Deep Neural Networks for Defects Detection in Gas Metal Arc Welding

Abstract

:1. Introduction

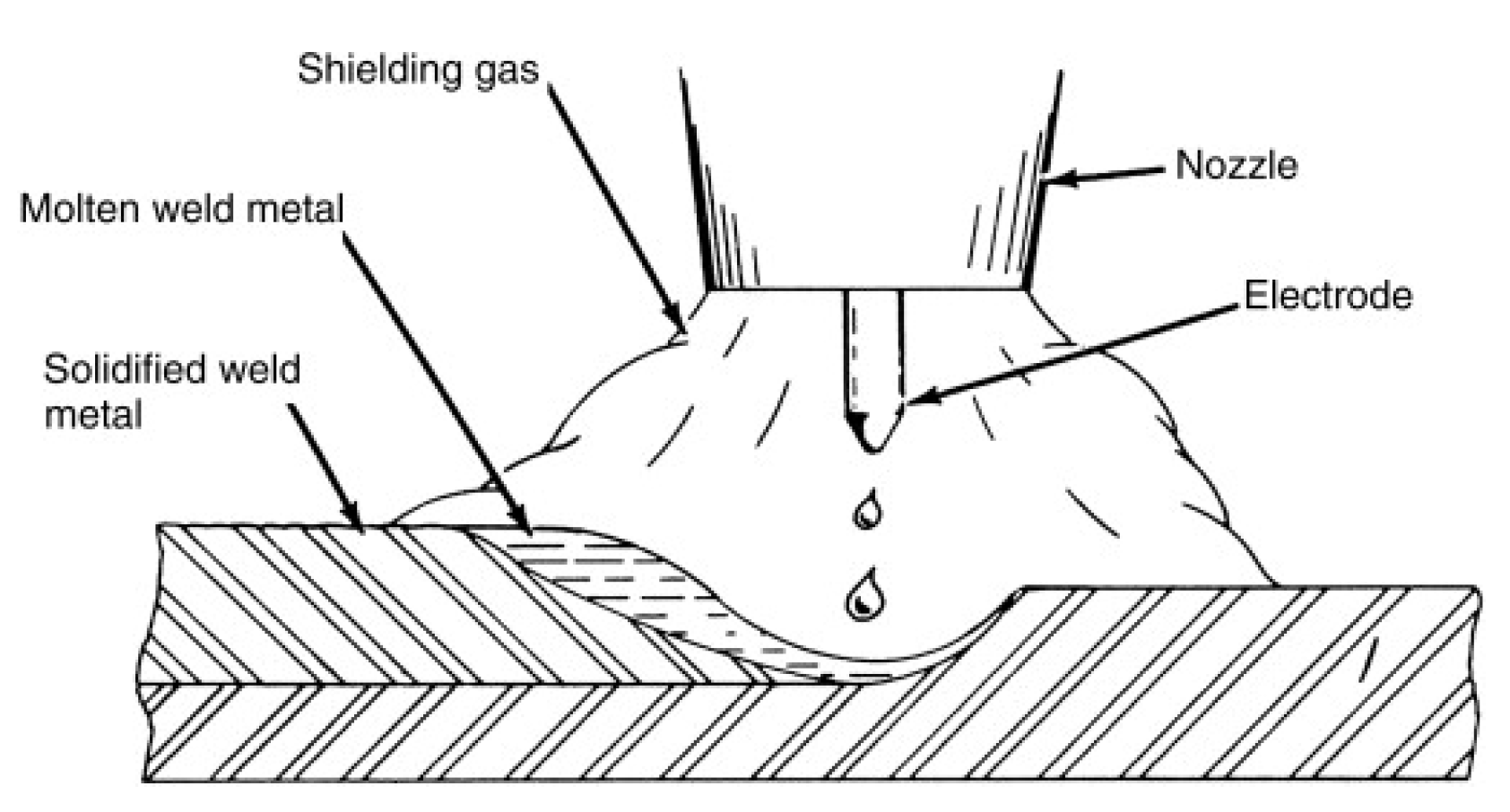

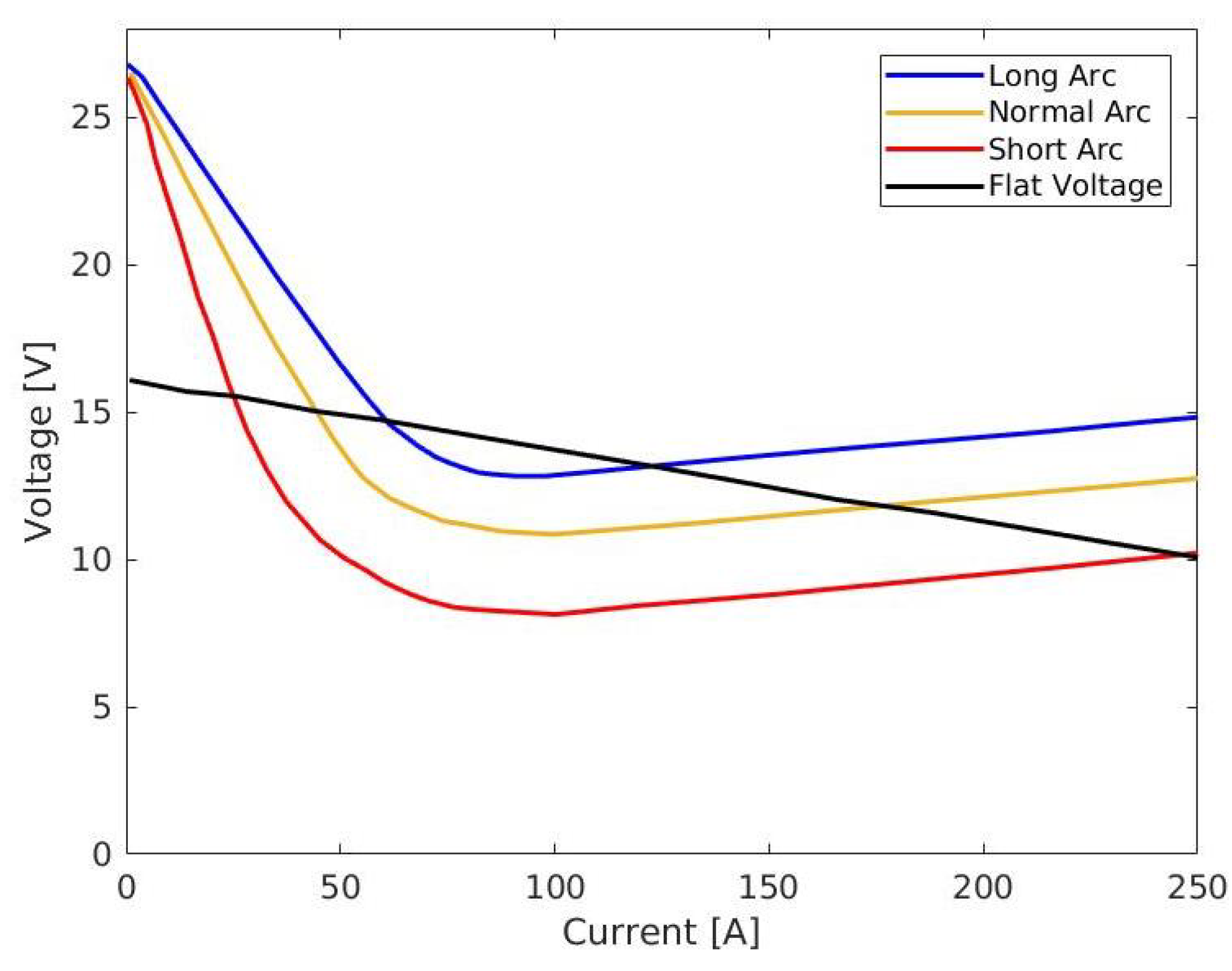

Review of GMAW Process and Defects

- Metallurgical discontinuities, which are problematic primarily due to the drop in mechanical properties of the joint and are typically identified through nondestructive testing.

- Metallurgical inhomogeneity, which is more complex to identify and assess.

2. Materials and Methods

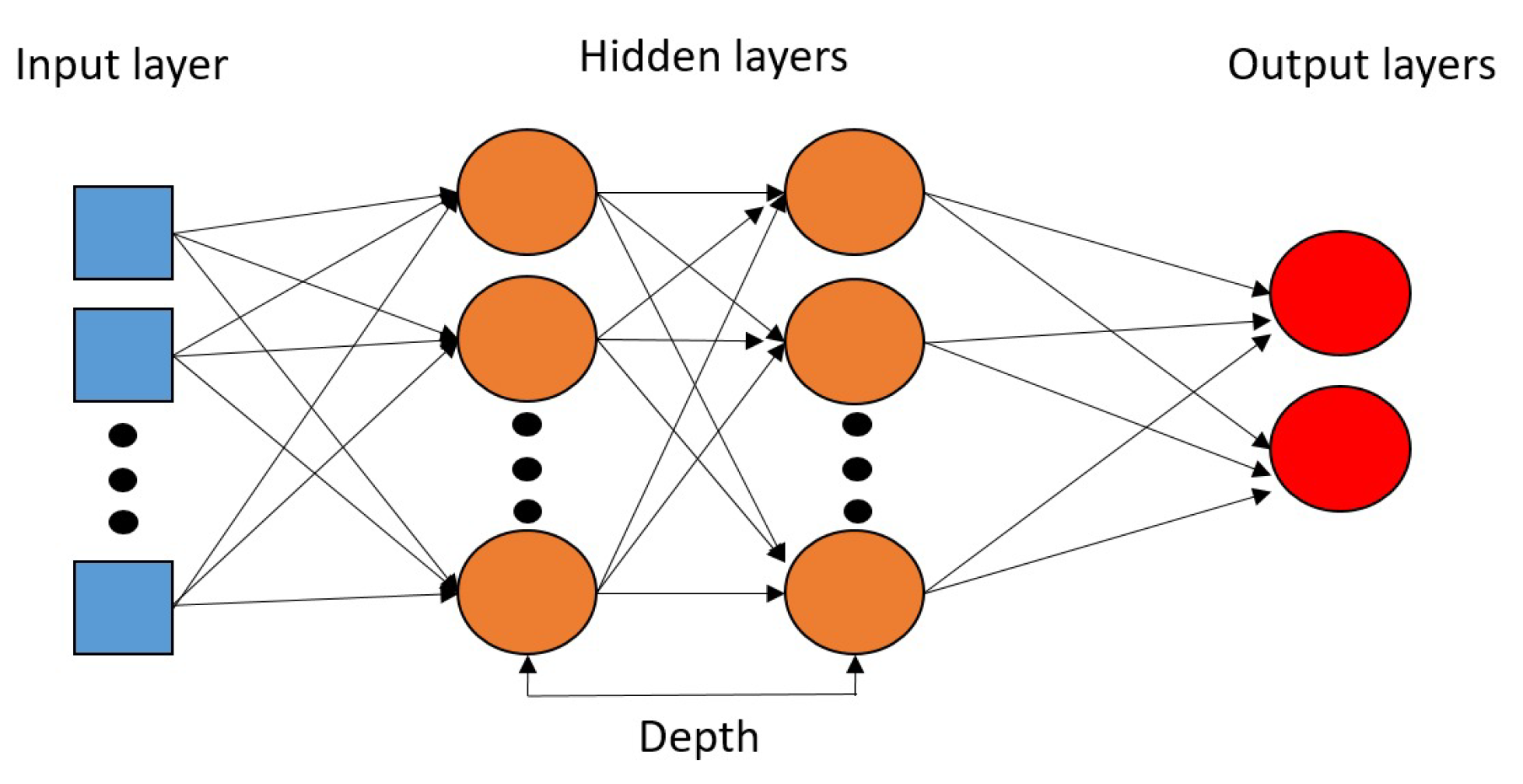

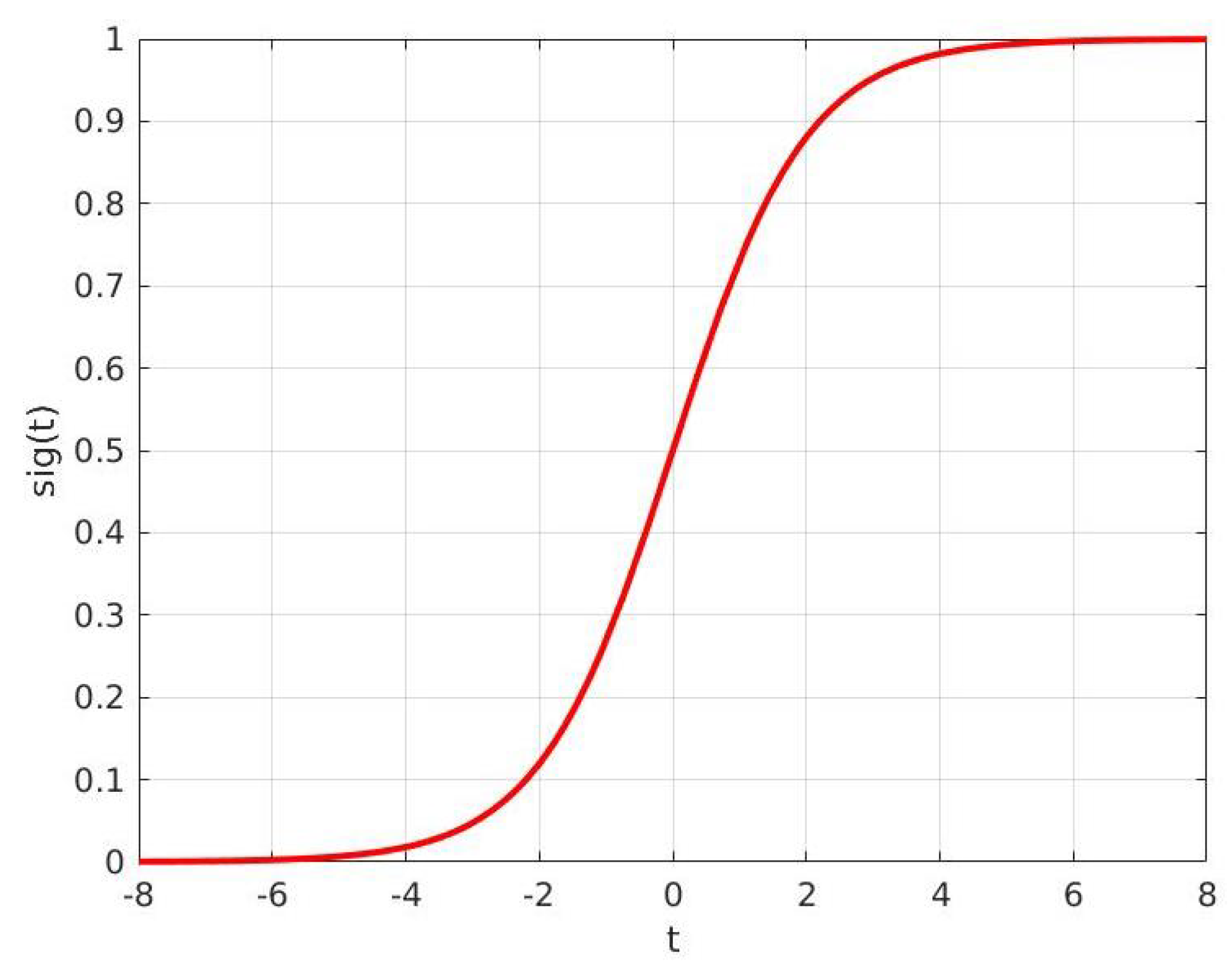

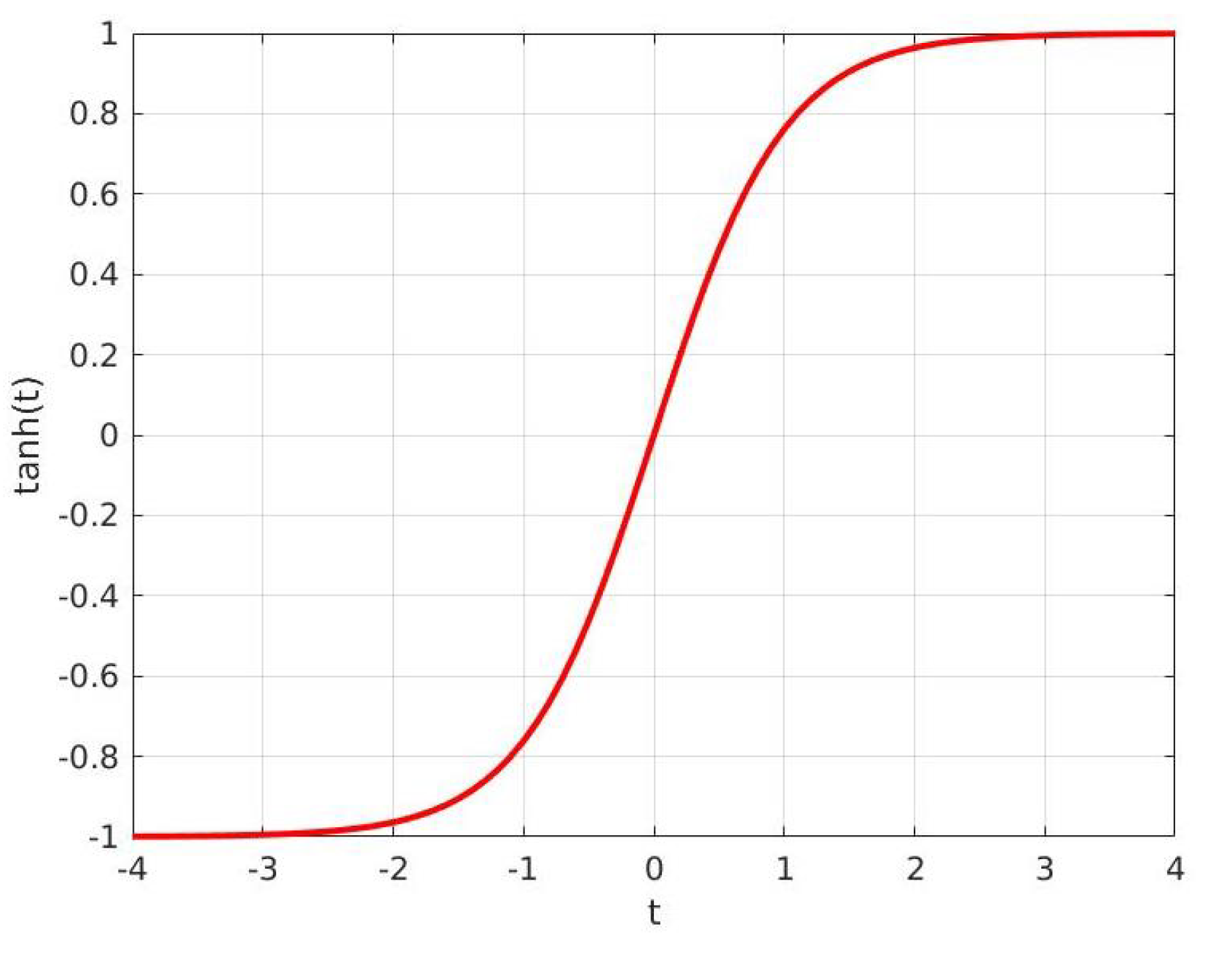

2.1. A Brief Summary of Artificial Neural Networks

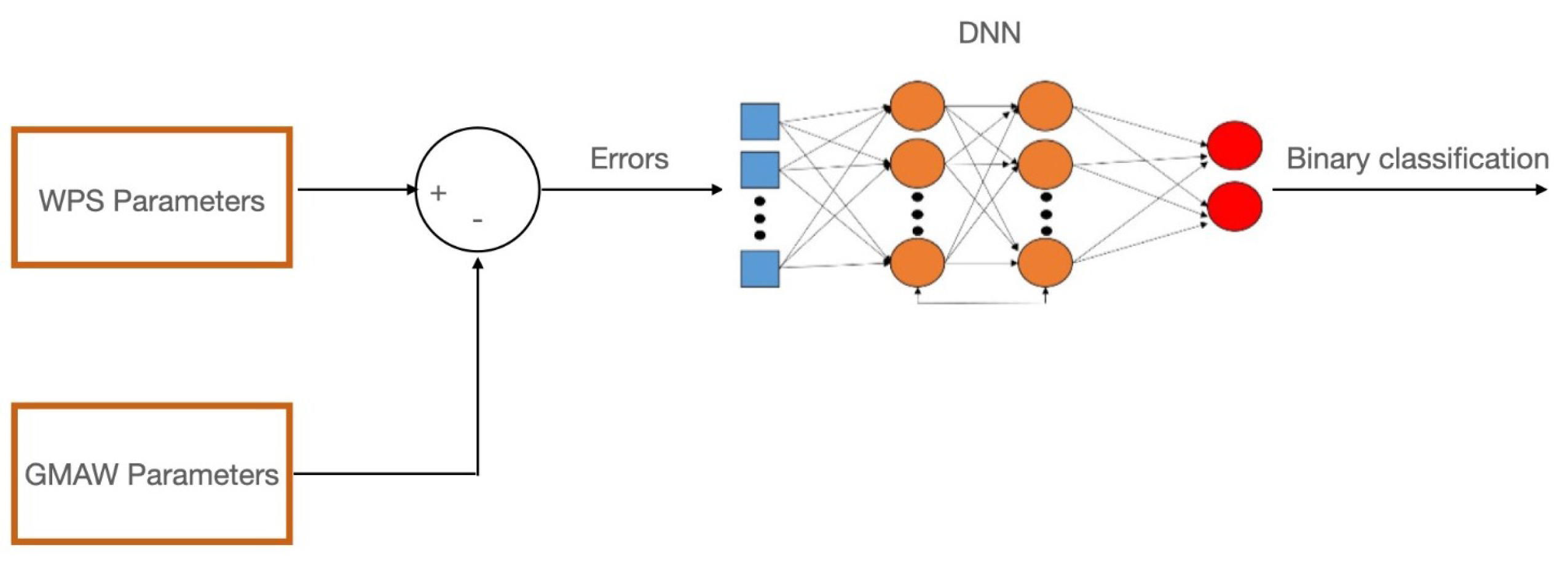

2.2. Development Workflow

2.2.1. Case Study and Data Collection

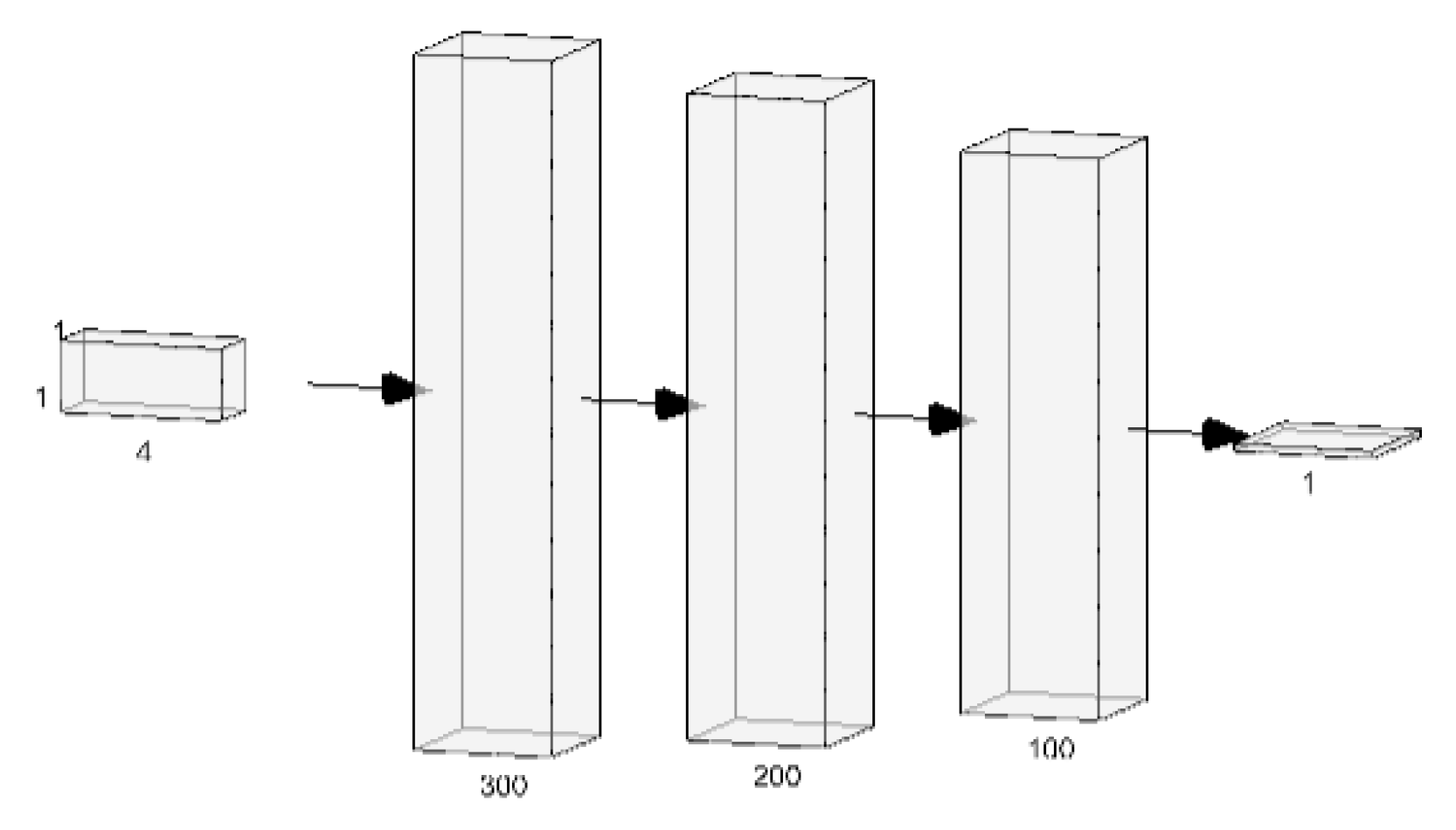

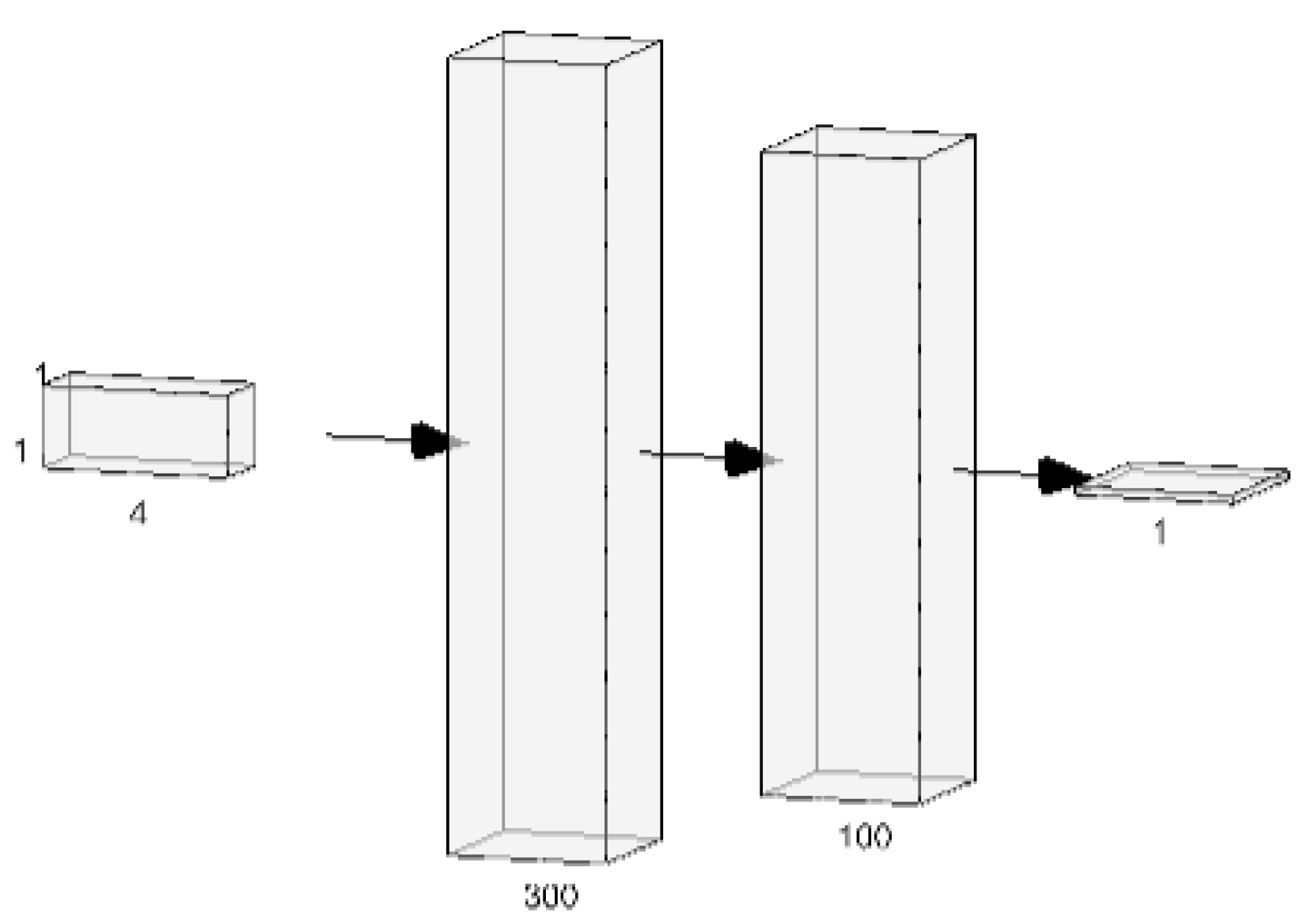

2.2.2. Choosing an Architecture

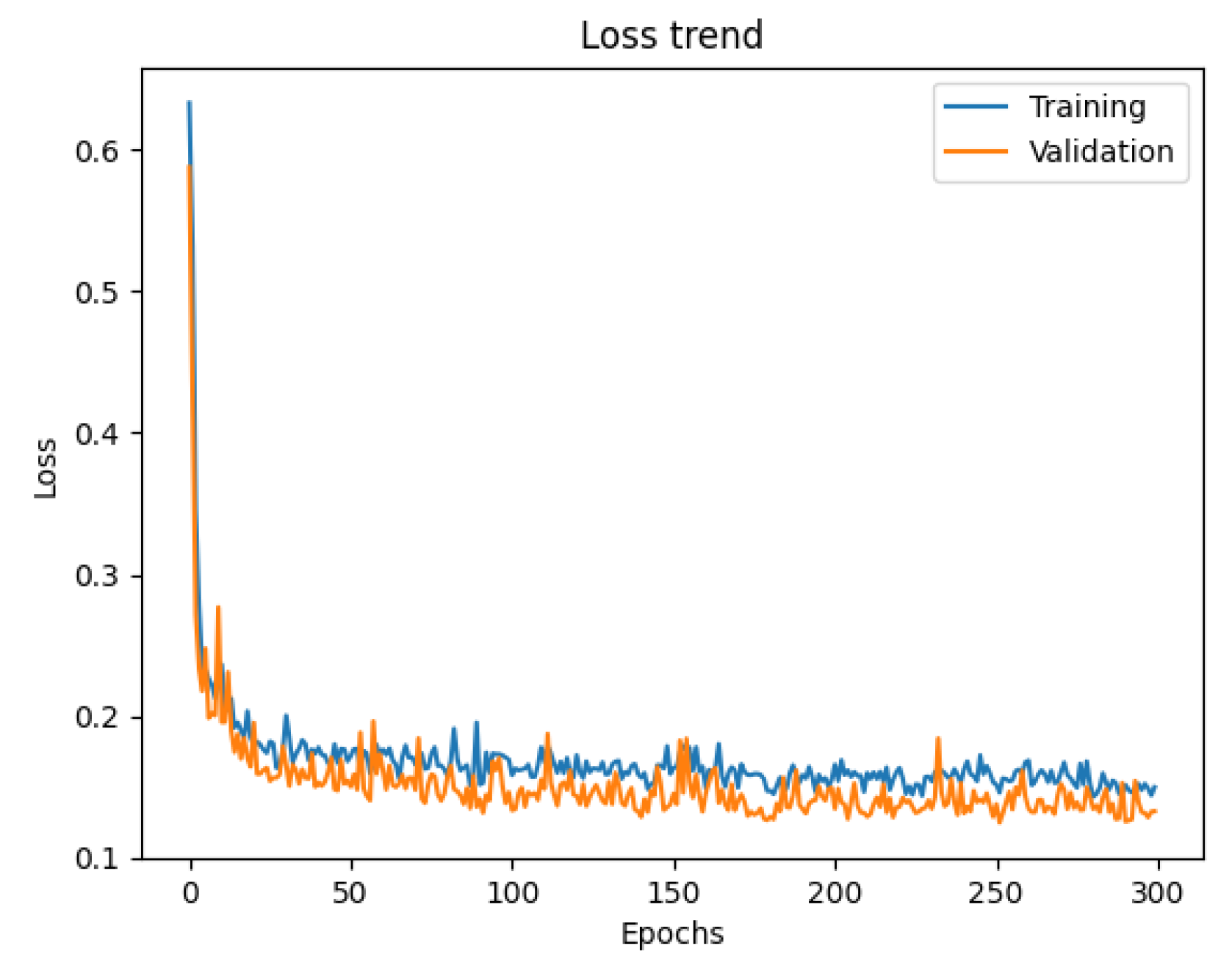

2.2.3. Training

3. Results

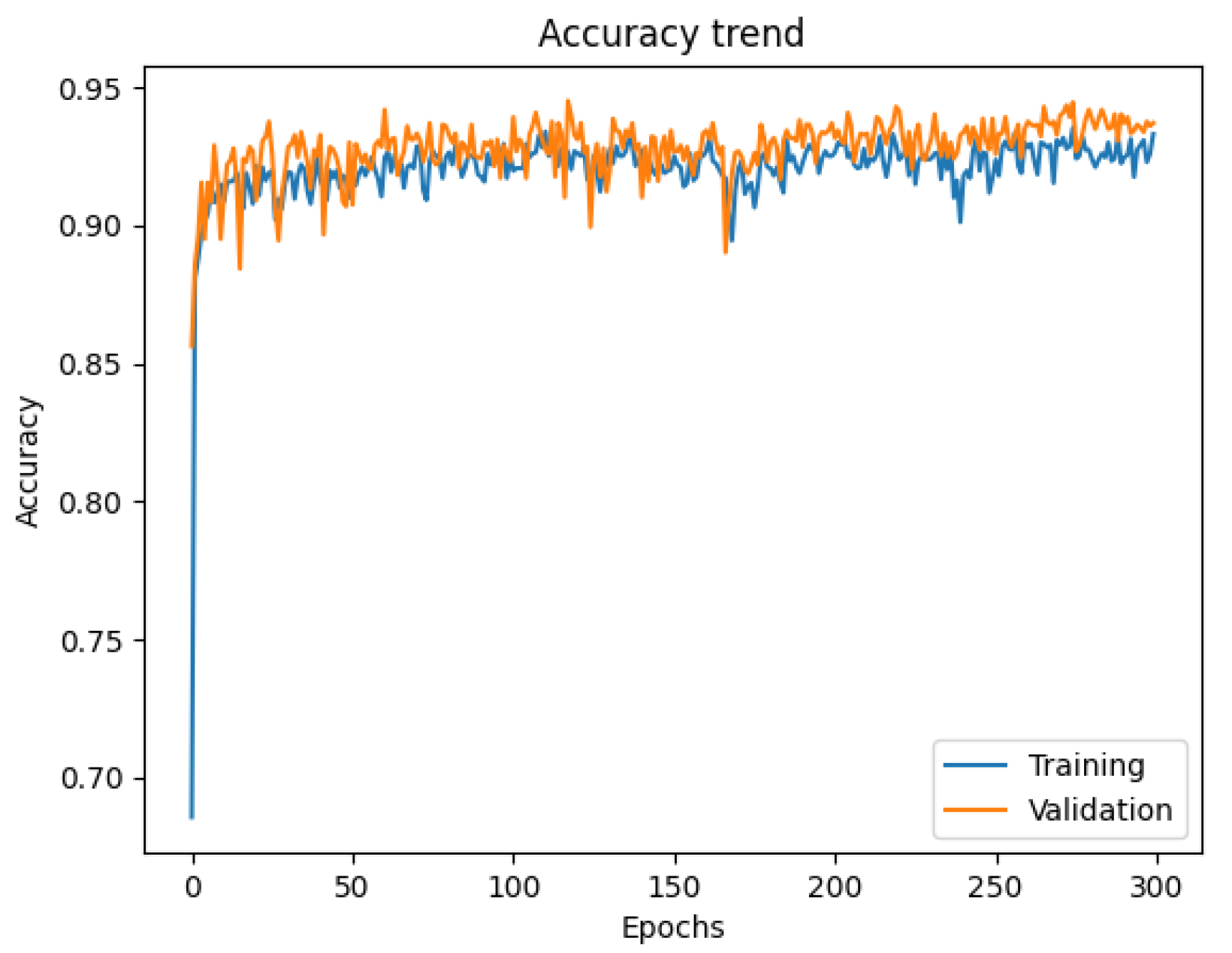

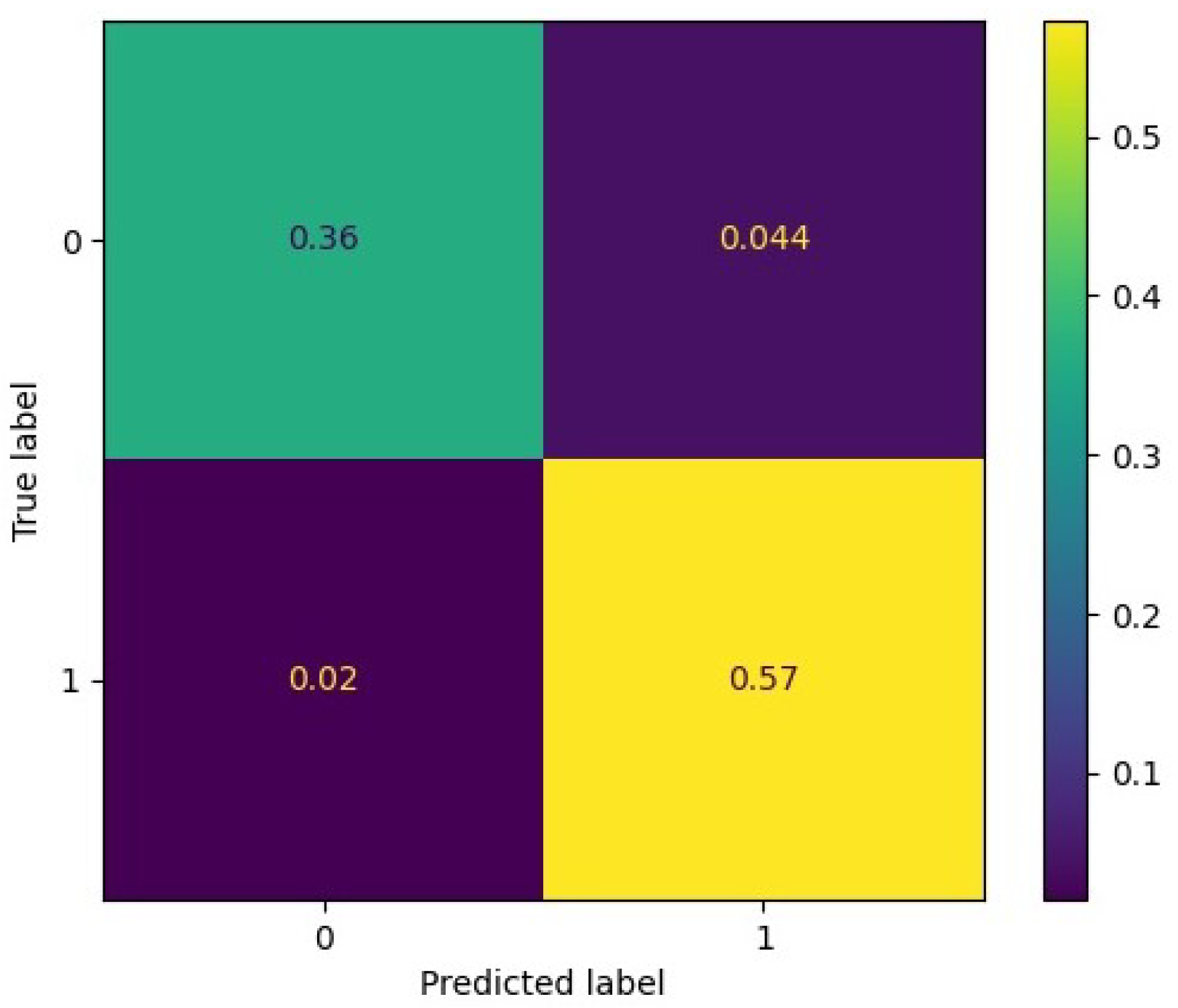

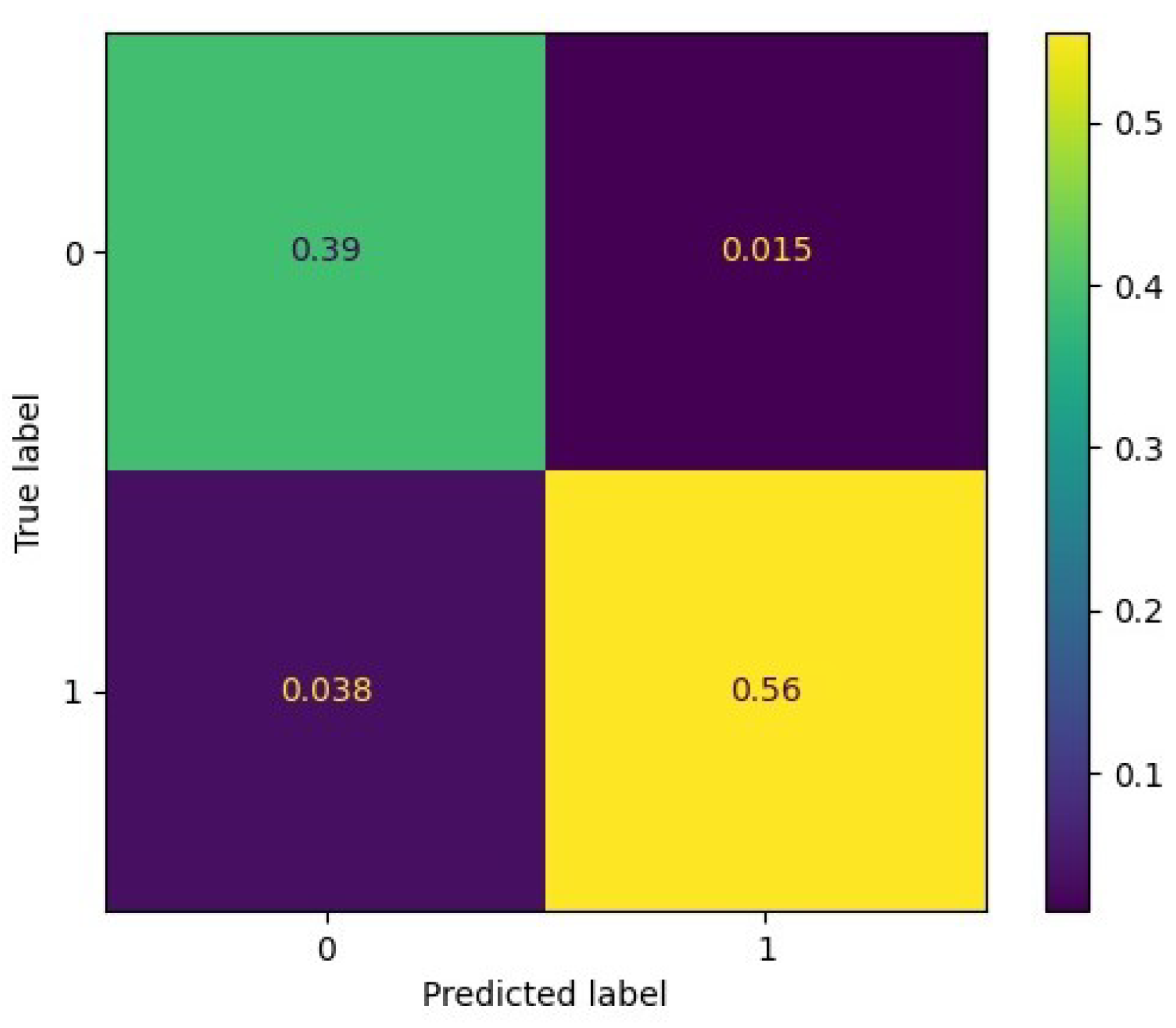

3.1. Architecture A

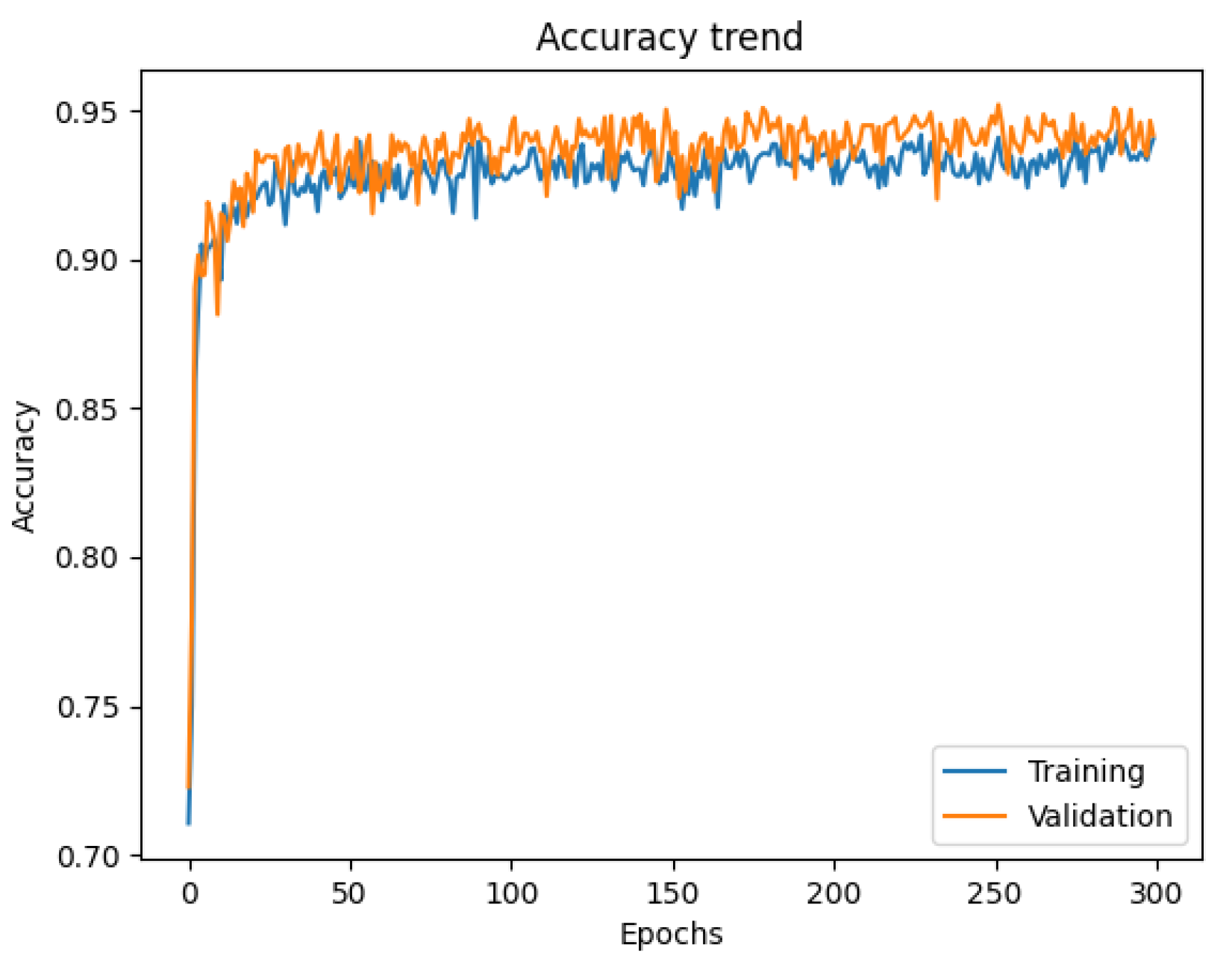

3.2. Architecture B

4. Conclusions and Future Developments

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| WPS | Welding Procedure Specification |

| GMAW | Gas Metal Arc Welding |

| ANN | Artificial Neural Networks |

References

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S. Modelling and prediction of Surface roughness in wire arc additive manufacturing using machine learning. J. Intell. Manuf. 2021, 1–16. [Google Scholar] [CrossRef]

- Deng, H.; Cheng, Y.; Feng, Y.; Xiang, J. Industrial Laser Welding Defect Detection and Image Defect Recognition Based on Deep Learning Model Developed. Symmetry 2021, 13, 1731. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Zhang, S.; Li, H.; Xu, Y.; Chen, S. Model-free adaptive iterative learning control of melt pool width in wire arc additive manufacturing. Int. Adv. Manuf. Technol. 2020, 110, 2131–2142. [Google Scholar] [CrossRef]

- Pan, J. Chapter 1: Dynamic behaviour of arc welding. In Arc Welding Control; Woodhead Publishing Ltd.: Cambridge, UK; CRC Press: Boca Raton, FL, USA, 2003; pp. 1–16. [Google Scholar]

- Weman, L. Chapter 2: Equipment for MIG welding. In MIG Welding Guide; Woodhead Publishing Ltd.: Cambridge, UK; CRC Press: Boca Raton, FL, USA, 2006; pp. 29–35. [Google Scholar]

- Weman, L. Chapter 9: Assessing weld quality in MIG welding. In MIG Welding Guide; Woodhead Publishing Ltd.: Cambridge, UK; CRC Press: Boca Raton, FL, USA, 2006; pp. 130–144. [Google Scholar]

- Mathers, G. Weld defects and quality control. In The Welding of Aluminium and Its Alloys; Woodhead Publishing Ltd.: Cambridge, UK; CRC Press: Boca Raton, FL, USA, 2002; pp. 199–215. [Google Scholar]

- Wei, E.; Farson, D.; Richardson, R.; Ludewig, H. Detection of Weld Surface Porosity by Statistical Analysis of Arc Current in Gas Metal Arc Welding. J. Manuf. Process. 2001, 3, 50–59. [Google Scholar] [CrossRef]

- By, J.; Johnson, A.; Carlson, N.M.; Smartt, H.B.; Clark, D.E. Process Control of GMAW: Sensing of Metal Transfer Mode. Weld. J. 1991, 70, 91. [Google Scholar]

- Pal, K.; Bhattacharya, S.; Pal, S.K. Investigation on arc sound and metal transfer modes for on-line monitoring in pulsed gas metal arc welding. J. Mater. Process. Technol. 2002, 210, 1397–1410. [Google Scholar] [CrossRef]

- Sreedhar, U.; Krishnamurthy, C.V.; Balasubramaniam, K.; Raghupathy, V.D.; Ravisankar, S. Automatic defect identification using thermal image analysis for online weld quality monitoring. J. Mater. Process. Technol. 2012, 212, 1557–1566. [Google Scholar] [CrossRef]

- Brobeg, P. Surface crack detection in welds using thermography. NDT & E Int. 2013, 57, 69–73. [Google Scholar] [CrossRef]

- Shin, S.; Jin, C.; Yu, J.; Rhee, S. Real-Time Detection of Weld Defects for Automated Welding Process Base on Deep Neural Network. Metals 2020, 10, 389. [Google Scholar] [CrossRef] [Green Version]

- Du, R.; Xu, Y.; Hou, Z.; Shu, J.; Chen, S. Strong noise image processing for vision-based seam tracking in robotic gas metal arc welding. Int. J. Adv. Manuf. Technol. 2019, 101, 2135–2149. [Google Scholar] [CrossRef]

- Nanni, L.; Maguolo, G.; Brahnam, S.; Paci, M. An Ensemble of Convolutional Neural Networks for Audio Classification. Appl. Sci. 2021, 11, 5796. [Google Scholar] [CrossRef]

- Jin, Z.; Li, H.; Gao, H. An intelligent weld control strategy based on reinforcement learning approach. Int. J. Adv. Manuf. Technol. 2019, 100, 2163–2175. [Google Scholar] [CrossRef]

- Chiroma, H.; Abdullahi, U.A.; Alarood, A.A.; Gabralla, L.A.; Rana, N.; Shuib, L.; Hashem, I.A.; Gbenga, D.E.; Abubakar, A.I.; Zeki, A.M.; et al. Progress on Artificial Neural Networks for Big Data Analytics: A Survey. IEEE Access 2019, 7, 70535–70551. [Google Scholar] [CrossRef]

- Hornik, K. Approximation capabilities of multilayer feedforward networks. Neural Netw. 1991, 4, 251–257. [Google Scholar] [CrossRef]

- Selmic, R.R.; Lewis, F.L. Neural-network approximation of piecewise continuous functions: Application to friction compensation. IEEE Trans. Neural Netw. 2002, 13, 745–751. [Google Scholar] [CrossRef] [Green Version]

- Ojha, V.K.; Abraham, A.; Snášel, V. Metaheuristic design of feedforward neural networks: A review of two decades of research. Eng. Appl. Artif. Intell. 2017, 60, 97–116. [Google Scholar] [CrossRef] [Green Version]

- Rasamoelina, A.D.; Adjailia, F.; Sinčák, P. A Review of Activation Function for Artificial Neural Network. In Proceedings of the IEEE 18th World Symposium on Applied Machine Intelligence and Informatics (SAMI), Herlany, Slovakia, 23–25 January 2020; pp. 281–286. [Google Scholar] [CrossRef]

- Bengio, Y.; Glorot, X. Understanding the difficulty of training deep feed forward neural networks. In Proceedings of the International Conference on Artificial Intelligence and Statistics, Sardinia, Italy, 13–15 May 2010; pp. 249–256. [Google Scholar]

- Datta, L. A Survey on Activation Functions and their relation with Xavier and He Normal Initialization. arXiv 2020, arXiv:abs/2004.06632. [Google Scholar]

- Srivastava, N.; Hinton, G.; Krizhevsky, A.; Sutskever, I.; Ruslan, S. Dropout: A Simple Way to Prevent Neural Networks from Overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. Available online: http://jmlr.org/papers/v15/srivastava14a.html (accessed on 21 February 2022).

- Gao, F.; Zhong, H. Study on the Large Batch Size Training of Neural Networks Based on the Second Order Gradient. arXiv 2020, arXiv:2012.08795. [Google Scholar]

- Kingma, D.P.; Ba, J. Adam: A Method for Stochastic Optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar]

- You, K.; Long, M.; Wang, J.; Jordan, M. How does learning rare decay help modern neural networks? arXiv 2019, arXiv:1908.01878. [Google Scholar]

- Tensorflow. Available online: https://www.tensorflow.org/ (accessed on 10 November 2021).

| Total samples | 2655 |

| Batch size | 64 |

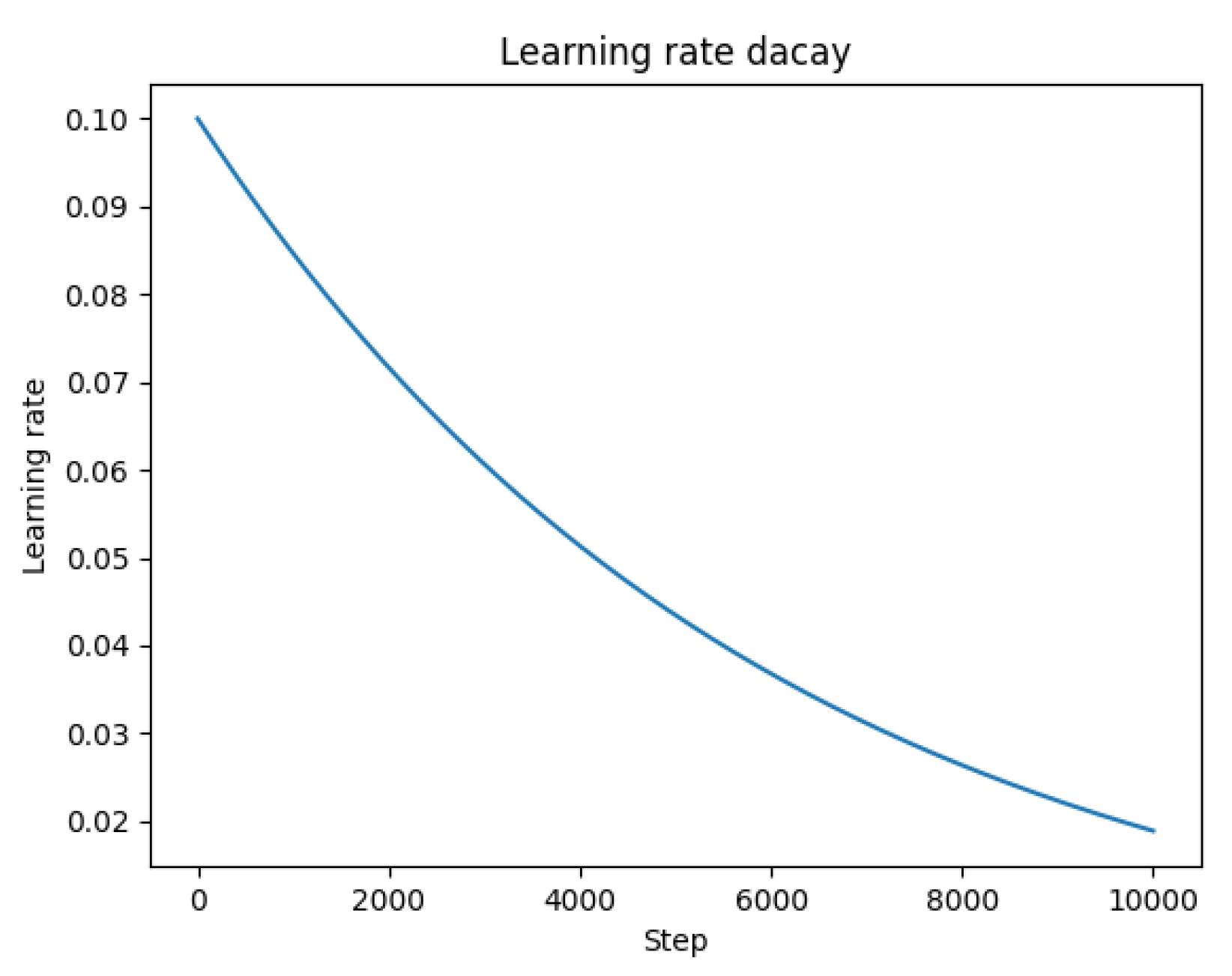

| Initial learning rate () | |

| Decay | 6000 |

| 1 × 10 | |

| Epochs | 300 |

| Step per epoch | 35 |

| Training size (% on the total) | |

| Validation size (% on the total) |

| Core NVIDIA CUDA | 896 |

| Boost Clock (MHz) | 1665 |

| Base Clock (MHz) | 1485 |

| Memory speed (Gbps) | 8 |

| Compute capability | |

| Microarchitecture | Turing |

| Final validation loss | |

| Final training loss | |

| Test accuracy | |

| Inference time (ms) |

| Final validation loss | |

| Final training loss | |

| Test accuracy | |

| Inference time (ms) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nele, L.; Mattera, G.; Vozza, M. Deep Neural Networks for Defects Detection in Gas Metal Arc Welding. Appl. Sci. 2022, 12, 3615. https://doi.org/10.3390/app12073615

Nele L, Mattera G, Vozza M. Deep Neural Networks for Defects Detection in Gas Metal Arc Welding. Applied Sciences. 2022; 12(7):3615. https://doi.org/10.3390/app12073615

Chicago/Turabian StyleNele, Luigi, Giulio Mattera, and Mario Vozza. 2022. "Deep Neural Networks for Defects Detection in Gas Metal Arc Welding" Applied Sciences 12, no. 7: 3615. https://doi.org/10.3390/app12073615

APA StyleNele, L., Mattera, G., & Vozza, M. (2022). Deep Neural Networks for Defects Detection in Gas Metal Arc Welding. Applied Sciences, 12(7), 3615. https://doi.org/10.3390/app12073615