Controlled Surface Morphology and Electrical Properties of Sputtered Titanium Nitride Thin Film for Metal–Insulator–Metal Structures

Abstract

1. Introduction

2. Experimental Section

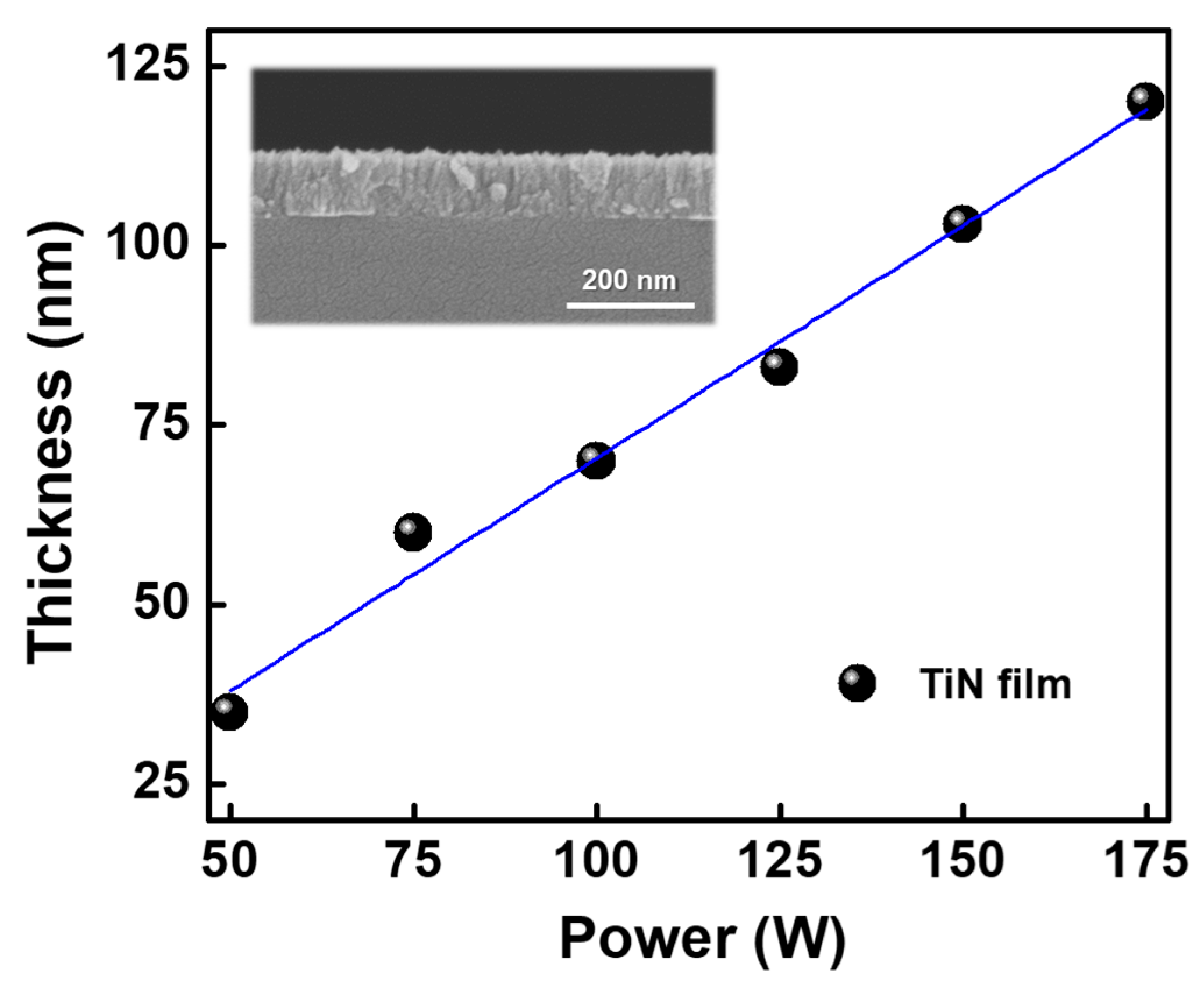

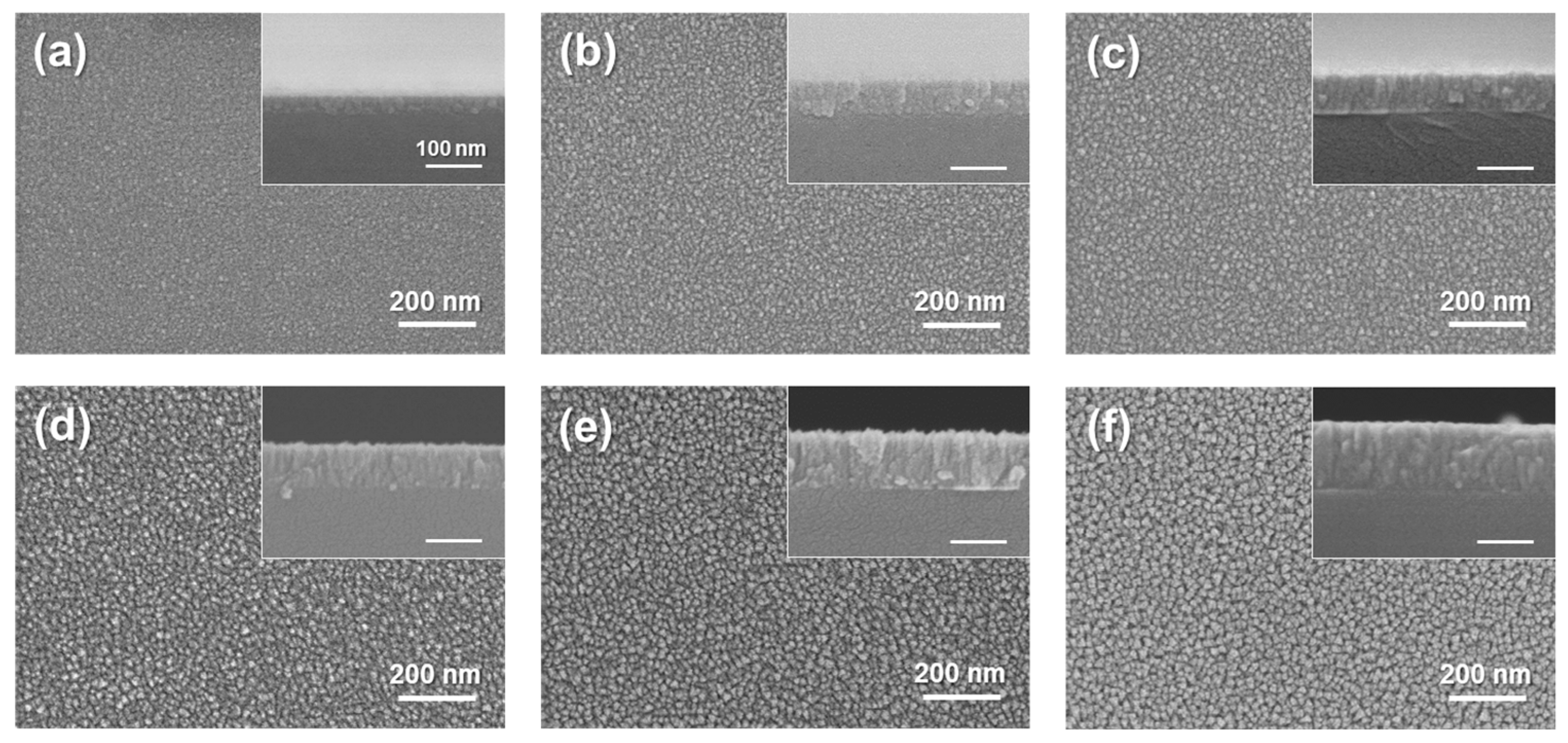

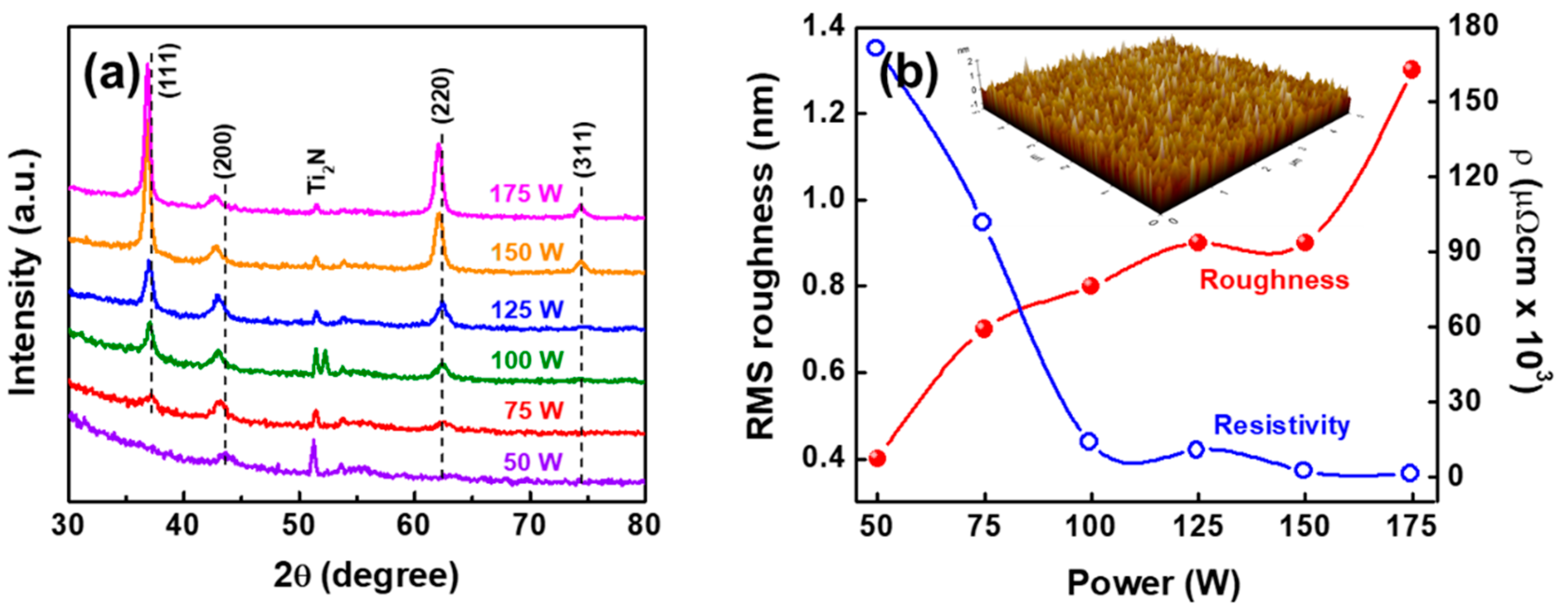

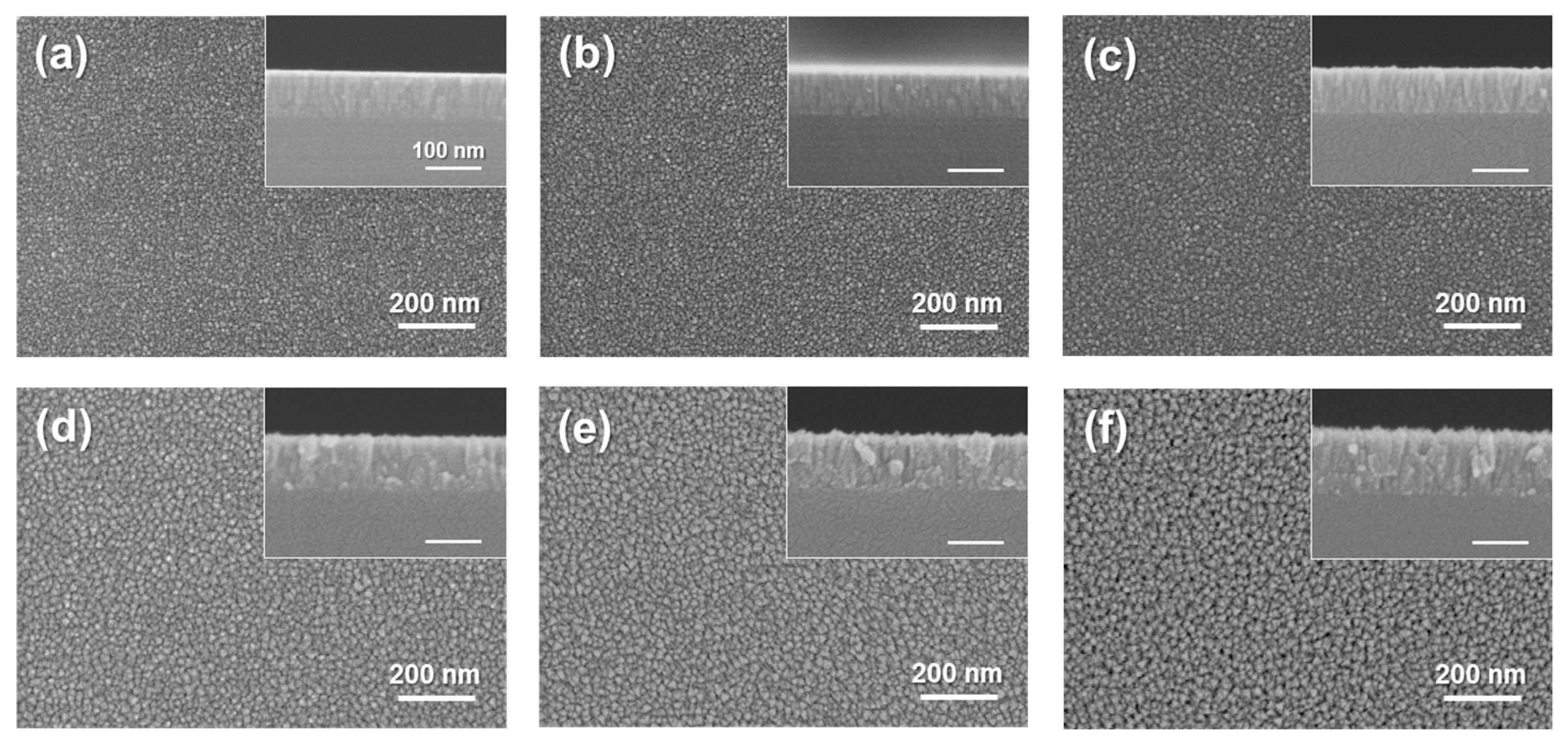

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Groenland, A.W.; Wolters, R.A.M.; Kovalgin, A.Y.; Schmitz, J. On the leakage problem of MIM capacitor due to improper etching of titanium nitride. In Proceedings of the STW.ICT Conference 2010, Veldhoven, The Netherlands, 18 November 2010. [Google Scholar]

- Yokoyama, N.; Hinode, K.; Homma, Y. LPCVD titanium nitride for ULSIs. J. Electrochem. Soc. 1991, 138, 190–195. [Google Scholar] [CrossRef]

- Tompkins, H.G.; Sellers, J.A.; Tracy, C. An inorganic antireflective coating for use in photolithography. J. Appl. Phys. 1993, 73, 3932–3938. [Google Scholar] [CrossRef]

- Lemme, M.C.; Efavi, J.K.; Mollenhauer, T.; Schmitdt, M.; Gottlob, H.D.B.; Wahlbrink, T.; Kurz, H. Nanoscale TiN metal gate technology for CMOS intergration. Microelectron. Eng. 2006, 83, 1551–1554. [Google Scholar] [CrossRef]

- Dimitriadis, C.A.; Logothetidis, S.; Alexandrou, I. Schottky barrier contacts of titanium nitride on n-type silicon. Appl. Phys. Lett. 1995, 66, 502–504. [Google Scholar] [CrossRef]

- Dauskardt, R.H.; Lane, M.; Ma, Q.; Krishna, N. Adhesion and debonding of multi-layer thin film structures. Eng. Fract. Mech. 1998, 61, 141–162. [Google Scholar] [CrossRef]

- Lukosius, M.; Walczyk, C.; Fraschke, M.; Wolansky, D.; Richter, H.; Wenger, C. High performance metal–insulator–metal capacitors with atomic vapor deposited HfO2 dielectric. Thin Solid Films 2010, 518, 4380–4384. [Google Scholar] [CrossRef]

- Su, J.; Boichot, R.; Blanquet, E.; Mercier, F.; Pons, M. Chemical vapor deposition of titanium nitride thin films: Kinetics and experiments. CrystEngComm 2019, 21, 3974–3981. [Google Scholar] [CrossRef]

- Charatan, R.M.; Gross, M.E.; Eaglesham, D.J. Plasma enhanced chemical vapor deposition of titanium nitride thin film using cyclopentadienyl cycloheptatrienyl titanium. J. Appl. Phys. 1994, 76, 4377–4382. [Google Scholar] [CrossRef]

- Buiting, M.J.; Otterloo, A.F.; Montree, A.H. Kinetic aspects of the LPCVD of titanium nitride from titanium tetrachloride and ammonia. J. Electrochem. Soc. 1991, 138, 500–505. [Google Scholar] [CrossRef]

- Heil, S.B.S.; Langereis, E.; Roozeboom, F.; van de Sande, M.C.M.; Kessels, W.M.M. Low-temperature deposition of TiN by plasma assisted atomic layer deposition. J. Electrochem. Soc. 2006, 153, 956–965. [Google Scholar] [CrossRef]

- Lal, K.; Meikap, A.K.; Chattopadhyay, S.K.; Chatterjee, S.K.; Ghosh, M.; Baba, K.; Hatada, R. Electrical resistivity of titanium nitride thin films prepared by ion beam-assisted deposition. Physica B 2001, 307, 150–157. [Google Scholar] [CrossRef]

- Leskelä, M.; Ritala, M. Atomic layer deposition chemistry: Recent developments and future challenges. Angew. Chem. Int. Ed. 2003, 42, 5548–5554. [Google Scholar] [CrossRef] [PubMed]

- Ponon, N.K.; Appleby, D.J.R.; Arac, E.; King, P.J.; Ganti, S.; Kwa, K.S.K.; O’Neill, A. Effect of deposition conditions and post deposition anneal on reactively sputtered titanium nitride thin films. Thin Solid Films 2015, 578, 31–37. [Google Scholar] [CrossRef]

- Jin, Y.; Kim, Y.G.; Kim, J.H.; Kim, D.K. Electrical properties of DC sputtered titanium nitride films with different processing conditions and substrates. J. Korean Ceram. Soc. 2005, 7, 455–460. [Google Scholar]

- Jeyachandran, Y.L.; Narayandass, S.K.; Mangalaraj, D.; Areva, S.; Mielczarski, J.A. Properties of titanium nitride films prepared by direct current magnetron sputtering. Mater. Sci. Eng. A 2007, 445–446, 223–236. [Google Scholar] [CrossRef]

- Zhou, C.; Li, T.; Wei, X.; Yan, B. Effect of the sputtering power on the structure, morphology and magnetic properties of Fe films. Metals 2020, 10, 896. [Google Scholar] [CrossRef]

- Aghajani, H.; Motlagh, M.S. Effect of temperature on surface characteristics of nitrogen ion implanted biocompatible titanium. J. Mater. Sci.-Mater. Med. 2017, 28, 29. [Google Scholar] [CrossRef]

- Chinsakolthanakorn, S.; Buranawong, A.; Chiyakun, S.; Limsuwan, P. Effects of titanium sputtering current on structure and morphology of TiZrN films prepared by reactive DC magnetron Co-sputtering. Mater. Sci. Appl. 2013, 4, 689–694. [Google Scholar] [CrossRef][Green Version]

- Hu, C.; Cai, J.; Li, Y.; Bi, C.; Gu, Z.; Zhu, J.; Zang, J.; Zheng, W. In situ growth of ultra-smooth or super-rough thin films by suppression of vertical or horizontal growth of surface mounds. J. Mater. Chem. C 2020, 8, 3248–3257. [Google Scholar] [CrossRef]

- Logothetidis, S.; Meletis, E.I.; Stergioudis, G.; Adjaottor, A.A. Room temperature oxidation behavior of TiN thin film. Thin Solid Films 1999, 338, 304–313. [Google Scholar] [CrossRef]

- Han, Z.; Tian, J.; Lai, Q.; Yu, X.; Li, G. Effect of N2 partial pressure on the microstructure and mechanical properties of magnetron sputtered CrNx films. Surf. Coat. Technol. 2003, 162, 189–193. [Google Scholar] [CrossRef]

- Wu, Z.T.; Qi, Z.B.; Zhang, D.F.; Wei, B.B.; Wang, Z.C. Evaluating the influence of adding Nb on microstructure, hardness and oxidation resistance of CrN coating. Surf. Coat. Technol. 2016, 289, 45–51. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dongquoc, V.; Seo, D.-B.; Anh, C.V.; Lee, J.-H.; Park, J.-H.; Kim, E.-T. Controlled Surface Morphology and Electrical Properties of Sputtered Titanium Nitride Thin Film for Metal–Insulator–Metal Structures. Appl. Sci. 2022, 12, 10415. https://doi.org/10.3390/app122010415

Dongquoc V, Seo D-B, Anh CV, Lee J-H, Park J-H, Kim E-T. Controlled Surface Morphology and Electrical Properties of Sputtered Titanium Nitride Thin Film for Metal–Insulator–Metal Structures. Applied Sciences. 2022; 12(20):10415. https://doi.org/10.3390/app122010415

Chicago/Turabian StyleDongquoc, Viet, Dong-Bum Seo, Cao Viet Anh, Jae-Hyun Lee, Jun-Hong Park, and Eui-Tae Kim. 2022. "Controlled Surface Morphology and Electrical Properties of Sputtered Titanium Nitride Thin Film for Metal–Insulator–Metal Structures" Applied Sciences 12, no. 20: 10415. https://doi.org/10.3390/app122010415

APA StyleDongquoc, V., Seo, D.-B., Anh, C. V., Lee, J.-H., Park, J.-H., & Kim, E.-T. (2022). Controlled Surface Morphology and Electrical Properties of Sputtered Titanium Nitride Thin Film for Metal–Insulator–Metal Structures. Applied Sciences, 12(20), 10415. https://doi.org/10.3390/app122010415