Abstract

In this study, the effect of replacing 5 or 10% of wheat flour with lyophilized kale (Brassica oleracea L. var. sabellica) on the rheology of dough and bread characteristics (physical and textural properties, sensory acceptability, staling tendency) was evaluated. The farinographic analysis showed an increase in the development time, index of tolerance to mixing, and water absorption. The share of lyophilized kale in the dough affected changes in its rheological properties, e.g., increased the values of storage and loss moduli with a decrease in the value of the phase shift angle (tan δ) from 0.36 to 0.31 at 1 rad/s. A significant decrease in the values of instantaneous and viscoelastic compliance was also observed, and an increase in the value of zero shear viscosity. The incorporation of lyophilized kale into the dough caused a noticeable decrease in bread volume by about 10%, and porosity, by about 8%, despite the lack of statistical significance. Statistically significant changes were found in pore size and the presence of large pores > 5 mm2 in the crumb, while pores density increased. The enrichment of bread with lyophilized kale influenced a decrease in the brightness of the crumb from 73.7 to 49.5 while increasing the proportion of yellow and green color as a result of a considerable increase in the content of chlorophyll pigments and carotenoids. Bread enriched with lyophilized kale had lower acceptability than the control bread. The enrichment of the bread with powdered kale also caused changes in the texture of the crumb, e.g., the hardness on the first day of the study was 2.14 N in the control bread, while in the bread with 10% kale content it was 6.46 N. In addition, the enriched bread showed a decrease in springiness, cohesiveness, and resilience.

1. Introduction

Bread is widely consumed around the world, therefore, plays a significant role in human nutrition [1]. Due to the growing awareness of health problems, the baking industry is trying to provide functional food with pro-health properties [2]. Studies on the nutritional value of bread are aimed at increasing the content of macronutrients (carbohydrates, proteins, fats, and dietary fiber), micronutrients (minerals and vitamins), and health-promoting components [2,3]. Attention is also paid to the sensory acceptability and shelf life of enriched products [4].

An example of the enrichment of baked goods with health-promoting ingredients can be the use of plant proteins, particularly proteins from legumes. Hoehnel et al. [5] developed a high-protein bread recipe in which wheat flour was partially replaced with ingredients derived from broad beans and carob. Ayele et al. [4], on the other hand, used the addition of soy flour and cassava to wheat flour, and Viswanathan and Ho [6] used the addition of sprouted red kidney beans. Graça et al. [7] obtained good sensory acceptance for wheat bread enriched with yogurt and cottage cheese.

The addition of kale (Brassica oleracea L. var. acephala) to bread may be an interesting alternative for the development of innovative bakery foods. Kale is a biennial vegetable belonging to the Brassicaceae family, which has been cultivated for centuries in many countries. It is consumed especially in the US, Japan, and the Mediterranean region [8]. Kale has been extensively studied for its nutritional value [9,10,11] attributed to the high content of bioactive components, including phenolic compounds, glucosinolates, chlorophylls, and carotenoids [12,13]. Kale leaves also contain quite a lot of minerals (Ca, K, Fe, Mg), vitamins (C, E), and unsaturated fatty acids [14,15]. It should also be noted that kale has a relatively high protein content. Korus [16] showed that it is a high-value protein containing significant amounts of glutamic acid, aspartic acid, proline, and leucine. Kale is also a very good source of dietary fiber, the consumption of which reduces the risk of cancer and cardiovascular diseases [17,18,19].

The consumption of kale has been shown to have antioxidant, anti-carcinogenic, and protective effects on the cardiovascular system and gastrointestinal tract [20,21,22]. Kale has been found to protect against high-fat diet (HFD)-induced dysfunction through mechanisms including lipid metabolism, endotoxemia, and inflammation [23]. Due to its health-promoting properties, it is used, among others, for the production of frozen foods, chips, drinks (smoothies), and vegetable pastes, but also in the production of dietary supplements or in the cosmetics industry. Thus, the use of this raw material in Thus, the use of this vegetable in bread baking can fit into the current nutritional trend related to the enrichment of products with ingredients with high health-promoting properties. For example, Klopsch et al. [24] enriched wheat bread in kale microgreens and fresh young kale leaves.

Therefore, the aim of our study was to investigate the effect of the addition of fully ripe kale leaves, in the form of lyophilizate, on the wheat dough, the quality, and the shelf-life of the resulting bread.

2. Materials and Methods

2.1. Materials

The materials were wheat flour (ash content max. 0.58%) (PZZ Krakow, Poland), salt, lyophilized yeast (Lesaffre, France), and water. Powdered lyophilized kale leaves with the following composition were used as an enrichment ingredient: protein 28.9 ± 0.92 g/100 g, dietary fiber 23.56 ± 0.21 g/100 g, including soluble fraction 5.27 ± 0.08 g/100 g, insoluble fraction 18.29 ± 0.12 g/100 g, starch 12.07 ± 0.25 g/100 g, total sugars 11.39 ± 0.39 g/100 g, ash 7.50 ± 0.11 g/100 g, total polyphenols 1236 ± 16 mg/100 g, chlorophylls (a + b) 766.7 ± 12.7 mg/100 g, carotenoids 205.0 ± 7.4 mg/100 g [25,26,27]. Kale leaves purchased from the local supermarket (Kraków, Poland) was blanched in water at 98 °C for 2.5 min. They were then frozen on freeze-dryer trays in an air-vented chamber (Feutron GmbH, Langenwetzendorf, Germany). Freezing was carried out at −40 °C for 90 min. The lyophilization process was started at a temperature of −25 °C (CHRIST Gamma 1–16 LSC freeze-dryer, Shrewsbury, UK). A moisture content of about 5% was achieved in the dried material after 30 h using. After drying, the material was ground in a GM200 grinder (Retsch, Haan, Germany), sieved, and stored in hermetically sealed vessels.

2.2. Dough and Bread Making

The dough was obtained from 350 g of wheat flour, 10.5 g of yeast, 7 g of salt, and 215 g of water. In enriched bread, lyophilized kale was added instead of 5 or 10% wheat flour. The amount of water added was optimized by the back extrusion method using a TA-XT2plus texturometer (Stable Micro Systems, Godalming, UK).

The dough was mixed for 10 min in spiral mixer type SP 12 (Diosna Dierks & Söhne GmbH, Osnabrück, Germany) and then fermented at 35 °C for 30 min. After fermentation, portions of 50 g dough were placed in molds and subjected to final fermentation for 30 min. The bread was baked in a at 230 °C for 20 min. After baking, the loaves were removed from the molds and cooled. Bread for storage tests was kept in polyethylene bags at room temperature.

2.3. Dough Rheological Tests

Farinographic evaluation of dough rheology was performed using a Farinograph-E (Brabender, Duisburg, Germany) equipped with a 50 g flour mixer, according to AACC standard 54-21.02 [28].

The rheological tests were carried out using MARS II oscillating rheometer (ThermoFisher Scientific, Waltham, MA, USA) at a temperature of 25 °C equipped with parallel serrated plates with a diameter of 35 mm and a gap size of 1 mm. The investigated samples were placed in the rheometer for 5 min for stress relaxation and temperature stabilization.

The spectra were recorded in the range of linear viscoelasticity at a constant strain amplitude of 0.3% in the angular frequency of 1–100 rad/s. The power law equations were used to describe the data obtained [29]:

G′—storage modulus (Pa), G′′—loss modulus (Pa), ω—angular frequency (rad/s), K′, K′′, n′, n′′—constants parameters.

Both tests, creep and recovery were carried out with constant creep strain τ0 = 5 Pa for 150 s. The recovery test was continued for 600 s. The Burgers model was used to describe the data [30]:

J—compliance (Pa−1), J0—instantaneous compliance (Pa−1), J1—viscoelastic compliance (Pa−1), η0 —zero shear viscosity (Pa∙s), λret—retardation time (s), and t1—time after which the stress was removed (s).

2.4. Evaluation of Composition and Physical Properties of Bread

Protein, dietary fiber, as well as total phenolic content were determined in the bread samples [25,26,27].

The bread volume was determined with a Volscan Profiler 600 (Stable Micro Systems, Godalming, UK). Investigation of crumb structure characteristics: slices of bread 2 cm thick were scanned (Plustek S-12, Plustek, Taiwan), and the results were obtained using the ImageJ program (NTH, Barron, WI, USA). The average pore size, pore density, porosity, and number of pores larger than 5 mm2 were determined [29].

2.5. Bread Crumb Color and the Content of Pigments

CIE L*a*b* crumb color analysis was performed according to the reflectance method with a Konica MINOLTA CM-3500d spectrometer (Konica Minolta Inc., Tokyo, Japan) (illuminant D65, observer 10°, geometry d/8).

2.6. Sensory Test of Bread

The test of sensory attributes of bread was performed in accordance with the Polish Standard PN-A-74108:1996 [31]. The 15 semi-trained panelists evaluated the following parameters: external appearance (max 5 points), crust color (max 3 points), thickness (max 4 points), other crust attributes (max 4 points), crumb-elasticity (max 4 points), porosity (max 3 points), other crumb attributes (max 3 points), and taste and aroma (max 6 points).

2.7. Texture Test of Bread

Texturograms characterizing the properties of the breadcrumb were obtained using a TA-XT2plus texturometer (Stable Micro Systems, Godalming, UK). Crumb samples in the shape of a cylinder (1 cm in diameter, 2 cm in height), taken from the central part of the loaves, were compressed twice with an aluminum P/35 cylindrical probe until 50% deformation at a compression speed of 5 mm/s. From the obtained texturograms, the crumb hardness, chewiness, springiness, cohesiveness, and resilience were determined. Calculations were carried out using Texture Exponent software (Stable Micro Systems, Godalming, UK). The analyses were conducted over three consecutive days.

2.8. Thermal Evaluation of Bread

The thermal characteristics of the crumb were performed using the DSC 204F1 Phoenix differential scanning calorimeter (Netzsch GmbH, Selb, Germany). In or determine the freezable water in bread after baking [32], about 12 mg of the crumb was sealed in hermetic aluminum vessels and frozen to −60 °C at a speed of 10 °C/min. The frozen samples were held for 5 min at this temperature, followed by heating to 50 °C at speed indicated above. The standard was the empty aluminum vessel. Temperatures: the beginning of transformation TO, maximum of transformation TP, end of transformation TE, as well as enthalpy of melting, were determined using Proteus Analysis software (Netzsch GmbH, Selb, Germany). The content of freezable water (FW) expressed in g/g was calculated using the following formula:

ΔH—enthalpy of ice melting (J∙g−1), ΔH0—latent heat of ice melting (334 J∙g−1).

In order to determine the staling rate of the bread crumb during the three-day storage tests, crumb samples (approximately 12 mg) were sealed in hermetic aluminum vessels and heated in a calorimeter to 100 °C at a speed of 10 °C/min. The standard was the empty aluminum vessel. The values of temperature and enthalpy of the thermal transformation were obtained from the Proteus Analysis program (Netzsch GmbH, Selb, Germany). The enthalpy values are given in J/g of dry weight.

2.9. Statistical Analysis

Data were analyzed using a one-way analysis of variance and Duncan’s post hoc test at the significance level of 0.05. In the case of storage tests, a two-way analysis of variance was used for the texture analysis and thermal properties. Statistica v. 13.0 (StatSoft Inc., Tulsa, OK, USA) was used to analyze the data.

3. Results and Discussion

3.1. Dough Rheological Tests

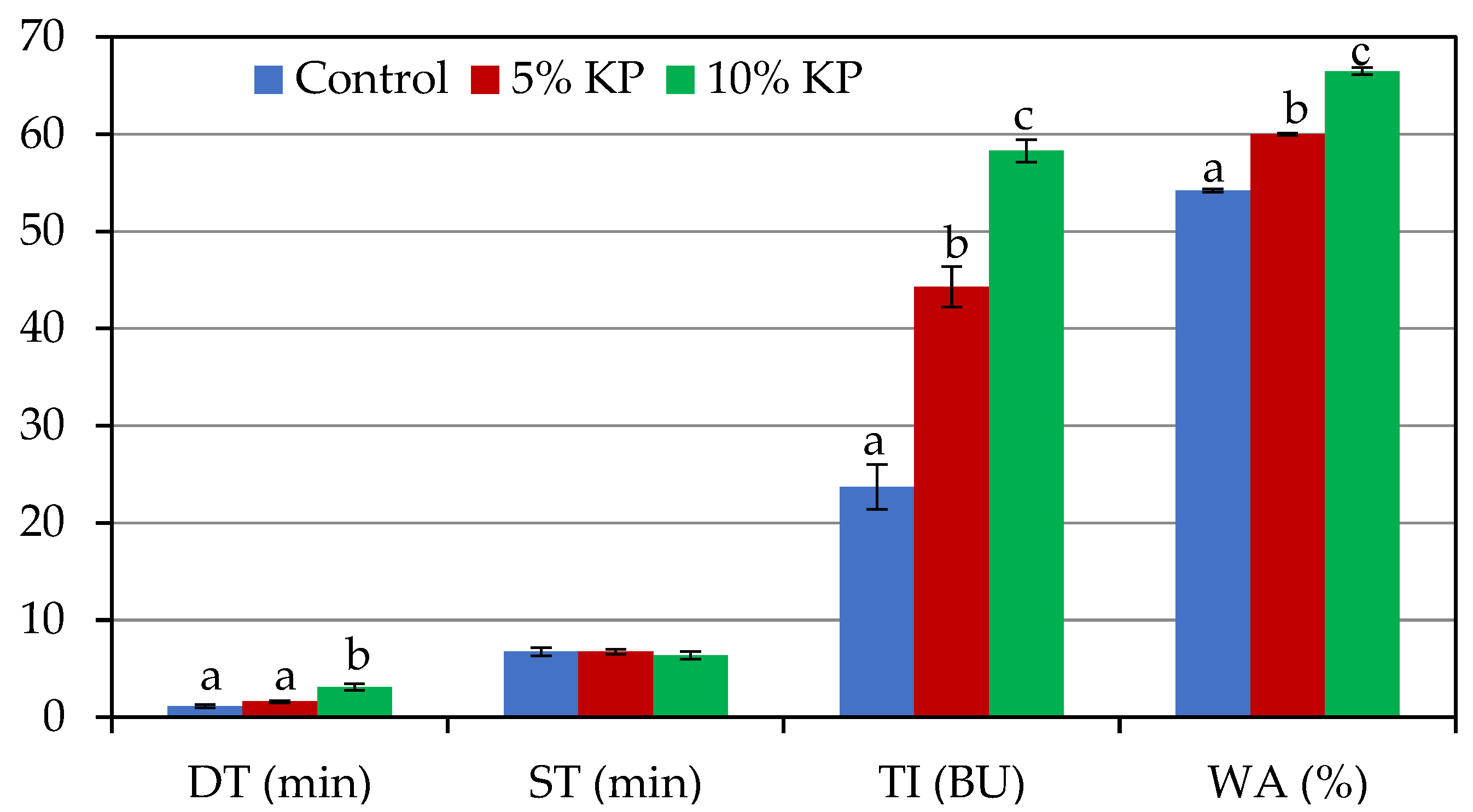

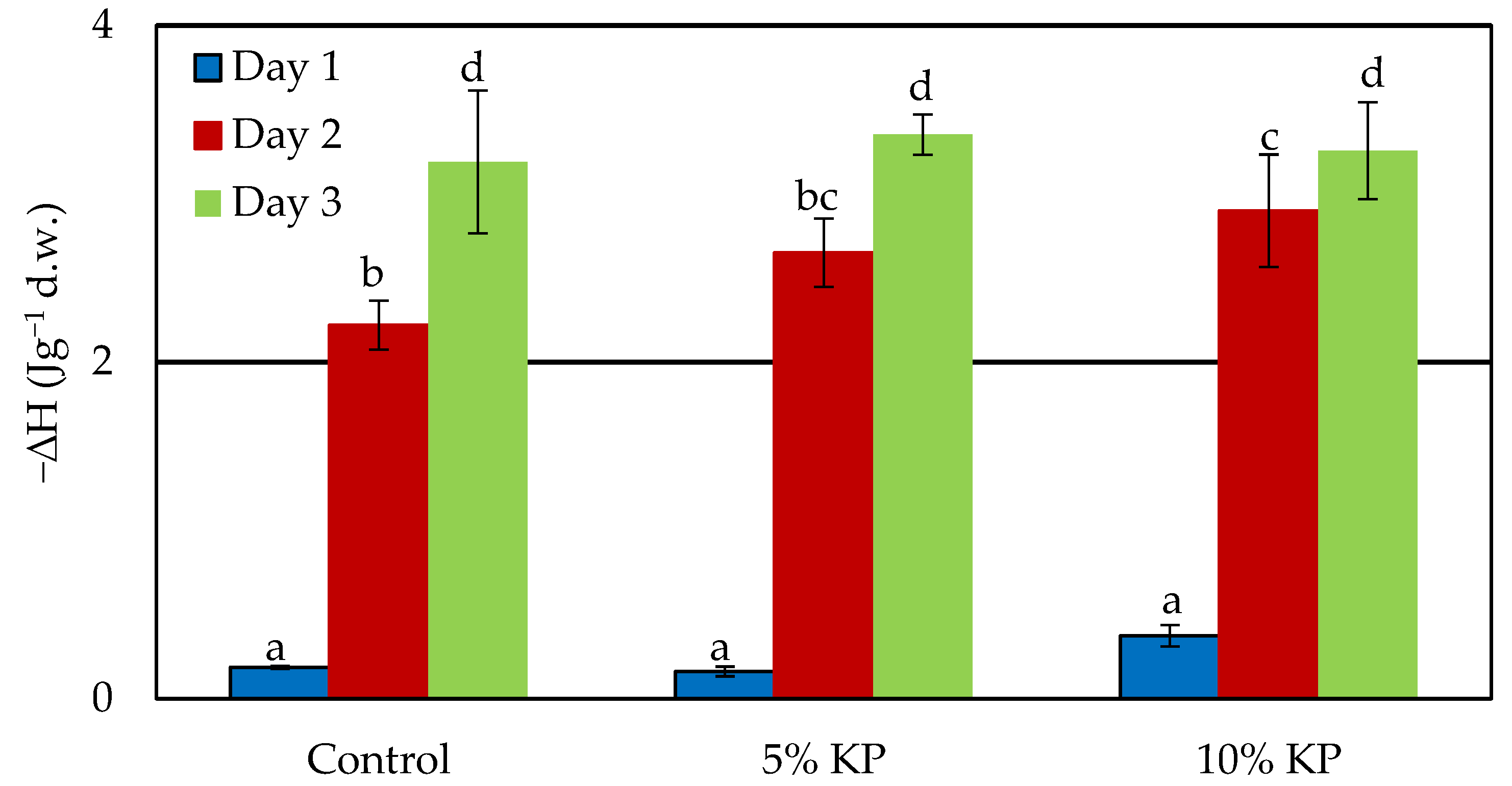

Evaluation of the effect of various recipes or technological modifications on the wheat dough is most often conducted by farinographic analysis. The kale powder increased the dough development time significantly (p < 0.05), but only for the higher −10% addition (Figure 1).

Figure 1.

Results of farinographic analysis: DT—development time, ST—stability time, TI—tolerance index, WA—water absorption; means marked with the same letters do not differ statistically at 0.05 level of confidence.

In contrast, recipe modification had no significant (p < 0.05) effect on dough stability time values. The addition of lyophilized kale to the dough resulted in a significant (p < 0.05) increase in the mixing tolerance index and water absorption. The increase in the value of the mixing tolerance index indicates a gluten weakening, which may be due to the introduction of compounds with different molecular weights and water-binding capacity into the dough, interfering with the formation of a gluten network. This confirms previous observations about the weakening of the dough structure due to the addition of various powdered vegetable raw materials. The dough structure weakening may be due to the dilution of structural proteins on the effect of replacing part of the flour with a gluten-free vegetable component [33], as well as mutual competition between gluten proteins and high-molecular-weight fiber components introduced with powdered kale for available water. Wang et al. [34] found an increase in water absorption in the dough and a weakening of the gluten network structure when celery powder was introduced into the recipe. Bigne et al. [35] noted that replacing wheat flour with mesquite flour causes changes in water absorption, and the resulting dough has less stability compared to wheat dough, which is affected by the weak development of the gluten network.

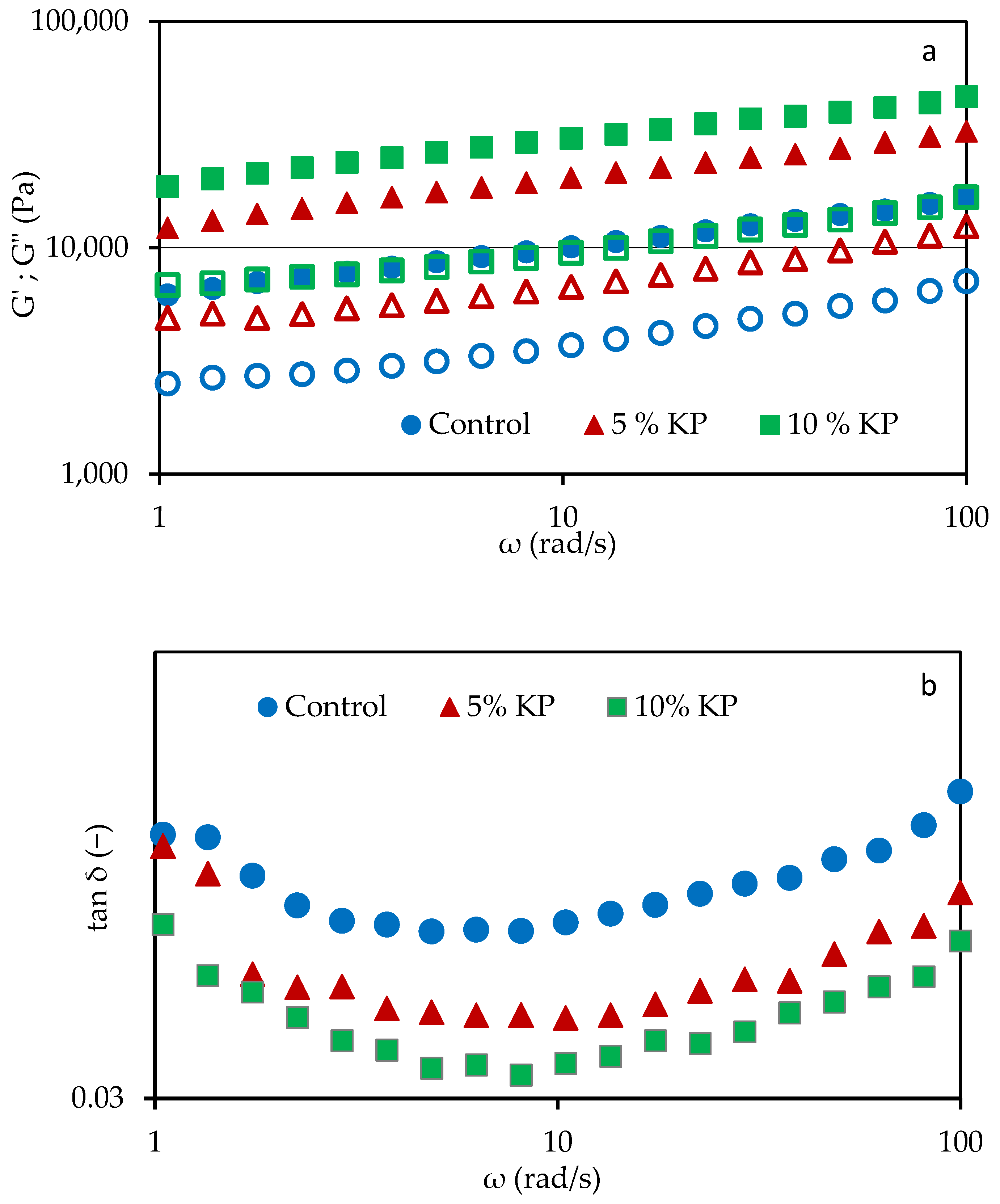

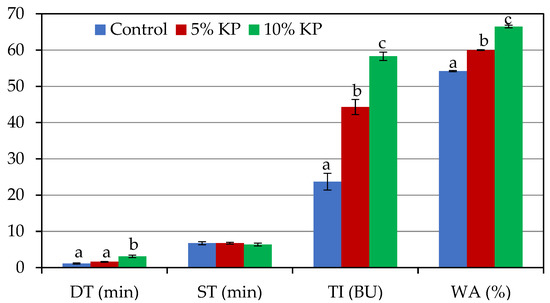

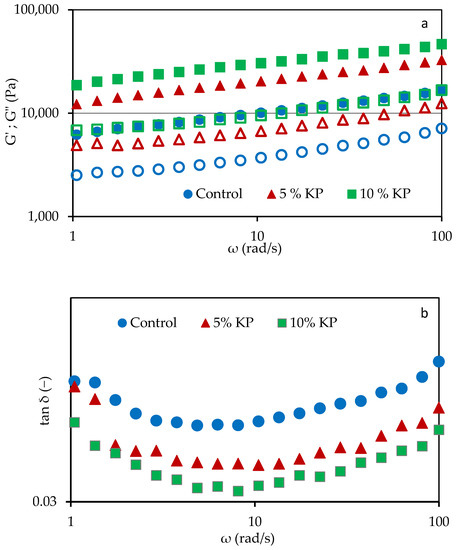

Also, small deformation rheological methods are used to evaluate various types of doughs and the impact of a recipe or technological changes. The obtained functional relationships G′, G′′ = f(ω) indicate that the values of the moduli of G′ are higher than those of G′′ (G′ > G′′) over the entire range of angular frequency. This indicates the domination of elastic characteristics over viscous ones, which is also supported by the tangent δ values ranging from 0.31 to 0.43 (Figure 2b). The addition of lyophilized kale resulted in an increase in the values of both moduli (Figure 2a) with a decrease in the tan δ values (Figure 2b). These observations confirmed the parameters of the power equations describing the sweep frequency curves (Table 1).

Figure 2.

Mechanical spectra (a) (G′—filled symbols, G′′—empty symbols) and shift angle tangent (tan δ = G′′/G′) (b) of the investigated doughs.

Table 1.

Rheological characteristics of the tested wheat and wheat-kale composite (KP) doughs.

The values of the K′ parameter, related to the beginning value of the module G′, significantly (p < 0.05) increased with an increase in the amount of kale lyophilizate, while the values of the n′ parameter significantly (p < 0.05) decreased with the increase in the share of kale. This indicates a decrease in the reliance of the G′ modulus from angular frequency, thus the dough structure strengthening in the range of small deformations. Similarly, for the parameter K′′ for which a significant (p < 0.05) increase was observed, and the parameter n′′ for which a significant decrease (p < 0.05) in value was found due to the addition of lyophilized kale. Since the increase in the values of both moduli was not proportional, these changes also exerted an effect on the values of tan δ, which significantly (p < 0.05) decreased (Figure 2b, Table 1), which indicates a strengthening of the dough.

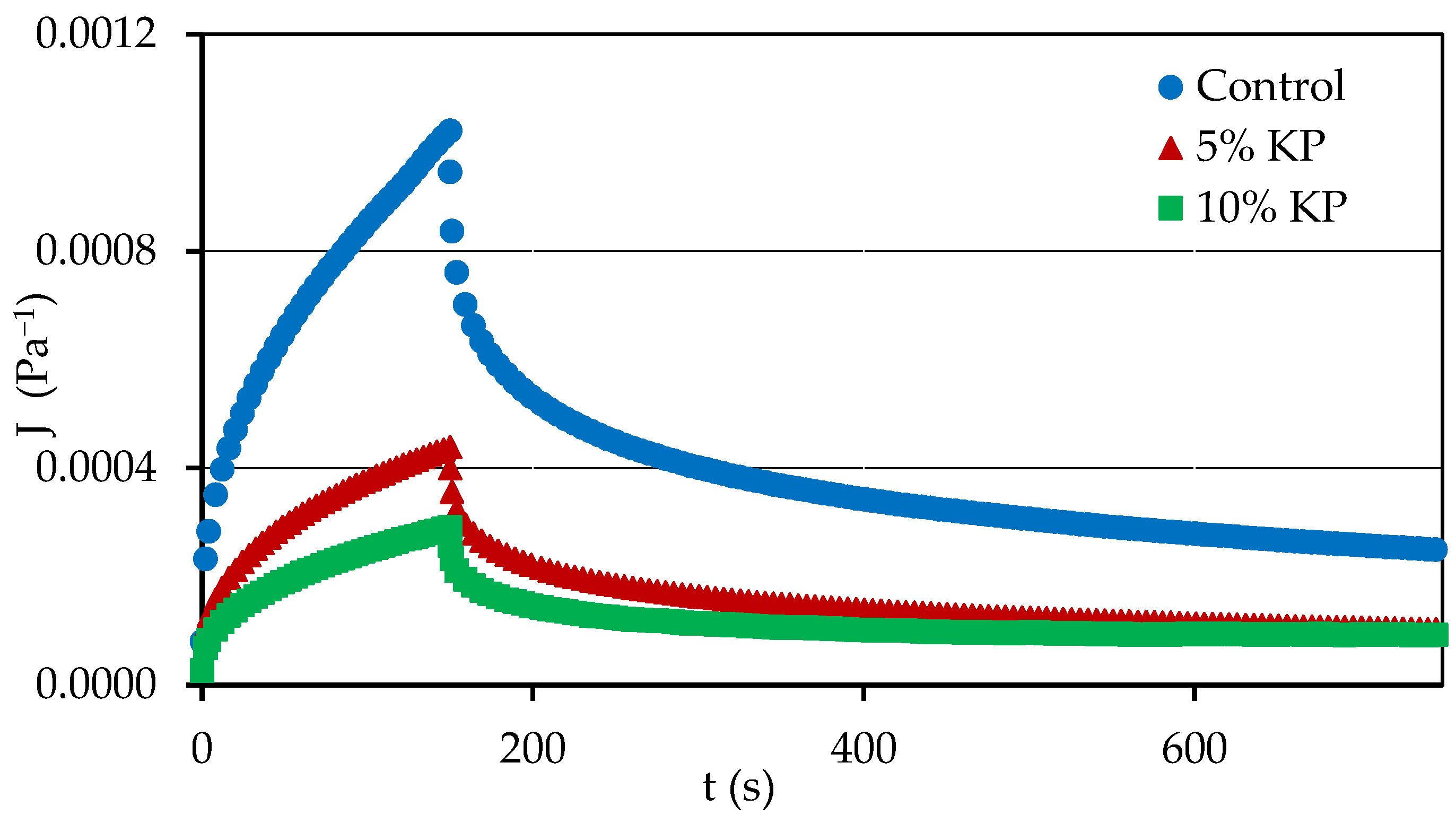

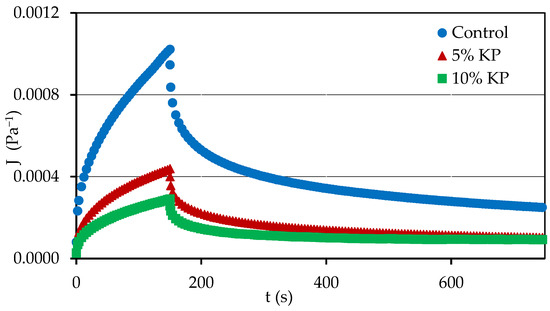

The curves in the creep phase reflect the changes in susceptibility over time at a constant stress value, while the curves of the recovery phase at zero strain reflect the energy stored in the material structure that is recovered (Figure 3). The addition of lyophilized kale to the dough resulted in a decrease (significant at p < 0.05) in susceptibility to stress the greater, the more flour was replaced with powdered kale. This is reflected in the values of instantaneous (J0) and viscoelastic compliance (J1), which significantly (p < 0.05) decreased as the proportion of lyophilized kale in the recipe increased. The strengthening of the dough in the range of small deformations is also confirmed by zero shear viscosity (η0), which significantly (p < 0.05) increased with an increasing amount of lyophilized kale (Table 1). In contrast, there was no significant impact of the kale powder on retardation time (Table 1). According to Mastromatteo et al. [36], the presence of non-hydrated vegetable flour in wheat dough resulted in competition for water by protein and starch forming the dough structure, which could lead to a tougher dough. The results obtained clearly indicate the dependence of the observed properties on the magnitude of the applied stress. In the range of small deformations, a strengthening of the dough structure was observed, resulting from the introduction into the system of high-molecular-weight components with high swelling capacity, which, despite the deterioration of the gluten network, maintain the structure of the dough analogous to that in rye bread. On the other hand, in the range of large deformations, due to the weakened gluten structure resulting from its smaller amount and limited hydration, the system is more susceptible to applied stress.

Figure 3.

Creep and recovery curves of control dough and samples with kale powder at different concentrations.

3.2. Composition and Physical Properties of Bread

Bread enrichment is aimed at improving its nutritional properties and supplementing the diet with bioactive compounds. However, changes made to the formulation should not adversely affect the other properties of the bread, including its sensory acceptability. One method of bread enrichment is the introduction of vegetable raw materials into the recipe, which enrich the bread mainly with dietary fiber and bioactive compounds [34,36,37,38]. The protein content in the control bread was 9.76 g/100 g, which confirms previous observations regarding various types of bread [3]. The highest 10% share of lyophilized kale resulted in a non-significant (p > 0.05) increase in protein content to 10.12 g/100 g. The lack of significant effect on the content of this component is due to the fact that wheat flour itself contains a significant amount of protein. The content of dietary fiber in the control bread was 2.62 g/100 g, including 0.93 g/100 g of the soluble fraction and 1.69 g/100 g of the insoluble fraction. The data obtained are slightly lower than the values reported for various types of bread by Fraś et al. [3]. The addition of kale lyophilizate resulted in a significant (p < 0.05) increase in the content of dietary fiber and its fractions. In the bread containing 10% of kale, 3.77 g of fiber per 100 g was found, including 1.14 g/100 g of the soluble fraction and 2.63 g/100 g of the insoluble fraction. The control bread analyzed had a relatively low content of total polyphenols at 7.16 mg/100 g due to their low content in wheat flour [39]. The addition of 5% and 10% lyophilized kale resulted in a significant (p < 0.05) increase in total polyphenol content to 48.87 mg/100 g and 87.44 mg/100 g, respectively. This confirms the previous observations concerning the possibility of enriching bread with polyphenols through the addition of raw vegetable materials.

The essential parameter characterizing the bread and providing an opportunity to assess the influence of the recipe composition is the volume and specific volume of the loaves.

The data summarized in Table 2 indicate that the lyophilized kale addition caused a small and non-significant (p > 0.05) decrease in the volume and specific volume of the bread. The available literature data indicate that replacing wheat flour with other ingredients, including lyophilized vegetables, can result in a decrease in loaf volume [37]. In turn, Wang et al. [34], who enriched bread with celery powder, obtained similar results. Dhillon et al. [40] found a decrease in bread volume when vegetable pastes were introduced into the recipe. Also, Lafarga et al. [38] observed a decrease in the specific weight of bread enriched with a broccoli-based preparation. In a study by Bigne et al. [35] and González-Montemayor et al. [41], the addition of mesquite flour to wheat dough resulted in a decrease in bread volume because the presence of mesquite interfered with the formation of the bread structure by weakening the gluten network. Ptitchkina et al. [42] enriched bread with pumpkin powder, observing an increase in volume at lower doses of this ingredient and a decrease in volume at higher doses. The addition of lyophilized kale to the dough resulted in some changes in the crumb structure, as reflected in the values of parameters determined by digital image analysis (Table 2). The presence of lyophilized kale caused a significant (p = 0.008) reduction in average pore diameter in comparison with the control bread, while the amount of kale was not significant. There was also a decrease in porosity, but the differences were non-significant (p > 0.05). In contrast, a significant (p = 0.021) increase in pore density with a simultaneous significant (p = 0.004) decrease in the number of large pores (>5 mm2) was observed for bread with a higher addition of lyophilized kale. These results indicate that the crumb of bread enriched in this way is characterized by a greater number of fine pores, which may favorably influence the acceptance of its structure.

Table 2.

Physical characteristics of the investigated wheat and wheat-kale (KP) composite bread.

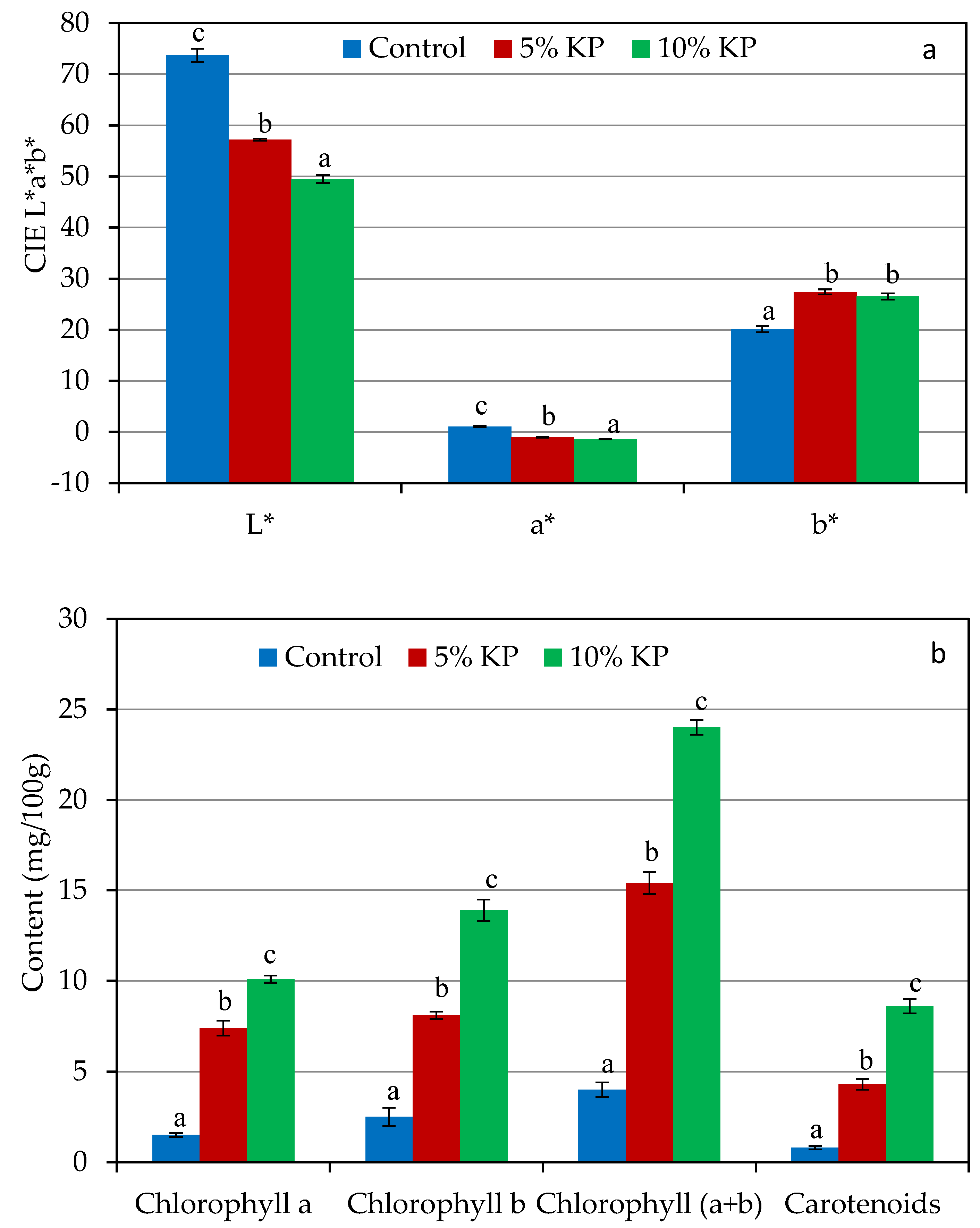

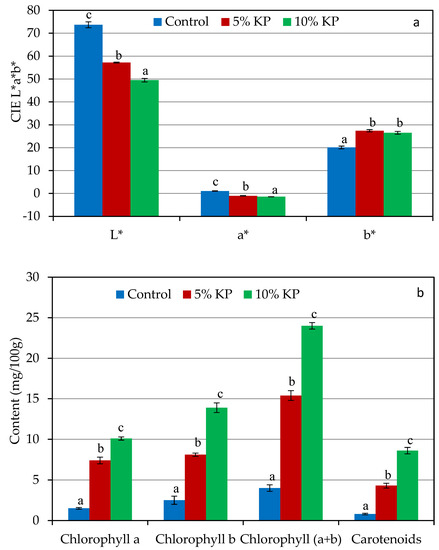

The determined color parameters (Figure 4a) also indicate significant changes in the appearance of the crumb. The highest value of the crumb L* parameter had the control bread indicating the brightness of the sample, and the presence of kale significantly (p < 0.05) reduced it. The a* parameter of the control sample showed positive values indicating the contribution of the red color. In contrast, the presence of lyophilized kale caused a shift in the value of this parameter toward negative values, indicating an increasing proportion of green color. Similarly, in the case of the parameter b* indicating the contribution of yellow color, bread with kale powder had significantly (p < 0.05) higher values for this parameter than the control sample, but without a clear effect of the enrichment level itself (Figure 4a).

Figure 4.

Color parameters (a) and chlorophyll and carotenoids content (b) of the investigated breadcrumbs; means marked with the same letters do not differ statistically at 0.05 level of confidence.

The changes in crumb color characteristics are due to the introduction of kale powder, the natural plant tissue pigments. The contents of chlorophylls a, b, their sum, and carotenoids in the control bread and samples with lyophilized kale are shown in Figure 4b. As the amount of kale lyophilizate increased, the content of individual pigments increased significantly (p < 0.05). The obtained results on color change reflect the literature data, which indicate that the use of vegetable or vegetable industry waste as ingredients in bakery products significantly affects their color [43]. Krupa Kozak et al. [44] observed a significantly darker color of the crumb and crust of gluten-free bread enriched with a broccoli-based preparation. In addition, such bread showed significantly lower negative values of the a* parameter and significantly higher values of the b* parameter than control bread, indicating an increase in the proportion of green and yellow color. Also, according to Lafarga et al. [38], bread enriched with a broccoli-based preparation has a higher intensity of green color, both in the crust and crumb. However, according to Drabińska et al. [45], this can adversely affect the acceptability of such products.

3.3. Bread Acceptability

The highest acceptability in terms of overall appearance was achieved by the control bread, and the modification of the recipe influenced a decrease in the acceptability of this attribute, but no significant (p > 0.05) differences were found.

In the evaluation of crust color, a downward trend in acceptability was noted, but also the differences were non-significant (p > 0.05). The crust of the enriched bread was characterized by a darker than control bread, greenish color, less characteristic of wheat bread, which reduced its acceptability. The presence of lyophilized kale also had a non-significant (p > 0.05) impact on the acceptability of crust thickness. In contrast, other crust characteristics were rated significantly (p < 0.05) lower than that of the control sample but with no variation in terms of lyophilized kale level. However, it can be assumed that the decisive influence on the results of this evaluation was the greenish color of the crust. A similar trend was found when evaluating the acceptability of crumb characteristics: springiness, porosity, and other properties. It was found, in all cases, a decreasing trend in acceptability, but with non-significant (p > 0.05) differences. On the other hand, the decline in acceptability in the case of taste and aroma was significant (Table 3), but the large values of standard deviations for the mean values resulted in no significant differences between them. This indicates that the panelists did not agree in assessing the acceptability of aroma and taste, which may be due to individual differences in preferences. These results are reflected in the work of other authors. Wang et al. [34] observed a significant adverse effect of the share of celery powder on the acceptability, both overall and of individual sensory attributes. Similarly, Drabińska et al. [45] noted that the share of broccoli-based powder in gluten-free cookies results in a significant decrease in product acceptability due to its green color, increase in hardness, and intense smell and taste. Danza et al. [33] also observed a decrease in the acceptability of individual organoleptic characteristics of baked goods enriched with yellow bell pepper flour. Also, Czaja et al. [39] observed a decrease in the acceptability of the taste of bread enriched with onion extract. On the other hand, Hobbs et al. [46] indicate that enriching baked goods with vegetable-based raw materials is an appropriate strategy for promoting and increasing their consumption, but the sensory acceptability of such products is closely connected with the kind of vegetables used. Probably, the appropriate promotion and health information for this type of product could favorably influence its sensory acceptability.

Table 3.

Sensory characteristics of the investigated wheat and wheat-kale (KP) composite bread.

3.4. Bread Texture

The texture of the bread is an essential criterion in assessing its quality. Analysis of the variation of its individual parameters allows for the assessment of the impact of a recipe or technological modifications and storage time on the quality. On the first day, the crumb of the control bread had the lowest hardness of 2.14 N (Table 4). The addition of lyophilized kale caused a significant (p < 0.05) increase in crumb hardness to a level of 6.46 N at a 10% bread enrichment level. In the case of resilience, springiness, and cohesiveness, lyophilized kale reduced these parameters the greater the level of enrichment, but only the highest 10% share of lyophilized kale caused statistically significant (p < 0.05) changes (Table 4). The springiness characteristic of fresh bread is important for consumers, as well as sufficient cohesiveness, to reduce the tendency for crumbling, and a decrease in the values of these parameters indicates a deterioration in the quality of the bread. Since chewiness is closely connected with hardness, the effect of lyophilized kale was analogous, and its values increased significantly (p < 0.05) as the amount of kale increased (Table 4). The results obtained are reflected in the literature data. Wang et al. [34] observed a significant decrease in springiness and resilience and an increase in chewiness and hardness of bread enriched with celery powder. Also, Ranawana et al. [47] found an increase in chewiness and hardness as well as a decrease in crumb cohesiveness of bread enriched with various lyophilized vegetables. Dhillon et al. [40] noted an increase in the hardness of the crumb of bread enriched with vegetable pastes.

Table 4.

Texture parameters of the investigated wheat and wheat-kale (KP) composite bread.

During storage, bread undergoes complex structural changes related to water migration, starch retrogradation, and reorganization of protein-starch complexes. These changes are generally referred to as staling, and their effects result in a deterioration of the consumer acceptability of bread. In instrumental measurement, bread staling is manifested by increasing hardness and chewiness and decreasing springiness and resilience [48]. The crumb of bread with 10% of lyophilized kale on the third day of the study had the highest hardness, and the share of kale, storage time, and the interaction of both factors had a significant (p < 0.05) impact on this parameter (Table 4). However, it is important to note the differences in the increment of crumb hardness values. For the control bread, the increase in hardness over three days of storage was 3.7 times, while for the crumb containing 10% lyophilized kale, it was 2.3 times. This indicates that the harder the crumb is after baking, the lower the growth rate of this parameter. An analogous trend was observed for chewiness (Table 4). On the other hand, the values of the other parameters characterizing texture decreased during storage, but the statistical variation was smaller, and for cohesiveness and resilience, the level of kale had a non-significant (p > 0.05) effect.

3.5. Thermal Properties of the Crumb

A sufficient lowering of the ambient temperature causes water to freeze in the crumb structure. Re-heating induces the melting of ice crystals observed on thermograms as an endothermic transformation, the onset of which reaches about −20 °C [32]. The values of parameters characterizing the endothermic transformation related to the melting of frozen water crystals are summarized in Table 5. The values of the transformation onset temperature varied from −10.3 to −9.0 °C and were lower for the control, with only the level of enrichment with kale having a significant (p < 0.05) effect. Similar values, ranging from −8.5 to −8.1 °C, for the onset of transformation were obtained by Ribotta and Le Bailc [32]. A greater statistical diversity was observed in the case of maximum transformation temperature, the values of which generally increased with increasing kale level and decreased for individual samples with storage time, but for the highest proportion of lyophilized kale, the changes were non-significant (p > 0.05). A similar trend was found for end-of-transformation temperature. Both the amount of kale and storage time had a significant impact on this parameter (Table 5).

Table 5.

Freezable water in investigated wheat and wheat-kale (KP) composite bread.

The values of transformation enthalpy increased with the level of addition of kale and decreased during the study, and the share of kale, storage time, and the interaction of both factors had a significant (p < 0.05) impact on the results. The observed changes in transformation enthalpy values correlate (r = 0.99) with the amount of freezable water, the content of which also increased with the amount of kale introduced and decreased during storage. These results correlate closely with the amount of water introduced into the dough to maintain its consistency. Since the enriching addition of lyophilized kale proved to be highly water-absorbent, the selection of the appropriate amount of water for each recipe was carried out based on the results of farinograph analysis. On the other hand, the decrease in freezable water content during storage is presumably due to the loss of crumb moisture, which moves toward the crust, and the incorporation of water molecules into the crystalline structure of starch, which forms during the staling of the bread. Similar results on changes in freezable water content during bread storage were obtained by Ribotta and Le Bailc [32].

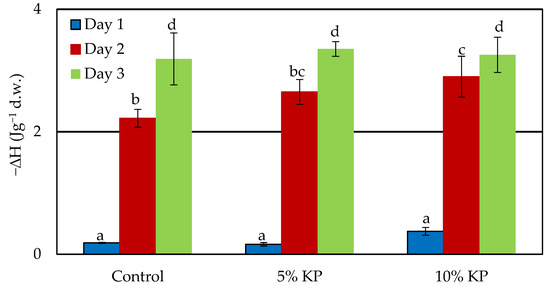

During the heating of the samples, the melting of recrystallized amylopectin occurs connected with endothermic transformation, the presence of which is associated with the retrogradation of starch polymers [49]. The onset temperature of this transformation ranged from 50.7–54.1 °C, while the temperature values at the maximum ranged from 63.1 to 65.2 °C, with no significant variation between the samples studied. In turn, the values of the final transformation temperature ranged from 70.0 to 77.6 °C, with only the time of storage having a significant (p < 0.05) effect on its values. The determined temperature ranges confirm the previous literature data [48,49]. The two-factor analysis of variance performed showed that only time of storage had a significant (p < 0.05) effect on the determined values. On the first day, the sample with the largest proportion of lyophilized kale had the highest enthalpy value of retrograded amylopectin distribution, but the differences between samples were non-significant (p > 0.05) (Figure 5).

Figure 5.

Effect of storage time on the enthalpy of amylopectin melting after retrogradation of the investigated wheat and wheat-kale (KP) composite bread; means marked with the same letters do not differ statistically at 0.05 level of confidence.

Similarly, on the second day, the crumb of bread enriched at the highest level showed the highest enthalpy, the value of which was significantly higher than that of the control. On the third day, no significant differences in the enthalpy values of the distribution of retrograded amylopectin were noted. The results obtained do not fully correlate with the analysis of crumb texture, which clearly indicates the progressive aging of the bread. The addition of lyophilized kale may modify this process while remaining unaffected by the retrogradation of amylopectin determined during thermal analysis. At the same time, the progressive hardening of the crumb is probably more related to the retrogradation of amylose or its complexes with high-molecular-weight components, as well as the loss of freezable water.

4. Conclusions

The results obtained clearly indicate the dependence of the observed rheological properties on the magnitude of the applied stress. An increase in the values of storage and loss moduli was observed in the range of small deformations with a decrease in the value of the phase shift angle, as well as a decrease in the value of compliance with an increase in zero shear viscosity value. The observed strengthening of the dough structure is due to the content in the system of high-molecular-weight components with high swelling capacity and competitive water absorption. On the other hand, an increase in the mixing tolerance index and dough development time was noted in the high strain range, indicating a deterioration of the dough strength. The weakened dough structure is due to less gluten in the system and limited hydration of gluten proteins. The addition of freeze-dried kale significantly increased the content of dietary fiber in the tested bread, both the soluble and insoluble fractions. However, the content of bioactive compounds increased the most-carotenoids and polyphenols. The addition of lyophilized kale caused a reduction in pore size and the number of large pores in the crumb while increasing the pore density. The changes in crumb structure characteristics appear to be favorable, but bread enriched with lyophilized kale was characterized by poorer acceptability of sensory attributes due to a significantly darker color with a distinctly greenish hue caused by the presence of chlorophylls. The share of kale powder in the recipe caused adverse changes in crumb texture. A significant increase in hardness was found, but a decrease in springiness, cohesiveness, and resilience. Introducing powdered vegetables into bread seems to be a good strategy for improving its nutritional value, but changes in quality result in a decrease in sensory acceptance. Therefore, proper health information is needed to promote such products.

Author Contributions

Conceptualization, A.K.; methodology, A.K., M.W., J.K. and L.J.; investigation, J.K., A.K., M.W. and L.J.; writing—original draft preparation, L.J.; writing—review and editing, J.K., M.W. and A.K.; supervision, J.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding. The work was financed by a subsidy of the Ministry of Education and Science Republic of Poland for the University of Agriculture in Krakow.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Khoozani, A.A.; Kebede, B.; Bekhit, A.E.-D.A. The effects of green banana flour fortification on volatiles compounds of bread: A fingerprinting approach. Appl. Food Res. 2022, 2, 100202. [Google Scholar] [CrossRef]

- Pycia, K.; Kapusta, I. Effect of hazelnut and walnut maturity stage and of amount of their additive on physicochemical and antioxidant properties of enriched wheat bread. Food Sci. Techn. Qual. 2020, 123, 62–81. [Google Scholar] [CrossRef]

- Fraś, A.; Gołębiewska, K.; Wiśniewska, M.; Mańkowski, D.R. Assessing content of selected nutrients and bioactives in different kinds of bread available on the polish market. Food Sci. Techn. Qual. 2022, 29, 63–77. [Google Scholar] [CrossRef]

- Ayele, H.H.; Bultosa, G.; Abera, T.; Astatkie, T. Nutritional and sensory quality of wheat bread supplemented with cassava and soybean flours. Cogent Food Agric. 2017, 3, 1331892. [Google Scholar] [CrossRef]

- Hoehnel, A.; Bez, J.; Petersen, I.L.; Amarowicz, R.; Juśkiewicz, J.; Arendt, E.K.; Zannini, E. Enhancing the nutritional profile of regular wheat bread while maintaining technological quality and adequate sensory attributes. Food Funct. 2020, 11, 4732–4751. [Google Scholar] [CrossRef]

- Viswanathan, K.; Ho, P. Fortification of white flat bread with sprouted red kidney bean (Phaseolus vulgaris). Acta Sci. Pol. Technol. Aliment. 2014, 13, 27–34. [Google Scholar] [CrossRef]

- Graça, C.; Raymundo, A.; Sousa, I. Wheat bread with dairy products—Technology, nutritional, and sensory properties. Appl. Sci. 2019, 9, 4101. [Google Scholar] [CrossRef]

- Daryadar, M.; Mairapetyan, K.; Tovmasyan, A.; Aleksanyan, J.; Tadevosyan, A.; Kalachyan, L.; Stepanyan, B.; Galstyan, H.; Asatryan, A. Productivity of leafy green vegetable kale in soilless cultivation conditions. J. Agri. Sci. Food Res. 2019, 10, 10–35248. [Google Scholar] [CrossRef]

- Alfawaz, H.A.; Wani, K.; Alrakayan, H.; Alnaami, A.M.; Al-Daghri, N.M. Awareness, knowledge and attitude towards 'superfood' kale and its health benefits among Arab adults. Nutrients 2022, 14, 245. [Google Scholar] [CrossRef]

- Korus, A. Changes in the content of minerals, B-group vitamins and tocopherols in processed kale leaves. J. Food Compos. Anal. 2020, 89, 103464. [Google Scholar] [CrossRef]

- Satheesh, N.; Workneh Fanta, S. Kale: Review on nutritional composition, bio-active compounds, anti-nutritional factors, health beneficial properties and value-added products. Cogent Food Agric. 2020, 6, 1811048. [Google Scholar] [CrossRef]

- Šamec, D.; Salopek-Sondi, B. Cruciferous (Brassicaceae) Vegetables. In Nonvitamin and Nonmineral Nutritional Supplements; Elsevier: Amsterdam, The Netherlands, 2019; pp. 195–202. ISBN 9780128124918. [Google Scholar]

- Abellán, Á.; Domínguez-Perles, R.; Moreno, D.A.; García-Viguera, C. Sorting out the value of cruciferous sprouts as sources of bioactive compounds for nutrition and health. Nutrients 2019, 11(2), 429. [Google Scholar] [CrossRef] [PubMed]

- Korus, A. Effect of pre-treatment and drying methods on the content of minerals, B-group vitamins and tocopherols in kale (Brassica oleracea L. var. acephala) leaves. J. Food Sci. Technol. 2022, 59, 279–287. [Google Scholar] [CrossRef] [PubMed]

- Prade, T.; Muneer, F.; Berndtsson, E.; Nynäs, A.-L.; Svensson, S.-E.; Newson, W.R.; Johansson, E. Protein fractionation of broccoli (Brassica oleracea, var. Italica) and kale (Brassica oleracea, var. Sabellica) residual leaves—A pre-feasibility assessment and evaluation of fraction phenol and fibre content. Food Bioprod. Process. 2021, 130, 229–243. [Google Scholar] [CrossRef]

- Korus, A. Amino acid retention and protein quality in dried kale (Brassica oleracea L. var. acephala). J. Food Process. Preserv. 2014, 38, 676–683. [Google Scholar] [CrossRef]

- Barber, T.M.; Kabisch, S.; Pfeiffer, A.F.H.; Weickert, M.O. The health benefits of dietary fibre. Nutrients 2020, 12, 3209. [Google Scholar] [CrossRef] [PubMed]

- Šamec, D.; Urlić, B.; Salopek-Sondi, B. Kale (Brassica oleracea var. acephala) as a superfood: Review of the scientific evidence behind the statement. Crit. Rev. Food. Sci. Nutr. 2019, 59, 2411–2422. [Google Scholar] [CrossRef]

- Yang, I.; Jayaprakasha, G.K.; Patil, B. In vitro digestion with bile acids enhances the bioaccessibility of kale polyphenols. Food Funct. 2018, 9, 1235–1244. [Google Scholar] [CrossRef] [PubMed]

- Biegańska-Marecik, R.; Radziejewska-Kubzdela, E.; Marecik, R. Characterization of phenolics, glucosinolates and antioxidant activity of beverages based on apple juice with addition of frozen and freeze-dried curly kale leaves (Brassica oleracea L. var. acephala L.). Food Chem. 2017, 230, 271–280. [Google Scholar] [CrossRef]

- Olsen, H.; Grimmer, S.; Aaby, K.; Saha, S.; Borge, G.I.A. Antiproliferative effects of fresh and thermal processed green and red cultivars of curly kale (Brassica oleracea L. convar. acephala var. sabellica). J. Agric. Food Chem. 2012, 60, 7375–7383. [Google Scholar] [CrossRef]

- Luang-In, V.; Saengha, W.; Buranrat, B.; Chantiratikul, A.; Ma, N.L. Cytotoxicity of selenium-enriched Chinese kale (Brassica oleracea var. alboglabra L.) seedlings against Caco-2, MCF-7 and HepG2 cancer cells. Pharmacogn. J. 2020, 12, 674–681. [Google Scholar] [CrossRef]

- Raychaudhuri, S.; Fan, S.; Kraus, O.; Shahinozzaman, M.; Obanda, D.N. Kale supplementation during high fat feeding improves metabolic health in a mouse model of obesity and insulin resistance. PLoS ONE 2021, 16, e0256348. [Google Scholar] [CrossRef] [PubMed]

- Klopsch, R.; Baldermann, S.; Hanschen, F.S.; Voss, A.; Rohn, S.; Schreiner, M.; Neugart, S. Brassica-enriched wheat bread: Unraveling the impact of ontogeny and breadmaking on bioactive secondary plant metabolites of pak choi and kale. Food Chem. 2019, 295, 412–422. [Google Scholar] [CrossRef] [PubMed]

- AOAC International. Official Methods of Analysis of AOAC International, 21st ed.; Latimer, G.W., Ed.; AOAC International: Rockville, Maryland, 2019; ISBN 978-0935584899. [Google Scholar]

- Lichtenthaler, H.K.; Buschmann, C. Chlorophylls and carotenoids: Measurement and characterization by UV-VIS spectroscopy. Curr. Protoc. Anal. Chem. 2001, 1, F4.3.1–F4.3.8. [Google Scholar] [CrossRef]

- Lichtenthaler, H.K.; Buschmann, C. Extraction of phtosynthetic tissues: Chlorophylls and carotenoids. Curr. Protoc. Anal. Chem. 2001, 1, F4.2.1–F4.2.6. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists International, 11th ed.; American Association of Cereal Chemists: Saint Paul, MN, USA, 2012. [Google Scholar]

- Korus, J.; Witczak, T.; Ziobro, R.; Juszczak, L. Linseed (Linum usitatissimum L.) mucilage as a novel structure forming agent in gluten-free bread. LWT-Food Sci. Technol. 2015, 62, 257–264. [Google Scholar] [CrossRef]

- Witczak, T.; Juszczak, L.; Ziobro, R.; Korus, J. Rheology of gluten-free dough and physical characteristics of bread with potato protein. J. Food Process. Eng. 2017, 40, e12491. [Google Scholar] [CrossRef]

- Polish Commitee for Standarization. Pieczywo—Metody Badań; PN-A-74108; PKN: Warsaw, Poland, 1996. [Google Scholar]

- Ribotta, P.D.; Le Bail, A. Thermo-physical assessment of bread during staling. LWT-Food Sci. Technol. 2007, 40, 879–884. [Google Scholar] [CrossRef]

- Danza, A.; Mastromatteo, M.; Cozzolino, F.; Lecce, L.; Lampignano, V.; Laverse, J.; Del Nobile, M.A. Processing and characterization of durum wheat bread enriched with antioxidant from yellow pepper flour. LWT-Food Sci. Technol. 2014, 59, 479–485. [Google Scholar] [CrossRef][Green Version]

- Wang, N.; Xu, Y.; Chao, H.; Zhang, M.; Zhou, Y.; Wang, M. Effects of celery powder on wheat dough properties and textural, antioxidant and starch digestibility properties of bread. J. Food Sci. Technol. 2020, 57, 1710–1718. [Google Scholar] [CrossRef]

- Bigne, F.; Puppo, M.C.; Ferrero, C. Fibre enrichment of wheat flour with mesquite (Prosopis spp.): Effect on breadmaking performance and staling. LWT-Food Sci. Technol. 2016, 65, 1008–1016. [Google Scholar] [CrossRef]

- Mastromatteo, M.; Danza, A.; Guida, M.; Del Nobile, M.A. Formulation optimisation of vegetable flour-loaded functional bread. Part II: Effect of the flour hydration on the bread quality. Int. J. Food Sci. Technol. 2012, 47, 2109–2116. [Google Scholar] [CrossRef]

- Mastromatteo, M.; Danza, A.; Guida, M.; Del Nobile, M.A. Formulation optimisation of vegetable flour-loaded functional bread Part I: Screening of vegetable flours and structuring agents. Int. J. Food Sci. Technol. 2012, 47, 1313–1320. [Google Scholar] [CrossRef]

- Lafarga, T.; Gallagher, E.; Bademunt, A.; Viñas, I.; Bobo, G.; Villaró, S.; Aguiló-Aguayo, I. Bioaccessibility, physicochemical, sensorial, and nutritional characteristics of bread containing broccoli co-products. J. Food Process. Preserv. 2019, 43, e13861. [Google Scholar] [CrossRef]

- Czaja, A.; Czubaszek, A.; Wyspiańska, D.; Sokół-Łętowska, A.; Kucharska, A.Z. Quality of wheat bread enriched with onion extract and polyphenols content and antioxidant activity changes during bread storage. Int. J. Food Sci. Technol. 2020, 55, 1725–1734. [Google Scholar] [CrossRef]

- Dhillon, B.; Kaur, K.; Sodhi, N.S.; Garg, R. Physicochemical, antioxidant and microbial properties of whole wheat breads formulated with the incorporation of vegetable paste. Food Meas. 2021, 15, 1068–1074. [Google Scholar] [CrossRef]

- González-Montemayor, A.M.; Solanilla-Duque, J.F.; Flores-Gallegos, A.C.; López-Badillo, C.M.; Ascacio-Valdés, J.A.; Rodríguez-Herrera, R. Green bean, pea and mesquite whole pod flours nutritional and functional properties and their effect on sourdough bread. Foods 2021, 10(9), 2227. [Google Scholar] [CrossRef]

- Ptitchkina, N.M.; Novokreschonova, L.V.; Piskunova, G.V.; Morris, E.R. Large enhancements in loaf volume and organoleptic acceptability of wheat bread by small additions of pumpkin powder: Possible role of acetylated pectin in stabilising gas-cell structure. Food Hydrocoll. 1998, 12, 333–337. [Google Scholar] [CrossRef]

- Majzoobi, M.; Poor, Z.V.; Jamalian, J.; Farahnaky, A. Improvement of the quality of gluten-free sponge cake using different levels and particle sizes of carrot pomace powder. Int. J. Food Sci. Technol. 2016, 51, 1369–1377. [Google Scholar] [CrossRef]

- Krupa-Kozak, U.; Drabińska, N.; Bączek, N.; Šimková, K.; Starowicz, M.; Jeliński, T. Application of broccoli leaf powder in gluten-free bread: An innovative approach to improve its bioactive potential and technological quality. Foods 2021, 10, 819. [Google Scholar] [CrossRef]

- Drabińska, N.; Ciska, E.; Szmatowicz, B.; Krupa-Kozak, U. Broccoli by-products improve the nutraceutical potential of gluten-free mini sponge cakes. Food Chem. 2018, 267, 170–177. [Google Scholar] [CrossRef] [PubMed]

- Hobbs, D.A.; Ashouri, A.; George, T.W.; Lovegrove, J.A.; Methven, L. The consumer acceptance of novel vegetable-enriched bread products as a potential vehicle to increase vegetable consumption. Food Res. Int. 2014, 58, 15–22. [Google Scholar] [CrossRef]

- Ranawana, V.; Campbell, F.; Bestwick, C.; Nicol, P.; Milne, L.; Duthie, G.; Raikos, V. Breads fortified with freeze-dried vegetables: Quality and nutritional attributes. Part II: Breads not containing oil as an ingredient. Foods 2016, 5, 62. [Google Scholar] [CrossRef] [PubMed]

- Witczak, M.; Korus, J.; Ziobro, R.; Juszczak, L. Waxy starch as dough component and anti-staling agent in gluten-free bread. LWT-Food Sci. Technol. 2019, 99, 476–482. [Google Scholar] [CrossRef]

- Korus, J.; Chmielewska, A.; Witczak, M.; Ziobro, R.; Juszczak, L. Rapeseed protein as a novel ingredient of gluten-free bread. Eur. Food Res. Technol. 2021, 247, 2015–2025. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).