Quality of Tomato Juice as Influenced by Non-Thermal Air Plasma Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Juice Preparation

2.2. Cold Plasma Treatment

2.3. Determination of Total Soluble Solids and pH

2.4. Determination of Lycopene

2.5. Determination of Ascorbic Acid

2.6. Determination of Color Parameters in Tomatoes Juice

2.7. Microbiological Analysis

2.8. Microscopic Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. Effect of CAP on Physicochemical Properties

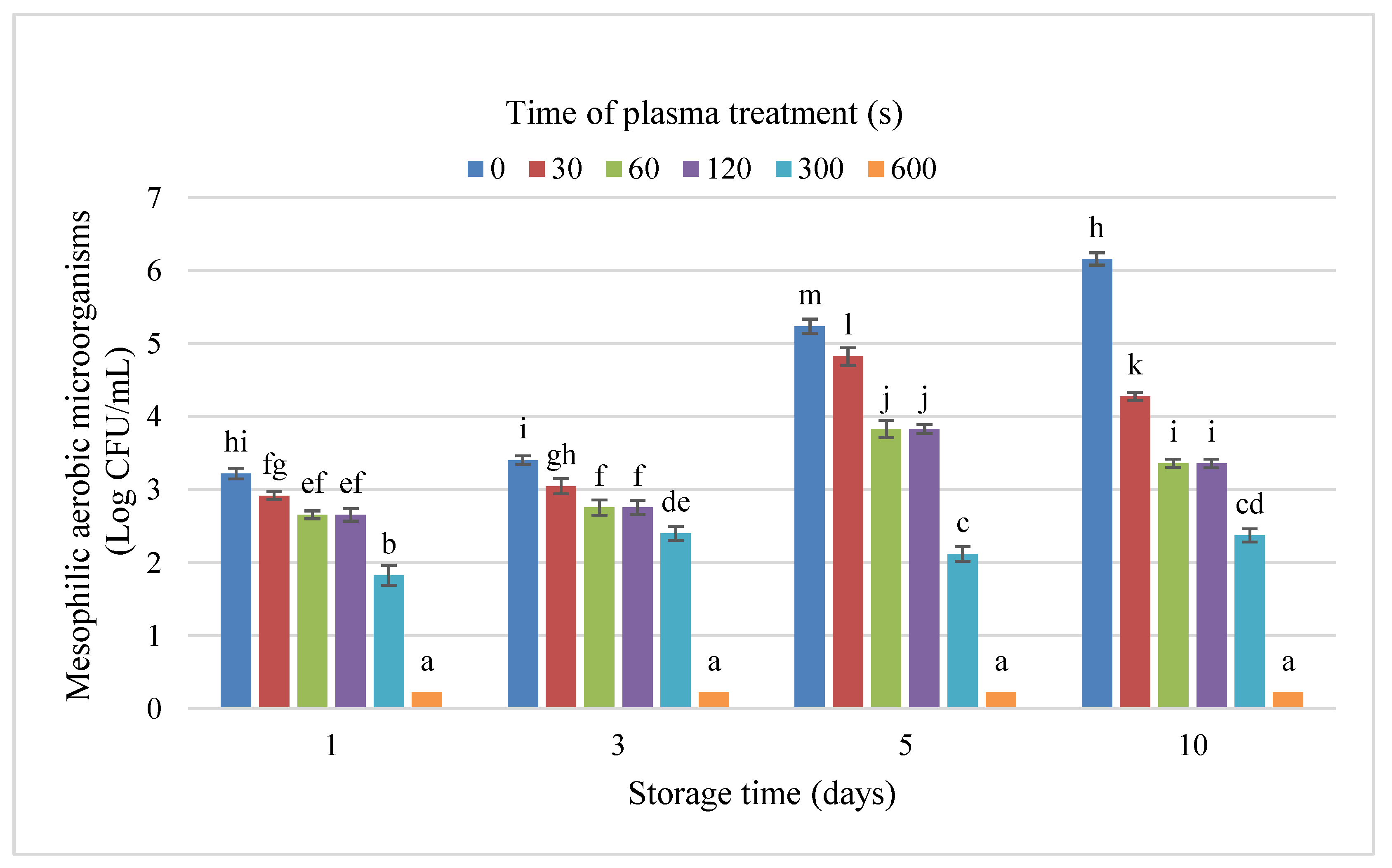

3.2. Effect of CAP on Microorganisms Eradication

3.3. Effect of CAP on the Structure of Tomato Juice

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benton, D.; Young, H.A. Role of fruit juice in achieving the 5-a-day recommendation for fruit and vegetable intake. Nutr. Rev. 2019, 77, 829–843. [Google Scholar] [CrossRef]

- Brunda, G.; Kavyashree, U.; Shetty, S.S.; Sharma, K. Comparative study of not from concentrate and reconstituted from concentrate of pomegranate juices on nutritional and sensory profile. Food Sci. Technol. Int. 2022, 28, 93–104. [Google Scholar] [CrossRef] [PubMed]

- Ivanova, N.N.; Khomich, L.M.; Beketova, N.A. Tomato juice nutritional profile. Vopr. Pitan. 2018, 87, 53–64. [Google Scholar] [PubMed]

- Saeeduddin, M.; Abid, M.; Jabbar, S.; Wu, T.; Hashim, M.M.; Awad, F.N.; Zeng, X. Quality assessment of pear juice under ultrasound and commercial pasteurization processing conditions. LWT-Food Sci. Technol. 2015, 64, 452–458. [Google Scholar] [CrossRef]

- Moussa-Ayoub, T.E.; Jäger, H.; Knorr, D.; El-Samahy, S.K.; Kroh, L.W.; Rohn, S. Impact of pulsed electric fields, high hydrostatic pressure, and thermal pasteurization on selected characteristics of Opuntia dillenii cactus juice. LWT-Food Sci. Technol. 2017, 79, 534–542. [Google Scholar] [CrossRef]

- Tian, Y.; Sun, L.; Yang, Y.; Gou, X.; Niu, P.; Guo, Y. Changes in the physicochemical properties, aromas and polyphenols of not from concentrate (NFC) apple juice during production. CYTA J. Food. 2018, 16, 755–764. [Google Scholar] [CrossRef]

- Asl, P.J.; Rajulapati, V.; Gavahian, M.; Kapusta, I.; Putnik, P.; Khaneghah, A.M.; Marszałek, K. Non-thermal plasma technique for preservation of raw or fresh foods: A review. Food Control. 2021, 134, 108560. [Google Scholar] [CrossRef]

- Ozen, E.; Singh, R.K. Atmospheric cold plasma treatment of fruit juices: A review. Trends Food Sci. Technol. 2020, 103, 144–151. [Google Scholar] [CrossRef]

- Laroque, D.A.; Seó, S.T.; Valencia, G.A.; Laurindo, J.B.; Carciofi, B.A.M. Cold plasma in food processing: Design, mechanisms, and application. J. Food Eng. 2022, 312, 110748. [Google Scholar] [CrossRef]

- Pawłat, J.; Starek-Wójcicka, A.; Kopacki, M.; Terebun, P.; Kwiatkowski, M.; Sujak, A.; Pascuzzi, S.; Santoro, F.; Andrejko, D. Germination Energy, Germination Capacity and Microflora of Allium cepa L. Seeds after RF Plasma Conditioning. Energies 2022, 15, 7687. [Google Scholar] [CrossRef]

- Almeida, F.D.; Cavalcante, R.S.; Cullen, P.J.; Frías, J.M.; Bourke, P.; Fernandes, F.A.; Rodrigues, S. Effects of atmospheric cold plasma and ozone on prebiotic orange juice. Innov. Food Sci. Emerg. Technol. 2015, 32, 127–135. [Google Scholar] [CrossRef]

- Illera, A.E.; Chaple, S.; Sanz, M.T.; Lu SNg, P.; Jones, J.; Carey, E.; Bourke, P. Effect of cold plasma on polyphenol oxidase inactivation in cloudy apple juice and on the quality parameters of the juice during storage. Food Chem. 2019, 3, 100049. [Google Scholar] [CrossRef] [PubMed]

- Terebun, P.; Kwiatkowski, M.; Hensel, K.; Kopacki, M.; Pawłat, J. Influence of Plasma Activated Water Generated in a Gliding Arc Discharge Reactor on Germination of Beetroot and Carrot Seeds. Appl. Sci. 2021, 11, 6164. [Google Scholar] [CrossRef]

- Tarabová, B.; Tampieri, F.; Maran, E.; Marotta, E.; Ostrihoňová, A.; Krewing, M.; Machala, Z. Chemical and Antimicrobial Effects of Air Non-Thermal Plasma Processing of Fresh Apple Juice with Focus on Safety Aspects. Foods 2021, 10, 2055. [Google Scholar] [CrossRef] [PubMed]

- Kučerová, K.; Henselová, M.; Slováková, Ľ.; Bačovčinová, M.; Hensel, K. Effect of Plasma Activated Water, Hydrogen Peroxide, and Nitrates on Lettuce Growth and Its Physiological Parameters. Appl. Sci. 2021, 11, 1985. [Google Scholar] [CrossRef]

- Dasan, B.G.; Boyaci, I.H. Effect of cold atmospheric plasma on inactivation of Escherichia coli and physicochemical properties of apple, orange, tomato juices, and sour cherry nectar. Food Bioproc. Tech. 2018, 11, 334–343. [Google Scholar] [CrossRef]

- Pawłat, J.; Terebun, P.; Kwiatkowski, M.; Tarabová, B.; Kovalova, Z.; Kučerová, K.; Machala, Z.; Janda, M.; Hensel, K. Evaluation of Oxidative Species in Gaseous and Liquid Phase Generated by Mini-Gliding Arc Discharge. Plasma Chem. Plasma. Process. 2019, 39, 627–642. [Google Scholar] [CrossRef]

- Brisset, J.L.; Pawlat, J. Chemical Effects of Air Plasma Species on Aqueous Solutes in Direct and Delayed Exposure Modes: Discharge, Post-discharge and Plasma Activated Water. Plasma Chem. Plasma Process. 2016, 36, 355–381. [Google Scholar] [CrossRef]

- Bruggeman, P.J.; Kushner, M.J.; Locke, B.R.; Gardeniers, J.G.E.; Graham, W.G.; Graves, D.B.; Hofman-Caris, R.C.H.M.; Maric, D.; Reid, J.R.; Ceriani, E.; et al. Plasma–liquid interactions: A review and roadmap. Plasma Sources Sci. Technol. 2016, 25, 053002. [Google Scholar] [CrossRef]

- Kučerová, K.; Machala, Z.; Hensel, K. Transient Spark Discharge Generated in Various N2/O2 Gas Mixtures: Reactive Species in the Gas and Water and Their Antibacterial Effects. Plasma Chem. Plasma Process. 2020, 40, 749–773. [Google Scholar] [CrossRef]

- Sruthi, N.U.; Josna, K.; Pandiselvam, R.; Kothakota, A.; Gavahian, M.; Khaneghah, A.M. Impacts of cold plasma treatment on physicochemical, functional, bioactive, textural, and sensory attributes of food: A comprehensive review. Food Chem. 2022, 368, 130809. [Google Scholar] [CrossRef] [PubMed]

- Pankaj, S.K.; Wan, Z.; Colonna, W.; Keener, K.M. Effect of high voltage atmospheric cold plasma on white grape juice quality. J. Sci. Food Agric. 2017, 97, 4016–4021. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.; Cheng, J.H.; Sun, D.W. Effects of dielectric barrier discharge cold plasma treatments on degradation of anilazine fungicide and quality of tomato (Lycopersicon esculentum Mill) juice. Int. J. Food Sci. Technol. 2021, 56, 69–75. [Google Scholar] [CrossRef]

- Umair, M.; Jabbar, S.; Nasiru, M.M.; Sultana, T.; Senan, A.M.; Awad, F.N.; Zhang, J. Exploring the potential of high-voltage electric field cold plasma (HVCP) using a dielectric barrier discharge (DBD) as a plasma source on the quality parameters of carrot juice. Antibiotics 2019, 8, 235. [Google Scholar] [CrossRef] [PubMed]

- Umair, M.; Jabbar, S.; Senan, A.M.; Sultana, T.; Nasiru, M.M.; Shah, A.A.; Jianhao, Z. Influence of combined effect of ultra-sonication and high-voltage cold plasma treatment on quality parameters of carrot juice. Foods 2019, 8, 593. [Google Scholar] [PubMed]

- Paixão, L.; Fonteles, T.V.; Oliveira, V.S.; Fernandes, F.A.; Rodrigues, S. Cold plasma effects on functional compounds of siriguela juice. Food Bioproc. Tech. 2019, 12, 110–121. [Google Scholar] [CrossRef]

- Fernandes, F.A.; Santos, V.O.; Rodrigues, S. Effects of glow plasma technology on some bioactive compounds of acerola juice. Food Res. Int. 2019, 115, 16–22. [Google Scholar] [CrossRef]

- Jabbari, S.S.; Jafari, S.M.; Dehnad, D.; Shahidi, S.A. Changes in lycopene content and quality of tomato juice during thermal processing by a nanofluid heating medium. J. Food Eng. 2018, 230, 1–7. [Google Scholar] [CrossRef]

- Wang, R.X.; Nian, W.F.; Wu, H.Y.; Feng, H.Q.; Zhang, K.; Zhang, J.; Zhu, W.D.; Becker, K.H.; Fang, J. Atmospheric-pressure cold plasma treatment of contaminated fresh fruit and vegetable slices: Inactivation and physiochemical properties evaluation. Eur. Phys. J. 2012, 66, 276. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, R.; Gan, Z.; Shao, T.; Zhang, X.; He, M.; Sun, A. Effect of cold plasma on blueberry juice quality. Food Chem. 2019, 290, 79–86. [Google Scholar] [CrossRef]

- Castro, D.R.G.; Mar, J.M.; Da Silva, L.S.; Da Silva, K.A.; Sanches, E.A.; Bezerra, J.D.A.; Rodrigues, S.; Fernandes, F.A.N.; Campelo, P.H. Improvement of the Bioavailability of Amazonian Juices Rich in Bioactive Compounds Using Glow Plasma Technique. Food Bioproc. Tech. 2020, 13, 670–679. [Google Scholar] [CrossRef]

- Sarangapani, C.K.; O’Toole, G.; Cullen, P.; Bourke, P. Atmospheric cold plasma dissipation efficiency of agrochemicals on blueberries. Innov. Food Sci. Emerg. Technol. 2017, 44, 235–241. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Rodrigues, S. Cold Plasma Processing on Fruits and Fruit Juices: A Review on the Effects of Plasma on Nutritional Quality. Processes 2021, 9, 2098. [Google Scholar] [CrossRef]

- Kovačević, D.B.; Putnik, P.; Dragović-Uzelac, V.; Pedisić, S.; Jambrak, A.R.; Herceg, Z. Effects of cold atmospheric gas phase plasma on anthocyanins and color in pomegranate juice. Food Chem. 2016, 190, 317–323. [Google Scholar] [CrossRef]

- Sohbatzadeh, F.; Yazdanshenas, H.; Soltani, A.H.; Shabannejad, A. An innovative strategy to rapidly inactivate 8.2-log Enterococcus faecalis in fresh pineapple juice using cold atmospheric plasma. Sci. Rep. 2021, 11, 16010. [Google Scholar] [CrossRef] [PubMed]

- Liao, X.; Li, J.; Muhammad, A.I.; Suo, Y.; Chen, S.; Ye, X.; Ding, T. Application of a dielectric barrier discharge atmospheric cold plasma (Dbd-Acp) for Eshcerichia coli inactivation in apple juice. J. Food Sci. 2018, 83, 401–408. [Google Scholar] [CrossRef] [PubMed]

| Storage Time (Days) | |||||

|---|---|---|---|---|---|

| Chemical Parameters | Time of Plasma Treatment (s) | 1 | 3 | 5 | 10 |

| pH | 0 (control) | 3.89 ± 0.02 Ac | 3.65 ± 0.06 Ab | 3.35 ± 0.05 Aa | NP |

| 30 | 4.41 ± 0.00 Ba | 4.41 ± 0.00 Ba | 4.42 ± 0.00 Ba | 4.43 ± 0.00 Aa | |

| 60 | 4.42 ± 0.01 Ba | 4.43 ± 0.01 Ba | 4.43 ± 0.00 Ba | 4.44 ± 0.00 Aa | |

| 120 | 4.46 ± 0.00 Ba | 4.46 ± 0.00 Ba | 4.48 ± 0.00B Ca | 4.48 ± 0.00 Aa | |

| 300 | 4.46 ± 0.00 Ba | 4.55 ± 0.00 Cb | 4.54 ± 0.03 Cb | 4.55 ± 0.01 Bb | |

| 600 | 4.45 ± 0.00 Ba | 4.53 ± 0.04 Cb | 4.52 ± 0.01 Cb | 4.57 ± 0.02 Bb | |

| Total Soluble Solids (°Brix) | 0 (control) | 3.67 ± 0.06 Aa | 3.57 ± 0.06 Aa | 3.33 ± 0.06 Ab | NP |

| 30 | 3.67 ± 0.06 Aa | 3.70 ± 0.00 Aa | 3.70 ± 0.00 Ba | 4.10 ± 0.00 Bb | |

| 60 | 3.70 ± 0.00 Aa | 3.70 ± 0.00 Aa | 3.87 ± 0.12 Bb | 4.00 ± 0.10 Bb | |

| 120 | 3.67 ± 0.06 Aa | 3.67 ± 0.06 Aa | 3.83 ± 0.06 BCab | 3.87 ± 0.06 Ab | |

| 300 | 3.80 ± 0.00 Aab | 3.70 ± 0.00 Aa | 3.93 ± 0.06 BCb | 3.83 ± 0.06 Aab | |

| 600 | 3.83 ± 0.06 Aab | 3.87 ± 0.06 Bab | 3.97 ± 0.15 Cb | 3.77 ± 0.06 Aa | |

| Lycopene (mg/100 g) | 0 (control) | 66.70 ± 1.20 Ab | 65.00 ± 0.23 Ab | 62.38 ± 0.24 Aa | NP |

| 30 | 67.37 ± 0.14 Aa | 67.36 ± 0.14 Aa | 67.37 ± 0.71 Ba | 65.96 ± 0.14 Aa | |

| 60 | 66.48 ± 0.78 Aa | 65.15 ± 0.49 Aa | 66.64 ± 0.42 Ba | 65.35 ± 0.49 Aa | |

| 120 | 65.20 ± 0.85 Aa | 64.79 ± 0.71 Aa | 64.19 ± 0.57 Aa | 64.86 ± 0.57 Aa | |

| 300 | 66.09 ± 0.21 Aa | 66.09 ± 1.13 Aa | 66.51 ± 0.49 Ba | 66.43 ± 0.07 Aa | |

| 600 | 66.50 ± 0.00 Aa | 65.86 ± 0.07 Aa | 66.74 ± 0.49 Ba | 66.43 ± 0.04 Aa | |

| Ascorbic acid (mg/100 g) | 0 (control) | 277.45 ± 0.49 Bc | 261.90 ± 0.71 Ab | 238.55 ± 0.64 Aa | NP |

| 30 | 275.60 ± 0.28 Ac | 273.15 ± 0.92 BCbc | 271.40 ± 0.14 Bb | 266.40 ± 0.42 Aa | |

| 60 | 273.55 ± 0.64 Ab | 272.20 ± 2.12 BCb | 271.80 ± 0.28 Bb | 266.60 ± 0.28 Aa | |

| 120 | 274.35 ± 0.64 Ab | 271.20 ± 0.14 Ba | 273.75 ± 0.92 BCb | 268.30 ± 0.85 Aa | |

| 300 | 273.30 ± 1.27 Aa | 272.35 ± 0.49 BCa | 273.25 ± 0.21 BCa | 270.05 ± 0.07 Ba | |

| 600 | 273.80 ± 2.12 Ab | 275.05 ± 0.92 Cb | 276.05 ± 0.21 Cb | 268.55 ± 0.78 ABa | |

| Time of Plasma Treatment (s) | Time Storage (Days) | Colour Attributes | ΔE | ||

|---|---|---|---|---|---|

| L* | a* | b* | |||

| 0 (Control) | 31.60 ± 0.09 g | 6.68 ± 0.33 h | 4.71 ± 0.22 f | NP | |

| 30 | 1 | 30.23 ± 0.02 e | 4.94 ± 0.01 d | 3.26 ± 0.01 bcd | 2.65 ± 0.38 b |

| 60 | 30.15 ± 0.03 de | 4.87 ± 0.01 d | 3.32 ± 0.02 cd | 2.68 ± 0.37 b | |

| 120 | 30.07 ± 0.03 d | 4.77 ± 0.04 de | 3.26 ± 0.01 bcd | 2.75 ± 0.38 g | |

| 300 | 29.77 ± 0.02 a | 4.51 ± 0.02 de | 3.09 ± 0.02 be | 2.94 ± 0.37 c | |

| 600 | 29.78 ± 0.03 a | 4.40 ± 0.02 abc | 3.22 ± 0.03 bc | 2.94 ± 0.37 c | |

| 0 (control) | 10 | 29.75 ± 0.04 a | 4.46 ± 0.01 bc | 2.93 ± 0.02 e | NP |

| 30 | 29.62 ± 0.03 bc | 4.43 ± 0.02 abc | 2.73 ± 0.02 a | 0.72 ± 0.06 d | |

| 60 | 29.55 ± 0.04 b | 4.15 ± 0.03 a | 2.58 ± 0.01 a | 1.14 ± 0.08 f | |

| 120 | 29.52 ± 0.02 b | 4.18 ± 0.03 ab | 2.70 ± 0.02 a | 1.06 ± 0.09 e | |

| 300 | 29.36 ± 0.02 f | 3.86 ± 0.06 g | 3.86 ± 0.06 a | 1.36 ± 0.12 a | |

| 600 | 29.70 ± 0.03 ac | 2.96 ± 0.01 f | 2.96 ± 0.01 d | 1.38 ± 0.15 a | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Starek-Wójcicka, A.; Sagan, A.; Terebun, P.; Kwiatkowski, M.; Osmólska, E.; Krajewska, M.; Grządka, E.; Matsuyama, N.; Hayashi, N.; Pawlat, J. Quality of Tomato Juice as Influenced by Non-Thermal Air Plasma Treatment. Appl. Sci. 2023, 13, 578. https://doi.org/10.3390/app13010578

Starek-Wójcicka A, Sagan A, Terebun P, Kwiatkowski M, Osmólska E, Krajewska M, Grządka E, Matsuyama N, Hayashi N, Pawlat J. Quality of Tomato Juice as Influenced by Non-Thermal Air Plasma Treatment. Applied Sciences. 2023; 13(1):578. https://doi.org/10.3390/app13010578

Chicago/Turabian StyleStarek-Wójcicka, Agnieszka, Agnieszka Sagan, Piotr Terebun, Michał Kwiatkowski, Emilia Osmólska, Marta Krajewska, Elżbieta Grządka, Narumol Matsuyama, Nobuya Hayashi, and Joanna Pawlat. 2023. "Quality of Tomato Juice as Influenced by Non-Thermal Air Plasma Treatment" Applied Sciences 13, no. 1: 578. https://doi.org/10.3390/app13010578

APA StyleStarek-Wójcicka, A., Sagan, A., Terebun, P., Kwiatkowski, M., Osmólska, E., Krajewska, M., Grządka, E., Matsuyama, N., Hayashi, N., & Pawlat, J. (2023). Quality of Tomato Juice as Influenced by Non-Thermal Air Plasma Treatment. Applied Sciences, 13(1), 578. https://doi.org/10.3390/app13010578