

| C3 | 310.2 | J2a |

| SMPs | Seismic Moment/N·m | Stress Drop/Pa | Apparent Stress/Pa | Apparent Volume/m3 |

|---|---|---|---|---|

| Chen et al. [40] | 109–1012 | 104–106 | 104–106 | / |

| Wu et al. [4] | 1010–1012 | 104–105 | 104–106 | / |

| Chen et al. [22] | 109–1012 | 103–105 | 104–106 | 105–107 |

| Calderoni et al. [41] | 1016–1018 | 106–107 | 106–107 | / |

| Ye et al. [42] | 1019–1023 | 106–107 | 106–107 | / |

| Kumar et al. [43] | 1017–1021 | 106–108 | / | / |

| Franceschina et al. [44] | 1011–1016 | 104–107 | 104–107 | / |

| Bressan et al. [45] | 1012–1015 | 104–107 | 104–107 | / |

| Present research | 109–1010 | 104–105 | 104–105 | 107–108 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Cao, A.; Liu, Y.; Bai, X.; Yan, Z.; Wang, S.; Wang, C. Understanding the Mechanism of Strong Mining Tremors near the Goaf Area of Longwall Mining: A Case Study. Appl. Sci. 2023, 13, 5364. https://doi.org/10.3390/app13095364

Yang Y, Cao A, Liu Y, Bai X, Yan Z, Wang S, Wang C. Understanding the Mechanism of Strong Mining Tremors near the Goaf Area of Longwall Mining: A Case Study. Applied Sciences. 2023; 13(9):5364. https://doi.org/10.3390/app13095364

Chicago/Turabian StyleYang, Yao, Anye Cao, Yaoqi Liu, Xianxi Bai, Zhenqian Yan, Songwei Wang, and Changbin Wang. 2023. "Understanding the Mechanism of Strong Mining Tremors near the Goaf Area of Longwall Mining: A Case Study" Applied Sciences 13, no. 9: 5364. https://doi.org/10.3390/app13095364

APA StyleYang, Y., Cao, A., Liu, Y., Bai, X., Yan, Z., Wang, S., & Wang, C. (2023). Understanding the Mechanism of Strong Mining Tremors near the Goaf Area of Longwall Mining: A Case Study. Applied Sciences, 13(9), 5364. https://doi.org/10.3390/app13095364