A Rough Discrete Fracture Network Model for Geometrical Modeling of Jointed Rock Masses and the Anisotropic Behaviour

Abstract

:1. Introduction

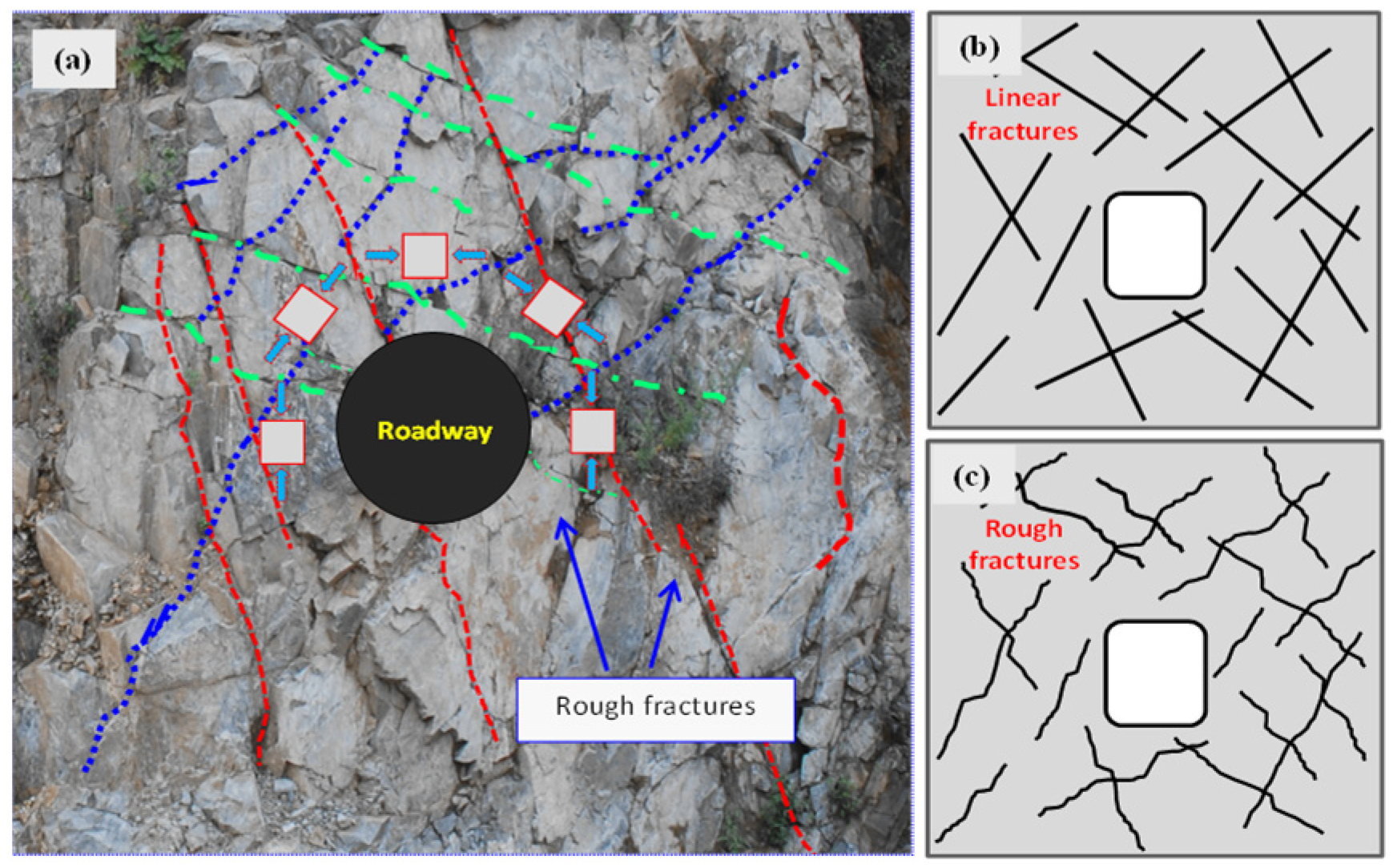

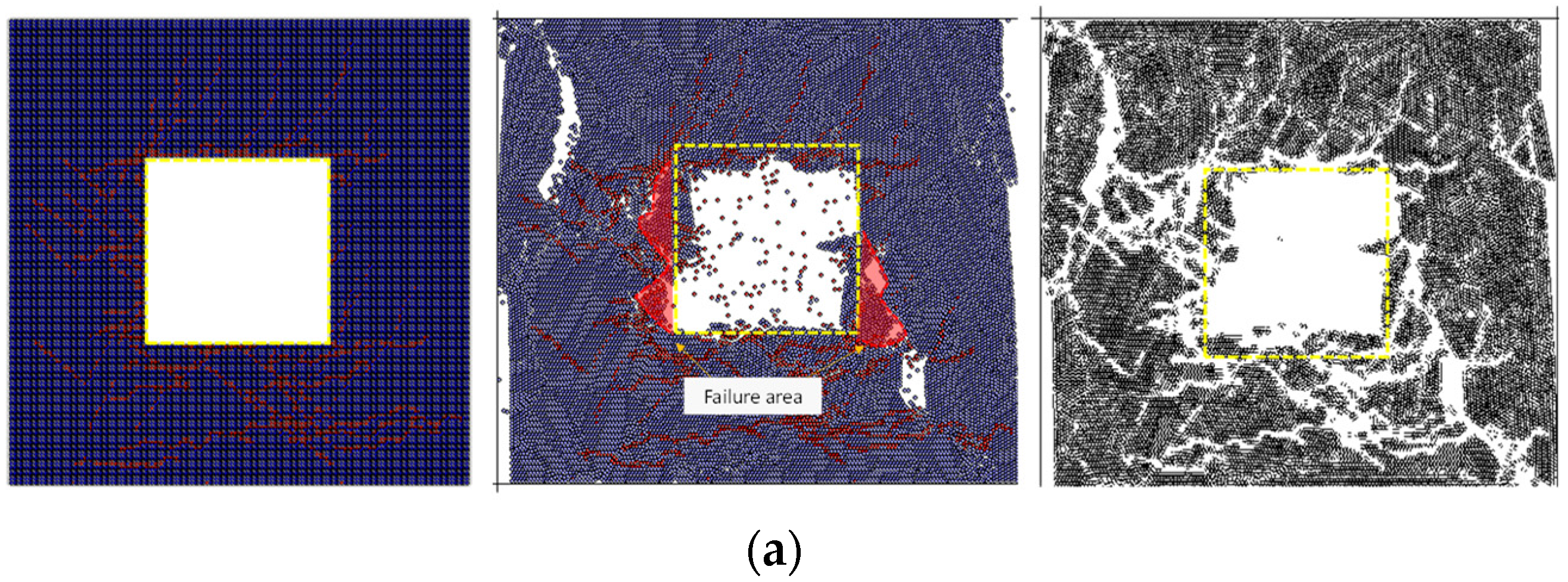

2. Characterization of the Rough Discrete Network Model

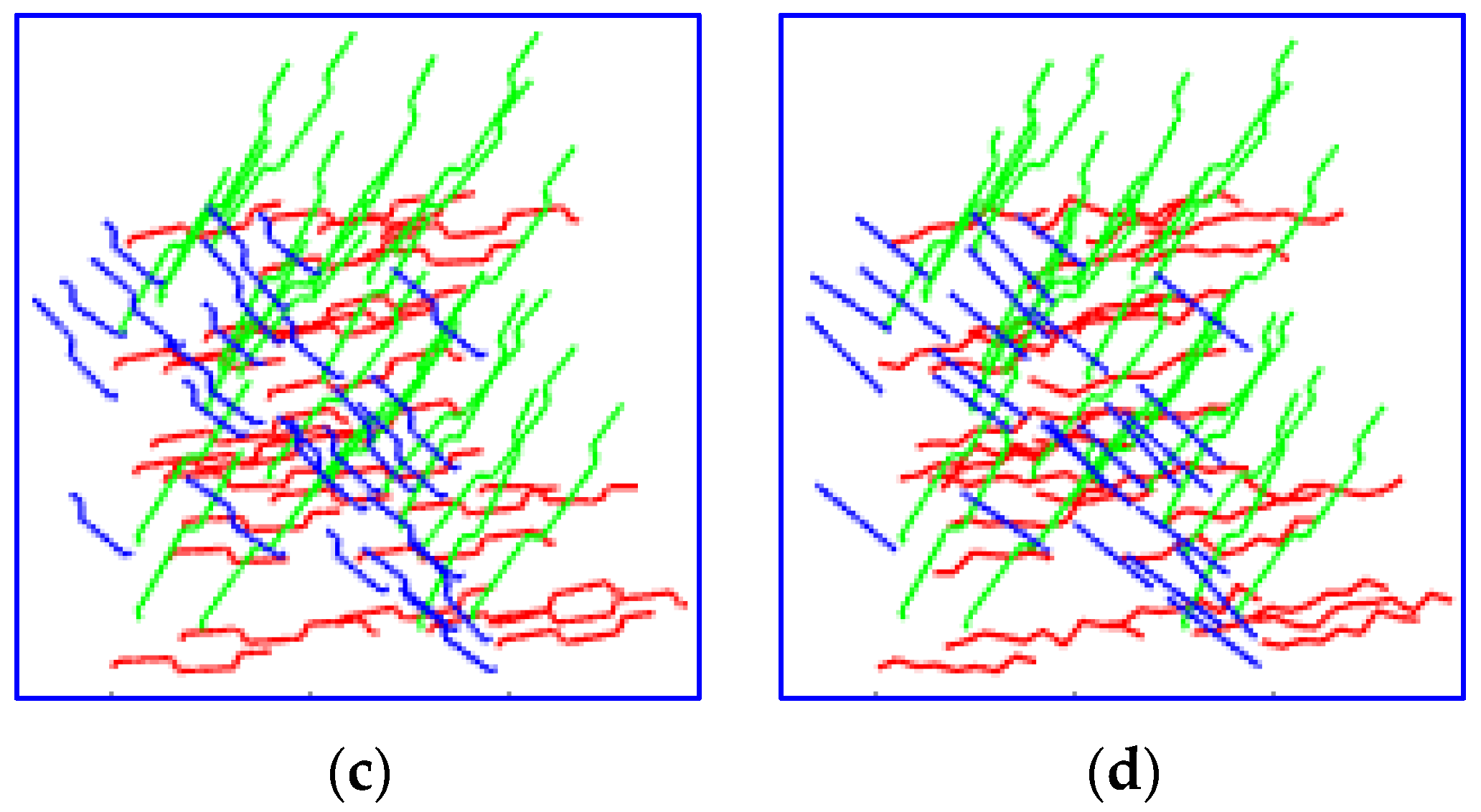

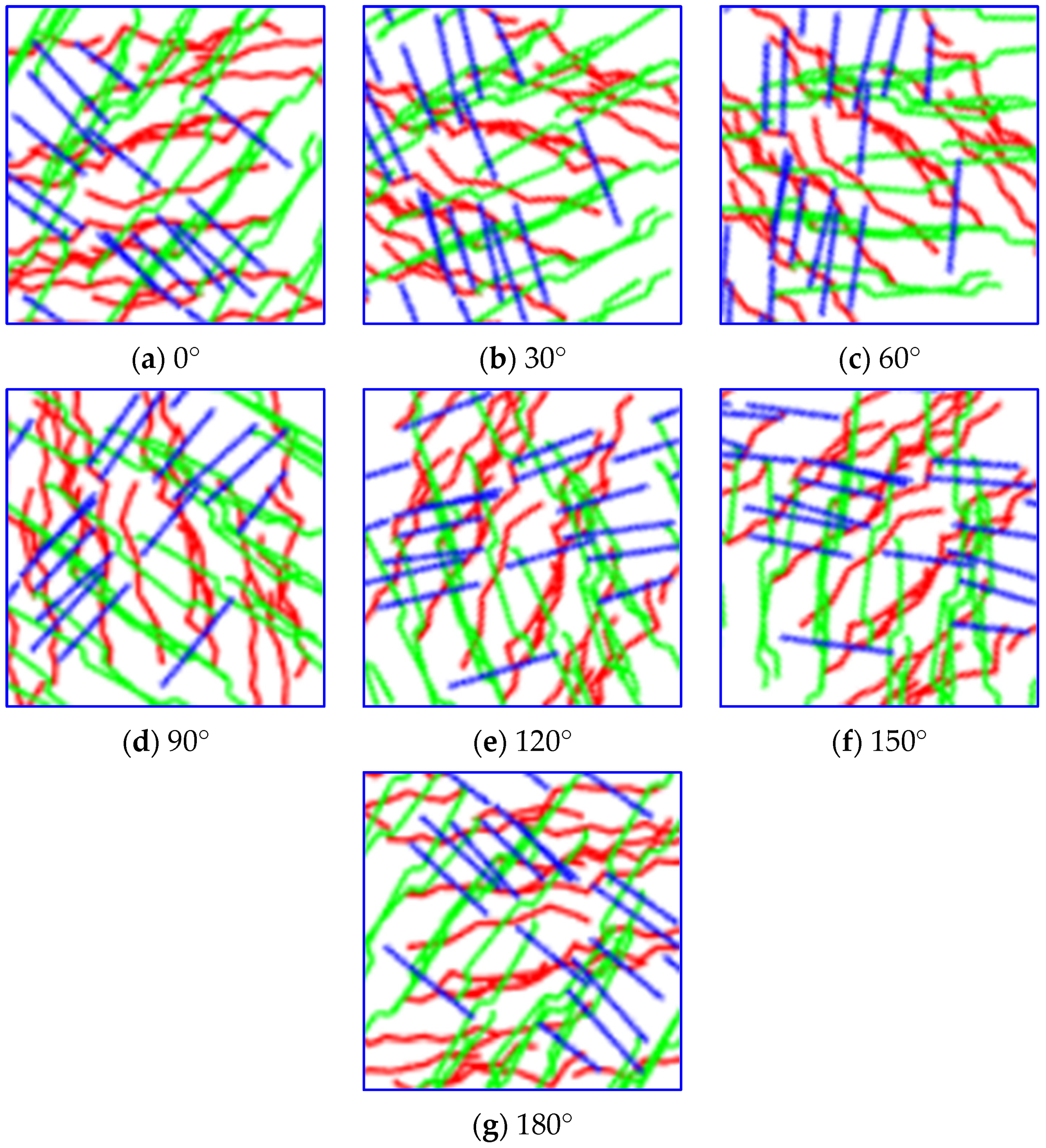

2.1. RDFN Modelling

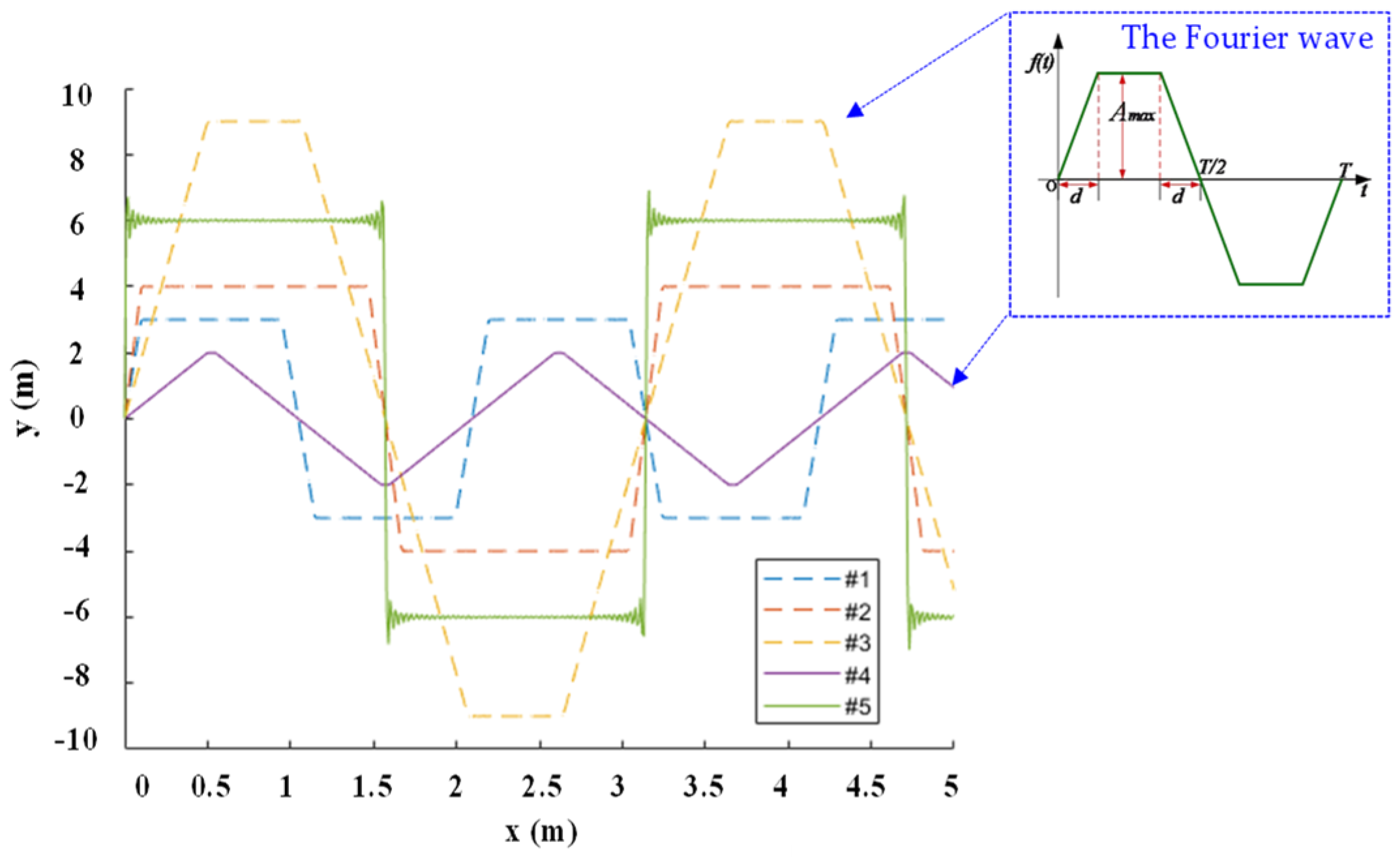

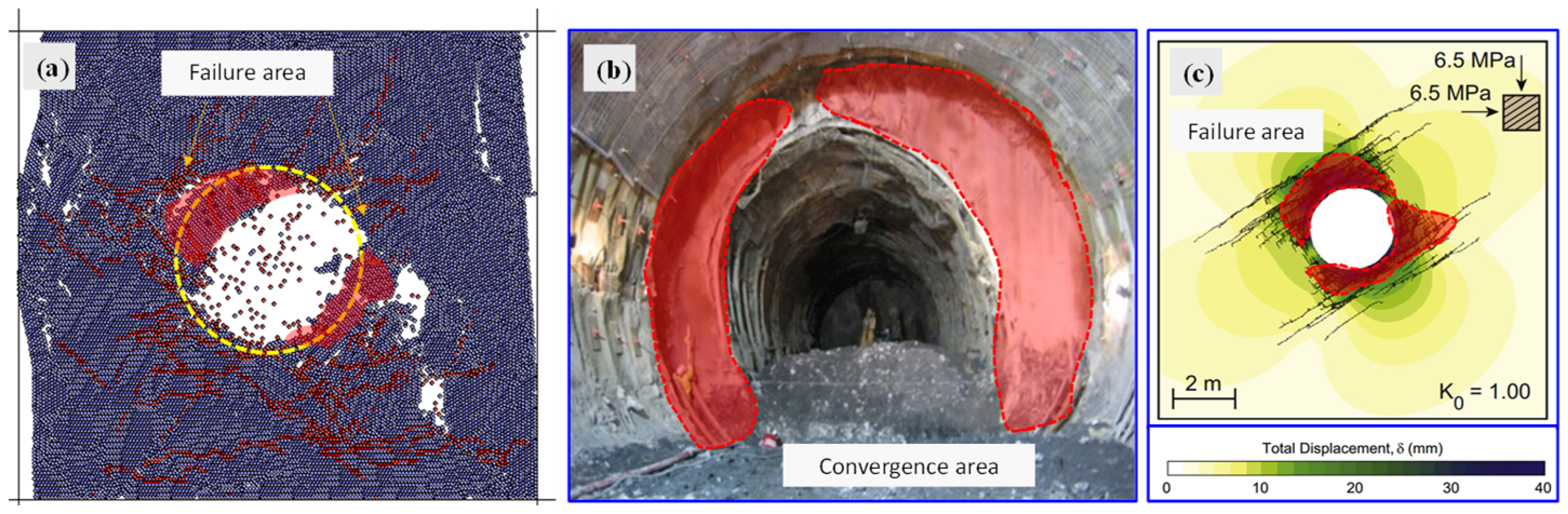

2.2. RDFN Model Based on Fourier Transform

3. Rock Mass Model Based on Digital Image Recognition

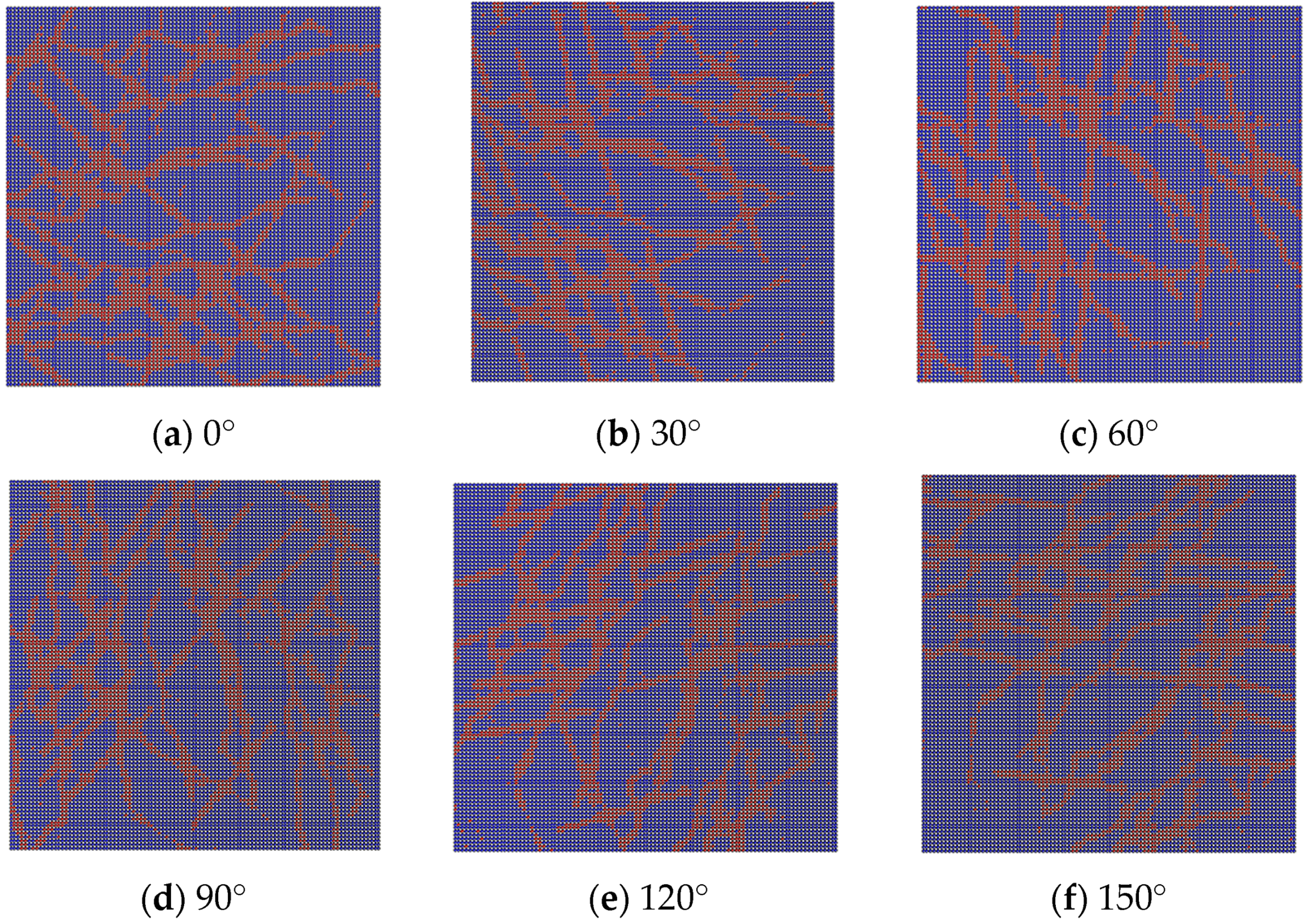

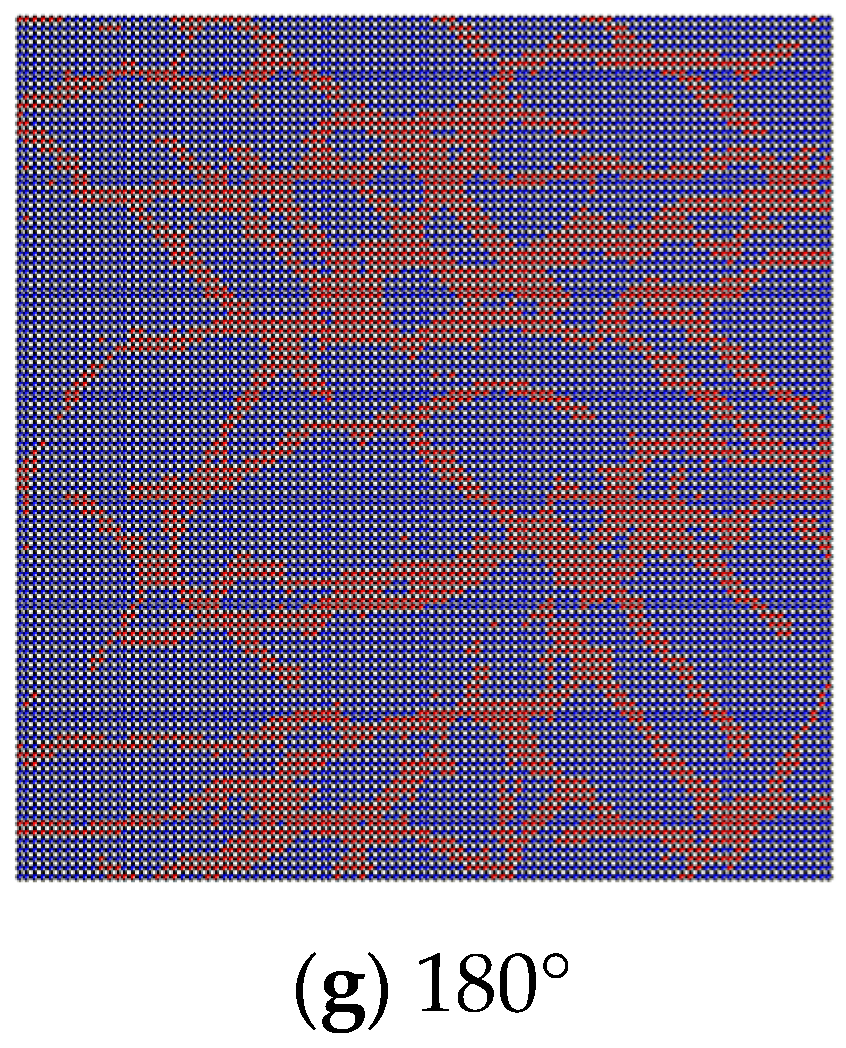

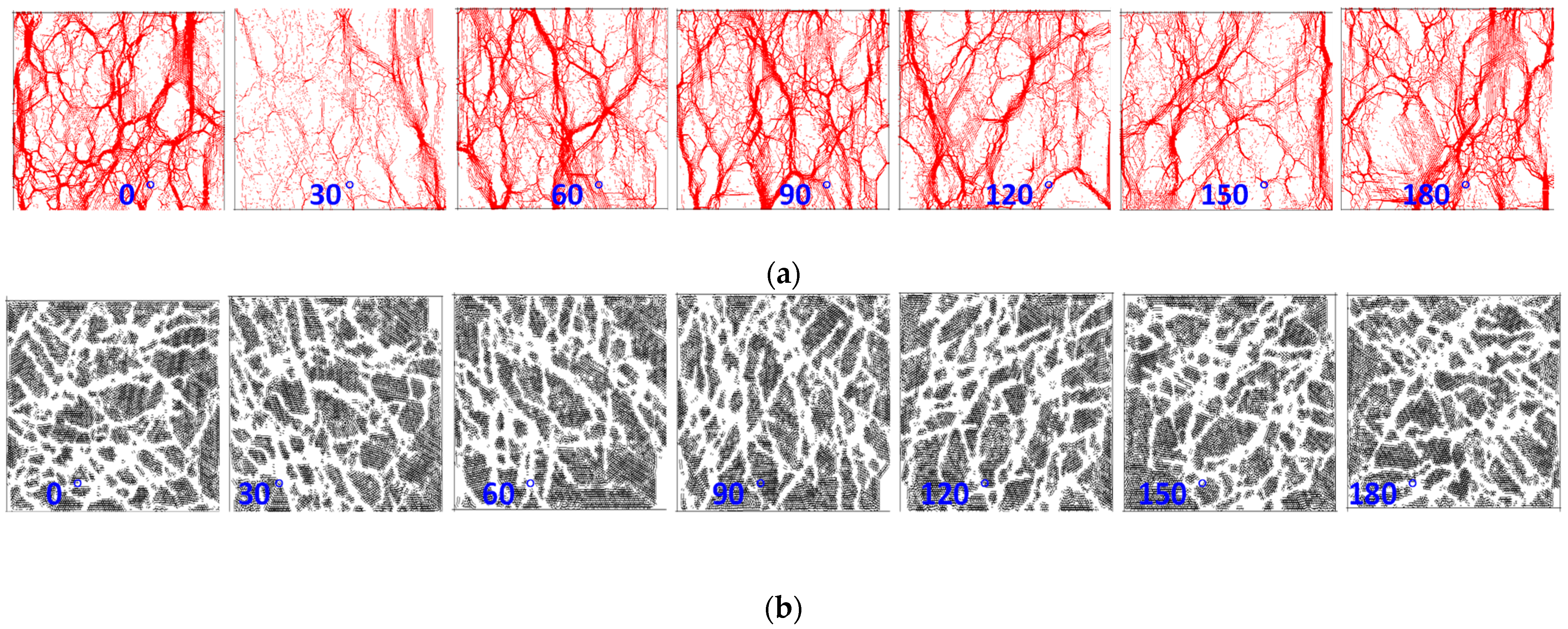

3.1. Principle of Image Recognition and the Numerical Model

3.2. Micro-Mechanical Parameters

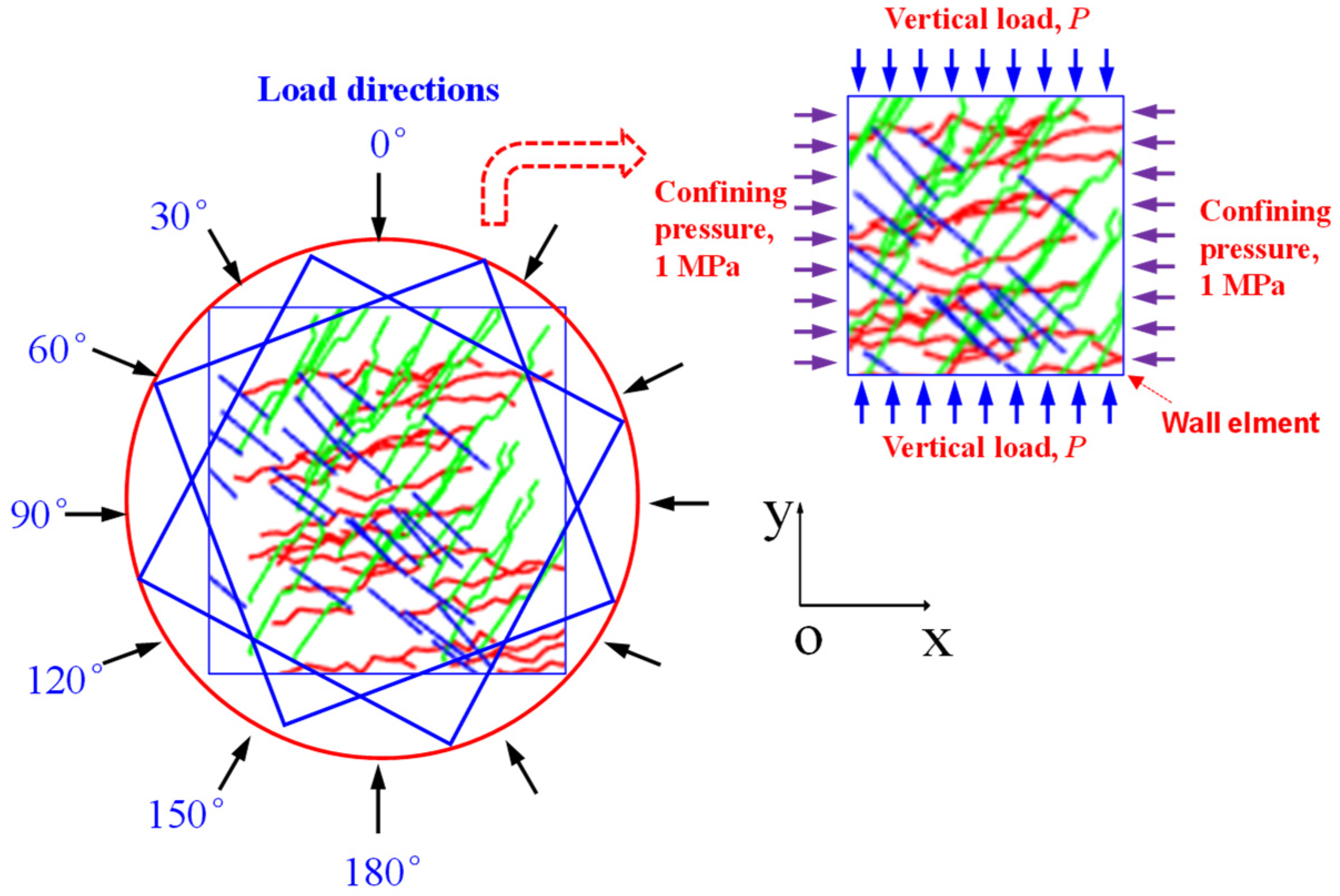

3.3. Numerical Analysis of the Anisotropic Mechanical Properties

4. Numerical Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Malan, D.F.; Spottiswoode, S.M. Time-dependent fracture zone behavior and seismicity surrounding deep level stopping operations. In Rockburst and Seismicity in Mines; Balkema, A.A., Ed.; CRC Press: Boca Raton, FL, USA, 1997; pp. 173–177. [Google Scholar]

- Sellers, E.J.; Klerck, P. Modeling of the effect of discontinuities on the extent of the fracture zone surrounding deep tunnels. Tunn. Undergr. Space Technol. 2000, 15, 463–469. [Google Scholar] [CrossRef]

- Liu, G.; Zhao, J.; Song, H.W. Numerical simulation study on influence of joint distribution on failure of rock mass. J. China Univ. Min. Technol. 2007, 36, 17–22. [Google Scholar]

- Chen, X.; Liao, Z.H.; Li, D.J. Experimental study of effects of joint inclination angle and connectivity rate on strength and deformation properties of rock masses under uniaxial compression. Chin. J. Rock Mech. Eng. 2011, 30, 781–789. [Google Scholar]

- Li, X.F.; Li, H.B.; Xia, X.; Feng, H.P. Numerical simulation study on mechanical characteristics of joint-like rocks in direct shear test. Rock Soil Mech. 2016, 37, 583–591. [Google Scholar]

- Xiao, W.M.; Deng, R.G.; Fu, X.M.; Wang, C.Y. Model test study on deformation and strength anisotropy of columnar jointed rock mass under uniaxial compression. Chin. J. Rock Mech. Eng. 2014, 33, 957–963. [Google Scholar]

- Zhou, H.; Meng, F.Z.; Zhang, C.Q.; Lu, J.J.; Xu, R.C. Experimental study on the influence of fractures with different positions and sizes on rock mass failure. Chin. J. Rock Mech. Eng. 2015, 34, 3018–3028. [Google Scholar]

- Li, H.B.; Liu, B.; Feng, H.P.; Zhang, L.Q. Study on shear deformation characteristics and failure mechanism of simulated rock joint specimens. Rock Soil Mech. 2018, 8, 1741–1746,1752. [Google Scholar]

- Wang, P.T.; Yang, T.H.; Yu, Q.L. Permeability tensor and seepage properties for jointed rock masses based on discrete fracture network model. Rock Soil Mech. 2013, 34, 448–455. [Google Scholar]

- Wang, J.L.; Chen, X.; Huang, Y.Y.; Zhang, Z.; Man, G. Computation of heterogeneous steady flow through two-dimensional discrete fracture network model in rock mass. Geotech. Investig. Surv. 2015, 4, 44–48. [Google Scholar]

- Ye, Z.Y.; Jiang, Q.H.; Liu, Y.Z.; Cheng, A.P.; Sun, F.T. Numerical analysis of unsaturated seepage flow through discrete fracture networks of rock. Rock Soil Mech. 2017, 38, 3332–3340. [Google Scholar]

- Wang, Y.; Li, X.; Liu, S.; He, J.; Li, T. Stability calculation for discrete fracture network of rock masses based on joint finite element method. Chin. J. Rock Mech. Eng. 2013, 32, 3337–3345. [Google Scholar]

- Jimenez, R.R.; Sitar, N. Influence of Stochastic Discontinuity Network Parameters on the Formation of Removable Blocks in Rock Slopes. Rock Mech. Rock Eng. 2018, 41, 563–585. [Google Scholar] [CrossRef]

- Lisa, H.; Christian, B.; Asa, F.; Gunnar, G.; Johan, F. A hard rock tunnel case study: Characterization of the water-bearing fracture system for tunnel grouting. Tunn. Undergr. Space Technol. 2012, 30, 132–144. [Google Scholar] [CrossRef]

- Macciotta, R.; Gräpel, C.; Skirrow, R. Fragmented rockfall volume distribution from photogrammetry-based structural mapping and discrete fracture networks. Appl. Sci. 2020, 10, 6977. [Google Scholar] [CrossRef]

- Kiuru, R.; Király, D.; Dabi, G.; Jacobsson, L. Comparison of DFN modelled microfracture systems with petrophysical data in excavation damaged zone. Appl. Sci. 2021, 11, 2899. [Google Scholar] [CrossRef]

- Nasseri, M.H.B.; Grasselli, G.; Mohanty, B. Fracture toughness and fracture roughness in anisotropic granitic rocks. Rock Mech. Rock Eng. 2010, 43, 403–415. [Google Scholar] [CrossRef]

- Tien, Y.M.; Kuo, M.C.; Juang, C.H. An experimental investigation of the failure mechanism of simulated transversely isotropic rocks. Int. J. Rock Mech. Min. Sci. 2006, 43, 1163–1181. [Google Scholar] [CrossRef]

- Brideau, M.; Ming, Y.; Stead, D. The role of tectonic damage and brittle rock fracture in the development of large rock slope failures. Geomorphology 2009, 103, 30–49. [Google Scholar] [CrossRef]

- Doug, S.; Wolter, A. A critical review of rock slope failure mechanisms: The importance of structural geology. J. Struct. Geol. 2015, 74, 1–23. [Google Scholar]

- Mustaqim, M.-N.M.; Song, K.I.; Kim, D.; Chang, I. Evolution of Joint Roughness Degradation from Cyclic Loading and Its Effect on the Elastic Wave Velocity. Rock Mech. Rock Eng. 2016, 49, 3363–3370. [Google Scholar]

- Barton, N. Review of a new shear strength criterion for rock joints. Eng. Geol. 1973, 7, 287–332. [Google Scholar] [CrossRef]

- Ge, Y.F.; Pinnaduwa, K.; Tang, H.N.; Xiong, C. Investigation of natural rock joint roughness. Comput. Geotech. 2014, 55, 290–305. [Google Scholar] [CrossRef]

- Xie, H.P.; Pariseau, W.G. Fractal estimation of joint roughness coefficients. Sci. China Series B 1994, 37, 1516–1524. [Google Scholar]

- Zhao, Y.L.; Wan, W.; Wang, W.J.; Wang, M.; Peng, Q.Y. Shear numerical simulation of random morphology rock joint and nonlinear shear dilatancy model. Chin. J. Rock Mech. Eng. 2013, 32, 1667–1675. [Google Scholar]

- Zhao, L.; Yu, C.; Huang, D.; Wang, X.; Zhang, S.; Jiao, K. Fourier-based reconstruction of rock joint and the statistical analysis of its morphology. J. Railw. Sci. Eng. 2017, 14, 1606–1613. [Google Scholar]

- Shen, M.R.; Zhang, Q.Z. Experimental study of shear deformation characteristics of rock mass discontinuities. Chin. J. Rock Mech. Eng. 2010, 29, 0713–0719. [Google Scholar]

- Cui, G.J.; Zhang, C.Q.; Han, H.C.; Zeng, Z.; Zhou, H.; Lu, J.J. Experimental study on shear behaviors of artificial joint under CNL and CNS boundary conditions. Chin. J. Rock Mech. Eng. 2019, 38, 3384–3392. [Google Scholar]

- Dang, W.G.; Chen, J.P.; Huang, L.C. Experimental study on the velocity-dependent frictional resistance of a rough rock fracture exposed to normal load vibrations. Acta Geotech. 2021, 16, 2189–2202. [Google Scholar] [CrossRef]

- Wang, P.T.; Ren, F.H.; Cai, M.F. Influence of joint geometry and roughness on the multiscale shear behaviour of fractured rock mass using particle flow code. Arab. J. Geosci. 2020, 13, 165–179. [Google Scholar] [CrossRef]

- Elmo, D.; Stead, D.; Eberhardt, E.; Vyazmensky, A. Applications of Finite/Discrete Element Modeling to Rock Engineering Problems. Int. J. Geomech. 2013, 13, 565–580. [Google Scholar] [CrossRef] [Green Version]

- Alghalandis, Y.F. ADFNE: Open source software for discrete fracture network engineering, two and three dimensional applications. Comput. Geosci. 2017, 102, 1–11. [Google Scholar] [CrossRef]

- Dershowitz, W.S.; Pointe, P.; Doe, T.W. Advances in Discrete Fracture Network Modeling. In Proceedings of the Jan., 2004 U.S. EPA/NGWA Fractured Rock Conference: State of the Science and Measuring Success in Remediation, Portland, ME, USA, 13–15 September 2004; pp. 882–894. [Google Scholar]

- Odling, N.E. Natural fracture profiles, fractal dimension and joint roughness coefficients. Rock Mech. Rock Eng. 1994, 27, 135–153. [Google Scholar] [CrossRef]

- Wang, P.T.; Yang, T.H.; Zhu, L.K.; Liu, H.L. Strength reduction method for rock slope stability analysis based on PFC2D. J. Northeast. Univ. (Nat. Sci.) 2013, 34, 127–130. [Google Scholar]

- Gong, L.; Nie, L.; Xu, Y. Discrete element analysis of the strength anisotropy of fiber-reinforced sands subjected to direct shear load. Appl. Sci. 2020, 10, 3693. [Google Scholar] [CrossRef]

- Wang, P.T.; Cai, M.F.; Ren, F.H. Anisotropy and directionality of tensile behaviours of a jointed rock mass subjected to numerical Brazilian tests. Tunn. Undergr. Space Technol. 2018, 73, 139–153. [Google Scholar] [CrossRef]

- Wang, P.; Ren, F.; Miao, S.; Cai, M.; Yang, T. Evaluation of the anisotropy and directionality of a jointed rock mass under numerical direct shear tests. Eng. Geol. 2017, 225, 29–41. [Google Scholar] [CrossRef]

- Wang, P.T.; Yang, T.H.; Zhou, J.R. Slope failure analysis considering anisotropic characteristics of foliated rock masses. Arab. J. Geosci. 2018, 11, 1–15. [Google Scholar] [CrossRef]

- Wang, P.; Yang, T.; Xu, T.; Cai, M.; Li, C. Numerical analysis on scale effect of elasticity, strength and failure patterns of jointed rock masses. Geosci. J. 2016, 20, 539–549. [Google Scholar]

- Mathieu, E. At the Mercy of the Mountain. Tunn. Tunn. Int. 2008, 21–24. Available online: https://www.pizzarotti.it/english/rass-30-at_the_mercy_of_the_mountain (accessed on 8 January 2022).

- Lisjak, A.; Garitte, B.; Grasselli, G.; Müller, H.R.; Vietor, T. The excavation of a circular tunnel in a bedded argillaceous rock (Opalinus Clay): Short-term rock mass response and FDEM numerical analysis. Tunn. Undergr. Space Technol. 2015, 45, 227–248. [Google Scholar] [CrossRef] [Green Version]

| Serial Number | Amplitude, (Amax)/m | Frequency, ω | Ascent Width, d/m | Fourier Series, n |

|---|---|---|---|---|

| #1 | 3 | 3 | 0.1 | 50 |

| #2 | 4 | 2 | 0.1 | 50 |

| #3 | 9 | 2 | 0.5 | 30 |

| #4 | 2 | 3 | 0.5 | 50 |

| #5 | 6 | 2 | 0.001 | 50 |

| Joint Type | Group | Linear Density (/m−1) | Dip (°) | Trace Length (m) | Amplitude (m) | Frequency | Series (n) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Mean | Deviation | Type | Mean | Variance | ||||||

| Straight joints | #1 | 0.3 | Evenly distributed | 0 | 15 | Evenly distributed | 3 | 2 | - | - | - |

| #2 | 0.25 | Evenly distributed | 45 | 15 | Evenly distributed | 5 | 1 | - | - | - | |

| #3 | 0.25 | Evenly distributed | 135 | 15 | Evenly distributed | 2 | 1 | - | - | - | |

| Fractal joints | #1 | 0.3 | Evenly distributed | 0 | 15 | Evenly distributed | 3 | 2 | 0.15 | - | - |

| #2 | 0.25 | Evenly distributed | 45 | 15 | Evenly distributed | 5 | 1 | 0.15 | - | - | |

| #3 | 0.25 | Evenly distributed | 135 | 15 | Evenly distributed | 2 | 1 | 0.15 | - | - | |

| Fourier joints | #1 | 0.3 | Evenly distributed | 0 | 15 | Evenly distributed | 3 | 2 | 0.15 | 0.5 | 50 |

| #2 | 0.25 | Evenly distributed | 45 | 15 | Evenly distributed | 5 | 1 | 0.15 | 0.75 | 10 | |

| #3 | 0.25 | Evenly distributed | 135 | 15 | Evenly distributed | 2 | 1 | 0.15 | 0.5 | 10 | |

| Mixed joints | #1 | 0.3 | Evenly distributed | 0 | 15 | Evenly distributed | 3 | 2 | 0.15 | - | - |

| #2 | 0.25 | Evenly distributed | 45 | 15 | Evenly distributed | 5 | 1 | 0.15 | 0.75 | 10 | |

| #3 | 0.25 | Evenly distributed | 135 | 15 | Evenly distributed | 2 | 1 | - | - | - | |

| Type | Total Number of Units | Rock Unit | Joint Unit | Ratio of Joint Units |

|---|---|---|---|---|

| PFC model | 22,500 | 19,477 | 3023 | 13.43% |

| Type | Micro-Parameters | Numerical Value |

|---|---|---|

| Particle properties | Ratio of particles, Rmax/Rmin | 1.7 |

| Particle density (kg/m3) | 2700 | |

| Static elastic modulus between particles (Pa) | 6.0e9 | |

| Particle method/Tangential stiffness ratio | 0.45 | |

| Coefficient of friction | 0.7 | |

| Parallel connection properties | Modulus of elasticity (GPa) | 5.4 |

| Normal/Tangential stiffness ratio | 0.45 | |

| Normal strength/Standard deviation (MPa) | 4.5/0.6 | |

| Shear strength/Standard deviation (MPa) | 5.0/0.7 | |

| Parallel bond radius multiplier | 1.0 |

| Angle | Total Number of Elements | Rock Elements | Joint Elements | Ratio of Joint |

|---|---|---|---|---|

| 0° | 10,000 | 7005 | 2995 | 29.95% |

| 30° | 10,000 | 7284 | 2716 | 27.16% |

| 60° | 10,000 | 7146 | 2854 | 28.54% |

| 90° | 10,000 | 6976 | 3024 | 30.24% |

| 120° | 10,000 | 7071 | 2929 | 29.29% |

| 150° | 10,000 | 7124 | 2876 | 71.24% |

| 180° | 10,000 | 6892 | 3108 | 68.92% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Liu, C.; Qi, Z.; Liu, Z.; Cai, M. A Rough Discrete Fracture Network Model for Geometrical Modeling of Jointed Rock Masses and the Anisotropic Behaviour. Appl. Sci. 2022, 12, 1720. https://doi.org/10.3390/app12031720

Wang P, Liu C, Qi Z, Liu Z, Cai M. A Rough Discrete Fracture Network Model for Geometrical Modeling of Jointed Rock Masses and the Anisotropic Behaviour. Applied Sciences. 2022; 12(3):1720. https://doi.org/10.3390/app12031720

Chicago/Turabian StyleWang, Peitao, Cao Liu, Zhenwu Qi, Zhichao Liu, and Meifeng Cai. 2022. "A Rough Discrete Fracture Network Model for Geometrical Modeling of Jointed Rock Masses and the Anisotropic Behaviour" Applied Sciences 12, no. 3: 1720. https://doi.org/10.3390/app12031720

APA StyleWang, P., Liu, C., Qi, Z., Liu, Z., & Cai, M. (2022). A Rough Discrete Fracture Network Model for Geometrical Modeling of Jointed Rock Masses and the Anisotropic Behaviour. Applied Sciences, 12(3), 1720. https://doi.org/10.3390/app12031720