An Experimental Study for Swelling Effect on Repairing of Cracks in Fine-Grained Clayey Soils

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

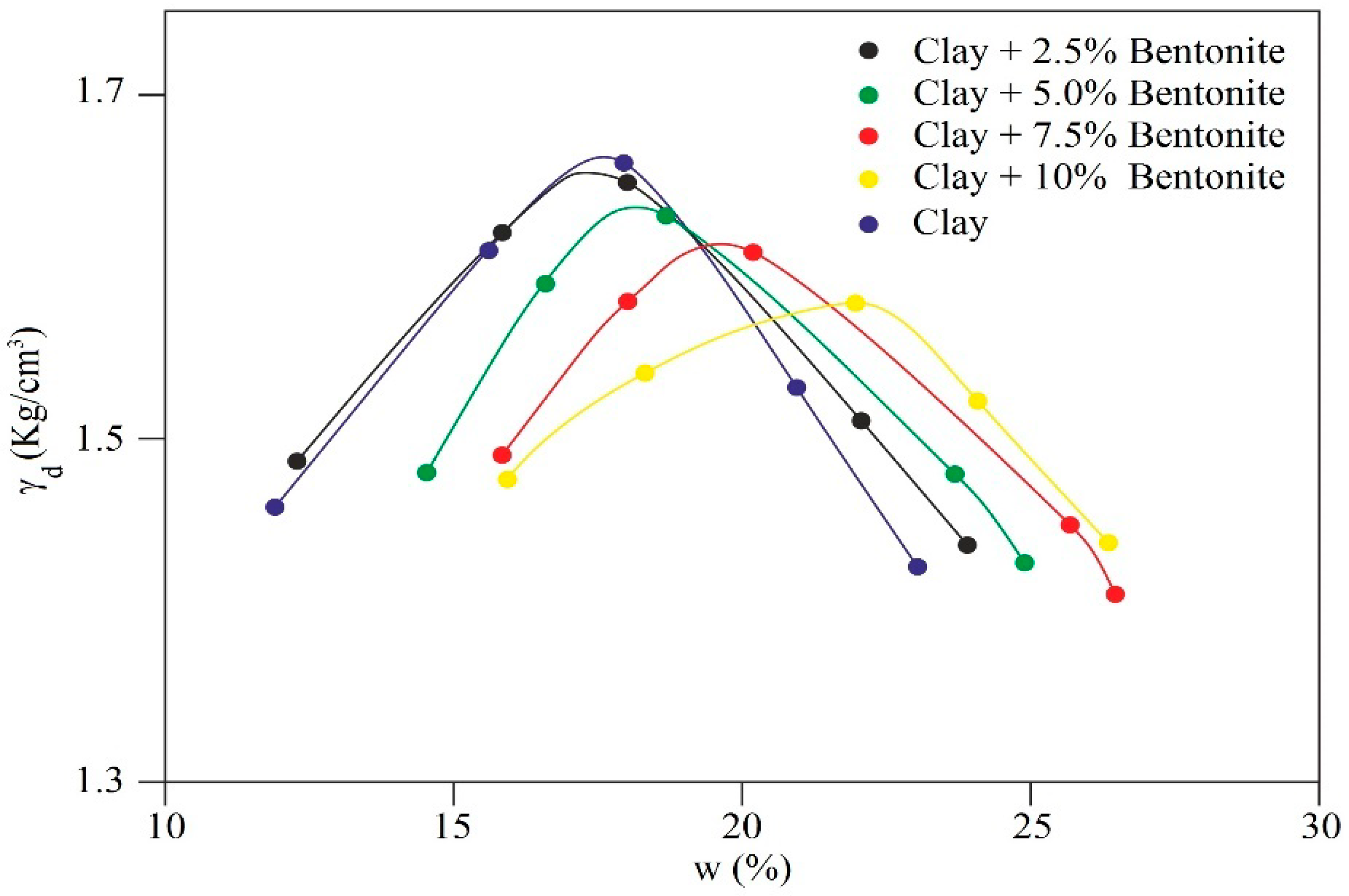

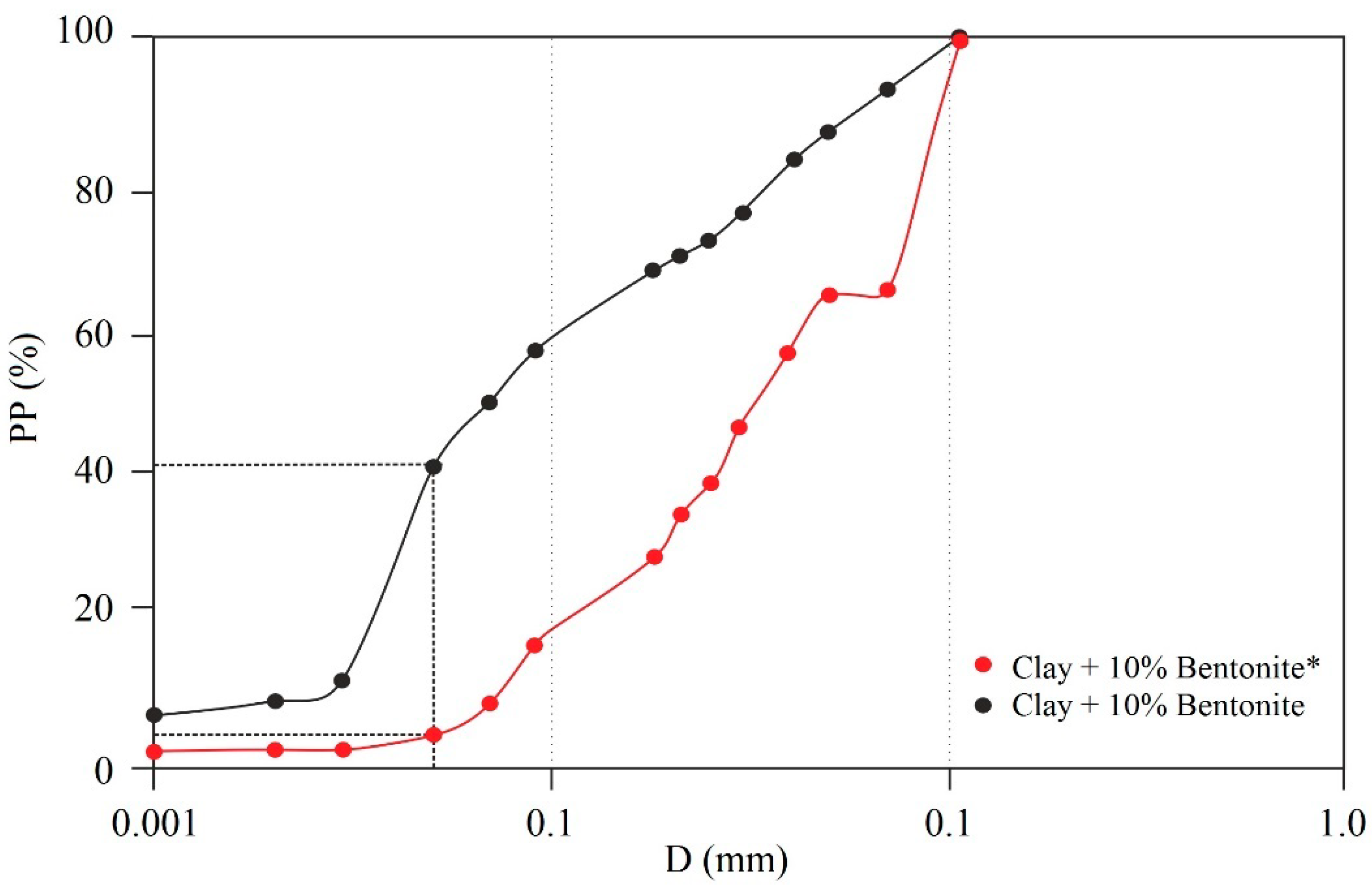

3.1. Geo-Engineering Characteristics

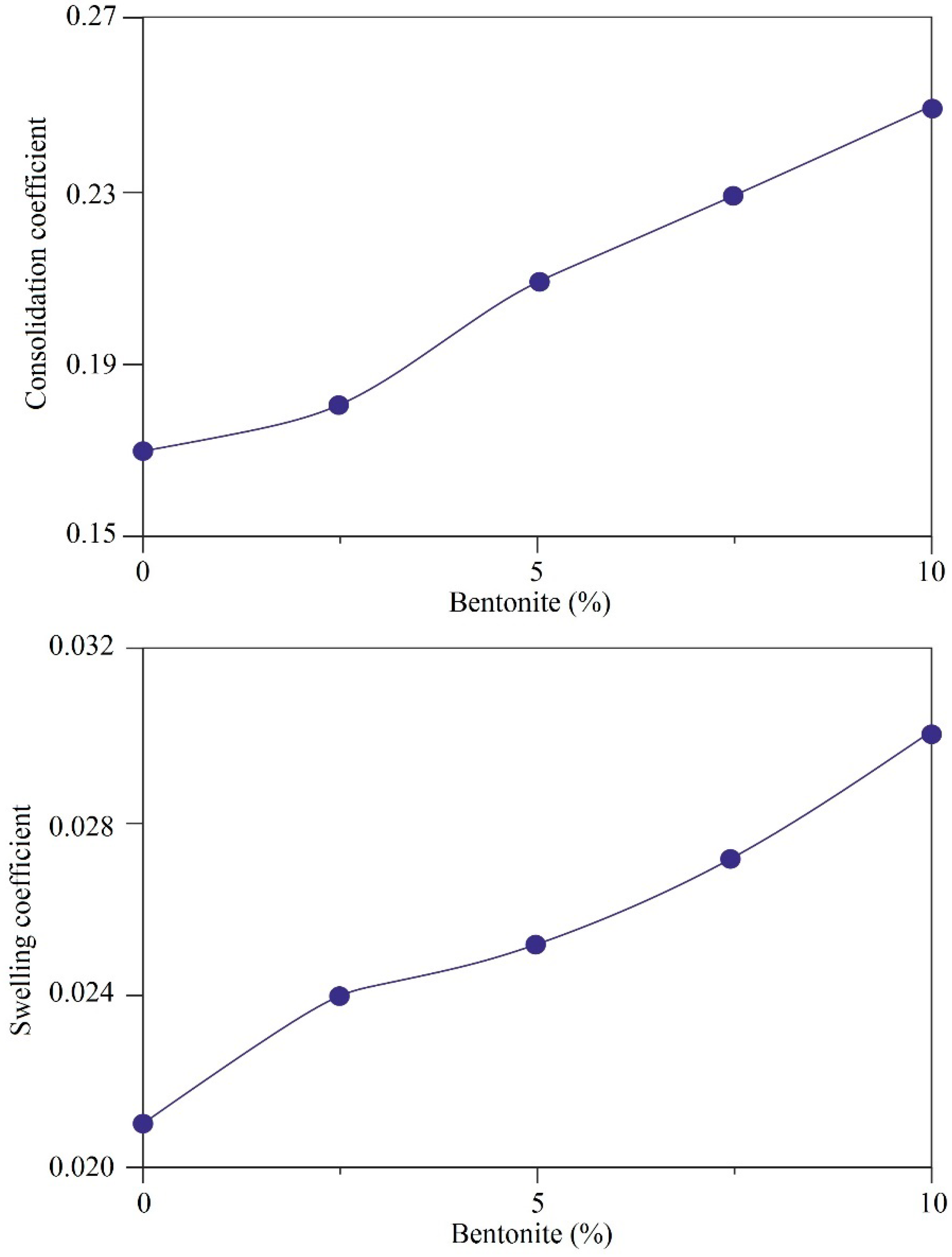

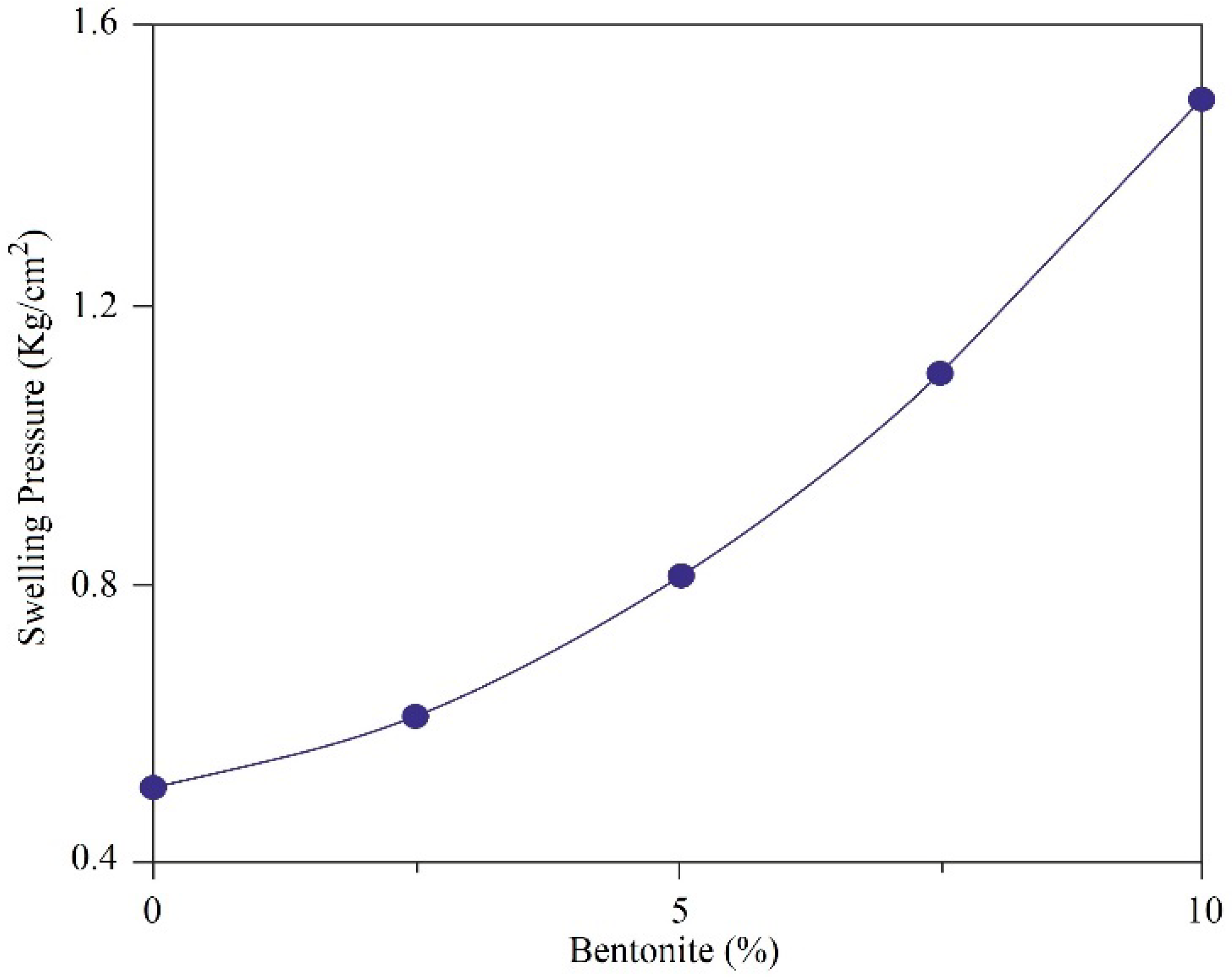

3.2. Swelling and Swell-Ability

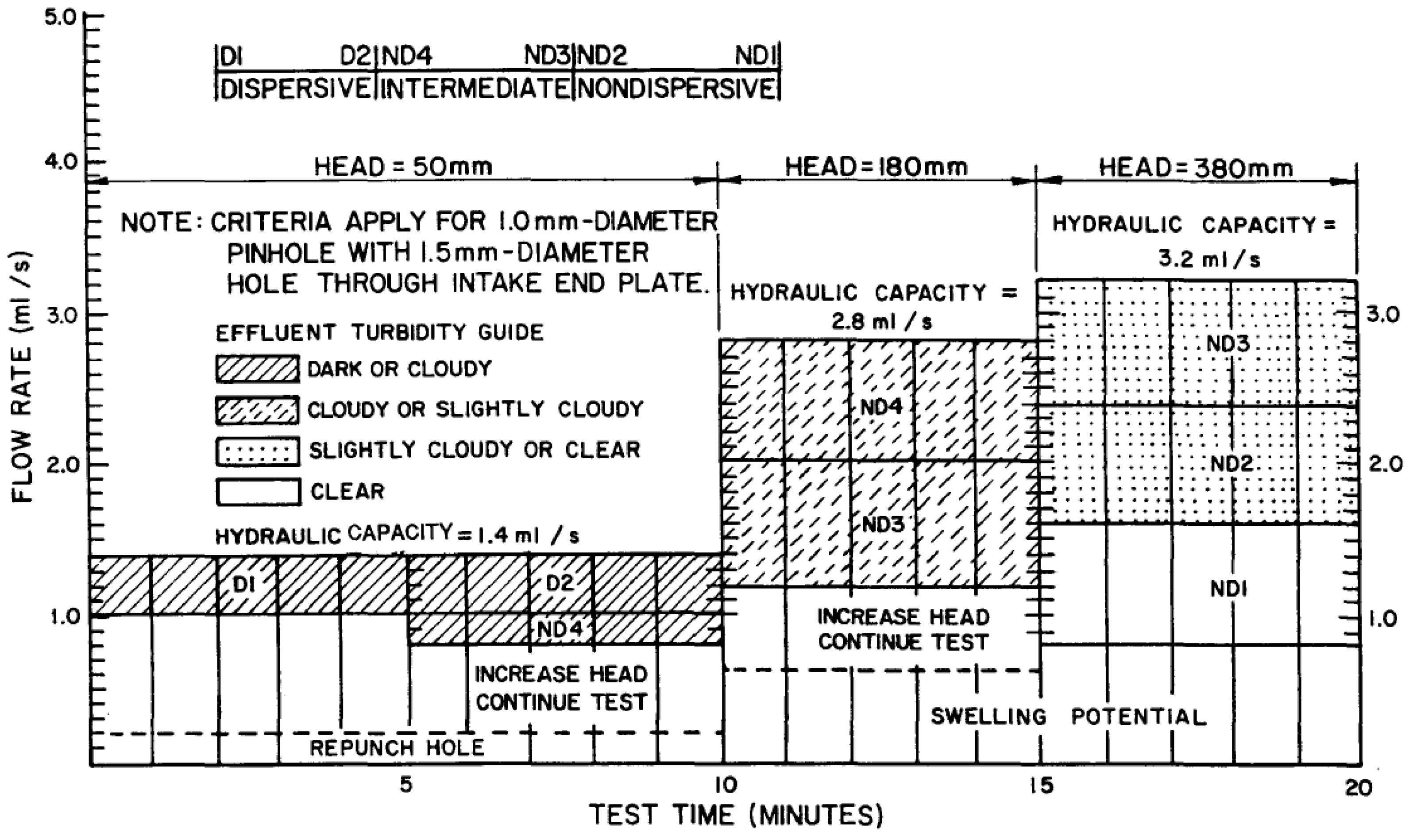

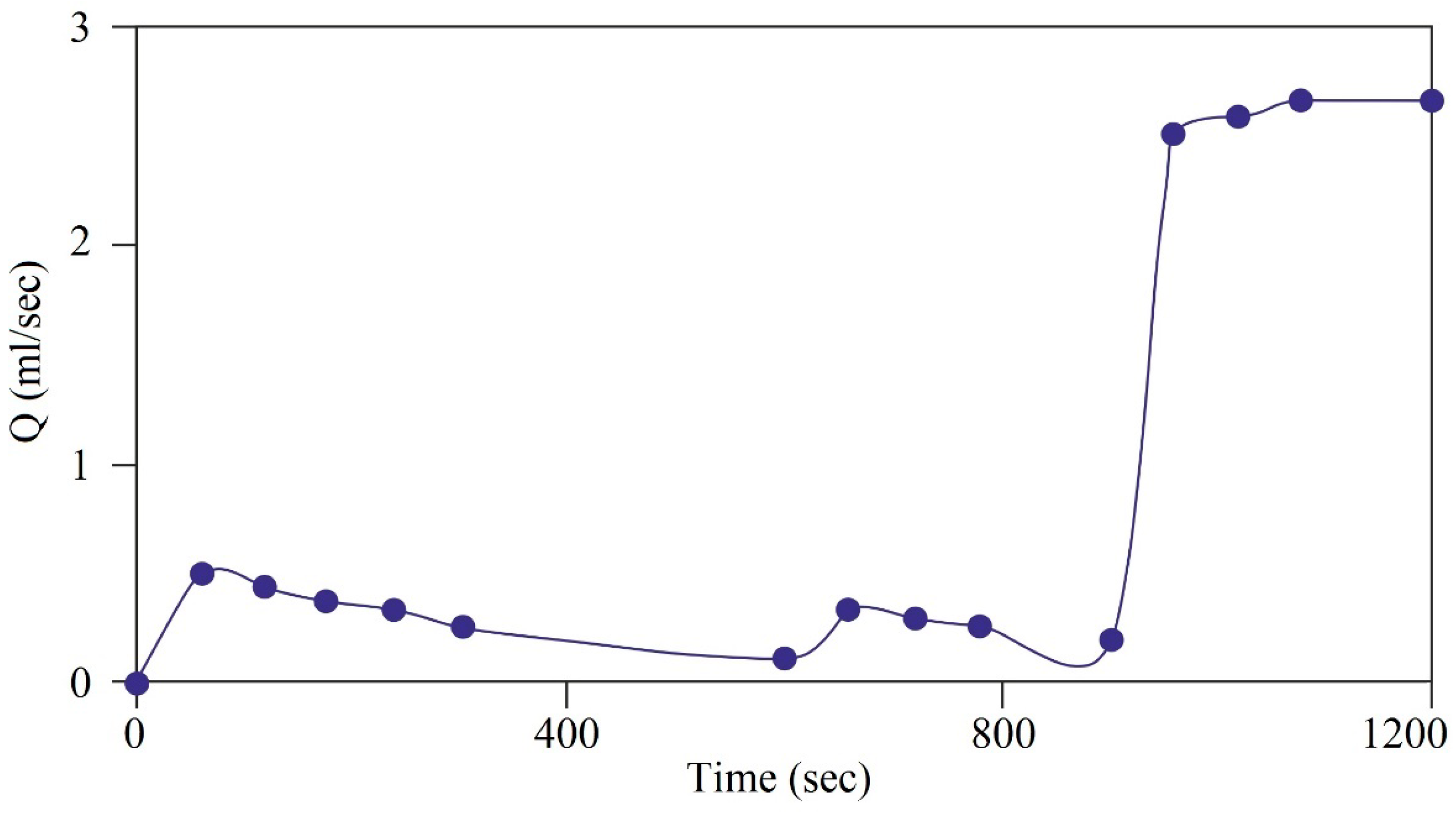

3.3. Self-Healing Process

4. Conclusions

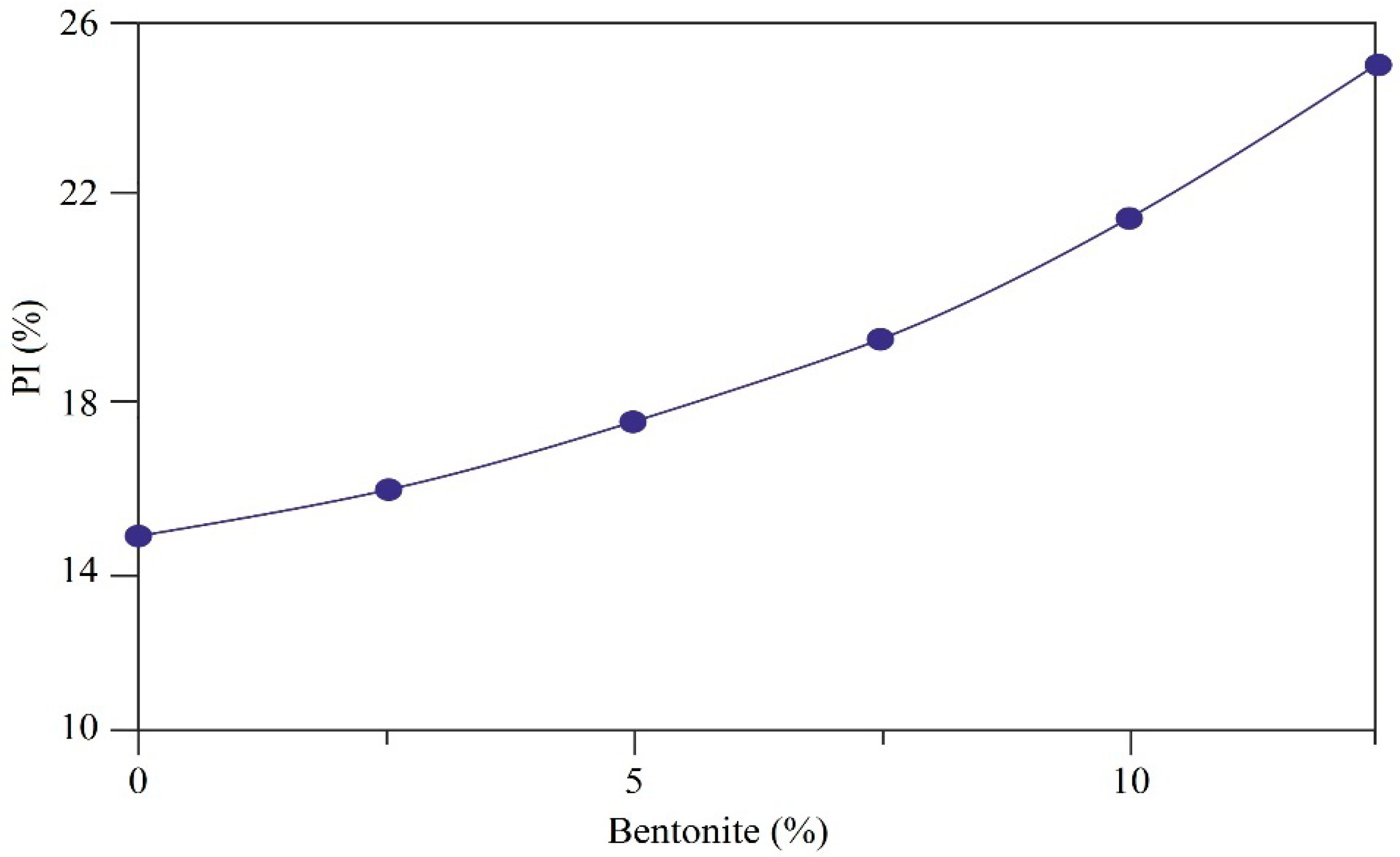

- By adding the weight percent of Bentonite to the clay soil, the water content liquid limit and plasticity index are increased, and the increase in plasticity index leads to further soil cohesion and further hydration and swelling of the soil, which in turn greatly contributes to the sealing of the created cracks. However, since the increase in the plasticity index causes cracks in the drying period, the increase in the weight percentage cannot exceed the standard limit. Based on the current recommendations, the plasticity index, in this case, should not exceed 25. Therefore, according to the obtained results, it is impossible to use 12.5% Bentonite in the mixture with clay soil;

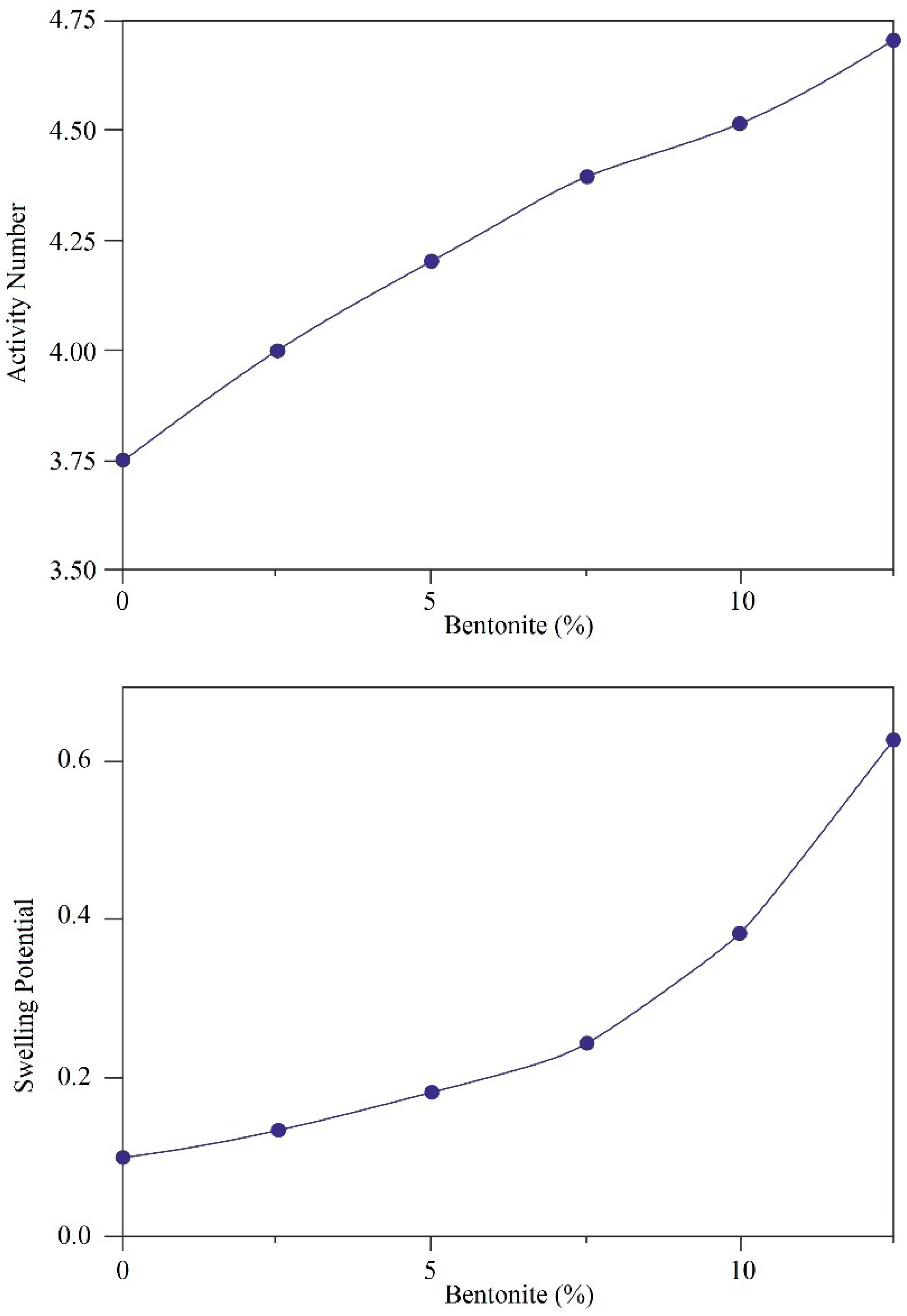

- Regarding Bentonite’s swelling potential and expansion property, the soil’s swelling potential is increased by adding a percentage of Bentonite to the clay soil, which has a key role in repairing the soil dam core cracks. By adding 12.5% Bentonite to the clay soil, the swelling potential of the mixture increases more than six times, from 0.1 to 0.63;

- By adding 10% Bentonite to the clay soil, the swelling pressure of the clay soil is increased by three times, which leads to an increase in the repairing power of the samples;

- Regarding the previous points, in the present research, the best combination of Bentonite with core clay repairs the cracks and is applicable in clay dam cores with a mixture of clay with 10% Bentonites;

- In this research, in order to verify and objectively observe the repairing of cracks, the researchers used a pinhole test. By comparing the test on the core clay sample, using a combination of clay with 10% Kaolin and a combination of clay with 10% Bentonite, it was noted that only in the sample of clay combined with 10% Bentonite did the flow of water gradually decrease during the test, so that even at the end of the test, despite the increase in the head, the speed of water outflow was diminished and almost stopped, which indicated the closing of the hole and repairing of the cracks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fell, R.; Wan, C.F.; Cyganiewicz, J.; Foster, M. Time for development of internal erosion and piping in embankment dams. J. Geotech. Geoenviron. Eng. 2003, 129, 307–314. [Google Scholar] [CrossRef]

- Angin, Z.; İkizler, S.B. Assessment of swelling pressure of stabilized Bentonite. Geomech. Eng. 2018, 15, 1219–1225. [Google Scholar] [CrossRef]

- Karalar, M.; Cavusli, M. Three dimensional seismic deformation-shear strain-swelling performance of America-California Oroville Earth-Fill Dam. Geomech. Eng. 2021, 24, 443–456. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, S.; Vallejo, L.; Wang, L. Numerical analysis of the causes of face slab cracks in Gongboxia rockfill dam. Eng. Geol. 2014, 181, 224–232. [Google Scholar] [CrossRef]

- Chen, N. Analysis on causes of cracks in concrete face slabs in water variation section of Gongboxia concrete face rockfill dam. Northwest Hydropower 2015, 2015, 23–27. [Google Scholar]

- Mohammadi, M.; Choobbasti, A.J. The effect of self-healing process on the strength increase in clay. J. Adhes. Sci. Technol. 2018, 32, 1750–1772. [Google Scholar] [CrossRef]

- Julina, M.; Thyagaraj, T. Combined effects of wet-dry cycles and interacting fluid on desiccation cracks and hydraulic conductivity of compacted clay. Eng. Geol. 2020, 267, 105505. [Google Scholar] [CrossRef]

- Valizadeh, M.; Choobbasti, A.J. Evaluation of nano-graphene effect on mechanical behavior of clayey sand with microstructural and self-healing approach. J. Adhes. Sci. Technol. 2020, 34, 299–318. [Google Scholar] [CrossRef]

- Baziar, M.H.; Saeidaskari, J.; Alibolandi, M. Effects of nanoclay on the treatment of core material in earth dams. J. Mater. Civ. Eng. 2018, 30, 04018250. [Google Scholar] [CrossRef]

- Roushangar, K.; Alami, M.T.; Houshyar, Y. Experimental Investigation of Self-healing Phenomenon of Clay in Earth Dams and its Influencing Factors. J. Water Soil Sci. 2019, 29, 15–25. [Google Scholar]

- Andalib, G.; Houshyar, Y.; Roushangar, K. Evaluation of Influencing Factors in Outflow Control and Self-healing Property of Clay Core (case study: Vanyar dam–Iran). Adv. Res. Civ. Eng. 2021, 3, 55–71. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhang, H.P.; Zhang, L.; Liang, Y. Experimental study on self-healing of crack in clay seepage barrier. Eng. Geol. 2013, 159, 31–35. [Google Scholar] [CrossRef]

- Ashayeri, I.; Yasrebi, S.S. Investigation of free swelling potential of compacted clayey soils. Modarres Civ. Eng. J. 2006, 25, 19–28. (In Persian) [Google Scholar]

- Kakuturu, S.; Reddi, L.N. Evaluation of the Parameters Influencing Self-Healing in Earth Dams. J. Geotech. Geoenviron. Eng. 2006, 132, 879–889. [Google Scholar] [CrossRef]

- Gueddouda, M.K.; Goual, I.; Lamara, M.; Aboubaker, N. Hydraulic conductivity and shear strength of compacted dune sand-bentonite mixtures. In Proceeding of the 16th International Conference on Construction and Building Technology, Kuala Lumpur, Malaysia, 20 June 2008. [Google Scholar]

- Soltani, A.; Raeesi, A.; Abdollahi, J. Effect of chemical quality of initial moisture on mechanical properties of swelling soil in wetting and drying cycles. Iran. J. Water Soil Res. 2014, 46, 71–79. (In Persian) [Google Scholar]

- Xu, W.; Li, Q.; Hu, Y.; Li, S. Wet swelling effect on crack performance of facing concrete for rockfill dams. Mag. Concr. Res. 2017, 69, 1055–1066. [Google Scholar] [CrossRef]

- Han, S.; Choi, E.K.; Park, W.; Yi, C.; Chung, N. Effectiveness of expanded clay as a bacteria carrier for self-healing concrete. Appl. Biol. Chem. 2019, 62, 19. [Google Scholar] [CrossRef]

- Tabassum, T.; Bheemasetti, T.V. Self-Healing and Desiccation Crack Behavior of Kaolinite-Rich Clay Soil. In Proceedings of the Geo-Congress 2020, Minneapolis, MN, USA, 25–28 February 2020; pp. 582–591. [Google Scholar]

- Roushangar, K.; Alami, M.T.; Houshyar, Y. Experimental investigation of bentonite impact on self-healing of clay soils. Arab. J. Geosci. 2020, 13, 1122. [Google Scholar] [CrossRef]

- Azarafza, M.; Akgün, H.; Asghari-Kaljahi, E. Assessment of rock slope stability by slope mass rating (SMR): A case study for the gas flare site in Assalouyeh, South of Iran. Geomech. Eng. 2017, 13, 571–584. [Google Scholar] [CrossRef]

- Azarafza, M.; Ghazifard, A.; Akgun, H.; Asghari-Kaljahi, E. Geotechnical characteristics and empirical geo-engineering relations of the South Pars Zone marls, Iran. Geomech. Eng. 2019, 19, 393–405. [Google Scholar] [CrossRef]

- Azarafza, M.; Hajialilue Bonab, M.; Akgün, H. Numerical analysis and stability assessment of complex secondary toppling failures: A case study for the south pars special zone. Geomech. Eng. 2021, 27, 481–495. [Google Scholar] [CrossRef]

- ASTM D422; Standard Test Method for Particle-Size Analysis of Soils. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D7928; Standard Test Method for Particle-Size Distribution (Gradation) of Fine-Grained Soils Using the Sedimentation (Hydrometer) Analysis. ASTM International: West Conshohocken, PA, USA, 2021.

- Zhu, X.; Zhang, Q.; Zang, W.; Shao, J.; Wang, Z.; Wu, X. Experimental Study on the Basic Properties of a Green New Coal Mine Grouting Reinforcement Material. ACS Omega 2020, 5, 16722–16732. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhang, Q.; Shao, J.; Zhang, W.; Wu, X.; Zhu, X. New Type of Similar Material for Simulating the Processes of Water Inrush from Roof Bed Separation. ACS Omega 2020, 5, 30405–30415. [Google Scholar] [CrossRef] [PubMed]

- ASTM D7263; Standard Test Methods for Laboratory Determination of Density and Unit Weight of Soil Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- Seed, H.B.; Woodward, R.J.; Lundgren, R. Prediction of swelling potential for compacted clays. J. Soil Mech. Found. Div. 1962, 88, 53–87. [Google Scholar] [CrossRef]

- ASTM D2435; Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D4647; Standard Test Methods for Identification and Classification of Dispersive Clay Soils by the Pinhole Test. ASTM International: West Conshohocken, PA, USA, 2020.

- U.S. Department of the Interior—Bureau of Reclamation. Characteristics of Dispersive and Problems Clay Soils; Research and Laboratory Services Division Materials Engineering Branch: Denver, CO, USA, 1991. [Google Scholar]

- Sherard, J.L.; Decker, R.S.; Ryker, N.L. Piping in earth dams of dispersive clay. In Proceedings of the Specialty Conference on Performance of Earth and Earth-Supported Structures, West Lafayette, IN, USA, 11–14 June 1972; pp. 584–626. [Google Scholar]

- El-Zein, A.; Airey, D.; Yu, B.; Esgandani, G.A.; Proust, G.; Dias-da-Costa, D.; Chen, S. Self-repair of cracks and defects in clay: A review of evidence, mechanisms, theories and nomenclature. Acta Geotech. 2021, 16, 3741–3760. [Google Scholar] [CrossRef]

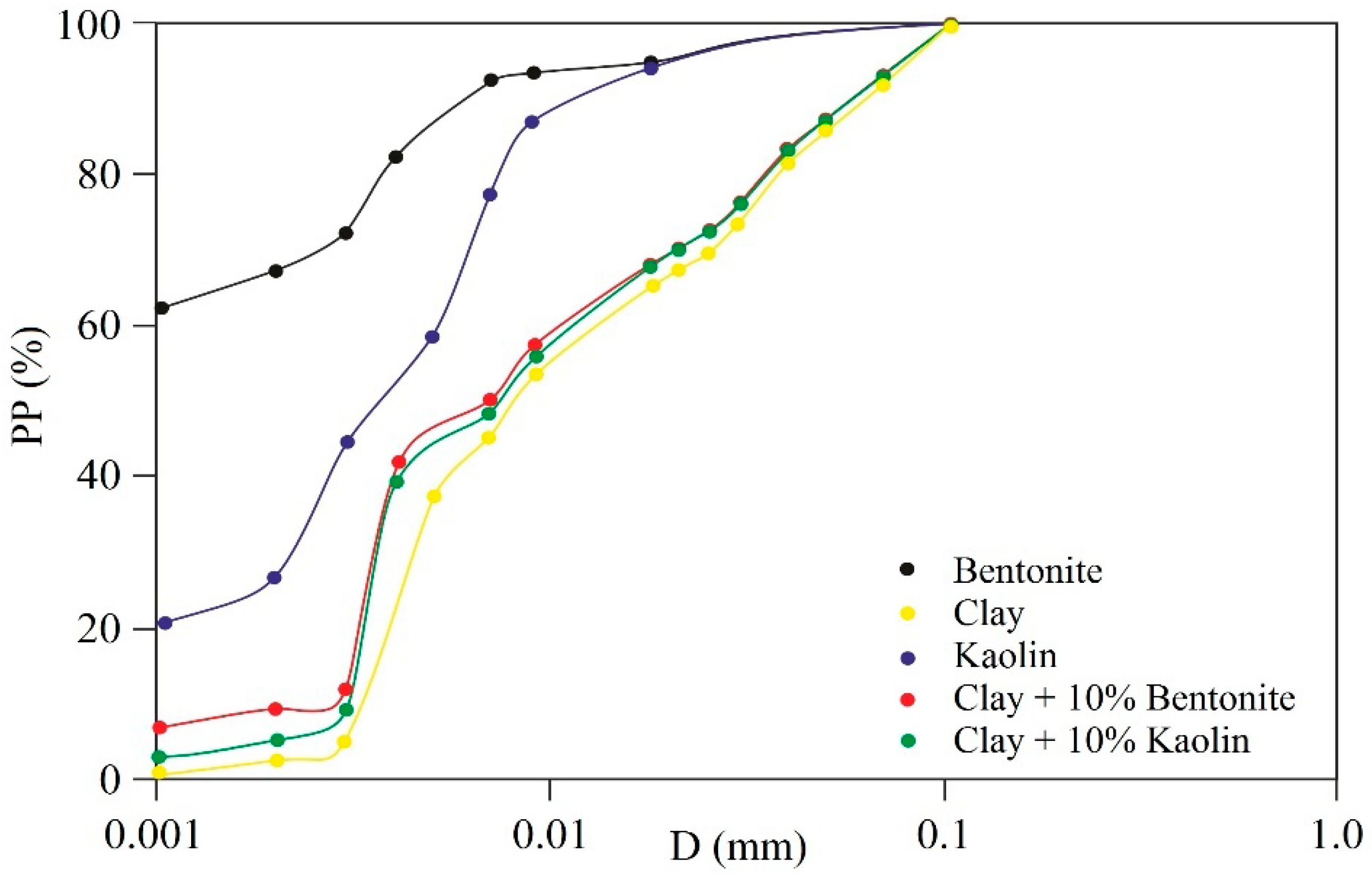

| Soil Type | USCS | Particle-Size Distribution (%) | Dry Density (g/cm3) | Water Content (%) | CC | ||

|---|---|---|---|---|---|---|---|

| D10 | D30 | D60 | |||||

| Bentonite | CH | 94 | 100 | 100 | 1.01 | 28.5 | 1.06 |

| Clay | CL | 58 | 94 | 100 | 1.46 | 11.7 | 1.52 |

| Kaolin | CL | 88 | 99 | 100 | 1.31 | 10.9 | 1.11 |

| Clay + 10% Bentonite | CL | 60 | 94 | 100 | 1.48 | 15.9 | 1.47 |

| Clay + 10% Kaolin | CL | 60 | 94 | 100 | 1.39 | 15.1 | 1.47 |

| Soil Type | USCS | Atterberg Limits (%) | Activity Number | Swelling Potential (%) [30] | |||

|---|---|---|---|---|---|---|---|

| LL | PL | PI | |||||

| Bentonite | CH | 415 | 60 | 355 | 5.7 | 4812 | Very high |

| Clay | CL | 40 | 25 | 15 | 3075 | 0.1 | Low |

| Kaolin | CL | 46 | 27 | 19 | 0.42 | 0.004 | Low |

| Clay + 10% Bentonite | CL | 51 | 28 | 23 | 4.5 | 0.38 | Medium |

| Clay + 10% Kaolin | CL | 42 | 25 | 17 | 3.8 | 1.9 | Low |

| Dispersive Classification | Head (mm) | Cloudiness of Flow at the End of Test | Hole Size after Test (mm) | |

|---|---|---|---|---|

| from Side | from Top | |||

| D1 | 50 | Dark | Very dark | ≥2.0 |

| D2 | 50 | Moderately dark | Dark | >1.5 |

| ND4 | 50 | Slightly dark | Moderately dark | ≤1.5 |

| ND3 | 180 | Barely visible | Slightly dark | ≥1.5 |

| 380 | Barely visible | Slightly dark | ≥1.5 | |

| ND2 | 1020 | Clear | Barely visible | <1.5 |

| ND1 | 1020 | Perfectly clear | Perfectly clear | 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikbakht, M.; Sarand, F.B.; Esmatkhah Irani, A.; Hajialilue Bonab, M.; Azarafza, M.; Derakhshani, R. An Experimental Study for Swelling Effect on Repairing of Cracks in Fine-Grained Clayey Soils. Appl. Sci. 2022, 12, 8596. https://doi.org/10.3390/app12178596

Nikbakht M, Sarand FB, Esmatkhah Irani A, Hajialilue Bonab M, Azarafza M, Derakhshani R. An Experimental Study for Swelling Effect on Repairing of Cracks in Fine-Grained Clayey Soils. Applied Sciences. 2022; 12(17):8596. https://doi.org/10.3390/app12178596

Chicago/Turabian StyleNikbakht, Mahdi, Fariba Behrooz Sarand, Arash Esmatkhah Irani, Masoud Hajialilue Bonab, Mohammad Azarafza, and Reza Derakhshani. 2022. "An Experimental Study for Swelling Effect on Repairing of Cracks in Fine-Grained Clayey Soils" Applied Sciences 12, no. 17: 8596. https://doi.org/10.3390/app12178596

APA StyleNikbakht, M., Sarand, F. B., Esmatkhah Irani, A., Hajialilue Bonab, M., Azarafza, M., & Derakhshani, R. (2022). An Experimental Study for Swelling Effect on Repairing of Cracks in Fine-Grained Clayey Soils. Applied Sciences, 12(17), 8596. https://doi.org/10.3390/app12178596