Assessment of the Possibility of Using Poppy Seed Cake for the Production of Oat Cookies

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Preparation of Dough

2.3. Baking Cookies

2.4. Determination of Moisture

2.5. Analysis of Protein Content

2.6. Determination of Fat Content

2.7. Determination of Fiber Content

2.8. Determination of Sugar Content

2.9. Determination of Polyphenol Content

2.10. Determination of Flavonoid Content

2.11. Determination of Textural Properties

2.12. Determination of the Color

2.13. Sensory Analysis

2.14. Statistical Analysis

3. Results

3.1. Chemical Composition

3.2. Textural Properties

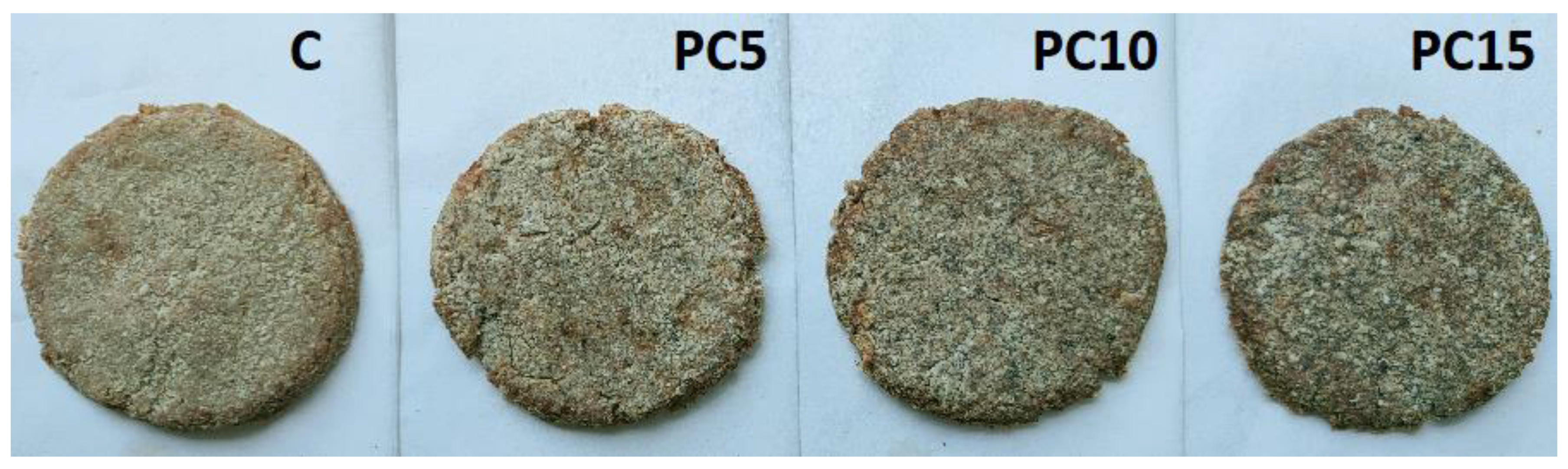

3.3. Color of Cookies

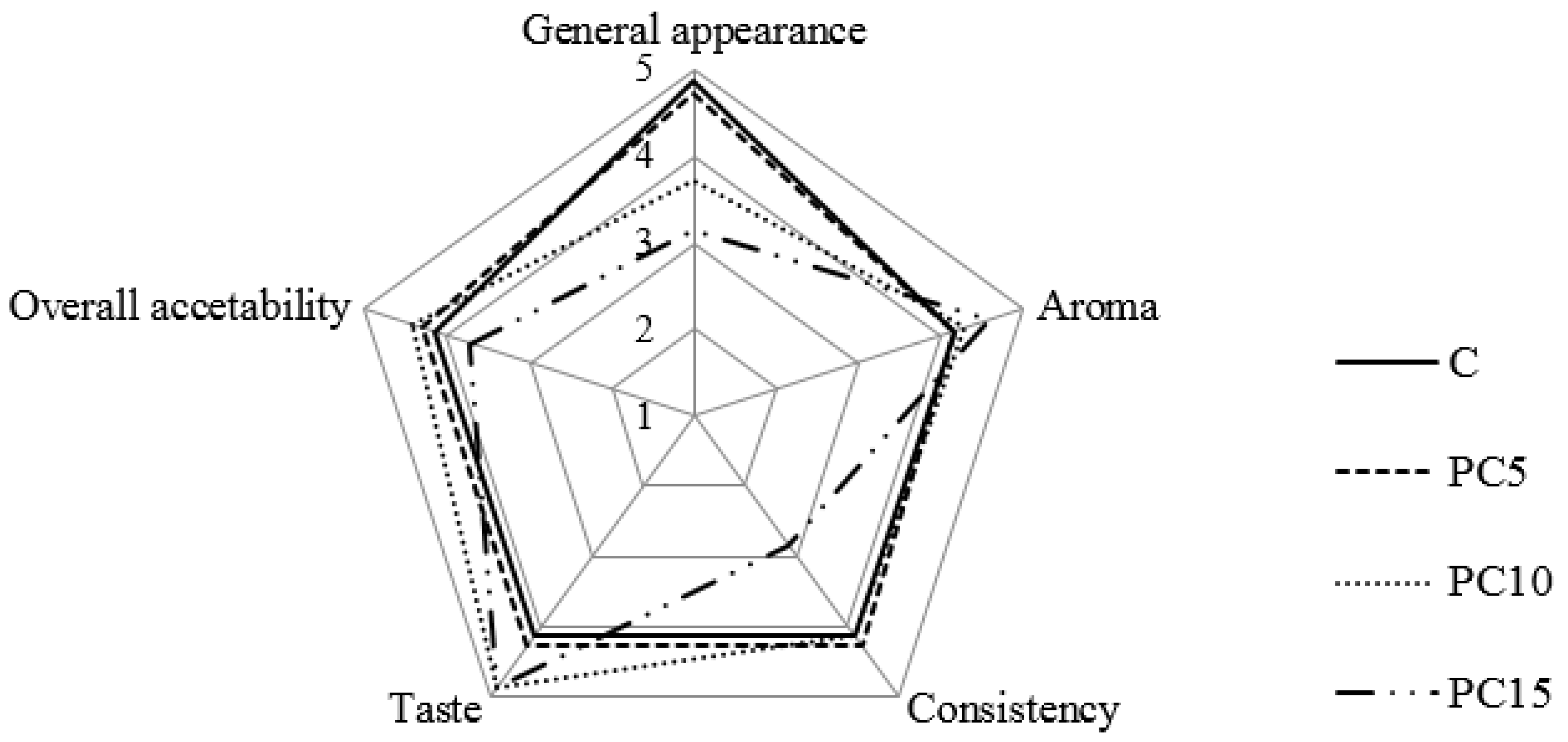

3.4. Sensory Quality

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Naebi, M.; Torbati, M.; Azadmard-Damirchi, S.; Siabi, S.; Savage, G.P. Changes in physicochemical properties of cold press extracted oil from Balangu (Lallemantia peltata) seeds during storage. J. Food Compos. Anal. 2021, 107, 104358. [Google Scholar] [CrossRef]

- Krulj, J.; Pezo, L.; Kojic, J.; Solarov, M.B.; Teslic, N. Quality evaluation of cold-pressed oils and semi-defatted cake flours obtained on semi-industrial scale. J. Food Nutr. Res. 2021, 59, 217–228. [Google Scholar]

- Sobczak, P.; Zawiślak, K.; Starek, A.; Żukiewicz-Sobczak, W.; Sagan, A.; Zdybel, B.; Andrejko, D. Compaction Process as a Concept of Press-Cake Production from Organic Waste. Sustainability 2020, 12, 1567. [Google Scholar] [CrossRef]

- Zarzycki, P.; Sykut-Domańska, E.; Sobota, A.; Teterycz, D.; Krawęcka, A.; Blicharz-Kania, A.; Andrejko, D.; Zdybel, B. Flaxseed Enriched Pasta—Chemical Composition and Cooking Quality. Foods 2020, 9, 404. [Google Scholar] [CrossRef]

- Bozan, B.; Temelli, F. Chemical composition and oxidative stability of flax, safflower and poppy seed and seed oils. Bioresour. Technol. 2008, 99, 6354–6359. [Google Scholar] [CrossRef]

- Muhammad, A.; Akhtar, A.; Aslam, S.; Khan, R.S.; Ahmed, Z.; Khalid, N. Review on physicochemical, medicinal and nutraceutical properties of poppy seeds: A potential functional food ingredient. Funct. Foods Heal. Dis. 2021, 11, 522–547. [Google Scholar] [CrossRef]

- Wawrzyniak, M.; Ogrodowczyk, M. Zawartość morfiny w makówkach z pędu głóownego i pędów bocznych rośliny maku lekarskiego Papaver somniferum L. Rośliny Oleiste-Oilseed Crops 2005, 26, 603–610. [Google Scholar]

- Azcan, N.; Kalender, B.O.; Kara, M. Investigation of Turkish Poppy Seeds and Seed Oils. Chem. Nat. Compd. 2004, 40, 370–372. [Google Scholar] [CrossRef]

- Özcan, M.M.; Atalay, Ç. Determination of seed and oil properties of some poppy (Papaver somniferum L.) varieties. Grasas y Aceites 2006, 57, 169–174. [Google Scholar] [CrossRef]

- Özbek, Z.A.; Ergönül, P.G. Determination of Physicochemical Properties, Fatty Acid, Tocopherol, Sterol, and Phenolic Profiles of Expeller–Pressed Poppy Seed Oils from Turkey. J. Am. Oil Chem. Soc. 2020, 97, 591–602. [Google Scholar] [CrossRef]

- Moslavac, T.; Jokić, S.; Aladić, K.; Galović, M.; Šubarić, D. Proizvodnja Hladno Prešanog Makovog ulja. Hranom do Zdravlja: Zbornik Radova 9; Međunarodnog Znanstveno-Stručnog Skupa: Osijek, Croatia, 2017; pp. 132–143. [Google Scholar]

- Bárta, J.; Bártová, V.; Jarošová, M.; Švajner, J.; Smetana, P.; Kadlec, J.; Filip, V.; Kyselka, J.; Berčíková, M.; Zdráhal, Z.; et al. Oilseed Cake Flour Composition, Functional Properties and Antioxidant Potential as Effects of Sieving and Species Differences. Foods 2021, 10, 2766. [Google Scholar] [CrossRef] [PubMed]

- Yılmaz, E.; Emir, D.D. Compositional and functional characterisation of poppy seed (Papaver somniferum L.) press cake meals. Qual. Assur. Saf. Crop. Foods 2017, 9, 141–151. [Google Scholar] [CrossRef]

- Türker, D.A.; Saraç, M.G.; Yetiman, A.E.; Doğan, M. Interfacial properties of poppy seed protein (Papaver somniferum L.) as an alternative protein source at oil/water interface: Influence of pH on stability, morphology and rheology. Eur. Food Res. Technol. 2021, 247, 2545–2556. [Google Scholar] [CrossRef]

- Levent, H.; Sayaslan, A.; Yeşil, S. Physicochemical and sensory quality of gluten-free cakes supplemented with grape seed, pomegranate seed, poppy seed, flaxseed, and turmeric. J. Food Processs. Preserv. 2021, 45, e15148. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 18th ed.; Association of Analytical Chemists International: Gaithersburg, MD, USA, 2006. [Google Scholar]

- Van Alfen, N.K. Encyclopedia of Agriculture and Food Systems; Academic Press Elsevier: Amsterdam, The Netherlands, 2014; pp. 273–288. ISBN 978-0-08-093139-5. [Google Scholar] [CrossRef]

- AACC. AACC International. Approved Methods of the American Association of Cereal Chemists Methods 32-10, 10th ed.; AACC International: St. Paul, MN, USA, 2000. [Google Scholar]

- PN 12630:2002 Soki owocowe i warzywne; Oznaczanie Zawartości Glukozy, Fruktozy, Sorbitolu i Sacharozy. Metoda Wysokosprawnej Chromatografii Cieczowej. Polski Komitet Normalizacyjny: Warsaw, Poland.

- ISO/DIS 13299; Sensory Analysis—Methodology—General Guidance for Establishing a Sensory Profile. ISO: Geneva, Switzerland, 1998.

- Archemowicz, B.; Kaszuba, J.; Puchalski, C.; Wisniewski, R. Porównanie cech fizycznych i sensorycznych płatków zbożowych różnego pochodzenia. Żywność Nauka Technologia Jakość 2016, 6, 55–63. [Google Scholar] [CrossRef]

- Rani, R.; Badwaik, L.S. Functional Properties of Oilseed Cakes and Defatted Meals of Mustard, Soybean and Flaxseed. Waste Biomass- Valorization 2021, 12, 5639–5647. [Google Scholar] [CrossRef]

- Giami, S.; Mepba, H.; Kiin-Kabari, D.; Achinewhu, S. Evaluation of the nutritional quality of breads prepared from wheat-fluted pumpkin (Telfairia occidentalis Hook) seed flour blends. Mater. Veg. 2003, 58, 1–8. [Google Scholar] [CrossRef]

- Zgórska, K.; Plawgo, A.; Wojtasik-Kalinowska, I.; Dymkowska-Malesa, M. Wpływ dodatku nasion lnianki na jakość pieczywa z pszenżyta. Postępy Techniki Przetwórstwa Spożywczego 2010, 1, 23–25. [Google Scholar]

- Grausgruber, H.; Scheiblauer, J.; Schönlechner, R.; Ruckenbauer, P.; Berghofer, E. Variability in Chemical Composition and Biologically Active Constituents of Cereals; BOUK-University of Natural Resources and Applied Life Sciences: Vienna, Austria, 2004; pp. 23–26. [Google Scholar]

- Boukid, F. Oat proteins as emerging ingredients for food formulation: Where we stand? Eur. Food Res. Technol. 2021, 247, 535–544. [Google Scholar] [CrossRef]

- Martínez, E.; García-Martínez, R.; Álvarez-Ortí, M.; Rabadán, A.; Pardo-Giménez, A.; Pardo, J. Elaboration of Gluten-Free Cookies with Defatted Seed Flours: Effects on Technological, Nutritional, and Consumer Aspects. Foods 2021, 10, 1213. [Google Scholar] [CrossRef]

- Dimitrios, B. Sources of natural phenolic antioxidants. Trends Food Sci. Technol. 2006, 17, 505–512. [Google Scholar] [CrossRef]

- Pojić, M.; Hadnađev, T.D.; Hadnađev, M.; Rakita, S.; Brlek, T. Bread Supplementation with Hemp Seed Cake: A By-Product of Hemp Oil Processing. J. Food Qual. 2015, 38, 431–440. [Google Scholar] [CrossRef]

- Yenge, G.B.; Desai, S.S.; Kad, V.P.; Narayankar, S.H.; More, D.D. Development of de-oiled pomegranate seed cake based fiber rich cookies. IJCS 2019, 7, 1776–1781. [Google Scholar]

- Bravo-Núñez, Á.; Gómez, M. Enrichment of Cakes and Cookies with Pulse Flours. A Review. Food Rev. Int. 2021, 1–19. [Google Scholar] [CrossRef]

- Wirkijowska, A.; Sobota, A.; Zarzycki, P.; Nawrocka, A.; Blicharz-Kania, A.; Andrejko, D. Chemical, technological, and sensory evaluation of the suitability of coconut by-products in white rolls. J. Sci. Food Agric. 2021, 102, 3370–3378. [Google Scholar] [CrossRef] [PubMed]

- Mohtarami, F. Effect of Carrot Pomace Powder and Dushab (Traditional Grape Juice Concentrate) on the Physical and Sensory Properties of Cakes: A Combined Mixtures Design Approach. Curr. Nutr. Food Sci. 2019, 15, 572–582. [Google Scholar] [CrossRef]

- Antonic, B.; Jancikova, S.; Dordevic, D.; Tremlova, B. Apple pomace as food fortification ingredient: A systematic review and meta-analysis. J. Food Sci. 2020, 85, 2977–2985. [Google Scholar] [CrossRef] [PubMed]

- Nakov, G.; Brandolini, A.; Hidalgo, A.; Ivanova, N.; Stamatovska, V.; Dimov, I. Effect of grape pomace powder addition on chemical, nutritional and technological properties of cakes. LWT 2020, 134, 109950. [Google Scholar] [CrossRef]

- Tate, P.V.; Chavan, J.K.; Patil, P.B.; Kadam, S.S. Processing of commercial peanut cake into food-grade meal and its utilization in preparation of cookies. Mater. Veg. 1990, 40, 115–121. [Google Scholar] [CrossRef]

| Probe Code | Amount of Ingredients | |||

|---|---|---|---|---|

| Oat Flakes g | Oat Flakes % | Poppy Seed Cake g | Poppy Seed Cake % | |

| C | 200 | 100 | 0 | 0 |

| PC5 | 190 | 95 | 10 | 5 |

| PC10 | 180 | 90 | 20 | 10 |

| PC15 | 170 | 85 | 30 | 15 |

| Moisture | Protein | Fat | Crude Fiber | Flavonoids | Polyphenols | |

|---|---|---|---|---|---|---|

| % | % d.b. | % d.b. | % d.b. | mg·100 gd.b.−1 | % d.b. | |

| C | 34.80 ± 0.02 a | 12.43 ± 0.15 a | 6.34 ± 0.01 a | 2.32 ± 0.02 a | - | 0.136 ± 0.002 a |

| PC5 | 33.83 ± 0.01 b | 13.14 ± 0.05 b | 6.70 ± 0.01 b | 3.18 ± 0.04 b | 0.333 ± 0.015 a | 0.119 ± 0.003 b |

| PC10 | 33.58 ± 0.13 c | 13.64 ± 0.01 c | 6.88 ± 0.01 c | 3.34 ± 0.03 c | 0.357 ± 0.006 a | 0.117 ± 0.002 b |

| PC15 | 32.86 ± 0.07 d | 14.09 ± 0.03 d | 6.98 ± 0.01 d | 3.62 ± 0.01 d | 0.357 ± 0.012 a | 0.104 ± 0.007 c |

| Saccharose | Glucose | Fructose | |

|---|---|---|---|

| % d.b. | % d.b. | % d.b. | |

| C | 7.03 ± 0.02 a | 4.70 ± 0.02 a | 6.97 ± 0.04 a |

| PC5 | 6.63 ± 0.06 b | 4.67 ± 0.01 a | 6.68 ± 0.02 b |

| PC10 | 6.46 ± 0.05 c | 4.66 ± 0.02 a | 6.57 ± 0.03 b |

| PC15 | 6.11 ± 0.03 d | 4.24 ± 0.15 b | 5.80 ± 0.09 c |

| Hardness | Elasticity | Chewiness | Cohesiveness | |

|---|---|---|---|---|

| N | - | N | - | |

| C | 172.3 ± 7.4 a | 0.843 ± 0.012 a | 86.5 ± 3.2 a | 0.595 ± 0.020 a |

| PC5 | 267.7 ± 5.0 b | 0.847 ± 0.023 a | 135.8 ± 9.2 b | 0.599 ± 0.015 a |

| PC10 | 303.7 ± 26.3 b | 0.817 ± 0.015 a | 144.6 ± 11.0 b | 0.583 ± 0.009 a |

| PC15 | 406.7 ± 12.9 c | 0.813 ± 0.021 a | 170.9 ± 3.7 c | 0.517 ± 0.003 b |

| L* | a* | b* | |

|---|---|---|---|

| C | 51.92 ± 0.64 a | 3.74 ± 0.11 a | 12.67 ± 0.66 a |

| PC5 | 51.45 ± 0.28 a | 3.52 ± 0.07 b | 11.95 ± 0.31 a |

| PC10 | 49.85 ± 0.44 b | 2.95 ± 0.18 c | 9.77 ± 0.40 b |

| PC15 | 46.57 ± 0.51 c | 2.73 ± 0.14 d | 8.91 ± 0.22 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blicharz-Kania, A.; Starek-Wójcicka, A.; Andrejko, D. Assessment of the Possibility of Using Poppy Seed Cake for the Production of Oat Cookies. Appl. Sci. 2022, 12, 9966. https://doi.org/10.3390/app12199966

Blicharz-Kania A, Starek-Wójcicka A, Andrejko D. Assessment of the Possibility of Using Poppy Seed Cake for the Production of Oat Cookies. Applied Sciences. 2022; 12(19):9966. https://doi.org/10.3390/app12199966

Chicago/Turabian StyleBlicharz-Kania, Agata, Agnieszka Starek-Wójcicka, and Dariusz Andrejko. 2022. "Assessment of the Possibility of Using Poppy Seed Cake for the Production of Oat Cookies" Applied Sciences 12, no. 19: 9966. https://doi.org/10.3390/app12199966

APA StyleBlicharz-Kania, A., Starek-Wójcicka, A., & Andrejko, D. (2022). Assessment of the Possibility of Using Poppy Seed Cake for the Production of Oat Cookies. Applied Sciences, 12(19), 9966. https://doi.org/10.3390/app12199966