Practical Experience in the Application of Energy Roofs, Ground Heat Storages, and Active Thermal Protection on Experimental Buildings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- ▪

- Engelmann Sensostar2 compact heat meters,

- ▪

- Testo 845 infrared thermometer,

- ▪

- MobIR M4 portable infrared camera.

2.2. Methods

- ▪

- Analysis and synthesis of knowledge in the field of energy (solar) roofs, ground heat storage, and active thermal protection (thermal barriers and other energy functions), Introduction;

- ▪

- ▪

- Inductive and analog form of creating variants of an innovative way of operation of combined building-energy systems, Section 2.2.1;

- ▪

- Development of an innovative circuit panel solution with integrated energy-active elements, Section 2.2.2;

- ▪

- Development of mathematical-physical models of envelopes with active thermal protection, Section 2.2.3;

- ▪

- Parametric study and analysis of the energy potential of active thermal protection in the function of thermal barrier, Section 3.1.1;

- ▪

- Synthesis of the knowledge obtained from the scientific research and transformation of the data into the design and implementation of the IDA I prefabricated house prototype, Section 3.1.2, and the EB2020 experimental house, Section 3.1.3;

- ▪

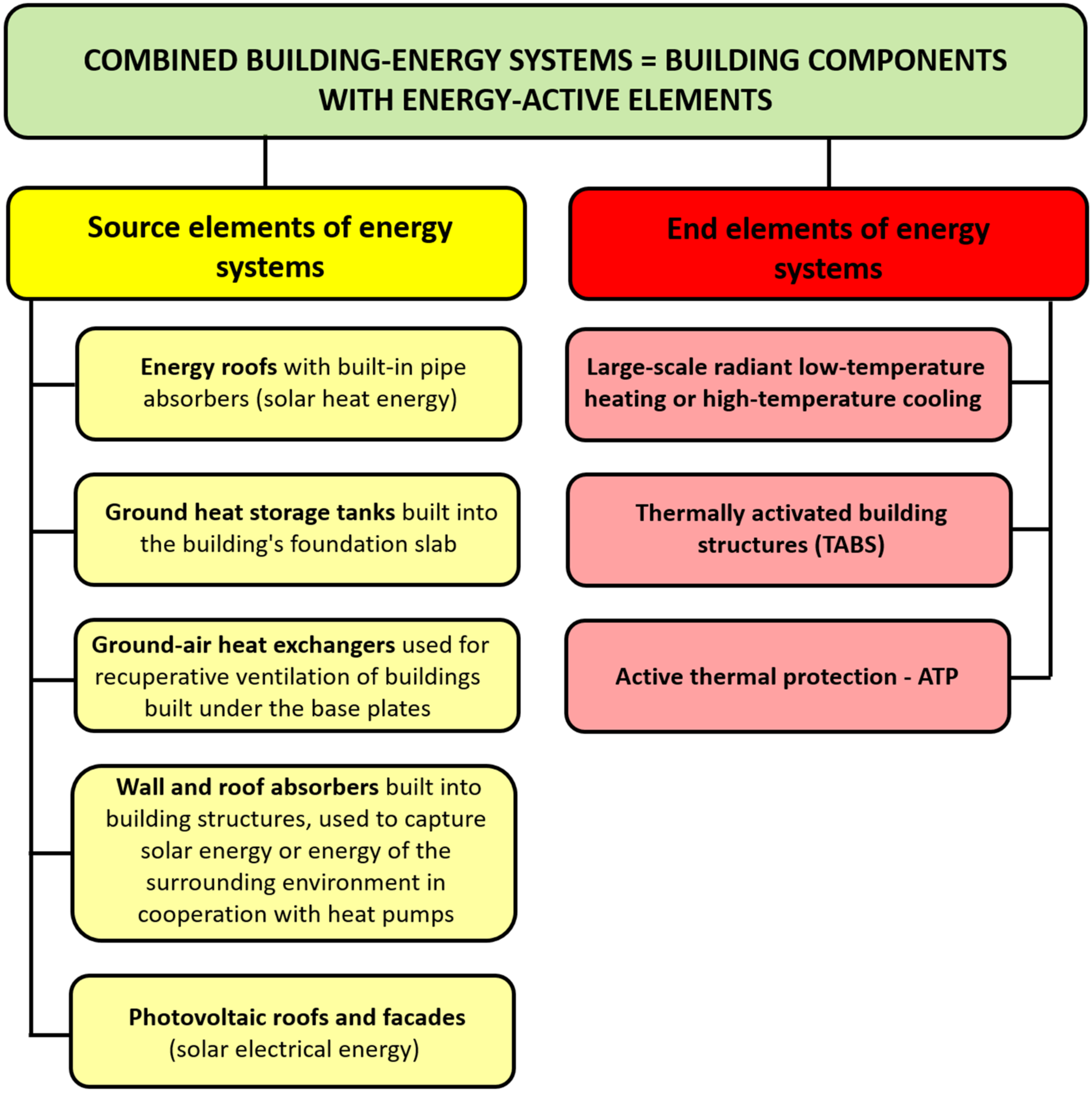

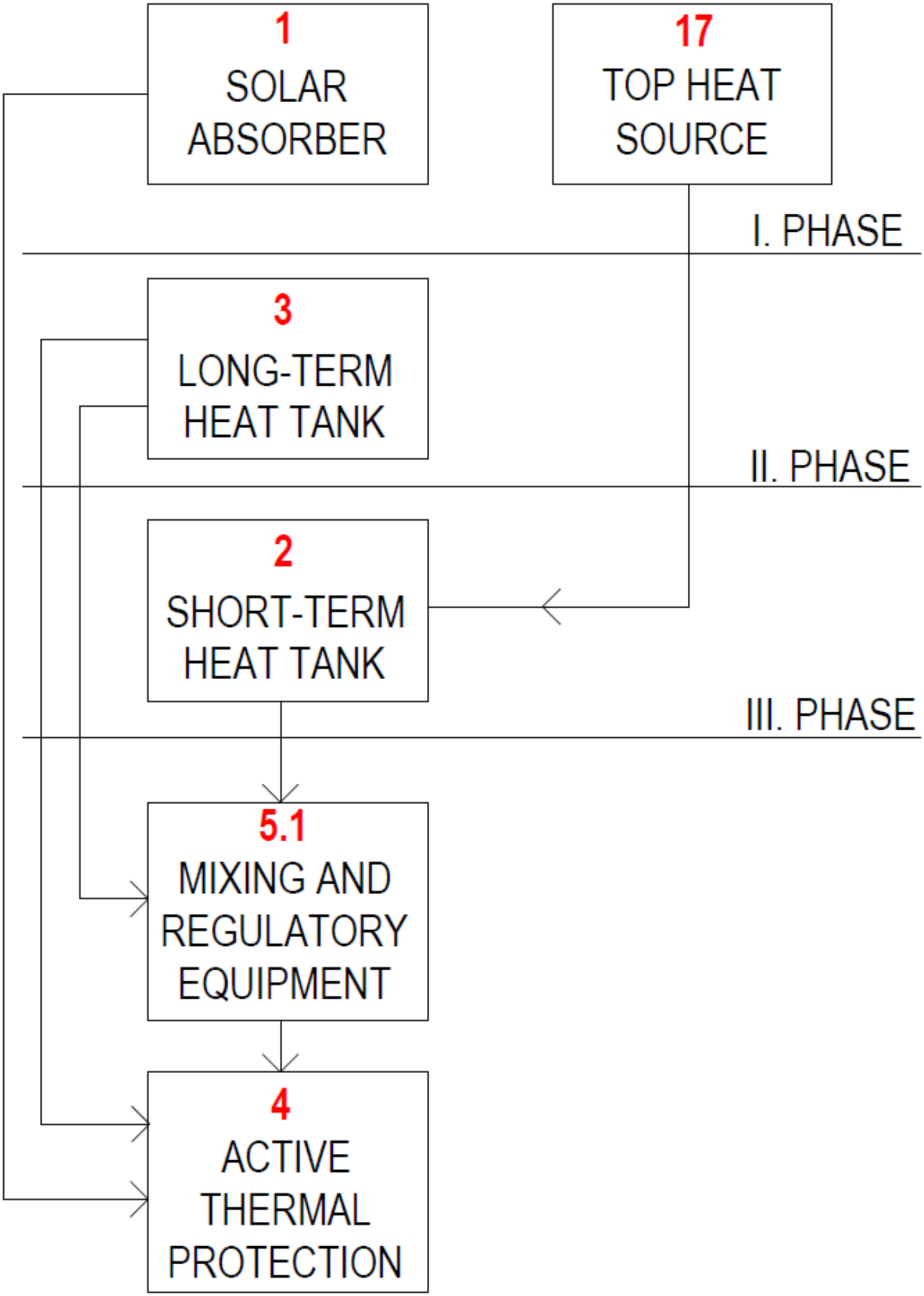

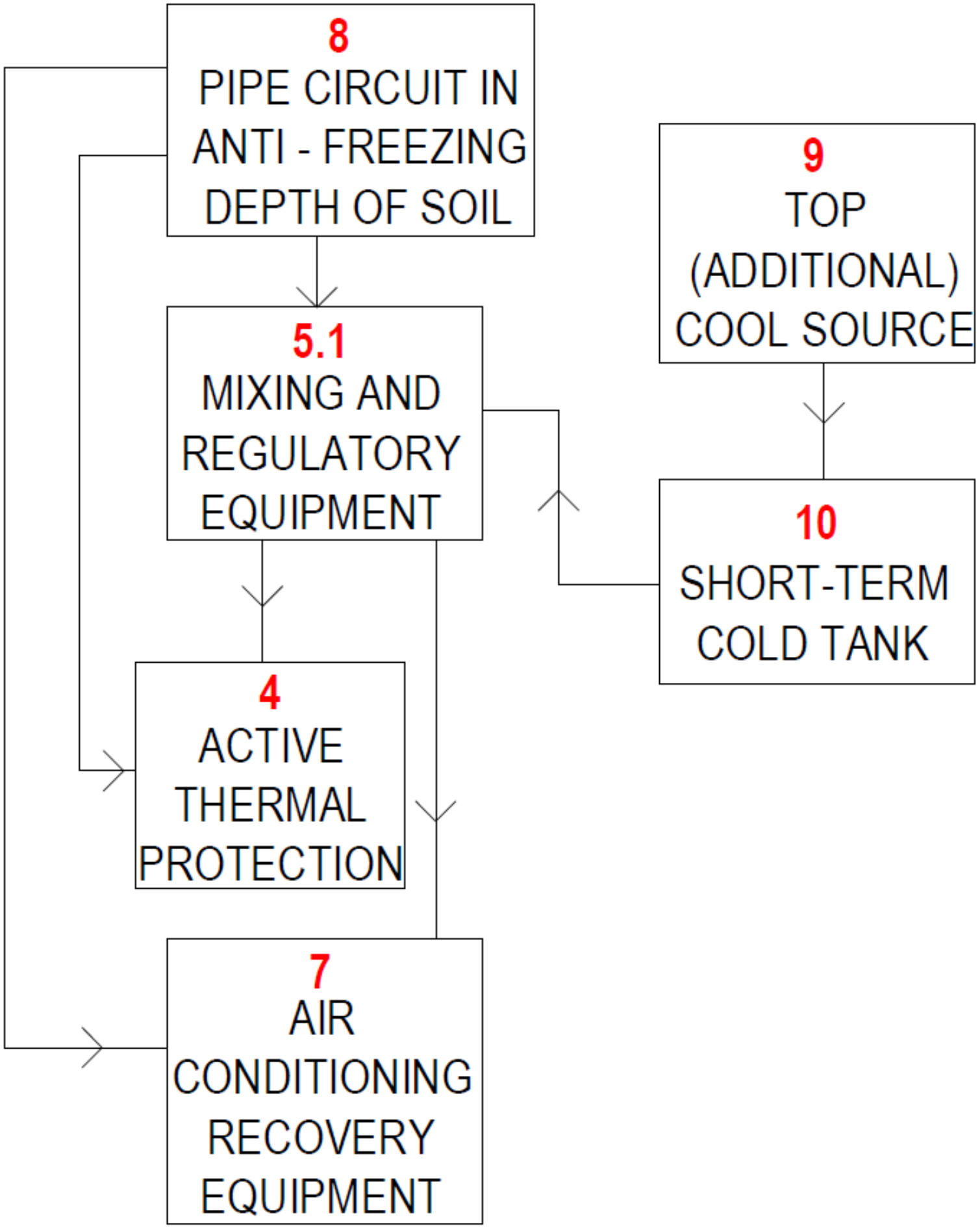

2.2.1. The Inductive and Analogical Form of Creating an Innovative Way of Operating a Combined Building-Energy System

- (a)

- Solar thermal energy storage operation;

- (b)

- Operation with active thermal protection;

- (c)

- Operation with low-temperature hot-water heating;

- (d)

- Operation with hot air heating;

- (e)

- Operation with cooling and/or ventilation;

- (f)

- Operation with preheating and reheating of domestic hot water;

- (g)

- Waste heat recovery operation.

Solar Thermal Energy Storage Operation

Operation with Active Thermal Protection

Operation with Low-Temperature Hot-Water Heating

Operation with Hot Air Heating

Operation with Cooling and/or Ventilation

Operation with Preheating and Reheating of Domestic Hot Water

Waste Heat Recovery Operation

2.2.2. The Development of an Innovative Circuit Panel Solution with Integrated Energy-Active Elements

2.2.3. Development of Mathematical-Physical Models of Envelopes with Active Thermal Protection

3. Results and Discussion in General

3.1. Results

- ▪

- Parametric study and analysis of the energy potential of active thermal protection in the function of thermal barrier;

- ▪

- The prototype of the prefabricated house IDA I;

- ▪

- The Experimental Family House EB2020.

3.1.1. Parametric Study and Analysis of the Energy Potential of Active Thermal Protection in the Function of Thermal Barrier

3.1.2. The Prototype of the Prefabricated House IDA I

3.1.3. The Experimental Family House EB2020

3.2. Discussion in General

4. Conclusions

- ▪

- The application of an energy (solar) roof (ESR) requires lower investment costs than conventional solar collectors, but experimental measurements have shown that the energy gain and the achieved outlet temperatures of the working fluid are significantly lower. To increase the ESR efficiency, applying a dark-colored roof covering is important and installing more circuits with a suitable distribution according to cardinal directions is important.

- ▪

- The use of ESR for low-temperature heating or supply of active thermal protection can only be implemented with a suitable heat storage solution. For hot water production, the ESR can only be used for preheating. The ESR could also be used as a collector for a heat pump, which would serve for heating, domestic hot water preparation, and cooling.

- ▪

- Heat accumulation in a conventional house slab foundation as a ground heat storage (GHS) is limited only to the application of active thermal protection in a thermal barrier (TB) function. It is insufficient for heating and domestic hot water. Heat accumulation from ESR and peak heat sources is recommended in large-capacity water storage tanks or in storage tanks with the change of state.

- ▪

- The use of ATP in wall heating and cooling is of practical significance only in building constructions with a high accumulation capacity on the inside in front of the ATP tubes, i.e., high bulk density, thermal conductivity, and thermal capacity, e.g., reinforced concrete.

- ▪

- Building structures that have a high thermal resistance in front of the ATP pipes are only suitable for the thermal barrier function. Parametric studies predict such structures to achieve high equivalent thermal resistance at relatively low mean temperatures of the heat transfer medium. For example, +10 to +15 °C represents a design with thermal insulation of 300 to 800 mm, see Table 1 in Section 3.1.1.

- ▪

- Based on the analysis of the parametric study results of the energy potential of individual technical solutions of reinforced concrete envelope panels with integrated energy active elements in Section 3.2., it can be concluded that the increase in heat loss due to the location of the tubes in the structure closer to the exterior is negligible for VARIANT II, semi-accumulation heating (TABS system), and VARIANT III, accumulation heating, compared to VARIANT I, direct heating, below 1% of the total delivered heat flux, Figure 30. The direct heat flux to the heated room is 89.17% for direct heating, VARIANT I, 73.36% for semi-accumulation heating (TABS system), VARIANT II and 58.46% for accumulation heating, VARIANT III of the total delivered heat flux, Figure 30. For simplicity, VARIANT I does not consider heat accumulation for the panel. For the panel design (TABS system), VARIANT II represents 14.84% and VARIANT III up to 29.86% heat accumulation of the total delivered heat flux, Figure 30. Variants II and III appear promising in heat/cool accumulation with an assumption of lower energy demand (at least 10%) than for low inertia walls.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Available online: http://www.isomax-terrasol.eu/home.html (accessed on 17 August 2022).

- Available online: https://www.rehau.com/sk-sk (accessed on 17 August 2022).

- Available online: https://www.rieder.cc/us/ (accessed on 17 August 2022).

- Li, Y.; Ding, D.; Liu, C.; Wang, C. A pixel-based approach to estimation of solar energy potential on building roofs. Energy Build. 2016, 129, 563–573. [Google Scholar] [CrossRef]

- Michael, J.J.; Selvarasan, I. Economic analysis and environmental impact of flat plate roof mounted solar energy systems. Sol. Energy 2017, 142, 159–170. [Google Scholar] [CrossRef]

- Walch, A.; Castello, R.; Mohajeri, N.; Scartezzini, J.L. Big data mining for the estimation of hourly rooftop photovoltaic potential and its uncertainty. Appl. Energy 2020, 262, 114404. [Google Scholar] [CrossRef]

- Lazzarotto, A. Developments in Ground Heat Storage Modeling. Ph.D. Dissertation, KTH Royal Institute of Technology, Stockholm, Sweden, 2015. [Google Scholar]

- Haq, H.M.; Hiltunen, E. An inquiry of ground heat storage: Analysis of experimental measurements and optimization of system’s performance. Appl. Therm. Eng. 2019, 148, 10–21. [Google Scholar] [CrossRef]

- Sun, T.; Yang, L.; Jin, L.; Luo, Z.; Zhang, Y.; Liu, Y.; Wang, Z. A novel solar-assisted ground-source heat pump (SAGSHP) with seasonal heat-storage and heat cascade utilization: Field test and performance analysis. Sol. Energy 2020, 201, 362–372. [Google Scholar] [CrossRef]

- Li, A.; Xu, X.; Sun, Y. A study on pipe-embedded wall integrated with ground source-coupled heat exchanger for enhanced building energy efficiency in diverse climate regions. Energy Build. 2016, 121, 139–151. [Google Scholar] [CrossRef]

- Kisilewicz, T.; Fedorczak-Cisak, M.; Barkanyi, T. Active thermal insulation as an element limiting heat loss through external walls. Energy Build. 2019, 205, 109541. [Google Scholar] [CrossRef]

- Iffa, E.; Hun, D.; Salonvaara, M.; Shrestha, S.; Lapsa, M. Performance evaluation of a dynamic wall integrated with active insulation and thermal energy storage systems. J. Energy Storage 2022, 46, 103815. [Google Scholar] [CrossRef]

- Kalús, D. The Contract for Work HZ 04–309–05—Design of a Passive House Using Solar and Geothermic Energy; K–TZB SvF STU: Bratislava, Slovakia, 2006. [Google Scholar]

- Cvíčela, M. Analysis of Wall Energy Systems. Ph.D. Dissertation, Faculty of Civil Engineering, Slovak University of Technology in Bratislava, Bratislava, Slovakia, 2011. [Google Scholar]

- Kalús, D. The Contract for Work HZ PG73/2011—Experimental Measurements, Analysis, and Determination of the Optimal Rate of Use of Renewable Energy Sources on a Prototype of a Family House EB2020 with Nearly Zero Energy Demand; K-TZB SvF STU: Bratislava, Slovakia, 2011–2013. [Google Scholar]

- Janík, P. Optimization of Energy Systems with Long-Term Heat Accumulation. Ph.D. Dissertation, Faculty of Civil Engineering, Slovak University of Technology in Bratislava, Bratislava, Slovakia, 2013. [Google Scholar]

- Available online: https://wbr.indprop.gov.sk/WebRegistre/UzitkovyVzor/Detail/5027-2010 (accessed on 17 August 2022).

- Available online: https://wbr.indprop.gov.sk/WebRegistre/UzitkovyVzor/Detail/5030-2010 (accessed on 17 August 2022).

- Available online: https://wbr.indprop.gov.sk/WebRegistre/UzitkovyVzor/Detail/5031-2010 (accessed on 17 August 2022).

- Available online: https://patents.google.com/patent/WO2011146025A1/und (accessed on 17 August 2022).

- Kalús, D.; Janík, P.; Kubica, M. Experimental house EB2020—Research and experimental measurements of an energy roof. Energy Build. 2021, 248, 111172. [Google Scholar] [CrossRef]

- Kalús, D.; Janík, P.; Koudelková, D.; Mučková, V.; Sokol, M. Contribution to research on ground heat storages as part of building energy systems using RES. Energy Build. 2022, 267, 112125. [Google Scholar] [CrossRef]

- Kalús, D.; Gašparík, J.; Janík, P.; Kubica, M.; Šťastný, P. Innovative building technology implemented into facades with active thermal protection. Sustainability 2021, 13, 4438. [Google Scholar] [CrossRef]

- Kalús, D.; Koudelková, D.; Mučková, V.; Sokol, M.; Kurčová, M. Contribution to the Research and Development of Innovative Building Components with Embedded Energy-Active Elements. Coatings 2022, 12, 1021. [Google Scholar] [CrossRef]

- Šimko, M.; Krajčík, M.; Šikula, O.; Šimko, P.; Kalús, D. Insulation panels for active control of heat transfer in walls operated as space heating or as a thermal barrier: Numerical simulations and experiments. Energy Build. 2018, 158, 135–146. [Google Scholar] [CrossRef]

- Standard STN 73 0540-2+Z1+Z2; Thermal Protection of Buildings. Thermal Performance of Buildings and Components. Part 2: Functional requirements. Slovenský Ústav Technickej Normalizácie: Bratislava, Slovakia, 2019.

- Babiak, J.; Olesen, B.W.; Petras, D. Low Temperature Heating and High Temperature Cooling. Embedded Water Based Surface Heating and Cooling Systems; Rakennusten Pintalaemmitys Ja-Jaeaehdytys. Rakenteisiin Upotetut Vesikiertoiset Pintalaemmitys-Ja Jaeaehdytysjaerjestelmaet. Available online: https://www.osti.gov/etdeweb/biblio/1030138 (accessed on 5 August 2022).

- Petráš, D. Nízkoteplotní Vytápění a Obnovitelné Zdroje Energie; Vydavateľstvo JAGA Group: Bratislava, Slovakia, 2008; 216p, ISBN 978-80-8076-069-4. [Google Scholar]

- Petráš, D.; Kalús, D.; Koudelková, D. Vykurovacie Sústavy, Cvičenie a Ateliérová Tvorba; STU: Bratislava, Slovakia, 2012; ISBN 978-80-227-3795-1. [Google Scholar]

- Ning, B.; Schiavon, S.; Bauman, F.S. A novel classification scheme for design and control of radiant system based on thermal response time. Energy Build. 2017, 137, 38–45. [Google Scholar] [CrossRef]

- Aste, N.; Angelotti, A.; Buzzetti, M. The influence of the external walls thermal inertia on the energy performance of well insulated buildings. Energy Build. 2009, 41, 1181–1187. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M.F.; Al-Hussain, S.N. Effect of thermal mass on performance of insulated building walls and the concept of energy savings potential. Appl. Energy 2012, 89, 430–442. [Google Scholar] [CrossRef]

- Schmelas, M.; Feldmann, T.; Wellnitz, P.; Bollin, E. Adaptive predictive control of thermo-active building systems (TABS) based on a multiple regression algorithm: First practical test. Energy Build. 2016, 129, 367–377. [Google Scholar] [CrossRef]

- Nemethova, E.; Petras, D.; Krajcik, M. Indoor environment in a high-rise building with lightweight envelope and thermally active ceiling. In Proceedings of the 12th REHVA World Congress (CLIMA 2016), Aalborg, Denmark, 22–25 May 2016; Volume 22, p. 2016. [Google Scholar]

- Široký, J.; Oldewurtel, F.; Cigler, J.; Prívara, S. Experimental analysis of model predictive control for an energy efficient building heating system. Appl. Energy 2011, 88, 3079–3087. [Google Scholar] [CrossRef]

| dTIext (m) | 0.075 | 0.100 | 0.125 | 0.150 | 0.175 | 0.200 | 0.250 | 0.300 | 0.400 |

| U (W/(m2·K)) | 0.167 | 0.150 | 0.137 | 0.125 | 0.115 | 0.107 | 0.093 | 0.083 | 0.068 |

| R (m2·K/W) | 5.802 | 6.478 | 7.154 | 7.829 | 8.505 | 9.181 | 10.532 | 11.883 | 14.586 |

| θTB (°C) | −0.190 | 1.860 | 3.540 | 4.930 | 6.100 | 7.110 | 8.730 | 10.000 | 11.830 |

| dTIext (m) | 0.500 | 0.600 | 0.700 | 0.800 | 0.900 | 1.000 | 1.500 | 2.000 | 3.000 |

| U (W/(m2·K)) | 0.057 | 0.05 | 0.044 | 0.039 | 0.035 | 0.032 | 0.022 | 0.017 | 0.012 |

| R (m2·K/W) | 17.289 | 19.991 | 22.694 | 25.397 | 28.099 | 30.802 | 44.316 | 57.829 | 84.856 |

| θTB (°C) | 13.090 | 14.02 | 14.73 | 15.28 | 15.74 | 16.11 | 17.29 | 17.92 | 18.58 |

| dTIext (m) | 0.075 | 0.100 | 0.125 | 0.150 | 0.175 | 0.200 | 0.250 | 0.300 | 0.400 |

| U (W/(m2·K)) | 0.167 | 0.150 | 0.137 | 0.125 | 0.115 | 0.107 | 0.093 | 0.083 | 0.068 |

| R (m2·K/W) | 5.802 | 6.478 | 7.154 | 7.829 | 8.505 | 9.181 | 10.532 | 11.883 | 14.586 |

| θTB (°C) | 31.21 | 30.68 | 30.25 | 29.89 | 29.59 | 29.33 | 28.91 | 28.58 | 28.11 |

| dTIext (m) | 0.500 | 0.600 | 0.700 | 0.800 | 0.900 | 1.000 | 1.500 | 2.000 | 3.000 |

| U (W/(m2·K)) | 0.057 | 0.05 | 0.044 | 0.039 | 0.035 | 0.032 | 0.022 | 0.017 | 0.012 |

| R (m2·K/W) | 17.289 | 19.991 | 22.694 | 25.397 | 28.099 | 30.802 | 44.316 | 57.829 | 84.856 |

| θTB (°C) | 27.78 | 27.54 | 27.36 | 27.22 | 27.10 | 27.00 | 26.70 | 26.54 | 26.37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalús, D.; Koudelková, D.; Mučková, V.; Sokol, M.; Kurčová, M.; Janík, P. Practical Experience in the Application of Energy Roofs, Ground Heat Storages, and Active Thermal Protection on Experimental Buildings. Appl. Sci. 2022, 12, 9313. https://doi.org/10.3390/app12189313

Kalús D, Koudelková D, Mučková V, Sokol M, Kurčová M, Janík P. Practical Experience in the Application of Energy Roofs, Ground Heat Storages, and Active Thermal Protection on Experimental Buildings. Applied Sciences. 2022; 12(18):9313. https://doi.org/10.3390/app12189313

Chicago/Turabian StyleKalús, Daniel, Daniela Koudelková, Veronika Mučková, Martin Sokol, Mária Kurčová, and Peter Janík. 2022. "Practical Experience in the Application of Energy Roofs, Ground Heat Storages, and Active Thermal Protection on Experimental Buildings" Applied Sciences 12, no. 18: 9313. https://doi.org/10.3390/app12189313

APA StyleKalús, D., Koudelková, D., Mučková, V., Sokol, M., Kurčová, M., & Janík, P. (2022). Practical Experience in the Application of Energy Roofs, Ground Heat Storages, and Active Thermal Protection on Experimental Buildings. Applied Sciences, 12(18), 9313. https://doi.org/10.3390/app12189313