1. Introduction

In civil and industrial buildings, plastic materials are usually limited to some complementary applications (e.g., pavement; door or window-frame; insulating/facing wall). Instead, in agricultural buildings, such as greenhouses and tunnels, they constitute the main constructive element, which delimits the external surface of the building, thus protecting the internal confined airspace against adverse meteorological events. Moreover, by virtue of their transparency properties to solar radiation, they develop a function of valorization of the incoming solar energy, which is used by crops for photosynthesis, at the same time being captured inside, hence improving the microclimatic characteristics of the internal environment as well [

1].

The agricultural plastic film market mainly covers greenhouse and mulching applications. Globally, in 2016, China had the largest area under protected cultivation, mainly under plastic greenhouses, estimated at 2.8 × 10

6 ha. Together with Korea and Japan, they account for 80% of the total area covered by greenhouses [

2]. According to the most recent estimations, in Europe in 2018, a total amount of 460,000 tons/year agricultural films were put on the market. Of these, 117,000 tons/year were for greenhouse covering application and 77,000 tons/year were for mulching. The rest was for livestock production [

3].

The progressive increase in the use of plastic material for crop protection needs a similar increase in studies on their technical characteristics, so as to suitably use and recycle them at the end of their useful life, in the framework of a Circular Economy approach, hence contributing to reducing the plastic footprint in agriculture [

4,

5,

6]. Indeed, the use of plastics in agriculture may create serious environmental problems, such as those connected with the management of large amounts of post-consumer material in areas characterized by a fragile environment and a marked tourism industry [

7]. A further increase in the use of agricultural plastic material should be therefore accompanied by scientific and technical efforts, aimed to reduce their environmental impact. To this aim, a better understanding of the factors hindering its mechanical recycling potential is paramount. In this sense, the conditions in which plastic materials conclude their useful life after application in agriculture are decisive. Among the main barriers to mechanical recycling, the low value of recycled products plays a considerable role. Therefore, it is crucial to analyze the most suitable conditions for the removal of plastic materials after ageing.

2. The Effect of Agrochemicals on Greenhouse Plastic Film for Recycling

The progressive degradation of plastic materials causes a change in their visible appearance, as well as in their chemical structure, and consequently on their physical and mechanical properties. Factors contributing to the more rapid degradation of plastics used in agriculture are related to atmospheric conditions, in particular the UV component of solar radiation [

8,

9]. Other factors that also intervene, albeit to a lesser extent, are [

10] air temperature and humidity, possible mechanical stress (especially caused by wind), contact with agrochemicals and possible internal stress related to the installation phase.

The degradation of plastic materials can be reduced, through the use of special additives [

11,

12,

13,

14,

15]. The further degradation of agricultural plastics at the end of their utilization period is directly related to the various disposal options. Describing, measuring and controlling the level of degradation of plastics is complicated by numerous technical, chemical and environmental factors [

16,

17]. Assessing the effects of polyethylene (PE) ageing through weathering is a crucial task to developing more durable materials, along with a better understanding of which additives can contribute to extending the life of these polymers [

18]. The global energy irradiated by the sun and arriving at a geographical area is usually accepted by the technical and scientific literature as being a relevant parameter and it is expressed in Langleys (Ly), the unit of energy distribution over an area (1 Ly = 1 cal/cm

2 = 41,840 J/m

2).

In order to understand the mechanisms of natural and artificial ageing processes of a triple-layer film made of low-density polyethylene (PE-LD) used as greenhouse cover, Dehbi et al. [

19] performed some experimental tests through natural ageing in Northern Algeria and artificial ageing at four different agricultural greenhouse simulating conditions of temperature and UV-A radiation. The results showed a significant decrease in the mechanical properties with ageing, which could be correlated with the structural changes in the film material. The natural ageing of the film in North Africa induced cleavage of the polymer chains, leading to more rapid degradation in the plastic film and, consequently, a reduction in its durability and service life, as well as mechanical recycling potential.

The existing standard test methods for measuring the mechanical properties of plastic films, however, do not provide the conditions for measuring the degradation of these properties when the plastic film is used as a covering material. Various accelerated ageing tests for plastic films have been proposed in recent years, but their relationship to actual ageing has not yet been sufficiently proven [

20]. In some cases, increased generation of degradation products, such as ketones, esters and alcohols (which is normal under natural conditions) was not observed under accelerated ageing conditions. A simple explanation may be that, under accelerated ageing conditions, cross-linking reactions occur due to the high number of radicals present in the polymer, thereby reducing the concentration of radicals taking part in the oxidation process. Under natural conditions, this “surplus” of radicals is not present and the radicals created combine with oxygen, resulting in peroxide radicals, which propagate oxidation. This observation is supported by the changes observed in the elongation at break. Under accelerated conditions, the direct consequence of cross-linking reactions is that the high elongation at break is maintained, until a relatively high level of oxidation occurs.

The scientific investigations performed so far have examined the combined effect of ageing and contact with agrochemicals on plastic greenhouse film. These mostly address the variations occurring in the technical properties of this material, rather than the consequences for its end-of-life phase. Specifically, by means of laboratory and field tests, all of these studies have investigated the effects of ageing on the distinct technical performances of plastic films used for greenhouses, i.e., radiometric properties and mechanical strength. To date, no research has been conducted that assesses the influence of non-natural ageing factors, such as the contact of the plastic film with agrochemicals under UV radiation [

21], on these materials, from a reusability and recyclability perspective.

An agricultural plastic material may be considered as having completed its working life when the main mechanical properties—principally, the percentage elongation at break, in the case of a plastic film—has reduced below 50% of the value it had in its virgin state. Therefore, the indicator of suitability for mechanical recycling is the presence of sufficient mechanical characteristics compared to the plastic waste material when it was new [

10]. The majority of agricultural plastic waste in Europe consists of PE-LD, PE-LD copolymers and, in some cases, linear PE-LD (PE-LLD) films from protected cultivation, shrink films and silage applications; thicknesses range from 20 to 250 μm [

22]. All of these products may contain a significant amount of additives (up to 15%). Greenhouse films are usually polystromatic and multilayered, containing ethylene-vinyl acetate (EVAC) or ethylene butyl acrylate copolymer (EBAC), while most films contain colorants and additives for UV protection (such as mulching films, irrigation pipes and tapes, containing carbon black). The mechanical properties of the recycled material may also be influenced by the presence of other factors, e.g., the addition of starch to PE-LD blends increases the tensile strength and the elongation at break, while it reduces the MFI values [

23,

24].

This paper contributes to expanding the knowledge on the degradation effects of films’ ageing in contact with agrochemicals. In this context, the results of laboratory tests on agricultural plastic films, which were artificially aged for different periods, and after being contaminated with two different agrochemicals, are presented.

3. Materials and Methods

Plastic film samples obtained from a PE-LD film commonly available in the market were alternatively contaminated with two agrochemicals. The first one was the anti-aphid insecticide EPIK SL VITHAL (active ingredient: Acetamiprid 50 g/L, producer: Ital-agro srl Salerano sul Lambro, LO, Italy).), classified as hazardous for the environment—

GHS09,

H410,

“very toxic to aquatic life with long-

lasting effects” [

25,

26]. The second agrochemical used was the fungicide CUMETA FLOW (active ingredients: Metalaxil-m 1.85%, copper hydroxide sulfate 15.40%, producer: Diachem S.p.A. Caravaggio (BG)—Italy), classified as an irritant—

GHS07,

H317 “May cause an allergic skin reaction + H319 Causes serious eye irritation”—and hazardous for the environment—

GHS09,

H410,

“very toxic to aquatic life with long-

lasting effects” [

25,

27]. These two agrochemicals have been selected, based on information received by agronomists and greenhouse farmers in Southern Italy, since they are among, respectively, the most used anti-aphid insecticide and fungicide.

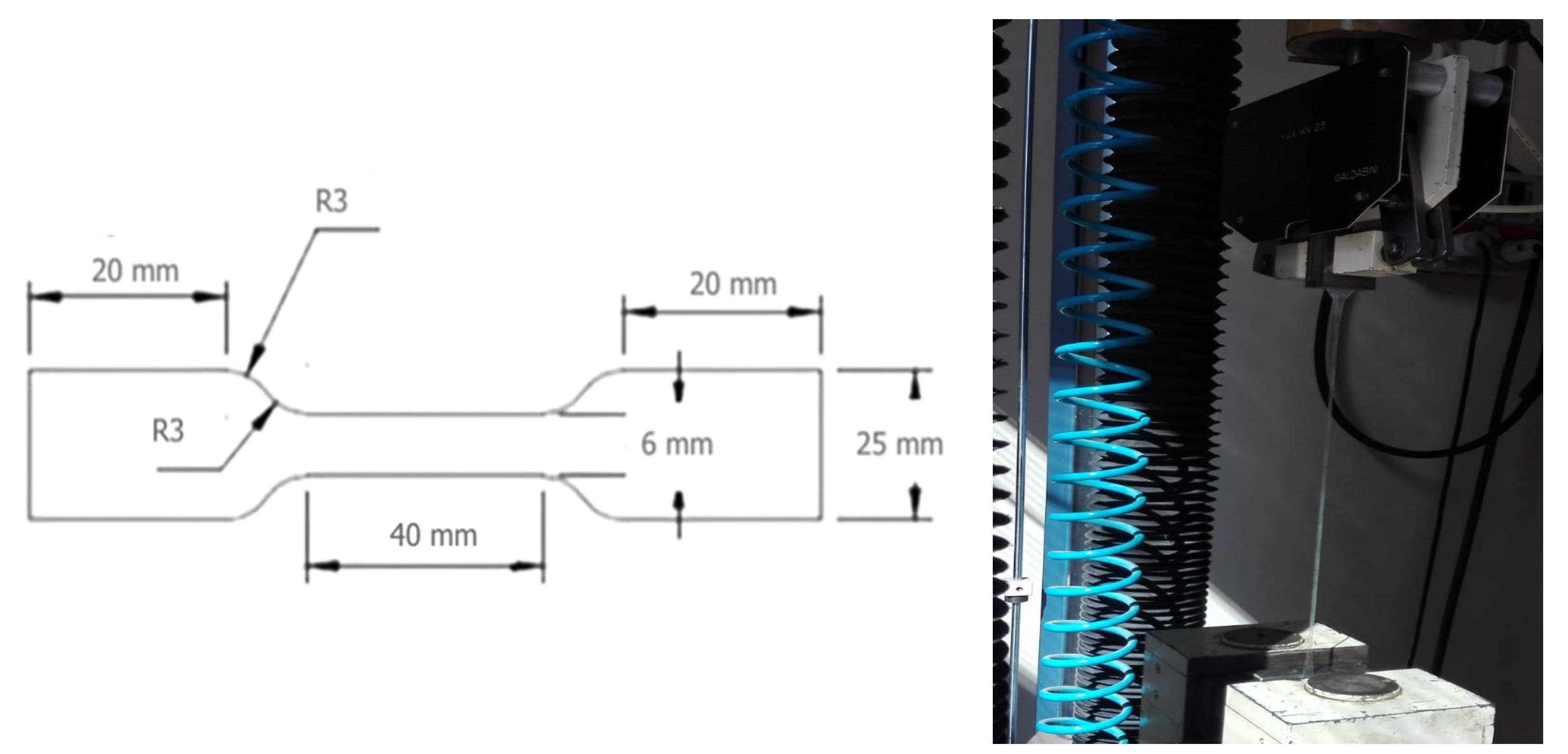

The two agrochemicals were sprayed on one side of the plastic film, simulating the process taking place in real conditions, when droplets are dispersed by the equipment spraying agrochemicals in liquid consistency on cultivated crops. To this aim, a simple sprayer—usually employed for phytosanitary treatment of domestic plants—was employed, spraying the plastic film before extracting specimens for tensile tests at a distance of 30 cm (

Figure 1). In this research, only one spraying was applied to plastic film, in order to simulate a simpler application first, corresponding to real conditions.

The specimens were then aged for 2 and 4 weeks in an ageing chamber (

Figure 1—right). The material was aged keeping a constant temperature of 20 °C in the ageing chamber. The ageing period was selected so as to simulate a corresponding ageing in open field in southern Italy, at the Municipality of Cellamare. There, a yearly global energy from the sun of 5554 MJ/m

2 = 132.74 kLy was detected in 2018. Since the energy released by the lamp of the ageing chamber has a power of 1000 W/m

2, this value corresponds to approximately 8 weeks of artificial ageing. Therefore, the tested periods of 2 and 4 weeks correspond to three and six months, respectively, in real conditions.

The PE-LD plastic film was also analyzed without any contamination, so as to have a reference sample. The tested materials are reported in

Table 1.

After the ageing process, each plastic film was tested through tensile tests and radiometric properties.

The mechanical properties were determined by tensile tests in the Laboratory of Material Testing at the SAFE School of the University of Basilicata, Italy. Ten specimens for each PE-LD film typology were cut according to the Italian UNI 8422 Standard [

28]. The tensile tests were conducted, using a computerized universal machine Galdabini PMA 10 with a load cell of 5 kN (

Figure 2), at constant deformation velocity of 200 [mm·min

−1]. The results obtained from tensile tests were reported in terms of maximum strength (σ

max) expressed in (MPa), and percentage elongation at break (A) expressed in (%).

The optical characteristics were analyzed by determining the absorbance in the wavenumbers to be 1650–1860 cm

−1 in a Iasco FT-IR spectro-radiometer. This allowed for the assessment of the change in the Carbonyl Index (CI) of the material during the ageing period, of which evolution on time was calculated with the following Equation [

10]:

where: CI = Carbonyl Index, (%); A

t = absorbance in the range 1650–1860 cm

−1 at time t (respectively 0, 2, 4 weeks), (%); A

0 = absorbance in the range 1650–1860 cm

−1 at time 0, (%); e = Molar absorbance coefficient, m; S = film thickness, m.

4. Results

The results of the mechanical tests are reported in

Table 2.

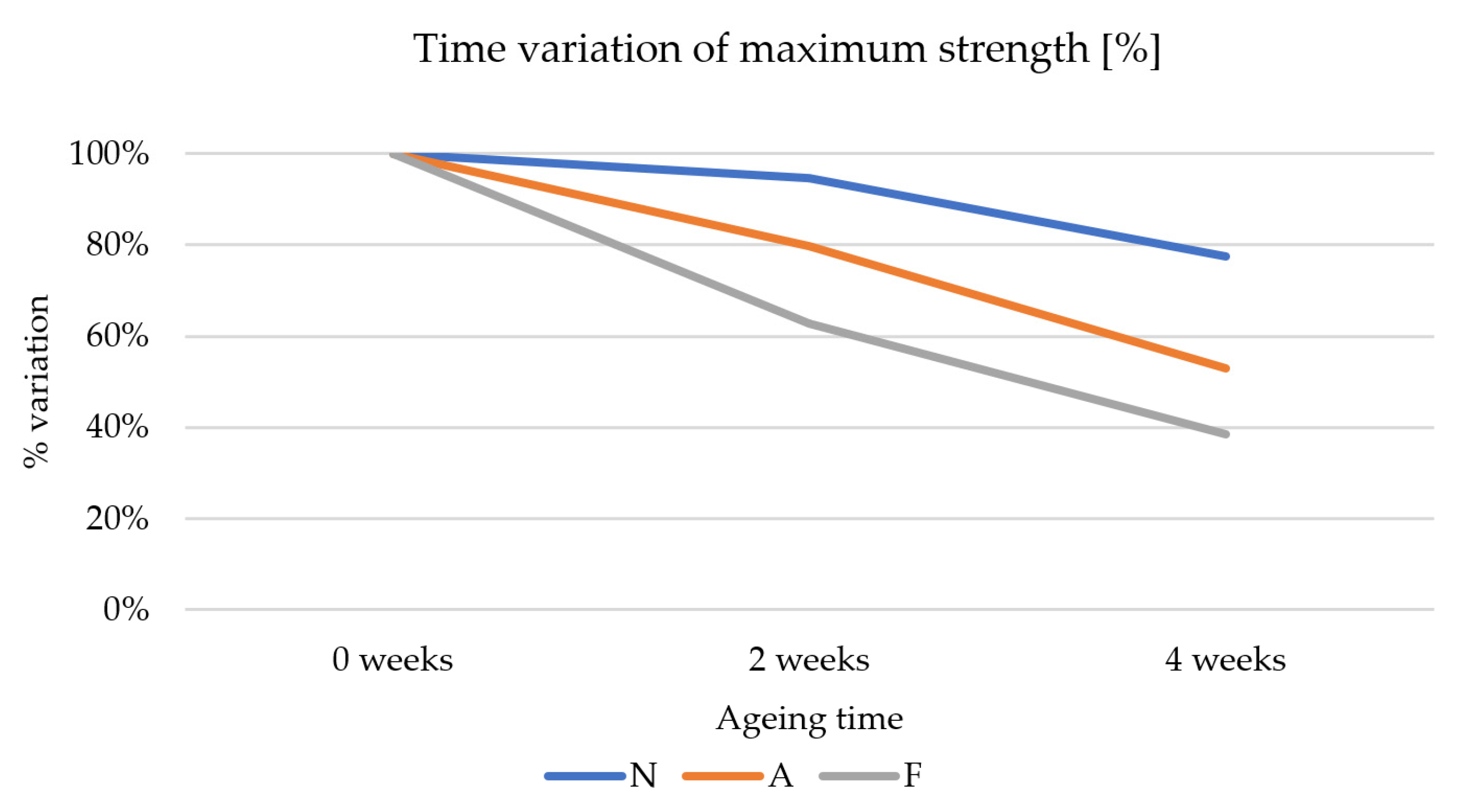

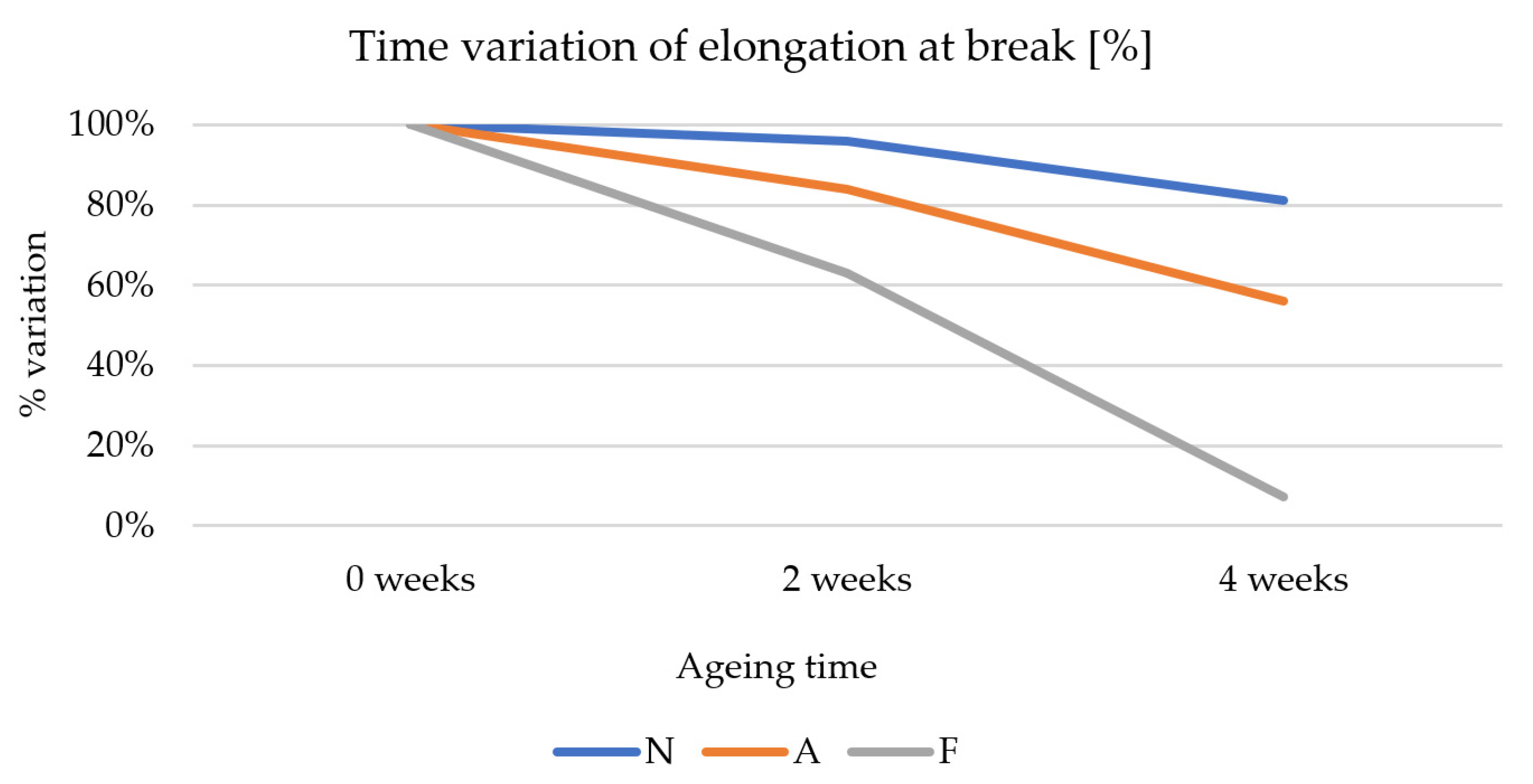

In

Figure 3 and

Figure 4 the results of the mechanical tests are reported in terms of percent variation over time compared to the value N0 of virgin PE-LD plastic film (i.e., the initial value has been considered = 100%). Specifically, these figures picture the variations in maximum strength and elongation at break due to ageing in contact with the respective contaminants. From these results, it is evident that the ageing of PE-LD plastic films in contact with agrochemicals greatly reduces their mechanical characteristics. After 4 weeks of artificial ageing, i.e., around six months in real conditions of ageing in Southern Italy, the material in contact with a pesticide/fungicide has reduced its elongation at break below 50% of the value as new, so it has to be removed.

The results in terms of Carbonyl Index (CI) confirm the tendency of the material to degrade rapidly when in contact with anti-aphid and fungicide contaminants. More specifically, as reported in

Table 3—where the percent increase in the Carbonyl Index over the different time period (i.e., after two weeks and after four weeks) are shown—the increase in CI of the uncontaminated sample is lower after 4 weeks of artificial ageing, clearly suggesting degradation effects taking place (mostly chain scissoring). On the other hand, the samples sprayed with agrochemicals experience a remarkable increase in CI values after 4 weeks of ageing. These samples are most likely undergoing degradation of the polymeric chains, whereby new carbonyl groups are being created, justifying an increase in the value [

29]. As in the case of mechanical performances, the sample contaminated with fungicide is subject to the most extensive degree of degradation through carbonyl bonds formation.

5. Discussion

The results obtained during this research show that the contact with agrochemicals plays a decisive role in the degradation process of the plastic film, confirming that agrochemicals generate by-products leading to degradation of greenhouse films together with a decrease in their mechanical and physical properties. The degradation due to agrochemicals was found to be dependent on their active principles, as well as on method and frequency of application. From the analysis of the decrease in the mechanical properties, it is possible to deduce that the effect of the UV radiation on the PE-LD film was revealed to be dominant, as expected, since it has been the main driver of the decay (

Figure 3 and

Figure 4). On the other hand, the synergistic effects and the relative importance of exposure to the two different agrochemicals in the degradation of the films were significant as well. Indeed, from the three treatments which have been applied—i.e., ageing after exposure to radiation only; ageing after exposure to radiation plus anti-aphid chemicals; ageing after exposure to radiation plus fungicide—there is an evident increase, according to this order, in the decay of both maximum strength and percentage elongation at break. Since the reduction in the elongation at break below the 50% of the virgin material is considered the technical criterion for defining the end of the useful working period and consequent need to remove the plastic film, it is clear that the contact with agrochemicals significantly worsens the ageing process of the plastic film, thus conducting to a reduced working life.

This increased reduction in mechanical properties boosted by the contact with agrochemicals, also entails that when entering the recycling stage, the material carries a low potential for being transformed into a closed-loop recycled material. This phenomenon is particularly clear in the case of PE-LD plastic film having been in contact with the fungicide, that has almost lost every mechanical property after 4 weeks of artificial ageing. In this case, its mechanical recycling would deliver a recycled material with no potential applications as a film. This is particularly true when considering the degradation occurring in polymers consequent to mechanical recycling, due to thermo-mechanical processes [

30,

31,

32].

The results presented here seem in accordance with several studies, which have been conducted to evaluate how agrochemical contamination is contributing to the concurrent action of other natural factors in the ageing of the plastic film used for covering greenhouses. Indeed, Briassoulis et al. [

33] analyzed the quantitative criteria which may be combined as a basis for the characterization of the degradation of PE-LD films (currently the most widespread greenhouse covering material in Mediterranean countries). The authors argued that the final characterization of the degradation of a greenhouse plastic film is mainly based on the change in percentage elongation at break. In this sense, the exposure of PE-LD film to weathering conditions (especially to solar irradiation in the range of 290–400 nm) affects its chemical structure and, consequently, its mechanical and physical properties. Briassoulis [

34] analyzed the synergistic effects of accelerated ageing on PE-LD greenhouse film by using an aggressive agrochemical (Vapam) under UV radiation. A non-stabilized film was used, in order to investigate the basic characteristics of ageing over a very short period. The ageing was assessed through changes in selected mechanical properties of the film, before and after ageing. A modified artificial ageing procedure was finally proposed, which was considered to simulate the weathering of PE-LD greenhouse film in a more realistic way. A series of experimental multilayer films, exposed to accelerated ageing in combination with agrochemicals, was examined by Briassoulis et al. [

35]. The authors showed that the presence of a barrier layer (ethylene vinyl alcohol—EVOH or polyamide—PA) adversely affects the mechanical behavior of multilayer films. The reduction in mechanical performance is due to the low ductility of these barrier layers, the failure of which propagates to the other layers, leading to premature failure of film structures.

From a morphological point of view, polyethylene is a semi-crystalline polymer with alternating crystalline and amorphous layers (two-phase system). Oxidation damage confined to the amorphous phase causes a break of the tie molecules that link the various crystalline lamellae and leads to a sudden loss in properties at the break. The previous observation is relevant to the assessment of the effect of ageing on the degree of crystallinity within the PE-LD film and correlating these with the changes in the overall mechanical properties. The degradation of the mechanical behavior of a PE-LD film is due to the changes that occur due to ageing of the molecular structure of the material. Any loss in chain length lowers the tensile strength and is a primary cause of premature failure and cracking. The gradual changes in the molecular structure due to ageing do not allow the polymer chains to reorient as before and provide additional resistance following the initial yield of the material. The energy carried by the UV portion of the sunlight is absorbed by a variety of structural defects. In this instance, additional groups (carbonyl, hydroxyl and/or hydroperoxide) will be built into the structure of the macromolecules as a result of photo-oxidation, leading to chain scissoring, a reduction in the average molecular weight and then deterioration of the physical–mechanical properties, to the extent that it makes the polymer no longer usable [

36]. The degradation process may be delayed by a special balance of inhibitors, engineered to the specific application and anticipated life expectancy of the plastic, thereby enabling a longer lifetime of the plastic material. In the case of plastic materials employed for crop protection, it is important to determine whether the design (i.e., the physical/chemical properties) of agricultural plastics allows them to be recycled. Briassoulis et al. [

37] tested the intrinsic characteristics (e.g., tensile strength, moisture, contaminants) of various categories of agricultural plastics during use, storage and transport, to determine the extent to which these characteristics may change over time and hinder the recyclability of the plastic material. The applications studied included plastics used in greenhouses, high tunnels, low tunnels, mulch and silage films. The study found that the intrinsic characteristics of most of the tested agricultural plastics did not present elements hindering their recyclability, with the exception of the PE films with pro-oxidants, which were considered as not being recyclable. The experimental data also showed that the Melt Flow Index (MFI) measurement may be considered to be a useful indication for the analysis of the degradation of some polymers after their useful lifetime, as well as after reprocessing. Finally, the exposure of most agricultural plastic waste categories to UV radiation from the sun during their useful lifetime does not lead to severe degradation that would make them “not recyclable” (because of their stabilization/additive systems).

The results of the present study appear in agreement also with other experimental research as well, as the one performed by Schettini and Vox [

38], who tested multilayer PE-LD/EVAC greenhouse films manufactured on purpose by adding different anti-UV stabilizer systems, that were exposed to natural, outdoor weathering at an experimental farm. Each film was tested as a cover for two low tunnels: one of them was sprayed on its inside face with commercial agrochemicals containing iron, chlorine and sulphur, while the other one was not sprayed, so as to be used as a reference. Radiometric tests were carried out on new film samples and obtained at the end of the test. Laboratory analysis of the uptake of selected contaminants was performed on the samples obtained at the end of the field exposure, in order to compare the relative effectiveness of the stabilizers. The final results showed that, within six months of the experimental field trials, the combined effect of natural weathering and agrochemicals did not significantly alter the radiometric properties of the films in the wavelength ranges of solar radiation and photosynthetically active radiation (PAR). In contrast, variations in up to 70% of the initial value were observed for stabilized films in the long-wavelength infrared (LWIR) wavelength range.

6. Conclusions

The results obtained during the present research show that the impact of agrochemicals on the plastic film is already considerable in the use-phase. They enable the evaluation of how agrochemical contamination and solar radiation influence the technical properties of a PE-LD greenhouse film, as well as its feasibility to be recycled into a new secondary product. Indeed, the effect of its exposure may result in dramatic deterioration of the film when applied alone, since it may accelerate ageing, with highly probable unfavorable repercussions on the feasibility of this material to undergo mechanical recycling processes. In this sense, future research should investigate how repeated application of agrochemicals, i.e., a common practice among farmers, influences the progressive behavior of the plastic film, reducing its mechanical properties, hence further compromising the possibilities for a successive mechanical recycling. Moreover, the possible changes in the polymeric chain occurring after ageing in contact with the anti-aphid and the fungicide (e.g., through FTNIR) should be investigated, as well as variations in the processability, comparing the values of the Melt Flow Index and the density of the different tested samples.