Mechanical Performance of Polymer Materials for Low-Temperature Applications

Featured Application

Abstract

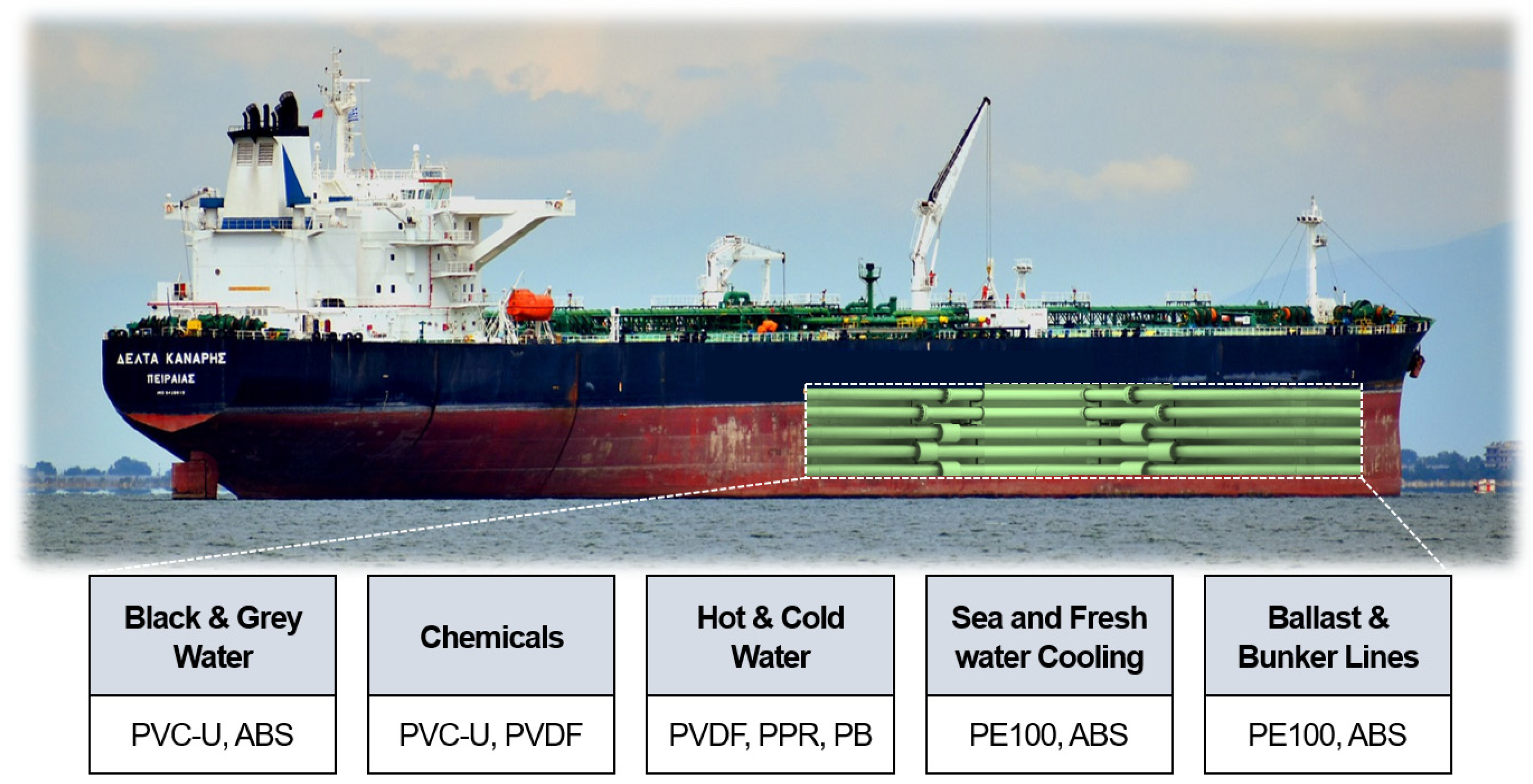

1. Introduction

2. Materials and Methods

2.1. Materials

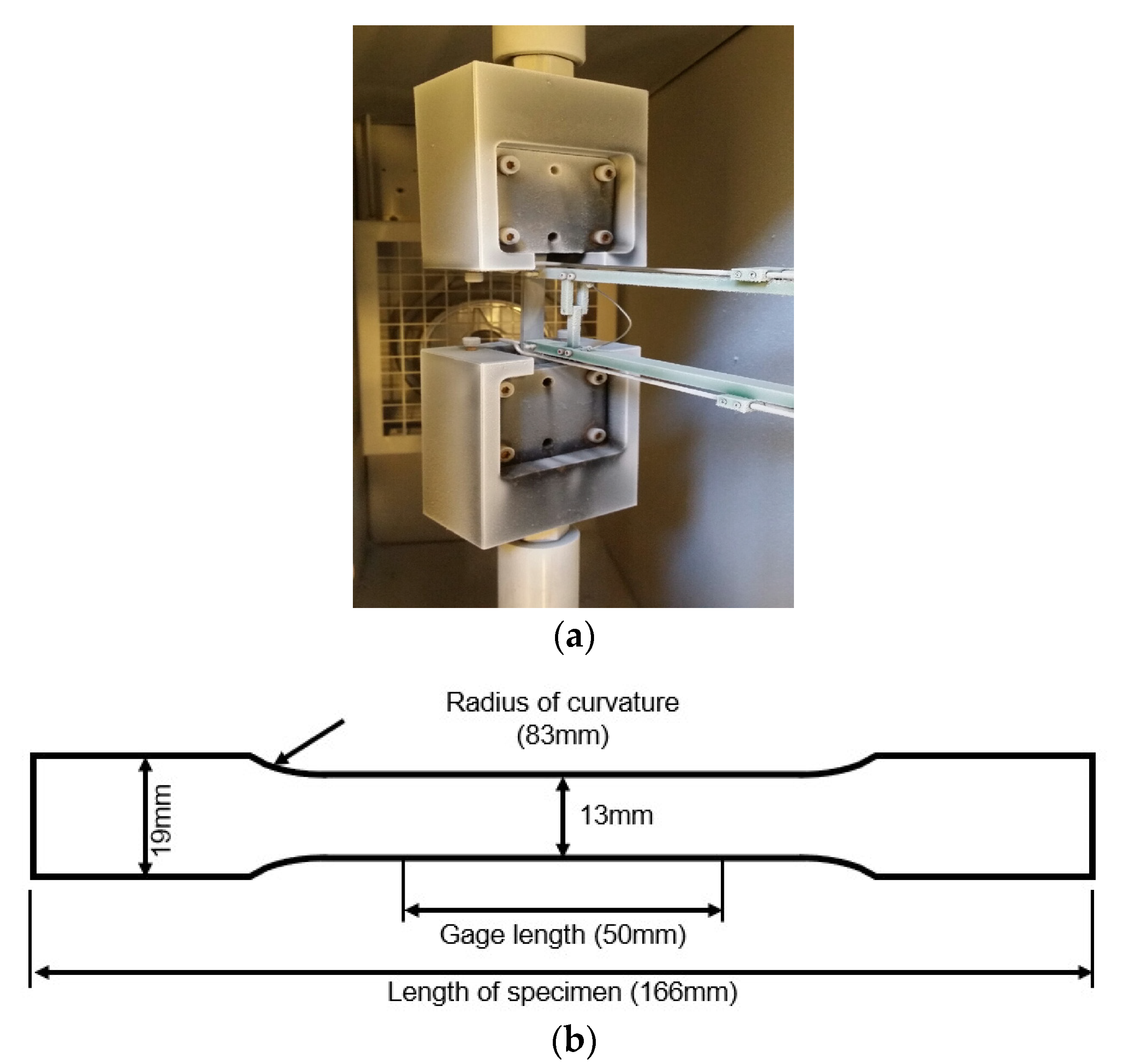

2.2. Experimental Apparatus

2.3. Experimental Scenario

3. Results and Discussion

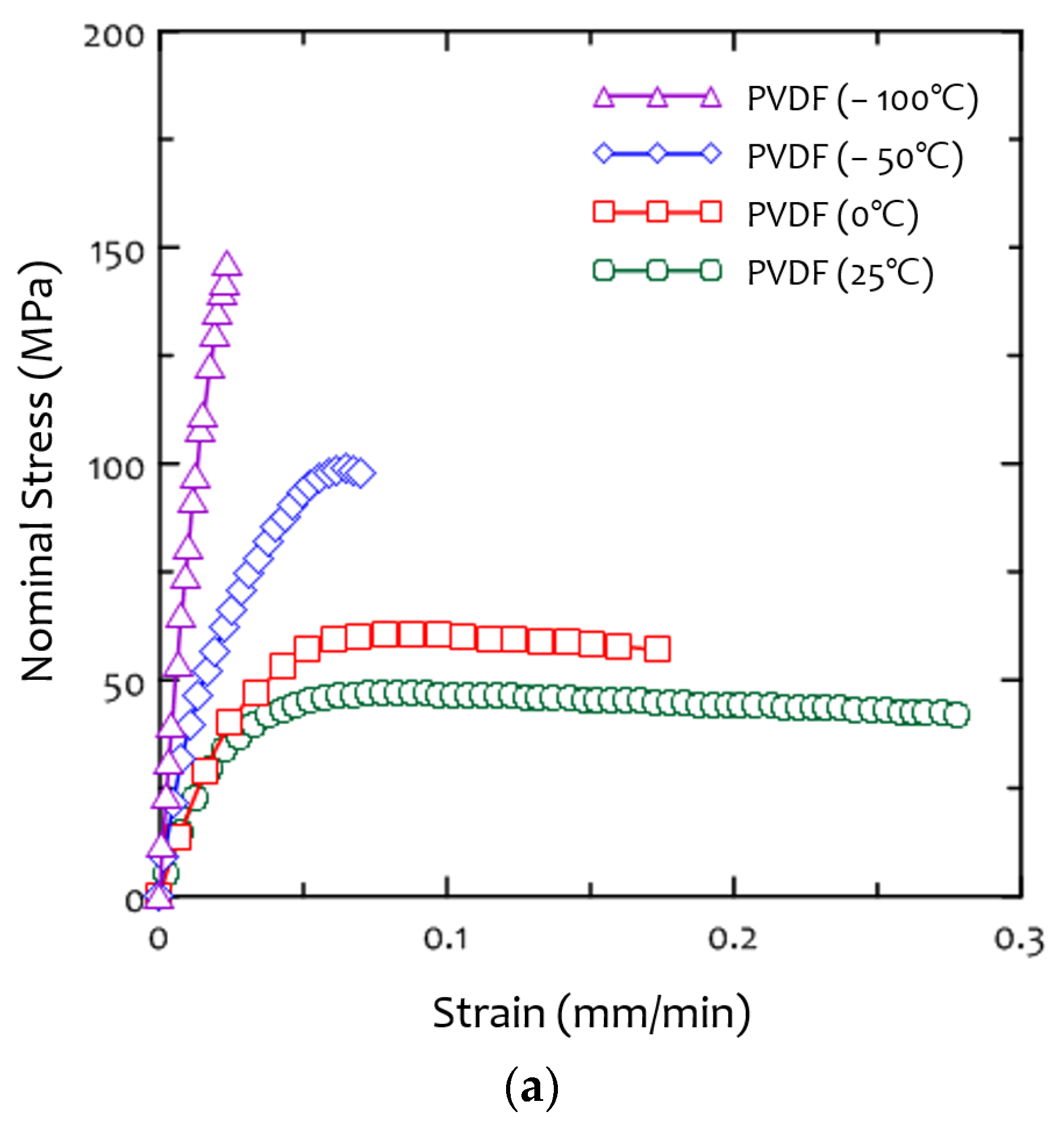

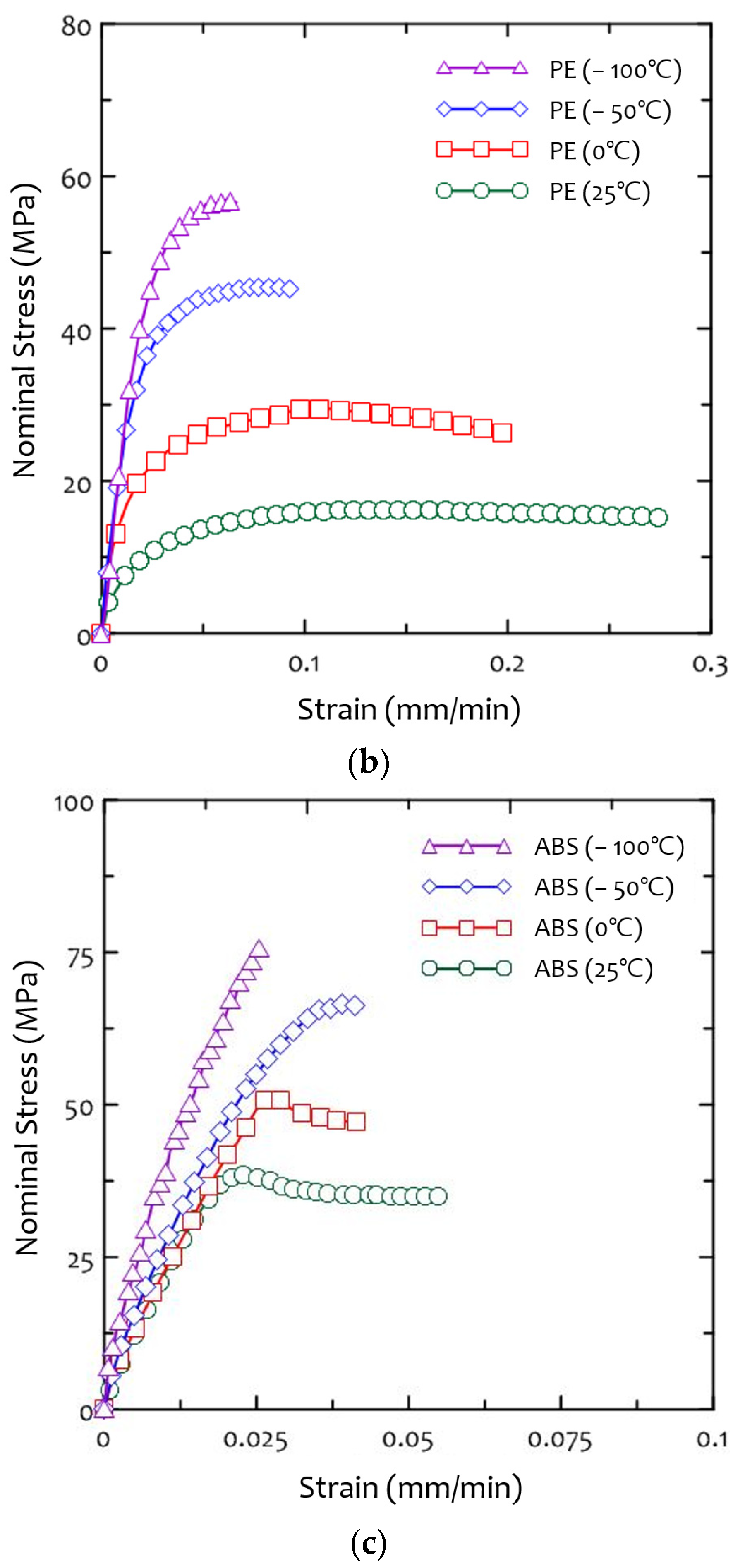

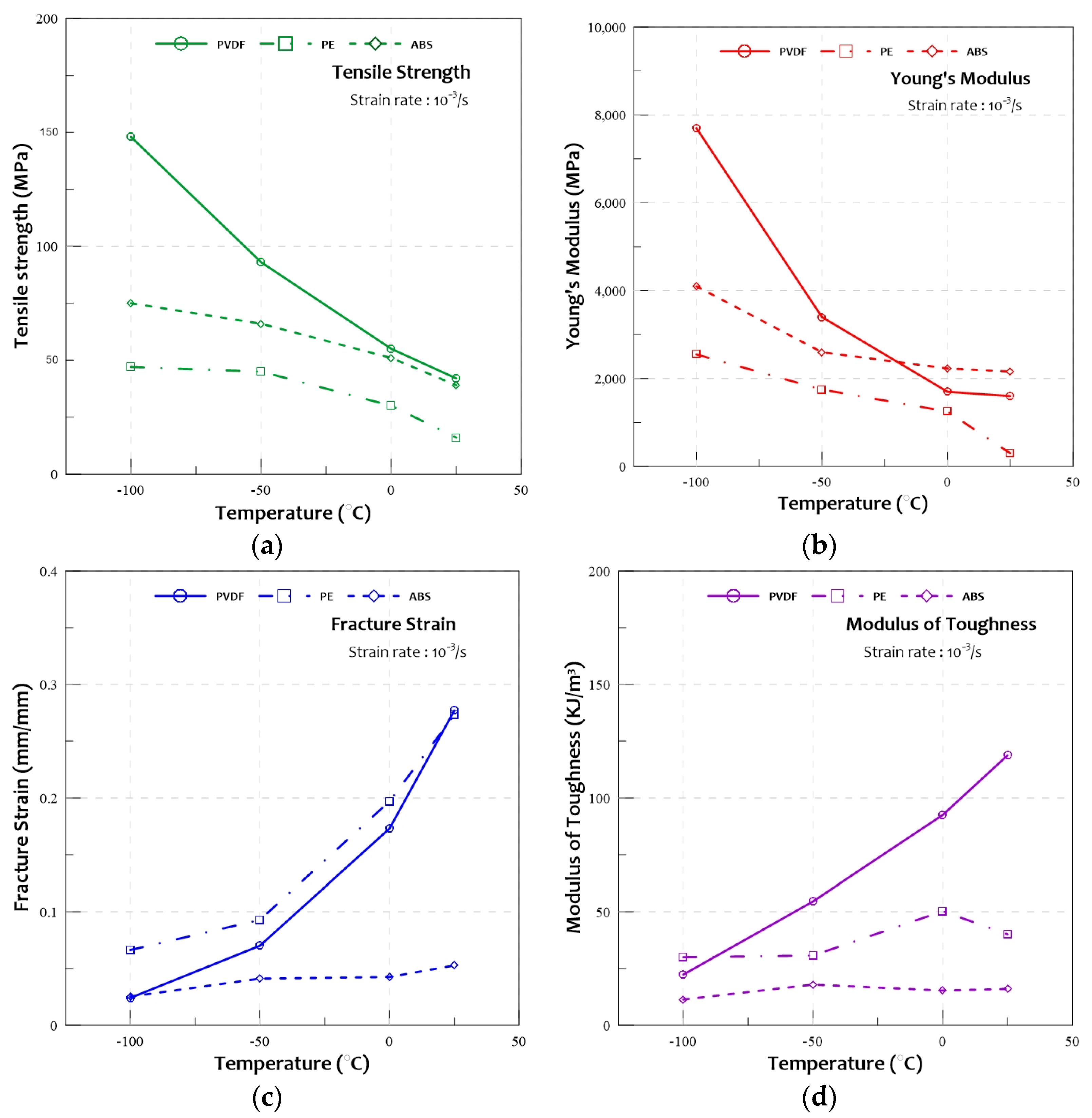

3.1. Effect of Temperature on Tensile Properties

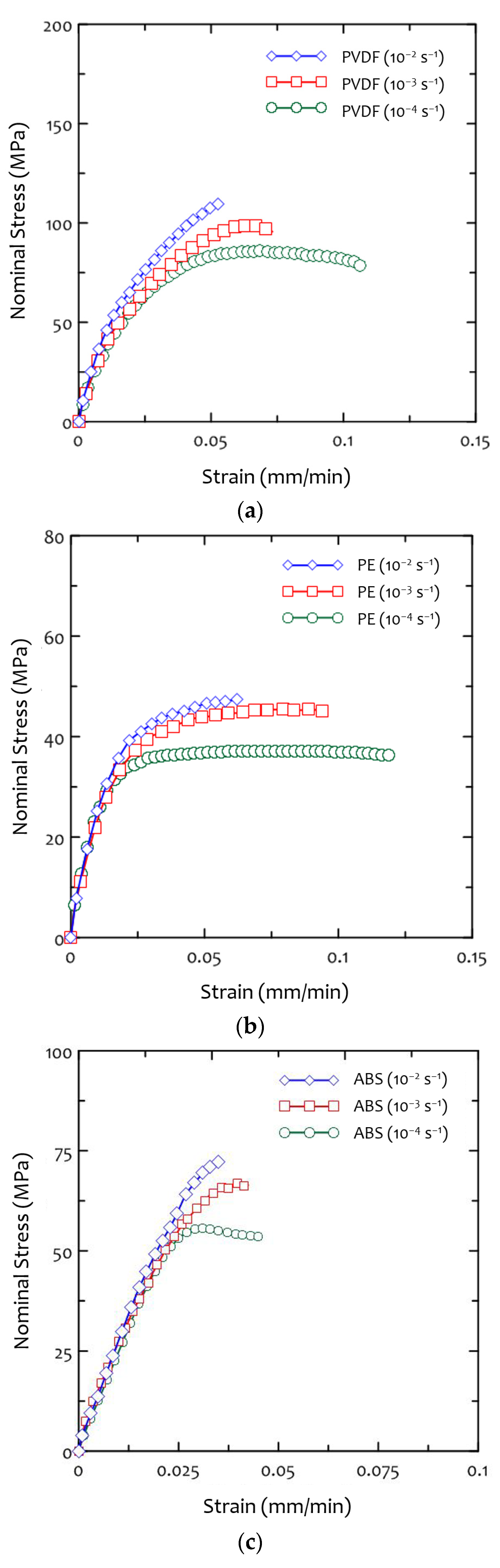

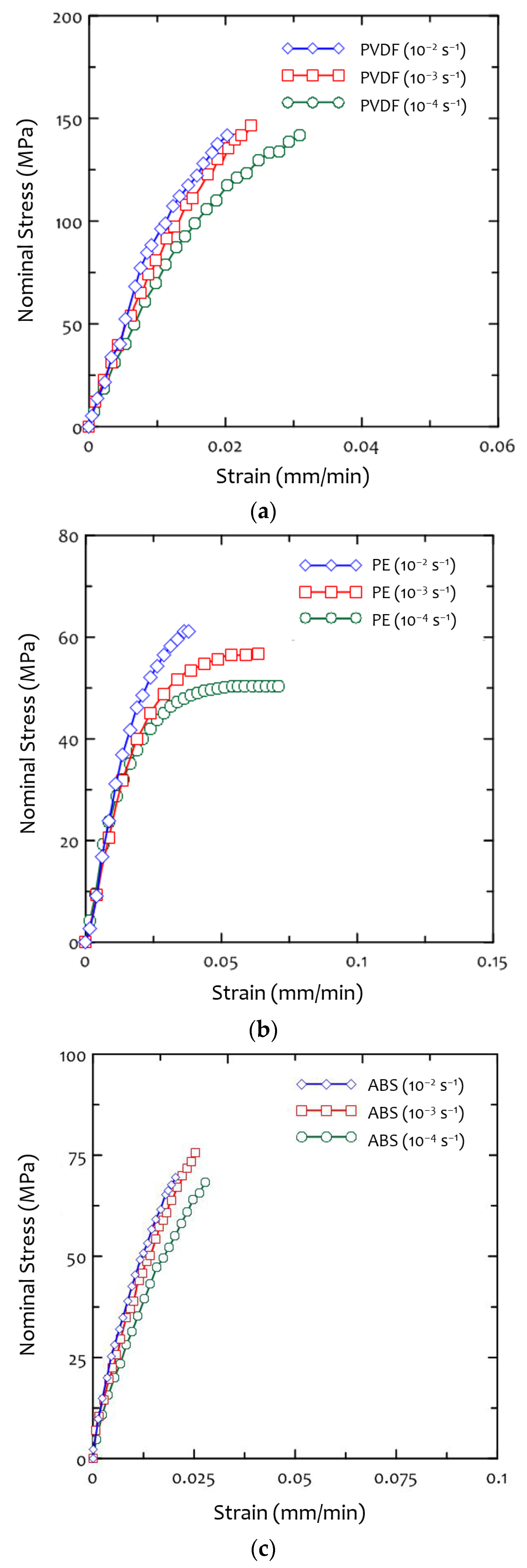

3.2. Effect of Strain Rate on Tensile Properties

3.3. Application under Low-Temperature Conditions in Ships and Offshore Structures

4. Conclusions

- As temperature decreased, the tensile strength and Young’s modulus of the tested polymers increased. However, the fracture strain and toughness markedly decreased in the cryogenic conditions. Hence, the effects of temperature variation on the durability of polymer materials should be investigated for industrial applications.

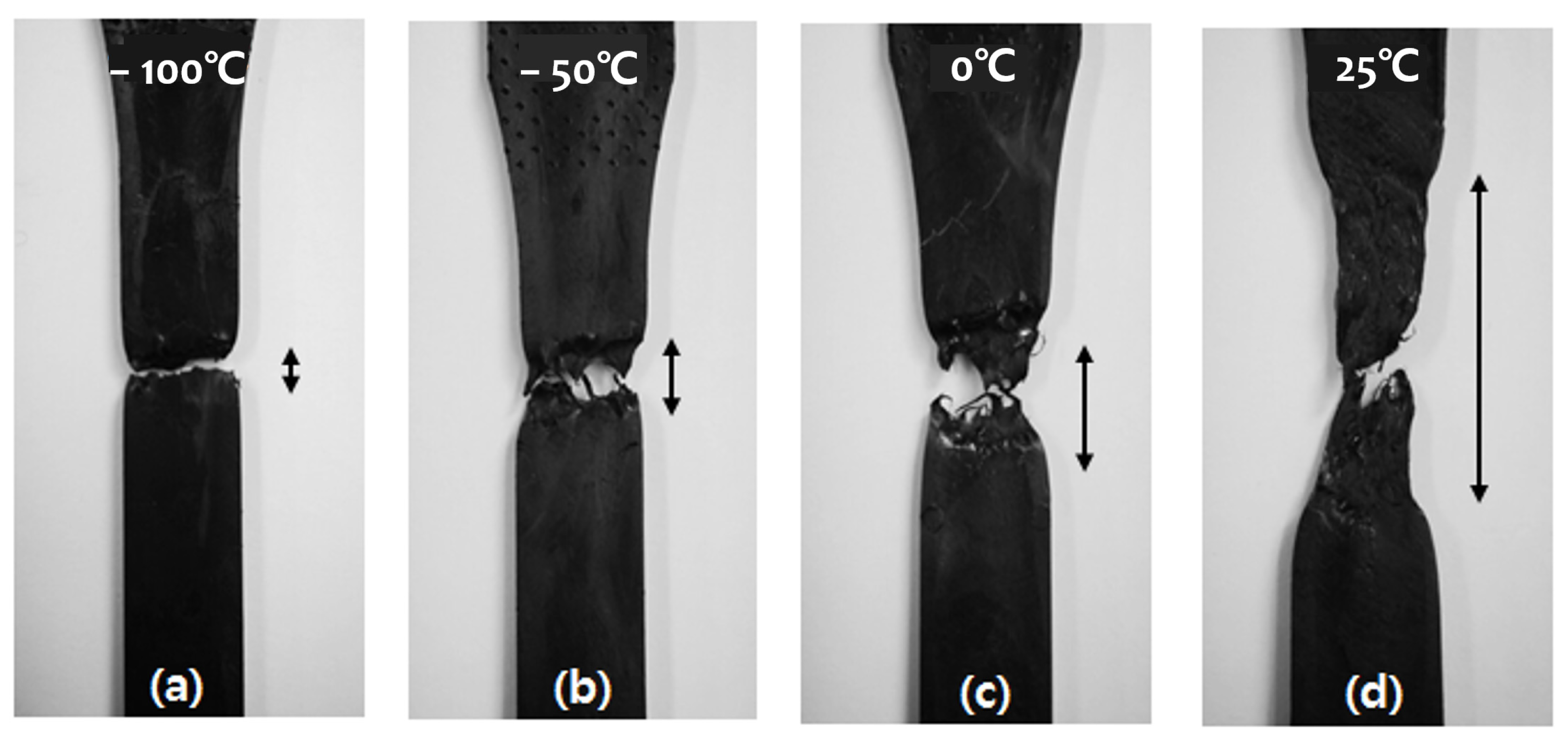

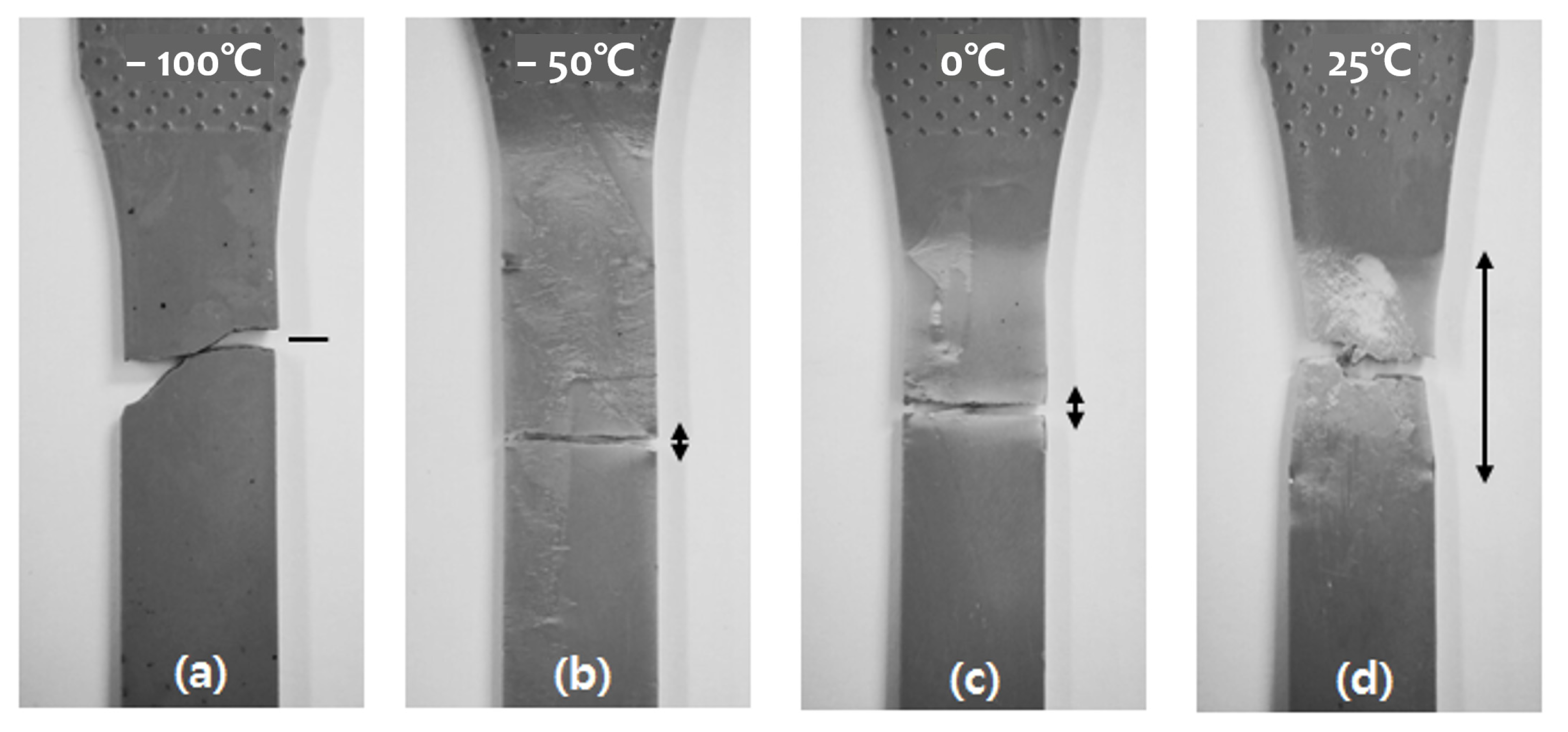

- The phase change from the ductile type to the brittleness type was observed by decreasing temperature. The fracture characteristics of PVDF and PE show the agglomerative and grainy forms and were considered to influence advanced tensile strength and elastic modulus.

- However, for ABS, the shape was featured by a flat plane surface in the fracture surface and took place with little or no preceding plastic deformation, except at room temperature. This means that fracture characteristics such as the ductility and malleability could be predicted by evaluating the plane macroscopic observation.

- At −50 °C, the tensile properties of the polymers indicate that the increase in tensile strength and decrease in elongation by fracture were due to an increased strain rate.

- At −100 °C, failure characteristics were not appreciably different from strain rates of 10–2 s–1 and 10–3 s–1. It is considered that the mechanical property of the polymers at −100 °C is influenced by low-temperature brittleness.

- When compared with mechanical properties, it was indicated that PVDF has superior capability, and each polymer shows different fracture surface in terms of ductility and brittleness. Hence, this type of polymer can be considered for application at a suitable temperature range.

- The tested polymers showed strain-rate- and temperature-dependent mechanical characteristics. The quantitative material properties tested at various temperatures and strain-rates can be used as material information for the finite element (FE) analysis and material parameters for the development of advanced constitutive models.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nie, W.Z.; Li, J.; Zhang, Y.F. Tensile properties of surface treated carbon fibre reinforced ABS/PA6 composites. Plast. Rubber Compos. 2010, 39, 16–20. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Tensile and thermomechanical properties of short carbon fiber reinforced polyamide 6 composites. Compos. Pt. B-Eng. 2013, 51, 270–275. [Google Scholar] [CrossRef]

- Molnár, S.; Rosenberger, S.; Gulyás, J.; Pukánszky, B. Structure and impact resistance of short carbon fiber reinforced polyamide 6 composites. J. Macromol. Sci. Part B-Phys. 1999, 38, 721–735. [Google Scholar] [CrossRef]

- Kim, W.; Argento, A.; Lee, E.; Flanigan, C.; Houston, D.; Harris, A.; Mielewski, D.F. High strain-rate behavior of natural fiber-reinforced polymer composites. J. Compos. Mater. 2011, 46, 1051–1065. [Google Scholar] [CrossRef]

- Laney, P. Use of Composite Pipe Materials in the Transportation of Natural Gas. Paper INEEL/EXT-0200992. 2002. [Google Scholar]

- Bai, J. Advanced Fibre-Reinforced Polymer Composites for Structural Applications; Woodhead Publishing: Oxford, UK, 2003. [Google Scholar]

- Ebert, C.; Hufenbach, W.; Langkamp, A.; Gude, M. Modelling of strain rate dependent deformation behavior of polypro-pylene. Polym. Test. 2011, 30, 183–187. [Google Scholar]

- Fang, Q.Z.; Wang, T.J.; Beom, H.G.; Zhao, H.P. Rate-dependent large deformation behavior of PC/ABS. Polymer 2009, 50, 296–304. [Google Scholar] [CrossRef]

- Reis, J.M.L.; Pacheco, L.J.; da Mattos, H.S. Influence of the temperature and strain rate on the tensile behavior of post-consumer recycled high-density polyethylene. Polym. Test. 2013, 32, 1576–1581. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Mechtcherine, V.; Tzounis, L. On the strain rate sensitivity of fused filament fabrication (FFF) processed PLA, ABS, PETG, PA6, and PP thermoplastic polymers. Polymers 2020, 12, 2924. [Google Scholar] [CrossRef]

- Nakai, K.; Yokoyama, T. Uniaxial compressive response and constitutive modeling of selected polymers over a wide range of strain rates. J. Dyn. Behav. Mater. 2015, 1, 15–27. [Google Scholar] [CrossRef]

- Varghese, J.; Murugan, R. Influence of orientation of extrusion direction and strain rate on the mechanical behaviour of extruded thermoplastic sheets. Mater. Today: Proc. 2018, 5, 24043–24049. [Google Scholar] [CrossRef]

- Farrokh, B.; Khan, A.S. A strain rate dependent yield criterion for isotropic polymers: Low to high rates of loading. Eur. J. Mech. A/Solids 2010, 29, 274–282. [Google Scholar] [CrossRef]

- Mulliken, A.D.; Boyce, M.C. Mechanics of the rate-dependent elastic-plastic deformation of glassy polymers from low to high strain rates. Int. J. Solids Struct. 2006, 43, 1331–1356. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Tensile behavior of high-density polyethylene including the effects of processing technique, thickness, temperature, and strain rate. Polymers 2020, 12, 1857. [Google Scholar] [CrossRef] [PubMed]

- Hund, J.; Granum, H.M.; Olufsen, S.N.; Holmstrom, P.H.; Johnsen, J.; Clausen, A.H. Impact of stress triaxiality, strain rate, and temperature on the mechanical response and morphology of PVDF. Polym. Test. 2022, 114, 107717. [Google Scholar] [CrossRef]

- Richeton, J.; Ahzi, S.; Vecchio, K.S.; Jiang, F.C.; Adharapurapu, R.R. Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: Characterization and modeling of the compressive yield stress. Int. J. Solids Struct. 2006, 43, 2318–2335. [Google Scholar] [CrossRef]

- Rae, P.J.; Brown, E.N. The properties of poly(tetrafluoroethylene) (PTFE) in tension. Polymer 2005, 46, 8128–8140. [Google Scholar] [CrossRef]

- Rae, P.J.; Dattelbaum, D.M. The properties of poly(tetrafluoroethylene) (PTFE) in compression. Polymer 2004, 45, 7615–7625. [Google Scholar] [CrossRef]

- Greig, J.M. Fracture Propagation in 250 mm and 315 mm Polyethylene Gas Pipes. 1985; British Gas Engineering Research Station Report No. E472. [Google Scholar]

- Zhuang, Z.; Guo, Y. Analysis of dynamic fracture mechanisms in gas pipelines. Eng. Fract. Mech. 1999, 64, 271–289. [Google Scholar] [CrossRef]

- Santos, R.M.; Pimenta, A.; Botelho, G.; Machado, A.V. Influence of the testing conditions on the efficiency and durability of stabilizers against ABS photo-oxidation. Polym. Test. 2013, 32, 78–85. [Google Scholar]

- Mun, H.; Kim, D. The optimum solution for the best performance of ABS. Polymer 2007, 31, 105–110. [Google Scholar]

- Tiganis, B.E.; Burn, L.S.; Davis, P.; Hill, A.J. Thermal degradation of acrylonitrile-butadiene-stryene (ABS) blends. Polym. Degrad. Stabil. 2002, 76, 425–434. [Google Scholar] [CrossRef]

- Laiarinandrasana, L.; Besson, J.; Lafarge, M.; Hochstetter, G. Temperature dependent mechanical behaviour of PVDF: Ex-periments and numerical modeling. Int. J. Plast. 2009, 25, 1301–1324. [Google Scholar] [CrossRef]

- Girard, D.; Castagnet, S.; Gacougnolle, J.L.; Hoschstetter, G. On the relevance of a notch creep test for the comprehension and prediction of slow crack growth in PVDF. Polym. Test. 2007, 26, 937–948. [Google Scholar] [CrossRef]

- Liu, F.; Hashim, L.A.; Liu, Y.; Abed, M.R.M.; Li, K. Progress in production and modification of PVDF membranes. J. Membr. Sci. 2011, 375, 1–27. [Google Scholar] [CrossRef]

- Chen, J.; Li, J.D.; Chen, C.X. Surface modification of polyvinylidene fluoride (PVDF) membranes by low-temperature plasma with grafting styrene. Plasma Sci. Technol. 2009, 11, 42–47. [Google Scholar]

- Gacougnolle, J.L.; Castagnet, S.; Werth, M. Post-mortem analysis of failure in polyvinylidene fluoride pipes tested under constant pressure in the slow crack growth regime. Eng. Fail. Anal. 2006, 13, 96–109. [Google Scholar] [CrossRef]

- Serban, D.A.; Weber, G.; Marsavina, L.; Vadim; Silberschmidt, V.; Hufenbach, W. Tensile properties of semi-crystalline thermoplastic polymers: Effects of temperature and strain rate. Polym. Test. 2013, 32, 413–425. [Google Scholar] [CrossRef]

| No. | Material | Temperature (°C) | Strain Rate (s−1) | UTM Speed (mm/min) |

|---|---|---|---|---|

| 1 | PE 100 | 25 | 10−3 | 3 |

| 2 | 0 | 10−3 | 3 | |

| 3 | −50 | 10−4 | 0.3 | |

| 4 | −50 | 10−3 | 3 | |

| 5 | −50 | 10−2 | 30 | |

| 6 | −100 | 10−4 | 0.3 | |

| 7 | −100 | 10−3 | 3 | |

| 8 | −100 | 10−2 | 30 | |

| 9 | PVDF | 25 | 10−3 | 3 |

| 10 | 0 | 10−3 | 3 | |

| 11 | −50 | 10−4 | 0.3 | |

| 12 | −50 | 10−3 | 3 | |

| 13 | −50 | 10−2 | 30 | |

| 14 | −100 | 10−4 | 0.3 | |

| 15 | −100 | 10−3 | 3 | |

| 16 | −100 | 10−2 | 30 | |

| 17 | ABS | 25 | 10−3 | 3 |

| 18 | 0 | 10−3 | 3 | |

| 19 | −50 | 10−4 | 0.3 | |

| 20 | −50 | 10−3 | 3 | |

| 21 | −50 | 10−2 | 30 | |

| 22 | −100 | 10−4 | 0.3 | |

| 23 | −100 | 10−3 | 3 | |

| 24 | −100 | 10−2 | 30 |

| Temp. (°C) | PVDF | PE | ABS | |||

|---|---|---|---|---|---|---|

| σT (MPa) | E (MPa) | σT (MPa) | E (MPa) | σT (MPa) | E (MPa) | |

| −100 | 148 (1.52) | 7700 (2.11) | 47 (1.92) | 2550 (2.86) | 75 (2.41) | 4100 (2.53) |

| −50 | 93 (1.38) | 3400 (1.82) | 45 (1.53) | 1750 (3.12) | 66 (1.89) | 2600 (1.45) |

| 0 | 55 (1.36) | 1700 (1.58) | 30 (1.62) | 1250 (2.52) | 51 (1.59) | 2230 (2.05) |

| 25 | 42 (1.25) | 1600 (1.55) | 16 (1.12) | 300 (2.21) | 39 (1.75) | 2160 (1.62) |

| Temp. (°C) | PVDF | PE | ABS | |||

|---|---|---|---|---|---|---|

| ut (MPa) | ut (MPa) | ut (MPa) | ||||

| −100 | 0.024 (1.94) | 22.30 (1.52) | 0.066 (1.62) | 30.00 (1.60) | 0.025 (2.55) | 11.35 (2.33) |

| −50 | 0.070 (1.34) | 54.54 (1.24) | 0.093 (1.42) | 30.72 (1.48) | 0.041 (1.43) | 17.92 (2.37) |

| 0 | 0.173 (1.62) | 92.52 (1.34) | 0.197 (1.34) | 50.24 (1.29) | 0.043 (1.35) | 15.30 (1.36) |

| 25 | 0.277 (1.22) | 118.8 (1.38) | 0.273 (1.32) | 40.08 (1.28) | 0.053 (1.30) | 16.02 (1.32) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; Kim, M.-S.; Jeon, H.-J.; Kim, J.-H.; Chun, K.W. Mechanical Performance of Polymer Materials for Low-Temperature Applications. Appl. Sci. 2022, 12, 12251. https://doi.org/10.3390/app122312251

Kim Y, Kim M-S, Jeon H-J, Kim J-H, Chun KW. Mechanical Performance of Polymer Materials for Low-Temperature Applications. Applied Sciences. 2022; 12(23):12251. https://doi.org/10.3390/app122312251

Chicago/Turabian StyleKim, Yongjin, Myung-Sung Kim, Hyeon-Jong Jeon, Jeong-Hyeon Kim, and Kang Woo Chun. 2022. "Mechanical Performance of Polymer Materials for Low-Temperature Applications" Applied Sciences 12, no. 23: 12251. https://doi.org/10.3390/app122312251

APA StyleKim, Y., Kim, M.-S., Jeon, H.-J., Kim, J.-H., & Chun, K. W. (2022). Mechanical Performance of Polymer Materials for Low-Temperature Applications. Applied Sciences, 12(23), 12251. https://doi.org/10.3390/app122312251