Abstract

In arid climates, the optical properties of plastic-covered greenhouses deteriorate very quickly. To examine the effect of greenhouse shape and orientation on the degradation rate of cover optical properties, four greenhouse prototypes were constructed in two shapes (duo-pitched roof and tunnel), covered with a 200 µm thick low-density polyethylene film. Two types were oriented in the North–South direction, the other two in the East–West direction, and all were exposed for one year to an arid climate. Samples were taken from the different surfaces of each cover for testing. The total transmittance (Ts) and reflectance (Rs) of the samples were measured and averaged to obtain the whole cover properties (T and R). Measurements were carried out periodically every 30 days for the four prototypes. The degradation behavior of the optical properties of each cover surface (Ts, Rs) and the whole cover (T, R) was investigated for the four film covers during the exposure time. Results show that the degradation rate of Ts depends on the surface location and the cover orientation. Among the different surfaces of the four prototype covers, the maximum difference in the Ts value between the E and N surfaces for the tunnel cover oriented in the N–S direction was 15.5%. Although the variation of the Ts value among the different cover surfaces was found, the time dependences of the whole cover transmittance (T) for the four covers tested were almost similar. Accordingly, the shape and orientation of the small size greenhouses did not significantly affect the degradation rate of the cover optical properties. In the four covers tested, the reduction in the global solar radiation transmittance (T) was 27–31% after one-year exposure compared to the new film. Nonlinear correlation was developed to predict the degradation rate of the cover transmittance as a function of the accumulated solar irradiance.

1. Introduction

The arid climatic conditions of the Arabian Peninsula are usually characterized by hot and long summer seasons and dusty and dry weather. In summer, the ambient temperature often exceeds 45 °C, the intensive solar radiation flux reaches 1200 Wm−2, and the relative humidity of the air drops below 10% [1]. Therefore, cultivation in greenhouses is necessary to protect crops from such harsh environments and enhance and manage crop production throughout the year [2]. Most of the greenhouse covers in the Arabian Peninsula are made of low-density polyethylene (LDPE) film owing to its relatively good mechanical and optical properties, combined with its competitive market price [3,4]. LDPE films have high solar and thermal radiation transmittances; this allows easy thermal energy release from the greenhouse and consequently reduces the greenhouse cooling requirement in summer. Several studies have reported different values for LDPE film transmittances in the solar (0.6–0.8) and thermal (0.5–0.75) radiation spectrum ranges. These transmittances depend on the film thickness and chemical composition and thermophysical properties of the film.

A serious problem with using plastic films to cover greenhouses in arid regions is their short lifetime, which is severely affected by harsh climatic conditions. The lifetime of the most widely used plastic films varies from one cultivating season to 2–3 years [5]. In the literature, the lifetime of plastic films has been reported to be, on average, four seasons in North–Central Europe and 2–3 seasons in the Mediterranean regions [3,5], and it is expected to be even lower under a harsh arid climate. Degradation of plastic-film-covered greenhouses is mainly due to their exposure to atmospheric agents such as solar radiation, high air temperature and relative humidity, wind, rainfall, and sandy storm, as in the desert of the Arabian Peninsula, as well as to chemical products used in greenhouses [6,7]. The degradation process of plastic films includes different interacting mechanisms such as photodegradation (due to the intensive solar radiation flux, including UV irradiance allocated with an extremely high air temperature), chemical degradation (due to reactions of the film with air pollutants and agrochemicals used in the greenhouse), and mechanical degradation (due to bond rupture under the influence of mechanical stress) [8]. The photodegradation mechanism is primarily responsible for the deterioration of the optical properties of films and their optical capacity (i.e., drastic reduction in film transmissivity). Degradation of the total radiative properties, i.e., integrated over the whole solar spectrum wave band (200–2500 nm), of plastic-film-covered greenhouses affected by climatic conditions (i.e., natural aging) is reported in the literature. For example, degradation of the optical properties of two types of LDPE films used to cover two E–W-oriented pitched-roof greenhouses was investigated; their transmittances to light reduced to 7.3% and 13.2% after the 24-month service [4]. The effect of sandy wind on the total transmittance of polyethylene (PE) film used to cover greenhouses was examined in the laboratory to simulate the sub-Saharan climatic conditions (north of Algeria) [9]. A drastic reduction in the film transmittance was observed because of the surface erosion of the film caused by the sandy wind [9]. The effect of dust accumulation on the total transmittance of a plastic film (0.2 mm thick) used to cover a solar heater system under tropical climatic conditions was tested [10]. The solar heater was oriented south, inclined 15° on the horizontal plane, and exposed to climatic agents for 30 days. The authors [10] reported that dust accumulation of 3.72 g m−2 reduced the total transmittance by about 12%. Exposing biodegradable plastic-film-covered low tunnels to the climatic conditions of Southern Italy for 140 days reduced the photosynthetically active radiation (PAR) transmissivity of these covers by about 13% [11]. The low tunnels were oriented in the N–S direction, and their results indicated that the reduction in the PAR transmissivity occurred mainly up to 500 MJ m−2 of cumulative solar radiation incident on the tunnels [11]. The effect of aging and condensation on the total transmittance of three types of PE films (each 140 μm thick) used to cover three venlo-type experimental greenhouses was examined under the Eastern Mediterranean climatic conditions [12]. The reduction in the transmittance due to the accumulation of dust and dirt was 8% after three-month exposure [12].

A study was conducted in Samsun, Turkey [13], to investigate the effect of dirt and vapor condensation on the light transmission of four types of PE used to cover eight prototypes, pitched-roof greenhouses, oriented in the E–W direction and exposed for three months to climatic agents. The average loss in light transmission due to dirt and condensation was estimated to be 9–15% [13]. Several studies have been conducted worldwide to investigate the effect of aging and climatic conditions on the optical properties of plastic films covering greenhouses. However, such studies have not been thoroughly performed for an arid climate. Few studies have been conducted under the arid climatic conditions of the Arabian Peninsula. The effect of dust and dirt on the solar transmittance of plastic films covering solar collectors was investigated [14,15,16]. It was observed that the harsh environment and dust accumulation drastically reduced the transmittance of the cover sheets, and consequently, the performance of the collectors decreased [14,15,16]. Under the arid climatic conditions of Riyadh, Saudi Arabia, degradation of the optical properties of 200 μm thick PE-film-covered greenhouse prototypes was investigated over a period of 13 months [17]. The cover transmittance deteriorated rapidly during the first three months of exposure; the relative losses of global and PAR solar radiation transmittance were 9% and 15.3%, respectively.

A survey of previous literature revealed that: (i) previous studies were conducted worldwide under climatic conditions different from an arid climate; (ii) neither the shape nor orientation of greenhouses was considered as a parameter linked to the degradation characteristics of film covers; (iii) a greenhouse cover consists of multi-surfaces with different orientations, receiving solar radiation with different intensities based on the surface orientation related to the sun position during the day; however, most previous studies did not specify the orientation of greenhouses. Therefore, degradation of the radiative properties of each surface is expected to be different from others depending on its position on the cover. In other words, the service life of each surface in the greenhouse may depend on the surface orientation of the cover; therefore, we have to answer an important question the growers need (i.e., if the farmer needs to replace the whole greenhouse cover surfaces at the end of their service life, or if some surfaces can serve for a longer time to reduce the maintenance cost). In this article, the words “optical properties” will be used for the total radiative properties of plastic film covers, integrated over the solar spectrum range (wavelength: 200–2500 nm).

The aim of this study was to investigate the effect of the greenhouse shape and its orientation on the degradation characteristics of the optical properties (transmittance T and reflectance R) of each surface of the cover. Four greenhouse prototypes in two shapes (pitched-roof and tunnel), covered with 0.2 mm thick LDPE films, were tested. Greenhouses of two prototypes were oriented in the N–S direction and the other two in the E–W direction, and all were exposed for one year to arid climatic agents. Degradation of the optical properties of each surface of the four prototypes was investigated individually and evaluated. However, the degradation characteristics of the spectral radiative properties (wavelength dependent) of LDPE covers in the PAR (400–7010 nm) and IR (700–2500 nm) were evaluated by the authors [18].

2. Materials and Methods

2.1. Experimental Procedure

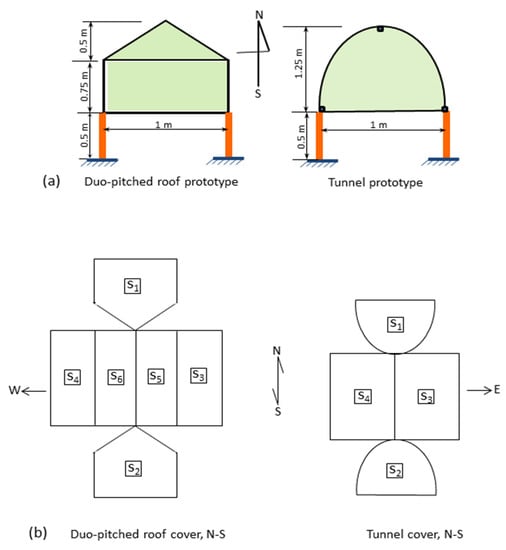

The experiment was conducted on the roof of the Agricultural Research and Experiment Station building, Agriculture Engineering Department, King Saud University (Riyadh, Saudi Arabia, 46°47′ E longitude and 24°39′ N latitude). In order to evaluate the effect of the greenhouse shape and its orientation on the degradation behavior of the radiometric properties of the film cover, four greenhouse prototypes were used, each with a floor surface area of 2 m2. Two prototypes were of the pitched-roof type, and the other two were of the tunnel type (Figure 1a). Wooden bars (a cross-section of 3 × 3 cm2 for each) were used to construct the prototypes; the dimensions of the greenhouse prototypes are illustrated, not to scale, in Figure 1a. Each prototype was covered with a 200 μm thick LDPE film, which is popular in the local market and commonly used for cladding greenhouses in Saudi Arabia and the Arabian Peninsula. The LDPE film cover was produced and supplied by Napco Modern Plastics Products Company-Sack Division Ltd. (Dammam, Saudi Arabia); the film density is 0.93 g cm−3; its melt flow index (MFI) of the raw material is 0.34 g/10 min; the MFI of the stabilized material is 11 g/10 min; the upper working temperature is 50–80 °C. The film includes different additives such as anti-UV, antioxidant, plasticizer, etc. However, the real film composition of the film was kept confidential by the supplier. Each prototype was mounted horizontally 0.5 m above the roof of the building using four identical wooden legs, each with a cross-section of 5 × 5 cm (Figure 1a). The base of each prototype was kept without covering to permit air exchange between the inside and the outside of the greenhouse prototype (ventilation process). Two types (one duo-pitched-shaped and one tunnel-shaped) were oriented longitudinally in the N–S direction, and the other two were oriented longitudinally in the E–W direction. The four prototypes were exposed to arid climatic agents for one year (from 1 October 2019, to 1 October 2020) without cleaning to represent the practical situations of commercial greenhouses in the farms. Samples were taken periodically one month from each cover and tested in the laboratory in order to assess the degradation of their radiative properties due to prolonged exposure to arid climatic agents. One-year exposure to a harsh arid environment is sufficient to represent the degradation behavior of film covers. Six strips (each of 20 cm × 20 cm) of the film cover were taken from six surfaces (one from each surface) of the duo-pitched-roof greenhouse prototype, and four similar strips were taken from the tunnel-type prototype.

Figure 1.

Schematic diagram, not to scale, to illustrate: (a) front view of the two greenhouse prototypes used in the study; (b) development (orthographic) of the cover surfaces for the two prototypes in the N–S orientation to show the sample locations on the cover; (c) orthographic in the E–W orientation.

In order to show the location of each strip on the cover for the two prototypes, the development of the cover surface of each prototype (orthographic) is illustrated in Figure 1b for the N–S orientation and in Figure 1c for the E–W orientation. Strips were cut carefully at the center of each surface; the samples were designated as s1–s6 for the duo-pitched roof prototype and s1–s4 for the tunnel-shaped prototype (Figure 1b,c). This procedure was performed periodically every one month to test the samples in the laboratory. The spectral transmittance (τλ) and reflectance (ρλ) of each sample were measured at normal incidence using a Black-Comet (StellarNet Inc., Tampa, FL, USA) spectrophotometer, scanning between 200 and 1700 nm at 0.5 nm intervals in the UV–vis–IR range. The measured data were averaged at each 5 nm interval. The samples were re-fixed, using transparent sticker spices, at the same locations immediately after the measurements to work again as part of the film cover. The sticker spices were small enough and were fixed on the corners of the sample perimeter. To avoid any possible influences of the stickers on the measured parameters, the measurements were applied to the central part of each sample and far from the sticker locations. The downward global solar radiation fluxes (SR) were measured using a CMP3 solar meter (Kipp & Zonen B.V. Inc., Bohemia, NY, USA), and the ambient air temperature and relative humidity were measured using a thermo-hygrometer DMA033 (LSI-Lastem, Milano, Italy). The solar meter and thermo-hygrometer were fixed over a wooden stand with a height of 1.8 m, positioned beside the greenhouse prototypes. These sensors were calibrated before use by means of a supplier. The measured parameters were recorded every 1 min, averaged over 5 min intervals, and saved in a data logger (LI-1400, 9 channels, LI-COR, Inc., Lincoln, NE, USA).

2.2. Data Analysis

The spectral transmittance and reflectance ( and ) of each sample of the cover (n is the number of samples in each cover; n = 4 for the tunnel prototypes and n = 6 for the duo-pitched roof prototypes) were measured. The total transmittance (Ts) and reflectance (Rs) of each sample were estimated as the weighted average values of the corresponding spectral properties, using the spectral distribution of solar irradiance measured at the ground level (Sλ in W m−2 nm) as a weighting function [19,20] as follows:

In the same way as in Equation (1), the total reflectance of each sample in the cover (Rs) was estimated by replacement with Equation (1). Numerical integration was carried out using the trapezoid rule [21]. Owing to the capacity of the available spectrophotometer, the upper limit of λ in Equation (1) was taken as 1700 nm instead of 2500 nm. This assumption does not affect the accuracy of the analysis because the remaining part of solar irradiance (Sλ), from 1700 nm to 2500 nm, is minor and can be neglected [22]. The total transmittance and reflectance of the cladding of the whole prototype (T and R) were obtained as the average values of the sample properties (Ts and Rs), weighted with respect to the relatively surface area, as: where Ai is the surface area, and n is the number of samples or the number of surfaces in the prototype. The absolute reduction in the cover transmittance (loss in transmittance) after a given period of exposure time t is defined as Tnew − Tt, where Tnew is the transmittance of the new material to solar radiation (at t = 0), and Tt is the cover transmittance after a period of time t. The relative loss in the cover transmittance (T) is defined by:

The degradation rate of the cover transmittance per day D (%) is defined by:

where ∆t is the interval of time between two measurements (30 days in the present study). The daily integral of the global solar radiation, DSR (MJ m−2) is estimated as:

where t1 and t2 are the sunrise and sunset times.

The Stats-Model library in Python was used to perform the statistical analysis. One-way and two-way ANOVA was applied to compare the degradation rates of the covers (i.e., four surfaces of the tunnel-type/six surfaces of the duo-pitched roof type) to explore the impact of both the shape and orientation of the greenhouse on the degradation rate of the cover optical properties.

3. Results and Discussion

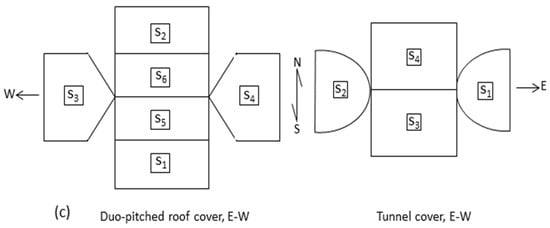

During the experiment period (1 October 2019–1 October 2020), and to link the environmental conditions with the degradation characteristic, meteorological parameters (i.e., solar radiation flux, maximum and minimum ambient air temperature, relative humidity, and wind speed) were taken from the weather station at King Saud University campus, Riyadh (i.e., representing the typical arid climatic conditions). The monthly averages of the maximum and minimum air temperatures (Tam,max and Tam,min), as well as the relative humidity (RH), were estimated and are depicted in Figure 2a. To be more representative, the incident solar radiation flux (SR, W m−2) was integrated over each day (DSR, Equation (4)) and submitted for each month as solar energy incident (SE) in MJ m−2, as depicted in Figure 2b. In addition, the monthly average of wind speed (Vw) was illustrated. In an arid climate similar to that in the central region of Saudi Arabia (i.e., the site of the experiment), Tam,max during the experiment in summer (Figure 2a) increased to values close to the upper working temperature limit of the LDPE film cover (50–80 °C). The low relative humidity (RH) induces dry weather throughout the year that negatively affects the lifetime of the film and its optical properties (Figure 2a). The intensive solar irradiance in arid regions makes the integrated solar energy incident on the cover surfaces reach 18 MJ m−2 per month in winter and 29 MJ m−2 per month in summer (Figure 2b). The degradation of the optical properties of plastic film covers is due to the combined effects of climatic factors, i.e., Tam,max, SE, Vw, and RH).

Figure 2.

Variation of the meteorological parameters during the year of experiment (1 October 2019–1 October 2020). (a) Monthly average of the maximum and minimum ambient air temperature and the relative humidity; (b) monthly average of the wind speed and monthly accumulated solar energy.

On the x-axis of the upcoming figures (i.e., exposure time (month)), zero time represents the new samples, where 1 is October, 2 is November, 3 is December, etc. Because all the cover surfaces are exposed to the same weather conditions, the optical properties of the sample (transmittance, Ts and reflectance, Rs) were assumed to be uniform for the surface that the sample was taken. In other words, the samples in Figure 1b,c represent the cover surfaces in terms of optical properties.

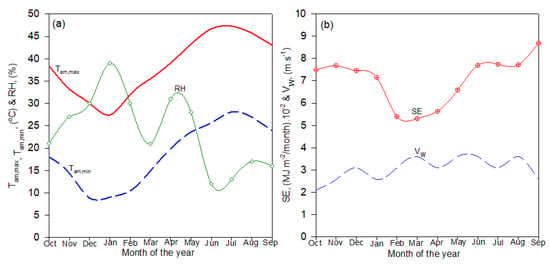

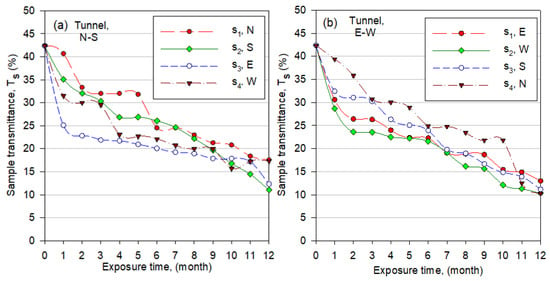

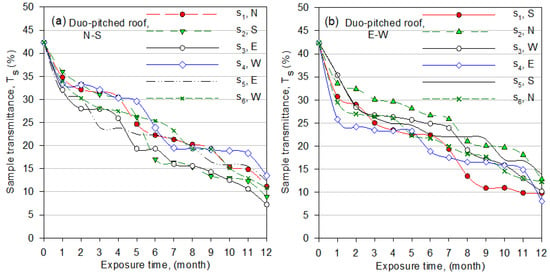

To show the degradation characteristics of the optical properties of each surface of the cover individually, the time course of the transmittance of each sample (Ts) taken from the cover of the tunnel prototype (s1–s4), oriented in the N–S and E–W directions, is illustrated in Figure 3a,b, respectively. In a similar manner, Figure 4a,b illustrates the time course of Ts for the samples (s1–s6) taken from the six surfaces of the duo-pitched roof cover prototype, oriented in the N–S (Figure 4a) and E–W (Figure 4b) directions.

Figure 3.

Degradation of the sample transmittances (Ts) with the exposure time for the tunnel prototype, oriented in the N–S (a) and E–W (b) directions under arid climatic conditions.

Figure 4.

Degradation of the sample transmittances (Ts) with the exposure time for the duo-pitched prototype, oriented in the N–S (a) and E–W (b) directions under arid climatic conditions.

The results in Figure 3 and Figure 4 indicate that the degradation of the cover sample transmittances (Ts) progressed rapidly during the first three months and the last three months of exposure; this is mainly due to the high ambient air temperature (see Figure 2a) and the intensive solar irradiance (see Figure 2b). This result is in accordance with the results of another study conducted in the same region [17].

Intensive solar irradiance in arid regions should have a major effect on the degradation of the cover transmittance. For the tunnel-type prototype, the N-oriented surfaces (e.g., s1 in Figure 3a and s4 in Figure 3b) received indirect solar radiation and should have a lower degradation rate compared to the other surfaces if the effect of solar intensity is only considered. However, the small size of the prototypes and the translucent nature of the film cover made all the cover surfaces receive solar radiation either directly or indirectly (after transmission through other surfaces). Consequently, deterioration of the film cover transmittance is attributed to the combined effect of solar radiation, dusty wind (i.e., common in the desert of Saudi Arabia; it happens several times a year), and film dirtiness (all the meteorological factors together). This effect, in general, drastically decreases the cover transmittance and increases the reflectance. The existing differences in the values of Ts among the different surfaces of the cover are also due to the direction of the dusty wind that is common at the site of the experiment.

For the N–S-oriented duo-pitched roof cover (Figure 4a), the maximum difference in Ts values was 15.5% (between the N and E surfaces) and 12.2% (between the N and W surfaces) when the prototype was oriented E–W (Figure 4b). For the vertical surfaces of the duo-pitched roof cover, oriented either in the N–S or E–W directions, the maximum difference in Ts values was 10.5%. This difference is mainly attributed to the combined effect of the dusty wind direction and the other meteorological parameters (such as dust accumulation, solar irradiance intensity, etc.). In the case of calm and clear weather (solar irradiance effect was only considered), the degradation rate of Ts for the N surfaces is expected to be lower than that of the other surfaces because the N surfaces usually receive indirect solar radiation with low solar intensity. However, this trend is not clear in Figure 3a,b and Figure 4 a,b because the greenhouse prototypes were small in size and exposed to desert climatic conditions, and degradation of the cover optical properties was due to the combined effect of the mereological parameters, not only solar radiation intensity.

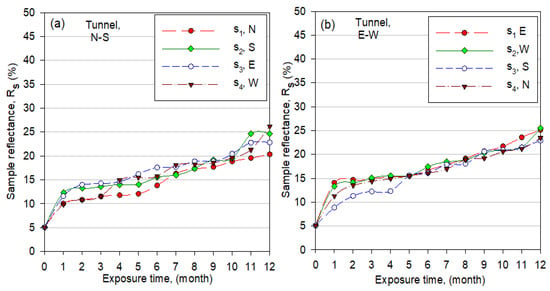

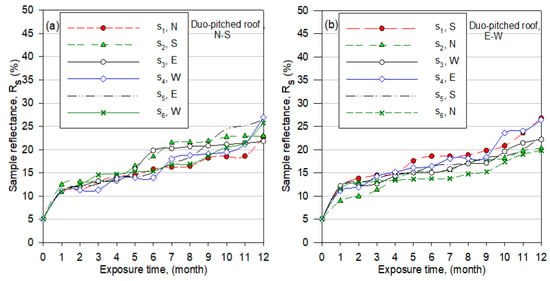

Aging and dust and dirt accumulation on cover surfaces increase the surface reflectance to solar radiation (Rs) with time of exposure. Figure 5a,b shows no significant difference in the values of Rs between the four surfaces of the tunnel-type cover (s1–s4) in both orientations (N–S and E–W). In Figure 6a,b, a maximum difference of 6–7% in the value of Rs can be found among the surfaces of the duo-pitched roof cover when it was oriented in the N–S and E–W directions. During one-year exposure in the desert of the arid climate (the site of the experiment), the combined weather parameters (solar radiation, dust, wind speed, etc.) showed nearly the same effect on the reflectance (Rs) increases in the different surfaces of each film cover. Reflectance is a surface phenomenon, and all the cover surfaces were exposed to the same weather conditions; therefore, the shape and orientation of the cover surfaces did not affect the reflectance value (Rs).

Figure 5.

Variation of the sample reflectances (Rs) affected by the exposure time for the tunnel prototype cover oriented in the N–S (a) and E–W (b) directions under arid climatic conditions.

Figure 6.

Variation of the sample reflectances (Rs) affected by the exposure time for the duo-pitched roof prototype cover oriented in the N–S (a) and E–W (b) directions under arid climatic conditions.

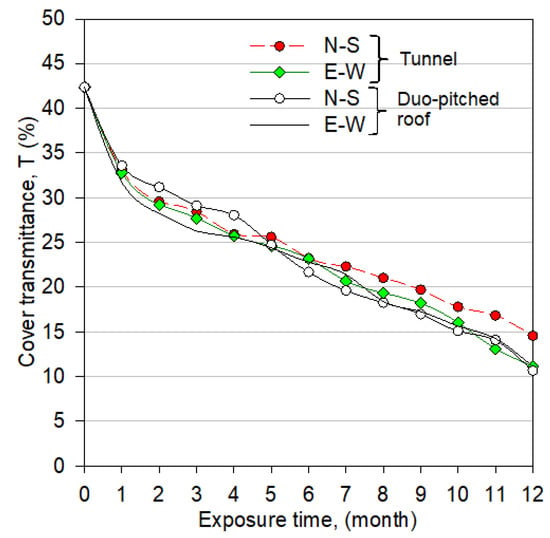

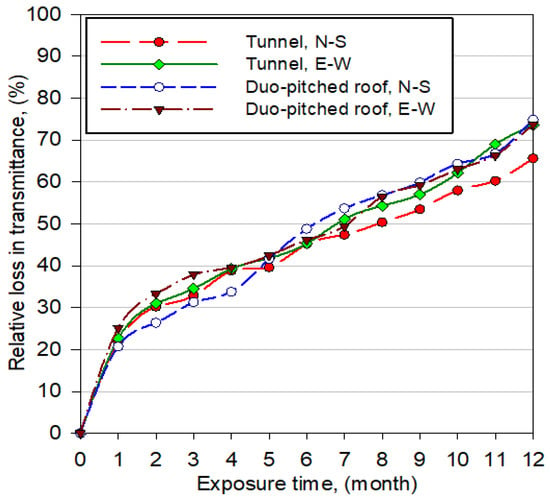

In order to explore the effect of the greenhouse shape and its orientation on the degradation characteristics of the transmittance of the film cover, the whole cover transmittance (T) was calculated as the average value of Ts for the cover samples of each prototype (see Section 2.2). The degradation characteristics of T for both the tunnel and duo-pitched roof covers, oriented in the N–S and E–W directions, are depicted in Figure 7. Some variation was found in the values of Ts among the different surfaces of the cover of each prototype. However, the results in Figure 7 show that there are no significant differences in the values of T among the tested covers of the four prototypes. In fact, in actual greenhouses, the degradation of the optical properties of a duo-pitched-roof greenhouse is usually higher than that of a tunnel because the metallic structure of the duo-pitched roof is much higher than the tunnel structure. Metallic structures absorb solar radiation and release heat; this increases the cladding temperature and deteriorates its optical, chemical, and thermophysical properties faster. Moreover, the N surface of a greenhouse cladding usually receives indirect solar radiation with low intensity; consequently, the degradation of the N surfaces is expected to be lower than the other surfaces of cladding. In Figure 7, at the end of the exposure time (one year), the absolute loss in the transmittance (Tnew–T) was 28% for the N–S-direction duo-pitched roof cover and was 31% for the cover of the other prototypes (i.e., E–W duo-pitched roof type, N–S tunnel type, and E–W tunnel type). The relative loss in the cover transmittance was estimated from Equation (2) for the four covers tested and is illustrated in Figure 8. This figure indicates that for exposing a greenhouse (having any shape and oriented in any direction) to the arid climatic agents for one year, the loss in the cover transmittance is expected to be around 65–75% of its initial value (the new cover transmittance).

Figure 7.

Average transmittance of the cover envelops (T), estimated for each prototype during the time of exposure to arid climatic agents.

Figure 8.

Relative losses in the cover transmittance estimated for the two greenhouse prototypes, oriented in the N–S and E–W directions and exposed for one year to the arid climatic agents.

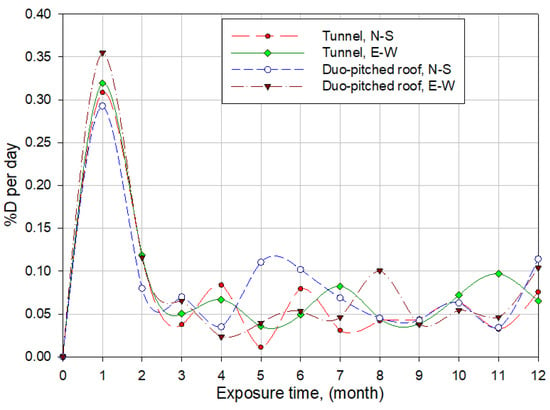

The results in the previous figures show a drastic reduction in the transmittance of the plastic-film-covered greenhouses after one year of exposure, which means that such covers cannot serve without cleaning for more than one year in arid regions. This is because the transmitted radiation would not fulfill the growth requirements of most crops grown in the greenhouses. Thus, the cover should be cleaned immediately to improve its optical performance. This is because cleaning the LDPE film covering a greenhouse by washing the film using a water stream enhanced the cover transmittance by 7–11% at the same site of the present study’s experiment [17]. Figure 9 illustrates the degradation rate of the cover transmittance with the exposure time (Equation (3)). The degradation rate processed rapidly in the first month of exposure; the rate of loss in the transmittance of the four covers tested reached 0.3–0.35% per day at the end of the first month and then drastically reduced to 0.07–0.1% per day at the end of the third month. After that, the degradation rate in the cover transmittance fluctuated between 0.01% and 0.1% per day for the four covers tested. The statistical analysis showed no significant differences in the degradation rate between the four cover surfaces (tunnel type) and between the six cover surfaces (duo-pitched roof type). Moreover, the degradation rates of the four prototypes were around 0.085%, and there were no differences between them, as shown in Table 1. This is because the tested greenhouse prototypes were in the same place and under the same climatic conditions, and the combined weather parameters have almost the same effect on the whole cover surfaces. On the other hand, it was difficult and expensive to use commercial greenhouses to perform the studies; therefore, small-size greenhouse prototypes were used to conduct the experiment. The results of the present study can be applied also for commercial greenhouses either duo-pitched roofs or tunnels oriented in the N–S or E–W directions.

Figure 9.

Time course of the degradation rate of the cover transmittance estimated for the two greenhouse prototypes oriented in the N–S and E–W directions and exposed to the arid climatic agents.

Table 1.

Average of the degradation rates (%) per day for both orientation and shape.

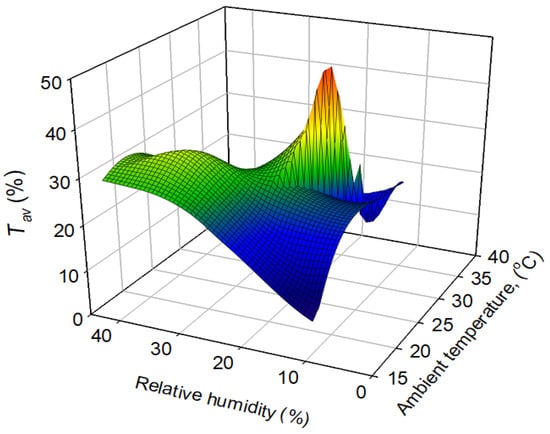

According to the statistical results, the different surfaces of each cover can be considered as one sample to link the degradation behavior of the cover transmittance with the meteorological parameters. Therefore, the data in Figure 7 were averaged to obtain the time course for the average transmittance of the four covers tested (Tav%) and plotted in Figure 10 as a function of the monthly averages of the ambient air temperature and relative humidity. Three-dimensional analysis was applied to the results in Figure 10 using the Table Curve-3D software package (ver-4.3, SYSTAT).

Figure 10.

Three-dimensional plot for the average transmittance of the four covers (Tav%) as a function of the monthly averages of the ambient air temperature and relative humidity during the exposure time.

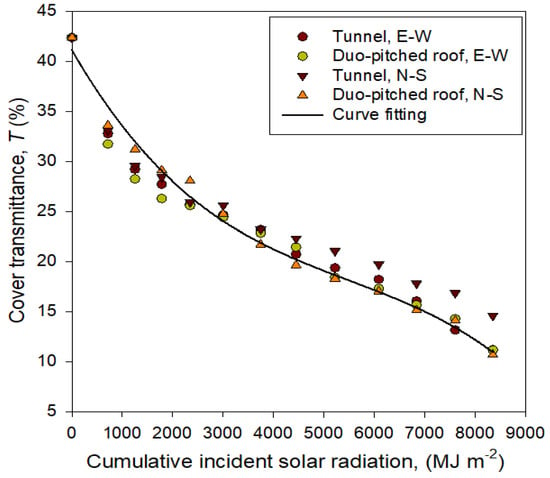

The best fitting of the data resulted in a full cubic regression polynomial with, unfortunately, a low r2 value of 0.58 and a high standard error of 10.8%. This was because degradation of plastic film properties depends mainly on the cumulative effects of climatic factors such as temperature, relative humidity, solar radiation flux, etc. This correlation cannot be used to predict the cover transmittance precisely during its service life in an arid climate. Because of the major influence of solar radiation on the degradation of the optical properties of plastic film covers, the time courses of T (%) estimated for the four covers tested (data in Figure 7) were plotted in Figure 11 against the accumulative solar radiation (CSR) measured during the exposure time. By fitting these data, a correlation could be obtained with a coefficient of determination (r2) of 0.99 and a standard error of 1%. This correlation is given by:

Figure 11.

Degradation of the cover transmittance (T%), for the four prototypes tested, affected by the cumulative incident solar radiation flux (MJ m−2) during the exposure time, from 1 October 2019, to 1 October, 2020.

Equation (5) can be used to predict the transmittance of a 200 μm thick LDPE-film-covered greenhouse having any shape, oriented in the N–S or E–W direction, during one-year exposure to an arid climate similar to that in the central region of Saudi Arabia. Films with this thickness (200 μm thick) are commonly used worldwide to cover greenhouses [5,6,7,8,14,15,16,17,18,19] because their mechanical and physical properties are the most suitable for greenhouse applications.

4. Conclusions

In arid regions, plastic films are used extensively to cover greenhouses because of their beneficial effect on the sustainability, quality, and productivity of crops. However, greenhouse growers face serious problems: fast degradation of the optical performance of the covers (drastic reduction in the cover transmittance) and the need to replace the cover immediately, which in turn increases the production cost.

This study described the degradation characteristics of the optical properties of different surfaces of the covers of four greenhouse prototypes (two duo-pitched roof-shaped and two tunnel-shaped), oriented in the N–S and E–W directions, and exposed for one year to arid climatic agents. The main conclusions that could be drawn from the present study are as follows:

- i.

- In some cases, the N and W cover surfaces showed a relatively lower degradation rate (i.e., rate of reduction in transmittance Ts) than the other surfaces. However, in general, the climatic agent (combined effect of solar radiation intensity, dust accumulation, dusty wind, etc.) has nearly the same effect on the degradation rate of the cover surfaces.

- ii.

- The shape or orientation of the prototypes had no significant effect on the degradation rate of the whole cover transmittance (T) to solar radiation. This is because the tested prototypes are small in size, and the surfaces are exposed nearly to the same weather conditions. Therefore, greenhouses of large size are recommended for such studies.

- iii.

- For the four covers tested, exposing them to arid climatic agents for one year reduced the transmittance of the cover (T) to global solar radiation by about 27–31% and increased the reflectance (R) by about 15–20% compared to the new film. Moreover, one-year exposure under a harsh arid environment is enough time to investigate the degradation behavior of the cover films.

- iv.

- Nonlinear regression correlation was presented (as a function of cumulated solar irradiance) to predict the cover transmittance to global solar irradiance at any time during the serving life of the film; the correlation is valid for any greenhouse, having any shape or orientation, under arid climatic conditions.

- v.

- In order to clearly determine the lifetime of each cover surface individually, further research should be conducted on large-size greenhouses to predict the degradation characteristics of each surface, as well as the optical constants (i.e., refractive index and extinction coefficient) under arid climatic agents.

Author Contributions

Conceptualization and methodology, A.M.A.-G., P.P. and I.A.-H.; validation, A.A.A. and A.I.; formal analysis, P.P. and I.A.-H.; investigation, A.M.A.-G.; resources, Shady; data creation, M.S. and A.I.; writing—original draft preparation, I.A.-H. and A.I.; writing—review and editing, A.M.A.-G. and P.P.; visualization, M.S. and A.I.; supervision, I.A.-H.; project administration, A.A.A. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to extend their sincere appreciation to the Deanship of Scientific Research at King Saud University for its funding of this research through the research group No. RG-1435-074.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| CSR | cumulative integrated solar irradiance on the cover (MJ m−2) |

| D | degradation rate of the cover transmittance (% day−1) |

| DSR | daily integral of solar irradiance (MJ m−2) |

| R | total reflectance of the film cover to global solar irradiance (%) |

| Rs | total reflectance of the cover sample to global solar radiation (%) |

| Sλ | spectral solar irradiance on the ground level (W m−2 nm−1) |

| SR | global solar irradiance on a horizontal surface (W m−2) |

| SE | monthly integral of solar irradiance (MJ m−2/month) |

| T | total transmittance of the film cover to global solar irradiance (%) |

| Tav | average cover transmittance estimated for the four prototypes tested (%) |

| Tnew | total transmittance of the new film to global solar irradiance (%) |

| Ts | total transmittance of the cover sample to global solar irradiance (%) |

| Tt | cover transmittance at a certain time, t (%) |

| ∆t | time interval (day) |

| spectral reflectance of the film sample to solar radiation (%) | |

| spectral transmittance of the film sample to solar radiation (%) |

References

- Abdel-Ghany, A.M.; Al-Helal, I.M.; Picuno, P.; Shady, M.R. Modified plastic net-houses as alternative agricultural structures for saving energy and water in hot and sunny regions. Renew. Energy 2016, 93, 332–339. [Google Scholar] [CrossRef]

- Al-Helal, I.M.; Abdel-Ghany, A.M. Energy partition and conversion of solar and thermal radiation into sensible and latent heat in a greenhouse under arid conditions. Energy Build. 2011, 43, 1740–1747. [Google Scholar] [CrossRef]

- Picuno, P. Innovative material and improved technical design for a sustainable exploitation of agricultural plastic film. Polym.-Plast. Technol. Eng. 2014, 53, 1000–1011. [Google Scholar] [CrossRef]

- Emekli, N.Y.; Buyuktas, K.; Bascetincelik, A. Changes of the light transmittance of the LDPE films during the service life for greenhouse application. J. Build. Eng. 2016, 6, 126–132. [Google Scholar] [CrossRef]

- Dilara, P.A.; Briassoulis, D. Degradation and stabilization of low-density polyethylene films used as greenhouse covering materials. J. Agric. Eng. Res. 2000, 76, 309–321. [Google Scholar] [CrossRef]

- Desriac, P. The effect of pesticides on the life of greenhouse film. Plasticulture 1991, 89, 9–16. [Google Scholar]

- Lemair, J. Control of weathering of polymers in plasticulture. Plasticulture 1993, 97, 17–22. [Google Scholar]

- Briassoulis, D.; Aristopoulou, A.; Bonora, M.; Verlodt, I. Degradation characterization of agricultural low-density polyethylene films. Biosyst. Eng. 2004, 88, 131–143. [Google Scholar] [CrossRef]

- Hassini, N.; Guenachi, K.; Hamou, A.; Saiter, J.M.; Marais, S.; Beucher, E. Polyethylene greenhouse cover aged under simulated sub-Saharan climatic conditions. Polym. Degrad. Stab. 2002, 75, 247–254. [Google Scholar] [CrossRef]

- Mastekbayeva, G.A.; Kumar, S. Effect of dust on the transmittance of low-density polyethylene glazing in a tropical climate. Sol. Energy 2000, 68, 135–141. [Google Scholar] [CrossRef]

- Scaracia-Mugnozza, G.; Schettini, E.; Vox, G. Effects of solar radiation on the radiometric properties of biodegradable films for agricultural applications. Biosyst. Eng. 2004, 87, 479–487. [Google Scholar] [CrossRef]

- Geoola, F.; Kashti, Y.; Levi, A.; Brickman, R. Quality evaluation of anti-drop properties of greenhouse cladding materials. Polym. Test. 2004, 23, 755–761. [Google Scholar] [CrossRef]

- Cemek, B.; Demir, Y. Testing of the condensation characteristics and light transmissions of different plastic film covering materials. Polym. Test. 2005, 24, 284–289. [Google Scholar] [CrossRef]

- Sayigh, A.A. Effect of dust on flat plate collectors. In Sun: Mankind’s Future Source of Energy; Elsevier: New York, NY, USA, 1978; Volume 2. [Google Scholar]

- El-Nashar, A. The effect of dust accumulation on the performance of evacuated tube collectors. Sol. Energy 1994, 53, 105–115. [Google Scholar] [CrossRef]

- Hegazy, A. Effect of dust accumulation on solar transmittance through glass covers of plate-type collectors. Renew. Energy 2001, 2, 525–540. [Google Scholar] [CrossRef]

- Al-Helal, I.M.; Al-Hamdan, A.M. Effect of arid environment on radiative properties of greenhouse polyethylene cover. Sol. Energy 2009, 83, 790–798. [Google Scholar] [CrossRef]

- Abdel-Ghany, A.M.; Al-Helal, I.M.; Kumar, A.; Alsadon, A.; Shady, M.; Ibrahim, A. Effect of aging on the spectral radiative properties of plastic film-covered greenhouse under arid conditions. Int. J. Thermophys. 2018, 39, 115. [Google Scholar] [CrossRef]

- Al-Mahdouri, A.; Baneshi, M.; Gonome, H.; Okajima, J.; Maruyama, S. Evaluation of optical properties and thermal performances of different greenhouse covering materials. Sol. Energy 2013, 96, 21–32. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; John Wiley & Sons: New York, NY, USA, 1991. [Google Scholar]

- Kreyszig, E. Advanced Engineering Mathematics, 6th ed.; John Wiley & Sons Inc.: New York, NY, USA, 1988. [Google Scholar]

- Abdel-Ghany, A.M.; Kozai, T.; Chun, C. Evaluation of selected greenhouse covers for use in regions with a hot climate. Jpn. J. Trop. Agric. 2001, 45, 242–250. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).