A Review of Recent Research into the Causes and Control of Noise during High-Speed Train Movement

Abstract

:1. Introduction

- (1)

- The causes of high-speed train noise and the distribution of the sound sources;

- (2)

- The current main research methods for high-speed train noise;

- (3)

- Traditional methods of high-speed train noise control;

- (4)

- Potential uses of acoustic metamaterials in the area of high-speed train noise.

2. High-Speed Train Noise Composition

2.1. High-Speed Train Aerodynamic Noise

2.2. High-Speed Train Mechanical Vibration Noise

2.2.1. Braking Noise

2.2.2. Wheel-Rail Noise

3. High-Speed Train Noise Research Methods

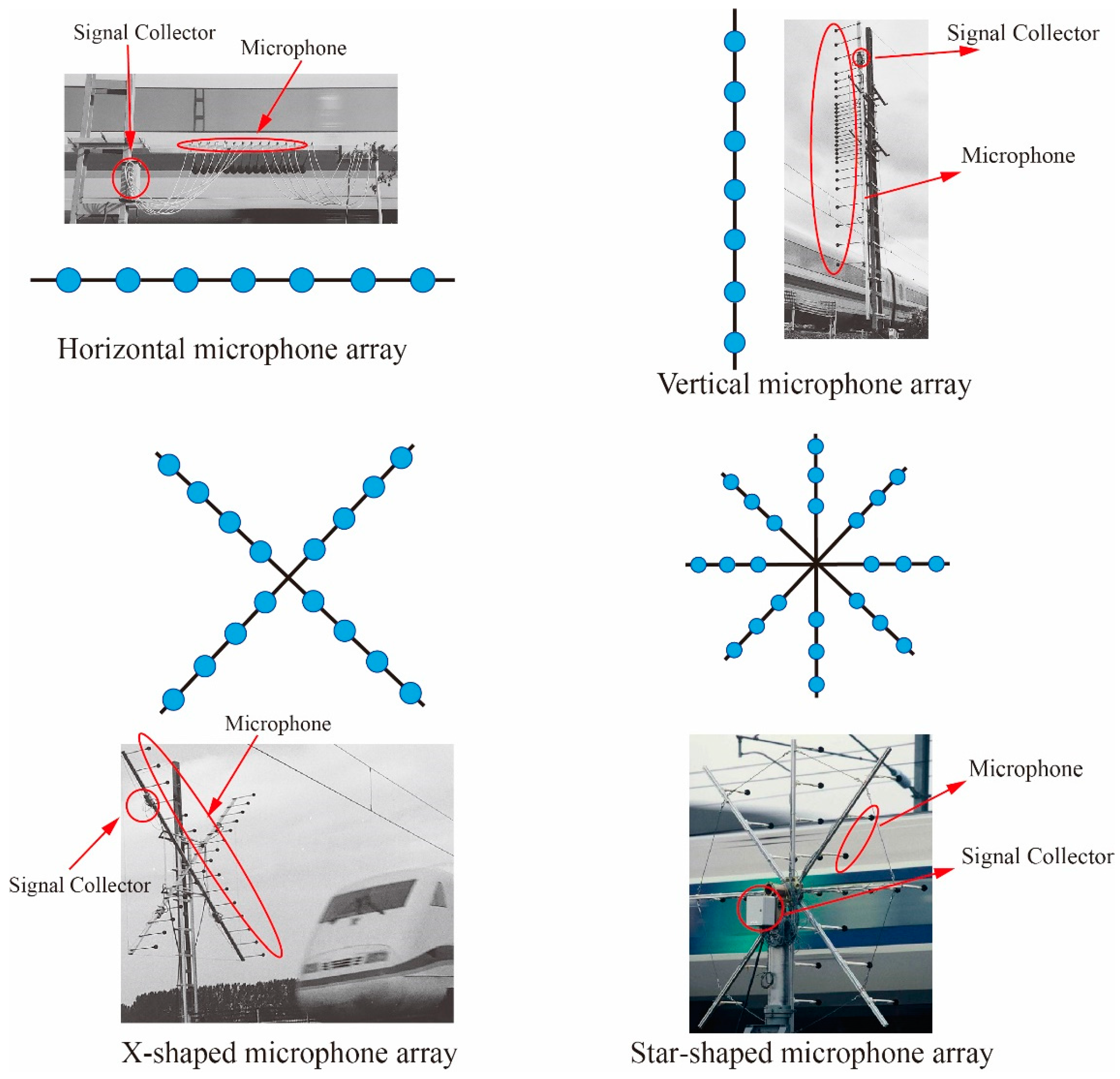

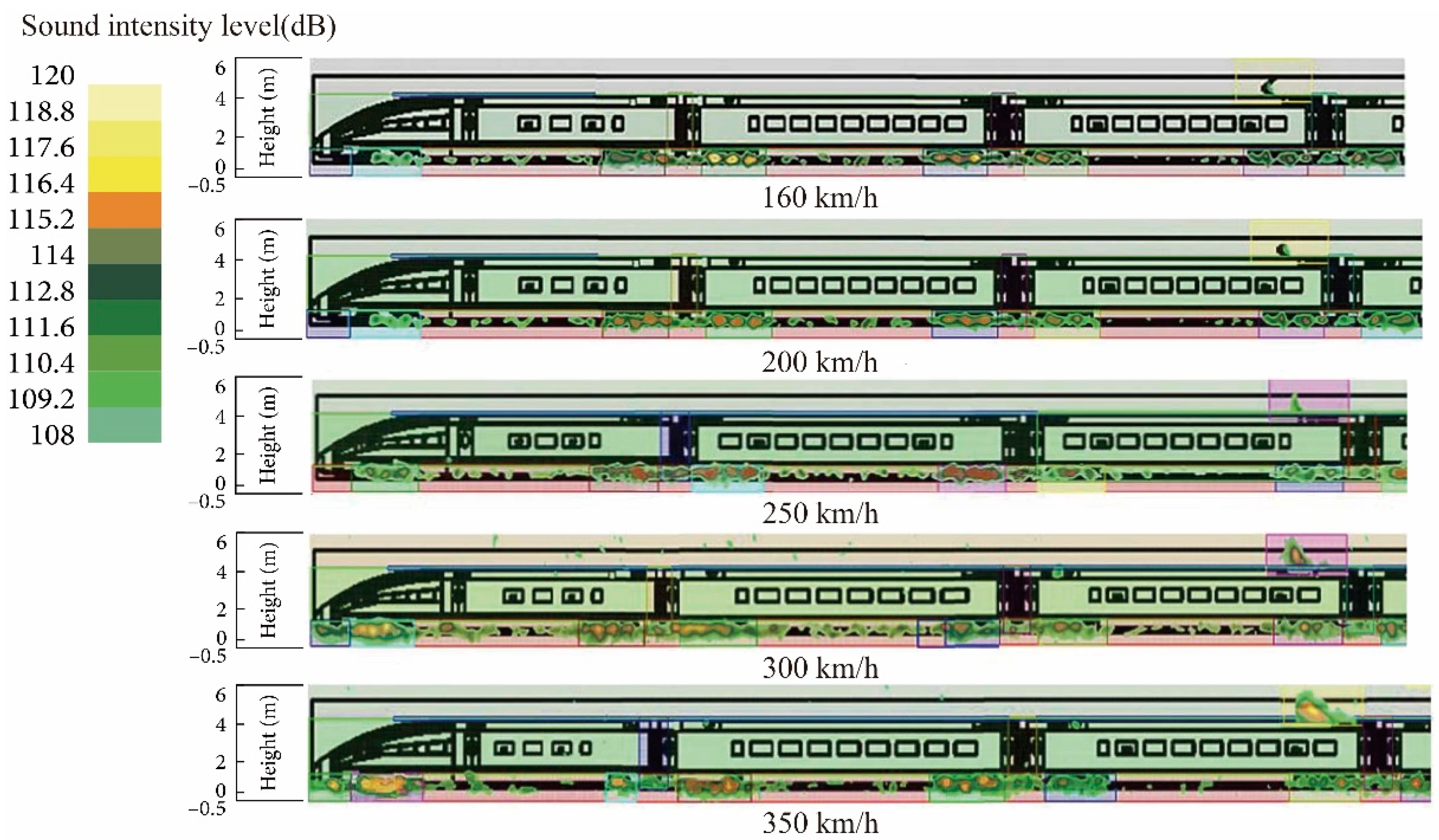

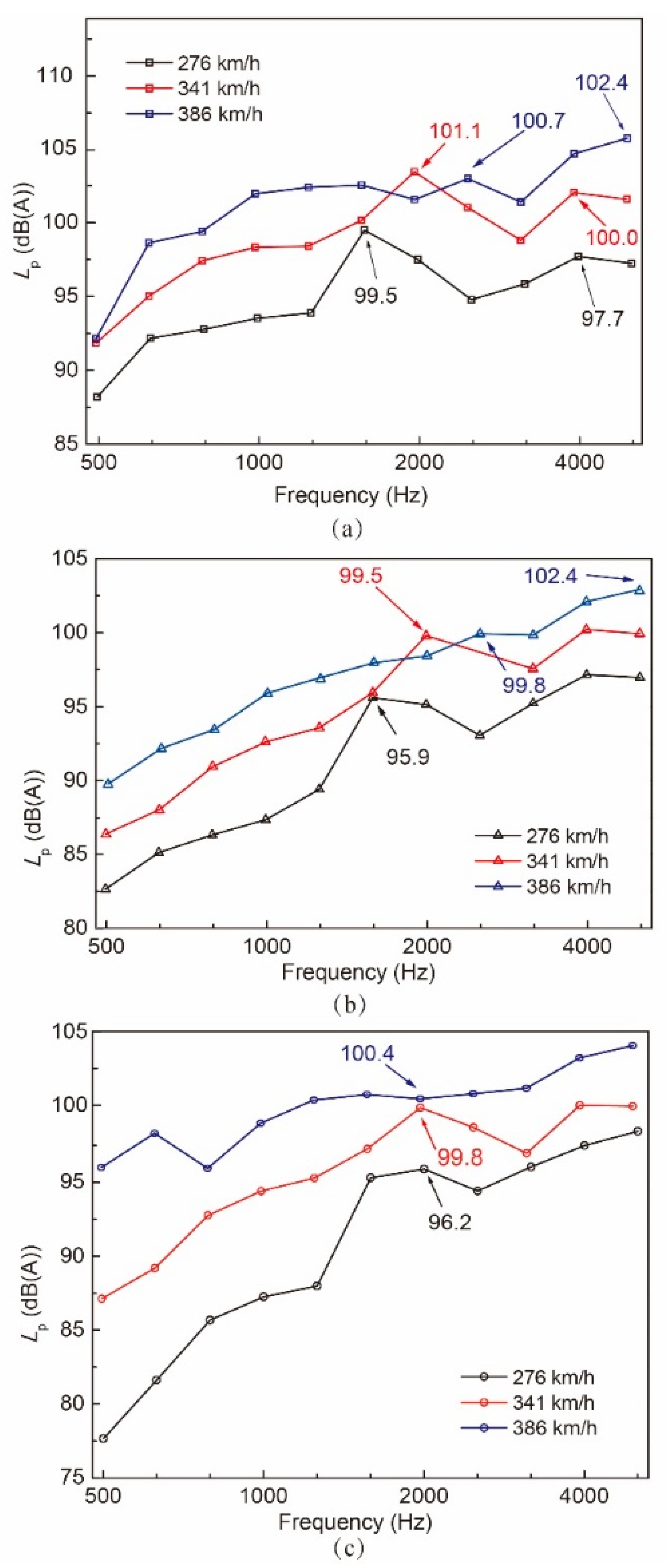

3.1. Real High-Speed Train Noise Tests

3.2. Wind-Tunnel Test

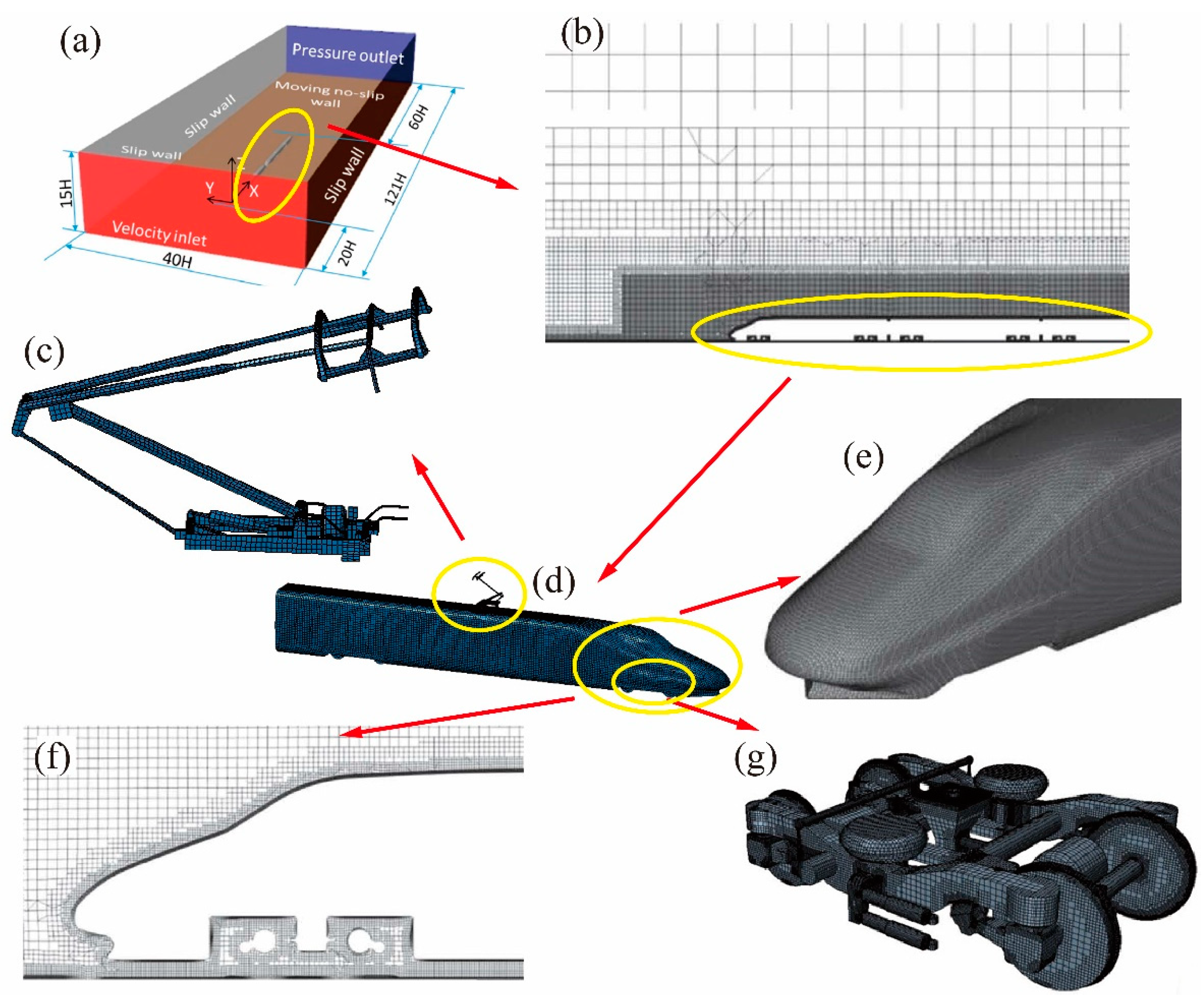

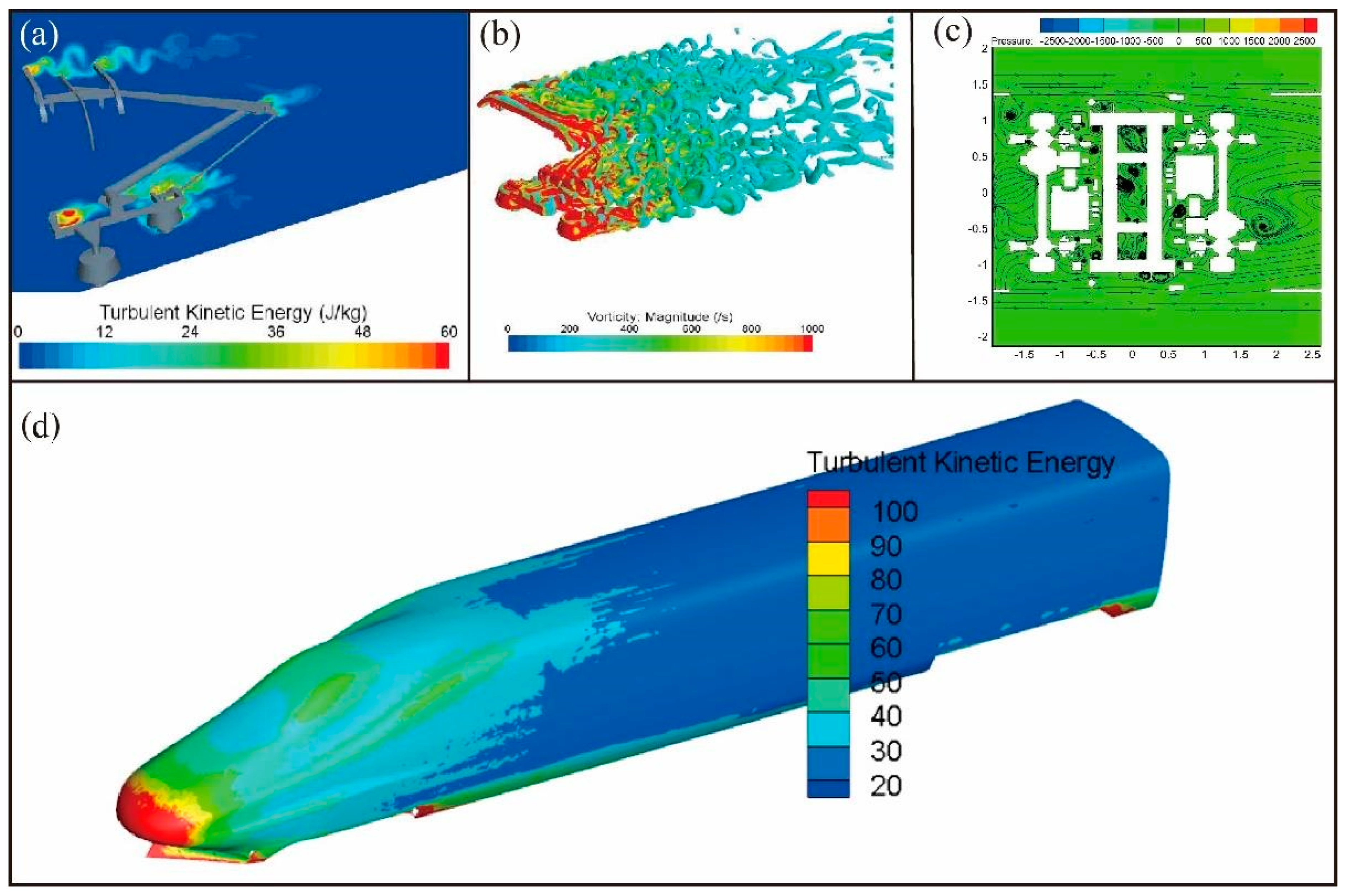

3.3. Numerical Simulation and Theoretical Research

4. High-Speed Train Noise Control Methods

4.1. Traditional Noise Control Methods for High-Speed Trains

4.1.1. Train Vibration Reduction

4.1.2. Train Body Sound Insulation

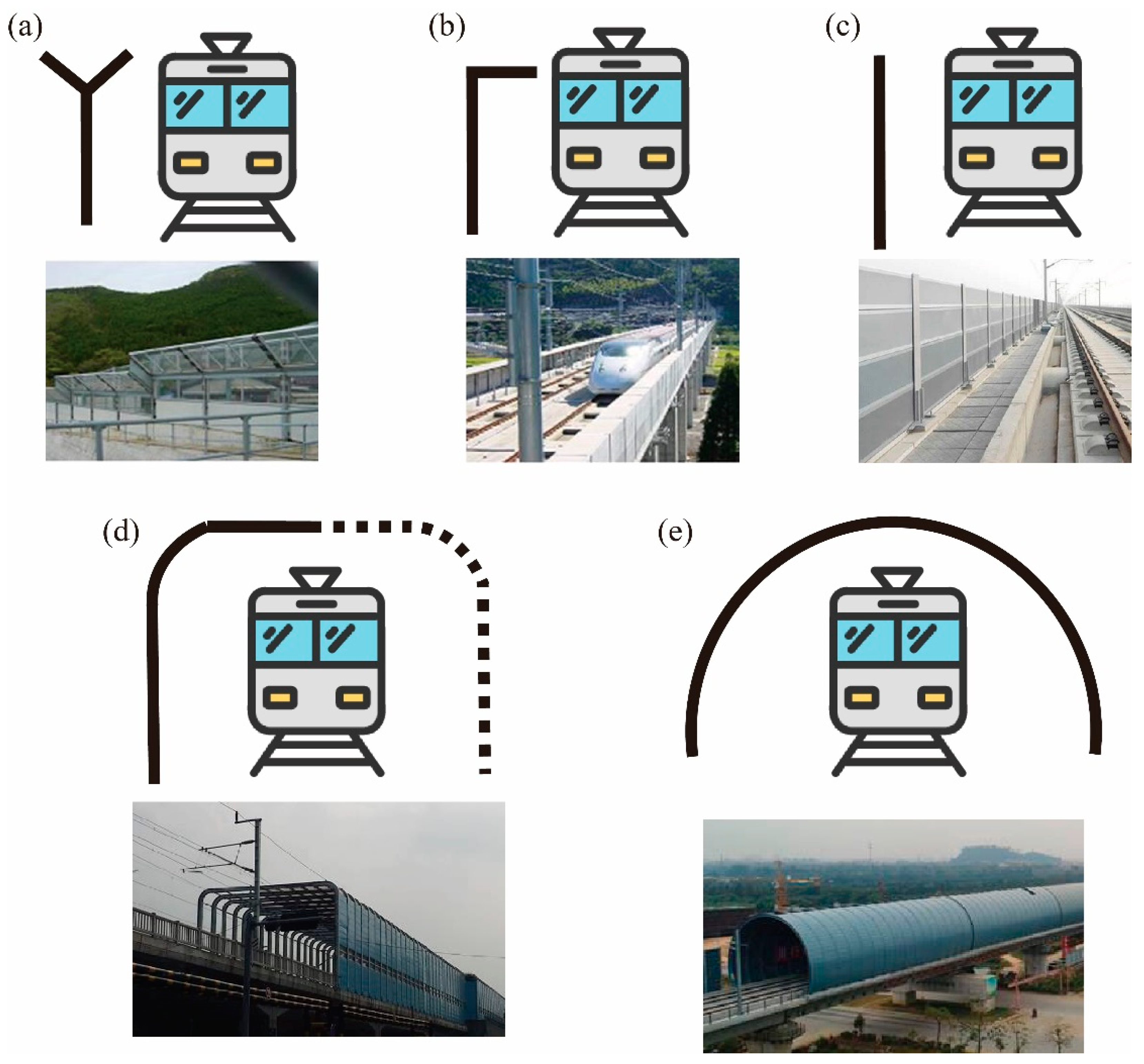

4.1.3. Railroad Sound Barriers

4.2. Acoustic Metamaterials Applied to High-Speed Train Noise Control

4.2.1. Definition and Development History of Acoustic Metamaterials

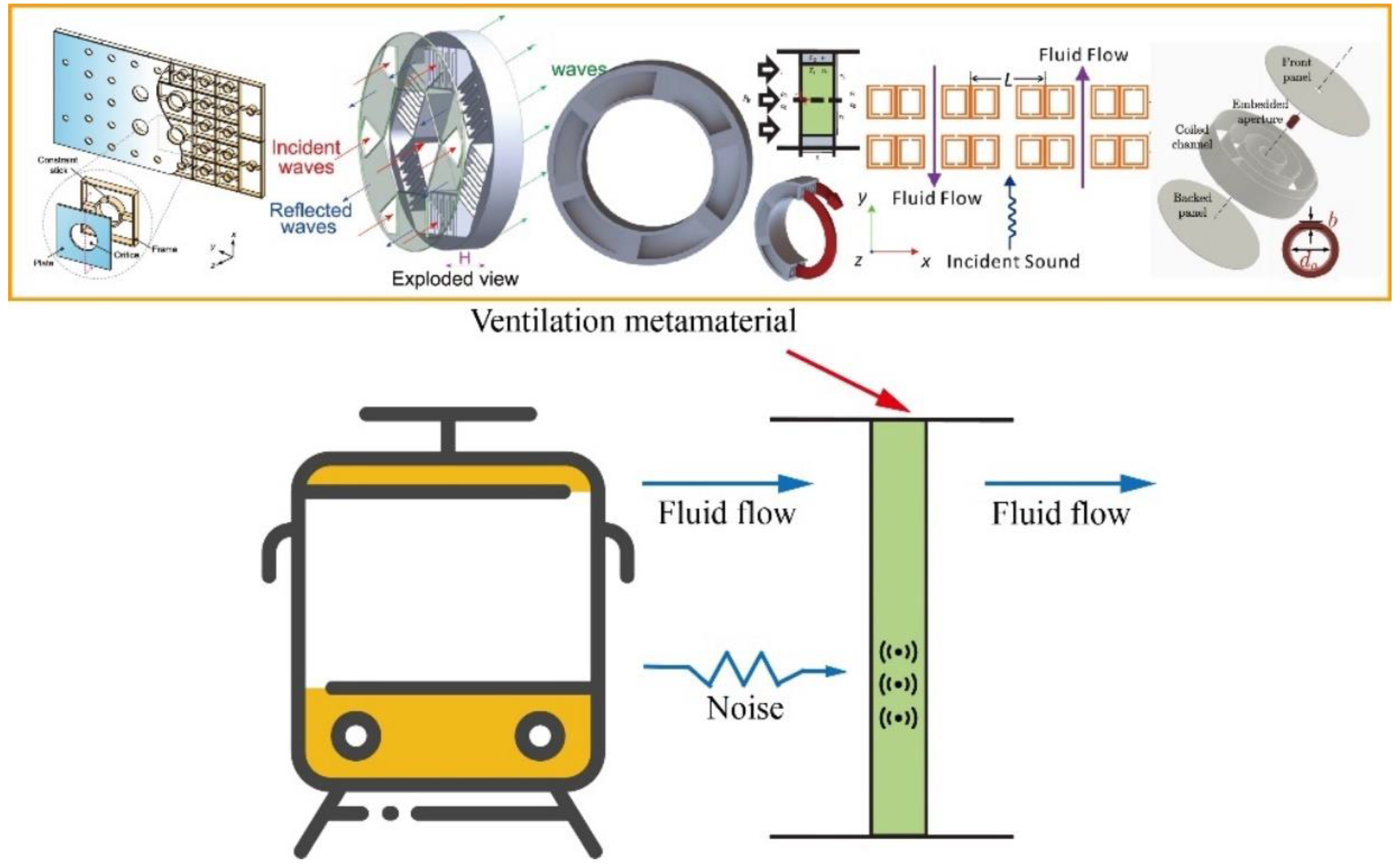

4.2.2. Metamaterials Applied to Railroad Sound Barriers

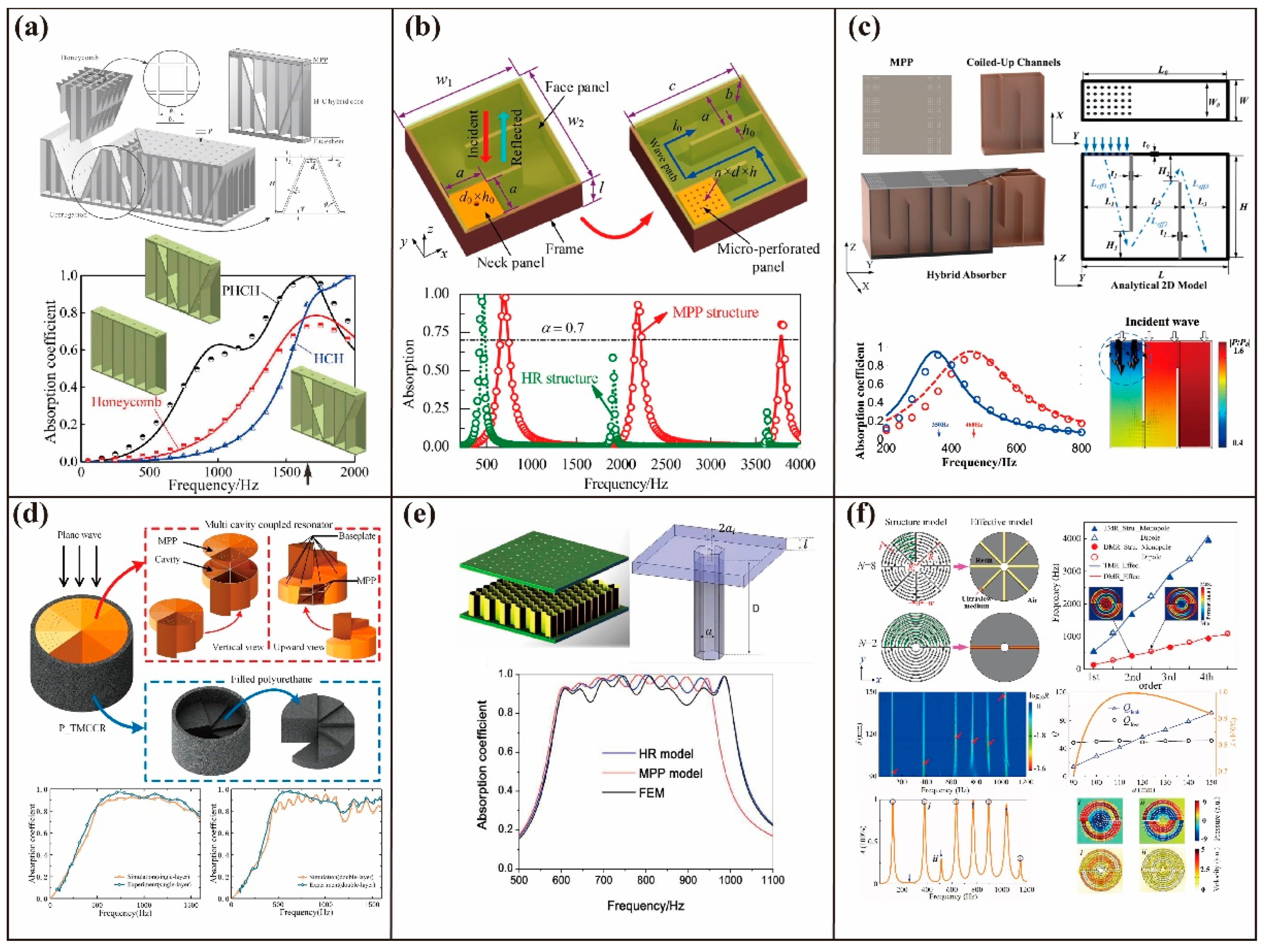

4.2.3. Application of Metamaterials in Train Car Bodies

5. Summary and Prospect

- (1)

- The main component of high-speed train noise has gradually changed from mechanical vibration noise to aerodynamic noise, and with the further increase in running speeds in the future, the aerodynamic noise will be further intensified. The structure of the high-speed train pantograph, high-speed train skirt, and high-speed train connection should be further optimized, and the noise problem should be emphasized in the optimization process.

- (2)

- The acoustic insulation level of traditional railroad sound barriers is limited and vulnerable to air pulsation stress. The introduction of acoustic metamaterials can largely improve their acoustic insulation performance, but at present, the structure of acoustic metamaterials is complicated, and their processing cost is high, so research on their manufacturing process and batch production is warranted.

- (3)

- It is difficult for the current body structure of high-speed trains to cope with low-frequency noise, and the narrow body structure cannot be arranged with thicker materials to realize sound absorption and insulation. Thus, future acoustic metamaterials may be the best means of achieving sound absorption and insulation in the train body.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siddall, W.R. No Nook Secure: Transportation and Environmental Quality—Comparative Studies in Society and History; Cambridge University Press: Cambridge, UK, 1974; Volume 16, pp. 2–23. [Google Scholar] [CrossRef]

- Floud, S.; Blangiardo, M.; Clark, C.; de Hoogh, K.; Babisch, W.; Houthuijs, D.; Swart, W.; Pershagen, G.; Katsouyanni, K.; Velonakis, M.; et al. Exposure to Aircraft and Road Traffic Noise and Associations with Heart Disease and Stroke in Six European Countries: A Cross-Sectional Study. Environ. Health 2013, 12, 89. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Banerjee, D.; Das, P.P.; Foujdar, A. Association between Road Traffic Noise and Prevalence of Coronary Heart Disease. Environ. Monit. Assess. 2014, 186, 2885–2893. [Google Scholar] [CrossRef] [PubMed]

- Wothge, J.; Belke, C.; Möhler, U.; Guski, R.; Schreckenberg, D. The Combined Effects of Aircraft and Road Traffic Noise and Aircraft and Railway Noise on Noise Annoyance-An Analysis in the Context of the Joint Research Initiative NORAH. Int. J. Environ. Res. Public Health 2017, 14, 871. [Google Scholar] [CrossRef] [Green Version]

- Beutel, M.; Brähler, E.; Ernst, M.; Klein, E.; Reiner, I.; Wiltink, J.; Michal, M.; Wild, P.; Schulz, A.; Münzel, T.; et al. Noise Annoyance Predicts Symptoms of Depression, Anxiety and Sleep Disturbance 5 Years Later. Findings from the Gutenberg Health Study. Eur. J. Public Health 2020, 30, 487–492. [Google Scholar] [CrossRef]

- Gu, X.A. Railway Environmental Noise Control in China. J. Sound Vib. 2006, 293, 1078–1085. [Google Scholar] [CrossRef]

- Segawa, T.; Fujimoto, M.; Saito, T.; Sakagoshi, O.; Tachibana, H. Assessment of Environmental Noise Immission in Japan. In Proceedings of the 2005 Congress and Exposition on Noise Control Engineering, Rio de Janeiro, Brazil, 7–10 August 2005; p. 6. [Google Scholar]

- Li, T.; Qin, D.; Zhou, N.; Zhang, W. Step-by-Step Numerical Prediction of Aerodynamic Noise Generated by High Speed Trains. Chin. J. Mech. Eng. 2022, 35, 28. [Google Scholar] [CrossRef]

- Thompson, D.J.; Latorre Iglesias, E.; Liu, X.; Zhu, J.; Hu, Z. Recent Developments in the Prediction and Control of Aerodynamic Noise from High-Speed Trains. Int. J. Rail Transp. 2015, 3, 119–150. [Google Scholar] [CrossRef]

- Tan, X.; Yang, Z.; Tan, X.; Wu, X.; Zhang, J. Vortex Structures and Aeroacoustic Performance of the Flow Field of the Pantograph. J. Sound Vib. 2018, 432, 17–32. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, Y.; Huang, H.; Wang, J.; Xu, Q. Research on the Effect of Non-Smooth Convex Hull Structure of High-Speed EMU on Air Resistance and Friction Noise. In Advances in Mechanical Design, Proceedings of the 2021 International Conference on Mechanical Design (ICMDE 2021), Sanya, China, 26–28 February 2021; Tan, J., Ed.; Springer: Singapore, 2022; pp. 2109–2119. [Google Scholar]

- Tang, R.; Zheng, W.; Li, S.F.; Liu, W.Y. Topology Optimization of Damping Material on Acoustic-Structural Systems for Minimizing Response Sensitivity. Int. J. Perform. Eng. 2021, 17, 26. [Google Scholar] [CrossRef]

- Zhang, Y. Reduction of Aerodynamic Noise of High-Speed Train Pantograph. J. Mech. Eng. 2017, 53, 94. [Google Scholar] [CrossRef]

- Liang, X.; Liu, H.; Dong, T.; Yang, Z.; Tan, X. Aerodynamic Noise Characteristics of High-Speed Train Foremost Bogie Section. J. Cent. South Univ. 2020, 27, 1802–1813. [Google Scholar] [CrossRef]

- Dai, W.; Zheng, X.; Hao, Z.; Qiu, Y.; Li, H.; Luo, L. Aerodynamic Noise Radiating from the Inter-Coach Windshield Region of a High-Speed Train. J. Low Freq. Noise Vib. Act. Control. 2018, 37, 590–610. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Qin, D.; Zhang, W.; Zhang, J. Study on the Aerodynamic Noise Characteristics of High-Speed Pantographs with Different Strip Spacings. J. Wind. Eng. Ind. Aerodyn. 2020, 202, 104191. [Google Scholar] [CrossRef]

- Cao, Y.; Bai, Y.; Wang, Q. Complexity Simulation on Application of Asymmetric Bionic Cross-Section Rod in Pantographs of High-Speed Trains. Complexity 2018, 2018, e3087312. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.Y.; Xiao, Y.G.; Shi, Y. Shape Optimization of High-Speed Train Pantograph Insulators for Low Aerodynamic Noise. Appl. Mech. Mater. 2013, 249, 646–651. [Google Scholar] [CrossRef]

- Wang, Y. Numerical Computation and Optimization Design of Pantograph Aerodynamic Noise. J. Vibroeng. 2016, 18, 1358–1369. [Google Scholar] [CrossRef]

- Ikeda, M.; Mitsumoji, T.; Sueki, T.; Takaishi, T. Aerodynamic Noise Reduction of a Pantograph by Shape-Smoothing of Panhead and Its Support and by the Surface Covering with Porous Material. In Noise and Vibration Mitigation for Rail Transportation Systems, Proceedings of the 10th International Workshop on Railway Noise, Nagahama, Japan, 18–22 October 2010; Maeda, T., Gautier, P.-E., Hanson, C.E., Hemsworth, B., Nelson, J.T., Schulte-Werning, B., Thompson, D., de Vos, P., Eds.; Springer: Tokyo, Japan, 2012; pp. 419–426. [Google Scholar]

- Liu, F.; Guo, H.; Hu, T.; Liu, P. Experimental Investigation on the Aeroacoustics of Circular Cylinders Covered with Metal Foam. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019. [Google Scholar]

- Kim, H.; Hu, Z.; Thompson, D. Numerical Investigation of the Effect of Cavity Flow on High Speed Train Pantograph Aerodynamic. Noise J. Wind Eng. Ind. Aerodyn. 2020, 201, 104159. [Google Scholar] [CrossRef]

- Yu, H.-H.; Li, J.-C.; Zhang, H.-Q. On Aerodynamic Noises Radiated by the Pantograph System of High-Speed Trains. Acta Mech. Sin. 2013, 29, 399–410. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Hu, Z.; Thompson, D. Effect of Different Typical High Speed Train Pantograph Recess Configurations on Aerodynamic Noise. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2021, 235, 573–585. [Google Scholar] [CrossRef]

- Eriksson, M.; Bergman, F.; Jacobson, S. On the Nature of Tribological Contact in Automotive Brakes. Wear 2002, 252, 26–36. [Google Scholar] [CrossRef]

- Graf, M.; Ostermeyer, G.P. Instabilities in the Sliding of Continua with Surface Inertias: An Initiation Mechanism for Brake Noise. J. Sound Vib. 2011, 330, 5269–5279. [Google Scholar] [CrossRef]

- Renault, A.; Massa, F.; Lallemand, B.; Tison, T. Experimental Investigations for Uncertainty Quantification in Brake Squeal Analysis. J. Sound Vib. 2016, 367, 37–55. [Google Scholar] [CrossRef]

- Majcherczak, D.; Dufre’noy, P.; Nai¨t-Abdelaziz, M. Third Body Influence on Thermal Friction Contact Problems: Application to Braking. J. Tribol. 2005, 127, 89–95. [Google Scholar] [CrossRef]

- Massi, F.; Berthier, Y.; Baillet, L. Contact Surface Topography and System Dynamics of Brake Squeal. Wear 2008, 265, 1784–1792. [Google Scholar] [CrossRef] [Green Version]

- Chiacchiari, L.; Thompson, D.J.; Squicciarini, G.; Ntotsios, E.; Loprencipe, G. Rail Roughness and Rolling Noise in Tramways. J. Phys. Conf. Ser. 2016, 744, 012147. [Google Scholar] [CrossRef] [Green Version]

- Thompson, D.J.; Hemsworth, B.; Vincent, N. Experimental Validation of the Twins Prediction Program for Rolling Noise, Part 1: Description of the Model and Method. J. Sound Vib. 1996, 193, 123–135. [Google Scholar] [CrossRef]

- Remington, P.J. Wheel/Rail Rolling Noise, I: Theoretical Analysis. J. Acoust. Soc. Am. 1987, 81, 1805–1823. [Google Scholar] [CrossRef]

- Thompson, D.J. Wheel-Rail Noise Generation, Part II: Wheel Vibration. J. Sound Vib. 1993, 161, 401–419. [Google Scholar] [CrossRef]

- Thompson, D.J. Wheel-Rail Noise Generation, Part III: Rail Vibration. J. Sound Vib. 1993, 161, 421–446. [Google Scholar] [CrossRef]

- Thompson, D.J. Wheel-Rail Noise Generation, Part IV: Contact Zone and Results. J. Sound Vib. 1993, 161, 447–466. [Google Scholar] [CrossRef]

- Jones, C.J.C.; Thompson, D.J. Extended Validation of a Theoretical Model for Railway Rolling Noise Using Novel Wheel and Track Designs. J. Sound Vib. 2003, 267, 509–522. [Google Scholar] [CrossRef]

- Vincent, N.; Bouvet, P.; Thompson, D.J.; Gautier, P.E. Theoretical Optimization of Track Components to Reduce Rolling Noise. J. Sound Vib. 1996, 193, 161–171. [Google Scholar] [CrossRef]

- Bouvet, P.; Vincent, N.; Coblentz, A.; Demilly, F. Optimization of Resilient Wheels for Rolling Noise Control. J. Sound Vib. 2000, 231, 765–777. [Google Scholar] [CrossRef]

- Cigada, A.; Manzoni, S.; Vanali, M. Vibro-Acoustic Characterization of Railway Wheels. Appl. Acoust. 2008, 69, 530–545. [Google Scholar] [CrossRef]

- Merideno, I.; Nieto, J.; Gil-Negrete, N.; Giménez Ortiz, J.G.; Landaberea, A.; Iartza, J. Theoretical Prediction of the Damping of a Railway Wheel with Sandwich-Type Dampers. J. Sound Vib. 2014, 333, 4897–4911. [Google Scholar] [CrossRef]

- Lee, S.; Lee, D.H.; Lee, J. Integrated Shape-Morphing and Metamodel-Based Optimization of Railway Wheel Web Considering Thermo-Mechanical Loads. Struct. Multidisc. Optim. 2019, 60, 315–330. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, Q.; Luo, K.; Xin, W.; Luo, X. Noise characteristics of urban rail transit viaduct installing damping rail. J. Traffic Transp. Eng. 2021, 21, 169–178. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, X.; Sheng, X.; Zhang, C.; Wang, R.; Jin, X. SEA and Contribution Analysis for Interior Noise of a High Speed Train. Appl. Acoust. 2016, 112, 158–170. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, X.; Sheng, X.; Fu, R.; Yao, D.; Jin, X. Characteristics of Interior Noise of a Chinese High-Speed Train under a Variety of Conditions. J. Zhejiang Univ. Sci. A 2017, 18, 617–630. [Google Scholar] [CrossRef]

- Barsikow, B. Experiences with Various Configurations of Microphone Arrays Used to Locate Sound Sources on Railway Trains Operated by the DB AG. J. Sound Vib. 1995, 193, 283–293. [Google Scholar] [CrossRef]

- Mellet, C.; Létourneaux, F.; Poisson, F.; Talotte, C. High Speed Train Noise Emission: Latest Investigation of the Aerodynamic/Rolling Noise Contribution. J. Sound Vib. 2006, 293, 535–546. [Google Scholar] [CrossRef]

- He, B.; Xiao, X.; Zhou, Q.; Li, Z.; Jin, X. Investigation into External Noise of a High-Speed Train at Different Speeds. J. Zhejiang Univ. Sci. A 2014, 15, 1019–1033. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Deng, T.; Wang, D.; Xu, F.; Xiao, X.; Sheng, X. An Experimental Investigation into the Difference in the External Noise Behavior of a High-Speed Train between Viaduct and Embankment Sections. Shock. Vib. 2022, 2022, 19. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, X.; Wang, D.; Yang, Y.; Fan, J. Source Contribution Analysis for Exterior Noise of a High-Speed Train: Experiments and Simulations. Shock. Vib. 2018, 2018, 13. [Google Scholar] [CrossRef] [Green Version]

- Noh, H.M. Noise-Source Identification of a High-Speed Train by Noise Source Level Analysis. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2017, 231, 717–728. [Google Scholar] [CrossRef]

- Baker, C.J.; Brockie, N.J. Wind Tunnel Tests to Obtain Train Aerodynamic Drag Coefficients: Reynolds Number and Ground Simulation Effects. J. Wind. Eng. Ind. Aerodyn. 1991, 38, 23–28. [Google Scholar] [CrossRef]

- Willemsen, E. High Reynolds Number Wind Tunnel Experiments on Trains. J. Wind. Eng. Ind. Aerodyn. 1997, 69, 437–447. [Google Scholar] [CrossRef]

- Nagakura, K. Localization of Aerodynamic Noise Sources of Shinkansen Trains. J. Sound Vib. 2006, 293, 547–556. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Hu, Z.W.; Thompson, D.J. Flow Simulation and Aerodynamic Noise Prediction for a High-Speed Train Wheelset. Int. J. Aeroacoustics 2014, 13, 533–552. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhang, J.; Sheng, X. Study on the Flow Behaviour and Aerodynamic Noise Characteristics of a High-Speed Pantograph under Crosswinds. Sci. China Technol. Sci. 2020, 63, 977–991. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, T.; Hemida, H.; Chen, Z.; Liu, H. Numerical Simulation of the Aerodynamic Characteristics of Double Unit Train. Eng. Appl. Comput. Fluid Mech. 2020, 14, 910–922. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Fu, L. Numerical Computation of Aerodynamic Noises of the High Speed Train with Considering Pantographs. J. Vibroengineering 2016, 18, 5588–5604. [Google Scholar] [CrossRef]

- Yang, H.; Liu, D. Numerical Study on the Aerodynamic Noise Characteristics of CRH2 High-Speed Trains. J. Vibroengineering 2017, 19, 3953–3967. [Google Scholar] [CrossRef]

- Sassa, T.; Sato, T.; Yatsui, S. Numerical Analysis of Aerodynamic Noise Radiation from a High-Speed Train Surface. J. Sound Vib. 2001, 247, 407–416. [Google Scholar] [CrossRef]

- Takaishi, T.; Sagawa, A.; Nagakura, K.; Maeda, T. Numerical Analysis of Dipole Sound Source around High Speed Trains. J. Acoust. Soc. Am. 2002, 111, 2601–2608. [Google Scholar] [CrossRef] [PubMed]

- Masson, E.; Paradot, N.; Allain, E. The Numerical Prediction of the Aerodynamic Noise of the TGV POS High-Speed Train Power Car. In Notes on Numerical Fluid Mechanics and Multidisciplinary Design, Proceedings of the 10th International Workshop on Railway Noise, Nagahama, Japan, 18–22 October 2010; Maeda, T., Gautier, P.-E., Hanson, C.E., Hemsworth, B., Nelson, J.T., Schulte-Werning, B., Thompson, D., de Vos, P., Eds.; Springer: Tokyo, Japan, 2012; pp. 437–444. [Google Scholar] [CrossRef]

- Wu, J. Numerical Computation and Improvement of Aerodynamic Radiation Noises of Pantographs. J. Vibroengineering 2017, 19, 3939–3952. [Google Scholar] [CrossRef]

- Sun, X.; Xiao, H. Numerical Modeling and Investigation on Aerodynamic Noise Characteristics of Pantographs in High-Speed Trains. Complexity 2018, 2018, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Qin, D.; Zhang, J. Effect of RANS Turbulence Model on Aerodynamic Behavior of Trains in Crosswind. Chin. J. Mech. Eng. 2019, 32, 85. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Zhang, J.; Thompson, D.; Iglesias, E.L.; Squicciarini, G.; Hu, Z.; Toward, M.; Lurcock, D. Aerodynamic Noise of High-Speed Train Pantographs: Comparisons between Field Measurements and an Updated Component-Based Prediction Model. Appl. Acoust. 2021, 175, 107791. [Google Scholar] [CrossRef]

- Feng, S.; Zhang, X.; Wang, L.; Zheng, Q.; Du, F.; Wang, Z. In Situ Experimental Study on High Speed Train Induced Ground Vibrations with the Ballast-Less Track. Soil Dyn. Earthq. Eng. 2017, 102, 195–214. [Google Scholar] [CrossRef]

- Li, T.; Su, Q.; Shao, K.; Liu, J. Numerical Analysis of Vibration Responses in High-Speed Railways Considering Mud Pumping Defect. Shock. Vib. 2019, 2019, 11. [Google Scholar] [CrossRef] [Green Version]

- Liang, L.; Li, X.; Yin, J.; Wang, D.; Gao, W.; Guo, Z. Vibration Characteristics of Damping Pad Floating Slab on the Long-Span Steel Truss Cable-Stayed Bridge in Urban Rail Transit. Eng. Struct. 2019, 191, 92–103. [Google Scholar] [CrossRef]

- Ge, X.; Ling, L.; Yuan, X.; Wang, K. Effect of Distributed Support of Rail Pad on Vertical Vehicle-Track Interactions. Constr. Build. Mater. 2020, 262, 120607. [Google Scholar] [CrossRef]

- Liu, L.; Liu, H.; Lv, R. Research on Noise and Vibration Reduction of Damped Wheel-Rail. Noise Vib. Worldw. 2010, 41, 44–48. [Google Scholar] [CrossRef]

- Connolly, D.; Giannopoulos, A.; Fan, W.; Woodward, P.K.; Forde, M.C. Optimising Low Acoustic Impedance Back-Fill Material Wave Barrier Dimensions to Shield Structures from Ground Borne High Speed Rail Vibrations. Constr. Build. Mater. 2013, 44, 557–564. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.; Kim, J. Comparison Study of Sound Transmission Loss in High Speed Train. Int. J. Railw. 2011, 4, 19–27. [Google Scholar] [CrossRef]

- Xin, F.X.; Lu, T.J. Sound Radiation of Orthogonally Rib-Stiffened Sandwich Structures with Cavity Absorption. Compos. Sci. Technol. 2010, 70, 2198–2206. [Google Scholar] [CrossRef]

- Xie, G.; Thompson, D.J.; Jones, C.J.C. A Modelling Approach for the Vibroacoustic Behaviour of Aluminium Extrusions Used in Railway Vehicles. J. Sound Vib. 2006, 293, 921–932. [Google Scholar] [CrossRef]

- Kim, S.; Seo, T.; Kim, J.; Song, D. Sound-Insulation Design of Aluminum Extruded Panel in Next-Generation High-Speed Train. Trans. Korean Soc. Mech. Eng. A 2011, 35, 567–574. [Google Scholar] [CrossRef]

- Qin, Z.H.; Zhang, Z.P.; Ren, F.; Li, H.B.; Liu, Z.H.; Zhang, Z.; Yuan, K.; Wang, Y.C. Application of FE-SEA Hybrid Method in Vibro-Acoustic Environment Prediction of Complex Structure. J. Phys. Conf. Ser. 2016, 744, 012238. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Squicciarini, G.; Thompson, D.; Ryue, J.; Xiao, X.; Yao, D.; Chen, J. A Modelling Approach for Noise Transmission through Extruded Panels in Railway Vehicles. J. Sound Vib. 2021, 502, 116095. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, X.; Sheng, X.; Yao, D.; Wang, R. An Acoustic Design Procedure for Controlling Interior Noise of High-Speed Trains. Appl. Acoust. 2020, 168, 107419. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, D.; Wang, R.; Xiao, X. Vibro-Acoustic Modelling of High-Speed Train Composite Floor and Contribution Analysis of Its Constituent Materials. Compos. Struct. 2021, 256, 113049. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, D.; Shen, M.; Wang, R.; Li, J.; Guo, S. Effect of Multi-Layered IIR/EP on Noise Reduction of Aluminium Extrusions for High-Speed Trains. Compos. Struct. 2021, 262, 113638. [Google Scholar] [CrossRef]

- Yao, D.; Zhang, J.; Wang, R.; Xiao, X. Vibroacoustic Damping Optimisation of High-Speed Train Floor Panels in Low- and Mid-Frequency Range. Appl. Acoust. 2021, 174, 107788. [Google Scholar] [CrossRef]

- Xin, F.X.; Lu, T.J.; Chen, C.Q. Vibroacoustic Behavior of Clamp Mounted Double-Panel Partition with Enclosure Air Cavity. J. Acoust. Soc. Am. 2009, 124, 3604–3612. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, X.; Thompson, D.; Squicciarini, G.; Wen, Z.; Li, Z.; Wu, Y. Sound Transmission Loss of Windows on High Speed Trains. J. Phys. Conf. Ser. 2016, 744, 012141. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Chen, X.; Liu, L.; Lu, W. Current Status and Prospects of Application of Sound Barrier for High-Speed Railway in China. IOP Conf. Ser. Earth Environ. Sci. 2019, 300, 032051. [Google Scholar] [CrossRef]

- Ekici, I.; Bougdah, H. A Review of Research on Environmental Noise Barriers. Build. Acoust. 2003, 10, 289–323. [Google Scholar] [CrossRef]

- May, D.N.; Osman, M.M. The Performance of Sound Absorptive, Reflective, and T-Profile Noise Barriers in Toronto. J. Sound Vib. 1980, 71, 65–71. [Google Scholar] [CrossRef]

- Defrance, J.; Jean, P. Integration of the Efficiency of Noise Barrier Caps in a 3D Ray Tracing Method. Case of a T-Shaped Diffracting Device. Appl. Acoust. 2003, 64, 765–780. [Google Scholar] [CrossRef]

- Baulac, M.; Defrance, J.; Jean, P. Optimisation with Genetic Algorithm of the Acoustic Performance of T-Shaped Noise Barriers with a Reactive Top Surface. Appl. Acoust. 2008, 69, 332–342. [Google Scholar] [CrossRef]

- Oldham, D.J.; Egan, C.A. A Parametric Investigation of the Performance of T-Profiled Highway Noise Barriers and the Identification of a Potential Predictive Approach. Appl. Acoust. 2011, 72, 803–813. [Google Scholar] [CrossRef]

- Venckus, Ž.; Grubliauskas, R.; Venslovas, A. The Research on the Effectiveness of the Inclined Top Type of a Noise Barrier. J. Environ. Eng. Landsc. Manag. 2012, 20, 155–162. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, R.; Cao, Z.; Wang, X.; Li, X. Acoustic Performance of a Semi-Closed Noise Barrier Installed on a High-Speed Railway Bridge: Measurement and Analysis Considering Actual Service Conditions. Measurement 2019, 138, 386–399. [Google Scholar] [CrossRef]

- Veselago, V.G. The Electrodynamics of Substances with Simultaneously Negative Values of ε and μ. Sov. Phys. Usp. 1968, 10, 509–514. [Google Scholar] [CrossRef]

- Narayanamurti, V.; Pohl, R.O. Tunneling States of Defects in Solids. Rev. Mod. Phys. 1970, 42, 201–236. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, X.; Mao, Y.; Zhu, Y.Y.; Yang, Z.; Chan, C.T.; Sheng, P. Locally Resonant Sonic Materials. Science 2000, 289, 1734–1736. [Google Scholar] [CrossRef]

- Zigoneanu, L.; Popa, B.-I.; Cummer, S.A. Three-Dimensional Broadband Omnidirectional Acoustic Ground Cloak. Nat. Mater. 2014, 13, 352–355. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, M.; Liu, X.-K.; Feng, L.; Li, J.; Huang, C.-P.; Chen, Y.-F.; Zhu, Y.-Y.; Zhu, S.-N.; Ming, N.-B. Extraordinary Acoustic Transmission through a 1D Grating with Very Narrow Apertures. Phys. Rev. Lett. 2007, 99, 174301. [Google Scholar] [CrossRef]

- Lu, M.; Zhang, C.; Feng, L.; Zhao, J.; Chen, Y.-F.; Mao, Y.-W.; Zi, J.; Zhu, Y.-Y.; Zhu, S.-N.; Ming, N.-B. Negative Birefraction of Acoustic Waves in a Sonic Crystal. Nat. Mater. 2007, 6, 744–748. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Yin, L.; Fang, N. Focusing Ultrasound with an Acoustic Metamaterial Network. Phys. Rev. Lett. 2009, 102, 194301. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Romero-García, V.; Theocharis, G.; Richoux, O.; Merkel, A.; Tournat, V.; Pagneux, V. Perfect and Broadband Acoustic Absorption by Critically Coupled Sub-Wavelength Resonators. Sci. Rep. 2016, 6, 19519. [Google Scholar] [CrossRef] [PubMed]

- Ang, L.Y.L.; Koh, Y.K.; Lee, H.P. Acoustic Metamaterials: A Potential for Cabin Noise Control in Automobiles and Armored Vehicles. Int. J. Appl. Mech. 2016, 8, 1650072. [Google Scholar] [CrossRef] [Green Version]

- Xing, J.; Xu, P.; Zhao, H.; Yao, S.; Wang, Q.; Li, B. Crashworthiness Design and Experimental Validation of a Novel Collision Post Structure for Subway Cab Cars. J. Cent. South Univ. 2020, 27, 2763–2775. [Google Scholar] [CrossRef]

- Gao, G.; Zhuo, T.; Guan, W. Recent Research Development of Energy-Absorption Structure and Application for Railway Vehicles. J. Cent. South Univ. 2020, 27, 1012–1038. [Google Scholar] [CrossRef]

- Qiu, X.; Li, X.; Zheng, J.; Wang, M. Fluctuating Wind Pressure on Vertical Sound Barrier during Two High-Speed Trains Passing Each Other. Int. J. Rail Transp. 2022, 10, 1–18. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, Y.; Liang, B.; Yang, J.; Yang, J.; Cheng, J. Omnidirectional Ventilated Acoustic Barrier. Appl. Phys. Lett. 2017, 111, 203502. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Au-Yeung, K.Y.; Li, X.; Roberts, R.C.; Tian, J.; Hu, C.; Huang, Y.; Wang, S.; Yang, Z.; Wen, W. High-Efficiency Ventilated Metamaterial Absorber at Low Frequency. Appl. Phys. Lett. 2018, 112, 103505. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.; Fang, X.; Wang, X.; Assouar, B.; Cheng, Q.; Li, Y. Acoustic Perfect Absorbers via Spiral Metasurfaces with Embedded Apertures. Appl. Phys. Lett. 2018, 113, 233501. [Google Scholar] [CrossRef]

- Ghaffarivardavagh, R.; Nikolajczyk, J.; Anderson, S.; Zhang, X. Ultra-Open Acoustic Metamaterial Silencer Based on Fano-like Interference. Phys. Rev. B 2019, 99, 024302. [Google Scholar] [CrossRef]

- Wang, X.; Luo, X.; Yang, B.; Huang, Z. Ultrathin and Durable Open Metamaterials for Simultaneous Ventilation and Sound Reduction. Appl. Phys. Lett. 2019, 115, 171902. [Google Scholar] [CrossRef]

- Kumar, S.; Lee, H.P. Labyrinthine Acoustic Metastructures Enabling Broadband Sound Absorption and Ventilation. Appl. Phys. Lett. 2020, 116, 134103. [Google Scholar] [CrossRef]

- Xie, S.; Yang, S.; Yan, H.; Li, Z. Sound Absorption Performance of a Conch-Imitating Cavity Structure. Sci. Prog. 2022, 105, 00368504221075167. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Assouar, B.M. Acoustic Metasurface-Based Perfect Absorber with Deep Subwavelength Thickness. Appl. Phys. Lett. 2016, 108, 063502. [Google Scholar] [CrossRef]

- Liu, C.R.; Wu, J.H.; Chen, X.; Ma, F. A Thin Low-Frequency Broadband Metasurface with Multi-Order Sound Absorption. J. Phys. D Appl. Phys. 2019, 52, 105302. [Google Scholar] [CrossRef] [Green Version]

- Long, H.; Gao, S.; Cheng, Y.; Liu, X. Multiband Quasi-Perfect Low-Frequency Sound Absorber Based on Double-Channel Mie Resonator. Appl. Phys. Lett. 2018, 112, 033507. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Hu, X. Three-Dimensional Single-Port Labyrinthine Acoustic Metamaterial: Perfect Absorption with Large Bandwidth and Tunability. Phys. Rev. Appl. 2016, 6, 064025. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Wu, J.; Yang, Z.; Ma, F. Ultra-Broadband Acoustic Absorption of a Thin Microperforated Panel Metamaterial with Multi-Order Resonance. Compos. Struct. 2020, 246, 112366. [Google Scholar] [CrossRef]

- Tang, Y.; Ren, S.; Meng, H.; Xin, F.; Huang, L.; Chen, T.; Zhang, C.; Lu, T.J. Hybrid Acoustic Metamaterial as Super Absorber for Broadband Low-Frequency Sound. Sci. Rep. 2017, 7, 43340. [Google Scholar] [CrossRef] [Green Version]

- Peng, X.; Ji, J.; Jing, Y. Composite Honeycomb Metasurface Panel for Broadband Sound Absorption. J. Acoust. Soc. Am. 2018, 144, EL255–EL261. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, D.; Xie, S.; Yang, S.; Li, Z. Sound Absorption Performance of Acoustic Metamaterials Composed of Double-Layer Honeycomb Structure. J. Cent. South Univ. 2021, 28, 2947–2960. [Google Scholar] [CrossRef]

- Wu, F.; Xiao, Y.; Yu, D.; Zhao, H.; Wang, Y.; Wen, J. Low-Frequency Sound Absorption of Hybrid Absorber Based on Micro-Perforated Panel and Coiled-up Channels. Appl. Phys. Lett. 2019, 114, 151901. [Google Scholar] [CrossRef]

- Xu, W.; Yu, D.; Wen, J. Simple Meta-Structure That Can Achieve the Quasi-Perfect Absorption throughout a Frequency Range of 200–500 Hz at 350 °C. Appl. Phys. Express 2020, 13, 047001. [Google Scholar] [CrossRef]

- Xie, S.; Li, Z.; Yan, H.; Yang, S. Ultra-Broadband Sound Absorption Performance of a Multi-Cavity Composite Structure Filled with Polyurethane. Appl. Acoust. 2022, 189, 108612. [Google Scholar] [CrossRef]

| Methods to Reduce Noise | Research Methods | Frequency Characteristics | Sound Pressure Level | Reference |

|---|---|---|---|---|

| Different strip spacing of the pantograph | CFD analysis | No effect | The sound pressure level of the standard noise measuring point is reduced by 2.8 dB with a spacing of 540 mm | [16] |

| Bionic pigeon feathers | CFD analysis | Around 1000 Hz (original model) Around 100 Hz (optimized model) | The total noise decreased by 10 dB | [17] |

| Pantograph insulators with elliptical section | CFD analysis | Tonal peaks are gradually reduced from 2 kHz | The peak sound pressure level of elliptical insulators decreased by 4 dB | [18] |

| Cylindrical rod and push rod applied to a layer of porous sound absorption material | CFD analysis, Wind tunnel test | No effect | The peak sound pressure level of the optimized pantograph decreased by 5 dB | [19] |

| Covering the fairings with a porous material | CFD analysis, Wind tunnel test | No effect | The optimized noise peak is 8 dB lower than the original noise peak | [20] |

| Covering the circular cylinder with metal foam | Wind tunnel test | Tonal peaks toward lower frequencies | The peak sound pressure level decreased by 5 dB at 216 km/h | [21] |

| Pantographs with and without the cavity | CFD analysis | No effect | The difference in OASPL between the pantographs with and without the cavity was approximately 4 dB at the side | [22] |

| The comparison of noise reduction effects for four types of pantographs covers | CFD analysis | No description | A pair of baffles with half of the height of the pantograph on both sides can lessen noise by about 3 dB | [23] |

| Noise contribution from high-speed train roof configuration of cavities, ramped cavities, flat roofs | CFD analysis | No effect | The flat roof with side insulation plates has the lowest overall noise levels. | [24] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, H.; Xie, S.; Jing, K.; Feng, Z. A Review of Recent Research into the Causes and Control of Noise during High-Speed Train Movement. Appl. Sci. 2022, 12, 7508. https://doi.org/10.3390/app12157508

Yan H, Xie S, Jing K, Feng Z. A Review of Recent Research into the Causes and Control of Noise during High-Speed Train Movement. Applied Sciences. 2022; 12(15):7508. https://doi.org/10.3390/app12157508

Chicago/Turabian StyleYan, Hongyu, Suchao Xie, Kunkun Jing, and Zhejun Feng. 2022. "A Review of Recent Research into the Causes and Control of Noise during High-Speed Train Movement" Applied Sciences 12, no. 15: 7508. https://doi.org/10.3390/app12157508

APA StyleYan, H., Xie, S., Jing, K., & Feng, Z. (2022). A Review of Recent Research into the Causes and Control of Noise during High-Speed Train Movement. Applied Sciences, 12(15), 7508. https://doi.org/10.3390/app12157508