1. Introduction

Each year, the International Federation for Robotics (IFR) publishes the “World Robotics” report, which is a reliable compilation of information about the robotics industry. The most important of the IFR statistics refers to the annual sales of robots. For more than a dozen years, the indicator increased rapidly until 2018, when the number of robots sold reached more than 422,000 units. Unfortunately, in 2019 and 2020, the number of robots delivered to the industry dropped to 382 and 380 thousand units, respectively (

Figure 1). On the other hand, it should be pointed out that in 2020, the number of robots operating worldwide increased by 10%, exceeding three million for the first time (

Figure 2) [

1].

The increasing number of robots working in factories translates into an increase in robotization density (the average number of units per 10,000 workers in industry), which increased to 126. South Korea remained the leader with a ratio of 932 (

Figure 3). The outlook for robotics is very good. IFR expects about 13% growth this year, which means the delivery of 435,000 units to clients. This will be due to the market’s recovery from the slowdown and customers’ growing needs for local unit production [

2].

The most common applications for industrial robots were handling (166,000 installations), welding (66,000) and assembly (47,000). Among handling applications, a special role is given to the palletization process, which allows goods to be fully prepared for storage and further distribution. It completes the logistics of products and ensures their efficient flow between the producer and the end customer [

3]. Therefore, palletization and depalletization processes are among the most common robotic processes found in practically all branches of industry [

4,

5,

6]. They include the palletization of products in a variety of packages, including boxes, cartons, trays and packs, crates, drums, cans, bags, and buckets. Designers of robotic palletizing stations try to develop flexible stations using industrial robots with dedicated equipment (grippers) [

7]. It would seem that such an approach gives the possibility of easy use of such workstations for various applications. Unfortunately, most gripper solutions available on the market are developed for a specific product, so the possibility of changing their parameters is very limited.

The problem of palletizing products on robotic workstations is a well-known issue. Almost every robot manufacturer has solutions dedicated to palletizing operations. However, when it comes to the design of the grippers themselves, it is focused on several solutions resulting from the type of goods to be palletized. This is related to the gripping method and characteristics of the palletized goods. A distinction is made between force, shape, and force-shape gripping. Solutions are patented in world and national databases [

8,

9,

10,

11].

In the case of goods packed in bulk packaging (cartons, packs), jaw grippers are often used, which cover the entire layer of goods, squeezing them from four sides. This solution is simple, cheap, and effective. However, for products that can be easily physically damaged, such solutions are problematic. The process of palletizing a layer of packages, such as jars or cans, requires a solution that allows to pick up many objects simultaneously, securing their mutual displacement during the palletizing process, as well as preventing any of the objects from dropping during the handling process. The correct palletizing process for this kind of product is provided by constructions that use roller shutters, which is why the name of this type of gripper is commonly called roller shutter grippers. In the case of goods that are characterized by an increased risk of damage because of the clamping arms of the gripper, it is necessary to use a device that allows one to pick up the goods using a shaped grip. Another example of palletized goods is powdered goods packed in bag-type packaging. In this case, so-called bag grippers are very often used, which, due to the method of picking (often from roller conveyors) and the characteristics of the bag and the way it is filled, require picking using a shaped grip.

Since all products manufactured in each factory must pass through a palletizing station, the palletizing process can be the bottleneck of a plant. The flexibility of industrial robots makes it possible to equip them with extended, multifunctional grippers that allow them to perform several different operations (including handling products, separators, and pallets). In the case of implementation of the optional tasks listed above, during the palletizing process, it is necessary to equip robots with additional equipment (e.g., product presence sensors and height sensors).

During the design and start-up of production cells, special attention should be focused on the cycle time of the robot. Often it is assumed that the use of maximum acceleration and speed values of the robot is the best solution to achieve short cycle times. However, this approach can cause undesirable phenomena in the form of tool vibration at process points. This prolongs the production cycle due to the necessity to stabilize the tool. This is particularly noticeable in applications where the robot often operates tools exceeding 100 kg in weight, e.g., spot welding, clinching, and palletizing. In the case of unfavorable phenomena, a common result is a decrease in the quality of the implemented process. Short cycle times to ensure long, trouble-free work of the robot can be achieved by conscious programming of the robot. This should be understood, for example, as selecting the optimal speeds and accelerations of the robot’s TCP (tool center point), allowing for the smooth operation of the device and fast and accurate stopping of the robot tool at process points (e.g., picking and placing products). This is especially important for applications where the robot is equipped with a tool of large weight and dimensions with a center of gravity located at a distance from the robot’s flange.

As part of the completed R&D project:

A roller shutter gripper was designed and manufactured;

A simulation of the FANUC robot operation in the ROBOGUIDE environment was prepared;

The correct functioning of the gripper on a real workstation was validated;

Tests of the gripper vibrations that occur during the palletizing process were conducted.

Inertial tests were performed using MTi XSENS sensors and a PHANTOM V210 high-speed camera. As a result of the work, the values of accelerations occurring on the robot’s flange and gripper were obtained, and the influence of the parameters of the robot’s motion trajectory on the occurrence of vibrations in the structure was studied.

Section two presents related work. Section three presents a description of the developed gripper, the test bench, and the sensors used. Section four contains the results of the tests. Section five summarizes the work carried out.

2. Related Works

The demand for the robotization of industrial processes is related to the possibilities of increasing the productivity of workstations and obtaining higher repeatability compared to manually executed processes. In the case of palletization processes, it is important to use appropriate tools, such as advanced grippers. They allow the realization of complex operations such as forming of goods, as well as algorithms for picking and placing goods. The handling of heavy loads (characteristic of the palletizing process) requires the use of a robust gripper design, as well as appropriate robot motion parameters to ensure optimal working conditions. Automated palletizing and depalletizing are becoming widely used practices in warehouses to automate and speed up logistics. On the other hand, the need to adapt existing logistics and production lines to a custom automated system can be a limitation to the use of standard robotic solutions. Such situations occur in smaller facilities, such as small manufacturing companies or supermarkets. In such cases, there is a need to develop specific grippers and then perform verification tests [

3,

12].

In addition to research publications focusing on the use of automation solutions in daily life [

13,

14], industry [

15] and innovative programming methods [

16,

17], many works focus on the analysis of the gripper design using CAD tools or on the programming and optimization of the robot’s motion trajectory. Today, the trajectory programming process can be done on-line and off-line. Off-line programming systems are now popular tools for the efficient design of robotic workstations. They allow to reduce the process of cell development and robot programming. The concept of creating a digital twin is to prepare a virtual system that largely reflects the physical workstation. Using the digital twin configuration together with virtual reality, the replication of trajectories between digital and real robots is ensured. Generating trajectories according to practical user requirements using commercial off-line robot programming systems is relatively straightforward [

18]. Unfortunately, these solutions usually do not allow for analysis of accelerations, forces and moments acting on both the gripper and the robot itself. In order to conduct advanced and reliable research, experimental studies are necessary. Measurement of vibrations of robot components and the tool (e.g., the gripper) can be carried out using a triaxial inertial measurement unit (IMU) or a vision system. The data obtained from the measurements allow for effective analysis and optimization of the robot’s performance [

15]. The IMU component allows for effective position tracking [

19] not only at target locations but continuously throughout the production cycle.

An important problem addressed in the literature related to equipment in robotic applications is the study of the dynamic performance and motion control of the manipulator [

20,

21]. From the point of view of control and parameterization of the movement of mechanisms, a key issue is the analysis of the process of their acceleration and deceleration, as well as the accuracy of reaching set position values. The characteristics of the motion dynamics of robot manipulators can greatly affect the loads that occur in kinematic joints [

22]. It is also important to ensure the optimal time trajectory of the palletizing robot motion, as shown in [

23]. During operation, the robot can perform complex motions characterized by sections of rapid deceleration and acceleration. These sections (especially when changing the direction of the robot) can influence the life cycle of the device and the accuracy of the realization of the motion trajectory. Their parameterization allows for a faster change of movement directions and a reduction in the vibration of the mechanical unit [

24].

Dynamics studies in a robotic cell should be implemented, taking into account the sensitive parts of the system that are under particularly heavy load during robot operations. These may include, for example, the robot’s wrist, tool clamping element and gripper [

25,

26,

27]. Therefore, the study of dynamics in the area of the wrist and gripper is critical, as it provides information on the effect of loads and gripper on the dynamic durability of the robot-tool system. Such analyses can indirectly allow minimization of energy consumption. This is one of the demands of Industry 4.0, where the reduction in energy consumption and the development of smart manufacturing are taken into account in the design of modern manufacturing systems [

28]. Improvements in efficiency can be based on analysis of energy consumption, equipment reliability, maintenance intervals and operating costs, as well as life cycle assessment [

29].

Robot vibration reduction can be realized by optimizing trajectories, as shown in [

30,

31,

32]. The fact that such considerations are important is confirmed by manufacturers that are trying to use systems that allow the reduction of robot vibration. An example is the FANUC company, which offers this type of system for spot welding operations and heavy load handling. Many researchers are focusing on issues related to motion optimization to reduce cycle time and vibration by parameterizing the robot’s speed and acceleration [

33,

34]. The research results in solutions for smoothing trajectories [

35], including proposed trajectory planning methods (e.g., the S-curve method using a segmented sigmoidal function) [

36]. According to [

37], minimizing the vibration of an industrial robot manipulator through multi-mode, time-varying input signal shaping can reduce the residual vibration by up to 90%. Another approach to reducing vibration is the ARX method [

38] (AutoRegressive with eXogenous), which is based on modeling of the robot-gripper system using exclusively experimental data and the design of an appropriate control system consisting of a typical feedforward PID controller and feedback that allow the force applied to the robot’s wrist to be dampened, thereby dampening vibrations on the effector. Further approaches are methods of adaptive intelligent control [

39] used for robots with a large number of degrees of freedom that have additional acceleration sensors that record the robot’s current dynamic parameters. However, they are not implemented in industrial robots due to hardware limitations and the method of overload detection (measurement of currents on servomotors). The papers [

40,

41] also confirm the advisability of conducting this type of research.

3. Materials and Methods

Designed and built by the authors as part of the R&D project, the roller shutter gripper is a multifunctional device that allows the handling of whole layers of products with dimensions of 1300 × 800 mm, separators and pallets. The weight of the gripper is 197.4 kg. Pneumatic systems are controlled by a pressure of 6 bar. The gripper is equipped with two AC motors used to drive the roller shutters. The programmable logic controller (PLC), which is an integral part of the device, is responsible for the correct operation of the gripper. The PLC’s software allows the realization of tasks (handling of goods, separators and pallets), taking into account information from sensors. The communication of the gripper with the robot was conducted via Ethernet [

42]. The roller shutter gripper is a modular design consisting of a base frame, guides with roller shutters, and an adapter that attaches the gripper to the robot flange (

Figure 4 and

Figure 5).

The base frame was designed as a double cross pattern made of light and rigid aluminum profiles ITEM 40 × 80. The dimensions of the frame were chosen to allow gripping the layer of products with dimensions of up to 1300 × 800 mm. Two roller shutters were designed, which run along the longer side of the pallet and converge to the center of the pallet when the gripper is closed. The drive system of the rollers is designed as two symmetrical chain modules moving in the side modules (

Figure 6). TSUBAKI’s ISO 12B-1 modular chain was used as the moving element. The chain is shaped using modules with embedded sprockets. The supporting element of the module is a lightweight aluminum profile ITEM 40 × 40.

The chain moves in a slider made of durable material with a very low coefficient of friction. As a result, the load from the products is not transferred to the chain and sprockets but to the slider and the gripper base structure. The chain modules are bolted to the gripper base frame and connected by rollers. For handling product layers of the required size and weight, steel rollers of the INTERROL 1200 series with a diameter of 30 mm and a load capacity of max. 120 N were used. The proposed gripper concept imposes special requirements for picking up goods from the production line. Rollers can be driven by an additional belt conveyor placed under the gripper at the pick-up point. This ensures smooth entry of the goods into the gripper.

Figure 7 shows the main dimensions of the gripper.

Table 1 shows the gripper parameters, such as the position of the center of mass relative to the X0Y0Z0 coordinate system located on the robot flange, moments of inertia

L relative to the center of mass of the gripper and moments of inertia

I relative to the X0Y0Z0 coordinate system. Those parameters were determined using the gripper CAD model in the SoliWorks CAD software.

3.1. The Test Bench Presentation

The tests of the roller shutter gripper were performed at the HITMARK company. The gripper was attached to a FANUC M-410iC/315 four-axis palletizing robot.

Figure 8 shows the components of the entire workstation.

Figure 9 shows the location of the MTi XSENS sensors and the tags for the camera. For simplicity of nomenclature, it is assumed that the sensor location on the gripper near the robot flange will be referred to as the robot flange location in the rest of the article. The vibration magnitude of the gripper at the process points was determined using a prepared measuring station. The bench includes a PC connected to a PHANTOM V210 camera via Ethernet. The prepared measurement station with PCC software allowed us to configure the camera, record videos, and analyze the vibration of the robot tool at the process point.

MTi XSENS sensors were connected to the PC via a USB interface. The MT Manager software was used to configure the sensors (

Figure 10). The software allowed the robot tool acceleration to be tracked in real time. The main aim of the research realized with this measurement system was to check the effect of changing the robot path parameters (TCP speed and acceleration/deceleration ramps) on the vibration of the gripper at the process point.

3.2. Measurement Methodology

As part of the R&D work, a roller shutter gripper was made to palletize the layers of the entire product. Once the gripper was made, the authors focused on developing a methodology that would allow them to perform tests to analyze the parameters of the robotic industrial process. Limitations related to the robot payload and the implemented process forced the development of a gripper characterized by low weight (197 kg) with relatively large dimensions. The main objective of the research was to verify the construction of the gripper, in particular its behavior at process points where the highest forces act on the gripper. It was assumed that due to the way the products are picked up from the conveyor (

Figure 11), the case for which the robot can operate at the highest speeds is the movement at a constant height with linear motion reaching the process position.

XSENS sensors were installed on the gripper (

Figure 9). One sensor was mounted at the robot flange, and the other sensor was near the picking point. The camera was positioned in such a way that image analysis could be performed to measure the displacement of the tag placed on the gripper (

Figure 9). Videos were recorded with a PHANTOM V210 high-speed camera with a resolution of 800 × 600 pix, 2000 frames/s. PCC software allowed us to analyze the character of the gripper’s vibrations, including the measurement of its maximum displacements at the process point. Using the presented values, before measuring the displacements, a calibration was performed to determine the scale (the relation between the image resolution of 800 × 600 pix and the observed image in millimeters). The scale was 0.212 mm/pix. During the calibration of the camera, an Edge Hipass 5 × 5 filter was used. On the test bench, a control program was prepared for a FANUC M-410iC/315 robot, considering its workspace and potential kinematic singularities. A linear motion TCP was programmed with a start point P1 with coordinates

x = −450 mm,

y = 2500 mm,

z = 75 mm and an end point P2 with coordinates

x = −450 mm,

y = −500 mm,

z = 75 mm. The point P2 was assumed to be the picking point of the product. The movement instructions in the control program were as follows:

where:

L—the type of robot movement interpolation (linear interpolation);

P(1)—the point of the robot’s trajectory;

R(51:SPEED)—the register in which the speed is stored;

FINE—the method of reaching a point;

ACC—the acceleration parameter, the value of which is stored in register 50.

A series of measurements were made using MTi XSENS accelerometers. During the tests for selected speeds (4000 mm/s, 3000 mm/s, 2000 mm/s, 1000 mm/s), the parameters of the acceleration function were changed to:

ACC25;

ACC50;

ACC75;

ACC100.

4. Evaluation

A digital twin of a real production workstation was developed in FANUC’s ROBOGUIDE environment. Tests were carried out to determine the maximum height of the stack for the adopted technical requirements. In

Figure 12, a visualization of the designed workstation is presented.

Assuming a distance of 2171 mm from the robot flange to the ground level and mounting the robot on a platform with a height of 1100 mm, a height of 3271 mm was reached. This is the maximum height at which the robot’s flange can be in its highest position. When determining the height of the palletized layer for the roller shutter gripper, it is necessary to take into consideration:

The gripper height, which was 700 mm;

The pallet height, which was 144 mml

The space to allow free manipulation of the gripper (assumed to be 117 mm).

As a result, the height of 2310 mm is the maximum stack height, which was confirmed on the real test bench.

4.1. Testing the Properties of the Gripper on a Real Test Bench

The designed roller shutter gripper is dedicated to handling full layers of products, which requires a specific loading method. The loading process involves transporting full layers of products inside the gripper after positioning it at the picking point. A crucial point in this process is the accurate positioning of the gripper in direct contact with the conveyor. Considering the large size and weight of the layers to be conveyed, it is necessary to reduce the weight of the gripper so that it meets the robotization requirements of the industrial process. However, reducing the mass of the gripper also affects its stiffness, which results in a deterioration of the quality of the industrial process and an increased production cycle time. The authors conducted a study to determine the nature of vibrations occurring when the developed gripper stops at a process point. The impact of the motion parameters of the industrial robot on the magnitude of these vibrations was also investigated. This will allow proper parameterization of the robot’s movements to reduce the occurrence of the undesirable phenomenon of structural vibration.

Figure 13 presents an example graph of the robot’s acceleration for the

X-axis, along which the robot’s movement was performed when approaching the process point. The graph shows characteristic sections where the robot is stationary, starts a movement, accelerates to a preset speed, moves at a preset speed, brakes, and stops at the process point.

Obtained results were processed using programs and scripts developed in the MATLAB environment. Data analysis was preceded by data preparation. This consisted of the following activities:

Importing the measurement data into the MATLAB structure;

Determining and selecting the range of data for analysis;

Reducing the constant bias component by examining the measurement silence period.

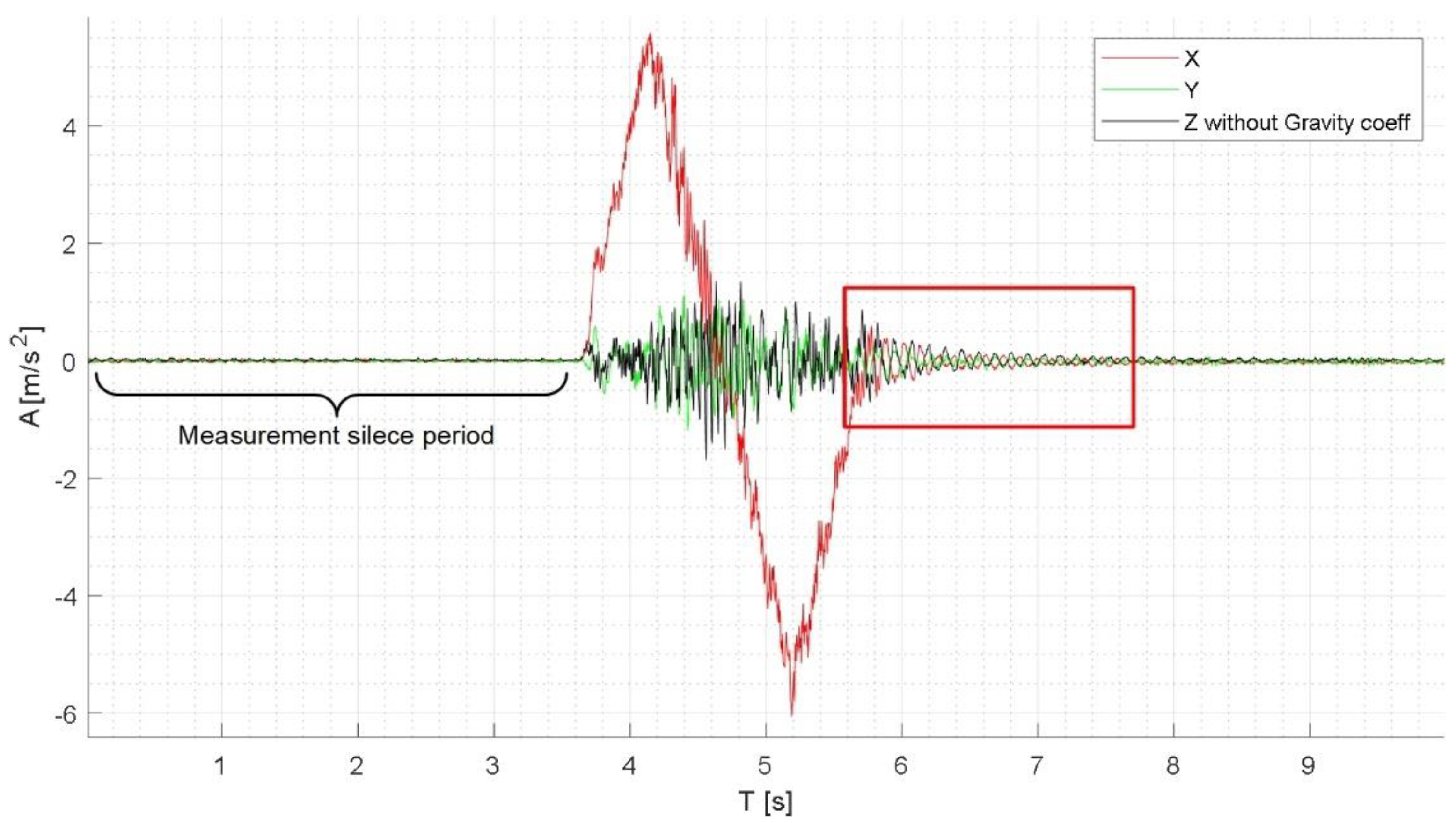

Figure 14 shows gripper acceleration plots measured with a triaxial XSENS sensor.

A detailed analysis of tool vibration (

Figure 15) was carried out for the tool stop area at the process point (red box in

Figure 14).

Considering the implementation of the process, the study was focused on the analysis of acceleration, velocity and displacement related to the X-axis (the direction of the robot’s approach to the retrieval point). A series of tests were carried out for the programmed speeds of the robot (4000 mm/s, 3000 mm/s, 2000 mm/s, and 1000 mm/s) while changing the acceleration coefficient (ACC100, ACC75, ACC50, ACC25).

Figure 16 shows the acceleration graphs of sensors mounted on the robot’s flange and on the gripper for the parameters V4000 and ACC100. A similar pattern of accelerations was observed for the other cases studied; the results are shown in

Table 2.

From the graph of one robot cycle (

Figure 16, red box), the moment of stopping at the measuring process point was selected (

Figure 17). A discrepancy was observed in the value of accelerations measured by sensors located on the robot’s flange and on the gripper.

The fading characteristic of the vibrations can be observed in

Figure 17. The maximum acceleration amplitude of the sensor on the gripper at the process point was 0.39 m/s

2, which is greater than the maximum acceleration amplitude of the sensor mounted on the robot’s flange (0.15 m/s

2). These values were measured for the robot’s V4000 and ACC100 parameters. For each test, 10 measurements were carried out.

Table 2 summarizes the average values of the results obtained for all measurements. From the results shown in the table, it can be noted that the acceleration values recorded by the sensor located at a greater distance from the robot flange are significantly greater than the vibrations generated at the robot flange. It is also noted that for high linear velocities (tests 3 and 4, tests 7 and 8), the maximum value of the acceleration of the sensor on the gripper at the stopping point is greater for ACC25 than for ACC50. This relationship does not occur for lower velocities. This could be a consequence of the gripper features related to its stiffness.

The data can be used to support developers in designing the robot’s motion path and selecting downtimes at process points.

The next step of the analysis was to develop scripts in the MATLAB environment to calculate and plot velocity graphs.

Figure 18 shows the script result of the calculated velocities for the parameters V4000 and ACC100.

Based on the analysis of acceleration at the robot process point, the authors focused on the study of velocity changes at the process point (red rectangle in

Figure 18). The area of interest is shown in

Figure 19.

Table 3 summarizes the peak values obtained with proprietary software written in the MATLAB environment. The inter-peak value “Delta” was determined as a parameter measured between the maximum and minimum amplitude values for the first two oscillations.

4.2. Determination of Displacement

The vibration magnitude of the gripper at the process points was measured using a PHANTOM V210 high-speed camera with PCC software. It allowed recording the occurrence, while the PCC software allowed analyzing the character of vibrations. The test tag (

Figure 20) placed on the gripper had the following dimensions:

Based on the known dimensions of the test tag and the Edge Hipass 5 × 5 filter, the camera was calibrated to establish the scale (the relationship between the image resolution of 800 × 600 pix and the observed view in millimeters—

Figure 21 and

Figure 22). The calculated scale was 0.212 mm/pix.

Table 4 summarizes the maximum displacement of the gripper for selected robot speeds. The amplitude of vibration of the gripper for the set parameters of V4000 and V3000 are comparable, and this is caused by the fact that the robot did not reach the maximum set speed on the programmed trajectory. For the set velocity

V = 4000 mm/s and

V = 3000 mm/s with 100% ACC parameter, the robot reached a maximum velocity

V = 2850 mm/s. The difference in values may be the result of measurement error caused by the resolution of the analyzed image. It is also noted that for the developed gripper, for high linear velocities (

Table 2), the maximum value of the acceleration measured on the gripper at the process point is greater for an

ACC parameter of 25 than for an

ACC of 50. Introducing an additional travel point

P3 (

Figure 23), where the motion parameters (velocity and acceleration) would be changed, there is the possibility to effectively reduce vibrations. The distance between points

P3 and

P2 remains open to discussion, which is a consequence of specific solutions for both the gripper design and the industrial process.

5. Conclusions

The article presents a study of the characteristics of a roller shutter gripper on a robotic palletizing station. The gripper developed by the authors is dedicated to handling whole layers of products, separators, and pallets. A PLC, which is an integral part of the device, is responsible for the correct operation of the gripper. The PLC’s software allows the realization of tasks (handling of products, separators, and pallets) using information from sensors. Communication of the gripper with the robot was implemented via Ethernet.

Property tests of the developed and built gripper were carried out using a FANUC robot, a vision system and XSENS triaxial sensors. The testing methodology suggested by the authors allows verification of the stiffness of the design and the influence of changes in the robot’s motion parameters on its behavior at process points. The presented test results confirm that as the robot’s motion speed decreases and the ACC coefficient decreases, the occurring vibration of the gripper structure decreases.

A robot with a higher structural stiffness compared to the gripper shows a change in the maximum acceleration value for the measuring point on the flange. For the measuring point located on the gripper, a disturbance in the decrease in the maximum acceleration value can be observed. This happens when the maximum velocity and the acceleration coefficient (ACC) change. This could be the result of the appearance of the structure’s own vibrations, which have a fading character but are not monotonous.

The results obtained can be used to support programmers in designing the robot’s motion path and selecting downtimes at process points. By adding an additional crossing point, where a change in the motion parameters (speed and acceleration) would occur, there would be an opportunity to effectively reduce vibrations.

The conducted research proves that the use of triaxial XSENS sensors and high-speed cameras allows to effectively perform determination-related analyses. In further work, the authors will focus on the possibility of using the proposed analysis technique to reduce vibrations of selected robotic manufacturing processes (e.g., spot welding).