Seismic Liquefaction of Saturated Calcareous Sands: Dynamic Centrifuge Test and Numerical Simulation

Abstract

:1. Introduction

2. Dynamic Centrifuge Tests

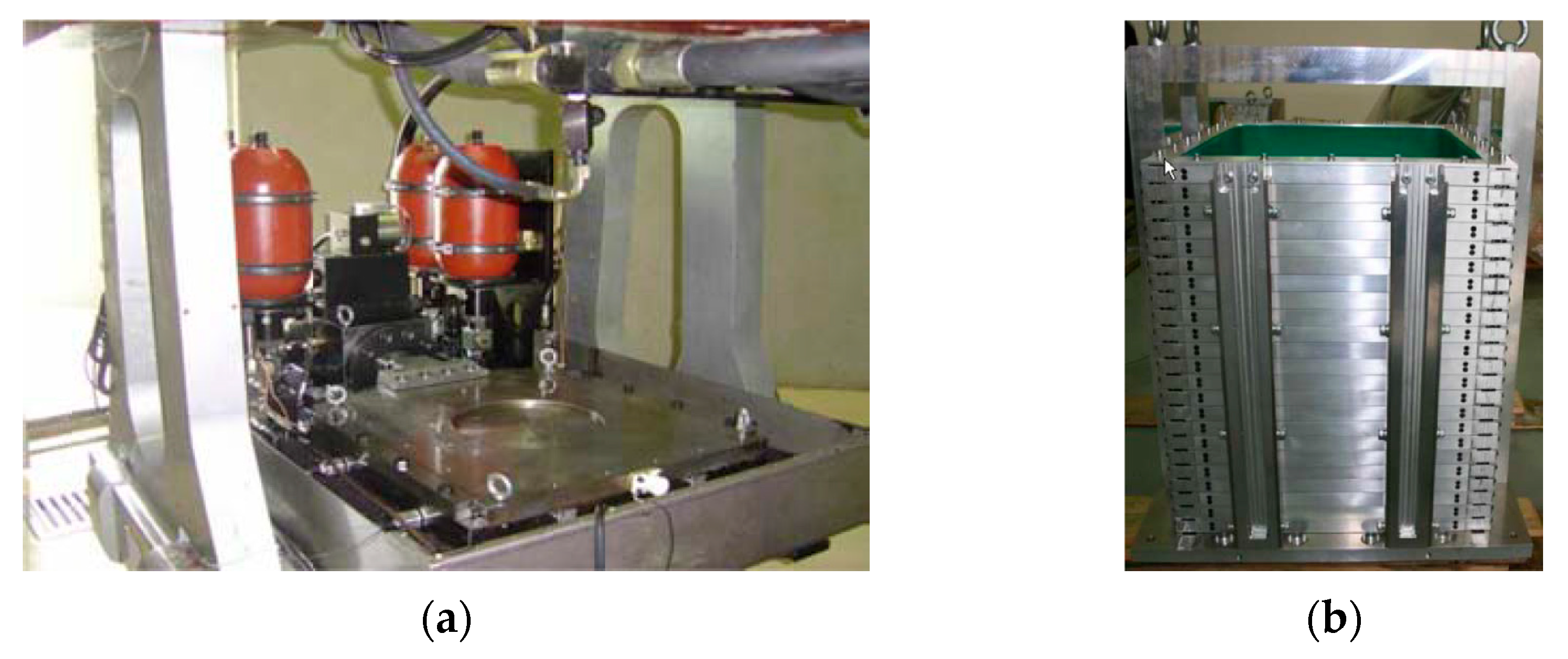

2.1. Test Facilities

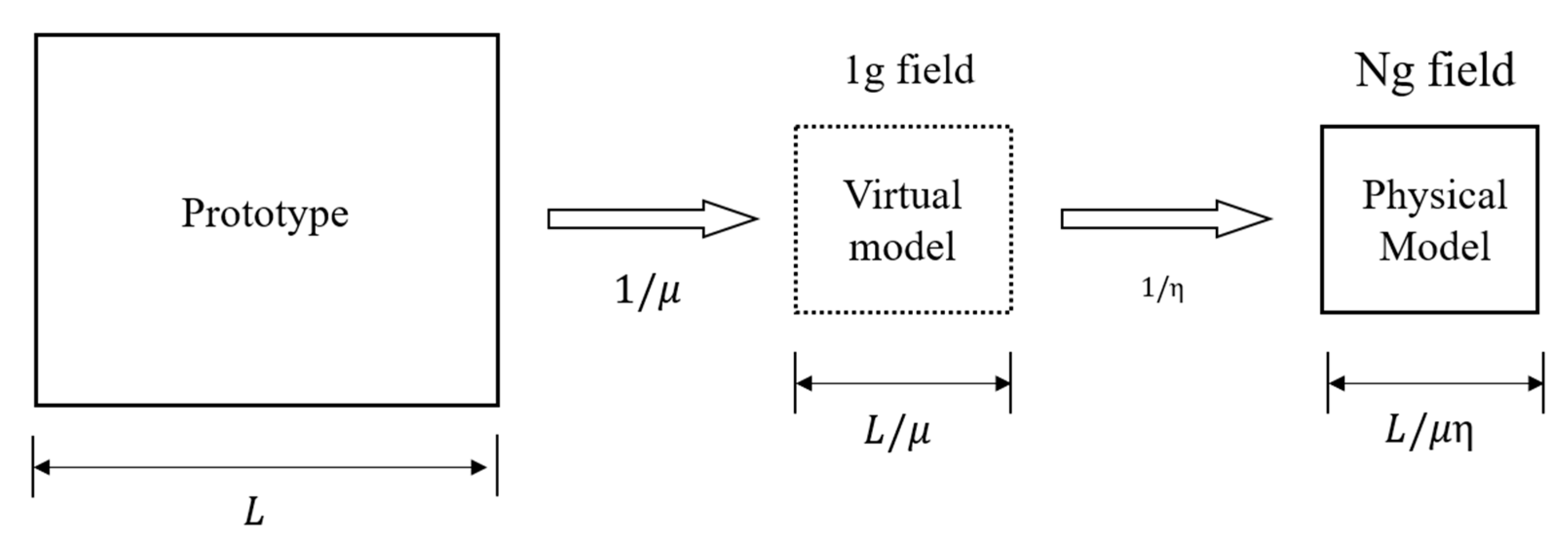

2.2. Scaling Law and Physical Models

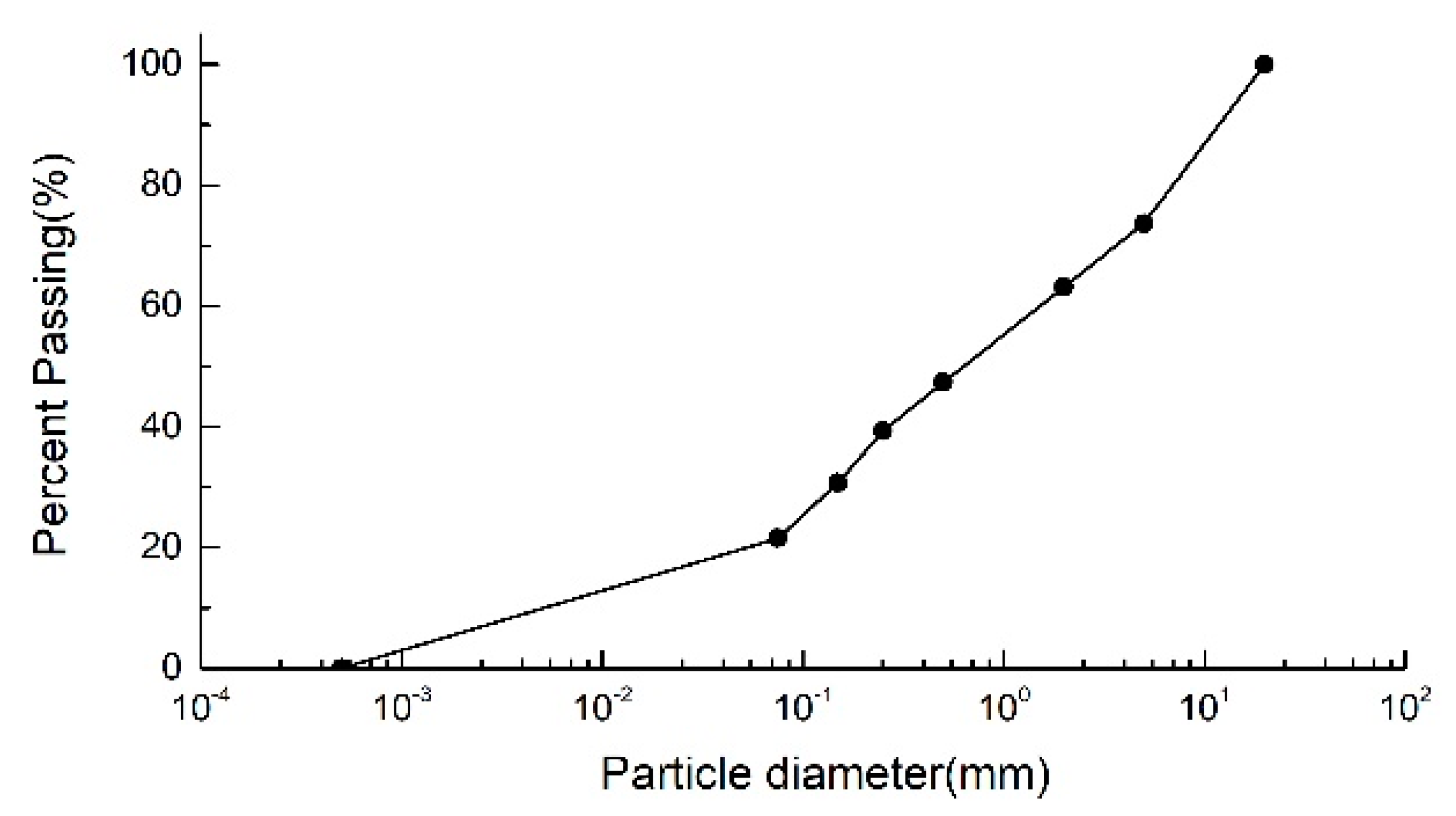

2.3. Test Materials and Model Preparation

2.4. Instrumentation Layout

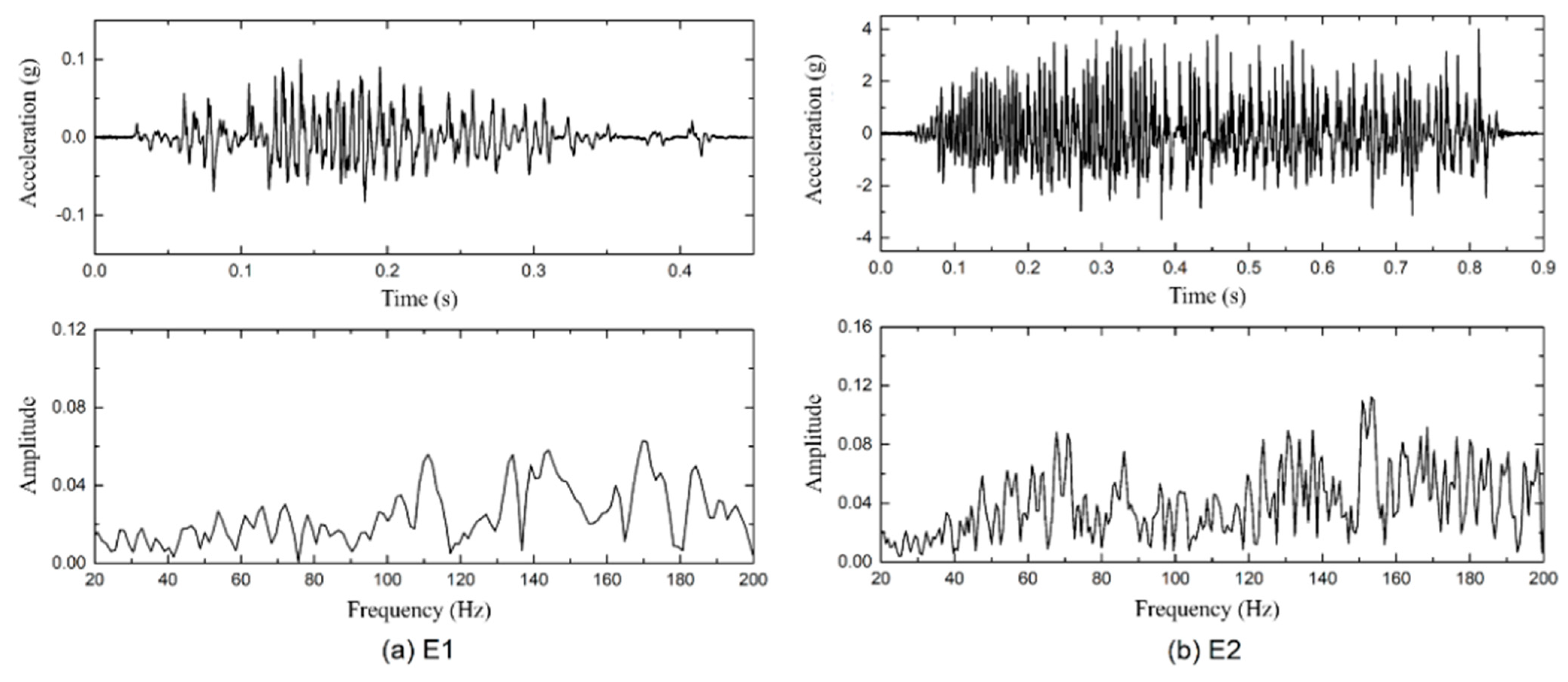

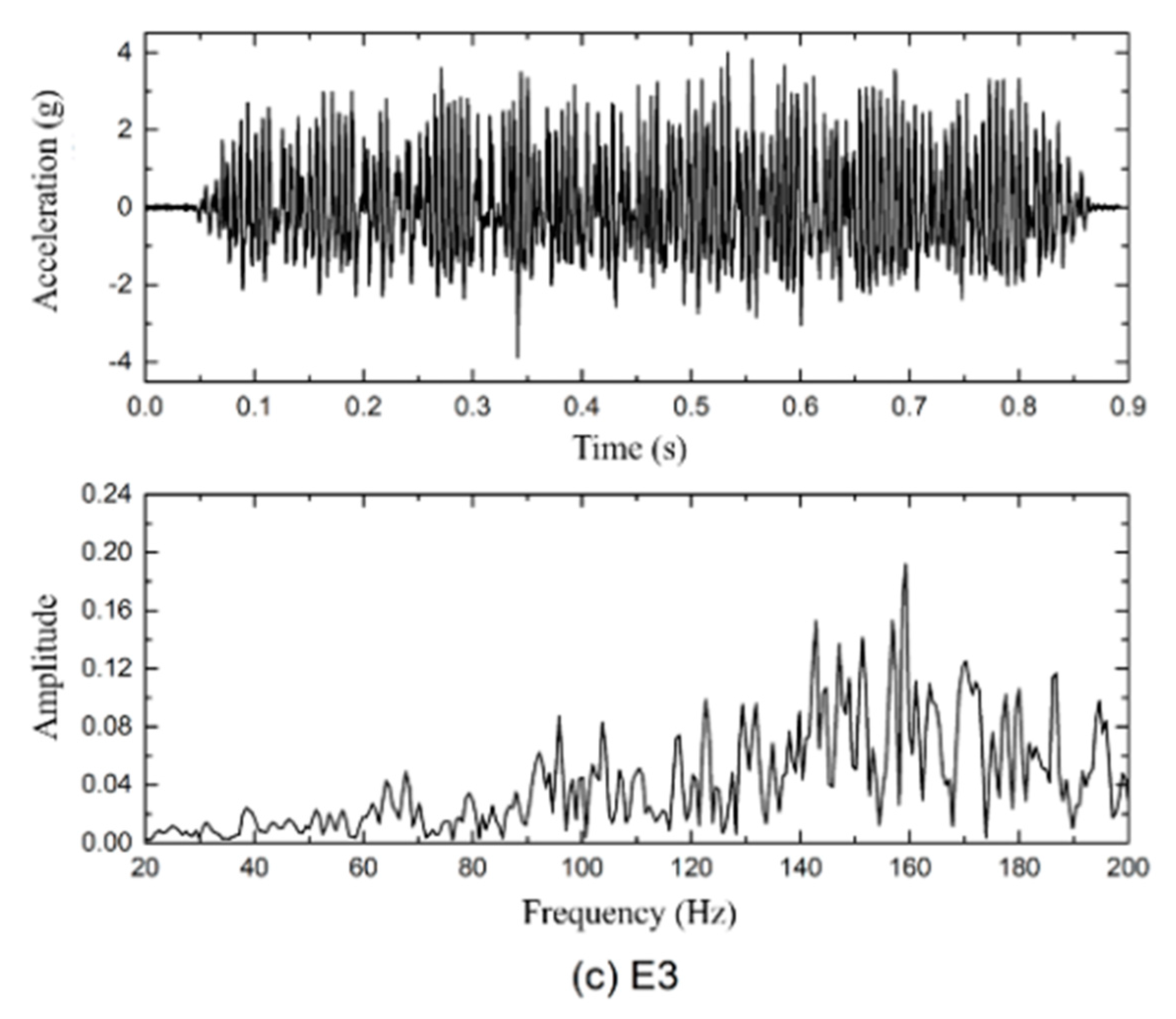

2.5. Input Ground Motions and Test Procedures

3. Experimental Results

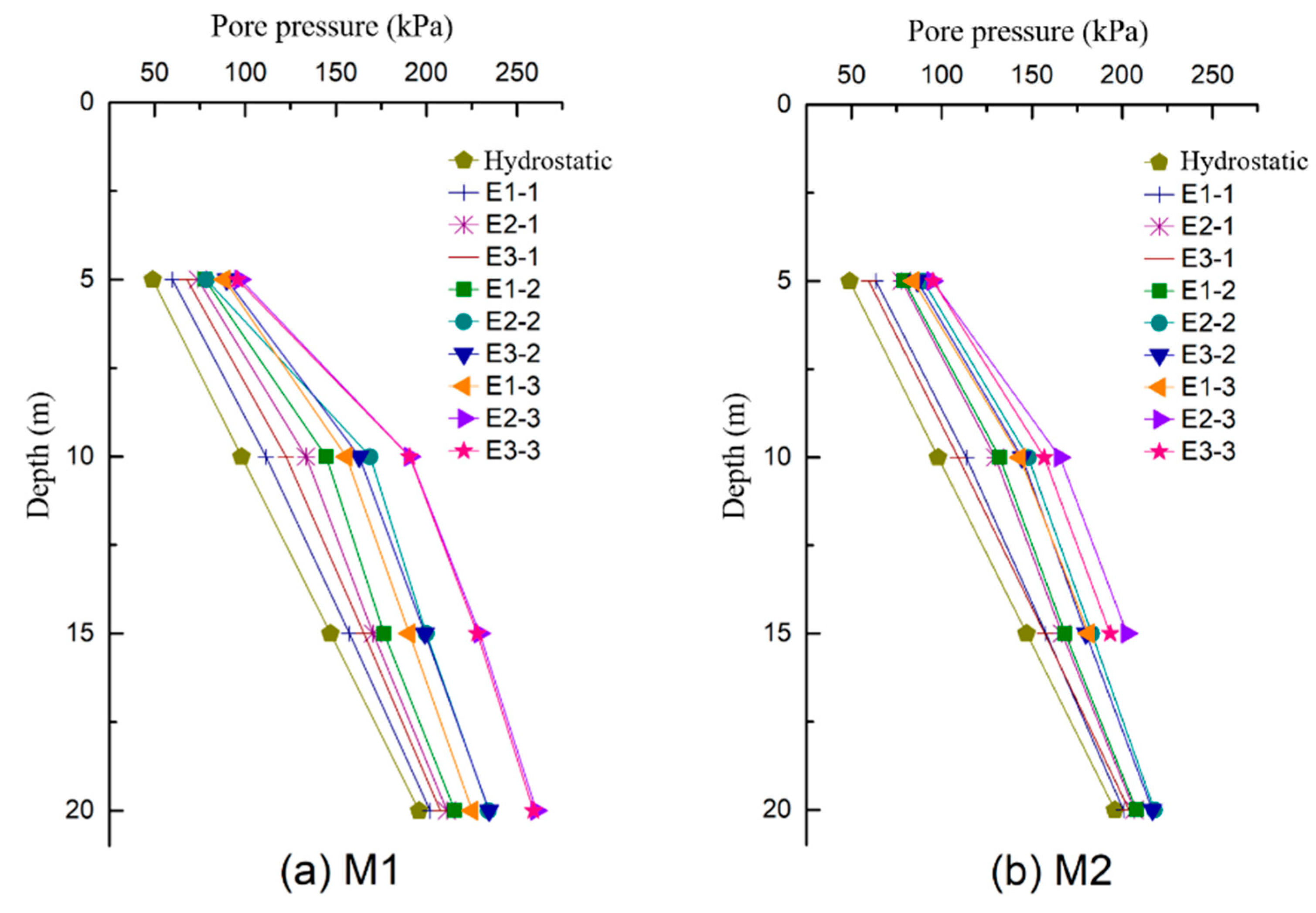

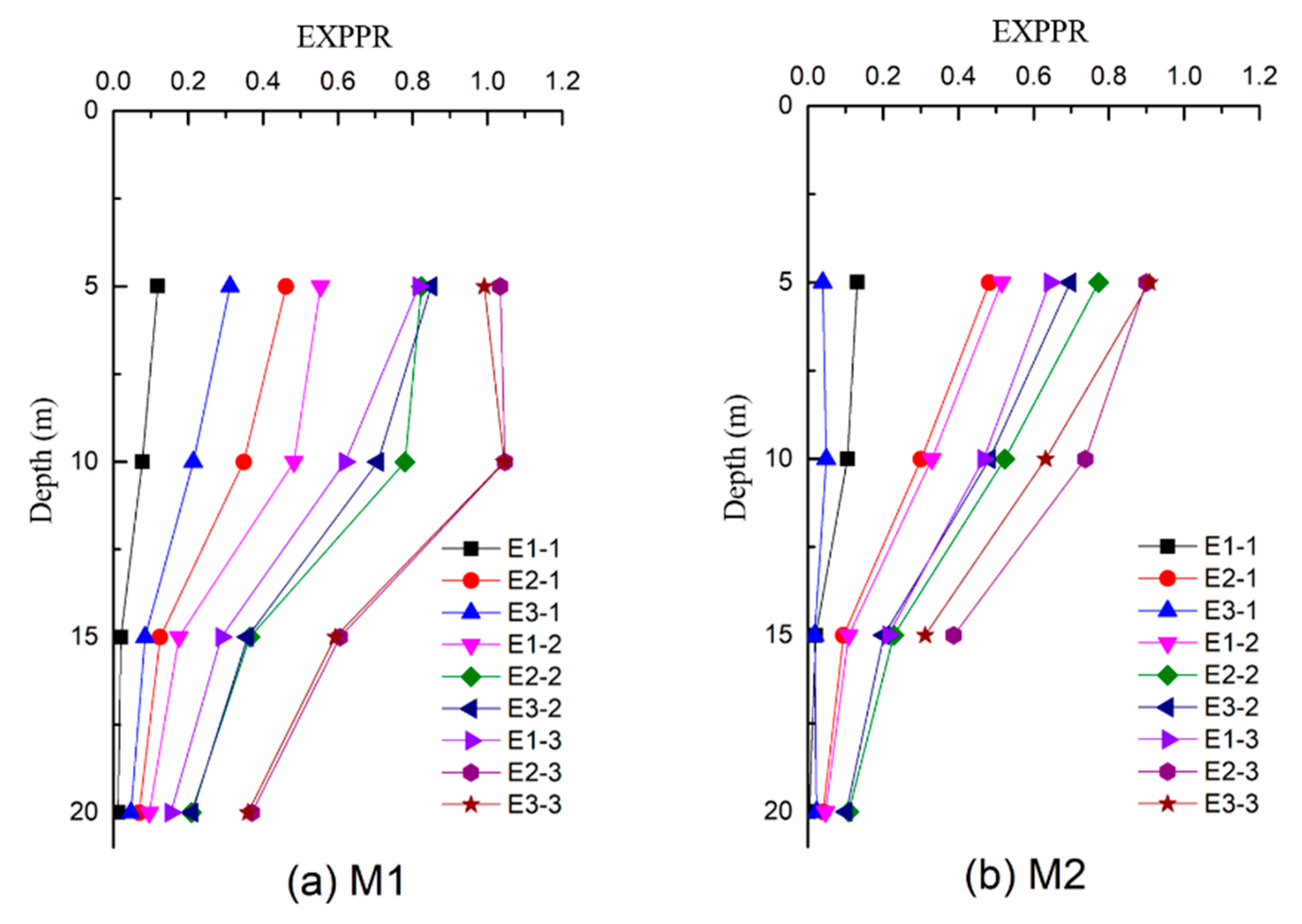

3.1. Excess Pore Pressure Response along the Depth

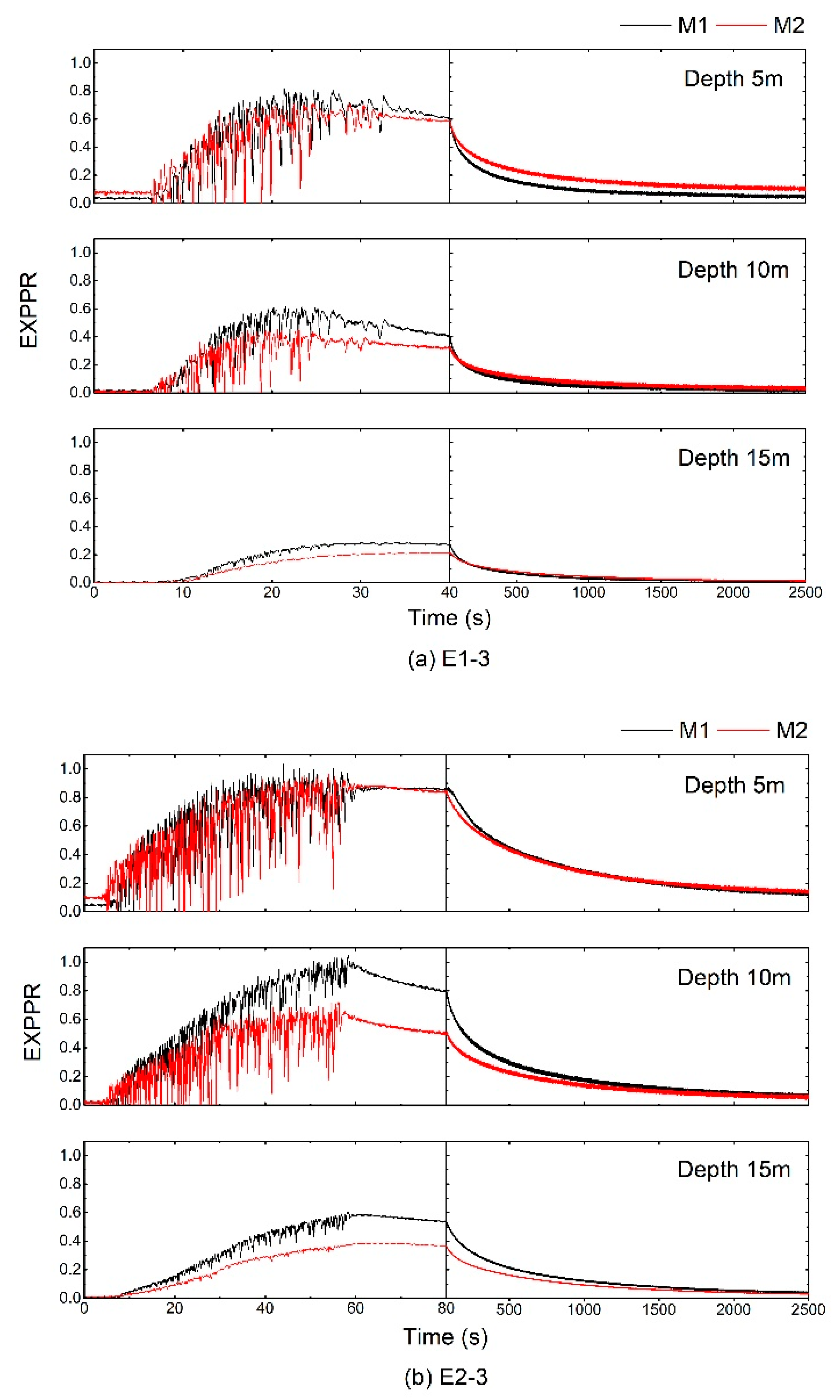

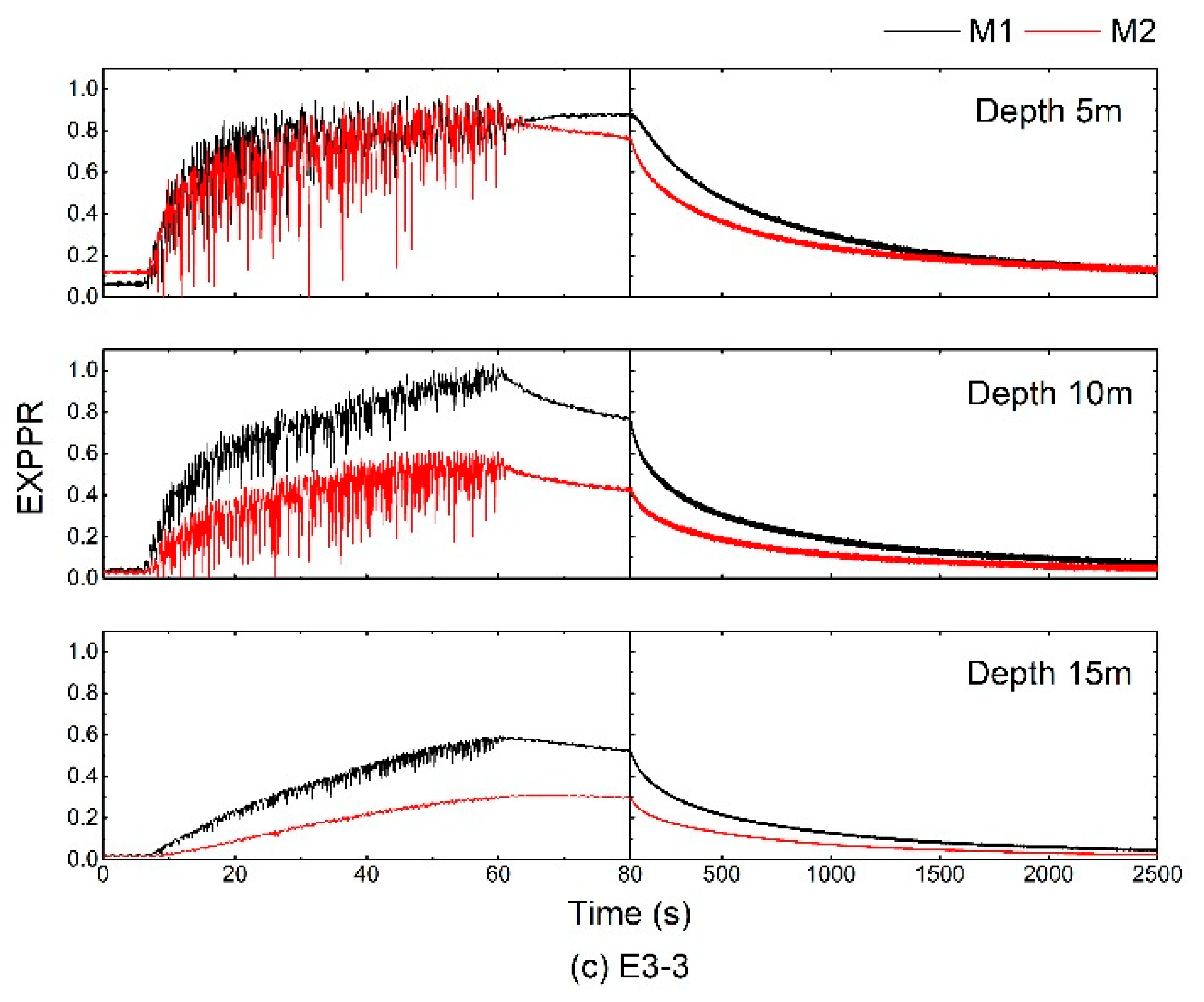

3.2. Excess Pore Pressure Time Histories during Strong Earthquakes

4. Numerical Simulation

4.1. Constitutive Model and Parameters

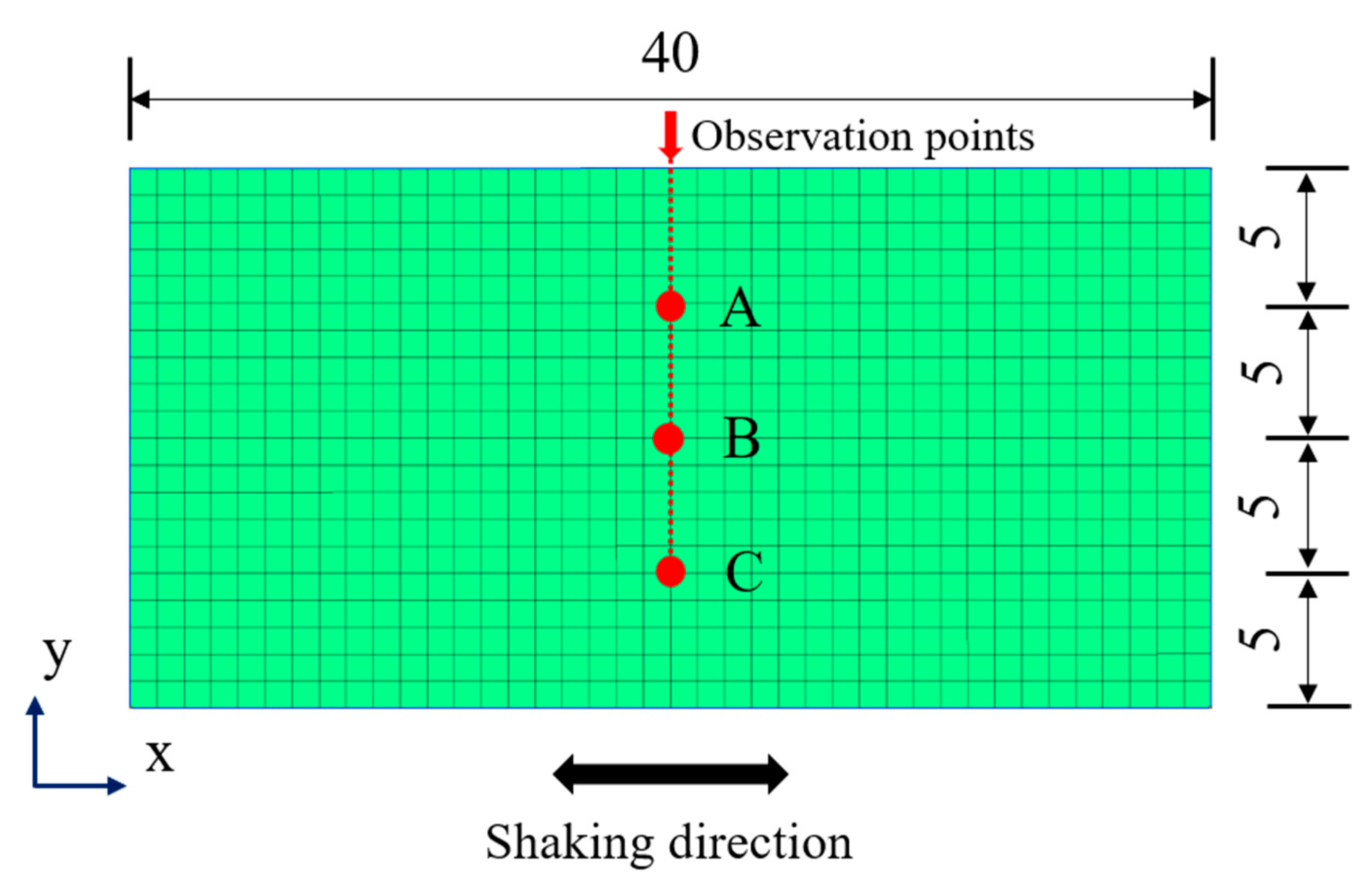

4.2. Finite Element Model and Computation Procedure

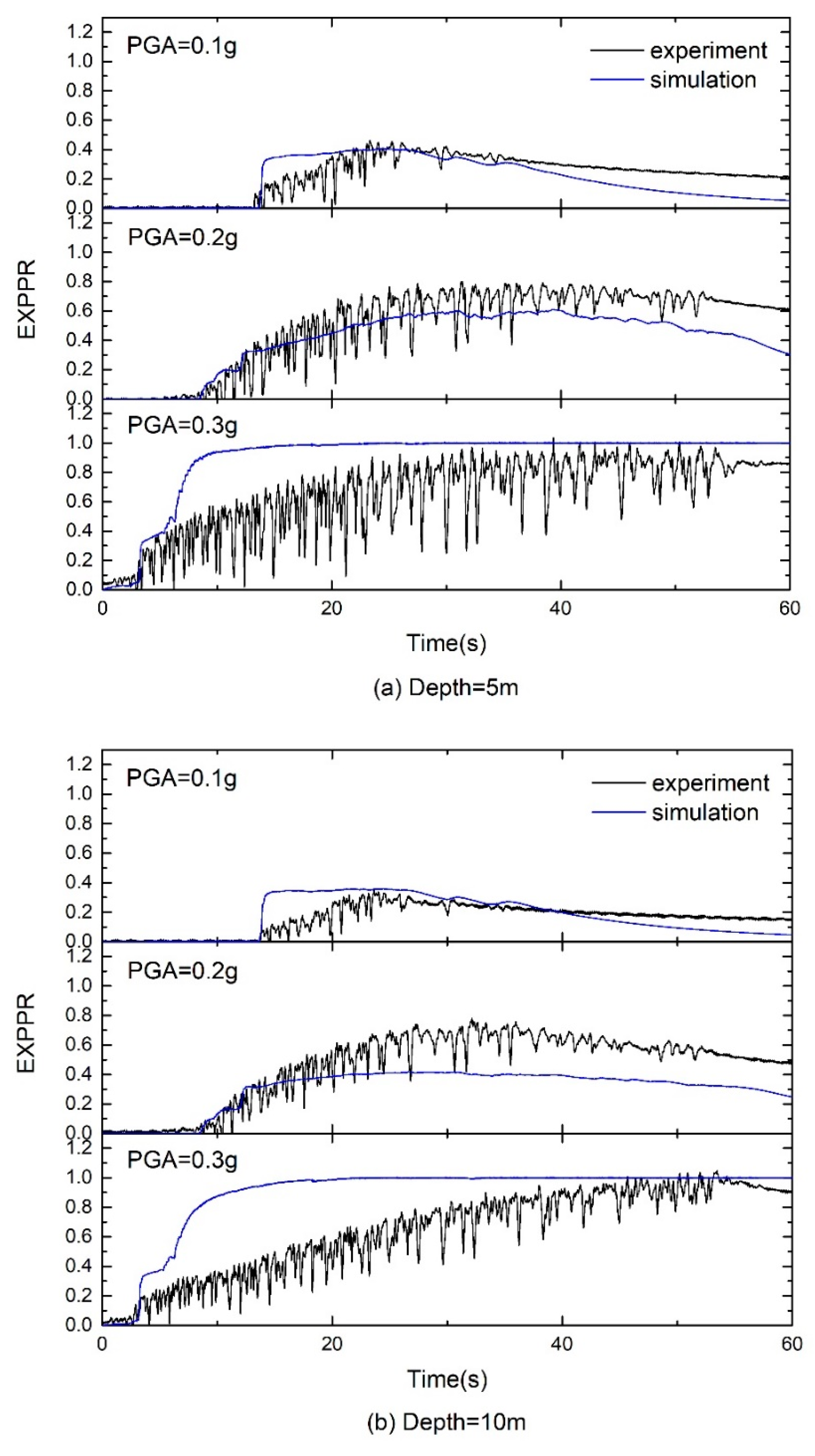

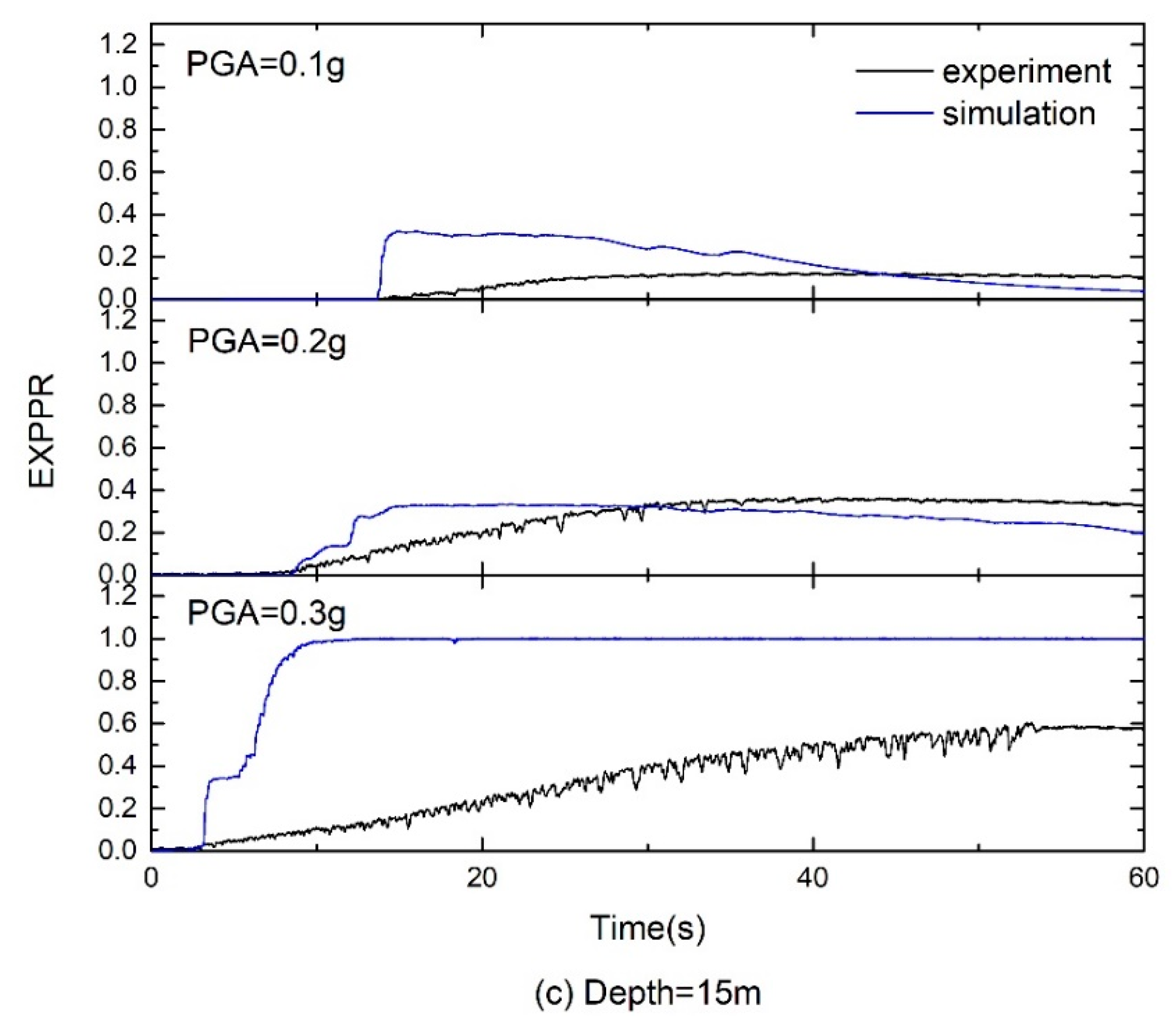

4.3. Simulation Results

5. Conclusions

- (1)

- The maximum value of EXPPR for the saturated calcareous sand ground will decrease with the increase of soil’s depth, while it will increase with the increase of the input ground motion’s peak acceleration and duration. The improvement of the relative density of can effectively strengthen the liquefaction resistance of the ground, reduce the peak pore pressure, and accelerate the dissipation process.

- (2)

- When subjected to earthquakes with 0.3 g peak acceleration, the saturated calcareous sand ground model witnessed the peak values of EXPPR reaching up to around 1.0 at the depth of 5–10 m, indicating a high potential of liquefaction under the same circumstances.

- (3)

- Based on Biot’s dynamic consolidation theory, the dynamic FE analysis using the PDMY constitutive model can well simulate the seismic response of the EXPP at the initial stage of pore pressure accumulation. However, generally, the pore pressure could build up and dissipate relatively faster in the numerical results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Avilés-Campoverde, D.; Chunga, K.; Ortiz-Hernández, E.; Vivas-Espinoza, E.; Toulkeridis, T.; Morales-Delgado, A.; Delgado-Toala, D. Seismically Induced Soil Liquefaction and Geological Conditions in the City of Jama due to the M7. 8 Pedernales Earthquake in 2016, NW Ecuador. Geosciences 2020, 11, 20. [Google Scholar] [CrossRef]

- Potter, S.H.; Becker, J.S.; Johnston, D.M.; Rossiter, K.P. An overview of the impacts of the 2010–2011 Canterbury earthquakes. Int. J. Disaster Risk Reduct. 2015, 14, 6–14. [Google Scholar] [CrossRef]

- Chiaro, G.; Koseki, J.; Kiyota, T. An Investigation on the Liquefaction-Induced Sloped Ground Failure during the 1964 Niigata Earthquake. In Geotechnical Hazards from Large Earthquakes and Heavy Rainfalls; Springer: Tokyo, Japan, 2017; pp. 133–143. [Google Scholar]

- Sassa, S.; Takagawa, T. Liquefied gravity flow-induced tsunami: First evidence and comparison from the 2018 Indonesia Sulawesi earthquake and tsunami disasters. Landslides 2019, 16, 195–200. [Google Scholar] [CrossRef]

- Rapti, I.; Lopez-Caballero, F.; Modaressi-Farahmand-Razavi, A.; Foucault, A.; Voldoire, F. Liquefaction analysis and damage evaluation of embankment-type structures. Acta Geotech. 2018, 13, 1041–1059. [Google Scholar] [CrossRef]

- Chian, S.; Tokimatsu, K.; Madabhushi, S.P.G. Soil liquefaction-induced uplift of underground structures: Physical and numerical modeling. J. Geotech. Geoenviron. Eng. 2014, 140, 04014057. [Google Scholar] [CrossRef]

- Cui, S.; Pei, X.; Jiang, Y.; Wang, G.; Fan, X.; Yang, Q.; Huang, R. Liquefaction within a bedding fault: Understanding the initiation and movement of the Daguangbao landslide triggered by the 2008 Wenchuan Earthquake (Ms = 8.0). Eng. Geol. 2021, 295, 106455. [Google Scholar] [CrossRef]

- Cubrinovski, M.; Bray, J.D.; Taylor, M.; Giorgini, S.; Bradley, B.; Wotherspoon, L.; Zupan, J. Soil liquefaction effects in the central business district during the February 2011 Christchurch earthquake. Seismol. Res. Lett. 2011, 82, 893–904. [Google Scholar] [CrossRef]

- Yasuda, S.; Towhata, I.; Ishii, I.; Sato, S.; Uchimura, T. Liquefaction-induced damage to structures during the 2011 great east Japan earthquake. J. JSCE 2013, 1, 181–193. [Google Scholar] [CrossRef]

- Tsai, C.C.; Hsu, S.Y.; Wang, K.L.; Yang, H.C.; Chang, W.K.; Chen, C.H.; Hwang, Y.W. Geotechnical reconnaissance of the 2016 ML6. 6 Meinong earthquake in Taiwan. J. Earthq. Eng. 2018, 22, 1710–1736. [Google Scholar] [CrossRef]

- Kiyota, T.; Furuichi, H.; Hidayat, R.F.; Tada, N.; Nawir, H. Overview of long-distance flow-slide caused by the 2018 Sulawesi earthquake, Indonesia. Soils Found. 2020, 60, 722–735. [Google Scholar] [CrossRef]

- Bird, J.F.; Bommer, J.J. Earthquake losses due to ground failure. Eng. Geol. 2004, 75, 147–179. [Google Scholar] [CrossRef]

- Shen, J.Y.; Wang, R. Study on engineering properties of calcareous sand. J. Eng. Geol. 2010, 18 (Suppl. S1), 26–32. (In Chinese) [Google Scholar]

- Zhu, C.Q.; Chen, H.Y.; Meng, Q.S.; Wang, R. Microscopic characterization of intra-pore structures of calcareous sands. Rock Soil Mech. 2014, 35, 1831–1836. (In Chinese) [Google Scholar]

- Seed, H.B.; Idriss, I.M. Simplified procedure for evaluating soil liquefaction potential. J. Soil Mech. Found. Div. ASCE 1971, 97, 1249–1273. [Google Scholar] [CrossRef]

- Rui, S.; Guo, Z.; Si, T.; Li, Y. Effect of particle shape on the liquefaction resistance of calcareous sands. Soil Dyn. Earthq. Eng. 2020, 137, 106302. [Google Scholar] [CrossRef]

- Xiao, P.; Liu, H.; Stuedlein, A.W.; Evans, T.M.; Xiao, Y. Effect of relative density and biocementation on cyclic response of calcareous sand. Can. Geotech. J. 2019, 56, 1849–1862. [Google Scholar] [CrossRef]

- Green, R.A.; Olson, S.M.; Cox, B.R.; Rix, G.J.; Rathje, E.; Bachhuber, J.; Martin, N. Geotechnical aspects of failures at Port-au-Prince seaport during the 12 January 2010 Haiti earthquake. Earthq. Spectra 2011, 27 (Suppl. S1), 43–65. [Google Scholar] [CrossRef]

- Shahnazari, H.; Jafarian, Y.; Tutunchian, M.A.; Rezvani, R. Undrained cyclic and monotonic behavior of Hormuz calcareous sand using hollow cylinder simple shear tests. Int. J. Civ. Eng. 2016, 14, 209–219. [Google Scholar] [CrossRef]

- Zhou, X.Z.; Chen, Y.M.; Liu, H.L.; Zhang, X.L. Experimental study on the cyclic behavior of loose calcareous sand under linear stress paths. Mar. Georesour. Geotechnol. 2020, 38, 277–290. [Google Scholar] [CrossRef]

- Yuan, X.M.; Zang, W.B.; Duan, Z.G.; Sun, R.; Wang, Y.L.; Zhang, W. Analysis for characteristics of seismic liquefaction in engineering sites of coralline soils. Chin. J. Rock Mech. Eng. 2019, 38 (Suppl. S2), 3799–3811. (In Chinese) [Google Scholar]

- Taylor, R.E. (Ed.) Geotechnical Centrifuge Technology; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Özcebe, A.G.; Giretti, D.; Bozzoni, F.; Fioravante, V.; Lai, C.G. Centrifuge and numerical modelling of earthquake-induced soil liquefaction under free-field conditions and by considering soil–structure interaction. Bull. Earthq. Eng. 2021, 19, 47–75. [Google Scholar] [CrossRef]

- Arulanandan, K.; Scott, R.F. Project VELACS—Control test results. J. Geotech. Eng. 1993, 119, 1276–1292. [Google Scholar] [CrossRef]

- Taboada-Urtuzuástegui, V.M.; Dobry, R. Centrifuge modeling of earthquake-induced lateral spreading in sand. J. Geotech. Geoenviron. Eng. 1998, 124, 1195–1206. [Google Scholar] [CrossRef]

- Popescu, R.; Prevost, J.H. Comparison between VELACS numerical ‘class A’ predictions and centrifuge experimental soil test results. Soil Dyn. Earthq. Eng. 1995, 14, 79–92. [Google Scholar] [CrossRef]

- Elgamal, A.; Zeghal, M.; Taboada, V.; Dobry, R. Analysis of site liquefaction and lateral spreading using centrifuge testing records. Soils Found. 1996, 36, 111–121. [Google Scholar] [CrossRef]

- Manzari, M.T.; Ghoraiby, M.E.; Zeghal, M.; Kutter, B.L.; Arduino, P.; Barrero, A.R.; Bilotta, E.; Chen, L.; Chen, R.; Chiaradonna, A.; et al. LEAP-2017: Comparison of the Type-B numerical simulations with centrifuge test results. In Model Tests and Numerical Simulations of Liquefaction and Lateral Spreading; Kutter, B., Manzari, M., Zeghal, M., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Kutter, B.L.; Carey, T.J.; Stone, N.; Bonab, M.H.; Manzari, M.T.; Zeghal, M.; Escoffier, S.; Haigh, S.K.; Madabhushi, G.S.P.; Hung, W.-Y.; et al. LEAP-UCD 2017 version 1.01 model specifications. In Model Tests and Numerical Simulations of Liquefaction and Lateral Spreading: LEAP-UCD-2017; Kutter, B., Manzari, M., Zeghal, M., Eds.; Springer: New York, NY, USA, 2019. [Google Scholar]

- Qiu, Z.; Elgamal, A. Numerical simulations of LEAP dynamic centrifuge model tests for response of liquefiable sloping ground. In Model Tests and Numerical Simulations of Liquefaction and Lateral Spreading; Springer: Cham, Switzerland, 2020; pp. 521–544. [Google Scholar]

- Lai, C.G.; Bozzoni, F.; Meisina, C.; Poggi, V.; Zuccolo, E.; Bonì, R.; Conca, D.; Famà, A.; Cosentini, R. Mapping the liquefaction hazard at different geographical scales. In Earthquake Geotechnical Engineering for Protection and Development of Environment and Constructions; CRC Press: Boca Raton, FL, USA, 2019; pp. 691–704. [Google Scholar]

- Meisina, C.; Bonì, R.; Bordoni, M.; Lai, C.G.; Famà, A.; Bozzoni, F.; Cosentini, R.M.; Castaldini, D.; Fontana, D.; Lugli, S.; et al. 3D Geological model reconstruction for liquefaction hazard assessment in the Po Plain. In Earthquake Geotechnical Engineering for Protection and Development of Environment and Constructions; CRC Press: Boca Raton, FL, USA, 2019; pp. 3837–3844. [Google Scholar]

- Li, P.; Dashti, S.; Badanagki, M.; Kirkwood, P. Evaluating 2D numerical simulations of granular columns in level and gently sloping liquefiable sites using centrifuge experiments. Soil Dyn. Earthq. Eng. 2018, 110, 232–243. [Google Scholar] [CrossRef]

- Tang, L.; Zhang, X.; Ling, X. Numerical simulation of centrifuge experiments on liquefaction mitigation of silty soils using stone columns. KSCE J. Civ. Eng. 2016, 20, 631–638. [Google Scholar] [CrossRef]

- Iai, S.; Tobita, T.; Nakahara, T. Generalised scaling relations for dynamic centrifuge tests. Geotechnique 2005, 55, 355–362. [Google Scholar] [CrossRef]

- Iai, S.; Sugano, T. Soil-structure interaction studies through shaking table tests. In Earthquake Geotechnical Engineering; A.A. Balkema, Brookfield: Rotterdam, The Netherlands, 1999; pp. 927–940. [Google Scholar]

- Tobita, T.; Iai, S.; Tann, L.; Yaoi, Y. Application of the generalised scaling law to saturated ground. Int. J. Phys. Model. Geotech. 2011, 11, 138–155. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Ma, Q.; Liu, K.; Chen, Y.M. Centrifuge model tests at Zhejiang University for LEAP-Asia-2019 and validation of the generalized scaling law. Soil Dyn. Earthq. Eng. 2021, 144, 106660. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, J.M. Advances in earthquake-induced liquefaction. Adv. Mech. 2007, 37, 575–589. (In Chinese) [Google Scholar]

- Yang, Z. Numerical Modeling of Earthquake Site Response Including Dilation and Liquefaction. Ph.D. Thesis, Columbia University, New York, NY, USA, 2000. [Google Scholar]

- Yang, Z.; Elgamal, A.; Parra, E. Computational model for cyclic mobility and associated shear deformation. J. Geotech. Geoenviron. Eng. 2003, 129, 1119–1127. [Google Scholar] [CrossRef]

- Elgamal, A.; Lu, J.; Forcellini, D. Mitigation of liquefaction-induced lateral deformation in a sloping stratum: Three-dimensional numerical simulation. J. Geotech. Geoenviron. Eng. 2009, 135, 1672–1682. [Google Scholar] [CrossRef]

- Asgari, A.; Oliaei, M.; Bagheri, M. Numerical simulation of improvement of a liquefiable soil layer using stone column and pile-pinning techniques. Soil Dyn. Earthq. Eng. 2013, 51, 77–96. [Google Scholar] [CrossRef]

- Rayamajhi, D.; Ashford, S.A.; Boulanger, R.W.; Ashford, S.A. Dense granular columns in liquefiable ground. I: Shear reinforcement and cyclic stress ratio reduction. J. Geotech. Geoenviron. Eng. 2016, 142, 04016023. [Google Scholar] [CrossRef]

- Rayamajhi, D.; Boulanger, R.W.; Ashford, S.A.; Elgamal, A. Dense granular columns in liquefiable ground. II: Effects on deformations. J. Geotech. Geoenviron. Eng. 2016, 142, 04016024. [Google Scholar] [CrossRef]

- Prevost, J.H. A simple plasticity theory for frictional cohesionless soils. Int. J. Soil Dyn. Earthq. Eng. 1985, 4, 9–17. [Google Scholar] [CrossRef]

- Gingery, J.R.; Elgamal, A.; Bray, J.D. Liquefaction model calibration: Element-level versus 1-D site response. In Proceedings of the 6th International Conference on Earthquake Geotechnical Engineering, Christchurch, New Zealand, 1–4 November 2015; pp. 1–4. [Google Scholar]

- Yang, Z.; Lu, J.; Elgamal, A. OpenSees Soil Models and Solid-Fluid Fully Coupled Elements: User’s Manual. Available online: http://www.soilquake.net/opensees/OSManual_UCSD_soil_models_2008.pdf (accessed on 1 July 2021).

| Indicators | Specifications |

|---|---|

| Maximum acceleration | 20 g |

| Maximum velocity | 38 cm/s |

| Maximum displacement | ±6 mm |

| Frequency range | 20~200 Hz |

| Bearing capacity | 300 kg |

| Maximum shaking duration | 1 s |

| Shaking table dimensions | 1400 × 1000 mm |

| Input loading | Sinusoidal or earthquake waves |

| Quality | Model | Prototype |

|---|---|---|

| Length | 1 | |

| Area | 1 | |

| Volume | 1 | |

| Density | 1 | 1 |

| Strain | 1 | |

| Stress | 1 | |

| Stiffness | 1 | |

| Acceleration | 1 | |

| Velocity | 1 | |

| Time | 1 | |

| Frequency | 1 | |

| Permeability | 1 |

| 2.37 | 1.65 g/cm3 | 1.26 g/cm3 | 0.88 | 0.44 | 0.62 mm |

| No. | Loading Condition | Peak Acceleration |

|---|---|---|

| 1 | White noise | 0.01 g |

| 2 | E1−1 | 0.1 g |

| 3 | E2−1 | 0.1 g |

| 4 | E3−1 | 0.1 g |

| 5 | White noise | 0.01 g |

| 6 | E1−2 | 0.2 g |

| 7 | E2−2 | 0.2 g |

| 8 | E3−2 | 0.2 g |

| 9 | White noise | 0.01 g |

| 10 | E1−3 | 0.3 g |

| 11 | E2−3 | 0.3 g |

| 12 | E3−3 | 0.3 g |

| 13 | White noise | 0.01 g |

| Parameters | Medium Dense Sand Dr = 50% |

|---|---|

| Density/(t−3) | 1.85 |

| Void ratio | 0.7 |

| Shear modulus/kPa | 1.21 × 105 |

| Bulk modulus/kPa | − * |

| Friction angle/() | 37 |

| PT angle/() | 32 |

| Peak shear strain | 0.1 |

| Reference confining pressure/kPa | 101 |

| Pressure dependent coefficient | 0.5 |

| Contraction parameter | 0.006/5.5/0.2 |

| Dilation parameter | 0.45/1.5/0.0 |

| Liquefaction parameter | 1.0/0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, W.; Yuan, Y.; Chen, P.; Liang, X.; Deng, J.; Li, C. Seismic Liquefaction of Saturated Calcareous Sands: Dynamic Centrifuge Test and Numerical Simulation. Appl. Sci. 2022, 12, 8701. https://doi.org/10.3390/app12178701

Lyu W, Yuan Y, Chen P, Liang X, Deng J, Li C. Seismic Liquefaction of Saturated Calcareous Sands: Dynamic Centrifuge Test and Numerical Simulation. Applied Sciences. 2022; 12(17):8701. https://doi.org/10.3390/app12178701

Chicago/Turabian StyleLyu, Weiqing, Yong Yuan, Pingshan Chen, Xiaocong Liang, Jiangxu Deng, and Chong Li. 2022. "Seismic Liquefaction of Saturated Calcareous Sands: Dynamic Centrifuge Test and Numerical Simulation" Applied Sciences 12, no. 17: 8701. https://doi.org/10.3390/app12178701

APA StyleLyu, W., Yuan, Y., Chen, P., Liang, X., Deng, J., & Li, C. (2022). Seismic Liquefaction of Saturated Calcareous Sands: Dynamic Centrifuge Test and Numerical Simulation. Applied Sciences, 12(17), 8701. https://doi.org/10.3390/app12178701