Response Surface Methodology as a Tool for Optimization of Pulsed Electric Field Pretreatment and Microwave-Convective Drying of Apple

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Design of Experiments—Response Surface Methodology (RSM)

2.3. Pulsed Electric Field Pretreatment

2.4. Microwave-Convective Drying

2.5. Dry Matter Content

2.6. Water Activity

2.7. Hygroscopic Properties

2.8. Rehydration Properties

2.9. Colour

2.10. Preparation of the Extracts

2.11. Total Phenolic Content

2.12. Antioxidant Activity (ABTS and DPPH Assays)

2.13. Statistical Analysis

3. Results and Discussion

3.1. Cell Disintegration Index

3.2. Drying Kinetics and Drying Times

3.3. Physicochemical Properties

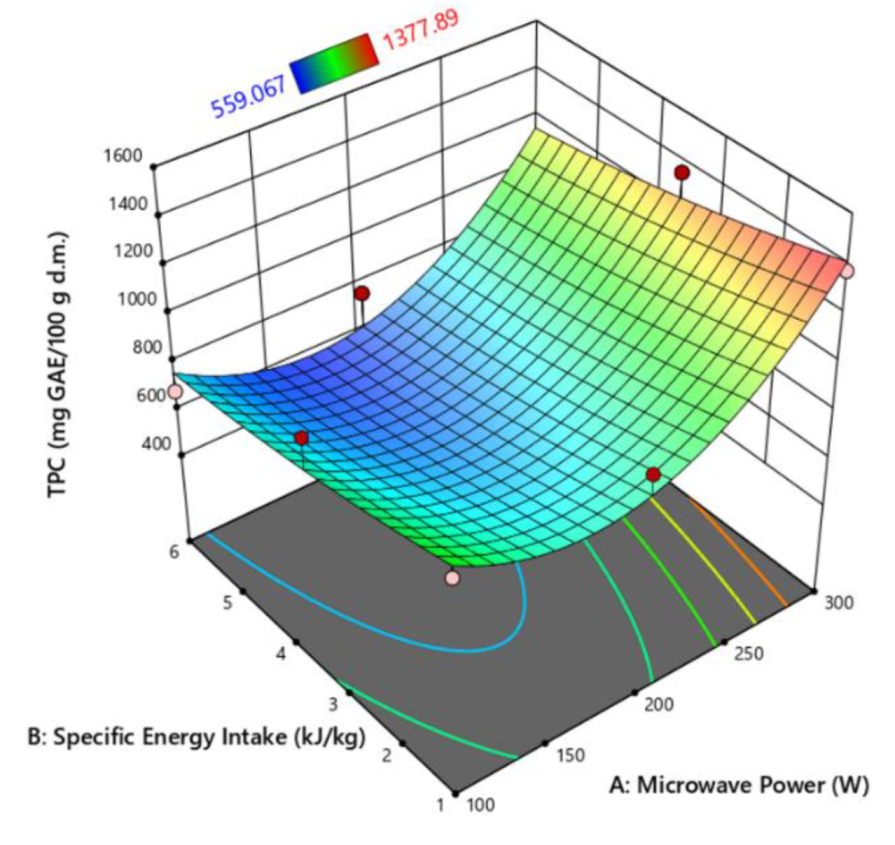

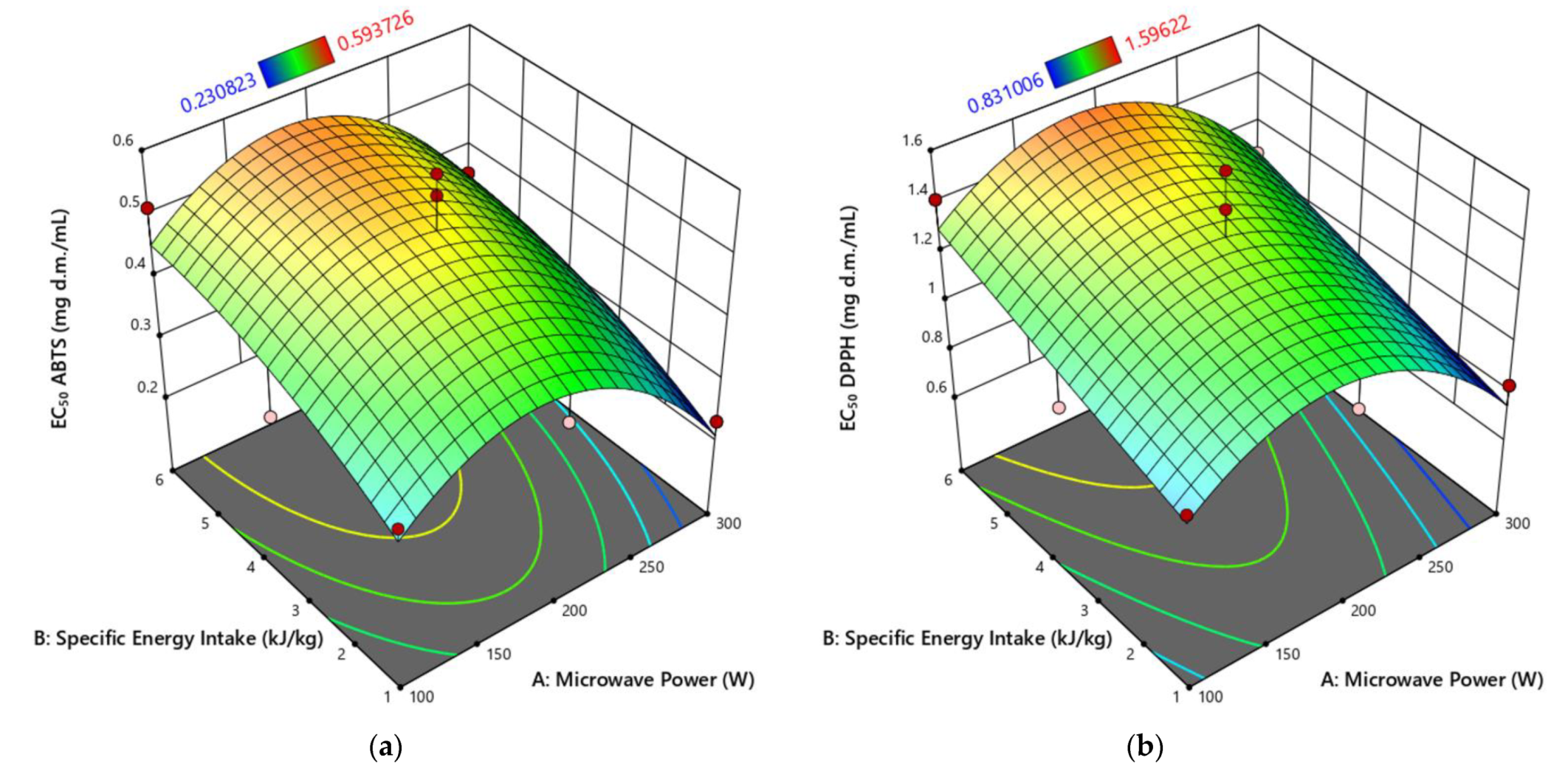

3.4. Optimization of PEF Pretreatment and Microwave-Convective Drying

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Osae, R.; Essilfie, G.; Alolga, R.N.; Akaba, S.; Song, X.; Owusu-Ansah, P.; Zhou, C. Application of non-thermal pretreatment techniques on agricultural products prior to drying: A review. J. Sci. Food Agric. 2020, 100, 2585–2599. [Google Scholar] [CrossRef]

- Boateng, I.D.; Yang, X.-M. Process optimization of intermediate-wave infrared drying: Screening by Plackett–Burman; comparison of Box-Behnken and central composite design and evaluation: A case study. Ind. Crops Prod. 2021, 162, 113287. [Google Scholar] [CrossRef]

- Sakare, P.; Prasad, N.; Thombare, N.; Singh, R.; Sharma, S.C. Infrared Drying of Food Materials: Recent Advances. Food Eng. Rev. 2020, 12, 381–398. [Google Scholar] [CrossRef]

- Llavata, B.; García-Pérez, J.V.; Simal, S.; Cárcel, J.A. Innovative pre-treatments to enhance food drying: A current review. Curr. Opin. Food Sci. 2020, 35, 20–26. [Google Scholar] [CrossRef]

- Ravichandran, K.S.; Krishnaswamy, K. Sustainable food processing of selected North American native berries to support agroforestry. Crit. Rev. Food Sci. Nutr. 2021, 1–26. [Google Scholar] [CrossRef]

- Hii, C.L.; Ong, S.P.; Yap, J.Y.; Putranto, A.; Mangindaan, D. Hybrid drying of food and bioproducts: A review. Dry. Technol. 2021, 39, 1554–1576. [Google Scholar] [CrossRef]

- Ghanbarian, D.; Torki-Harchegani, M.; Sadeghi, M.; Pirbalouti, A.G. Ultrasonically improved convective drying of peppermint leaves: Influence on the process time and energetic indices. Renew. Energy 2020, 153, 67–73. [Google Scholar] [CrossRef]

- Bantle, M.; Eikevik, T.M. A study of the energy efficiency of convective drying systems assisted by ultrasound in the production of clipfish. J. Clean. Prod. 2014, 65, 217–223. [Google Scholar] [CrossRef]

- Morais, R.M.S.C.; Morais, A.M.M.B.; Dammak, I.; Bonilla, J.; Sobral, P.J.A.; Laguerre, J.-C.; Afonso, M.J.; Ramalhosa, E.C.D. Functional Dehydrated Foods for Health Preservation. J. Food Qual. 2018, 2018, 1739636. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.Y.; Wang, R.F.; Kudra, T. Uniformity Issue in Microwave Drying. Dry. Technol. 2011, 29, 652–660. [Google Scholar] [CrossRef]

- Guzik, P.; Kulawik, P.; Zając, M.; Migdał, W. Microwave applications in the food industry: An overview of recent developments. Crit. Rev. Food Sci. Nutr. 2021, 1–20. [Google Scholar] [CrossRef]

- Maftoonazad, N.; Dehghani, M.R.; Ramaswamy, H.S. Hybrid microwave-hot air tunnel drying of onion slices: Drying kinetics, energy efficiency, product rehydration, color, and flavor characteristics. Dry. Technol. 2020, 1–21. [Google Scholar] [CrossRef]

- Horuz, E.; Bozkurt, H.; Karataş, H.; Maskan, M. Simultaneous application of microwave energy and hot air to whole drying process of apple slices: Drying kinetics, modeling, temperature profile and energy aspect. Heat Mass Transf. 2018, 54, 425–436. [Google Scholar] [CrossRef]

- Miraei Ashtiani, S.-H.; Sturm, B.; Nasirahmadi, A. Effects of hot-air and hybrid hot air-microwave drying on drying kinetics and textural quality of nectarine slices. Heat Mass Transf. 2018, 54, 915–927. [Google Scholar] [CrossRef]

- Nathakaranakule, A.; Paengkanya, S.; Soponronnarit, S. Durian chips drying using combined microwave techniques with step-down microwave power input. Food Bioprod. Process. 2019, 116, 105–117. [Google Scholar] [CrossRef]

- Wiset, L.; Poomsa-Ad, N.; Onsaard, W. Drying characteristics and quality evaluation in microwave-assisted hot air drying of cherry tomato. Eng. Appl. Sci. Res. 2021, 48, 724–731. [Google Scholar] [CrossRef]

- Junqueira, J.R. de J.; Corrêa, J.L.G.; Ernesto, D.B. Microwave, convective, and intermittent microwave-convective drying of pulsed vacuum osmodehydrated pumpkin slices. J. Food Process. Preserv. 2017, 41, e13250. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, M.; Mujumdar, A.S. Comparison of Three New Drying Methods for Drying Characteristics and Quality of Shiitake Mushroom (Lentinus edodes). Dry. Technol. 2014, 32, 1791–1802. [Google Scholar] [CrossRef]

- Ostermeier, R.; Hill, K.; Dingis, A.; Töpfl, S.; Jäger, H. Influence of pulsed electric field (PEF) and ultrasound treatment on the frying behavior and quality of potato chips. Innov. Food Sci. Emerg. Technol. 2021, 67, 102553. [Google Scholar] [CrossRef]

- Yu, Y.; Jin, T.Z.; Fan, X.; Wu, J. Biochemical degradation and physical migration of polyphenolic compounds in osmotic dehydrated blueberries with pulsed electric field and thermal pretreatments. Food Chem. 2018, 239, 1219–1225. [Google Scholar] [CrossRef]

- Tylewicz, U.; Tappi, S.; Mannozzi, C.; Romani, S.; Dellarosa, N.; Laghi, L.; Ragni, L.; Rocculi, P.; Dalla Rosa, M. Effect of pulsed electric field (PEF) pre-treatment coupled with osmotic dehydration on physico-chemical characteristics of organic strawberries. J. Food Eng. 2017, 213, 2–9. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Y.; Sun, D.-W.; Zhu, Z. Effects of high-voltage electric field produced by an improved electrode system on freezing behaviors and selected properties of agarose gel. J. Food Eng. 2019, 254, 25–33. [Google Scholar] [CrossRef]

- Liu, Z.-W.; Zeng, X.-A.; Ngadi, M. Enhanced extraction of phenolic compounds from onion by pulsed electric field (PEF). J. Food Process. Preserv. 2018, 42, e13755. [Google Scholar] [CrossRef]

- Alam, M.R.; Lyng, J.G.; Frontuto, D.; Marra, F.; Cinquanta, L. Effect of Pulsed Electric Field Pretreatment on Drying Kinetics, Color, and Texture of Parsnip and Carrot. J. Food Sci. 2018, 83, 2159–2166. [Google Scholar] [CrossRef]

- Telfser, A.; Gómez Galindo, F. Effect of reversible permeabilization in combination with different drying methods on the structure and sensorial quality of dried basil (Ocimum basilicum L.) leaves. LWT Food Sci. Technol. 2019, 99, 148–155. [Google Scholar] [CrossRef]

- Ostermeier, R.; Giersemehl, P.; Siemer, C.; Töpfl, S.; Jäger, H. Influence of pulsed electric field (PEF) pre-treatment on the convective drying kinetics of onions. J. Food Eng. 2018, 237, 110–117. [Google Scholar] [CrossRef]

- Lebovka, N.I.; Shynkaryk, N.V.; Vorobiev, E. Pulsed electric field enhanced drying of potato tissue. J. Food Eng. 2007, 78, 606–613. [Google Scholar] [CrossRef]

- Neri, L.; Giancaterino, M.; Rocchi, R.; Tylewicz, U.; Valbonetti, L.; Faieta, M.; Pittia, P. Pulsed electric fields (PEF) as hot air drying pre-treatment: Effect on quality and functional properties of saffron (Crocus sativus L.). Innov. Food Sci. Emerg. Technol. 2021, 67, 102592. [Google Scholar] [CrossRef]

- Andreou, V.; Dimopoulos, G.; Tsonas, T.; Katsimichas, A.; Limnaios, A.; Katsaros, G.; Taoukis, P. Pulsed Electric Fields-Assisted Drying and Frying of Fresh Zucchini. Food Bioprocess Technol. 2021, 14, 2091–2106. [Google Scholar] [CrossRef]

- Liu, C.; Pirozzi, A.; Ferrari, G.; Vorobiev, E.; Grimi, N. Effects of Pulsed Electric Fields on Vacuum Drying and Quality Characteristics of Dried Carrot. Food Bioprocess Technol. 2020, 13, 45–52. [Google Scholar] [CrossRef]

- Liu, C.; Pirozzi, A.; Ferrari, G.; Vorobiev, E.; Grimi, N. Impact of pulsed electric fields on vacuum drying kinetics and physicochemical properties of carrot. Food Res. Int. 2020, 137, 109658. [Google Scholar] [CrossRef]

- Liu, C.; Grimi, N.; Lebovka, N.; Vorobiev, E. Effects of pulsed electric fields treatment on vacuum drying of potato tissue. LWT Food Sci. Technol. 2018, 95, 289–294. [Google Scholar] [CrossRef]

- Fauster, T.; Giancaterino, M.; Pittia, P.; Jaeger, H. Effect of pulsed electric field pretreatment on shrinkage, rehydration capacity and texture of freeze-dried plant materials. LWT 2020, 121, 108937. [Google Scholar] [CrossRef]

- Wiktor, A.; Parniakov, O.; Toepfl, S.; Witrowa-Rajchert, D.; Heinz, V.; Smetana, S. Sustainability and bioactive compound preservation in microwave and pulsed electric fields technology assisted drying. Innov. Food Sci. Emerg. Technol. 2021, 67, 102597. [Google Scholar] [CrossRef]

- Huang, X.-L.; Yang, W. Experiments on microwave drying of carrot slices using pulsed electric field pre-treatment. Nongye Gongcheng Xuebao Trans. Chin. Soc. Agric. Eng. 2010, 26, 325–330. [Google Scholar] [CrossRef]

- Huang, X.-L.; Yang, W.; Wang, N. Effects of Pulsed Electric Field (PEF) Pre- treated on Potatoes Microwave Drying Characteristics. Acad. Period. Farm Prod. Process. 2009, 3, 189. [Google Scholar]

- Huang, X.-L.; Yang, W.; Li, Y.-Y. Research on Microwave Drying Technology of Potato Slices with Pulsed Electric Field (PEF) Pre-treated. J. Kunming Univ. Sci. Technol. 2009, 6, 98–102. [Google Scholar]

- Yang, W.; Huang, X.-L.; Zhang, F.-J.; Li, P. Microwave Drying Kinetics of Potato Slices with Pulsed Electric Field Pre-treatment. J. Kunming Univ. Sci. Technol. 2012, 37. Available online: https://www.semanticscholar.org/paper/Microwave-Drying-Kinetics-of-Potato-Slices-with-Pei/b9c67c206dd8fa6e7e463ff3dc22e99579931bd0 (accessed on 27 February 2022).

- Liu, C.; Grimi, N.; Lebovka, N.; Vorobiev, E. Convective air, microwave, and combined drying of potato pre-treated by pulsed electric fields. Dry. Technol. 2019, 37, 1704–1713. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.-L.; Vidyarthi, S.K.; Wang, Q.-H.; Gao, L.; Li, B.-R.; Wei, Q.; Liu, Y.-H.; Xiao, H.-W. Effects of different drying methods on drying kinetics, physicochemical properties, microstructure, and energy consumption of potato (Solanum tuberosum L.) cubes. Dry. Technol. 2021, 39, 418–431. [Google Scholar] [CrossRef]

- Mannozzi, C.; Cecchini, J.P.; Tylewicz, U.; Siroli, L.; Patrignani, F.; Lanciotti, R.; Rocculi, P.; Dalla Rosa, M.; Romani, S. Study on the efficacy of edible coatings on quality of blueberry fruits during shelf-life. LWT Food Sci. Technol. 2017, 85, 440–444. [Google Scholar] [CrossRef]

- Bednarska, M.A.; Janiszewska-Turak, E. The influence of spray drying parameters and carrier material on the physico-chemical properties and quality of chokeberry juice powder. J. Food Sci. Technol. 2020, 57, 564–577. [Google Scholar] [CrossRef] [Green Version]

- Witrowa-Rajchert, D.; Lewicki, P.P. Rehydration properties of dried plant tissues. Int. J. Food Sci. Technol. 2006, 41, 1040–1046. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. [14] Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. In Methods in Enzymology; Academic Press: Cambridge, MA, USA, 1999; Volume 299, pp. 152–178. [Google Scholar]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Rybak, K.; Wiktor, A.; Witrowa-Rajchert, D.; Parniakov, O.; Nowacka, M. The Quality of Red Bell Pepper Subjected to Freeze-Drying Preceded by Traditional and Novel Pretreatment. Foods 2021, 10, 226. [Google Scholar] [CrossRef]

- Chauhan, O.P.; Sayanfar, S.; Toepfl, S. Effect of pulsed electric field on texture and drying time of apple slices. J. Food Sci. Technol. 2018, 55, 2251–2258. [Google Scholar] [CrossRef]

- Kudra, T. Energy Aspects in Drying. Dry. Technol. 2004, 22, 917–932. [Google Scholar] [CrossRef]

- Delgado, J.M.P.Q.; da Silva, M.V. Food Dehydration: Fundamentals, Modelling and Applications. In Transport Phenomena and Drying of Solids and Particulate Materials; Delgado, J.M.P.Q., Barbosa de Lima, A.G., Eds.; Springer: Cham, Switzerland, 2014; Volume 48, pp. 69–94. ISBN 9783319040530. [Google Scholar]

- Aghilinategh, N.; Rafiee, S.; Hosseinpour, S.; Omid, M.; Mohtasebi, S.S. Real-time color change monitoring of apple slices using image processing during intermittent microwave convective drying. Food Sci. Technol. Int. 2016, 22, 634–646. [Google Scholar] [CrossRef]

- Yildiz, G.; İzli, G. Influence of microwave and microwave-convective drying on the drying kinetics and quality characteristics of pomelo. J. Food Process. Preserv. 2019, 43, e13812. [Google Scholar] [CrossRef]

- Dehghannya, J.; Farshad, P.; Khakbaz Heshmati, M. Three-stage hybrid osmotic–intermittent microwave–convective drying of apple at low temperature and short time. Dry. Technol. 2018, 36, 1982–2005. [Google Scholar] [CrossRef]

- Horuz, E.; Bozkurt, H.; Karataş, H.; Maskan, M. Effects of hybrid (microwave-convectional) and convectional drying on drying kinetics, total phenolics, antioxidant capacity, vitamin C, color and rehydration capacity of sour cherries. Food Chem. 2017, 230, 295–305. [Google Scholar] [CrossRef]

- Kaveh, M.; Amiri Chayjan, R.; Taghinezhad, E.; Rasooli Sharabiani, V.; Motevali, A. Evaluation of specific energy consumption and GHG emissions for different drying methods (Case study: Pistacia atlantica). J. Clean. Prod. 2020, 259, 120963. [Google Scholar] [CrossRef]

- Osae, R.; Essilfie, G.; Alolga, R.N.; Bonah, E.; Ma, H.; Zhou, C. Drying of ginger slices—Evaluation of quality attributes, energy consumption, and kinetics study. J. Food Process Eng. 2020, 43, e13348. [Google Scholar] [CrossRef]

- Knorr, D.; Angersbach, A. Impact of high-intensity electric field pulses on plant membrane permeabilization. Trends Food Sci. Technol. 1998, 9, 185–191. [Google Scholar] [CrossRef]

- Aghilinategh, N.; Rafiee, S.; Gholikhani, A.; Hosseinpur, S.; Omid, M.; Mohtasebi, S.S.; Maleki, N. A comparative study of dried apple using hot air, intermittent and continuous microwave: Evaluation of kinetic parameters and physicochemical quality attributes. Food Sci. Nutr. 2015, 3, 519–526. [Google Scholar] [CrossRef]

- Wray, D.; Ramaswamy, H.S. Novel Concepts in Microwave Drying of Foods. Dry. Technol. 2015, 33, 769–783. [Google Scholar] [CrossRef]

- Sacilik, K.; Elicin, A.K. The thin layer drying characteristics of organic apple slices. J. Food Eng. 2006, 73, 281–289. [Google Scholar] [CrossRef]

- Doymaz, İ.; Soydan, M. An experimental study on thin-layer drying characteristics of apple slices. Lat. Am. Appl. Res. 2021, 51, 119–126. [Google Scholar] [CrossRef]

- Schultz, E.L.; Mazzuco, M.M.; Machado, R.A.F.; Bolzan, A.; Quadri, M.B.; Quadri, M.G.N. Effect of pre-treatments on drying, density and shrinkage of apple slices. J. Food Eng. 2007, 78, 1103–1110. [Google Scholar] [CrossRef]

- Beigi, M. Hot air drying of apple slices: Dehydration characteristics and quality assessment. Heat Mass Transf. 2016, 52, 1435–1442. [Google Scholar] [CrossRef]

- Rahman, M.S. Glass Transition and State Diagram of Foods. In Handbook of Food Preservation; Rahman, M.S., Ed.; CRC Press: Boca Raton, FL, USA, 2007; pp. 335–363. ISBN 9780429191084. [Google Scholar]

- Horuz, E.; Bozkurt, H.; Karataş, H.; Maskan, M. Drying kinetics of apricot halves in a microwave-hot air hybrid oven. Heat Mass Transf. 2017, 53, 2117–2127. [Google Scholar] [CrossRef]

- Zarein, M.; Samadi, S.H.; Ghobadian, B. Investigation of microwave dryer effect on energy efficiency during drying of apple slices. J. Saudi Soc. Agric. Sci. 2015, 14, 41–47. [Google Scholar] [CrossRef] [Green Version]

- Dadi, D.W.; Emire, S.A.; Hagos, A.D.; Eun, J.-B. Physical and Functional Properties, Digestibility, and Storage Stability of Spray- and Freeze-Dried Microencapsulated Bioactive Products from Moringa stenopetala Leaves Extract. Ind. Crops Prod. 2020, 156, 112891. [Google Scholar] [CrossRef]

- Fijalkowska, A.; Nowacka, M.; Witrowa-Rajchert, D. The physical, optical and reconstitution properties of apples subjected to ultrasound before drying. Ital. J. Food Sci. 2017, 29, 343–356. [Google Scholar] [CrossRef]

- Dellarosa, N.; Frontuto, D.; Laghi, L.; Dalla Rosa, M.; Lyng, J.G. The impact of pulsed electric fields and ultrasound on water distribution and loss in mushrooms stalks. Food Chem. 2017, 236, 94–100. [Google Scholar] [CrossRef]

- Kaur, K.; Singh, A.K. Drying kinetics and quality characteristics of beetroot slices under hot air followed by microwave finish drying. African J. Agric. Res. 2014, 9, 1036–1044. [Google Scholar] [CrossRef] [Green Version]

- Khraisheh, M.A.M.; McMinn, W.A.M.; Magee, T.R.A. Quality and structural changes in starchy foods during microwave and convective drying. Food Res. Int. 2004, 37, 497–503. [Google Scholar] [CrossRef]

- Tiwari, B.K.; Patras, A.; Brunton, N.; Cullen, P.J.; O’Donnell, C.P. Effect of ultrasound processing on anthocyanins and color of red grape juice. Ultrason. Sonochem. 2010, 17, 598–604. [Google Scholar] [CrossRef]

- Won, Y.-C.; Min, S.C.; Lee, D.-U. Accelerated Drying and Improved Color Properties of Red Pepper by Pretreatment of Pulsed Electric Fields. Dry. Technol. 2015, 33, 926–932. [Google Scholar] [CrossRef]

- Alaei, B.; Dibagar, N.; Chayjan, R.A.; Kaveh, M.; Taghinezhad, E. The effect of short and medium infrared radiation on some drying and quality characteristics of quince slices under vacuum condition. Qual. Assur. Saf. Crop. Foods 2018, 10, 371–381. [Google Scholar] [CrossRef]

- Deng, J.; Yang, H.; Capanoglu, E.; Cao, H.; Xiao, J. Technological aspects and stability of polyphenols. In Polyphenols: Properties, Recovery, and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 295–323. ISBN 9780128135723. [Google Scholar]

- Aghilinategh, N.; Rafiee, S.; Hosseinpour, S.; Omid, M.; Mohtasebi, S.S. Optimization of intermittent microwave–convective drying using response surface methodology. Food Sci. Nutr. 2015, 3, 331–341. [Google Scholar] [CrossRef]

- Sultana, B.; Anwar, F.; Ashraf, M.; Saari, N. Effect of drying techniques on the total phenolic contents and antioxidant activity of selected fruits. J. Med. Plants Res. 2012, 6, 161–167. [Google Scholar] [CrossRef]

- Zhou, L.; Cao, Z.; Bi, J.; Yi, J.; Chen, Q.; Wu, X.; Zhou, M. Degradation kinetics of total phenolic compounds, capsaicinoids and antioxidant activity in red pepper during hot air and infrared drying process. Int. J. Food Sci. Technol. 2016, 51, 842–853. [Google Scholar] [CrossRef]

- Gülçin, İ.; Küfrevioǧlu, Ö.İ.; Oktay, M.; Büyükokuroǧlu, M.E. Antioxidant, antimicrobial, antiulcer and analgesic activities of nettle (Urtica dioica L.). J. Ethnopharmacol. 2004, 90, 205–215. [Google Scholar] [CrossRef]

| Run | Factor 1 | Factor 2 | ||

|---|---|---|---|---|

| Microwave Power [W] | Coded Value | Specific Energy Intake [kJ/kg] | Coded Value | |

| 1 | 200 | 0 | 3.5 | 0 |

| 2 | 300 | 1 | 6 | 1 |

| 3 | 200 | 0 | 6 | 1 |

| 4 | 300 | 1 | 1 | −1 |

| 5 | 300 | 1 | 3.5 | 0 |

| 6 | 200 | 0 | 3.5 | 0 |

| 7 | 100 | −1 | 3.5 | 0 |

| 8 | 100 | −1 | 6 | 1 |

| 9 | 200 | 0 | 1 | −1 |

| 10 | 200 | 0 | 3.5 | 0 |

| 11 | 100 | −1 | 1 | −1 |

| Microwave Power [W] | Specific Energy Intake [kJ/kg] | Sample Code | CDI [-] | d.m. [%] | ∆E [-] |

|---|---|---|---|---|---|

| 100 | 0 | MW-CD100 | - | 92.5 ± 0.0 b | 12.8 ± 3.2 abc |

| 1 | MW-CD100_PEF1 | 0.09 | 92.6 ± 0.0 b | 14.2 ± 3.0 bcd | |

| 3.5 | MW-CD100_PEF3.5 | 0.23 | 92.4 ± 0.0 b | 11.8 ± 2.6 abc | |

| 6 | MW-CD100_PEF6 | 0.36 | 90.7 ± 0.1 a | 14.2 ± 1.8 bcd | |

| 200 | 0 | MW-CD200 | - | 94.4 ± 0.1 cd | 13.7 ± 4.0 abcd |

| 1 | MW-CD200_PEF1 | 0.09 | 94.8 ± 0.2 de | 11.6 ± 2.9 ab | |

| 3.5 | MW-CD200_PEF3.5 | 0.27 | 94.4 ± 0.2 c | 13.7 ± 3.3 bc | |

| 6 | MW-CD200_PEF6 | 0.36 | 94.9 ± 0.1 e | 16.1 ± 3.1 bcd | |

| 300 | 0 | MW-CD300 | - | 96.5 ± 0.1 f | 16.5 ± 4.2 cd |

| 1 | MW-CD300_PEF1 | 0.08 | 96.4 ± 0.1 f | 9.0 ± 2.4 a | |

| 3.5 | MW-CD300_PEF3.5 | 0.21 | 96.5 ± 0.0 f | 15.9 ± 4.3 bcd | |

| 6 | MW-CD300_PEF6 | 0.37 | 97.1 ± 0.0 g | 17.9 ± 3.8 d |

| Response | Model | R2 | CV [%] | p-Value (Model) | p-Value (Lack of Fit) |

|---|---|---|---|---|---|

| Drying Time | Quadratic | 0.9846 | 6.51 | 0.0002 | 0.3464 |

| Water Activity | Quadratic | 0.9471 | 4.60 | 0.0033 | 0.4502 |

| H72h | Quadratic | 0.9541 | 0.4477 | 0.0023 | 0.4658 |

| RR | Linear | 0.5437 | 5.43 | 0.0433 | 0.3580 |

| SSL | Linear | 0.5753 | 3.55 | 0.0325 | 0.2979 |

| TPC | Quadratic | 0.8755 | 15.52 | 0.0259 | 0.1358 |

| EC50 ABTS | Reduced Quadratic | 0.7966 | 17.02 | 0.0285 | 0.4117 |

| EC50 DPPH | Reduced Quadratic | 0.7608 | 14.26 | 0.0449 | 0.6957 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matys, A.; Dadan, M.; Witrowa-Rajchert, D.; Parniakov, O.; Wiktor, A. Response Surface Methodology as a Tool for Optimization of Pulsed Electric Field Pretreatment and Microwave-Convective Drying of Apple. Appl. Sci. 2022, 12, 3392. https://doi.org/10.3390/app12073392

Matys A, Dadan M, Witrowa-Rajchert D, Parniakov O, Wiktor A. Response Surface Methodology as a Tool for Optimization of Pulsed Electric Field Pretreatment and Microwave-Convective Drying of Apple. Applied Sciences. 2022; 12(7):3392. https://doi.org/10.3390/app12073392

Chicago/Turabian StyleMatys, Aleksandra, Magdalena Dadan, Dorota Witrowa-Rajchert, Oleksii Parniakov, and Artur Wiktor. 2022. "Response Surface Methodology as a Tool for Optimization of Pulsed Electric Field Pretreatment and Microwave-Convective Drying of Apple" Applied Sciences 12, no. 7: 3392. https://doi.org/10.3390/app12073392

APA StyleMatys, A., Dadan, M., Witrowa-Rajchert, D., Parniakov, O., & Wiktor, A. (2022). Response Surface Methodology as a Tool for Optimization of Pulsed Electric Field Pretreatment and Microwave-Convective Drying of Apple. Applied Sciences, 12(7), 3392. https://doi.org/10.3390/app12073392