Mechanical Properties and Engineering Applications of Special Soils—Dynamic Shear Modulus and Damping of MICP-Treated Calcareous Sand at Low Strains

Abstract

1. Introduction

2. Materials and Methods

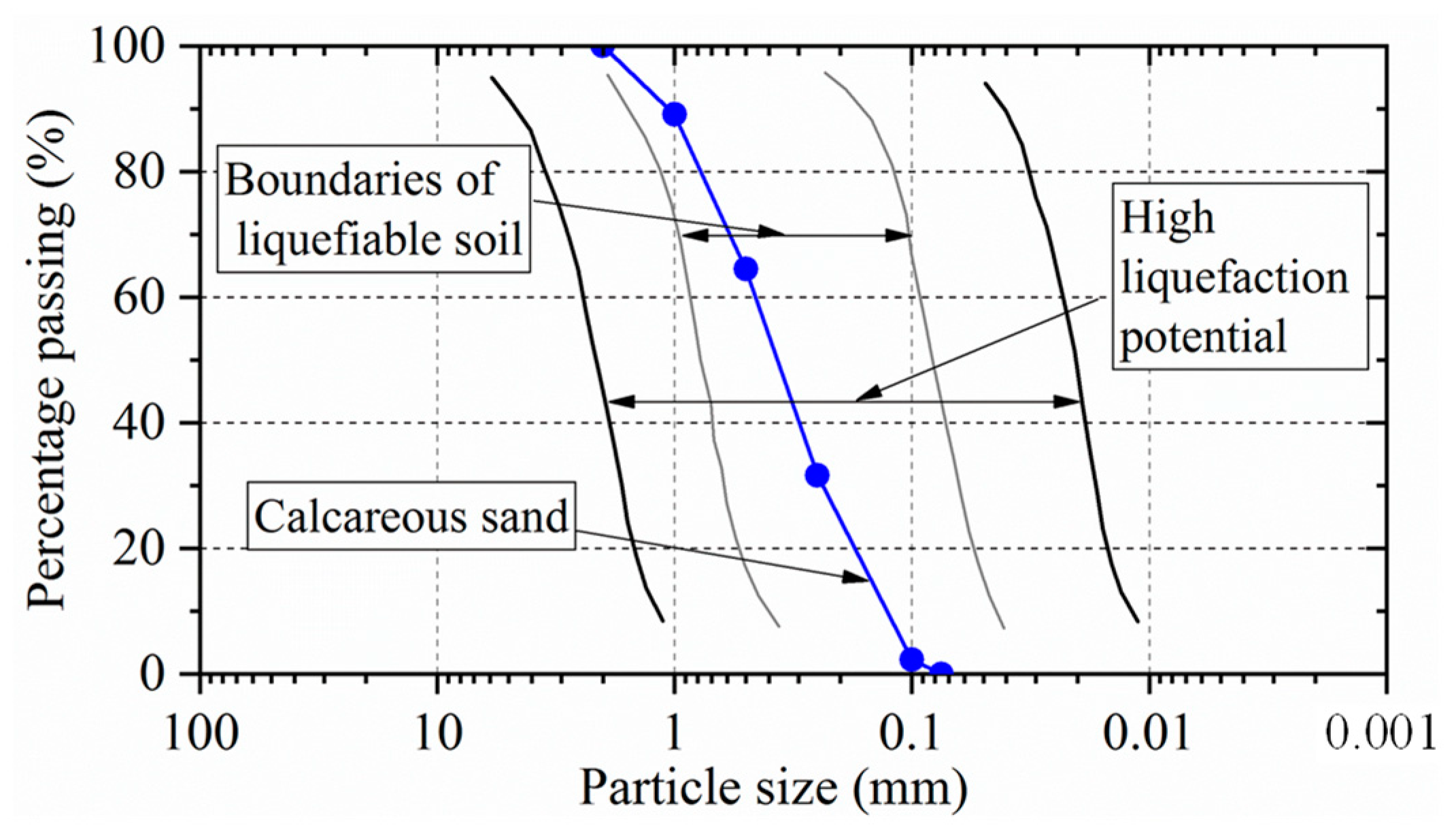

2.1. Material Properties

2.2. MICP Treatment Procedure

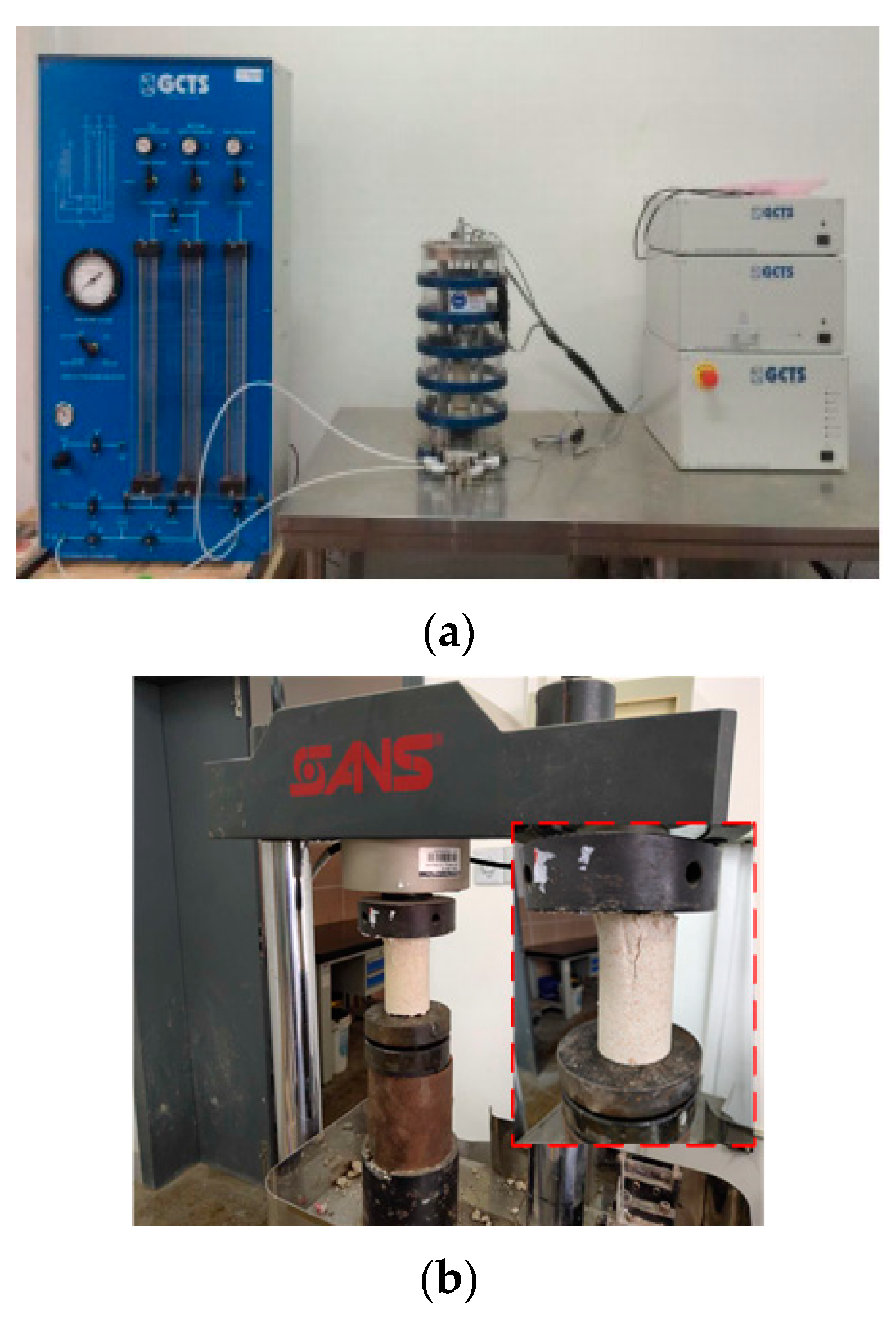

2.3. Equipment and Testing Procedure

2.4. Experimental Program

3. Experimental Results

3.1. Dynamic Shear Modulus of MICP-Treated Calcareous Sands

3.2. Initial Shear Modulus, G0

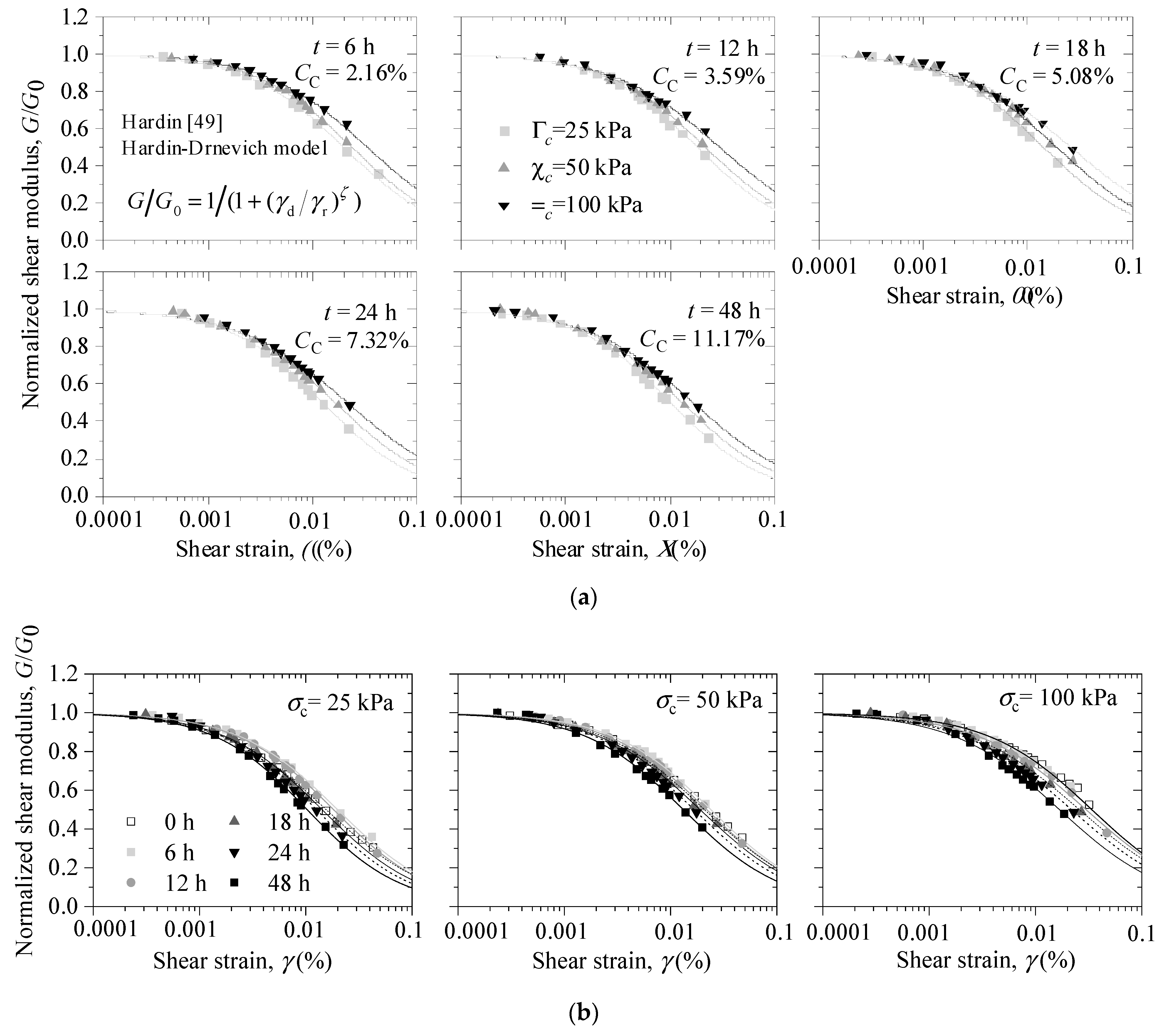

3.3. Degradation Characteristics of Normalized Dynamic Shear Modulus

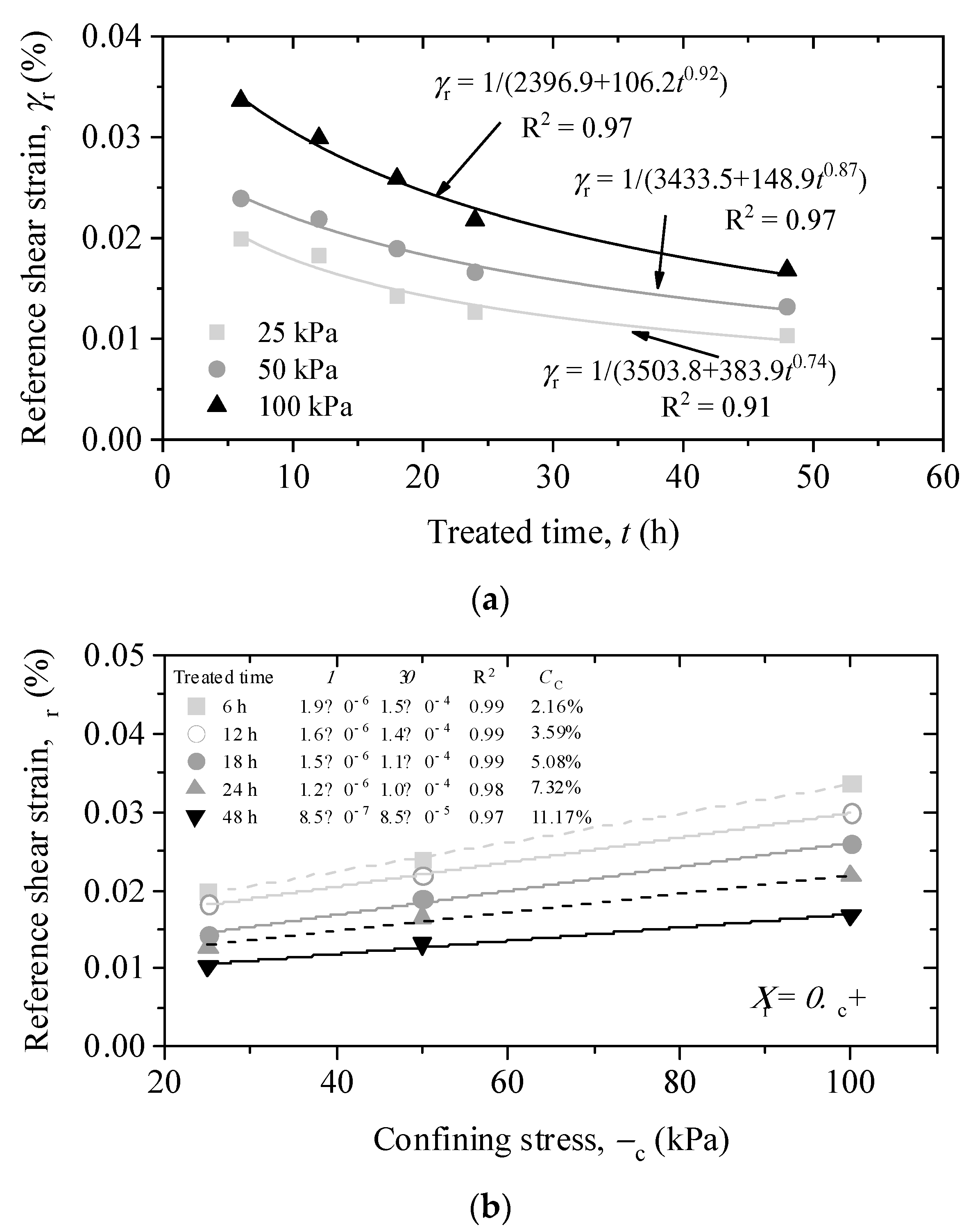

3.4. Correlation between γr and t, σc

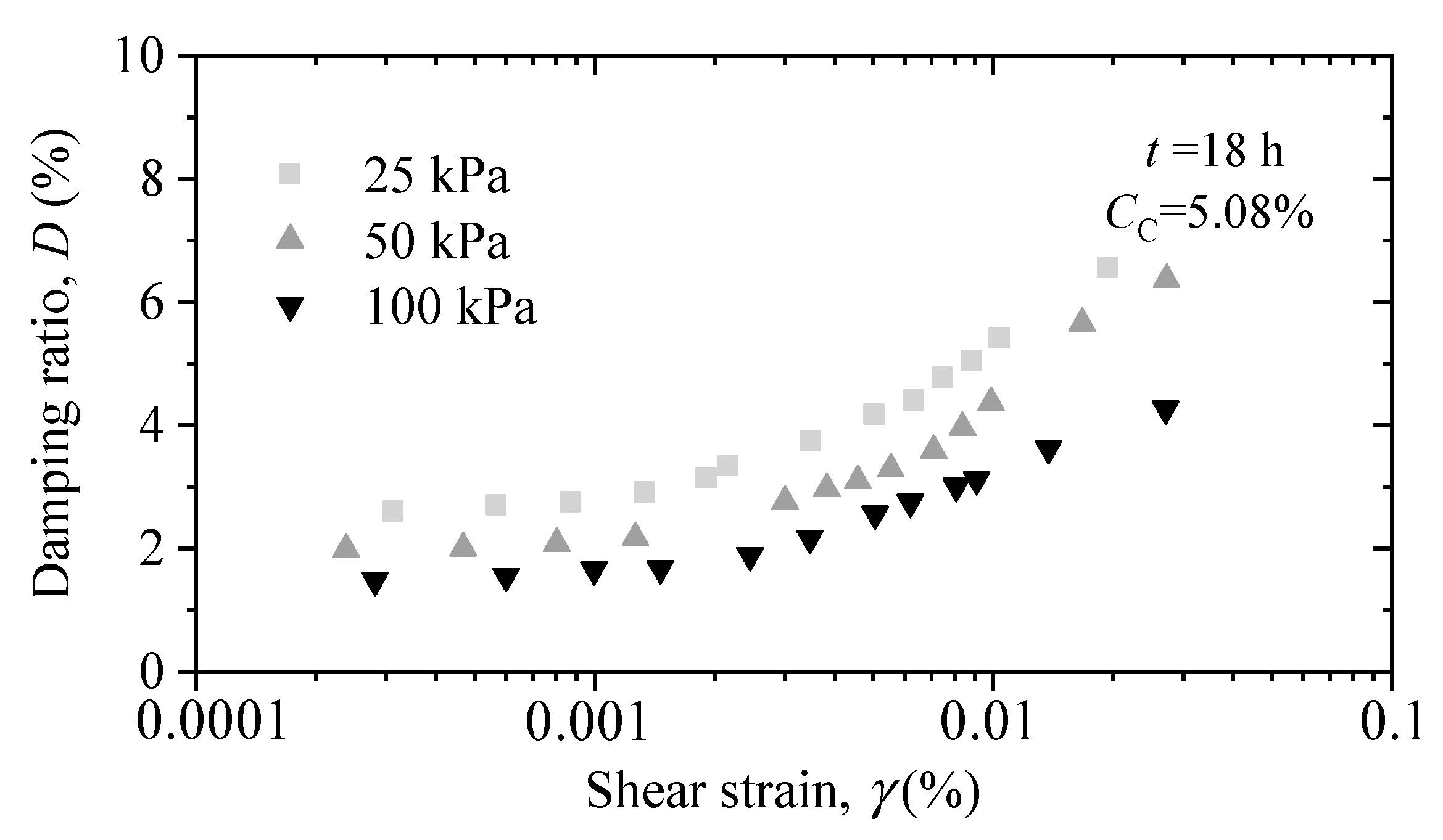

3.5. Dynamic Shear Modulus of MICP-Treated Calcareous Sands

4. Discussion

5. Conclusions

- The initial dynamic shear modulus and the unconfined compressive strength rose significantly after MICP treatment, indicating that MICP treatment improves the dynamic properties and strength of calcareous sand. The treated calcareous sand sample showed a higher strain sensitivity (strain-dependent) than that of untreated sands, and the strain sensitivity increased with the increase in treatment duration, demonstrating that the brittleness of the MICP-treated calcareous sands grew during treatment. The Hardin–Drnevich model can describe the G/G0 attenuation law of MICP-treated calcareous sand. The shear modulus of the MICP-treated sand eventually approached that of the untreated calcareous sand when the shear strain was approximately 0.03%.

- The difference between the shear modulus of the treated sand and the at of untreated sand became more evident as the confining stress increased because of the reduced pore volume of samples and the increase in the contact between the particles. The MICP-cemented calcareous sand improved significantly in the initial dynamic shear modulus G0. The relationship between G0 and the confining pressure σc, as well as between G0 and the unconfined compressive strength qu, can be described by a power function.

- The variation in the reference shear strain γr under various confining pressures dropped gradually with increasing treatment time, indicating that the influence of the confining pressure on the attenuation curve of the dynamic shear modulus of the MICP-treated calcareous sand decreased during the treatment process. The power function and the linear function can describe the relationship between γr, t, and σc. The confining stress substantially impacted the response of the damping ratio in the treated sample. The threshold calcium carbonate content was about 7%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, P.; Liu, H.L.; Xiao, Y.; Stuedlein, A.W.; Evans, T.M. Liquefaction resistance of bio-cemented calcareous sand. Soil Dyn. Earthq. Eng. 2018, 107, 9–19. [Google Scholar] [CrossRef]

- Giretti, D.; Fioravante, V.; Been, K.; Dickenson, S.; Mesri, G.; Kane, T. Mechanical properties of a carbonate sand from a dredged hydraulic fill. Geotechnique 2020, 70, 937–942. [Google Scholar] [CrossRef]

- Sasanakul, I.; Gassman, S.; Ruttithivaphanich, P.; Dejphumee, S. Characterization of shear wave velocity profiles for South Carolina Coastal Plain. AIMS Geosci. 2019, 5, 303–324. [Google Scholar] [CrossRef]

- Sharma, S.S.; Ismail, M.A. Monotonic and Cyclic Behavior of Two Calcareous Soils of Different Origins. J Geotech. Geoenviron. Eng. 2006, 132, 1581–1591. [Google Scholar] [CrossRef]

- Javdanian, H.; Jafarian, Y. Dynamic shear stiffness and damping ratio of marine calcareous and siliceous sands. Geo Mar. Lett. 2018, 38, 315–322. [Google Scholar] [CrossRef]

- Shahnazari, H.; Rezvani, R. Effective parameters for the particle breakage of calcareous sands: An experimental study. Eng. Geol. 2013, 159, 98–105. [Google Scholar] [CrossRef]

- Qin, Z.G.; Yuan, X.M.; Cao, Z.Z.; M, H.G. Applicability and quality evaluation of foundation treatment method for backfilled coral sand site. J. Nat. Disasters 2021, 1, 78–88. (In Chinese) [Google Scholar]

- Whiffin, V.S.; van Paassen, L.; Harkes, M.P. Microbial Carbonate Precipitation as a Soil Improvement Technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Ivanov, V.; Chu, J. Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev. Environ. Sci. Bio. Technol. 2008, 7, 139–153. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B.; Duan, H. Modification of nanoparticles for the strength enhancing of cement-stabilized dredged sludge. J. Rock Mech. Geotech. Eng. 2021, 13, 694–704. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B. Strength properties of cement-stabilized dredged sludge incorporating nano-SiO2 and straw fiber. Int. J. Geomech. 2021, 21, 04021119. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B. Stabilization of Dredged Sediment Using Activated Binary Cement Incorporating Nanoparticles. J. Mater. Civ. Eng. 2022, 34, 04021381. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N.; Sharma, M. Micro-mechanical performance evaluation of expansive soil biotreated with indigenous bacteria using MICP method. Sci. Rep. 2021, 11, 10324. [Google Scholar] [CrossRef] [PubMed]

- Rajasekar, A.; Moy, C.K.S.; Wilkinson, S. MICP and advances towards eco-friendly and economical applications[C]//IOP Conference Series: Earth and Environmental Science. IOP Publ. 2017, 78, 012016. [Google Scholar]

- Xiao, Y.; Zhang, Z.; Stuedlein, A.W.; Evans, T.M. Liquefaction Modeling for Biocemented Calcareous Sand. J. Geotech. Geoenviron. Eng. 2021, 147, 04021149. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, Y.; Wang, S.; Evans, T.M.; Stuedlein, A.W.; Chu, J.; Zhao, C.; Wu, H.; Liu, H. Homogeneity and mechanical behaviors of sands improved by a temperature-controlled one-phase MICP method. Acta Geotech. 2021, 16, 1417–1427. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Mujah, D. Influence of Key Environmental Conditions on Microbially Induced Cementation for Soil Stabilization. J. Geotech. Geoenviron. Eng. 2017, 143, 1–11. [Google Scholar] [CrossRef]

- DeJong, J.T.; Fritzges, M.B.; Nüsslein, K. Microbially Induced Cementation to Control Sand Response to Undrained Shear. J. Geotech. Geoenviron. Eng. 2006, 132, 1381–1392. [Google Scholar] [CrossRef]

- Feng, K.; Montoya, B.M. Influence of confinement and cementation level on the behavior of microbial-induced calcite precipitated Sands under monotonic drained loading. J. Geotech. Geoenviron. Eng. 2015, 2, 04015057. [Google Scholar] [CrossRef]

- Minto, J.M.; Lunn, R.J.; El Mountassir, G. Development of a Reactive Transport Model for Field-Scale Simulation of Microbially Induced Carbonate Precipitation. Water Resour. Res. 2019, 55, 7229–7245. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, N.; Jin, Y.; Li, Q.; Xu, J. Application of microbially induced calcium carbonate precipitation (MICP) in sand embankments for scouring/erosion control. Mar. Georesources Geotechnol. 2020, 39, 1459–1471. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Liu, H.; Zhang, Z.; Ding, X. Performance evaluation of a MICP-treated calcareous sandy foundation using shake table tests. Soil Dyn. Earthq. Eng. 2019, 129, 105959. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.; Cord-Ruwisch, R. Bio-cementation of sandy soil using microbially induced carbonate precipitation for marine environments. Geotechnique 2014, 64, 1010–1013. [Google Scholar] [CrossRef]

- Lin, H.; Suleiman, M.T.; Brown, D.G.; Kavazanjian, E. Mechanical behavior of sands treated by microbially induced carbonate precipitation. J. Geotech. Geoenviron. Eng. 2016, 142, 04015066. [Google Scholar] [CrossRef]

- Paassen, L.A.V. Biogrout, Ground Improvement by Microbial Induced Carbonate Precipitation; Delft University of Technology The Nethelands: Delft, The Netherlands, 2009. [Google Scholar]

- Fioravante, V.; Giretti, D.; Jamiolkowski, M. Small strain stiffness of carbonate Kenya Sand. Eng. Geol. 2013, 161, 65–80. [Google Scholar] [CrossRef]

- Giang, P.H.H.; Van Impe, P.O.; Van Impe, W.F.; Menge, P.; Haegeman, W. Small-strain shear modulus of calcareous sand and its dependence on particle characteristics and gradation. Soil Dyn. Earthq. Eng. 2017, 100, 371–379. [Google Scholar] [CrossRef]

- Jafarian, Y.; Javdanian, H.; Haddad, A. Dynamic properties of calcareous and siliceous sands under isotropic and anisotropic stress conditions. Soils Found. 2018, 58, 172–184. [Google Scholar] [CrossRef]

- He, H.; Li, W.; Senetakis, K. Small strain dynamic behavior of two types of carbonate sands. Soils Found. 2019, 59, 571–585. [Google Scholar] [CrossRef]

- Shi, J.; Haegeman, W.; Cnudde, V. Anisotropic small-strain stiffness of calcareous sand affected by sample preparation, particle characteristic and gradation. Géotechnique 2021, 71, 305–319. [Google Scholar] [CrossRef]

- Shi, J.; Haegeman, W.; Xu, T. Effect of non-plastic fines on the anisotropic small strain stiffness of a calcareous sand. Soil Dyn. Earthq. Eng. 2020, 139, 106381. [Google Scholar] [CrossRef]

- Morsy, A.M.; Salem, M.A.; Elmamlouk, H.H. Evaluation of dynamic properties of calcareous sands in Egypt at small and medium shear strain ranges. Soil Dyn. Earthq. Eng. 2018, 116, 692–708. [Google Scholar] [CrossRef]

- Hassanlourad, M.; Salehzadeh, H.; Shahnazari, H. Dilation and particle breakage effects on the shear strength of calcareous sands based on energy aspects. Int. J. Civ. Eng. 2008, 6, 108–119. [Google Scholar]

- Khalil, A.; Khan, Z.H.; Attom, M.; El Emam, M.; Fattah, K. Dynamic Properties of Calcareous Sands from Urban Areas of Abu Dhabi. Appl. Sci. 2022, 12, 3325. [Google Scholar] [CrossRef]

- Liang, K.; He, Y.; Chen, G.X. Experimental study of dynamic shear modulus and damping ratio characteristics of coral sand from Nansha Islands. Rock Soil Mech. 2020, 1, 23–38. (In Chinese) [Google Scholar]

- Jafarian, Y.; Javdanian, H. Small-strain dynamic properties of siliceous-carbonate sand under stress anisotropy. Soil Dyn. Earthq. Eng. 2020, 131, 106045. [Google Scholar] [CrossRef]

- Shi, J.; Xiao, Y.; Hu, J.; Wu, H.; Liu, H.; Haegeman, W. Small-strain shear modulus of calcareous sand under anisotropic consolidation. Can. Geotech. J. 2022, 59, 878–888. [Google Scholar] [CrossRef]

- Lang, L.; Li, F.; Chen, B. Small-strain dynamic properties of silty clay stabilized by cement and fly ash. Constr. Build. Mater. 2019, 237, 117646. [Google Scholar] [CrossRef]

- Subramaniam, P.; Banerjee, S.; Ku, T. Shear Modulus and Damping Ratio Model for Cement Treated Clay. Int. J. Géoméch. 2019, 19, 06019010. [Google Scholar] [CrossRef]

- Feng, K.; Montoya, B.M. Drained Shear Strength of MICP Sand at Varying Cementation Levels. In Proceedings of the IFCEE 2015, San Antonio, TX, USA, 17–21 March 2015; pp. 2242–2251. [Google Scholar]

- Simatupang, M.; Okamura, M.; Hayashi, K.; Yasuhara, H. Small-strain shear modulus and liquefaction resistance of sand with carbonate precipitation. Soil Dyn. Earthq. Eng. 2018, 115, 710–718. [Google Scholar] [CrossRef]

- Acar, Y.B.; El-Tahir, E.T.A. Low strain dynamic properties of artificially cemented sand. J. Geotech. Eng. 1986, 112, 1001–1015. [Google Scholar] [CrossRef]

- Saxena, S.K.; Avramidis, A.S.; Reddy, K. Dynamic moduli and damping ratios for cemented sands at low strains. Can. Geotech. J. 1988, 25, 353–368. [Google Scholar] [CrossRef]

- Lin, B.; Zhang, F.; Feng, D.; Tang, K.; Feng, X. Dynamic shear modulus and damping ratio of thawed saturated clay under long-term cyclic loading. Cold Reg. Sci. Technol. 2018, 145, 93–105. [Google Scholar] [CrossRef]

- Gao, H.; Xia, S.; Chen, F.; Stuedlein, A.W.; Li, X.; Wang, Z.; Shen, Z.; Chen, X. Dynamic shear modulus and damping of cemented and uncemented lightweight expanded clay aggregate (LECA) at low strains. Soil Dyn. Earthq. Eng. 2021, 142, 106555. [Google Scholar] [CrossRef]

- Tsuchida, H. Prediction and remedial measures against liquefaction of sandy soil. In Annual Seminar of Port and Harbour Research Institute; International Association of Ports and Harbors: Tokyo, Japan, 1970; Volume 3, pp. 1–33. (In Japanese) [Google Scholar]

- Hardin, B.O.; Drnevich, V.P. Shear Modulus and Damping in Soils: Design Equations and Curves. J. Soil Mech. Found. Div. 1972, 98, 667–692. [Google Scholar] [CrossRef]

- Consoli, N.C.; da Fonseca, A.V.; Cruz, R.C.; Heineck, K.S. Fundamental Parameters for the Stiffness and Strength Control of Artificially Cemented Sand. J. Geotech. Geoenviron. Eng. 2009, 135, 1347–1353. [Google Scholar] [CrossRef]

- Porcino, D.; Ghionna, V.N.; Granata, R.; Marcianò, V. Laboratory determination of mechanical and hydraulic properties of chemically grouted sands. Geomech. Geoengin. 2016, 11, 164–175. [Google Scholar] [CrossRef]

- Liu, Q.F.; Zhuang, H.Y.; Wu, Q.; Zhao, K.; Chen, G.X. Experimental study on dynamic modulus and damping ratio of rubber-sand mixtures over a wide strain range. J. Earthq. Tsunami 2022, 16, 2140006. [Google Scholar] [CrossRef]

- Hardin, B.O.; Drnevich, V.P. Shear Modulus and Damping in Soils: Measurement and Parameter Effects (Terzaghi Leture). J. Soil Mech. Found. Div. 1972, 98, 603–624. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Mei, G.X.; Yu, X.B. Dynamic Shear Modulus and Damping Ratio of Waste Granular Rubber and Cement Soil Mixtures. Adv. Mater. Res. 2011, 243-249, 2091–2094. [Google Scholar] [CrossRef]

- Delfosse-ribay, E.; Djeran-maigre, I.; Cabrillac, R.; Gouvenot, D. Shear modulus and damping ratio of grouted sand. Soil Dyn. Earthq. Eng. 2004, 24, 461–471. [Google Scholar] [CrossRef]

- San, P.A.; Lee, M.; Graddy, C.; Kolbus, C.M.; Khan, M.; Zamani, A. Meter-scale biocementation experiments to advance process control and reduce impacts: Examining spatial control, ammonium by-product removal, and chemical reductions. J. Geotech. Geoenviron. Eng. 2020, 146, 1–14. [Google Scholar]

- Cheng, L.; Shahin, M.A.; Cord-Ruwisch, R. Soil stabilization by microbial-induced calcite precipitation (MICP). In Proceedings of the Investigation Into Some Physical and Environmental Aspects, 7th International Congress on Environmental Geotechnics: ICEG 2014. Barton: Engineers Australia, Melbourne, Australia, 10–14 November 2014. [Google Scholar]

- Chu, J.; Ivanov, V.; Naeimi, M. Optimization of calcium-based bioclogging and biocementation of sand. Acta Geotech. 2014, 9, 277–285. [Google Scholar] [CrossRef]

- Choi, S.G.; Chang, I.; Lee, M.; Lee, J.H.; Han, J.T.; Kwon, T.H. Review on geotechnical engineering properties of sands treated by microbially induced calcium carbonate precipitation (MICP) and biopolymers. Constr. Build. Mater. 2020, 246, 118415. [Google Scholar] [CrossRef]

| Sand | D50 (mm) | D10 (mm) | Cu | Cc | Gs | emin | emax |

|---|---|---|---|---|---|---|---|

| Calcareous sand | 0.38 | 0.13 | 3.55 | 0.97 | 2.73 | 1.02 | 1.44 |

| Reagent | Concentration |

|---|---|

| Yeast extract | 20 g/L |

| NH4Cl | 10 g/L |

| MnCl2·H2O | 12 mg/L |

| NiCl2·6H2O | 24 mg/L |

| Distilled water | 1000 g/L |

| 1 mol/L NaOH | pH value of approximately 9 |

| Group | Case | Test | Treatment Time (Hours) | Effective Confining Stress σc (kPa) | Dr (%) | m (g) | e0 | Δm (g) | CC (%) |

|---|---|---|---|---|---|---|---|---|---|

| Group UN | UN1 | RCT | / | 25 | 41.3 | 236.4 | 1.27 | / | / |

| UN2 | RCT | / | 50 | 39.2 | 235.5 | 1.28 | / | / | |

| UN3 | RCT | / | 100 | 40.5 | 236.0 | 1.27 | / | / | |

| Group M-A | M11 | RCT | 6 | 25 | 40.1 | 235.9 | 1.27 | 5.28 | 2.24 |

| M12 | RCT | 6 | 50 | 38.6 | 235.2 | 1.28 | 5.02 | 2.13 | |

| M13 | RCT | 6 | 100 | 42.3 | 236.8 | 1.26 | 4.98 | 2.10 | |

| M21 | RCT | 12 | 25 | 39.5 | 235.6 | 1.27 | 8.56 | 3.63 | |

| M22 | RCT | 12 | 50 | 40.9 | 236.2 | 1.27 | 8.67 | 3.67 | |

| M23 | RCT | 12 | 100 | 41.1 | 236.3 | 1.27 | 8.21 | 3.47 | |

| M31 | RCT | 18 | 25 | 39.5 | 235.6 | 1.27 | 11.42 | 4.85 | |

| M32 | RCT | 18 | 50 | 39.9 | 235.8 | 1.27 | 12.61 | 5.35 | |

| M33 | RCT | 18 | 100 | 40.2 | 235.9 | 1.27 | 11.89 | 5.04 | |

| M41 | RCT | 24 | 25 | 41.8 | 236.6 | 1.26 | 17.67 | 7.47 | |

| M42 | RCT | 24 | 50 | 39.8 | 235.7 | 1.27 | 16.93 | 7.18 | |

| M43 | RCT | 24 | 100 | 40.8 | 236.2 | 1.27 | 17.24 | 7.30 | |

| M51 | RCT | 48 | 25 | 40.2 | 235.9 | 1.27 | 25.24 | 10.70 | |

| M52 | RCT | 48 | 50 | 37.9 | 234.9 | 1.28 | 26.96 | 11.48 | |

| M53 | RCT | 48 | 100 | 39.4 | 235.5 | 1.27 | 26.68 | 11.33 | |

| Group M-B | M1 | UCT | 6 | / | 42.1 | 236.7 | 1.26 | 5.98 | 2.53 |

| M2 | UCT | 12 | / | 40.8 | 236.2 | 1.27 | 8.65 | 3.66 | |

| M3 | UCT | 18 | / | 42.5 | 236.9 | 1.26 | 13.54 | 5.72 | |

| M4 | UCT | 24 | / | 41.1 | 236.3 | 1.27 | 17.65 | 7.47 | |

| M5 | UCT | 48 | / | 39.5 | 235.6 | 1.27 | 27.16 | 11.53 |

| Treatment Time, t (h) | Confining Stress, σc | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 25 kPa | 50 kPa | 100 kPa | |||||||

| ζ | γr/% | R2 | ζ | γr/% | R2 | ζ | γr/% | R2 | |

| 6 | 0.93 | 0.01989 | 0.997 | 0.93 | 0.02389 | 0.997 | 0.88 | 0.03362 | 0.991 |

| 12 | 0.95 | 0.01844 | 0.997 | 0.92 | 0.02186 | 0.996 | 0.84 | 0.02990 | 0.984 |

| 18 | 0.94 | 0.01423 | 0.996 | 0.90 | 0.01893 | 0.998 | 0.83 | 0.02590 | 0.998 |

| 24 | 0.97 | 0.01264 | 0.992 | 0.92 | 0.01660 | 0.990 | 0.84 | 0.02180 | 0.988 |

| 48 | 0.99 | 0.01029 | 0.997 | 0.93 | 0.01317 | 0.995 | 0.87 | 0.01679 | 0.993 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Guo, J.; Chen, Y.; Han, Y.; Yi, R.; Gao, H.; Liu, L.; Liu, H.; Shen, Z. Mechanical Properties and Engineering Applications of Special Soils—Dynamic Shear Modulus and Damping of MICP-Treated Calcareous Sand at Low Strains. Appl. Sci. 2022, 12, 12175. https://doi.org/10.3390/app122312175

Zhang X, Guo J, Chen Y, Han Y, Yi R, Gao H, Liu L, Liu H, Shen Z. Mechanical Properties and Engineering Applications of Special Soils—Dynamic Shear Modulus and Damping of MICP-Treated Calcareous Sand at Low Strains. Applied Sciences. 2022; 12(23):12175. https://doi.org/10.3390/app122312175

Chicago/Turabian StyleZhang, Xinlei, Jun Guo, Yumin Chen, Yi Han, Ruibo Yi, Hongmei Gao, Lu Liu, Hanlong Liu, and Zhifu Shen. 2022. "Mechanical Properties and Engineering Applications of Special Soils—Dynamic Shear Modulus and Damping of MICP-Treated Calcareous Sand at Low Strains" Applied Sciences 12, no. 23: 12175. https://doi.org/10.3390/app122312175

APA StyleZhang, X., Guo, J., Chen, Y., Han, Y., Yi, R., Gao, H., Liu, L., Liu, H., & Shen, Z. (2022). Mechanical Properties and Engineering Applications of Special Soils—Dynamic Shear Modulus and Damping of MICP-Treated Calcareous Sand at Low Strains. Applied Sciences, 12(23), 12175. https://doi.org/10.3390/app122312175