Compressive Strength of Aged Timber Members in Traditional Building: Considering Differences in Heartwood and Sapwood

Abstract

:1. Introduction

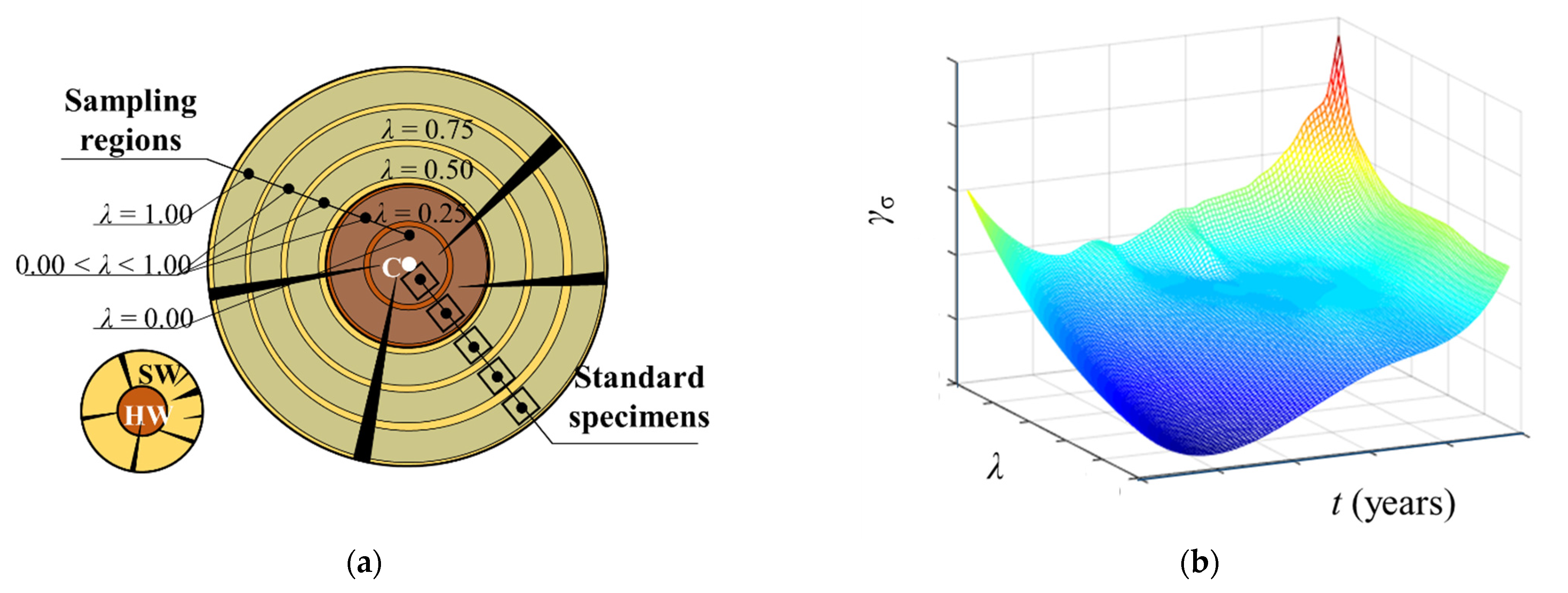

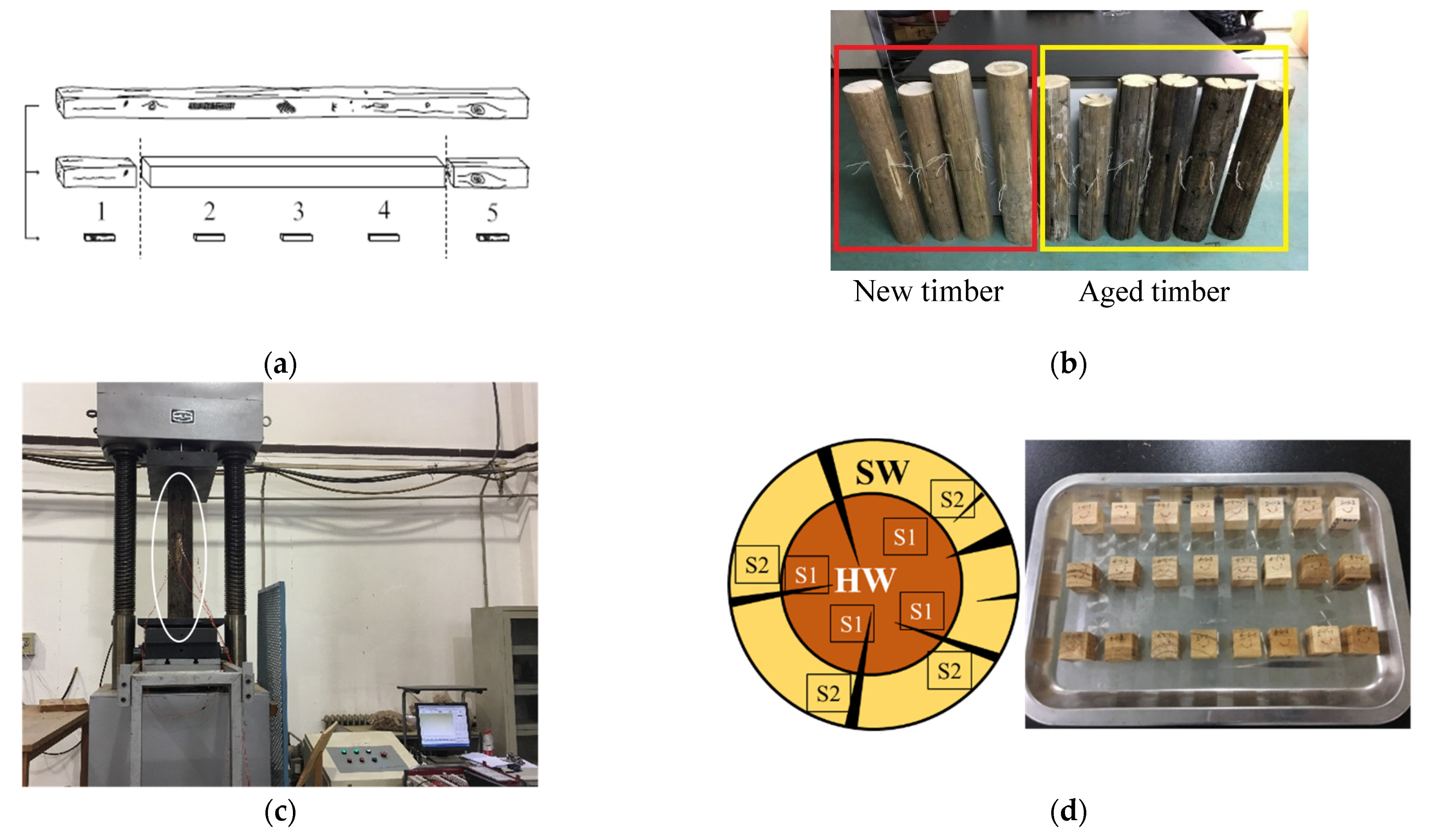

2. Materials and Methods

3. Results and Discussion

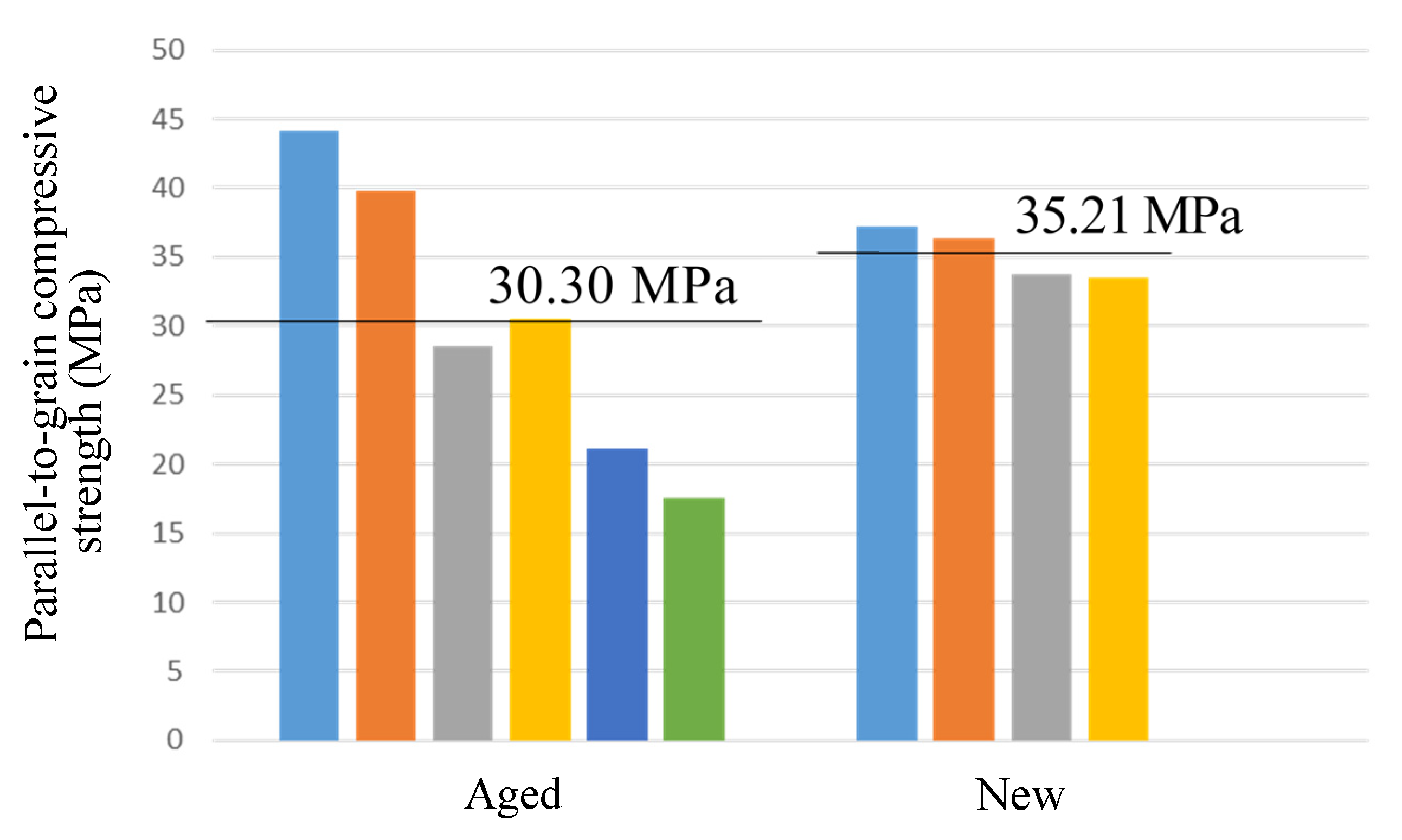

3.1. Test Data Analysis

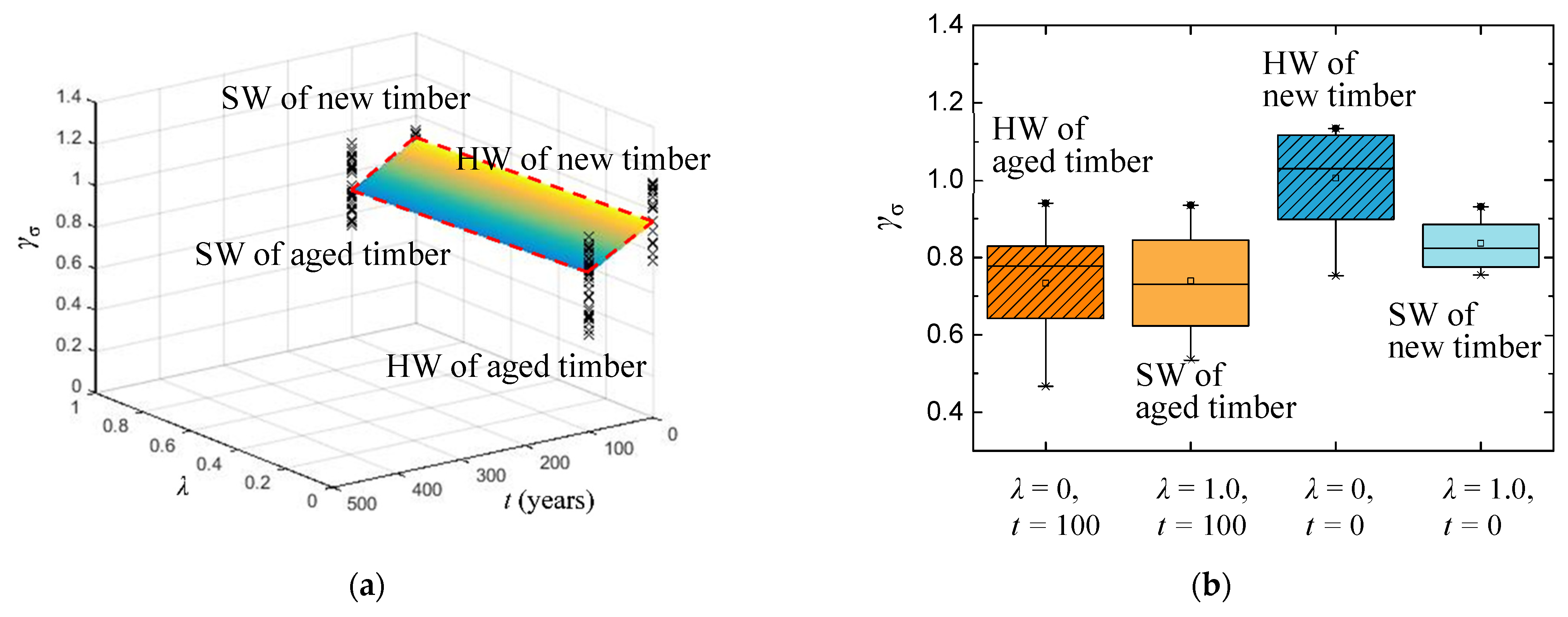

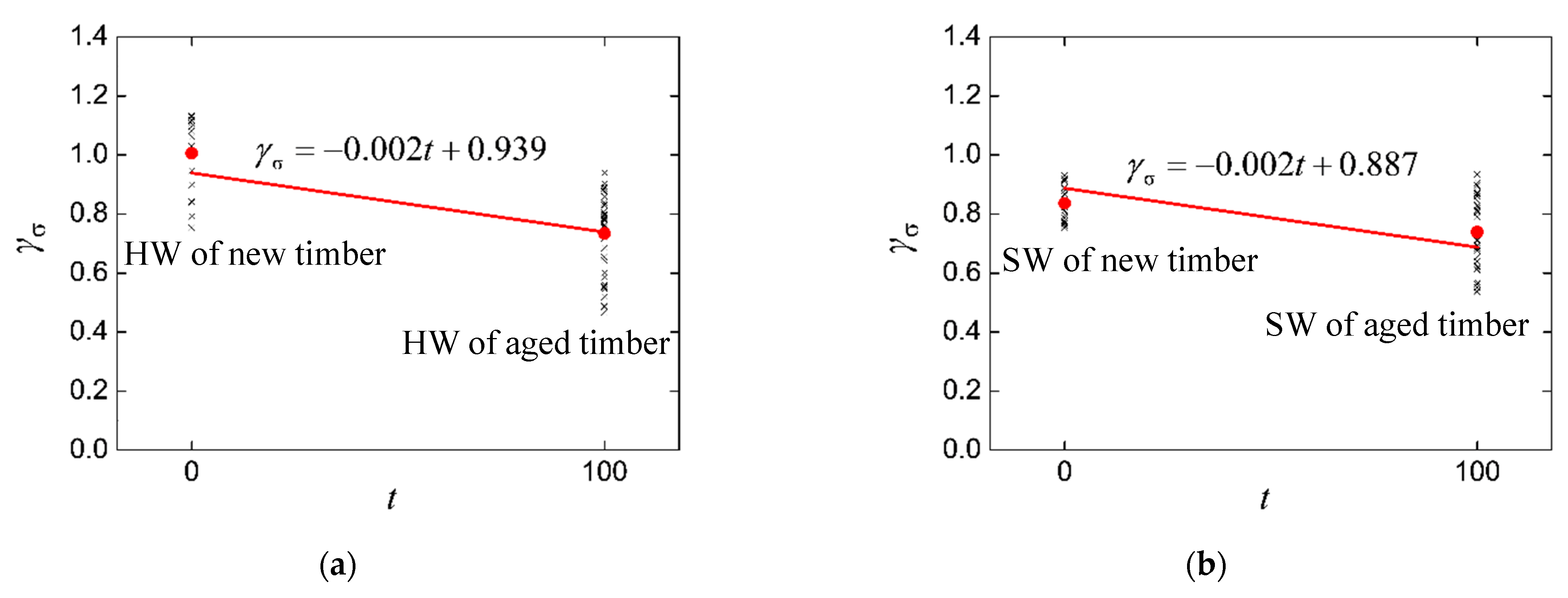

3.2. Relationship of Compressive Strength

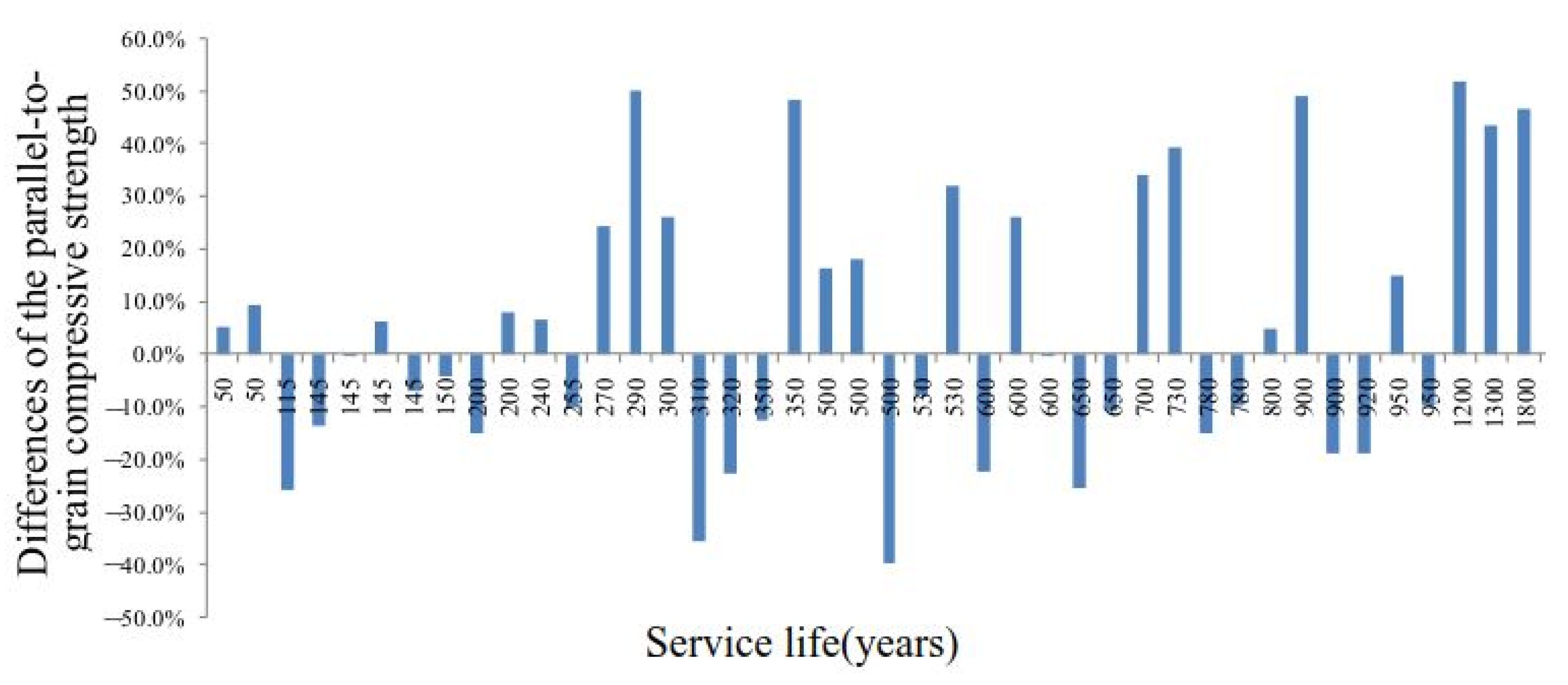

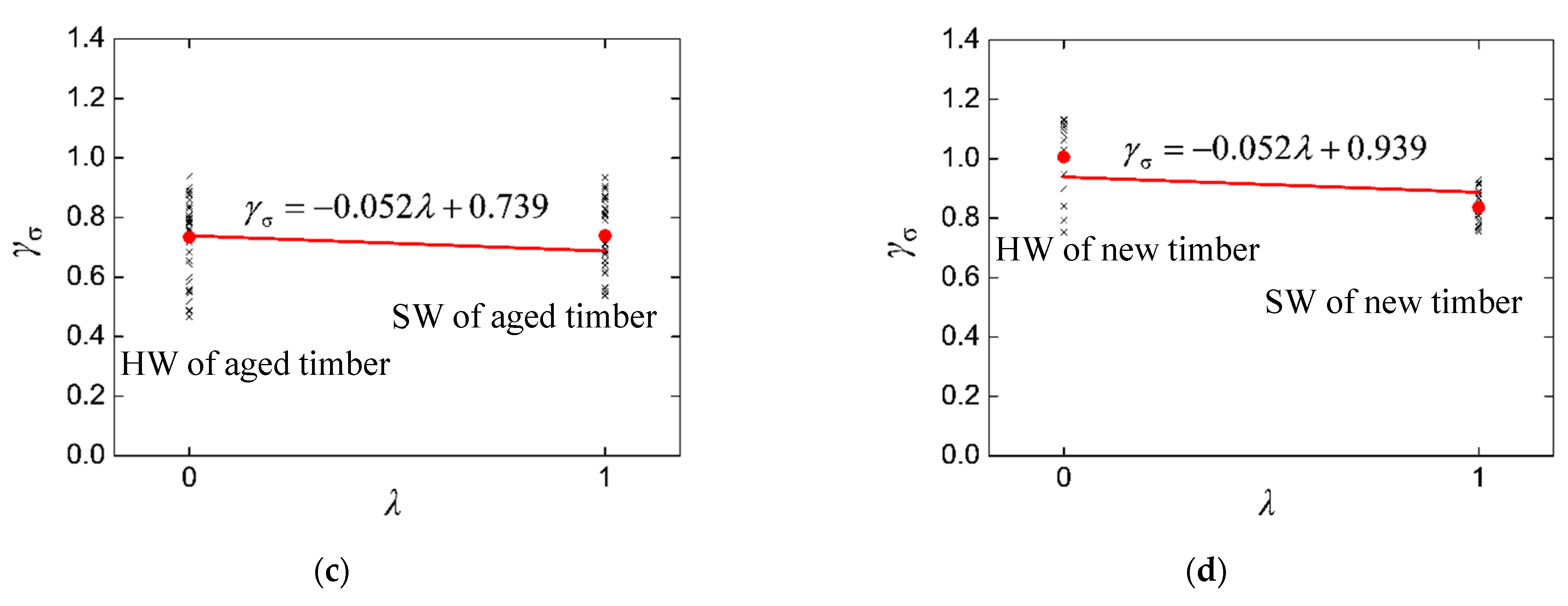

4. Degradation of Compressive Strength with Time

5. Conclusions

- (1)

- The variation of compressive strength of the aged CL in the radial direction was small, not exceeding 2.0%, which was significantly less than that of the new CL.

- (2)

- The compressive strength of the HW of the aged CL was nearly 20.0% larger than that of the new CL. The compressive strength of the SW of the aged and new CL were similar, with less than a 1.0% difference.

- (3)

- After the long-term (100 years) action of axial load and environmental effects on the aged CL, the compressive strength of the aged log segments was nearly 14.0% lower than that of the new log segments.

- (4)

- The fitted model for the estimation of parallel-to-grain compressive strength of the log segments gave estimates with less than 13.0% error, which was better than the estimates calculated based on the Chinese National Standard.

- (5)

- A lower stress level is associated with similar failure strengths of both the HW and SW. The HW and SW may fail at the same load when the stress level is low enough.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Study | Wood Species | Service Life (years) | Parallel-to-Grain Compressive Strength (MPa) | |

|---|---|---|---|---|

| Aged | New | |||

| [7,11,40] | Zelkova schneideriana | 650 | 48.0 | 64.5 |

| 530 | 59.6 | |||

| 350 | 56.4 | |||

| 320 | 49.9 | |||

| 310 | 41.5 | |||

| 240 | 68.7 | |||

| [6,9,11,40] | Platycladus orientalis | 1300 | 45.4 | 31.6 |

| 1200 | 48.0 | |||

| 900 | 47.1 | |||

| 730 | 44.0 | |||

| 700 | 42.4 | |||

| 530 | 41.7 | |||

| 350 | 46.9 | |||

| [41,42] | Tectona grandis | 1800 | 81.5 | 55.5 |

| Pterocarpus indicus | 500 | 79.3 | 68.2 | |

| [43] | Picea abies. | 300 | 63.0# | 50.0# |

| [40] | Picea asperata | 600 | 29.9 | 38.6 |

| Cupressus funebris | 200 | 46.2 | 54.3 | |

| Larix gmelinii | 920 | 46.8 | 57.6 | |

| [44] | Larix gmelinii | 900 | 46.8 | 57.6 |

| Pterocarya stenopter | 600 | 53.9 | 42.7 | |

| [16,17,18] | Zelkova schneideriana | 255 | 42.8 | 47.6 |

| Pinus densiflora | 115 | 35.3 | 27.9 | |

| 270 | 34.7 | |||

| 290 | 41.9 | |||

| [45] | Larix gmelinii | 145 | 44.18 | 51.28 * |

| Pinus sp. | 145 | 32.73 | 32.75 * | |

| 50 | 34.50 | |||

| Picea asperata | 145 | 44.18 | 41.57 * | |

| Cunninghamia lanceolata | 145 | 29.20 | 31.37 * | |

| Pinus sp. | 50 | 45.49 | 41.60 * | |

| [46] | Cunninghamia lanceolata | 150 | 32.30 | 33.70 |

| [4] | Pterocarya stenopter | ** | 26.90 | 40.20 |

| [26] | Pinus sp. | 950 | 15%↑ | |

| 650 | 11% ↓ | |||

| 500 | 18% ↑ # | |||

| 200 | 8% ↑ # | |||

| Pterocarya stenopter | 950 | 10% ↓ # | ||

| 780 | 15% ↓ # | |||

| 780 | 10% ↓ # | |||

| 600 | —# | |||

| Ulmus rubra | 800 | 5% ↑ # | ||

References

- Li, T.; Qin, H. Structural analysis and repair of Yingxian wooden tower. Eng. Mech. 2005, 22 (Suppl. S1), 199–212. [Google Scholar]

- Becker, P.; Rautenstrauch, K. Time-dependent material behavior applied to timber columns under combined loading. Part I: Creep deformation. Holz Roh-Werkst. 2001, 59, 380–386. [Google Scholar] [CrossRef]

- Navi, P.; Pittet, V.; Plummer, C.J.G. Transient moisture effects on wood creep. Wood Sci. Technol. 2002, 36, 447–462. [Google Scholar] [CrossRef]

- Yang, N.; Li, P.; Law, S.S.; Yang, Q. Experimental research on mechanical properties of timber in ancient Tibetan building. J. Mater. Civ. Eng. 2012, 24, 635–643. [Google Scholar] [CrossRef]

- Li, J.; Wu, Y.; Ma, Y. Functional Wood; Science Press: Beijing, China, 2011. [Google Scholar]

- Kohara, J. Studies on the durability of wood I: Mechanical properties of aged timbers. Sci. Rep. Saikyo Univ. Agric. 1952, 2, 116–131. [Google Scholar]

- Kohara, J. Studies on the durability of wood III: Mechanical properties of aged timbers. Sci. Rep. Saikyo Univ. Agric. 1953, 4, 98–109. [Google Scholar]

- Kohara, J. Studies on the permanence of wood V, shrinkage and swelling of old timbers about 300–1300 years ago. Bull. Kyoto Prefect. Univ. 1953, 5, 81–88. (In Japanese) [Google Scholar]

- Kohara, J. Studies on the permanence of wood VI: The changes of mechanical properties of aged timbers. Sci. Rep. Saikyo Univ. Agric. 1954, 6, 164–174. [Google Scholar]

- Kohara, J. Studies on the permanence of wood IX: The influence of age on the elasticity of wood. J. Jpn. For. Soc. 1954, 36, 364–368. [Google Scholar]

- Kohara, J.; Okamoto, H. Studies of Japanese aged timbers. Sci. Rep. Saikyo Univ. Agric. 1961, 10, 894–899. [Google Scholar]

- Kuipers, J. Effect of age and/or load on timber strength. In Proceedings of the 19th CIB-W18/19-6-1, Florence, Italy, 20 September 1986. [Google Scholar]

- Rug, W.; Seemann, A. Strength of aged timber. Build. Res. Inf. 1991, 19, 31–37. [Google Scholar] [CrossRef]

- Deppe, H.J.; Ruhl, H. Evaluation of historical construction timber. Density and compression. Holz Roh-Werkst. 1993, 51, 379–383. [Google Scholar] [CrossRef]

- Fridley, K.J.; Mitchell, J.B.; Hunt, M.O.; Senft, J.F. Effect of 85 years of service on mechanical properties of timber roof members. Part 1. Experimental observations. For. Prod. J. 1996, 46, 72–78. [Google Scholar]

- Hirashima, Y.; Sugihara, M.; Sasaki, Y.; Ando, K.; Yamasaki, M. Strength properties of aged wood I: Tensile strength properties of aged Keyaki and Akamatsu woods. J. Jpn. Wood Res. Soc. 2004, 50, 301–309. [Google Scholar]

- Hirashima, Y.; Sugihara, M.; Sasaki, Y.; Ando, K.; Yamasaki, M. Strength properties of aged wood II: Compressive strength properties, shearing strength and hardness of aged keyaki and akamatsu woods. J. Jpn. Wood Res. Soc. 2004, 50, 368–375. [Google Scholar]

- Hirashima, Y.; Sugihara, M.; Sasaki, Y.; Ando, K.; Yamasaki, M. Strength properties of aged wood III: Static and impact bending strength properties of aged keyaki and akamatsu woods. J. Jpn. Wood Res. Soc. 2005, 51, 146–152. [Google Scholar] [CrossRef]

- Yokoyama, M.; Gril, J.; Matsuo, M.; Yano, H.; Sugiyama, J.; Clair, B.; Kubodera, S.; Mistutani, T.; Sakamoto, M.; Ozaki, H. Mechanical characteristics of aged Hinoki wood from Japanese historical buildings. Comptes Rendus Phys. 2009, 10, 601–611. [Google Scholar] [CrossRef] [Green Version]

- Noguchi, T.; Obataya, E.; Ando, K. Effects of aging on the vibrational properties of wood. J. Cult. Herit. 2012, 13, S21–S25. [Google Scholar] [CrossRef]

- Gerhards, C.C. Time-related effects of loading on wood strength: A linear cumulative damage theory. Wood Sci. 1979, 11, 139–144. [Google Scholar]

- Gerhards, C.C.; Link, C.L. A cumulative damage model to predict load duration characteristics of lumber. Wood Fiber Sci. 1987, 19, 147–164. [Google Scholar]

- Foschi, R.O.; Folz, B.R.; Yao, F.Z. Reliability-Based Design of Wood Structures; First Folio Printing Corp. Ltd.: Vancouver, BC, Canada, 1989. [Google Scholar]

- Zhuang, X. Reliability Study of North American Chinese Timber Structures Design Code. Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2004; pp. 1–102. [Google Scholar]

- Ranta Maunus, A.; Fonselius, M.; Kurkela, J.; Toratti, T. Reliability analysis of timber structures. In VTT Research Notes 2109; VTT Technical Research Centre of Finland: Espoo, Finland, 2001; pp. 1–102. [Google Scholar]

- Wang, S.; Chen, J.; Tsai, M.; Lin, C.; Yang, T. Grading of softwood lumber using non-destructive techniques. J. Mater. Processing Technol. 2008, 208, 149–158. [Google Scholar] [CrossRef]

- ASTM D 6570-00; Standard Practice for Assigning Allowable Properties for Mechanically-Graded Lumber. American Society for Testing and Materials: Philadelphia, PA, USA, 2003.

- BS EN 14081-2; 2005 Timber Structures-Strength Graded Structural Timber with Rectangular Cross Section-Part 2: Machine grading; Additional Requirements for Initial Type Testing. European Committee for Standardization: Brussels, Belgium, 2005.

- Fridley, K.J.; Tang, R.C.; Soltis, L.A. Hygrothermal effects on load-duration behavior of structural lumber. J. Struct. Eng. 1992, 118, 1023–1038. [Google Scholar] [CrossRef]

- Hanhijarvi, A. Advances in the knowledge of the influence of moisture changes on the long-term mechanical performance of timber structures. Mater. Struct. 2000, 33, 43–49. [Google Scholar] [CrossRef]

- GB 1927-1943-91; Testing Methods for Physical and Mechanical Properties of Wood. Research Institute of Wood Industry, Chinese Academy of Forestry: Beijing, China, 1992.

- GB/T 2009; China National Standardization Management Committee. General Requirements for Physical and Mechanical Tests of Wood. China Standard Press: Beijing, China, 2009.

- Xu, B.; Liu, K.; Bouchar, A. Mechanical properties and set recovery of compressed poplar with glycerin pretreatment. Wood Res. 2020, 65, 293–302. [Google Scholar] [CrossRef]

- Zhu, X.; Yi, S.; Gao, Y.; Zhang, J.R.; Ni Ch Luo, X. Influence of welded depth and CuCl2 pretreated dowels on wood dowel welding. J. Wood Sci. 2017, 63, 445–454. [Google Scholar] [CrossRef]

- Handbook of Timber Structure Design; China Architecture and Building Press: Beijing, China, 2005.

- Wang, X. Research on Evaluation Method of Reliability-Based Residual Life of Historic Timber Structure. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2008. [Google Scholar]

- Sørensen, J.; Staffan, S.; Stang, B. Reliability-based calibration of load duration factors for timber structures. Struct. Saf. 2005, 27, 153–169. [Google Scholar] [CrossRef] [Green Version]

- Li, T. The Main Structural Damages and Damage Mechanism Analysis on Yingxian Wooden Tower. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2004. [Google Scholar]

- Qin, S.; Yang, N. Strength degradation and service life prediction of timber in ancient Tibetan building. Eur. J. Wood Wood Prod. 2018, 76, 731–747. [Google Scholar] [CrossRef]

- Ni, S.; Li, Y. Survey of tree species for wood materials used in historical buildings and analysis of their mechanical properties. Sichuan Build. Sci. 1994, 1, 11–14. [Google Scholar]

- Narayanamurti, D.; Ghosh, S.S.; Prasad, B.N.; George, J. Note on examination of an aged timber specimen. Eur. J. Wood Wood Prod. 1958, 16, 245–247. [Google Scholar] [CrossRef]

- Narayanamurti, D.; Prasad, B.N.; Verma, G.M. Examination of aged timbers–Part III: Aged Pterocarpus specimen from tirupathi. Eur. J. Wood Wood Prod. 1961, 19, 47–50. [Google Scholar] [CrossRef]

- Schulz, H.; Aufseß, H.V.; Verron, T. Properties of a spruce beam after 300 years in roof construction. Eur. J. Wood Wood Prod. 1984, 42, 109. [Google Scholar]

- Chen, G. Researches on timber material changing which affect buildings form in ancient architecture construction. Tradit. Chin. Archit. Gard. 2003, 3, 49–52. [Google Scholar]

- Huang, R.; Jin, H.; Shi, Z.; Xia, R.; Li, H.; Liu, X. Study on physico-mechanical properties of ancient architecture of the palace museum. In Proceedings of the First National Symposium on Biomass Materials Science and Technology, Beijing, China, 19 August 2007; pp. 502–507. [Google Scholar]

- Xu, M.; Wiu, H. New method of aging for historic timber structure buildings. Earthq. Resist. Eng. Retrofit. 2009, 31, 96–98. [Google Scholar]

- Cheng, J.; Yang, J.; Liu, P. China Wood Record; China Forestry Press: Beijing, China, 1992. [Google Scholar]

| Serial Number | Size (mm) | |||

|---|---|---|---|---|

| Diameter | Length | |||

| One End | Other End | |||

| Aged | CL-1 | 120/128 | 140/145 | 2910 |

| CL-2 | 150/150 | 150/155 | 3470 | |

| CL-3 | 95/130 | 125/150 | 2680 | |

| New | CL-4 | 138/138 | 150/160 | 4000 |

| CL-5 | 127/128 | 165/190 | 4000 | |

| Samples | Test Index | Specimens | Number of Samples/Test | Dimensions (mm) | |||

|---|---|---|---|---|---|---|---|

| Aged CL (t = 100) | New CL (t = 0) | Length | Width | Height | |||

| Standard specimens | Compressive strength (fc,0) | S1 (λ = 0.00) | 42 | 24 | 20 | 20 | 30 |

| S2 (λ = 1.00) | 42 | 24 | |||||

| Air-dried density (ρ) | S1 (λ = 0.00) | 23 | 12 | 20 | 20 | 20 | |

| S2 (λ = 1.00) | 23 | 12 | |||||

| Logs | Compressive strength (fc,0,log) | - | 6 | 4 | 12R | - | - |

| Tests | Aged CL | New CL | Differences | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HW | SW | (%) | HW | SW | (%) | |||||||

| SD | SD | SD | SD | |||||||||

| fc,0 (MPa) | 42.96 | 8.00 | 42.16 | 7.74 | 1.90 | 35.96 | 3.67 | 42.35 | 4.03 | −15.09 | 19.47 | −0.45 |

| ρ (g/cm3) | 0.407 | 0.065 | 0.401 | 0.057 | 1.66 | 0.349 | 0.022 | 0.391 | 0.025 | −10.70 | 16.60 | 2.43 |

| Aged CL | New CL | Difference | ||

|---|---|---|---|---|

| SD | SD | |||

| 30.30 | 9.40 | 35.21 | 1.58 | −13.94 |

| Serial Number | (MPa) | HW (λ = 0) | SW (λ = 1) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| γσ | (MPa) | (MPa) | (%) | γσ | (MPa) | (MPa) | (%) | ||

| Aged CL-1 (t = 100) | 41.98 | 0.739 | 50.56 | 37.37 | 12.35 | 0.687 | 49.96 | 34.32 | 22.32 |

| Aged CL-2 (t = 100) | 29.56 | 0.739 | 39.75 | 29.37 | 0.64 | 0.687 | 40.07 | 27.53 | 7.38 |

| Aged CL-3 (t = 100) | 19.37 | 0.739 | 34.79 | 25.71 | 24.65 | 0.687 | 33.21 | 22.82 | 15.11 |

| New CL-4 (t = 0) | 36.76 | 0.939 | 33.92 | 31.85 | 15.40 | 0.887 | 45.30 | 40.18 | 8.51 |

| New CL-5 (t = 0) | 33.66 | 0.939 | 40.04 | 37.60 | 10.47 | 0.887 | 39.39 | 34.94 | 3.67 |

| Sample Type | K | ||||||

|---|---|---|---|---|---|---|---|

| Aged CL | 1.00 | 0.96 | 1.00 | 0.90 | 0.75 | 1.00 | 0.65 |

| New CL | 1.00 | 0.96 | 1.00 | 0.90 | 0.75 | 0.72 | 0.47 |

| Serial Number | (MPa) | K | (MPa) | (MPa) | (%) |

|---|---|---|---|---|---|

| Aged CL-1 (t = 100) | 41.98 | 0.65 | 50.27 | 32.68 | 22.15 |

| Aged CL-2 (t = 100) | 29.56 | 0.65 | 39.91 | 25.94 | 12.25 |

| Aged CL-3 (t = 100) | 19.37 | 0.65 | 34.00 | 22.10 | 14.09 |

| New CL-4 (t = 0) | 36.76 | 0.47 | 39.61 | 18.62 | 49.35 |

| New CL-5 (t = 0) | 33.66 | 0.47 | 39.61 | 18.62 | 44.68 |

| Stress level (MPa) | 0.25 | 0.30 | 0.35 |

| Residual strength ratio | 0.077 | 0.556 | 0.781 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Gao, C.; Liu, K.; Zhu, Y.; Wang, J. Compressive Strength of Aged Timber Members in Traditional Building: Considering Differences in Heartwood and Sapwood. Appl. Sci. 2022, 12, 7719. https://doi.org/10.3390/app12157719

Yang Q, Gao C, Liu K, Zhu Y, Wang J. Compressive Strength of Aged Timber Members in Traditional Building: Considering Differences in Heartwood and Sapwood. Applied Sciences. 2022; 12(15):7719. https://doi.org/10.3390/app12157719

Chicago/Turabian StyleYang, Qingshan, Chao Gao, Ke Liu, Yingming Zhu, and Juan Wang. 2022. "Compressive Strength of Aged Timber Members in Traditional Building: Considering Differences in Heartwood and Sapwood" Applied Sciences 12, no. 15: 7719. https://doi.org/10.3390/app12157719

APA StyleYang, Q., Gao, C., Liu, K., Zhu, Y., & Wang, J. (2022). Compressive Strength of Aged Timber Members in Traditional Building: Considering Differences in Heartwood and Sapwood. Applied Sciences, 12(15), 7719. https://doi.org/10.3390/app12157719