Aerodynamic Characteristics of Supersonic Rocket-Sled Involving Waverider Geometry

Abstract

1. Introduction

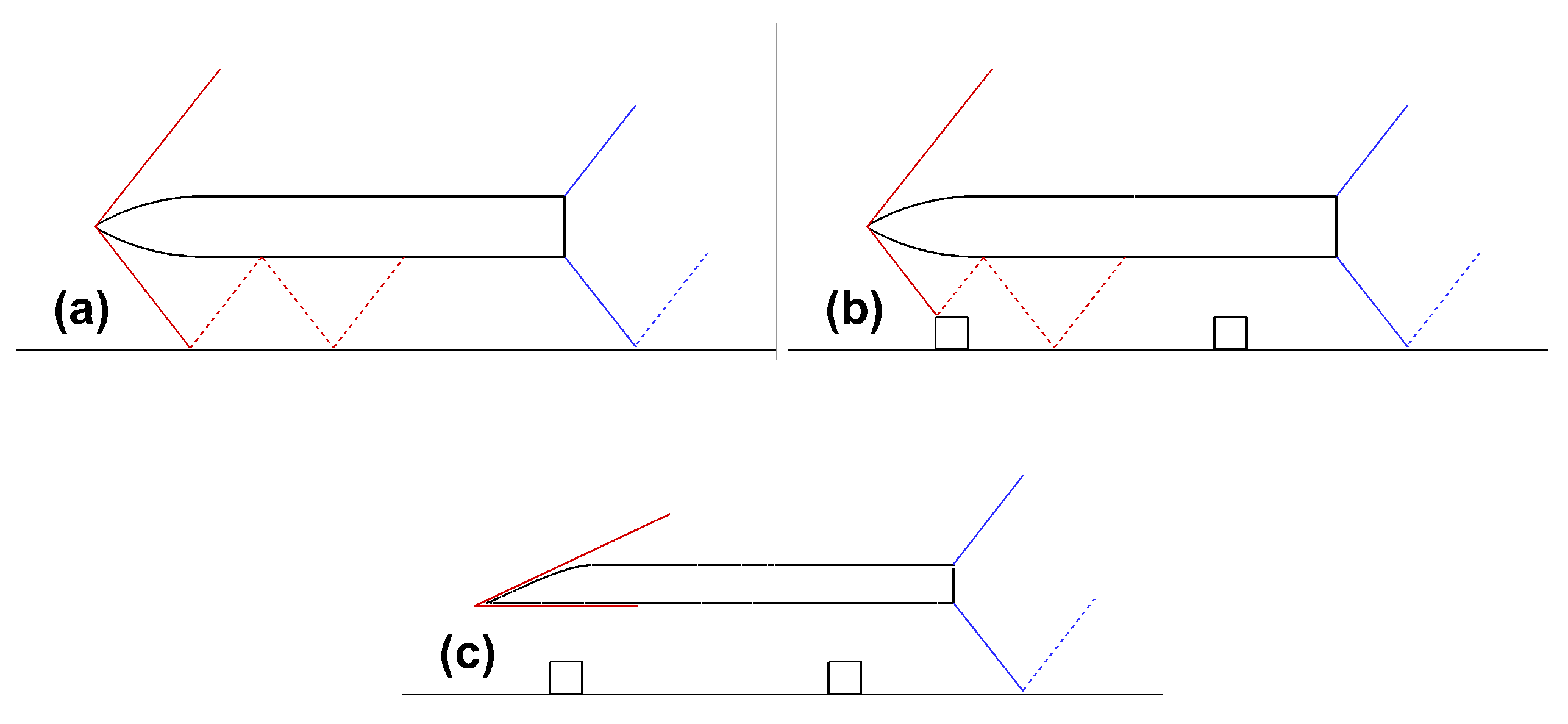

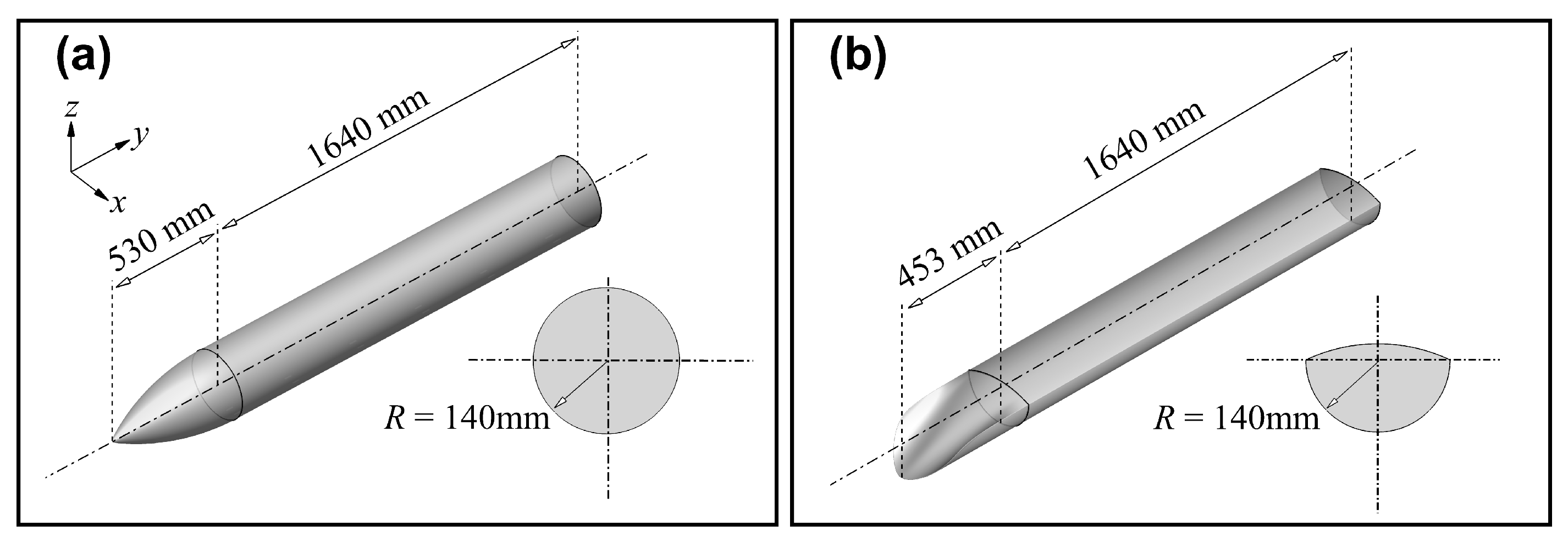

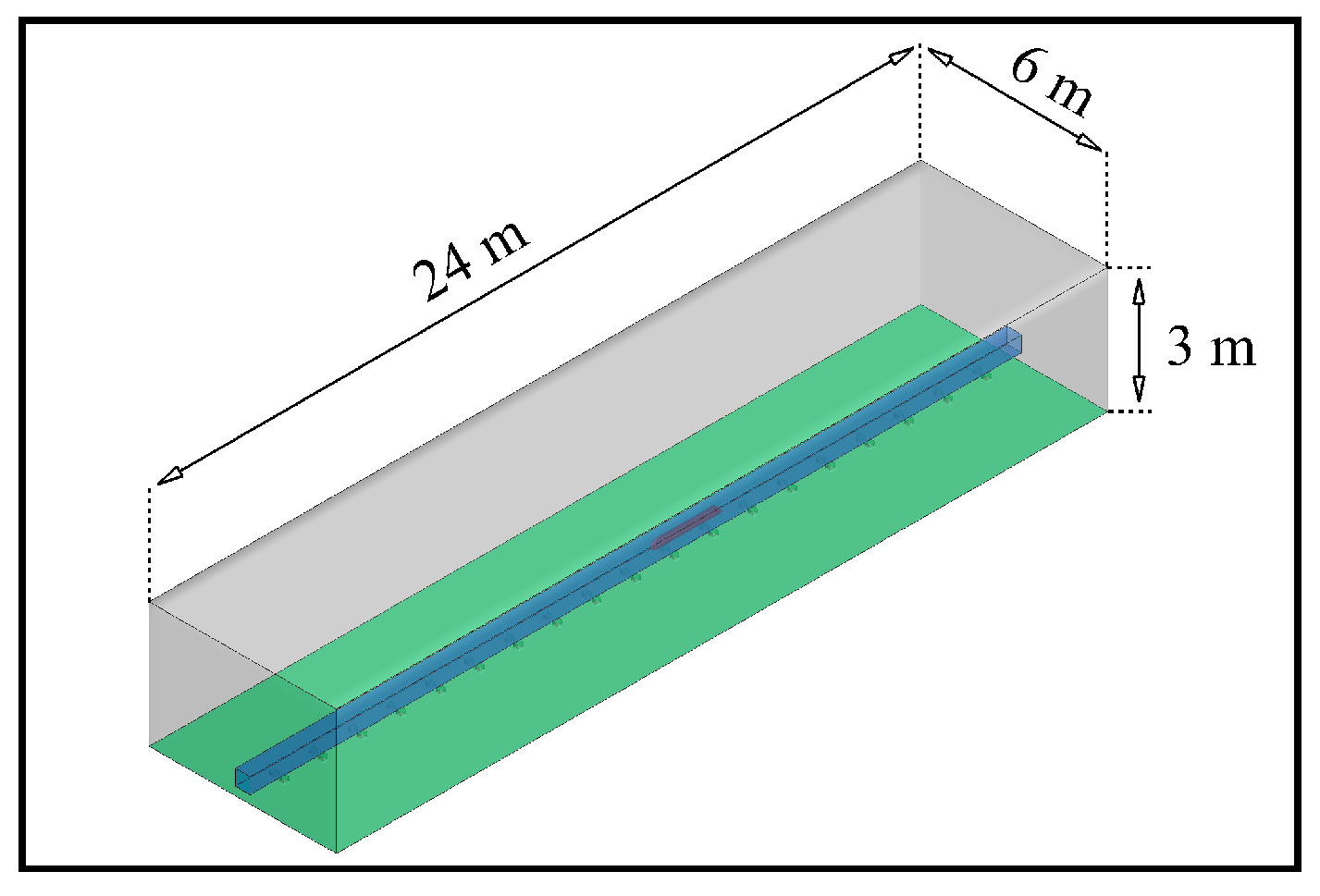

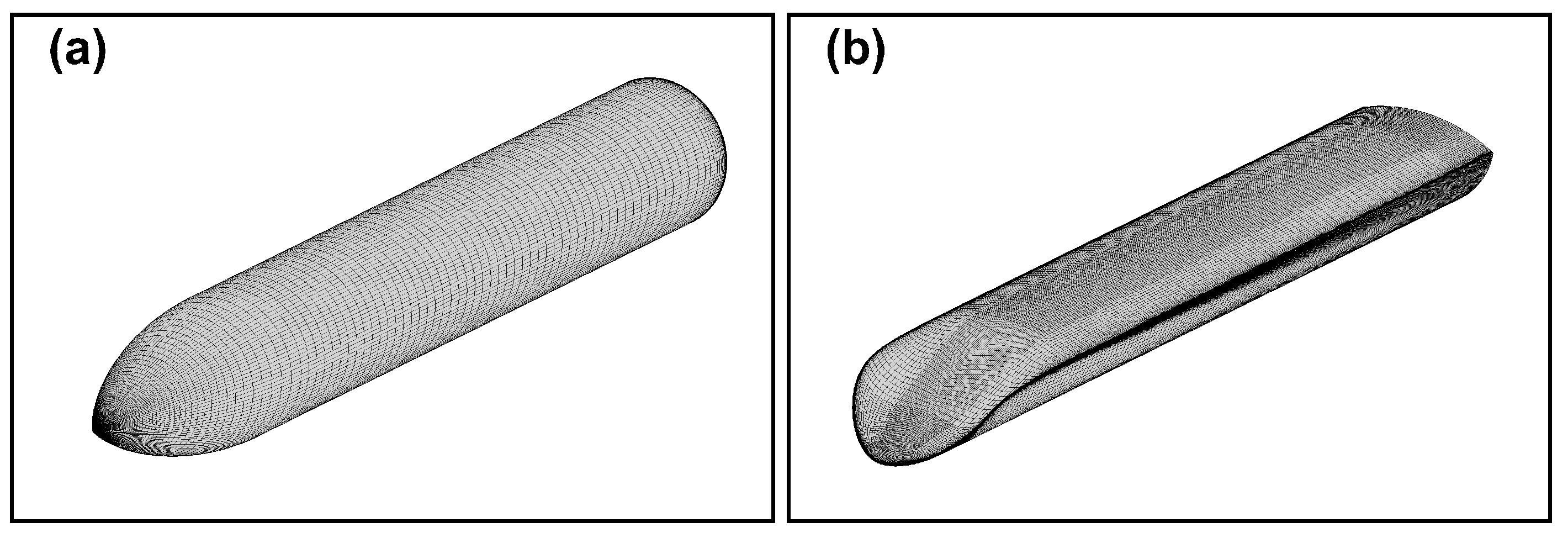

2. Simulation and Numerical Methodology

2.1. Governing Equations

2.2. The Scale Adaptive Simulation Model

2.3. The Dynamic Grid Method

3. Results and Discussion

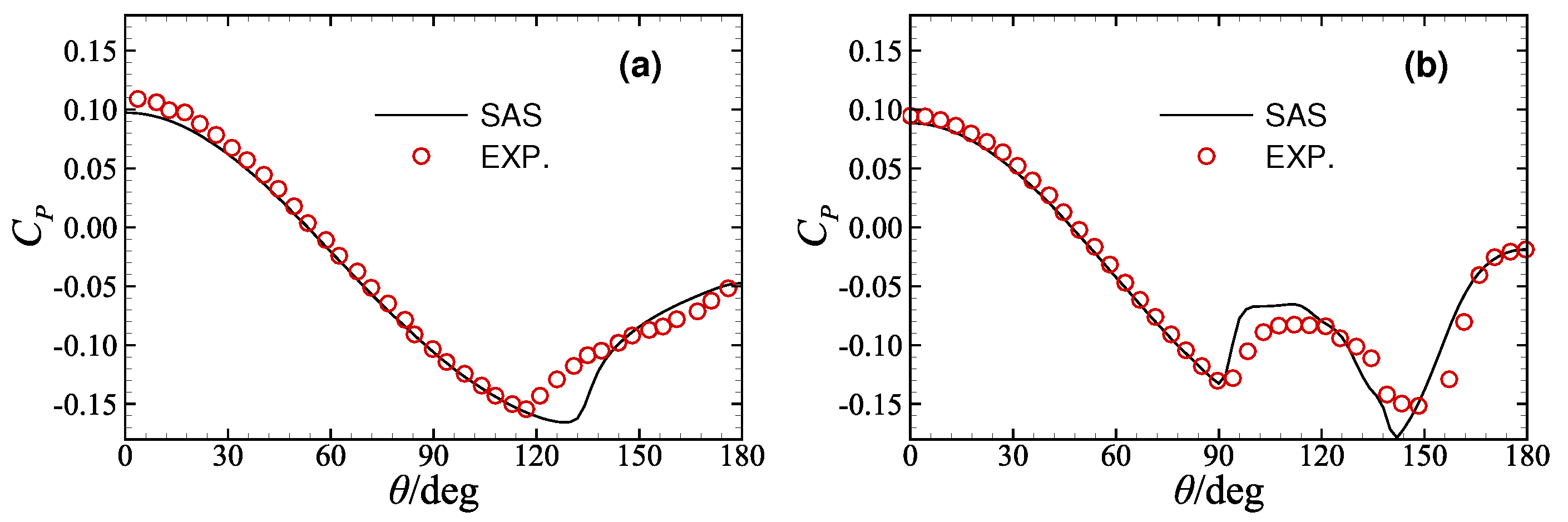

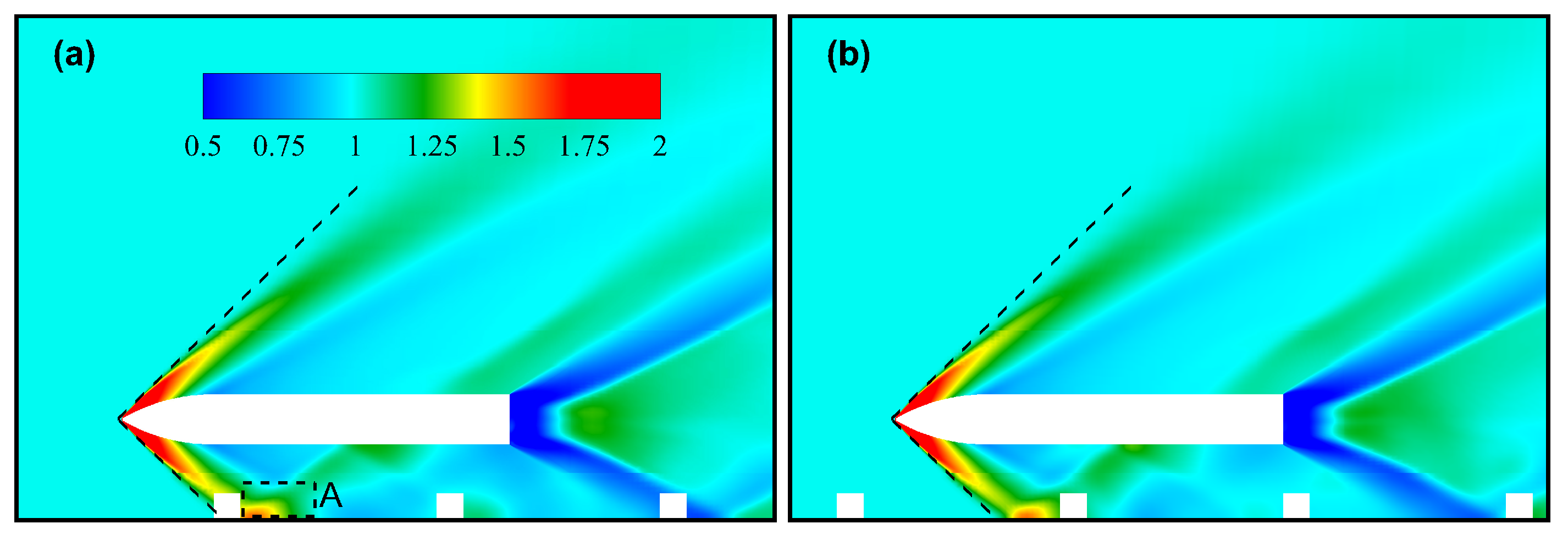

3.1. Validation and Computational Reviews

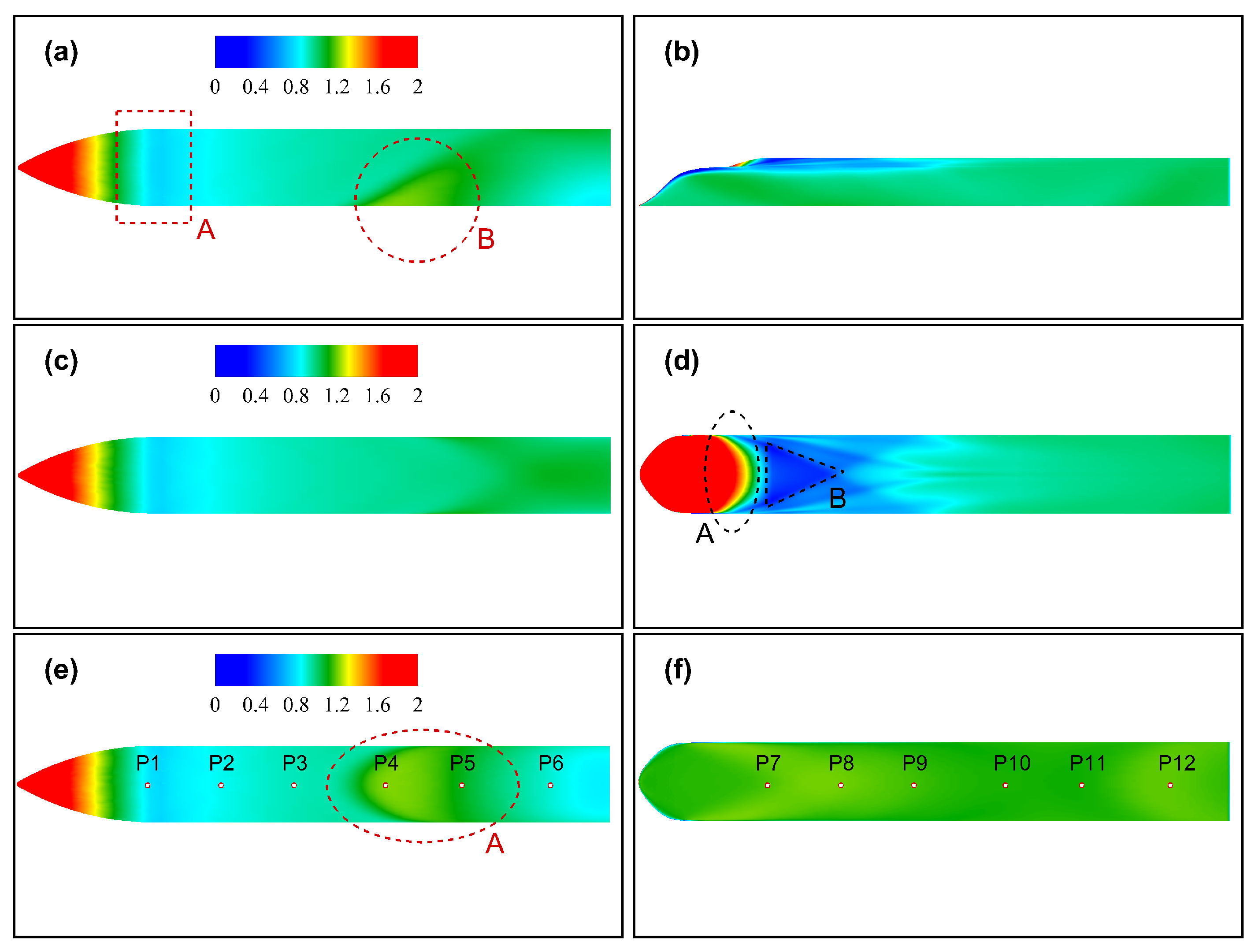

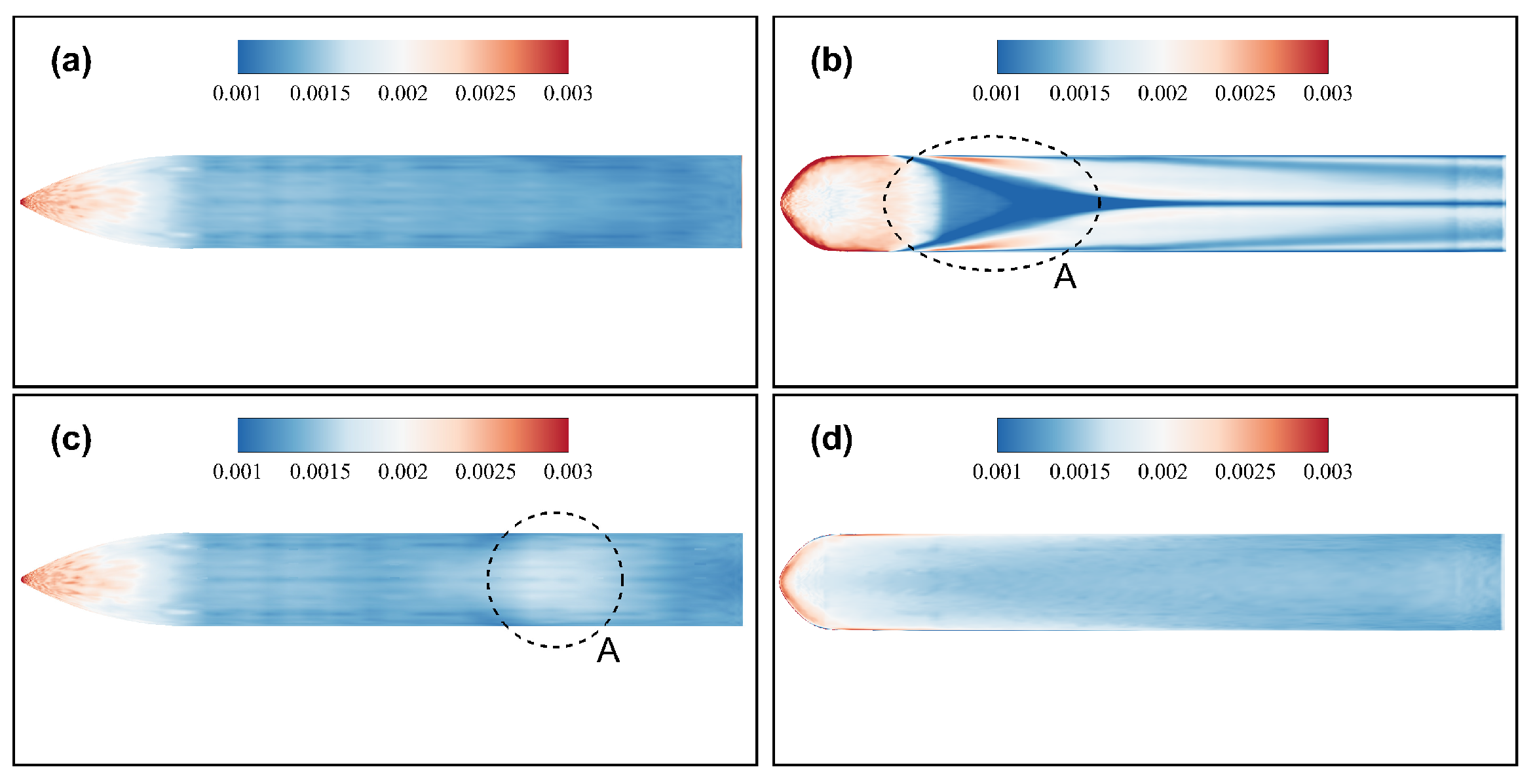

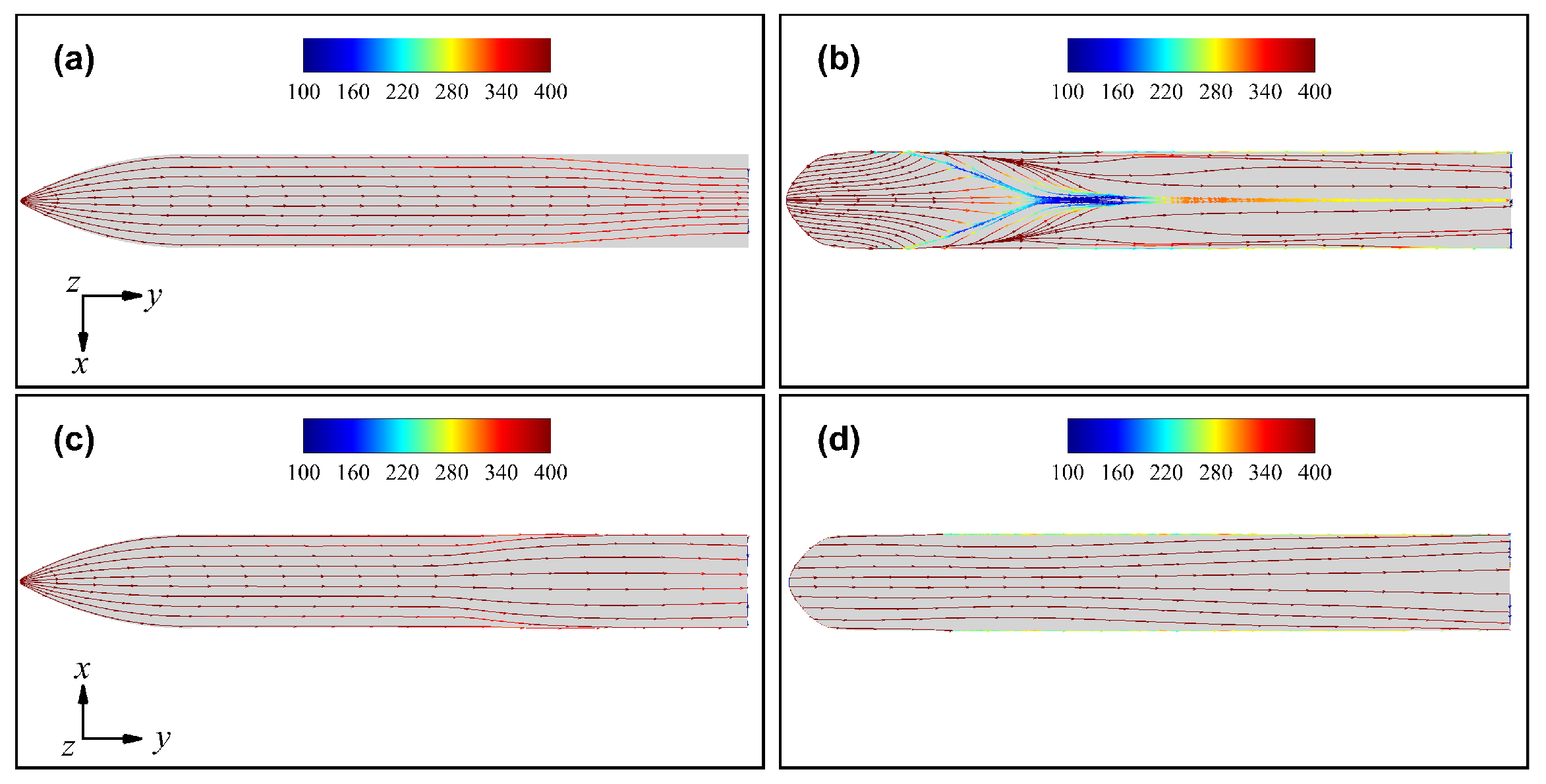

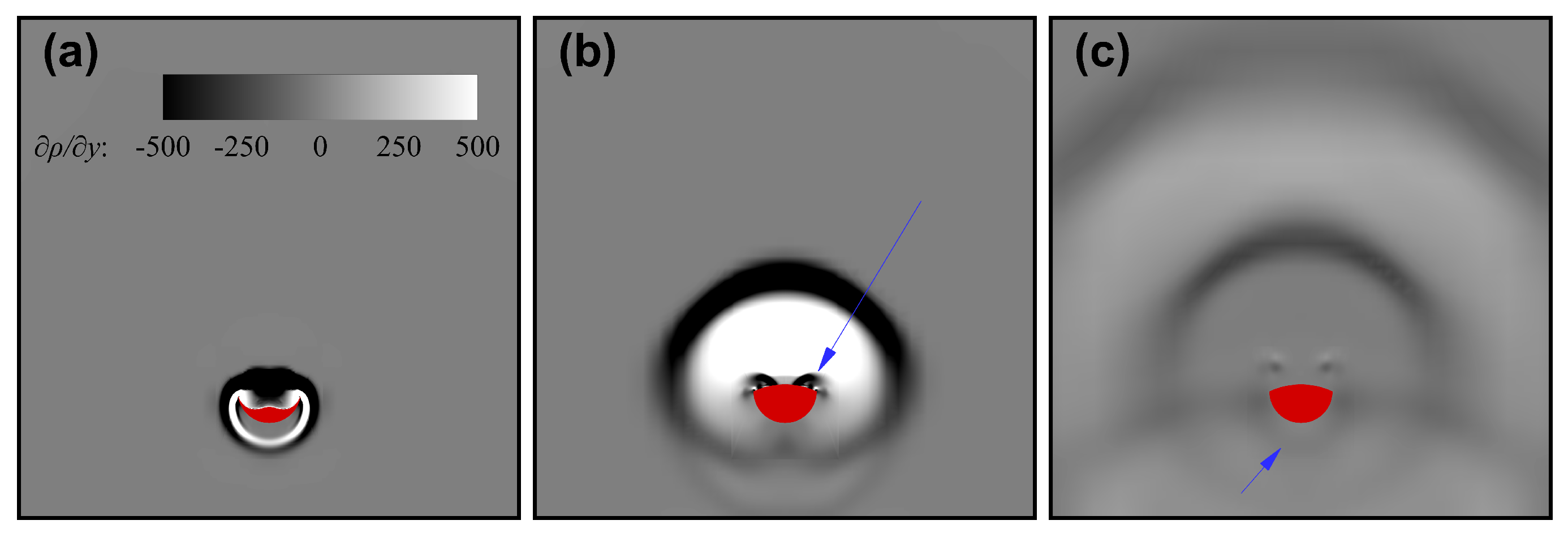

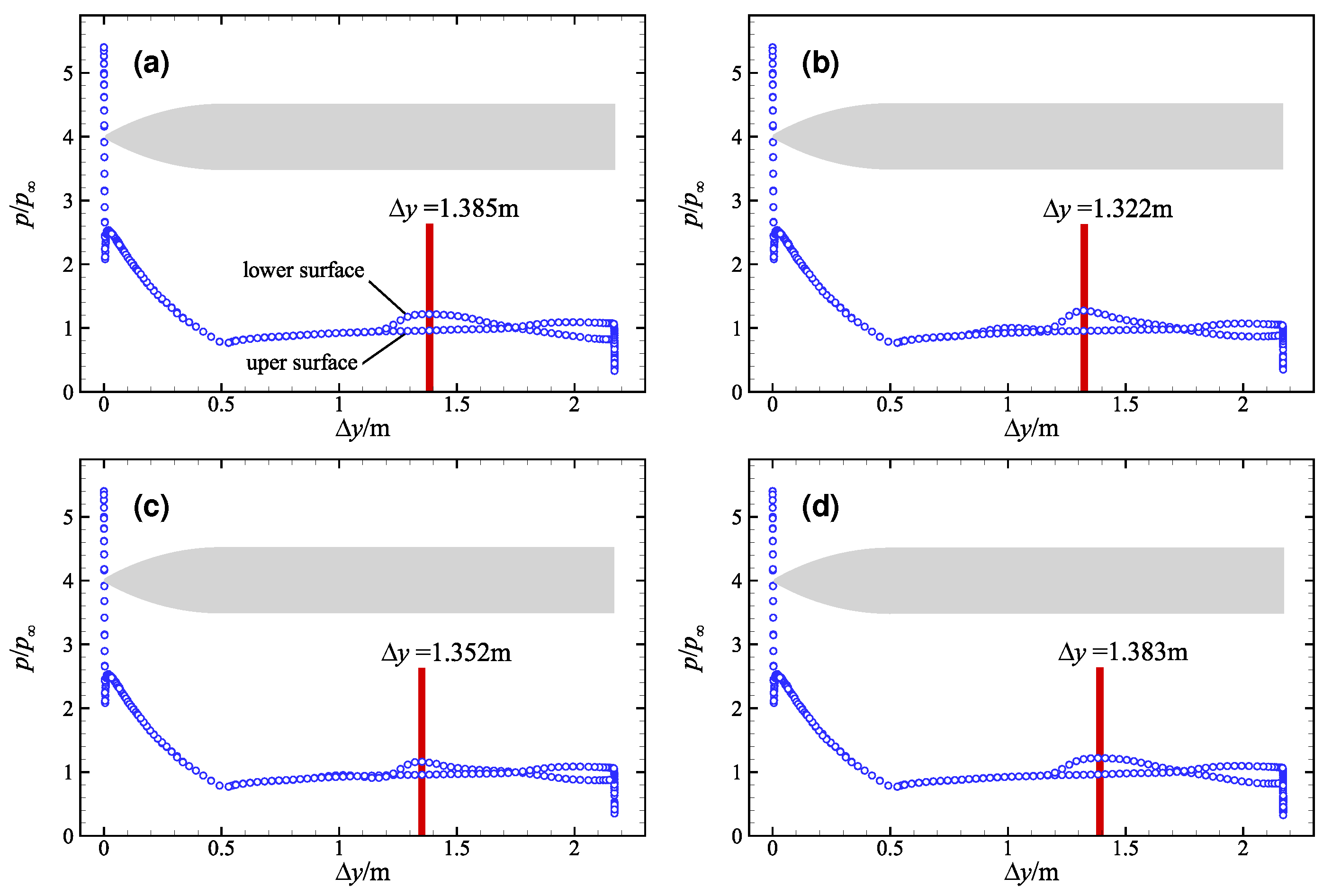

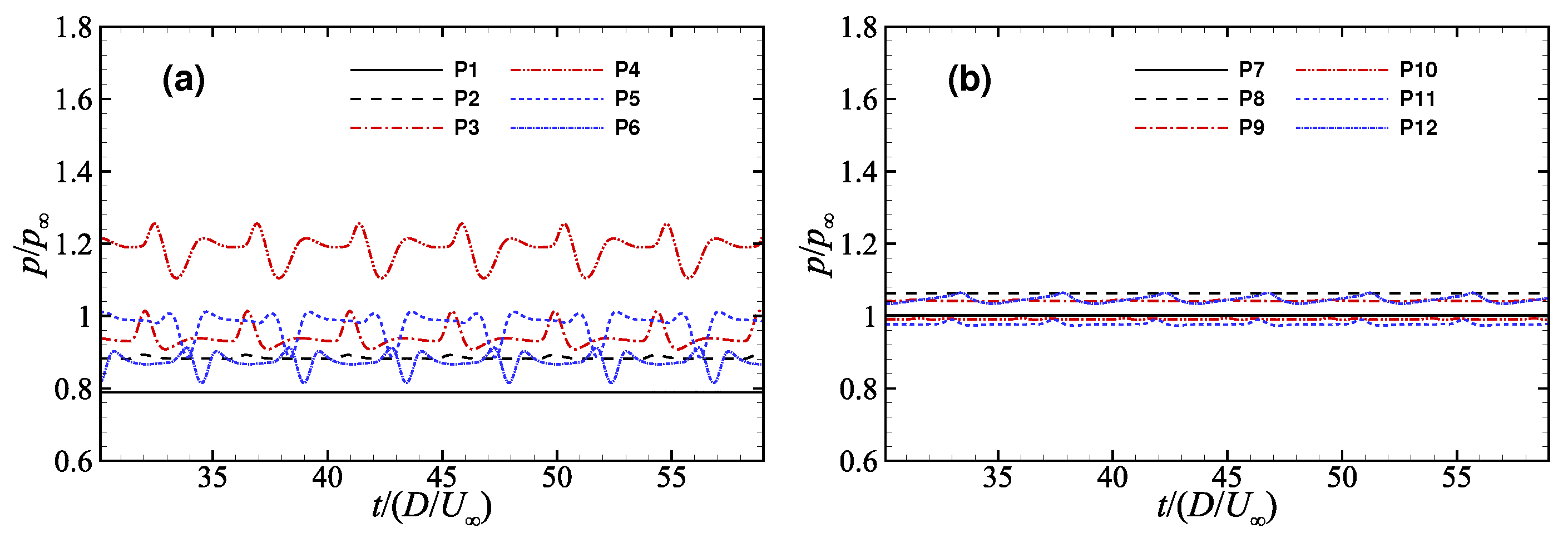

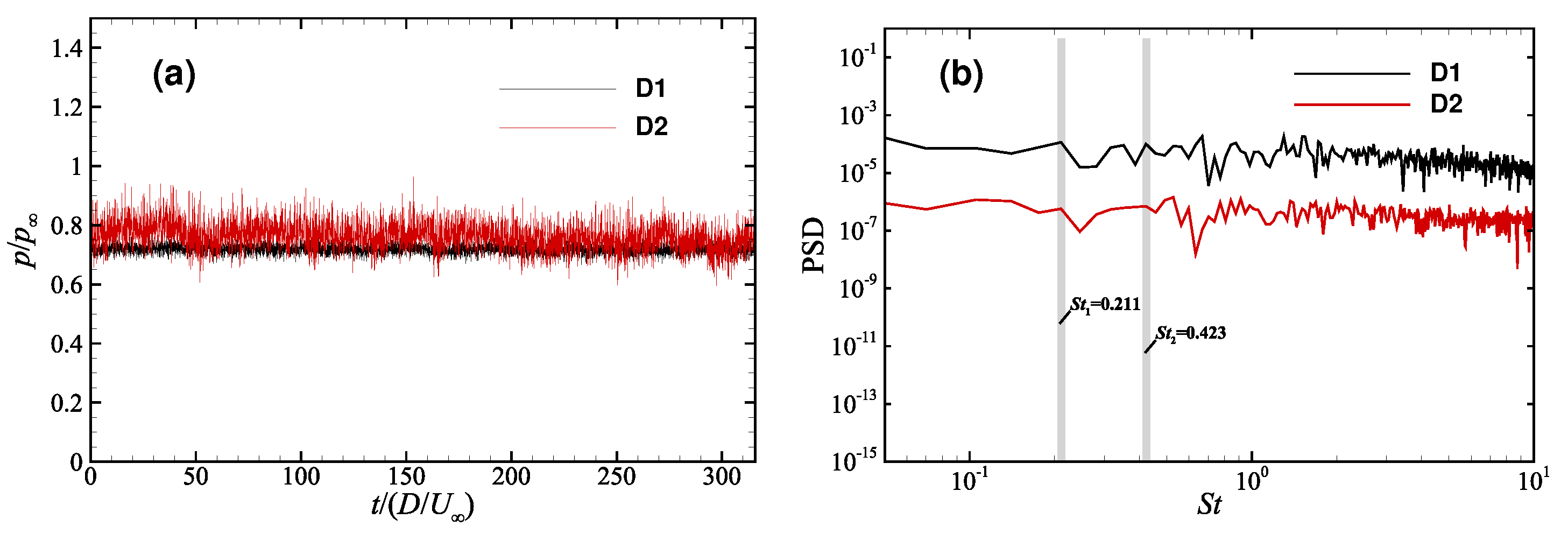

3.2. The Flow Field Characteristics

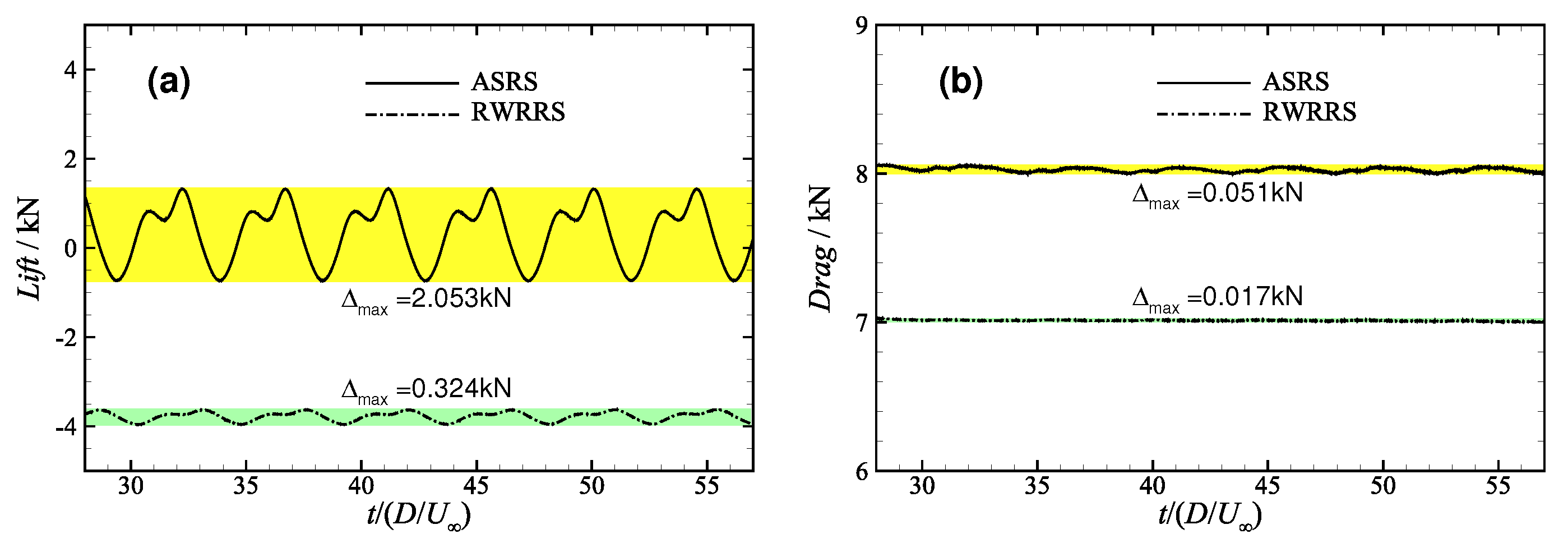

3.3. Force Characteristics

3.4. Spectral Analysis and Acoustic Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schmisseur, J.D. Hypersonics into the 21st century: A perspective on AFOSR-sponsored research in aerothermodynamics. Prog. Aerosp. Sci. 2013, 72, 3–16. [Google Scholar] [CrossRef]

- Szmerekovsky, A.G.; Palazotto, A.N. Structural dynamic considerations for a hydrocode analysis of hypervelocity test sled impacts. AIAA J. 2006, 44, 1350–1359. [Google Scholar] [CrossRef]

- Ayers, G.H.; Hooser, M.D.; Black, D.E.; Leader, A.M. Exploration of dynamic rocket sled modeling parameters at Holloman High Speed Test Track. AIAA Paper 2009-1707 2009. [Google Scholar] [CrossRef]

- Krupovage, D.J.; Mixon, L.C.; Pokorny, O.T. Wind-tunnel and full-scale forces on rocket sleds. J. Spacecr. Rockets. 1967, 4, 1346–1351. [Google Scholar] [CrossRef]

- Rigali, D.J.; Reltz, L.V. High speed monorail rocket sleds for aerodynamic testing at high Reynolds numbers. J. Spacecr. Rockets. 1968, 5, 1341–1346. [Google Scholar] [CrossRef]

- Slotnick, J.; Khodadoust, A.; Alonso, J.; Darmofal, D.; Gropp, D.; Lurie, E.; Mavriplis, D. CFD Vision 2030 Study: A Path to Revolutionary Computational Aerosciences; NASA/CR-218178; NASA Langley Research Center: Hampton, VA, USA, 2014. [Google Scholar]

- Lumb, S.B.; Bosmajian, N. Non-vitiated hypersonic propulsion system testing at the Holloman High Speed Test Track. AIAA Paper 2005-3896 2005. [Google Scholar] [CrossRef]

- Lofthouse, A.J.; Hughson, M.C.; Palazotto, A.N. Computational aerodynamic analysis of the flow field about a hypervelocity test sled. AIAA Paper 2003-981 2003. [Google Scholar] [CrossRef]

- Hegedus, M.C.; Mendenhall, M.R.; Perkins, S.C.; Stremel, P.M.; Faltz, J.A. Engineering analysis for rocket sled aerodynamics. AIAA Paper 2006-664 2006. [Google Scholar] [CrossRef]

- Schoenfeld, W.P. Requirements for upgrading the Holloman High Speed Test Track computational fluid dynamics analytical capability. AIAA Paper 2000-2288 2000. [Google Scholar] [CrossRef]

- Xu, C.Y.; Zhang, T.; Yu, Y.Y.; Sun, J.H. Effect of von Karman length scale in scale adaptive simulation approach on the prediction of supersonic turbulent flow. Aerosp. Sci. Technol. 2019, 86, 630–639. [Google Scholar] [CrossRef]

- Wang, B.; Zheng, J.; Yu, Y.Y.; Lv, R.M.; Xu, C.Y. Shock-wave/rail-fasteners interaction for two rocket sleds in the supersonic flow regime. Fluid Dyn. Mater. Process. 2020, 16, 675–684. [Google Scholar] [CrossRef]

- Lamb, J.L. Critical Velocities for Rocket Sled Excitation of Rail Resonance. Johns Hopkins Apl Tech. Dig. 2020, 21, 448–458. [Google Scholar] [CrossRef]

- Turnbull, D.; Hooser, C.; Hooser, D.M.; Myers, J. Soft sled test capability at the Holloman High Speed Test Track. AIAA Paper 2010-1708 2010. [Google Scholar] [CrossRef]

- Cattafesta, L.N.; Sheplak, M. Actuators for active flow control. Annu. Rev. Fluid Mech. 2011, 43, 247–272. [Google Scholar] [CrossRef]

- Choi, H.; Jeon, W.P.; Kim, J. Control of flow over a bluff body. Annu. Rev. Fluid Mech. 2008, 40, 113–139. [Google Scholar] [CrossRef]

- Collis, S.S.; Joslin, R.D.; Seifert, A.; Theofilis, V. Issues in active flow control: Theory, control, simulation, and experiment. Prog. Aerosp. Sci. 2004, 40, 237–289. [Google Scholar] [CrossRef]

- Stanewsky, E.; Delery, J.; Fulker, J.; Geibler, W. Book reviews: EUROSHOCK—Drag reduction by passive shock control. AIAA J. 1999, 37, 406–408. [Google Scholar] [CrossRef]

- Delery, J.M. shockwave/turbulent boundary layer interaction and its control. Prog. Aerosp. Sci. 1985, 22, 209–280. [Google Scholar] [CrossRef]

- Yagiz, B.; Kandil, O.; Pehlivanoglu, Y.V. Drag minimization using active and passive flow control techniques. Aerosp. Sci. Technol. 2011, 17, 21–31. [Google Scholar] [CrossRef]

- Saunders, D.; Slater, J.; Dippold, V.; Lee, J.; Sanders, B.; Weir, L. TBCC inlet experiments and analysis. In FAP Annual Review; NASA FAP Annual Meeting-Hypersonic Project; NASA Langley Research Center: Hampton, VA, USA, 2007. [Google Scholar]

- Min, B.Y.; Lee, J.W.; Byun, Y.H. Numerical investigation of the shock interaction effect on the lateral jet controlled missile. Aerosp. Sci. Technol. 2006, 10, 385–393. [Google Scholar] [CrossRef]

- Li, W.C.; Jin, D.P.; Zhao, Y.H. Efficient nonlinear reduced-order modeling for synthetic-jet-based control at high angle of attack. Aerosp. Sci. Technol. 2017, 62, 98–107. [Google Scholar] [CrossRef]

- Kim, Y.C.; Roh, T.S.; Huh, H.; Lee, H.J. Study on the combined effect of various injection conditions on the drag reduction by a counter-flow jet in supersonic flow. Aerosp. Sci. Technol. 2019, 98, 150580. [Google Scholar] [CrossRef]

- Cao, S.L.; Li, Y.; Zhang, J.Z.; Decuchi, Y. Lagrangian analysis of mass transport and its influence on the lift enhancement in a flow over the airfoil with a synthetic jet. Aerosp. Sci. Technol. 2019, 86, 11–20. [Google Scholar] [CrossRef]

- Duvigneau, R.; Visonneau, M. Simulation and optimization of stall control for an airfoil with a synthetic jet. Aerosp. Sci. Technol. 2006, 10, 279–287. [Google Scholar] [CrossRef]

- Becker, R.; King, R.; Petz, R.; Nitsche, W. Adaptive closed-loop separation control on a high-lift configuration using extremum seeking. AIAA J. 2007, 45, 1382–1392. [Google Scholar] [CrossRef]

- Djavareshkian, M.H.; Esmaeli, A.; Parsani, A. Aerodynamics of smart flap under ground effect. Aerosp. Sci. Technol. 2011, 15, 642–652. [Google Scholar] [CrossRef]

- Seifert, A.; Greenblatt, D.; Wygnanski, I.J. Active separation control an overview of Reynolds and Mach numbers. Aerosp. Sci. Technol. 2004, 8, 569–582. [Google Scholar] [CrossRef]

- Chernyshev, S.L.; Gamirullin, M.D.; Khomich, V.Y.; Kuryachii, A.P.; Litvinov, V.M. Electrogasdynamic laminar flow control on a swept wing. Aerosp. Sci. Technol. 2016, 59, 155–161. [Google Scholar] [CrossRef]

- Yan, H.; Gaitonde, D. Numerical study on effect of a thermal bump in supersonic flow control. AIAA Paper 2008-3790 2008. [Google Scholar] [CrossRef]

- Zhang, C.; Bijay, K.S. Investigation on drag reduction performance of aero engine blade with micro-texture. Aerosp. Sci. Technol. 2018, 72, 380–396. [Google Scholar] [CrossRef]

- Dietz, G. Passive shock control concept for drag reduction in transonic flow. J. Aircr. 2005, 42, 794–799. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Yan, C.Y.; Chen, H.X.; Yin, Y.H. Study of riblet drag reduction for an infinite span wing with different sweep angles. Chin. J. Aeronaut. 2020, 33, 3125–3137. [Google Scholar] [CrossRef]

- Ahmed, M.Y.M.; Qin, N. Metamodels for aerothermodynamic design optimization of hypersonic spiked blunt bodies. Aerosp. Sci. Technol. 2010, 14, 364–376. [Google Scholar] [CrossRef]

- Luo, D.H.; Huang, D.G.; Sun, X.J. Passive flow control of a stalled airfoil using a microcylinder. J. Wind Eng. Ind. Aerodyn. 2017, 170, 256–273. [Google Scholar] [CrossRef]

- Xu, C.; Mao, Y.; Hu, Z. Control of cylinder wake flow and noise through a downstream porous treatment. Aerosp. Sci. Technol. 2019, 88, 233–243. [Google Scholar] [CrossRef]

- Gaster, M.; Grosch, C.E.; Jackson, T.L. The velocity field created by a shallow bump in a boundary layer. Phys. Fluids 1994, 6, 3079–3085. [Google Scholar] [CrossRef][Green Version]

- Zhang, Y.F.; Fang, X.M.; Chen, H.X.; Fu, S.; Duan, Z.Y.; Zhang, Y.J. Supercritical natural laminar flow airfoil optimization for regional aircraft wing design. Aerosp. Sci. Technol. 2015, 43, 152–164. [Google Scholar] [CrossRef]

- He, X.L.; Li, J.C.; Mader, C.A.; Yildirim, A.Y.; Martin, J.R.R.A. Robust aerodynamic shape optimization—From a circle to an airfoil. Aerosp. Sci. Technol. 2019, 87, 48–61. [Google Scholar] [CrossRef]

- Capriotti, D.; Anderson, J.D.; Bowcutt, K.G. Viscous optimized hypersonic waveriders. AIAA Paper 1987-272 1987. [Google Scholar] [CrossRef]

- Corda, S.; Anderson, J.D. Viscous optimized hypersonic waveriders designed from axisymmetric flow fields. AIAA Paper 1988-369 1988. [Google Scholar] [CrossRef]

- Rudd, L. Longitudinal Dynamic Stability and Control of Mission Oriented Hypersonic Waverider Vehicles. Ph.D. Thesis, University of Maryland, College Park, MA, USA, 2001. [Google Scholar]

- Starkey, R.P.; Lewis, M.J. Simple analytical model for parametric studies of hypersonic waveriders. J. Spacecr. Rockets. 2020, 36, 516–523. [Google Scholar] [CrossRef]

- Doig, G. Transonic and supersonic ground effect aerodynamics. Prog. Aerosp. Sci. 2014, 69, 1–28. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Menter, F.R.; Egorov, Y. The scale-adaptive simulation method for unsteady turbulent flow predictions. Part 1: Theory and model description. Flow Turbul. Combust. 2010, 85, 113–138. [Google Scholar] [CrossRef]

- Egorov, Y.; Menter, F.R. The scale-adaptive simulation method for unsteady turbulent flow predictions. Part 2: Application to complex flows. Flow Turbul. Combust. 2010, 85, 139–165. [Google Scholar] [CrossRef]

- Menter, F.R.; Egorov, Y. A Scale Adaptive Simulation Model using Two-Equation Models. AIAA Paper 2005-1095 2005. [Google Scholar] [CrossRef]

- Birch, T.J.; Allen, J.M.; Wilcox, F.J. Force, surface pressure and flowfield measurements on slender missiles at supersonic speeds. AIAA Paper 2000-4207 2000. [Google Scholar] [CrossRef]

- Zhao, Z.T.; Huang, W.; Li, Y.; Yang, Y.G. An overview of research on wide-speed range waverider configuration. Prog. Aerosp. Sci. 2020, 113, 100606. [Google Scholar] [CrossRef]

- Doig, G.; Barber, T.J.; Leonardi, E.; Neely, A.J.; Kleine, H. Aerodynamics of a supersonic projectile in proximity to a solid surface. AIAA J. 2010, 48, 2916–2930. [Google Scholar] [CrossRef]

- Silnikov, M.V.; Chernyshov, M.V.; Uskov, V.N. Analytical solutions for Prandtl–Meyer wave–oblique shock overtaking interaction. Acta Astronaut. 2014, 99, 175–183. [Google Scholar] [CrossRef]

- Doig, G.; Wang, S.B.; Kleine, H.; Young, J. Aerodynamic analysis of projectiles in ground effect at near-sonic Mach numbers. AIAA J. 2016, 54, 150–160. [Google Scholar] [CrossRef]

- Zuo, F.Y.; Memmolo, A.; Huang, G.P.; Pirozzoli, S. Direct numerical simulation of conical shockwave–turbulent boundary layer interaction. J. Fluid Mech. 2019, 877, 167–195. [Google Scholar] [CrossRef]

- Langston, L.S.; Boyle, M.T. A new surface-streamline flow-visualization technique. J. Fluid Mech. 1982, 125, 53–57. [Google Scholar] [CrossRef]

- Zhang, H.X.; Zhang, S.H.; Tian, H.; Zhang, L.P.; Li, Q. Separation on fixed surface for three dimensional compressible unsteady flows(in chinese). Acta Aerodyn. Sin. 2012, 30, 421–428. [Google Scholar] [CrossRef]

- Tobak, M.; Peake, D. Topology of three dimensional separated flows. Ann. Rev. Fluid Mech. 1982, 14, 61–85. [Google Scholar] [CrossRef]

- Kalkhoran, I.M.; Smart, M.K. Aspects of shockwave-induced vortex breakdown. Prog. Aerosp. Sci. 2000, 36, 63–95. [Google Scholar] [CrossRef]

- Javad, S.Y. Effects of boundary-layer bleed parameters on supersonic intake buzz. Aerosp. Sci. Technol. 2021, 120, 107246. [Google Scholar]

- Lee, H.P.; Lim, K.M.; Kumar, S. Noise assessment of elevated rapid transit railway lines and acoustic performance comparison of different noise barriers for mitigation of elevated railway tracks noise. Appl. Acoust. 2021, 183, 108340. [Google Scholar] [CrossRef]

| Pattern | Methods | Advantages | Disadvantages |

|---|---|---|---|

| Active | Jet [22,23,24,25,26] | Easy to maintain, cost-effective | Affects performance and operating life |

| Active | Structural deformation [27,28] | Adaptable, effective | Complex, big weight |

| Active | Periodic excitation [29,30] | Compact construction and energy saving | Limited control scope |

| Active | Heating [31] | Simple structure | Weak ability |

| Passive | Changing surface condition [32,33,34] | Effective | Difficult to adjust and narrow applicability |

| Passive | Adding extra objects [35,36,37,38] | Simple in theory | Difficult to apply |

| Passive | Shape optimization [39,40] | Adaptable, effective | Complex process and limited control scope |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Wang, B.; Xu, C.; Sun, J. Aerodynamic Characteristics of Supersonic Rocket-Sled Involving Waverider Geometry. Appl. Sci. 2022, 12, 7861. https://doi.org/10.3390/app12157861

Yu Y, Wang B, Xu C, Sun J. Aerodynamic Characteristics of Supersonic Rocket-Sled Involving Waverider Geometry. Applied Sciences. 2022; 12(15):7861. https://doi.org/10.3390/app12157861

Chicago/Turabian StyleYu, Yuanyuan, Bin Wang, Changyue Xu, and Jianhong Sun. 2022. "Aerodynamic Characteristics of Supersonic Rocket-Sled Involving Waverider Geometry" Applied Sciences 12, no. 15: 7861. https://doi.org/10.3390/app12157861

APA StyleYu, Y., Wang, B., Xu, C., & Sun, J. (2022). Aerodynamic Characteristics of Supersonic Rocket-Sled Involving Waverider Geometry. Applied Sciences, 12(15), 7861. https://doi.org/10.3390/app12157861