The Use of Artificial Intelligence for Assessing the Pro-Environmental Practices of Companies

Abstract

Featured Application

Abstract

1. Introduction

1.1. Review of the Literature

1.2. Reference to Greater Poland

- Finance—an area in which pro-environmental action is aimed at securing better economic results;

- Customers—an area in which the needs of beneficiaries are taken care of, safe work conditions are provided to internal customers, and a competitive edge of the enterprise is built;

- Environmental protection-related operational activity—an area of economic resource management and mitigation of environmental impacts;

- To investigate whether there are differences in the introduction of environmental issues in SMEs and LEs in the Greater Poland Voivodship;

- To examine whether companies in the Greater Poland Voivodship are equally aware of the impact of their business activities and their products on the environment;

- To discover novel, more rapid, and simpler methods to analyze the environmental friendliness of companies, including more efficient models based on artificial intelligence.

2. Materials and Methods

2.1. Material

2.2. Methods

2.3. Statistical Analysis

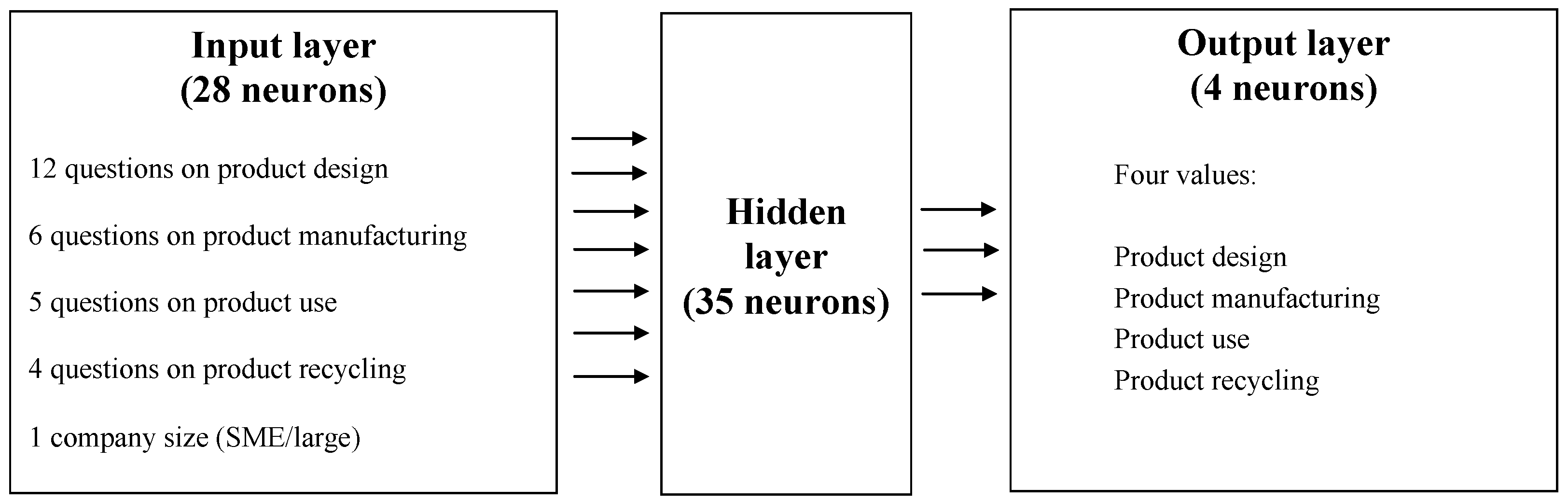

2.4. Computational Analysis

3. Results

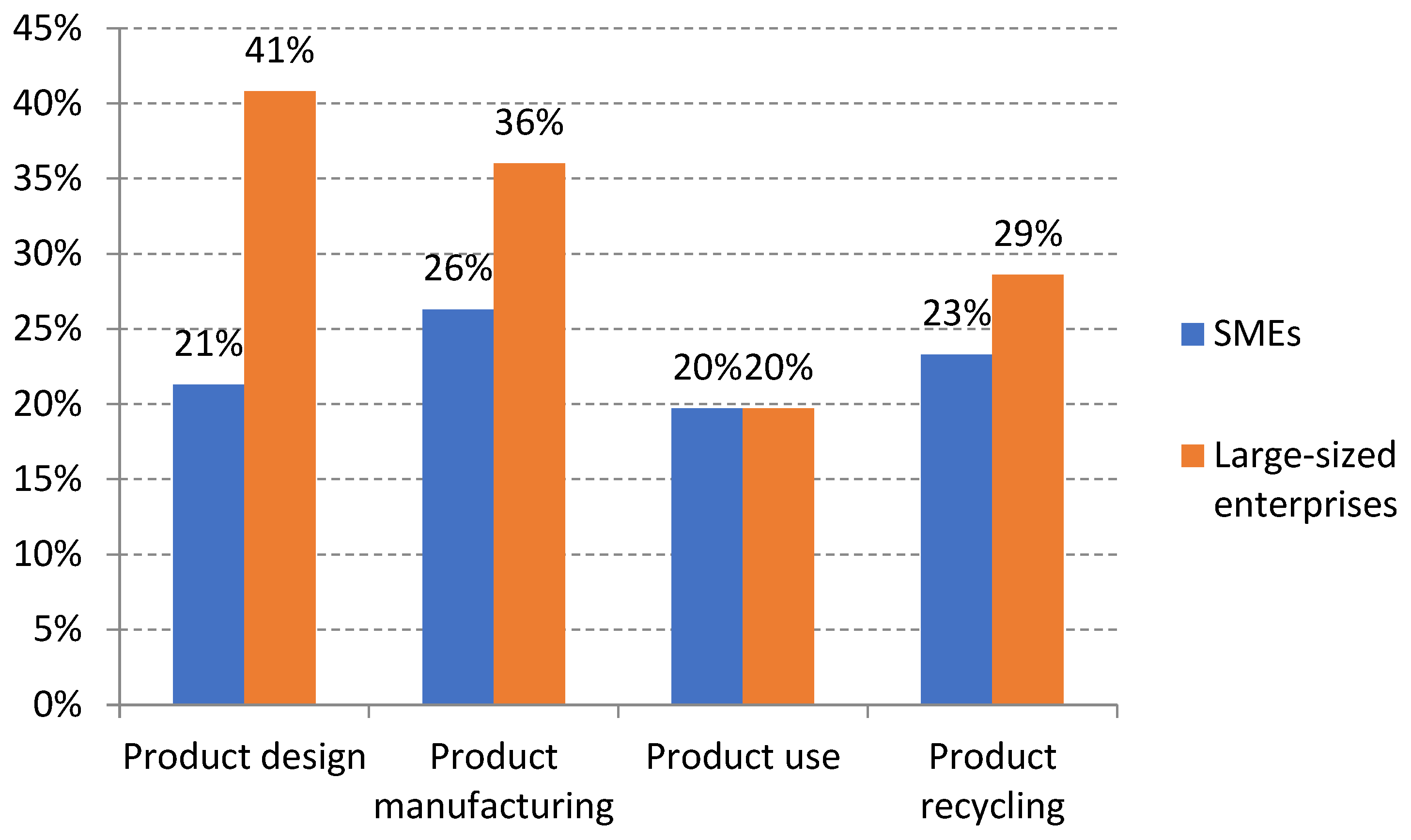

3.1. Analysis of Data Obtained from the Questionnaires

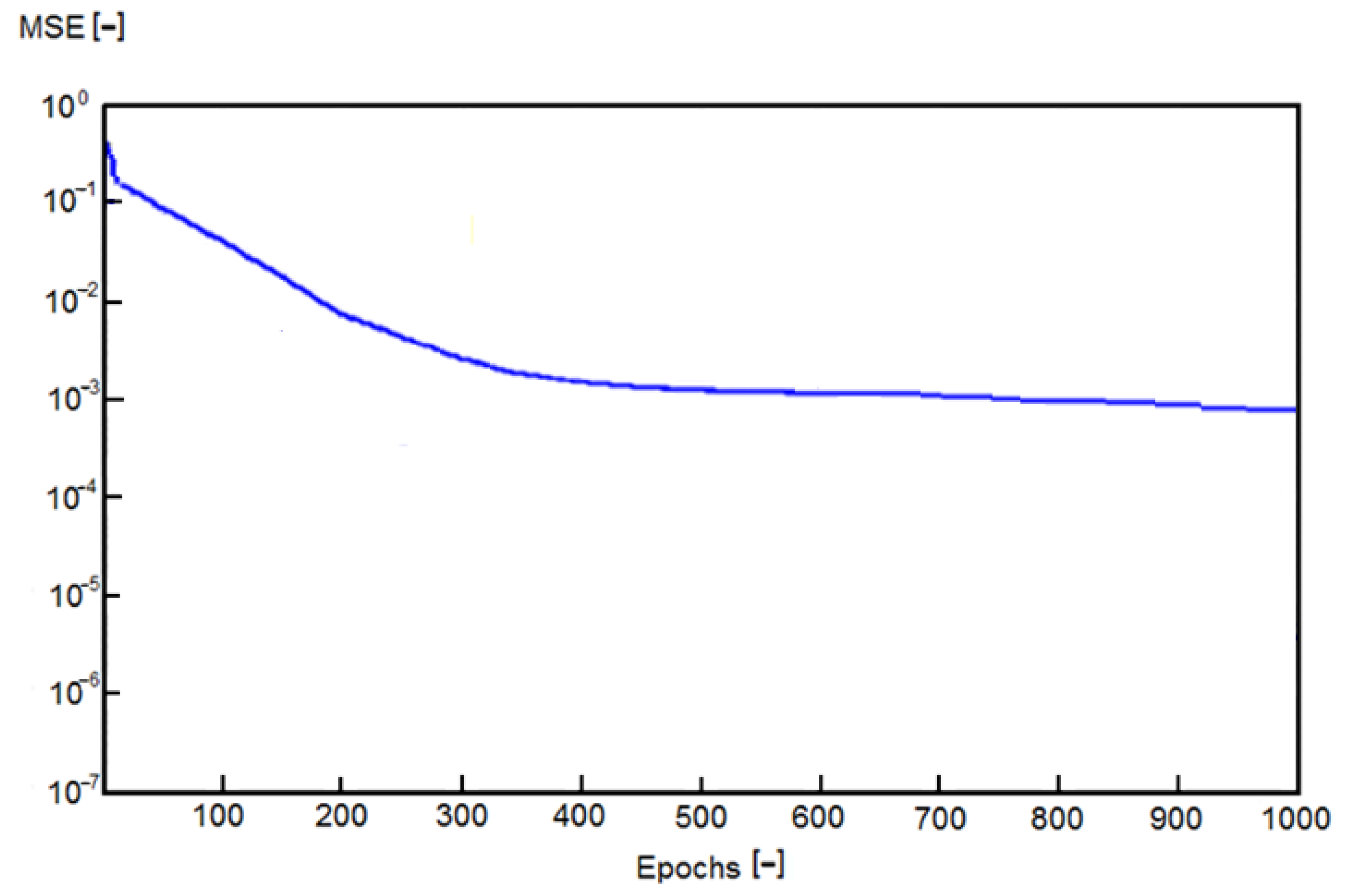

3.2. Computational Analysis

4. Discussion

4.1. Achieved Results

4.2. Limits of the Study

4.3. Expected Impacts

- Social impacts:

- Building public awareness of environmentally friendly products and services and pro-environmental producers;

- Education regarding green order, respect for the environment and its resources, while harmoniously co-existing with human beings;

- Shaping the behavior of environmentally conscious customer groups;

- Research into the formation of a pro-ecological market, market preferences, and the promotion of pro-environmental behavior;

- Shaping general global trends in the area of human smart cities as communities.

- Impacts on research:

- Inspiration for further research into innovative pro-environmental organizational processes, production, new products, and service families;

- Sustainability as one of the key criteria in all scientific disciplines.

- Impacts on industry and trade:

- Adaptation of industrial processes utilized at present toward sustainability;

- The emergence of novel functionalities, including those expected by from pro-eco customers;

- Product development strategies through simple improvements or the replacement of modules rather than the replacement of entire products;

- Personalized 3D printing using environmentally friendly materials;

- The spread of the zero-waste paradigm in manufacturing.

4.4. Directions for Future Research

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Domańska, A. Environmental awareness as part of corporate social responsibility of the pharmaceutical and medical industry. Zesz. Nauk. Politech. Częstochowskiej Zarządzanie 2013, 10, 138–145. [Google Scholar]

- General Characteristics of the Wielkopolska Province. Available online: http://wzk.poznan.uw.gov.pl/sites/default/files/zalaczniki/ogolna_charakterystyka_cz2.pdf (accessed on 30 October 2022).

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; A Renewed EU strategy 2011-14 for Corporate Social Responsibility; European Commission: Brussels, Belgium, 2011.

- Innovation and CRS at SMEs. Raport2012. Available online: http://odpowiedzialnybiznes.pl (accessed on 30 October 2022).

- van Hemel, C.; Cramer, J. Barriers and stimuli for ecodesign in SMEs. J. Clean. Prod. 2002, 10, 439–453. [Google Scholar] [CrossRef]

- Coté, R.; Booth, A.; Louis, B. Eco-efficiency and SMEs in Nova Scotia, Canada. J. Clean. Prod. 2006, 14, 542–550. [Google Scholar] [CrossRef]

- Erkko, S.; Melanen, M.; Mickwitz, P. Eco-efficiency in the Finnish EMAS reports—A buzz word? J. Clean. Prod. 2005, 13, 799–813. [Google Scholar] [CrossRef]

- Netregs. SME-Nvironment England. A Review of Changing Environmental Attitudes and Behaviours among Small and Medium-Sized Businesses in England. 2005. Available online: http://www.netregs.gov.uk/netregs/1169119/?lang=_e (accessed on 30 October 2022).

- Fernández-Viñé, M.B.; Gómez-Navarro, T.; Capuz-Rizo, S.F. Eco-efficiency in the SMEs of Venezuela. Current status and future perspectives. J. Clean. Prod. 2010, 18, 736–746. [Google Scholar] [CrossRef]

- Capuz, S.; Gómez, T.; Viñoles, R.; López, R.; Bastante, M.; Vivancos, J.; Ferrer, P. Situación actual y perspectivas del Ecodiseñoen las PyMEs de la ComunidadValencian; Universidad Politécnica de Valencia: Valencia, Spain, 2003. [Google Scholar]

- Vives, A.; Corral, A.; Isusi, I. Responsabilidad Social de la Empresaen las PyMEs de Latinoamérica. Subdepartamento de EmpresaPrivada y MercadosFinancieros Banco Interamericano de Desarrollo (BID), Washington 2005. Available online: http://www.cumpetere.com/documents/rse%20en%20pymes.pdf (accessed on 30 October 2022).

- Stoyell, J.L.; Norman, P.; Howarth, C.R.; Vaughan, R. Results of a questionnaire investigation on the management of environmental issues during conceptual design. A case study of two large made-to-order companies. J. Clean. Prod. 1999, 7, 457–464. [Google Scholar] [CrossRef]

- Guzmán, L. PropuestaMetodológica para la Integración del Factor Ambientalen el Diseño de Productos y de Procesos, a Través del Sistema de Gestión, en la Industria del Mueble. Caso de Estudio: Sector del Mueble del Estado de Jalisco (México). Ph.D. Thesis, Universidad Politécnica de Valencia, Valencia, Spain, 2005. [Google Scholar]

- Dekoninck, E.A.; Domingo, L.; O’Hare, J.A.; Pigosso, D.C.A.; Reyes, T.; Troussier, N. Defining the challenges for ecodesign implementation in companies: Development and consolidation of a Framework. J. Clean. Prod. 2016, 135, 410–425. [Google Scholar] [CrossRef]

- Cai, W.; Zhou, X. On the drivers of eco-innovation: Empirical evidence from China. J. Clean. Prod. 2014, 79, 239–248. [Google Scholar] [CrossRef]

- Bey, N.; Hauschild, M.Z.; McAloone, T.C. Drivers and barriers for implementation of environmental strategies in manufacturing companies. CIRP Ann. Manuf. Technol. 2013, 62, 43–46. [Google Scholar] [CrossRef]

- Kara, S.; Ibbotson, S.; Kayis, B. 2014. Sustainable product development in practice: An international survey. J. Manuf. Technol. Manag. 2014, 25, 848–872. [Google Scholar] [CrossRef]

- Akman, G.; Pişkin, H.; Okudan Kremer, G. Evaluating ecodesign activities of manufacturing companies in a developing country. In Proceedings of the ASME 23rd International Conference on Design Theory and Methodology; 16th Design for Manufacturing and the Life Cycle Conference, Washington, DC, USA, 28–31 August 2011; Volume 9, pp. 995–1001. [Google Scholar]

- Baumann, H.; Boons, F.; Bragd, A. Mapping the green product development field: Engineering, policy and business perspectives. J. Clean. Prod. 2002, 10, 409–425. [Google Scholar] [CrossRef]

- Hart, S.L.; Dowell, G. Anatural-resource-based view of the firm: Fifteen years after. J. Manag. 2011, 37, 1464–1479. [Google Scholar]

- Bryke, M.; Starzyńska, B. Human Lean Green conception as the instrument of sustainability of organizational development oriented towards the increase of its effectiveness. Res. Pap. Wrocław Univ. Econ. 2015, 77, 119–136. [Google Scholar]

- Gangala, C.; Modi, M.; Manupati, V.K.; Varela, M.L.R.; Machado, J.; Trojanowska, J. Cycle Time Reduction in Deck Roller Assembly Production Unit with Value Stream Mapping Analysis. In World Conference on Information Systems and Technologies, Proceedings of the World CIST 2017: Recent Advances in Information Systems and Technologies, Madeira, Portugal, 11–13 April 2017; Rocha, Á., Correia, A., Adeli, H., Reis, L., Costanzo, S., Eds.; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2017; Volume 571, pp. 509–518. [Google Scholar] [CrossRef]

- Rodrigues, V.P.; Pigosso, D.C.A.; McAloone, T.C. Measuring the implementation of ecodesign management practices: A review and consolidation of process-oriented performance indicators. J. Clean. Prod. 2017, 156, 293–309. [Google Scholar] [CrossRef]

- McAloone, T.; Bey, N. Environmental Improvement through Product Development: A Guide; Danish Environmental Protection Agency: Copenhagen, Denmark, 2009.

- Grajewski, D.; Diakun, J.; Wichniarek, R.; Dostatni, E.; Buń, P.; Górski, F.; Karwasz, A. Improving the Skills and Knowledge of Future Designers in the Field of Ecodesign Using Virtual Reality Technologies. Procedia Comput. Sci. 2015, 75, 348–358. [Google Scholar] [CrossRef]

- Dostatni, E.; Diakun, J.; Grajewski, D.; Wichniarek, R.; Karwasz, A. Multi-agent system to support decision-making process in design for recycling. Soft Comput. 2016, 20, 4347–4361. [Google Scholar] [CrossRef]

- Kujawińska, A.; Vogt, K. Human factors in visual control. Manag. Prod. Eng. Rev. 2015, 6, 25–31. [Google Scholar] [CrossRef]

- Kujawińska, A.; Vogt, K.; Wachowiak, F. Ergonomics as Significant Factor of Sustainable Production. In Technology Management for Sustainable Production and Logistics, Book Series: EcoProduction; Golińska, P., Kawa, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 193–203. [Google Scholar]

- Pigosso, D.C.; McAloone, T.C.; Rozenfeld, H. Characterization of the state-of-the-art and identification of main trends for eco design tools and methods: Classifying three decades of research and implementation. J. Indian Inst. Sci. 2015, 95, 405–427. [Google Scholar]

- Pigosso, D.C.A.; Rozenfeld, H.; McAloone, T.C. Ecodesign maturity model: A management framework to support ecodesign implementation into manufacturing companies. J. Clean. Prod. 2013, 59, 160–173. [Google Scholar] [CrossRef]

- Diakun, J.; Dostatni, E.; Grajewski, D.; Wichniarek, R.; Karwasz, A.; Brzezinski, W.; Ciechanowicz, B. Modelling and Recycling-Oriented Assessment of Household Appliances. In International Conference on Intelligent Systems in Production Engineering and Maintenance, Proceedings of the Intelligent Systems in Production Engineering and Maintenance—ISPEM 2017, Wrocław, Poland, 28–29 September2017; Burduk, A., Mazurkiewicz, D., Eds.; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2017; Volume 637, pp. 306–315. [Google Scholar] [CrossRef]

- Bovea, M.D.; Gallardo, A. The influence of impact assessment methods on materials selection for eco-design. Mater. Des. 2006, 27, 209–215. [Google Scholar] [CrossRef]

- Köhler, A.R. Challenges for eco-design of emerging technologies: The case of electronic textiles. Mater. Des. 2013, 51, 51–60. [Google Scholar] [CrossRef]

- Kiurski, J.S.; Maric, B.B.; Oros, I.B.; Keci, V.S. The ecodesign practice in Serbian printing industry. J.Clean. Prod. 2017, 149, 1200–1209. [Google Scholar] [CrossRef]

- Kujawińska, A.; Diering, M.; Rogalewicz, M.; Żywicki, K.; Hetman, Ł. Soft Modelling-Based Methodology of Raw Material Waste Estimation, Intelligent Systems in Production Engineering and Maintenance. In International Conference on Intelligent Systems in Production Engineering and Maintenance, Proceedings of theIntelligent Systems in Production Engineering and Maintenance–ISPEM 2017, Wrocław, Poland, 28–29 September 2017; Burduk, A., Mazurkiewicz, D., Eds.; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2017; Volume 637, pp. 407–417. [Google Scholar] [CrossRef]

- Rojek, I.; Jagodziński, M. Hybrid Artificial Intelligence System in Constraint Based Scheduling of Integrated Manufacturing ERP Systems. In International Conference on Hybrid Artificial Intelligence Systems, Proceedings of theHAIS 2012: Hybrid Artificial Intelligent Systems, Salamanca, Spain, 28–30 March 2012; Corchado, E., Snášel, V., Abraham, A., Woźniak, M., Graña, M., Cho, S.B., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2012; Volume 7209, pp. 229–240. [Google Scholar] [CrossRef]

- Rojek, I. Technological Process Planning by the Use of Neural Networks. Artif. Intell. Eng. Des. Anal. Manuf. 2017, 31, 1–15. [Google Scholar] [CrossRef]

- Dostatni, E.; Diakun, J.; Grajewski, D.; Wichniarek, R.; Karwasz, A. Multi-agent system to support decision-making process in ecodesign. In Proceedings of the 10th International Conference on Soft Computing Models in Industrial and Environmental Applications (SOCO), Burgos, Spain, 15–17 June 2015; pp. 463–474. [Google Scholar] [CrossRef]

- Jasiulewicz-Kaczmarek, M. Integrating Lean and Green Paradigms in Maintenance Management. In Proceedings of the 19th IFAC World Congress Cape Town, Cape Town, South Africa, 25–29 August 2014; pp. 4471–4476. [Google Scholar]

- European Commission. Recast of the RoHS Directive–Environment-European Commission. 2014. Available online: http://ec.europa.eu/environment/waste/rohs_eee/ (accessed on 30 October 2022).

- European Commission. Waste Electrical and Electronic Equipment–Environment-European Commission. Retrieved. 2014. Available online: http://ec.europa.eu/environment/waste/weee/legis_en.htm (accessed on 30 October 2022).

- Boks, C. The soft side of ecodesign. J. Clean. Prod. 2006, 14, 1346–1356. [Google Scholar] [CrossRef]

- Boks, C.; Stevels, A. Essential perspectives for design for environment. Experiences from the electronics industry. Int. J. Prod. Res. 2007, 45, 4021–4039. [Google Scholar] [CrossRef]

- Sihvonen, S.; Partanen, J. Implementing environmental considerations within product development practices: A survey on employees’ perspectives. J. Clean. Prod. 2016, 125, 189–203. [Google Scholar] [CrossRef]

- Brones, F.; Carvalho, M.M. From 50 to 1: Integrating literature toward a systemic ecodesign model. J. Clean. Prod. 2015, 96, 44–57. [Google Scholar] [CrossRef]

- Deutz, P.; McGuire, M.; Neighbour, G. Eco-design practice in the context of a structured design process: An interdisciplinary empirical study of UK manufacturers. J. Clean. Prod. 2013, 39, 117–128. [Google Scholar] [CrossRef]

- Poulikidou, S.; Tyskeng, A.; Björklund, S. Empirical study on integration of environmental aspects into product development: Processes, requirements and the use of tools in vehicle manufacturing companies in Sweden. J. Clean. Prod. 2014, 81, 34–45. [Google Scholar] [CrossRef]

- Ammenberg, J.; Sundin, E. Products in environmental management systems: Drivers, barriers and experiences. J. Clean. Prod. 2005, 13, 405–415. [Google Scholar] [CrossRef]

- Le Pochat, S.; Bertoluci, G.; Froelich, D. Integrating ecodesign by conducting changes in SMEs. J. Clean. Prod. 2007, 15, 671–680. [Google Scholar] [CrossRef]

- Pigosso, D.C.; McAloone, T.C.; Rozenfeld, H. Systematization of best practices for ecodesign implementation. In Proceedings of the International Design Conference–Design, London, UK, 2–4 September 2014; pp. 1651–1662. [Google Scholar]

- Short, T.; Lee-Mortimer, A.; Luttropp, C.; Johansson, G. Manufacturing, sustainability, ecodesign and risk: Lessons learned from a study of Swedish and English companies. J. Clean. Prod. 2012, 37, 342–352. [Google Scholar] [CrossRef]

- Adner, R. Ecosystem as Structure: An Actionable Construct for Strategy. J. Manag. 2017, 43, 39–58. [Google Scholar] [CrossRef]

- Joo, J.; Shin, M.M. Building sustainable business ecosystems through customer participation: A lesson from South Korean cases. Asia Pac. Manag. Rev. 2018, 23, 1–11. [Google Scholar] [CrossRef]

- MA-Millennium Ecosystem Assessment. Ecosystems and Human Well-being: Synthesis; Island Press: Washington, DC, USA, 2005. [Google Scholar]

- Report on Survey on Awareness, Attitudes and Behaviours of Poles in 2009–2015 [Raport z analizy badań świadomości, postaw i zachowań ekologicznych Polaków przeprowadzonych w Polsce w latach 2009–2015], Report prepared for the Polish Ministry of Environment by the Social Research Team at TNS Poland. TNS 2015. (In Polish). Available online: https://www.gov.pl/web/nfosigw/raport-z-analizy-badan-swiadomosci-postaw-i-zachowan-ekologicznych-polakow-przeprowadzonych-w-polsce-w-latach-2009-2015 (accessed on 30 October 2022).

- Sędek, A. The method for evaluating the environmental approach of manufacturing companies. Zesz. Nauk. Politech. Śląskiej Organ. I Zarządzanie 2010, 53, 379–391. [Google Scholar]

- Starzyńska, B.; Hamrol, A. Excellence toolbox: Decision support system for quality tools and techniques selection and application. Total Qual. Manag. Bus. Excell. 2013, 24, 577–595. [Google Scholar] [CrossRef]

- Pisek, J. The Structure of a Questionnaire–Preparing A Survey; J. Lompa Pedagogical Provincial Library in Katowice, Branch in Pszczyna (Poland): Pszczyna, Poland, 2019; Available online: https://e-pedagogiczna.edu.pl/upload/file/dzialalnoscedu/ANKIETA-szkolenie_dla_student_363w.pdf (accessed on 30 October 2022).

- Piechowiak, J.; Kowalski, Ł. Analysis of EnvironmentalSolutionSimplemented in Manufacturingcompanies [Analiza rozwiązań proekologicznych stosowanych w przedsiębiorstwach produkcyjnych]. Master’s Thesis, Faculty of Mechanical Engineering and Management, Poznań University of Technology, Poznań, Poland, 2015. (In Polish). [Google Scholar]

- Selech, J.; Joachimiak-Lechman, K.; Klos, Z.; Kulczycka, J.; Kurczewski, P. Life cycle thinking in small and medium enterprises: The results of research on the implementation of life cycle tools in Polish SME-s Part 3: LCC-related aspects. Int. J. Life Cycle Assess. 2014, 19, 1119–1128. [Google Scholar] [CrossRef]

- Li, Y.; Hou, X.; Zhang, W.; Xiong, W.; Wang, L.; Zhang, S.; Wang, P.; Wang, C. Integration of life cycle assessment and statistical analysis to understand the influence of rainfall on WWTPs with combined sewer systems. J. Clean. Prod. 2018, 172, 2521–2530. [Google Scholar] [CrossRef]

- Grant, A.; Ries, R.; Thompson, P. Quantitative approaches in life cycle assessment—Part 1—Descriptive statistics and factor analysis. Int. J. Life Cycle Assess. 2016, 21, 903–911. [Google Scholar] [CrossRef]

- Ganesapillai, M.; Sinha, A.; Mehta, R.; Tiwari, A.; Chellappa, V.; Drewnowski, J. Design and Analysis of Artificial Neural Network (ANN) Models for Achieving Self-Sustainability in Sanitation. Appl. Sci. 2022, 12, 3384. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, S.; Zhang, J.; Tang, L.; Bai, Y. Using Artificial Neural Network Algorithm and Remote Sensing Vegetation Index Improves the Accuracy of the Penman-Monteith Equation to Estimate Cropland Evapotranspiration. Appl. Sci. 2021, 11, 8649. [Google Scholar] [CrossRef]

- Fernández-López, A.; Marín-Sánchez, D.; García-Mateos, G.; Ruiz-Canales, A.; Ferrández-Villena-García, M.; Molina-Martínez, J.M. A Machine Learning Method to Estimate Reference Evapotranspiration Using Soil Moisture Sensors. Appl. Sci. 2020, 10, 1912. [Google Scholar] [CrossRef]

- Menapace, A.; Zanfei, A.; Righetti, M. Tuning ANN Hyperparameters for Forecasting Drinking Water Demand. Appl. Sci. 2021, 11, 4290. [Google Scholar] [CrossRef]

- Chen, Y.; Song, L.; Liu, Y.; Yang, L.; Li, D. A Review of the Artificial Neural Network Models for Water Quality Prediction. Appl. Sci. 2020, 10, 5776. [Google Scholar] [CrossRef]

- Ma, Y.-J.; Zhai, M.-Y. A Dual-Step Integrated Machine Learning Model for 24h-Ahead Wind Energy Generation Prediction Based on Actual Measurement Data and Environmental Factors. Appl. Sci. 2019, 9, 2125. [Google Scholar] [CrossRef]

- Faraji, J.; Abazari, A.; Babaei, M.; Muyeen, S.M.; Benbouzid, M. Day-Ahead Optimization of Prosumer Considering Battery Depreciation and Weather Prediction for Renewable Energy Sources. Appl. Sci. 2020, 10, 2774. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Macko, M. AI-optimized technological aspects of the material used in 3D printing processes for selected medical applications. Materials 2020, 13, 5437. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Macko, M.; Szczepański, Z.; Dostatni, E. Optimization of extrusion-based 3D printing process using neural networks for sustainable development. Materials 2021, 14, 2737. [Google Scholar] [CrossRef]

- Prokopowicz, P.; Mikołajewski, D.; Tyburek, K.; Mikołajewska, E. Computational gait analysis for post-stroke rehabilitation purposes using fuzzy numbers, fractal dimension and neural networks. Bull. Pol. Acad. Sci. Tech. Sci. 2020, 68, 191–198. [Google Scholar]

- Prokopowicz, P.; Mikołajewski, D. Fuzzy Approach to Computational Classification of Burnout—Preliminary Findings. Appl. Sci. 2022, 12, 3767. [Google Scholar] [CrossRef]

- Pasini, A. Artificial neural networks for small dataset analysis. J. Thorac. Dis. 2015, 7, 953–960. [Google Scholar] [PubMed]

- Feng, S.; Zhou, H.; Dong, H. Using deep neural network with small dataset to predict material defects. Mater. Des. 2019, 162, 300–310. [Google Scholar] [CrossRef]

- Elliott, A.C.; Woodward, W.A. Statistical Analysis Quick Reference Guidebook: With SPSS Examples; Sage Publications: Thousand Oaks, CA, USA, 2007. [Google Scholar]

- Rojek, I. Neural networks as performance improvement models in intelligent CAPP systems. Control Cybern. 2010, 39, 55–68. [Google Scholar]

- Rojek, I.; Kowal, M.; Stoic, A. Predictive compensation of thermal deformations of ball screws in CNC machines using neural networks. Tehnicki Vjesnik 2017, 24, 1697–1703. [Google Scholar]

- Rojek, I. Hybrid Neural Networks as Prediction Models. In Artificial Intelligence and Soft Computing, Lecture Notes in Artificial Intelligence; Rutkowski, L., Scherer, R., Tadeusiewicz, R., Zadeh, L.A., Zurada, J.M., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 88–95. [Google Scholar]

- Rojek, I. Classifier models in intelligent CAPP systems. In Man-Machine Interactions, Advances in Intelligent and Soft Computing; Cyran, K.A., Kozielski, S., Peters, J.F., Stanczyk, U., Wakulicz-Deja, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 311–319. [Google Scholar]

- Tatomir, A.; McDermott, C.; Bensabat, J.; Class, H.; Edlmann, K.; Taherdangkoo, R.; Saute, M. Conceptual model development using a generic Features, Events, and Processes (FEP) database for assessing the potential impact of hydraulic fracturing on groundwater aquifers. Adv. Geosci. 2018, 45, 185–192. [Google Scholar] [CrossRef]

| Area | Factors |

|---|---|

| Knowledge and development | Optimum level of capital expenditures on environmental protection Implementation of an environmental management system Having environmental protection programs in place and planning environmental protection activities Motivating employees to comply with the environmental rules and assessment of their performance in this respect |

| Environmental protection-related operational activity | Efficient consumption of resources and materials Use of renewable energy sources Compliance with laws on environmental protection Reductions in SO2, NO2, greenhouse gases, and dust emissions Reduction in the amount of waste and wastewater produced |

| Customers | Maintaining good relations with local communities—reductions in waste, pollution, and noise Organization of social initiatives Competitiveness Ability to gain and retain customers |

| Finance | Economic efficiency of the use of the environment Good cost/benefit balance in the area of environmental protection Optimization of the cost of resources |

| Proportion of Positive Answers to the Maximum Possible Number of Positive Answers | ||

|---|---|---|

| Product Design | Small and Medium-Sized Enterprises | Large-Sized Enterprises |

| Positive | 165 | 245 |

| Neutral | 31 | 14 |

| Negative | 53 | 31 |

| Final result | 165 − 53 = 112 | 245 − 31 = 214 |

| Obtained | 112 | 214 |

| Max | 525 | 525 |

| Percentage value | 112/525 × 100% = 21% | 214/525 × 100% = 41% |

| Product manufacturing | Small and medium-sized enterprises | Large-sized enterprises |

| Positive | 92 | 114 |

| Neutral | 12 | 10 |

| Negative | 13 | 9 |

| Final result | 92 − 13 = 79 | 114 − 9 = 105 |

| Obtained | 79 | 105 |

| Max | 300 | 300 |

| Positive | 79/300 × 100% = 26% | 105/300 × 100% = 36% |

| Product use | Small and medium-sized enterprises | Large-sized enterprises |

| Positive | 117 | 130 |

| Neutral | 6 | 4 |

| Negative | 28 | 41 |

| Obtained | 89 | 89 |

| Max | 450 | 450 |

| Percentage value | 89/450 × 100% = 20% | 89/450 × 100% = 20% |

| Product recycling | Small and medium-sized enterprises | Large-sized enterprises |

| Positive | 59 | 73 |

| Neutral | 6 | 7 |

| Negative | 3 | 0 |

| Final result | 59 − 3 = 56 | 73 − 0 = 73 |

| Obtained | 56 | 73 |

| Max | 240 | 240 |

| Percentage value | 56/240 × 100% = 23% | 73/225 × 100% = 29% |

| ANN Structure | Activation Function in the Hidden Layer | Activation Function in the Output Layer |

|---|---|---|

| MLP 28-25-4 | Sigmoid | Sigmoid |

| MLP 28-30-4 | Sigmoid | Sigmoid |

| MLP 28-35-4 | Sigmoid | Sigmoid |

| MLP 28-40-4 | Sigmoid | Sigmoid |

| MLP 28-45-4 | Sigmoid | Sigmoid |

| Network Name | Quality (Learning) | Quality (Testing) |

|---|---|---|

| MLP 28-25-4 | 0.8783 | 0.8871 |

| MLP 28-30-4 | 0.8912 | 0.9042 |

| MLP 28-35-4 | 0.9318 | 0.9366 |

| MLP 28-40-4 | 0.8933 | 0.9089 |

| MLP 28-45-4 | 0.8716 | 0.8823 |

| Network Name | (R)MSE |

|---|---|

| MLP 28-25-4 | 0.02 |

| MLP 28-30-4 | 0.01 |

| MLP 28-35-4 | 0.001 |

| MLP 28-40-4 | 0.01 |

| MLP 28-45-4 | 0.01 |

| Value % | Environmental Performance |

|---|---|

| 0–20 | Definitely not |

| 21–40 | Rather not |

| 41–60 | Neutral |

| 61–80 | Rather yes |

| 81–100 | Definitely yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dostatni, E.; Mikołajewski, D.; Rojek, I. The Use of Artificial Intelligence for Assessing the Pro-Environmental Practices of Companies. Appl. Sci. 2023, 13, 310. https://doi.org/10.3390/app13010310

Dostatni E, Mikołajewski D, Rojek I. The Use of Artificial Intelligence for Assessing the Pro-Environmental Practices of Companies. Applied Sciences. 2023; 13(1):310. https://doi.org/10.3390/app13010310

Chicago/Turabian StyleDostatni, Ewa, Dariusz Mikołajewski, and Izabela Rojek. 2023. "The Use of Artificial Intelligence for Assessing the Pro-Environmental Practices of Companies" Applied Sciences 13, no. 1: 310. https://doi.org/10.3390/app13010310

APA StyleDostatni, E., Mikołajewski, D., & Rojek, I. (2023). The Use of Artificial Intelligence for Assessing the Pro-Environmental Practices of Companies. Applied Sciences, 13(1), 310. https://doi.org/10.3390/app13010310