Heat Conduction and Cracking of Functionally Graded Materials Using an FDEM-Based Thermo-Mechanical Coupling Model

Abstract

:1. Introduction

2. Fundamentals of the Continuous–Discontinuous Thermo-Mechanical Coupling Model

2.1. The Continuous–Discontinuous Heat Conduction Model

2.2. Thermal Stress Calculation

2.3. FDEM Mechanical Fracture Calculation

2.3.1. FDEM Control Equation

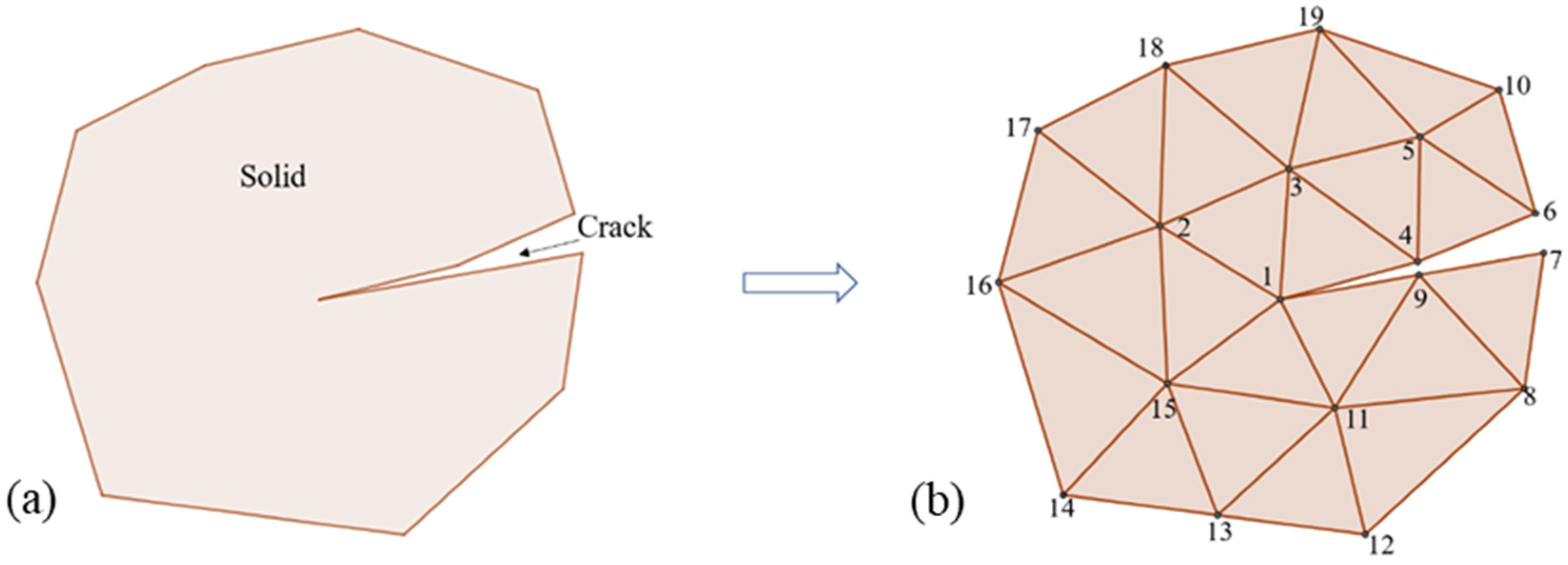

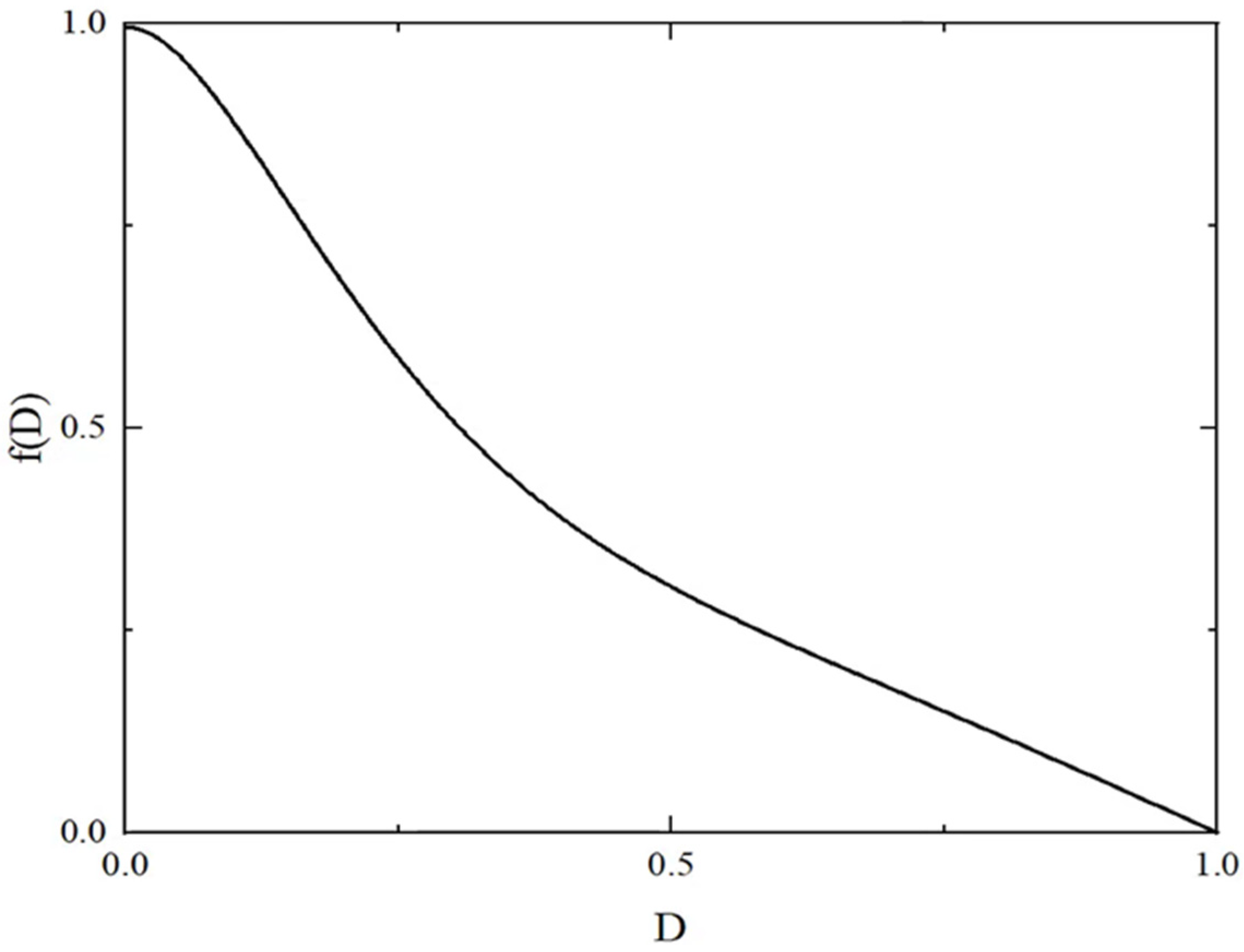

2.3.2. Fracture Simulation

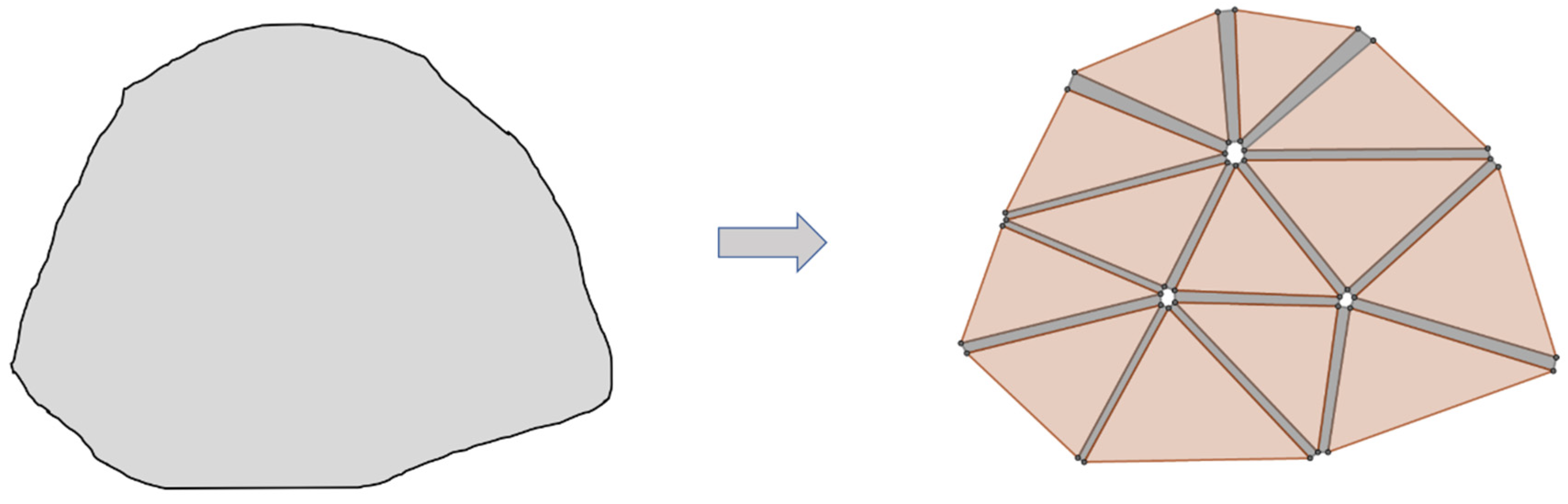

3. Model Setup of FGMs in FDEM

4. Model Validation

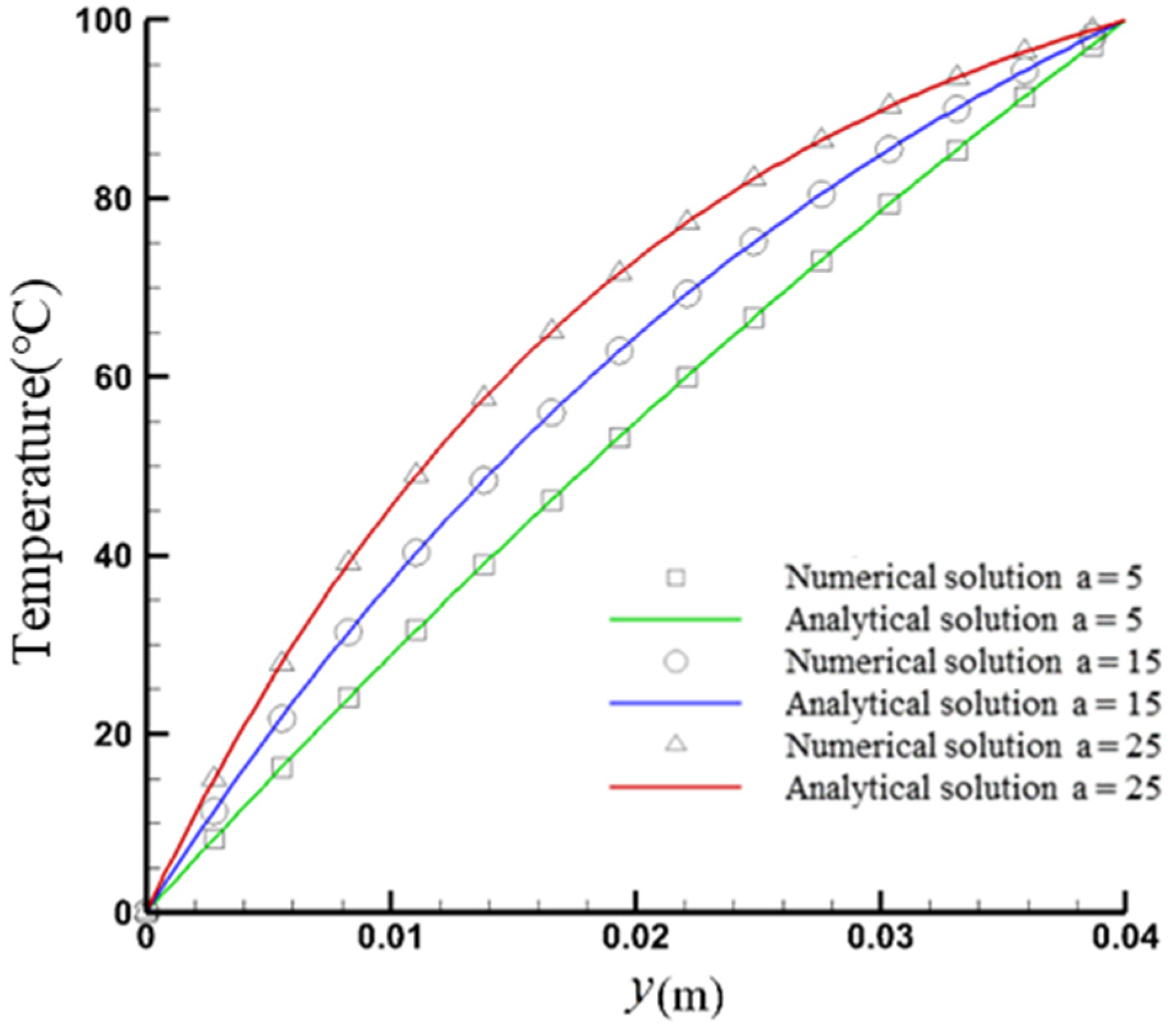

4.1. Verification of Steady-State Heat Conduction for the FGM Model

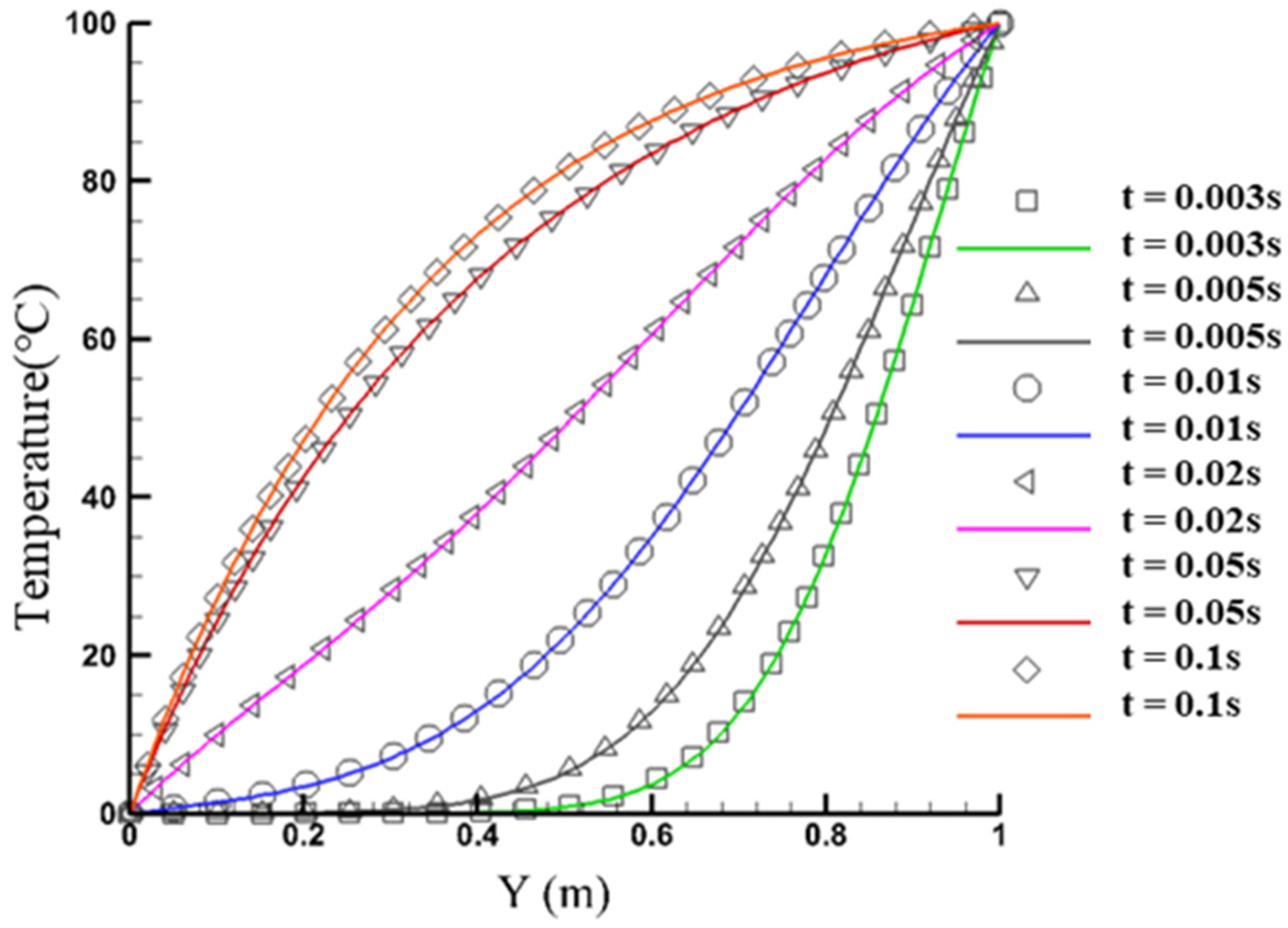

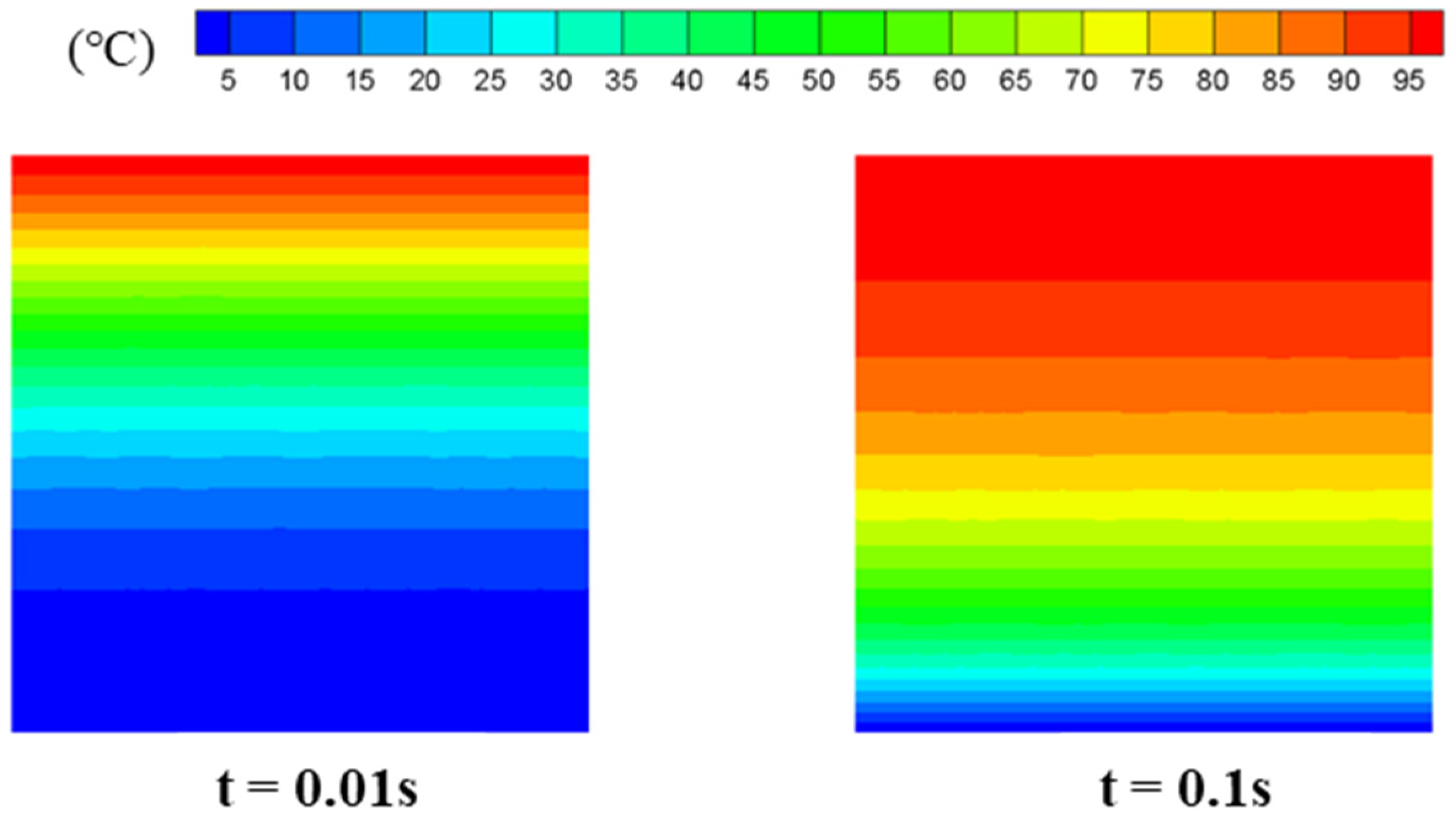

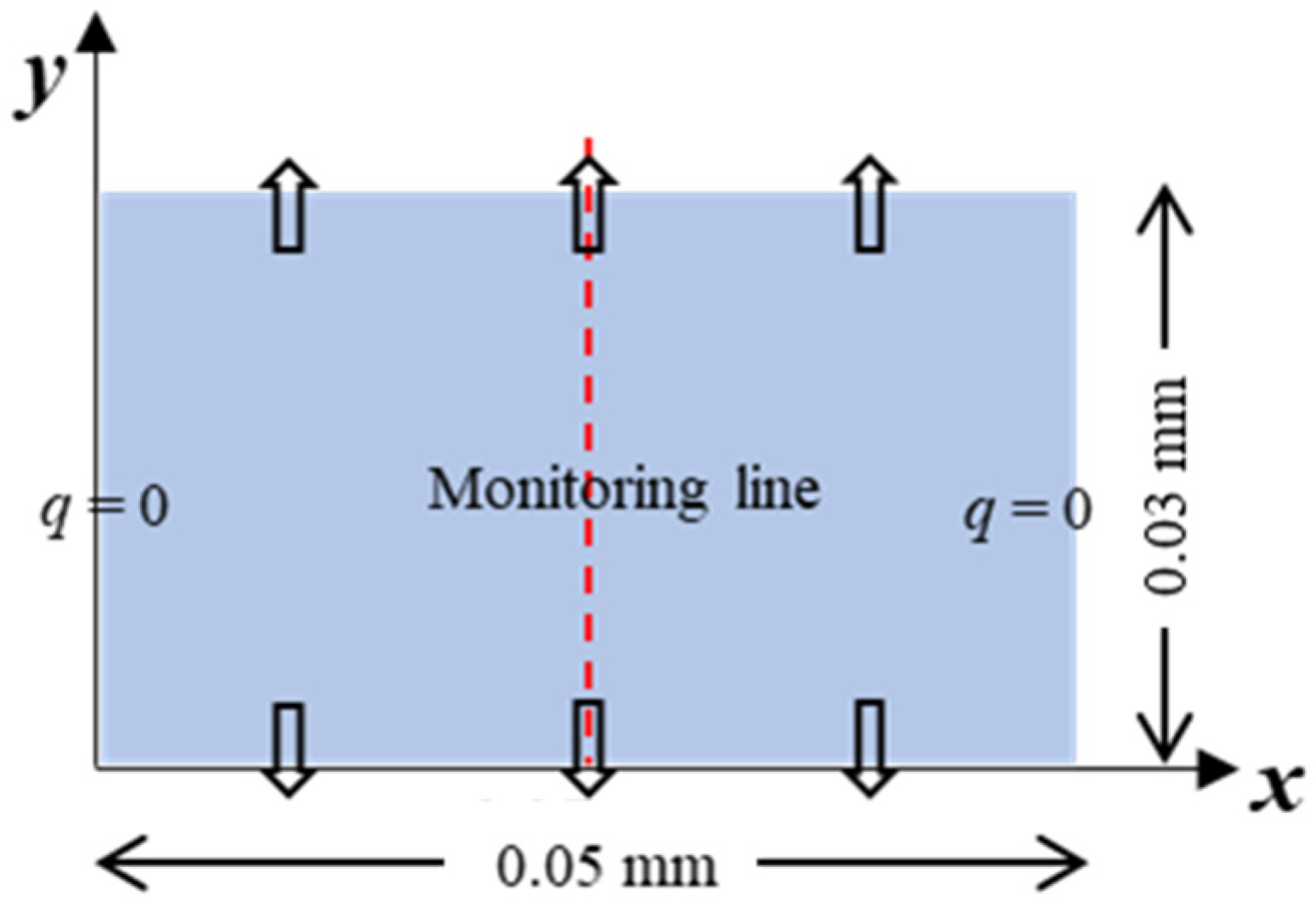

4.2. Verification of Transient Heat Conduction in FGMs

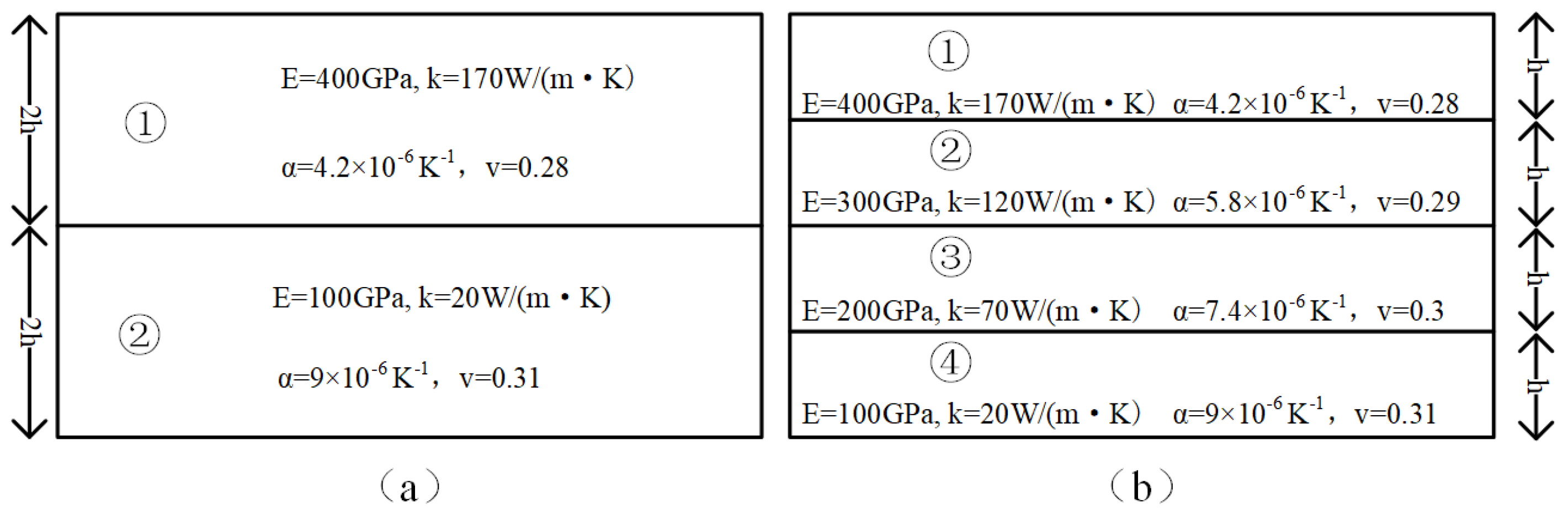

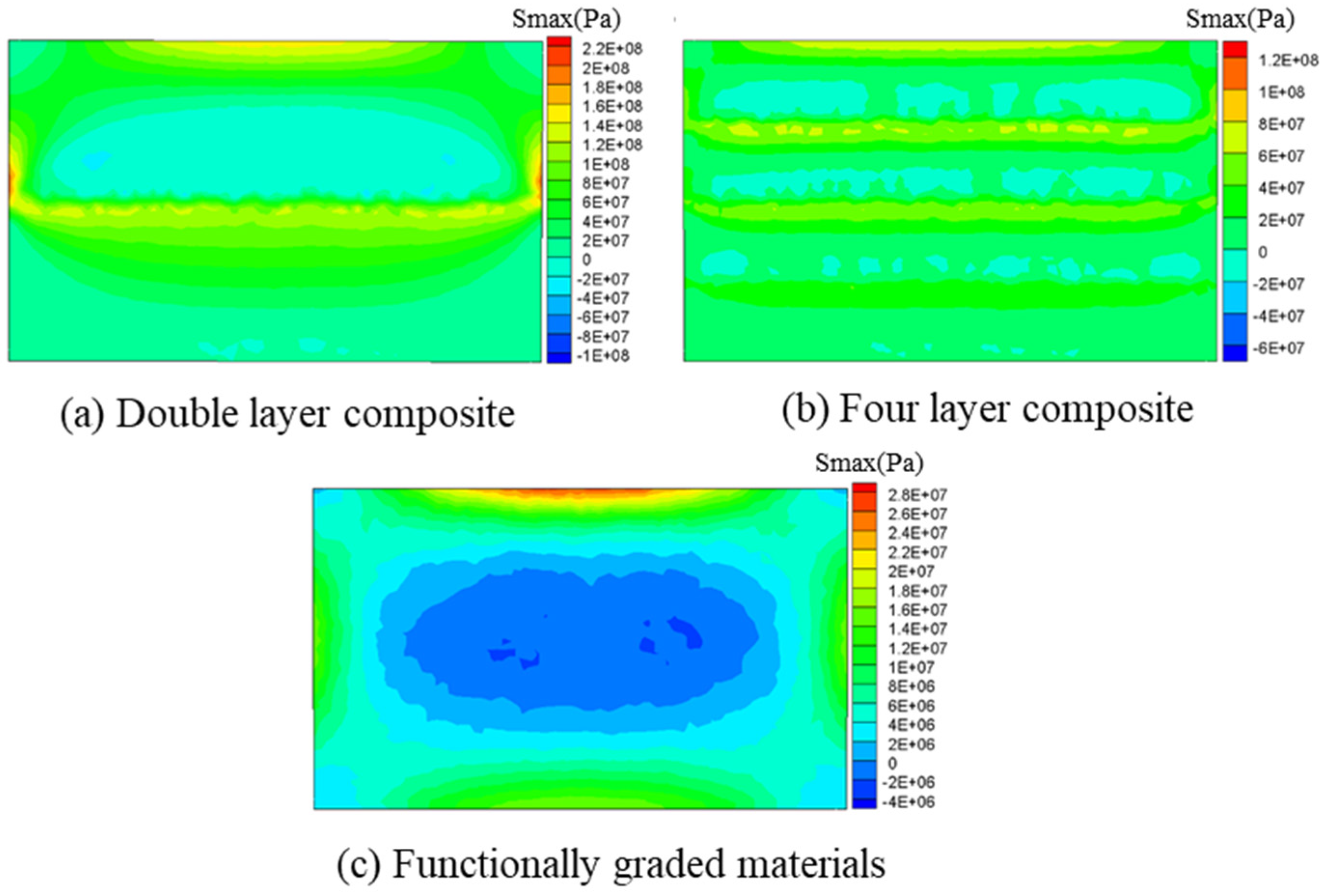

5. Thermal Stress Analysis of FGMs and Composite Materials

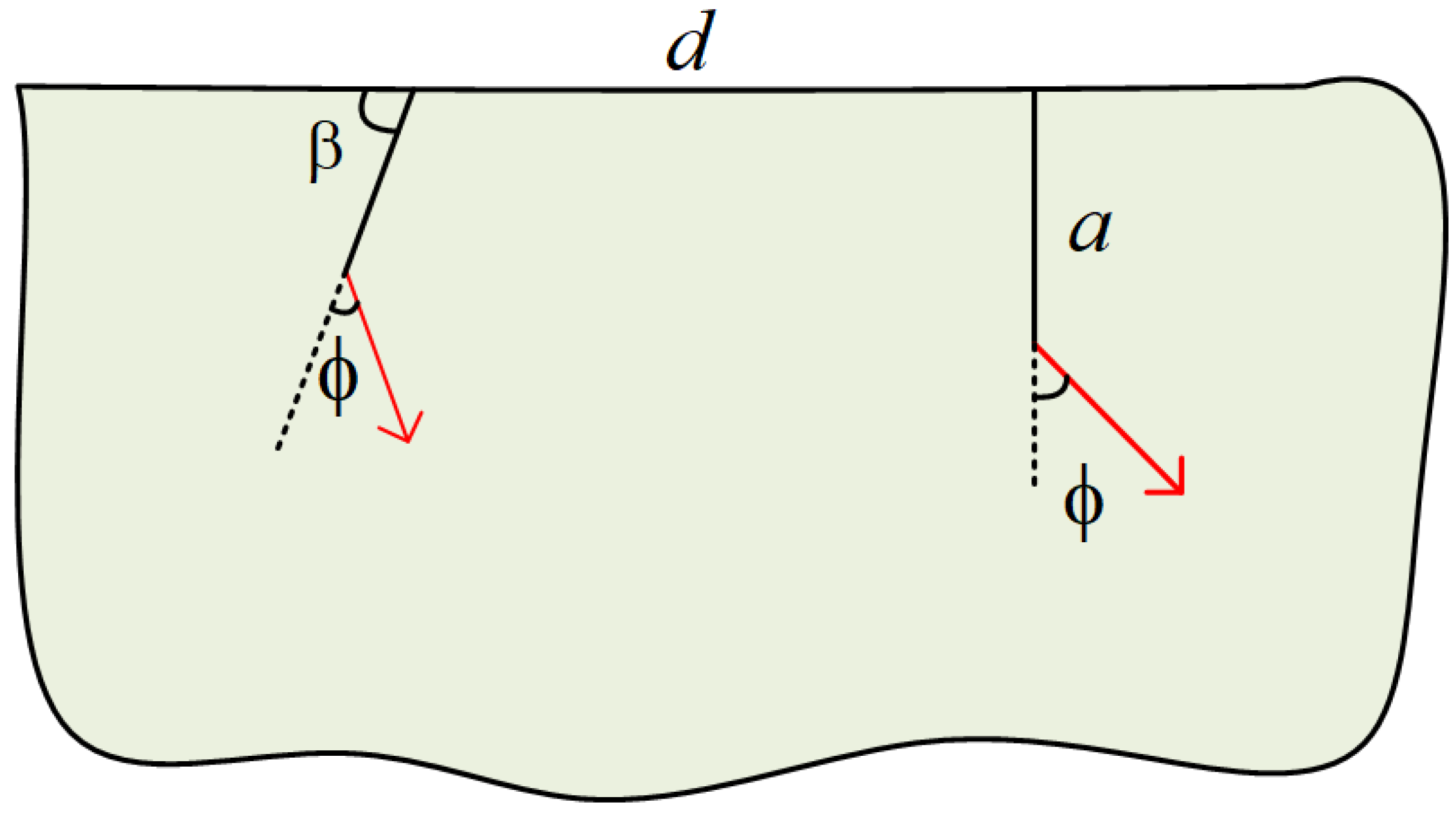

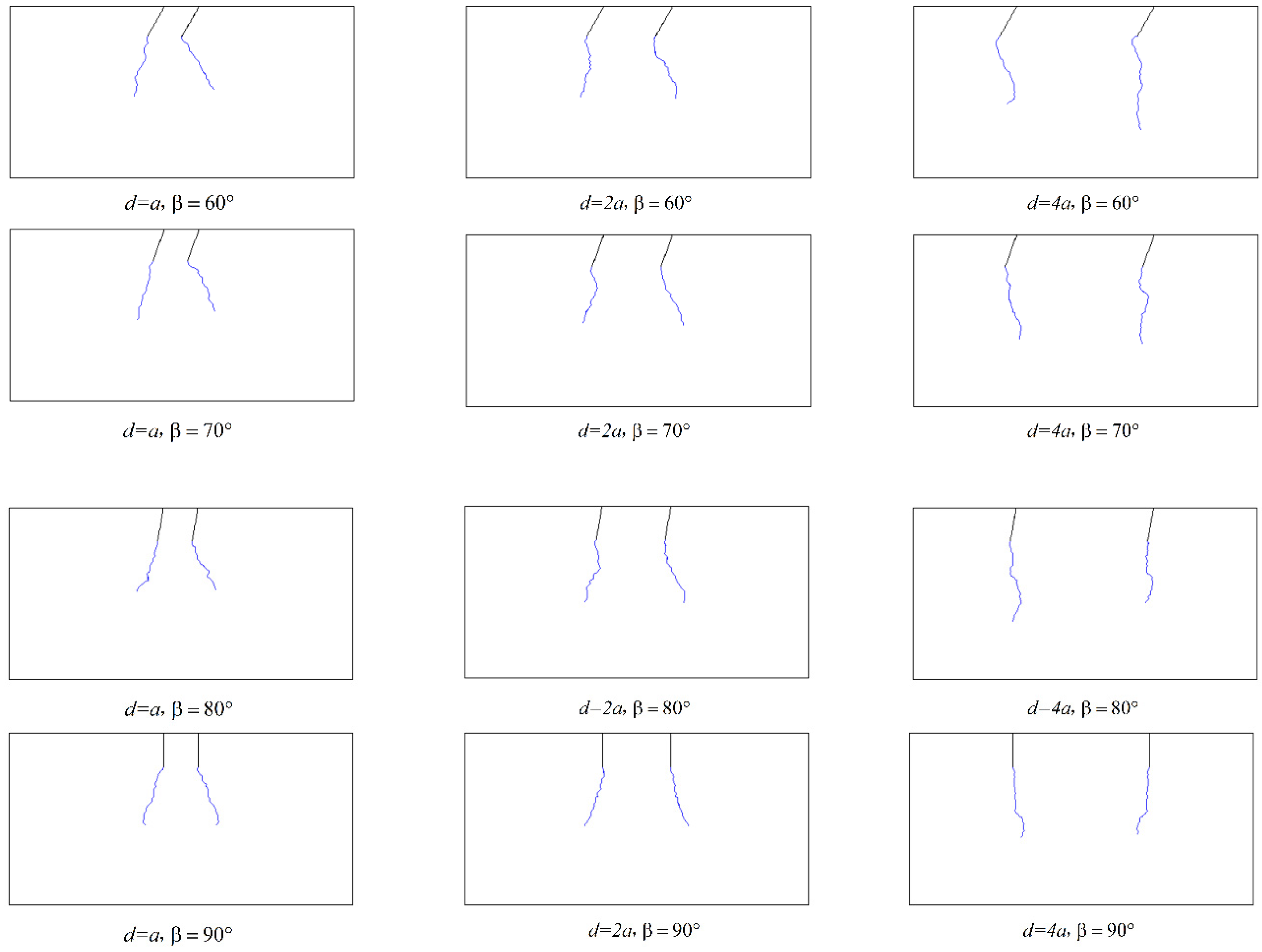

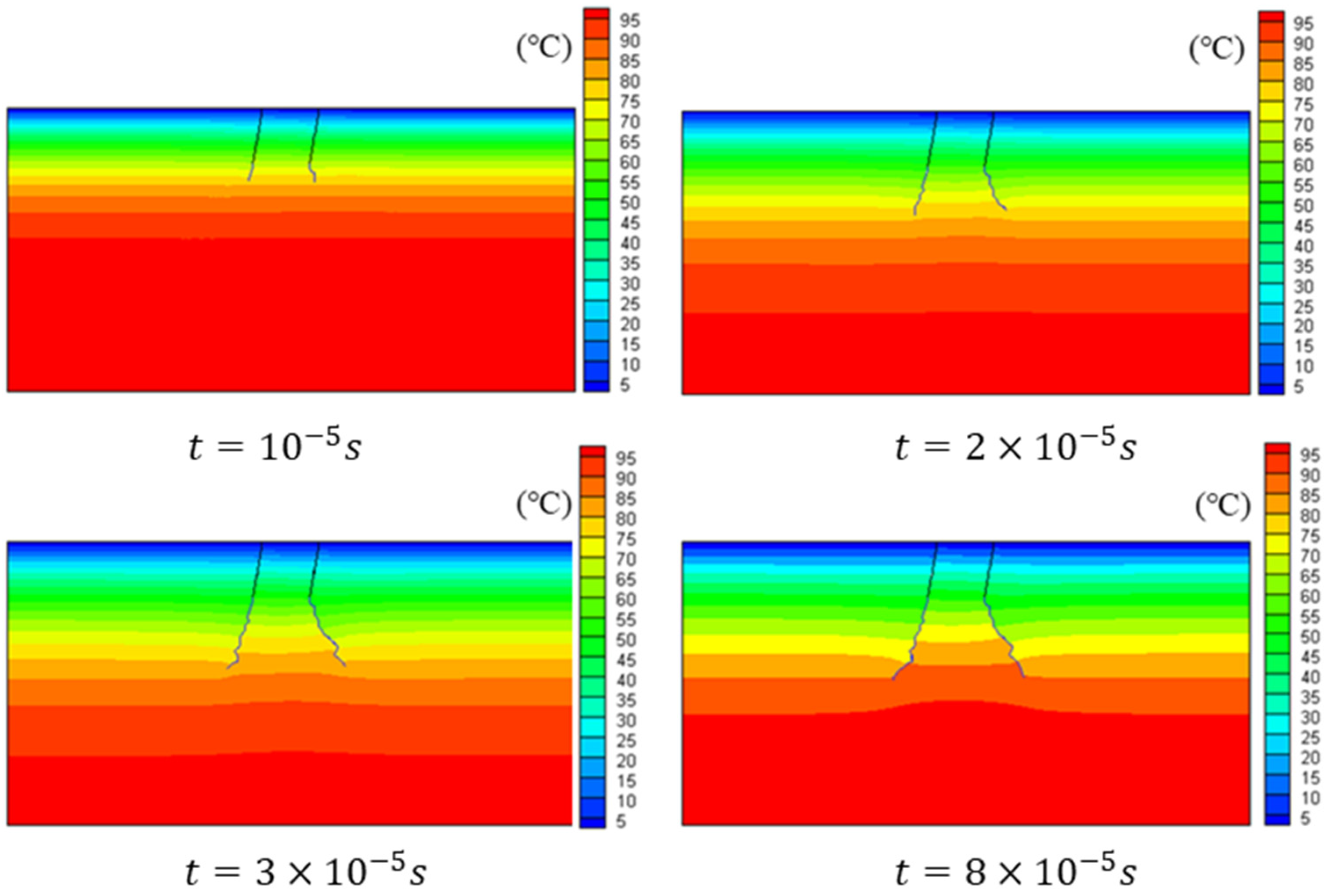

6. Thermal Cracking Simulation in FGMs

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rabin, B.H.; Shiota, I. Functionally Gradient Materials. MRS Bull. 1995, 20, 14–18. [Google Scholar] [CrossRef]

- Tang, X. Analytical solutions of temperature fields for an opthotropic place with a central crack under remote uniform heat flows. Eng. Mech. 2007, 24, 28–33. [Google Scholar]

- Li, S.R.; Fan, L.L. Dynamic responses of functionally graded material beams under thermal shock. J. Vib. Eng. 2009, 22, 371–378. [Google Scholar]

- Obata, Y.; Noda, N. Steady thermal-stresses in a hollow circular-cylinder and a hollow sphere of a functionally gradient material. J. Therm. Stresses 1994, 17, 471–487. [Google Scholar] [CrossRef]

- Tanigawa, Y.; Ootao, Y.; Kawamura, R. Thermal bending of laminated composite rectangular plates and nonhomogeneous plates due to partial heating. J. Therm. Stresses 1991, 14, 285–308. [Google Scholar] [CrossRef]

- Lanhe, W. Thermal buckling of a simply supported moderately thick rectangular FGM plate. Compos. Struct. 2004, 64, 211–218. [Google Scholar] [CrossRef]

- Shodja, A.; Ghahremaninejad, A. An FGM coated elastic solid under thermomechanical loading: A two-dimensional linear elastic approach. Surf. Coat. Technol. 2006, 200, 4050–4064. [Google Scholar] [CrossRef]

- Alibeigloo, A. Exact solution for thermo-elastic response of functionally graded rectangular plates. Compos. Struct. 2010, 92, 113–121. [Google Scholar] [CrossRef]

- Zenkour, A.; Sobhy, M. Thermal buckling of various types of FGM sandwich plates. Compos. Struct. 2010, 93, 93–102. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, R.; Ai, S.; He, R.; Pei, Y.; Fang, D. Load distribution in threads of porous metal–ceramic functionally graded composite joints subjected to thermomechanical loading. Compos. Struct. 2015, 134, 680–688. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.Y.; Guo, L.C.; Bai, X.M.; Yu, H.J. Finite element analysis of functionally graded plate with a crack under thermal load. J. Harbin Inst. Technol. 2011, 43, 12–15. [Google Scholar]

- Peng, C.; Chen, A. Numerical simulation for a functionally graded thick-walled cylinder with cracks under thermal shock. J. Vib. Shock 2017, 36, 64–70. [Google Scholar]

- Moghaddam, A.; Alfano, M. Thermoelastic analysis of surface cracks in FGMs hollow cylinders using the interaction energy integral method. Eng. Fract. Mech. 2018, 202, 103–115. [Google Scholar] [CrossRef]

- Dai, K.; Liu, G.; Han, X. Thermomechanical analysis of functionally graded material plates using element-free Galerkin method. Comput. Struct. 2005, 83, 1487–1502. [Google Scholar] [CrossRef]

- Sutradhar, A.; Paulino, G.; Gray, L. Transient heat conduction in homogeneous and non-homogeneous materials by the Laplace transform Galerkin boundary element method. Eng. Anal. Bound. Elem. 2002, 26, 119–132. [Google Scholar] [CrossRef]

- Ashrafi, H.; Shariyat, M.; Asemi, K. A time-domain boundary element method for quasistatic thermoviscoelastic behavior modeling of the functionally graded materials. Int. J. Mech. Mater. Des. 2013, 9, 295–307. [Google Scholar] [CrossRef] [Green Version]

- Yu, B.; Zhou, H.; Yan, J.; Meng, Z. A differential transformation boundary element method for solving transient heat conduction problems in functionally graded materials. Numer. Heat Transf. Part A Appl. 2016, 70, 293–309. [Google Scholar] [CrossRef]

- Baojing, Z. Radial Integration Boundary Element Method for Transient Thermal-Mechanics Analysis of FGMs and Its Application; Dalian University of Technology: Dalian, China, 2015. [Google Scholar]

- Garg, S.; Plant, M. Numerical simulation of thermal fracture in functionally graded materials using element-free Galerkin method. Sadhana-Acad. Proc. Eng. Sci. 2017, 42, 417–431. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Qin, Q.H.; Kang, Y. A meshless model for transient heat conduction in functionally graded materials. Comput. Mech. 2006, 38, 51–60. [Google Scholar] [CrossRef]

- Wang, H.; Qin, Q.H. Meshless approach for thermo-mechanical analysis of functionally graded materials. Eng. Anal. Bound. Elem. 2008, 32, 704–712. [Google Scholar] [CrossRef]

- Wang, F.; Guo, Y.; Huang, W. Study on Transient thermal response for functionally graded materials based on peridynamic theory. J. Northwestern Polytech. Univ. 2019, 37, 903–908. [Google Scholar] [CrossRef] [Green Version]

- Hu, G.; Zhang, H.; Tan, Y. Numerical manifold study of steady heat conduction problems in functionally graded material. Chin. J. Appl. Mech. 2017, 34, 311–317. [Google Scholar]

- Yan, C.; Fan, H.; Zheng, Y.; Zhao, Y.; Ning, F. Simulation of the thermal shock of brittle materials using the finite-discrete element method. Eng. Anal. Bound. Elem. 2020, 115, 142–155. [Google Scholar] [CrossRef]

- Yan, C.; Ren, Y.; Yang, Y. A 3D thermal cracking model for rockbased on the combined finite–discrete element method. Comput. Part. Mech. 2019, 7, 881–901. [Google Scholar] [CrossRef]

- Yan, C.; Jiao, Y.Y.; Zheng, H. A three-dimensional heat transfer and thermal cracking model considering the effect of cracks on heat transfer. Int. J. Numer. Anal. Methods Geomech. 2019, 43, 1825–1853. [Google Scholar] [CrossRef]

- Yan, C.; Jiao, Y.-Y. A 2D discrete heat transfer model considering the thermal resistance effect of fractures for simulating the thermal cracking of brittle materials. Acta Geotech. 2019, 15, 1303–1319. [Google Scholar] [CrossRef]

- Yan, C.; Jiao, Y.-Y.; Zheng, H. A fully coupled three-dimensional hydro-mechanical finite discrete element approach with real porous seepage for simulating 3D hydraulic fracturing. Comput. Geotech. 2018, 96, 73–89. [Google Scholar] [CrossRef]

- Yan, C.; Jiao, Y.-Y.; Yang, S. A 2D coupled hydro-thermal model for the combined finite-discrete element method. Acta Geotech. 2018, 14, 403–416. [Google Scholar] [CrossRef]

- Yan, C.; Jiao, Y.Y. FDEM-TH3D: A three-dimensional coupled hydrothermal model for fractured rock. Int. J. Numer. Anal. Methods Geomech. 2018, 43, 415–440. [Google Scholar] [CrossRef] [Green Version]

- Yan, C.; Jiao, Y.-Y. A 2D fully coupled hydro-mechanical finite-discrete element model with real pore seepage for simulating the deformation and fracture of porous medium driven by fluid. Comput. Struct. 2018, 196, 311–326. [Google Scholar] [CrossRef]

- Yan, C.; Zheng, H. FDEM-flow3D: A 3D hydro-mechanical coupled model considering the pore seepage of rock matrix for simulating three-dimensional hydraulic fracturing. Comput. Geotech. 2017, 81, 212–228. [Google Scholar] [CrossRef]

- Yan, C.; Zheng, H. A new potential function for the calculation of contact forces in the combined finite–discrete element method. Int. J. Numer. Anal. Meth. Geomech 2017, 41, 265–283. [Google Scholar] [CrossRef]

- Yan, C.; Zheng, H. A coupled thermo-mechanical model based on the combined finite-discrete element method for simulating thermal cracking of rock. Int. J. Rock Mech. Min. Sci. 2017, 91, 170–178. [Google Scholar] [CrossRef]

- Yan, C.; Zheng, H. A two-dimensional coupled hydro-mechanical finite-discrete model considering porous media flow for simulating hydraulic fracturing. Int. J. Rock Mech. Min. Sci. 2016, 88, 115–128. [Google Scholar] [CrossRef]

- Yan, C.; Zheng, H.; Sun, G.; Ge, X. Combined Finite-Discrete Element Method for Simulation of Hydraulic Fracturing. Rock Mech. Rock Eng. 2015, 49, 1389–1410. [Google Scholar] [CrossRef]

- Wang, T.; Yan, C.; Wang, G.; Zheng, Y.; Ke, W.; Jiao, Y.-Y. Numerical study on the deformation and failure of soft rock roadway induced by humidity diffusion. Tunn. Undergr. Space Technol. 2022, 126, 104565. [Google Scholar] [CrossRef]

- Wang, T.; Yan, C.; Zheng, H.; Zheng, Y.; Wang, G. Microfracture behavior and energy evolution of heterogeneous mudstone subjected to moisture diffusion. Comput. Geotech. 2022, 150, 104918. [Google Scholar] [CrossRef]

- Wang, T.; Yan, C.; Zheng, Y.; Jiao, Y.-Y.; Zou, J. Numerical study on the effect of meso-structure on hydraulic conductivity of soil-rock mixtures. Comput. Geotech. 2022, 146, 104726. [Google Scholar] [CrossRef]

- Yan, C.Z.; Fan, H.W.; Huang, D.R.; Wang, G. A 2D mixed fracture-pore seepage model and hydromechanical coupling for fractured porous media. Acta Geotech. 2021, 16, 3061–3086. [Google Scholar] [CrossRef]

- Yan, C.Z.; Gao, Y.K.; Guo, H. A FDEM based 3D discrete mixed seepage model for simulating fluid driven fracturing. Eng. Anal. Bound. Elem. 2022, 140, 447–463. [Google Scholar] [CrossRef]

- Yan, C.Z.; Guo, H.; Tang, Z.C. Three-dimensional continuous-discrete pore-fracture mixed seepage model and hydro-mechanical coupling model to simulate hydraulic fracturing. J. Pet. Sci. Eng. 2022, 215, 110510. [Google Scholar] [CrossRef]

- Yan, C.Z.; Ma, H.; Tang, Z.C.; Ke, W.H. A Two-Dimensional Moisture Diffusion Continuous Model for Simulating Dry Shrinkage and Cracking of Soil. Int. J. Geomech. 2022, 22, 04022172. [Google Scholar] [CrossRef]

- Yan, C.Z.; Tong, Y.; Luo, Z.Q.; Ke, W.H.; Wang, G. A two-dimensional grouting model considering hydromechanical coupling and fracturing for fractured rock mass. Eng. Anal. Bound. Elem. 2021, 133, 385–397. [Google Scholar] [CrossRef]

- Yan, C.Z.; Wang, T.; Gao, Y.K.; Ke, W.H.; Wang, G. A Three-Dimensional Grouting Model Considering Hydromechanical Coupling Based on the Combined Finite-Discrete Element Method. Int. J. Geomech. 2022, 22, 04022189. [Google Scholar] [CrossRef]

- Yan, C.Z.; Wang, T.; Ke, W.H.; Wang, G. A 2D FDEM-based moisture diffusion-fracture coupling model for simulating soil desiccation cracking. Acta Geotech. 2021, 16, 2609–2628. [Google Scholar] [CrossRef]

- Yan, C.Z.; Wang, X.; Huang, D.R.; Wang, G. A new 3D continuous-discontinuous heat conduction model and coupled thermomechanical model for simulating the thermal cracking of brittle materials. Int. J. Solids Struct. 2021, 229, 111123. [Google Scholar] [CrossRef]

- Yan, C.Z.; Wei, D.S.; Wang, G. Three-dimensional finite discrete element-based contact heat transfer model considering thermal cracking in continuous-discontinuous media. Comput. Methods Appl. Mech. Eng. 2022, 388, 114228. [Google Scholar] [CrossRef]

- Yan, C.Z.; Xie, X.; Ren, Y.H.; Ke, W.H.; Wang, G. A FDEM-based 2D coupled thermal-hydro-mechanical model for multiphysical simulation of rock fracturing. Int. J. Rock Mech. Min. Sci. 2022, 149, 104964. [Google Scholar] [CrossRef]

- Yan, C.Z.; Yang, Y.; Wang, G. A new 2D continuous-discontinuous heat conduction model for modeling heat transfer and thermal cracking in quasi-brittle materials. Comput. Geotech. 2021, 137, 104231. [Google Scholar] [CrossRef]

- Yan, C.Z.; Zheng, H. Three-Dimensional Hydromechanical Model of Hydraulic Fracturing with Arbitrarily Discrete Fracture Networks using Finite-Discrete Element Method. Int. J. Geomech. 2017, 17, 04016133. [Google Scholar] [CrossRef]

- Yan, C.Z.; Zheng, Y.C.; Huang, D.R.; Wang, G. A coupled contact heat transfer and thermal cracking model for discontinuous and granular media. Comput. Methods Appl. Mech. Eng. 2021, 375, 113587. [Google Scholar] [CrossRef]

- Yan, C.Z.; Zheng, Y.C.; Ke, W.H.; Wang, G. A FDEM 3D moisture migration-fracture model for simulation of soil shrinkage and desiccation cracking. Comput. Geotech. 2021, 140, 104425. [Google Scholar] [CrossRef]

- Munjiza, A.; Andrews, K.; White, J. Combined single and smeared crack model in combined finite-discrete element analysis. Int. J. Numer. Methods Eng. 1999, 44, 41–57. [Google Scholar] [CrossRef]

- Munjiza, A.A. The Combined Finite-Discrete Element Method; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Cao, L.L.; Qin, Q.H.; Zhao, N. A hybrid Trefftz graded finite element method to steady-state heat conduction functionally graded material. Chin. J. Appl. Mech. 2015, 10, 222–226. [Google Scholar]

- Sutradhar, A.; Paulino, G.H. The simple boundary element method for transient heat conduction in functionally graded materials. Comput. Methods Appl. Mech. Eng. 2004, 193, 4511–4539. [Google Scholar] [CrossRef]

- Petrova, V.; Schmauder, S. A theoretical model for the study of thermal fracture of functionally graded thermal barrier coatings with a system of edge and internal cracks. Theor. Appl. Fract. Mech. 2020, 108, 102605. [Google Scholar] [CrossRef]

| Thermal Physical Parameters | Ceramic | Metal |

|---|---|---|

| Elastic modulus E (GPa) | 117 | 66 |

| Poisson’s ratio v | 0.333 | 0.321 |

| Thermal expansion coefficient α (K−1) | 7.11 × 10−6 | 10.3 × 10−6 |

| Heat conduction coefficient k (W/(m·K)) | 2.036 | 18.1 |

| Heat capacity Cp (J/(kg·K)) | 615.6 | 808.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, D.; Fan, H.; Yan, C.; Wang, T.; Yang, Y.; Ali, S.; Wang, G. Heat Conduction and Cracking of Functionally Graded Materials Using an FDEM-Based Thermo-Mechanical Coupling Model. Appl. Sci. 2022, 12, 12279. https://doi.org/10.3390/app122312279

Han D, Fan H, Yan C, Wang T, Yang Y, Ali S, Wang G. Heat Conduction and Cracking of Functionally Graded Materials Using an FDEM-Based Thermo-Mechanical Coupling Model. Applied Sciences. 2022; 12(23):12279. https://doi.org/10.3390/app122312279

Chicago/Turabian StyleHan, Du, Hongwei Fan, Chengzeng Yan, Tie Wang, Yu Yang, Sajid Ali, and Gang Wang. 2022. "Heat Conduction and Cracking of Functionally Graded Materials Using an FDEM-Based Thermo-Mechanical Coupling Model" Applied Sciences 12, no. 23: 12279. https://doi.org/10.3390/app122312279

APA StyleHan, D., Fan, H., Yan, C., Wang, T., Yang, Y., Ali, S., & Wang, G. (2022). Heat Conduction and Cracking of Functionally Graded Materials Using an FDEM-Based Thermo-Mechanical Coupling Model. Applied Sciences, 12(23), 12279. https://doi.org/10.3390/app122312279