Integrated Fuzzy-Logic and Triple-Loop PI-Based Management Strategy for a Lead-Acid/Lithium-Ion Hybrid Battery Energy Storage System

Abstract

:1. Introduction

- We develop and propose a HESS using a fully active topology approach that will supply the vehicle’s required cold cranking current for starting because it provides a higher degree of control freedom and efficiency. This development and proposal add an influence to studies in [5,27] and [28], wherein [5], the study discusses the challenges that may face LIBs when used for SLI functions. Additionally, in [27], the authors propose potential methods for using hybrid ESSs for SLI functions.

- We develop an integrated fuzzy-logic and triple-loop PI-based controller to effectively distribute the power between the ESSs. The integrated solution ensures that the batteries operate within their desired limits. A contribution that enhances the performance in [29], in which the study assessed the system in terms of improving vehicle range only.

- We compare the performance of a single source battery for the HESS in terms of delivering the required cold cranking current.

- We enhance the performance of LAB in terms of lifespan and storage capacity improvement.

- We develop the HESS that has great longevity, less weight, and is reliable for use in the automotive sector.

- We propose a battery life determination using a fatigue-cycle counting approach because it is well established and easy to implement.

2. State-of-the-Art Literature Analysis

3. Materials and Methods

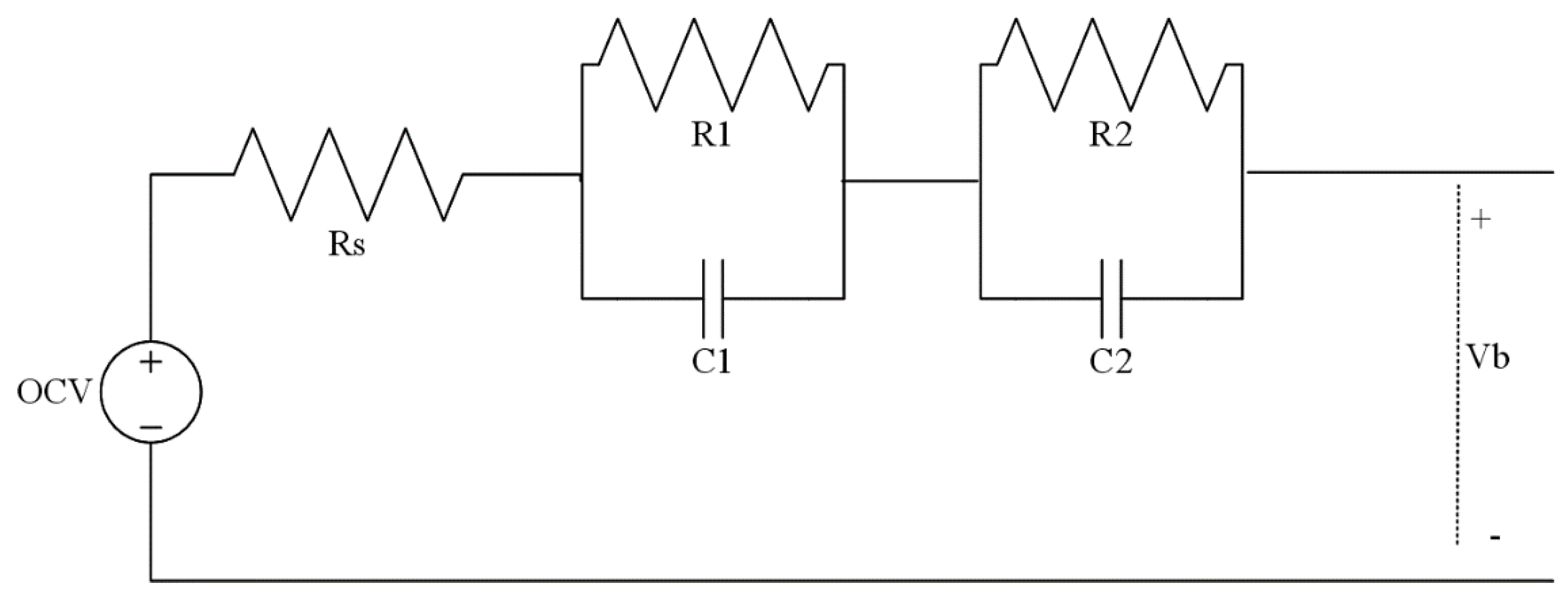

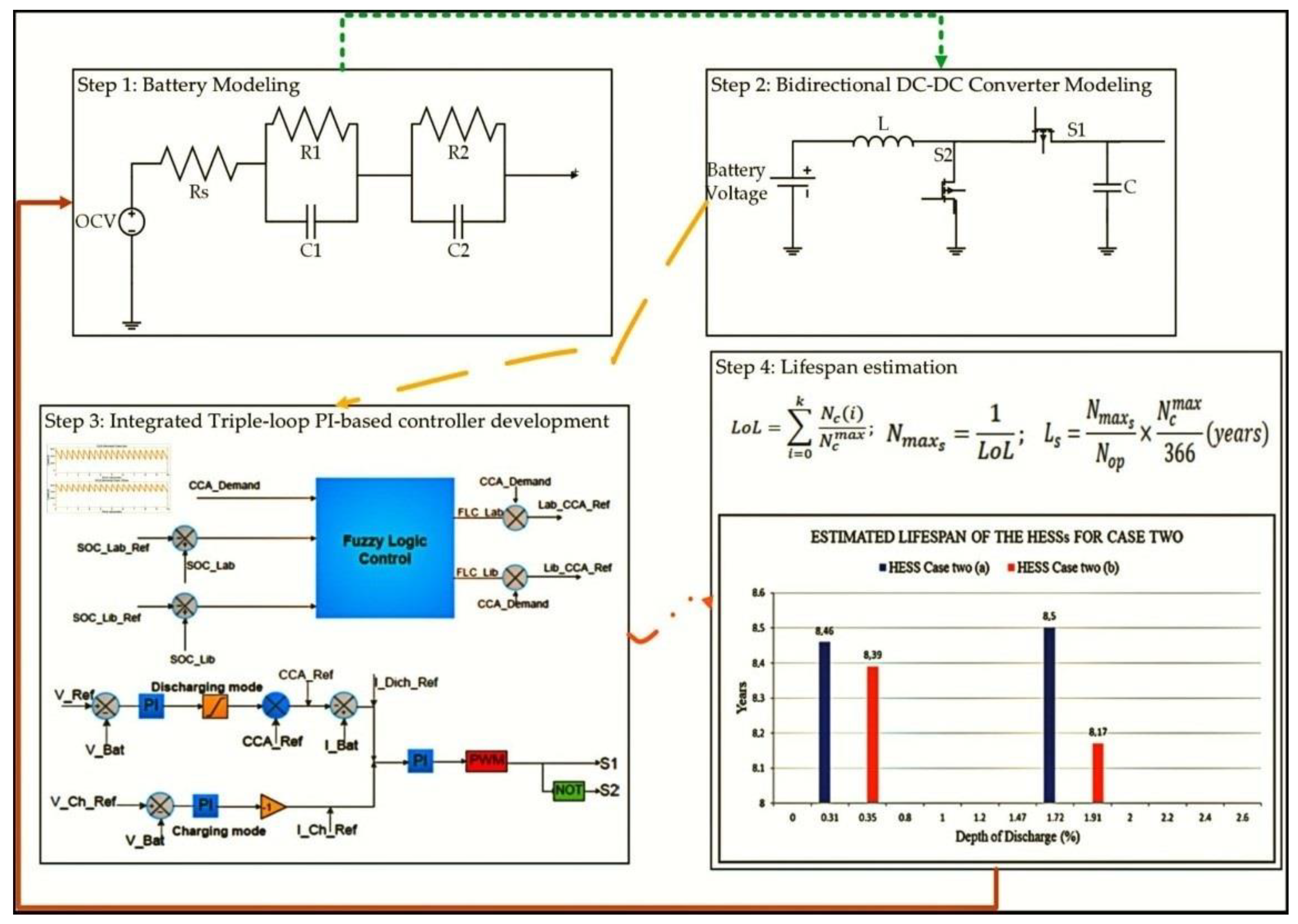

3.1. Battery Equivalent Circuit Model

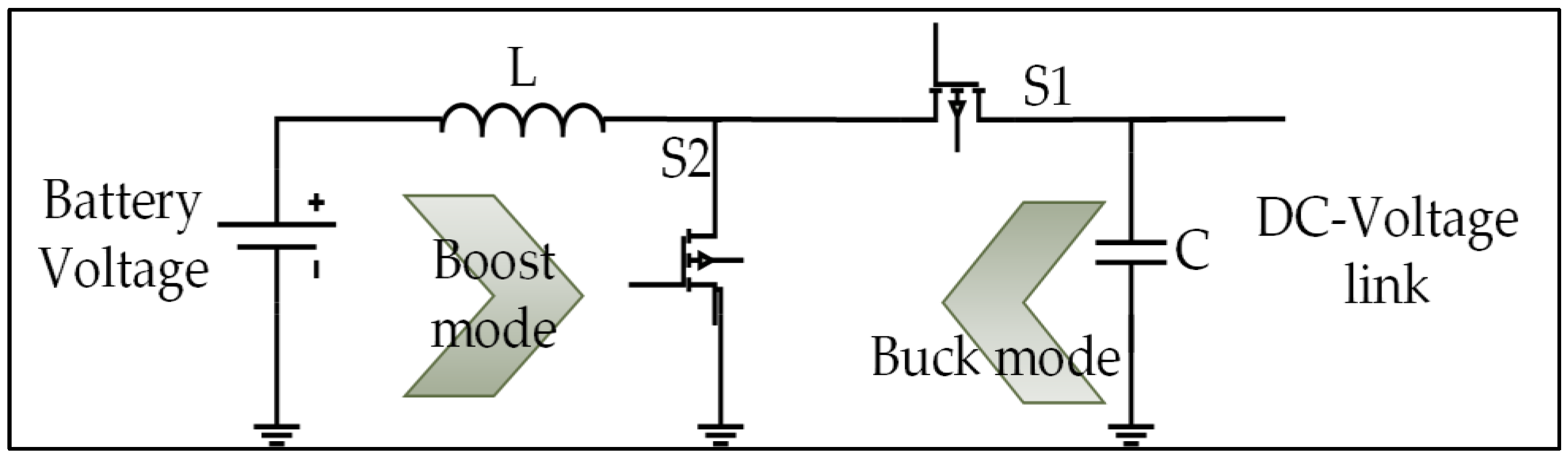

3.2. Bidirectional DC-DC Converter

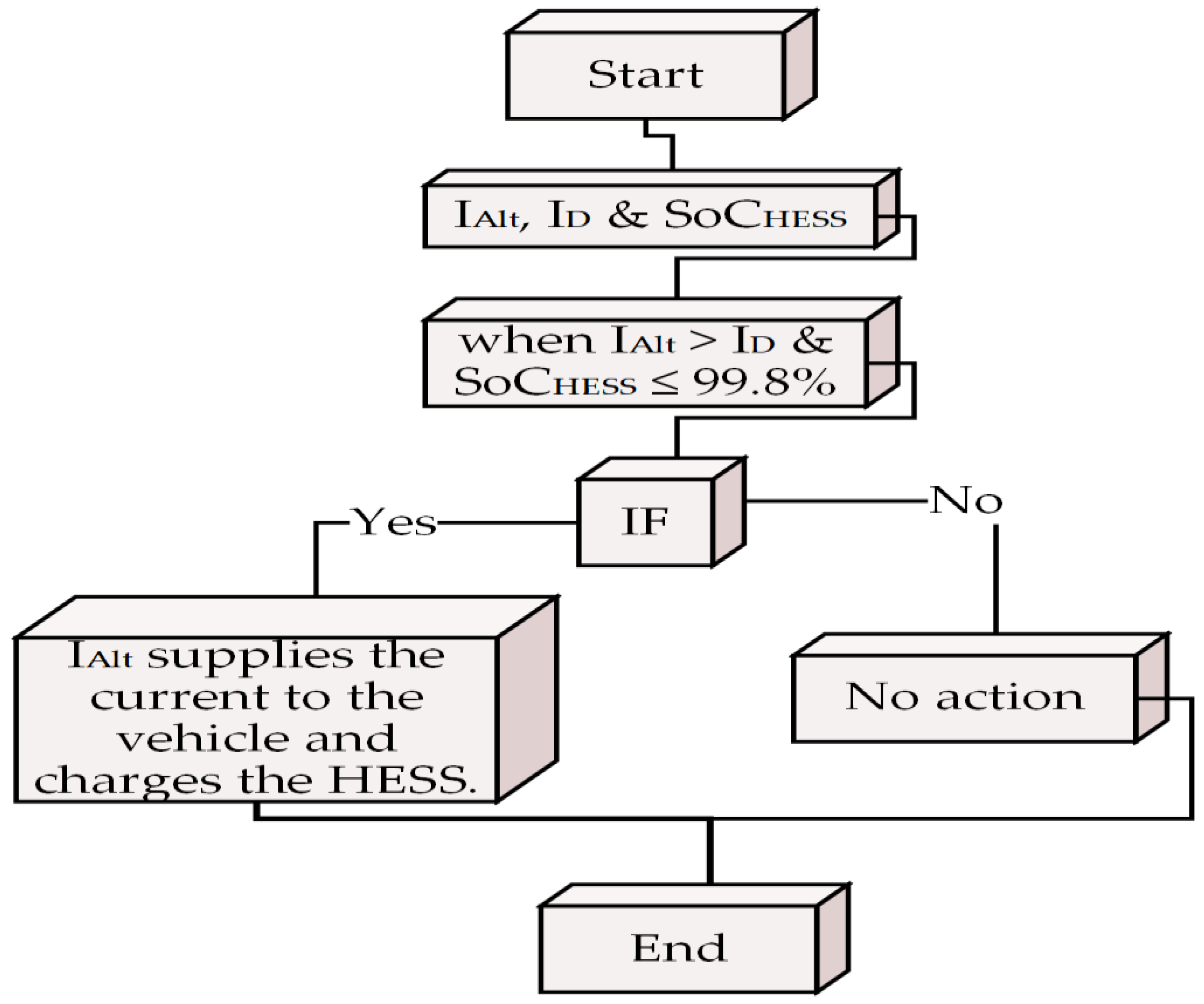

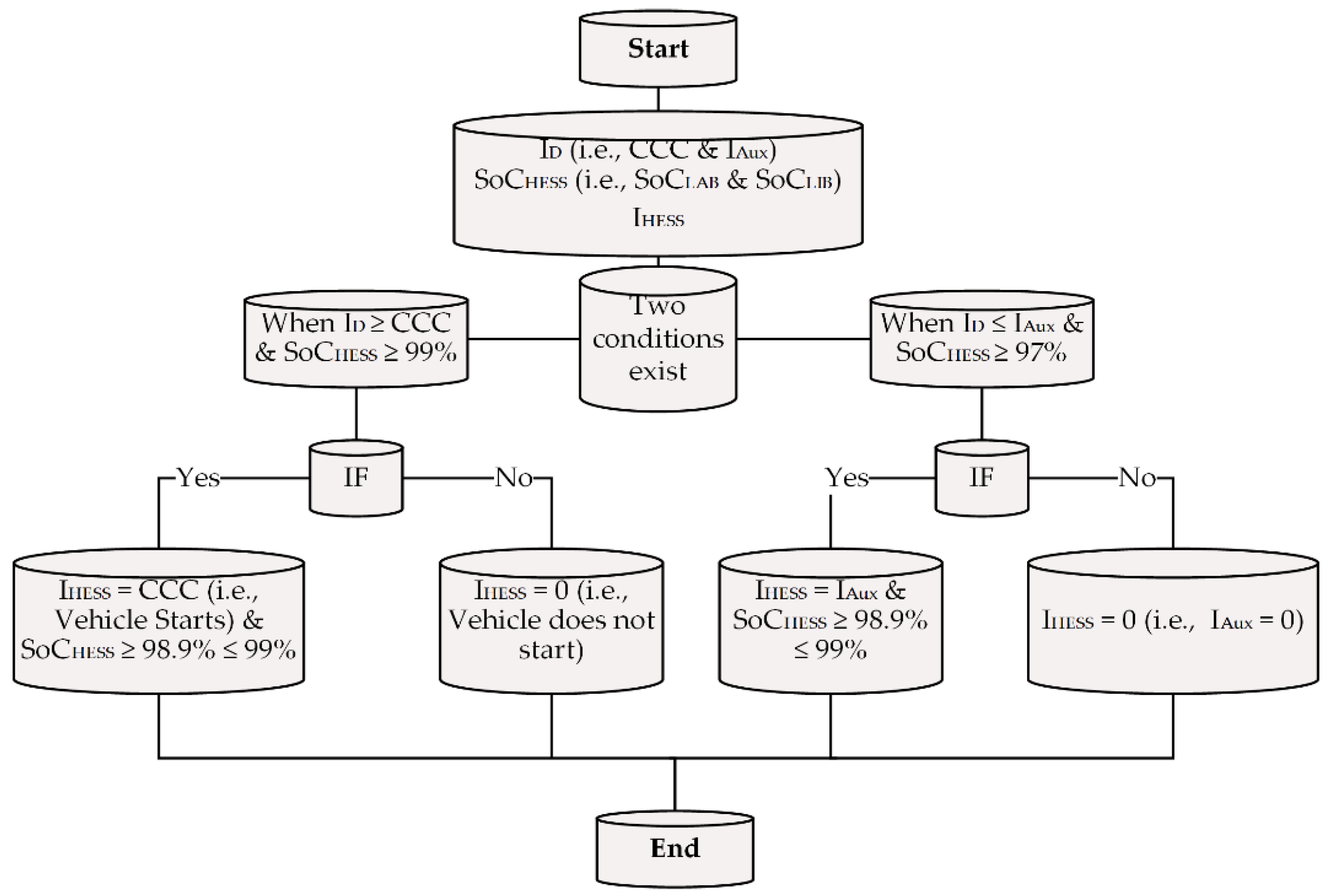

3.3. Battery Management System

- when , the alternator supplies the current to the vehicle while charging the battery simultaneously. While during discharging, the following conditions have to be met;

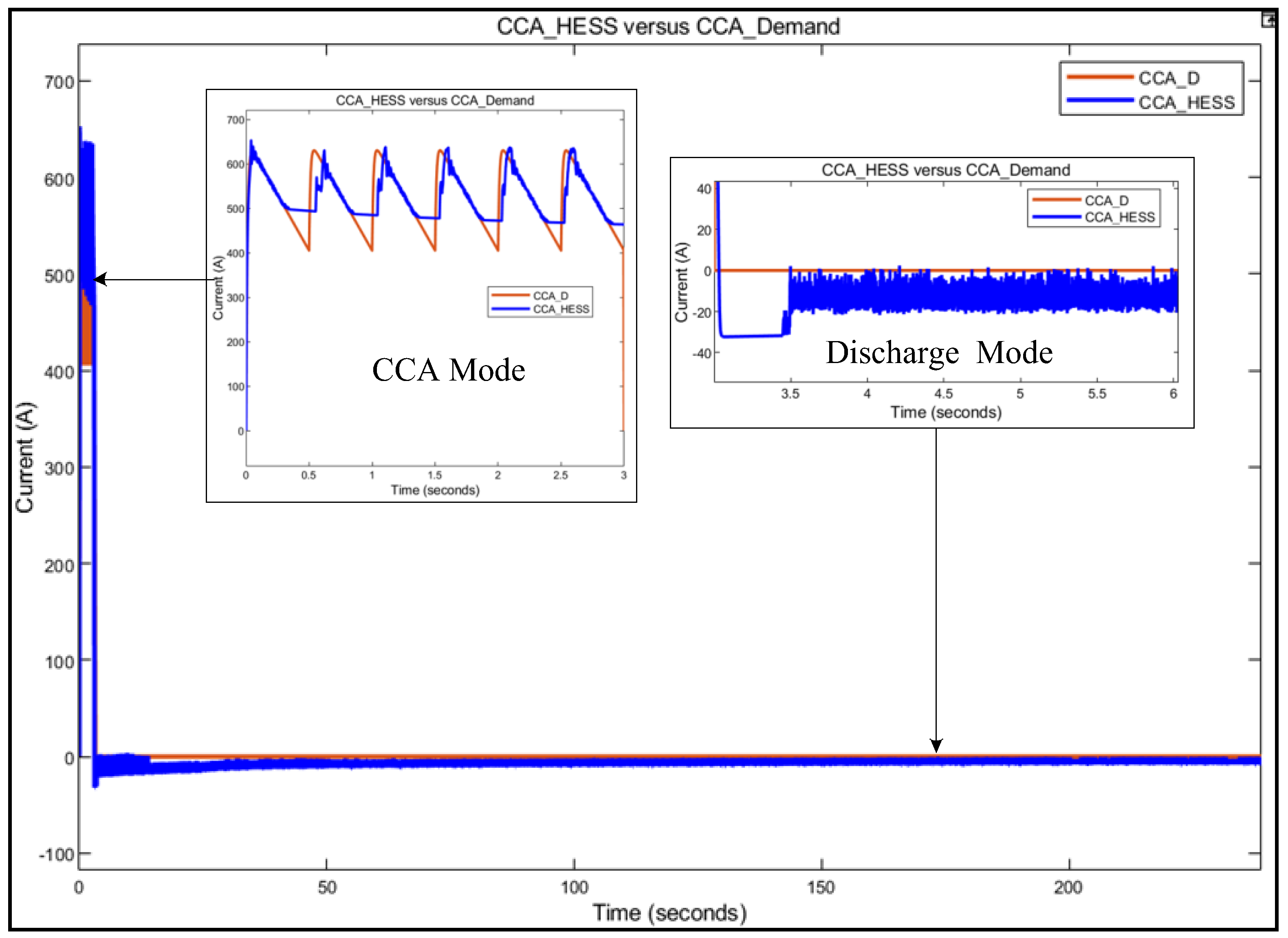

- when and the (i.e., ), which means that the HESS supplies the required CCC to start the vehicle while maintaining the HESS SoC above 98.9%.

- when and , means that the HESS supplies the auxiliary loads of the vehicle while sustaining the HESS state-of-charge above 97%.

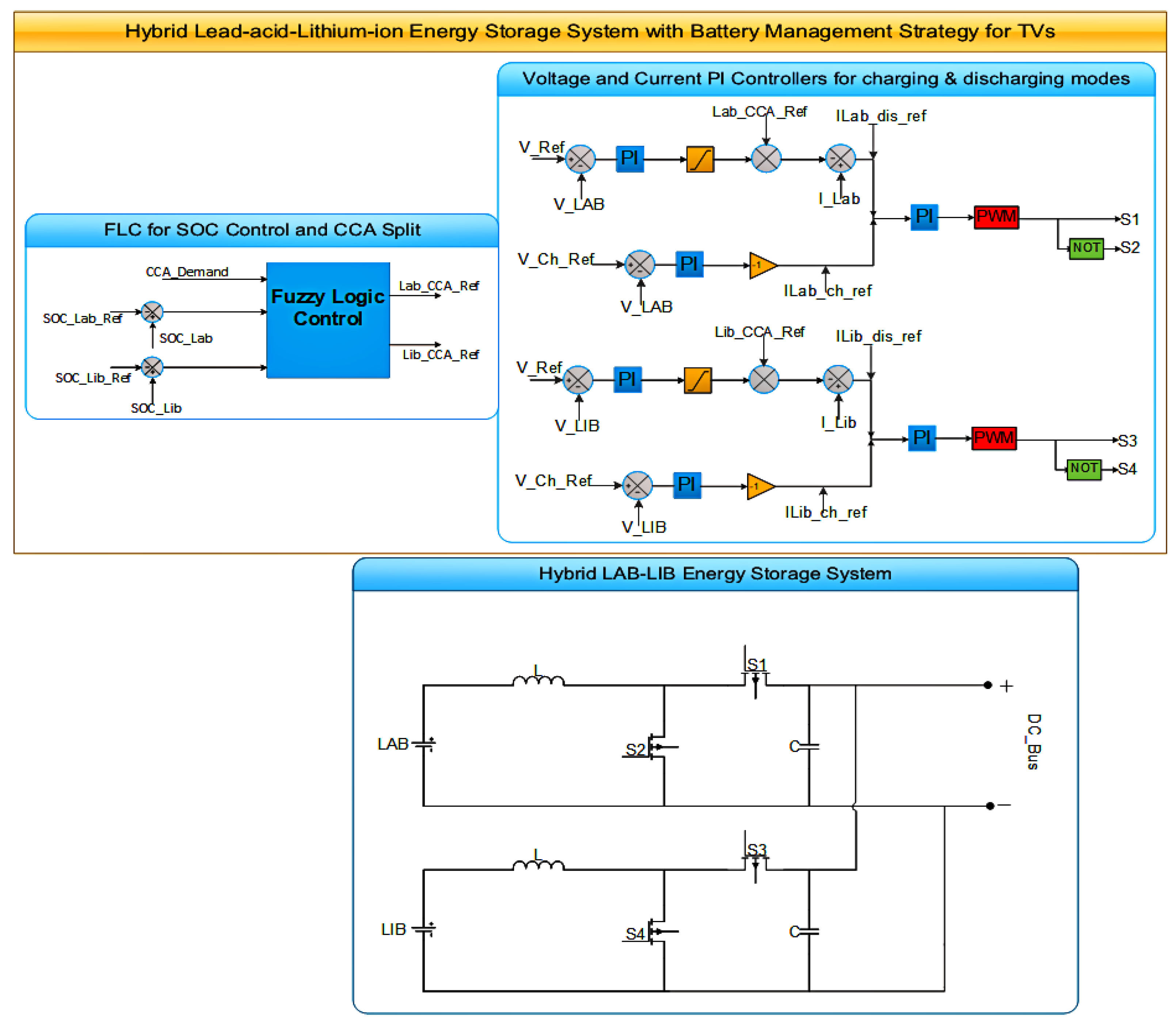

Integrated Fuzzy-Logic and Triple-Loop PI-Based Control

- is the membership function during the start-up function, LAB supplied between 45% and 70% of the required startup current, and supplied about 30% to 70% depending on the operating scenario.

- Zero is the mode when there is no action from the HESS, it means the HESS will not charge or discharge.

- resembles the vehicle in running operation, where the alternator is producing more energy than required for the vehicle and the difference is used to charge the HESS. Decision-making rules are part of the fuzzy logic where the decisions are made. The rules and database are developed and defined to meet the desired output. Fuzzy logic control rules are represented by understanding and knowledge of human operators in the form of linguistic variables. It is normally represented as a sequence of the form “IF-THEN”, leading to algorithms describing what action or output should be taken inaction of the currently observed information, which includes both input and feedback if a closed-loop control system is applied [40,42]. FLC “IF-THEN” rule associates a condition defined using linguistic variables and fuzzy sets to obtain a certain output. “IF” is normally used to capture the knowledge by using elastic conditions. THEN is used to give the conclusion or output in linguistic variable form. These rules are normally used in fuzzy inference systems to compute the degree to which the input data match the condition of the rule, where:

- IF is equal to CCC and are high, Then is equal to (i.e., ), which means the HESS will supply the required current, where each battery supplies the current based on the reference current given by the FLC.

- IF and are not high; Then is zero, which means that the system is balanced and HESS will not charge or discharge. Defuzzification: Defuzzification is the FLC output; it produces a quantifiable result in crisp logic based on the input membership, fuzzy rules and corresponding degrees processing fuzzy rules to a crisp set. The defuzzification method used in this proposed FLC is the centroid method. The FLC generate two outputs which are the percentage reference that which battery must supply. The output FLC reference is multiplied by the required CCC to form the reference CCC of each battery. The is used to give the reference SoC and to ensure the within the limits, where the and . The and . Setting the SoC within limits helps guard against overcharging the battery, also deep release, along with avoiding keeping the LIB at full SoC by disconnecting the battery from the alternator. Figure 6 shows the proposed HESS with BMS for TVs. The batteries were connected in parallel and each connected in series with a bidirectional DC–DC buck-boost converter. The two converters’ output was connected to the DC-Bus.

3.4. Lifespan Estimation

- From the battery datasheet, the curve showing the number of cycles of a battery as a function of DoD until it reaches the end of its lifetime was utilised.

- The SoC represents the battery capacity in percentage.

- The curve represents battery lifespan in days as a function of its float charging voltage and temperature. Therefore, based on the data obtained from [50], the loss-of-life (LoL) and maximum expected lifespan in years of batteries are estimated according to [46,47,49]. The LoL of the batteries is the sum over all types of operation during the observation period; it was estimated using the following Formula (21) as in [37]:where, , is the battery DoD and stands for DoD and was used during the discharge operation mode. When DoD is 100%, it means that the battery is fully discharged. represent the number of performed cycles at DoD, is the number of cycles to failure, which was attained when 80% of the battery capacity was utilised [49]. Thus, the battery end-of-life (EoL) with several DoD was attained when the LoL was 1 [38,46,49,51]. This can further be formulated as: when , then . Hence, the battery lifespan is represented by the maximum number of services of the battery, and represented by Equation (22) as in [37,47];

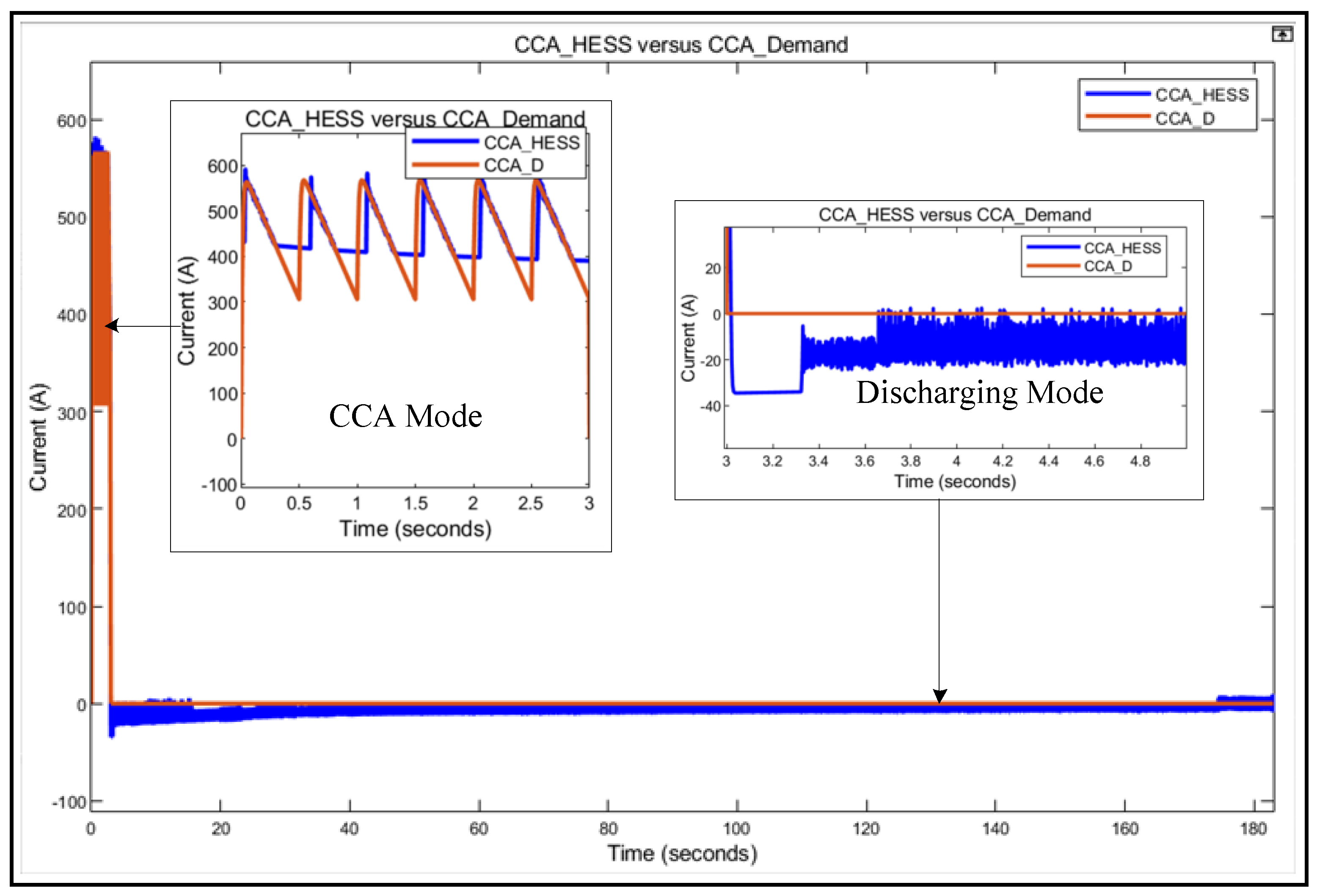

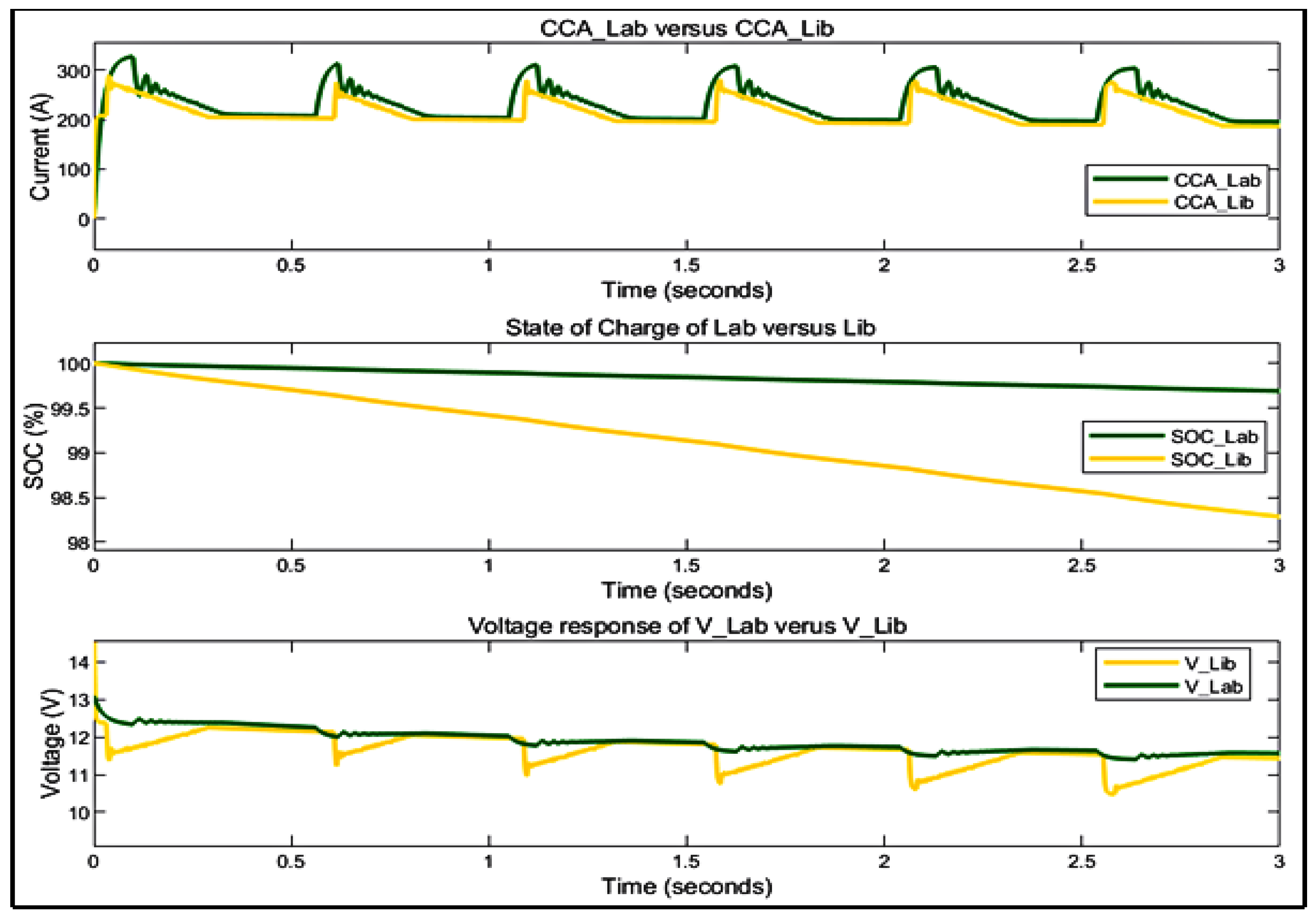

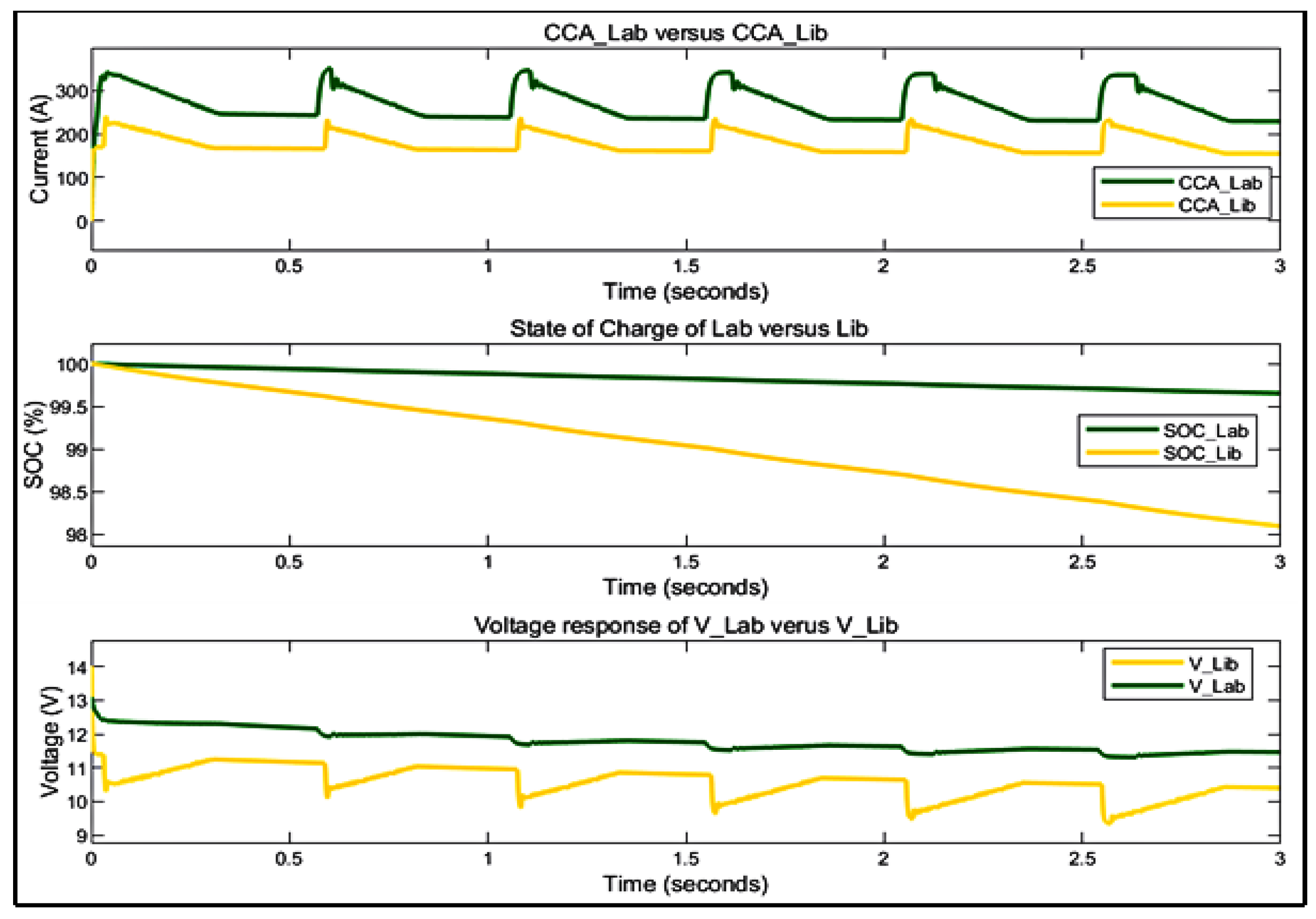

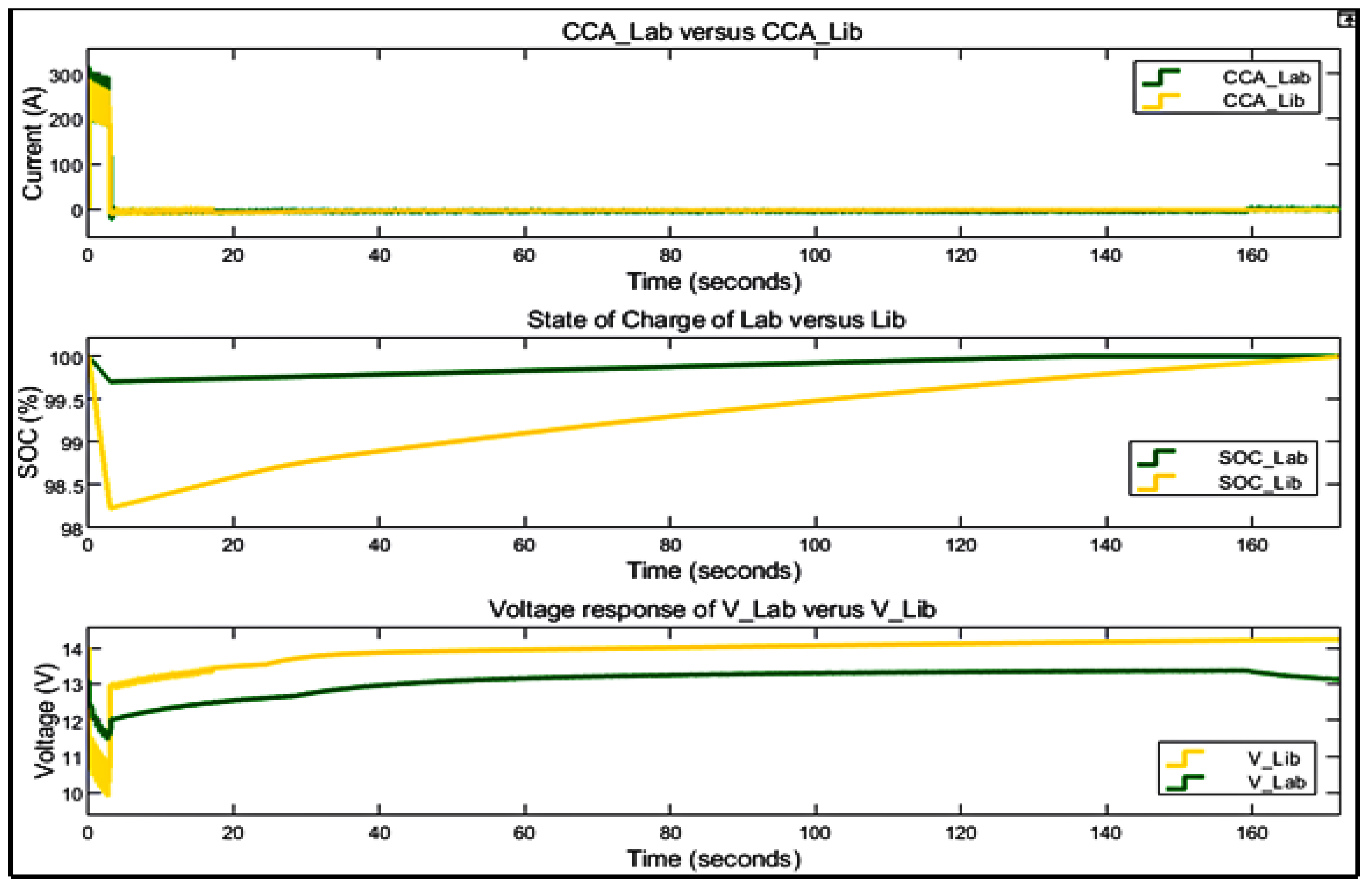

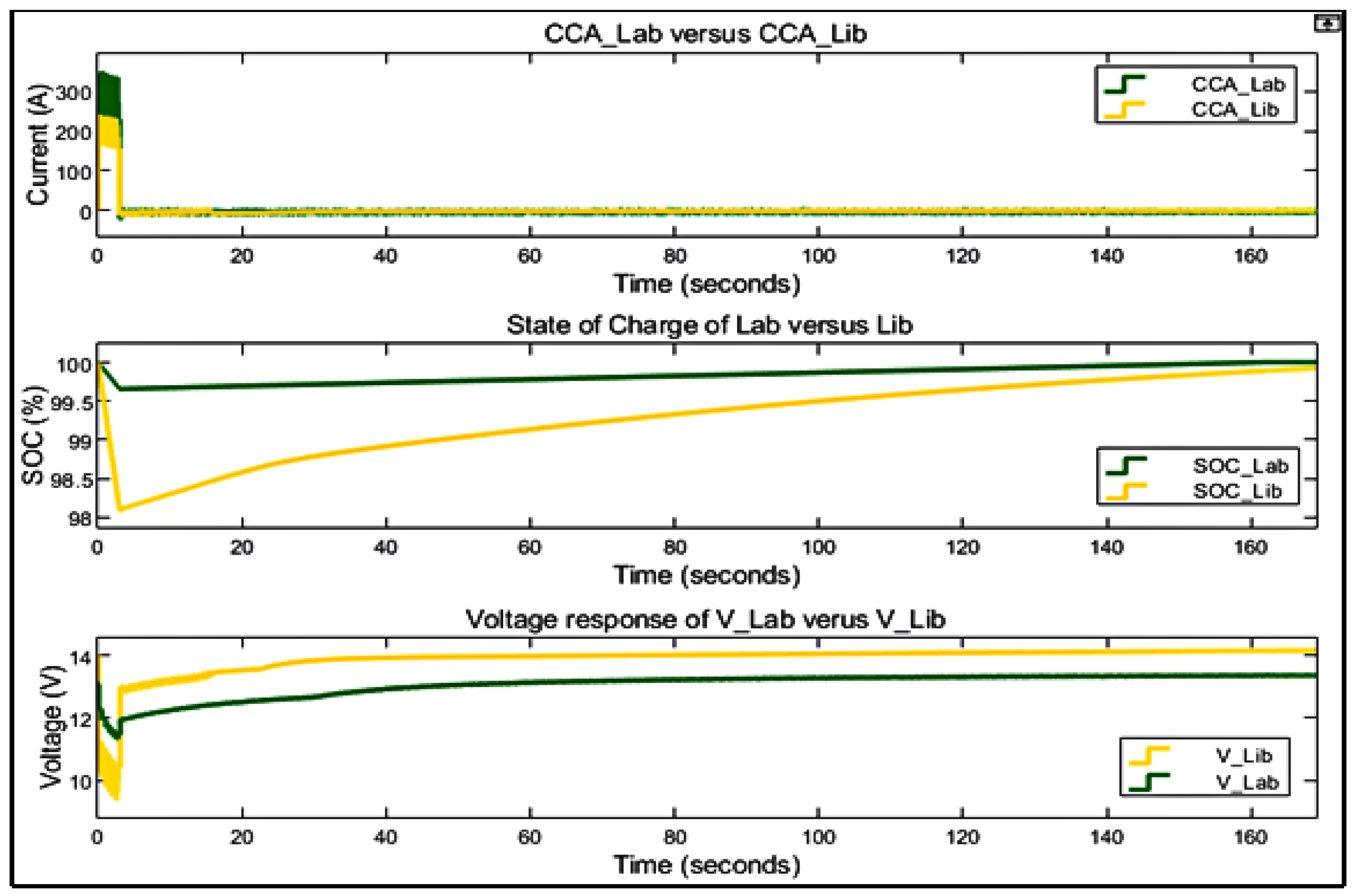

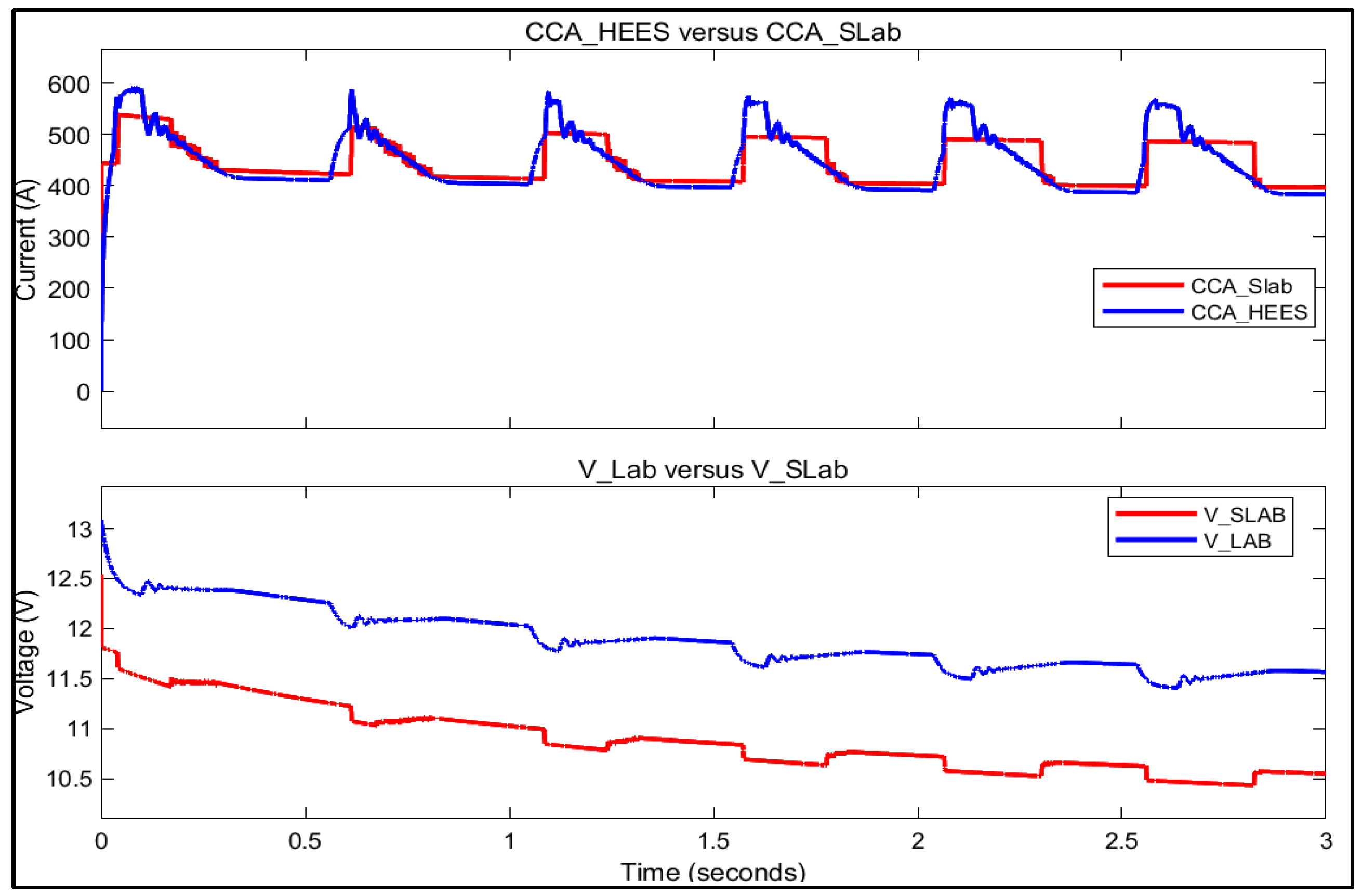

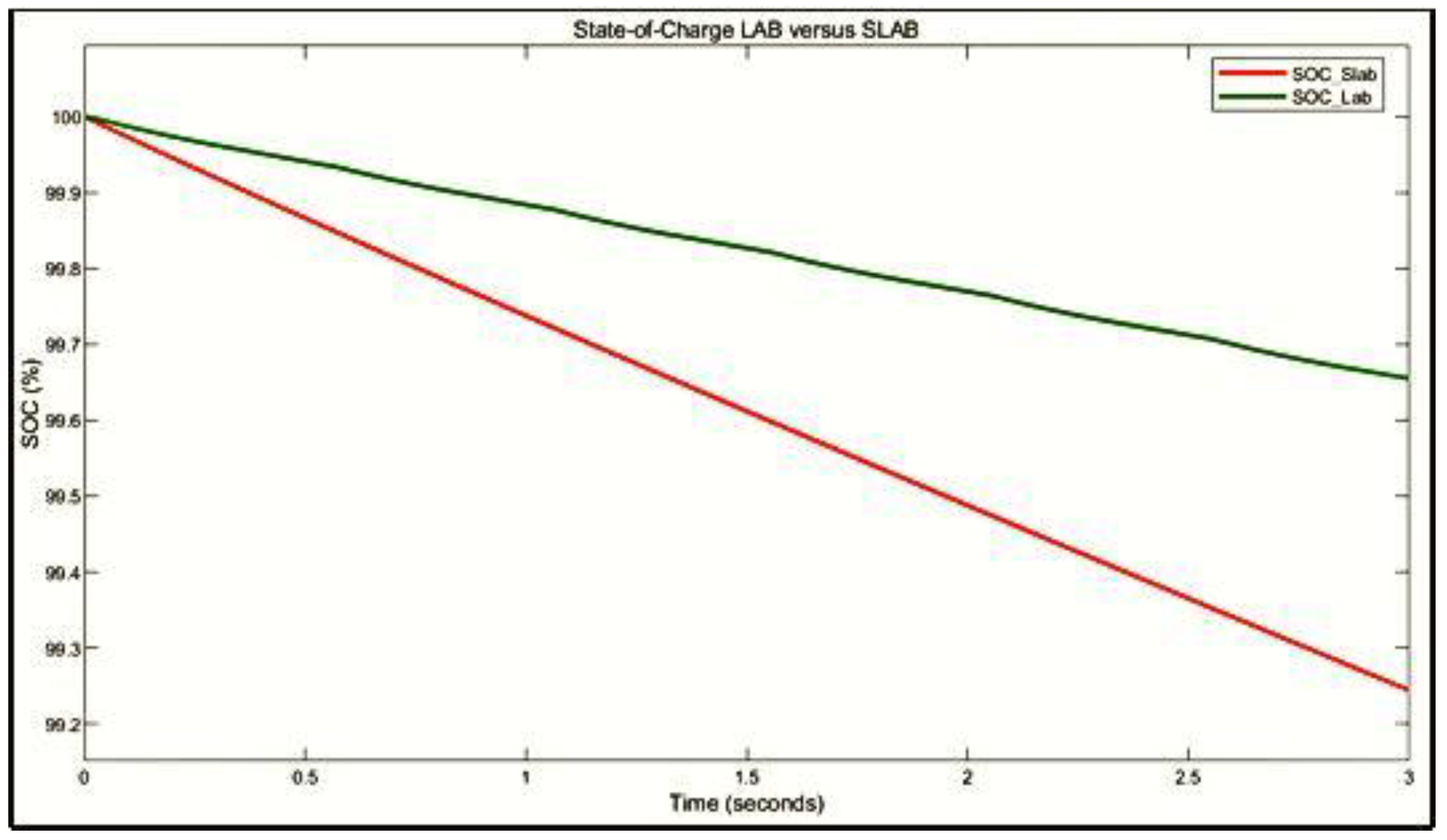

4. Results and Discussions

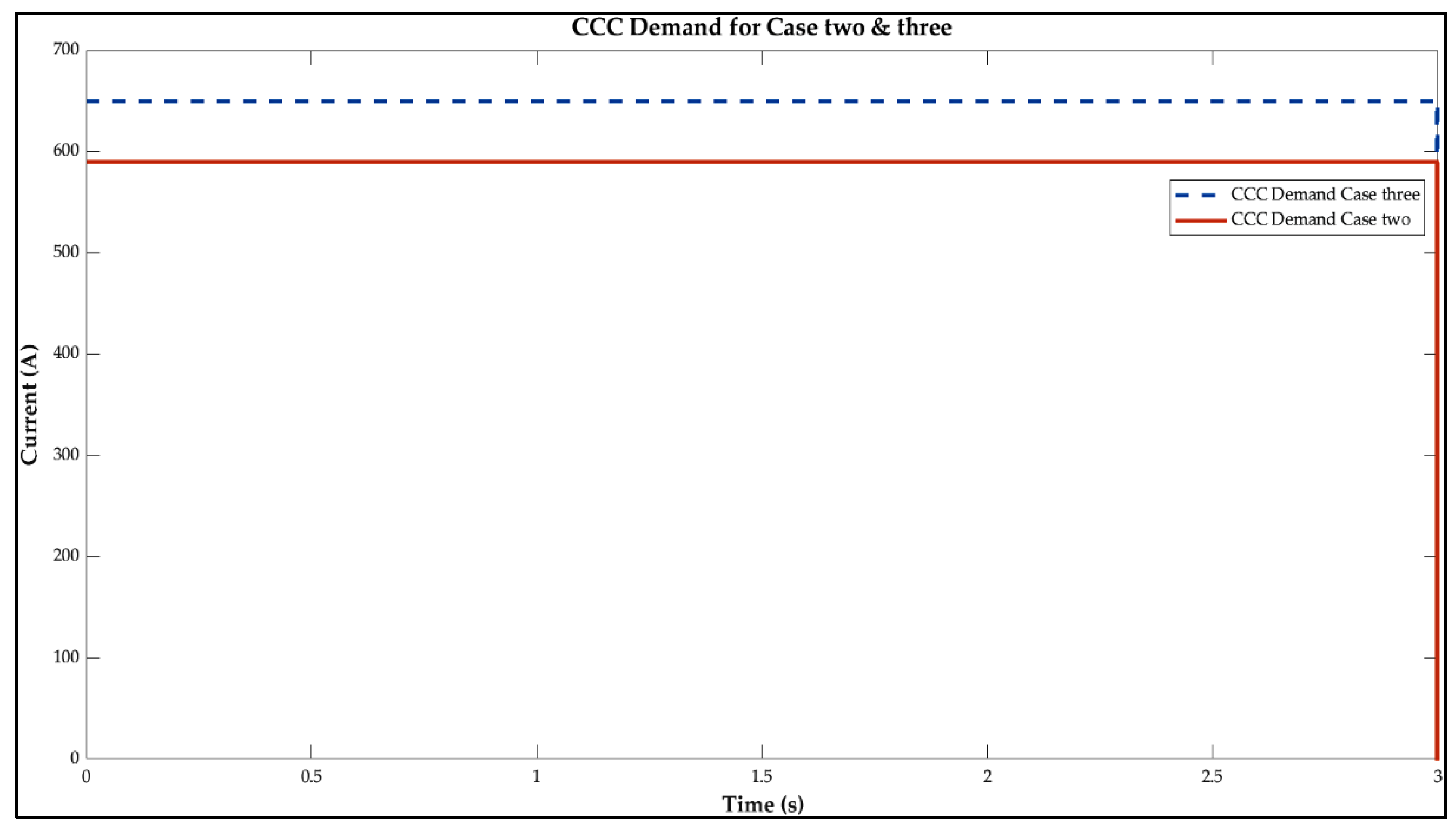

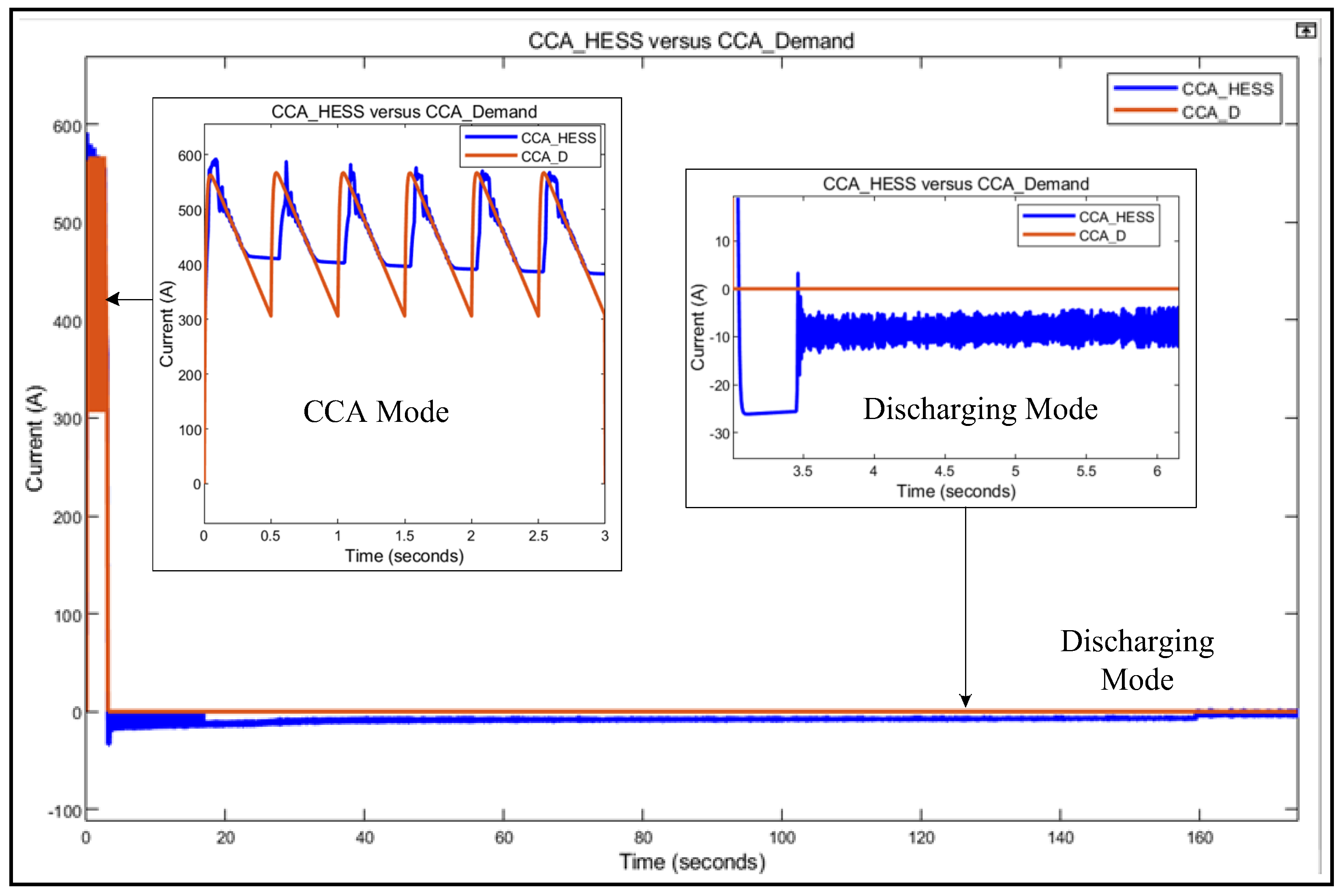

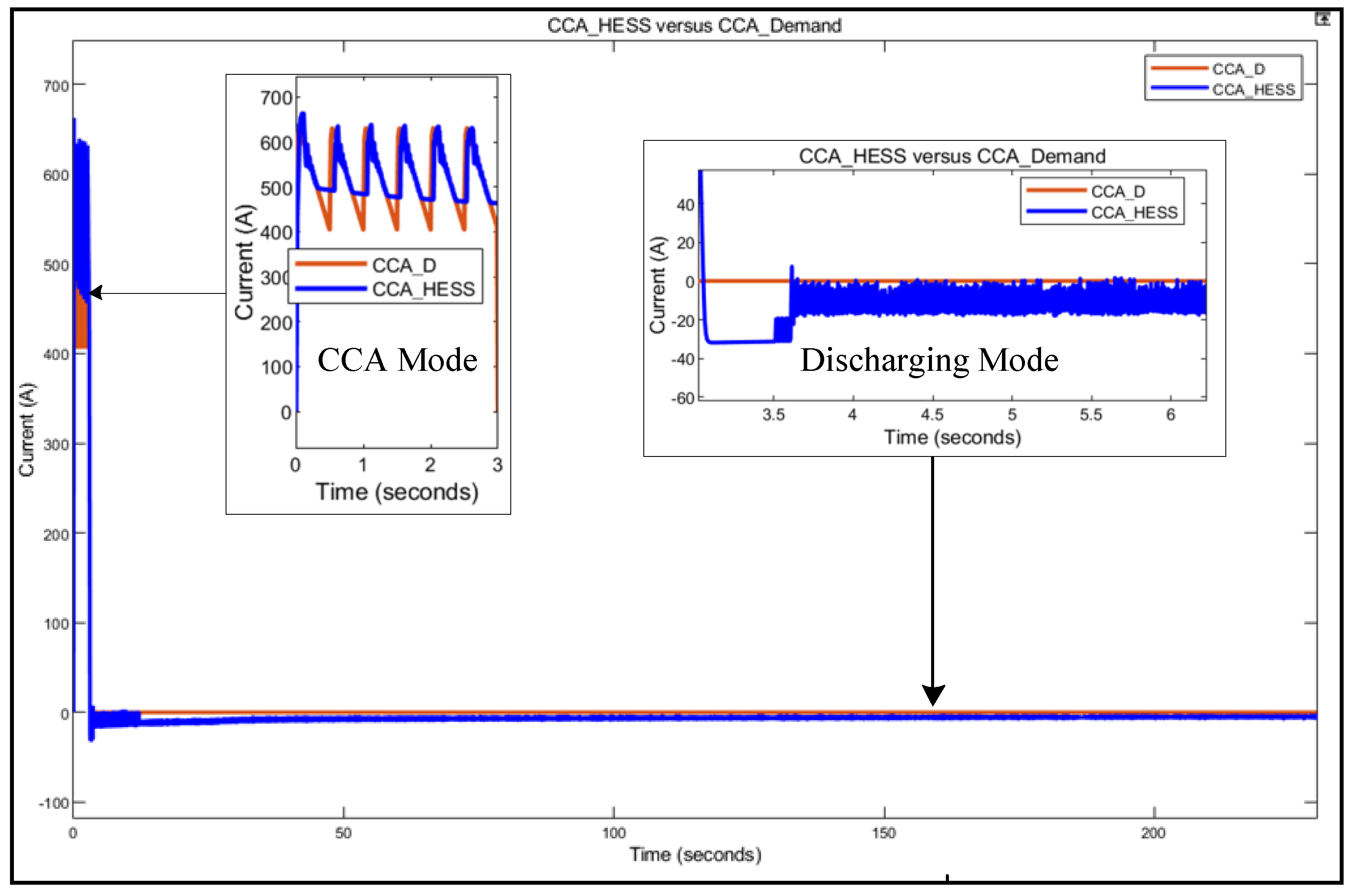

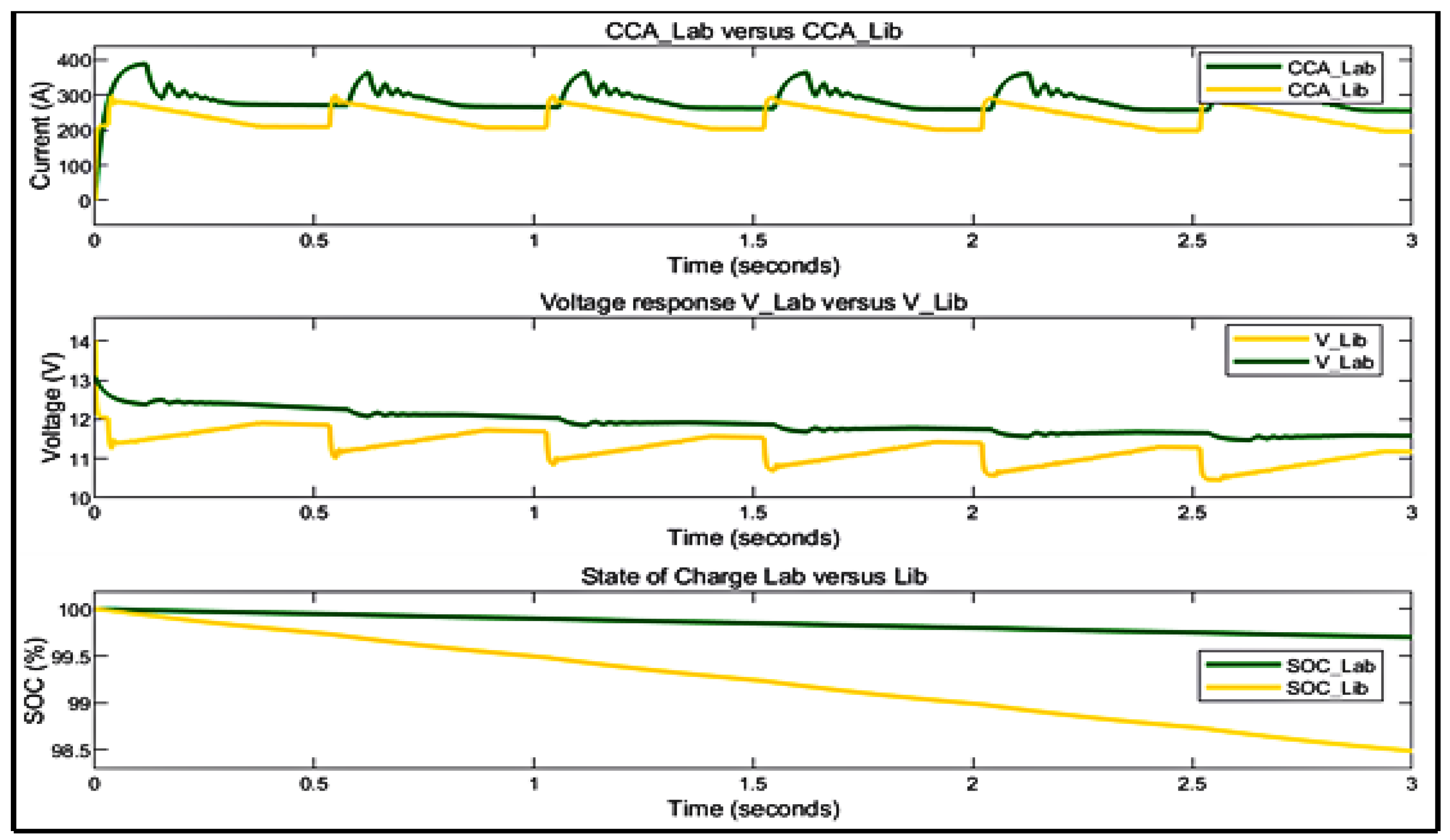

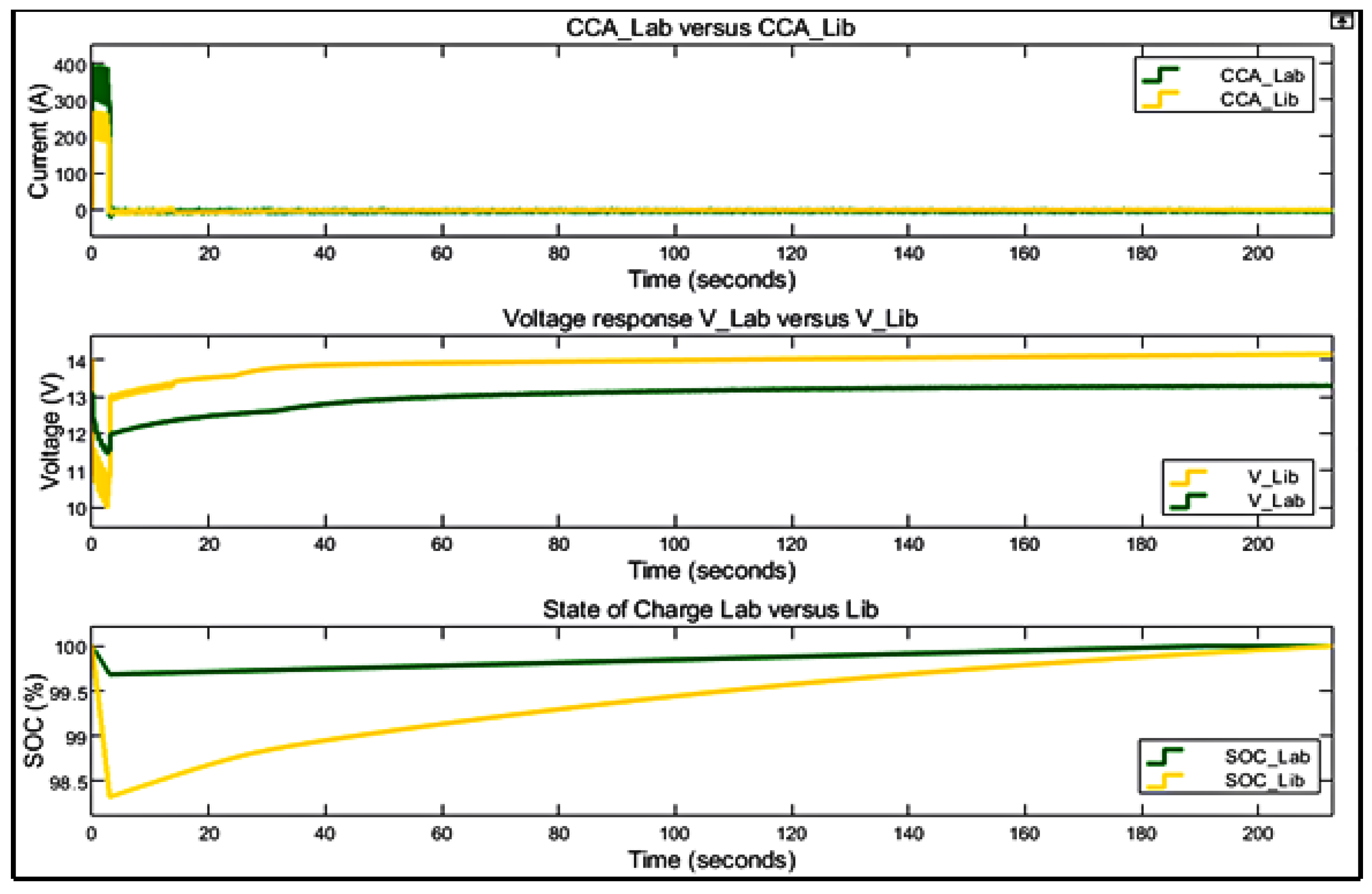

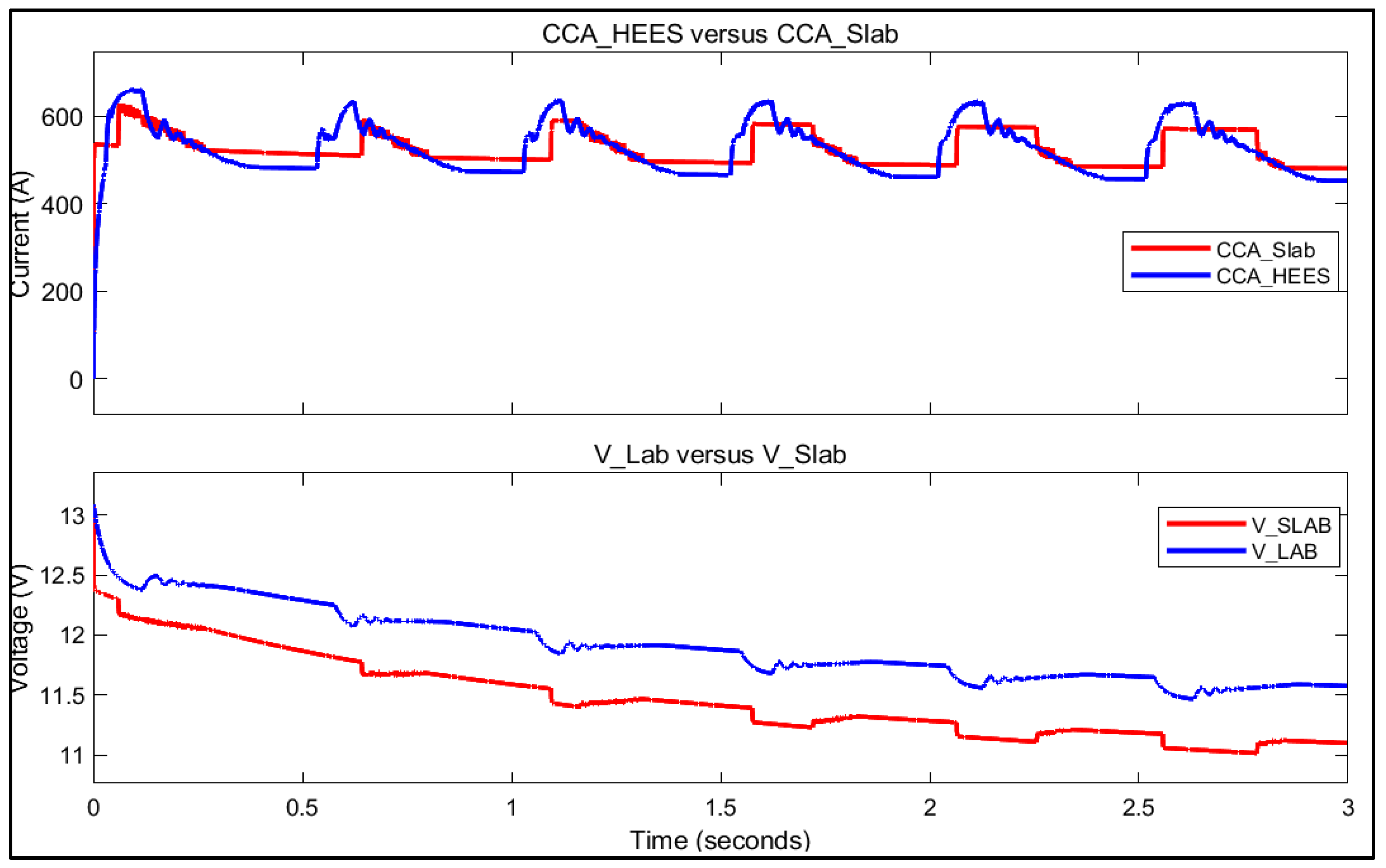

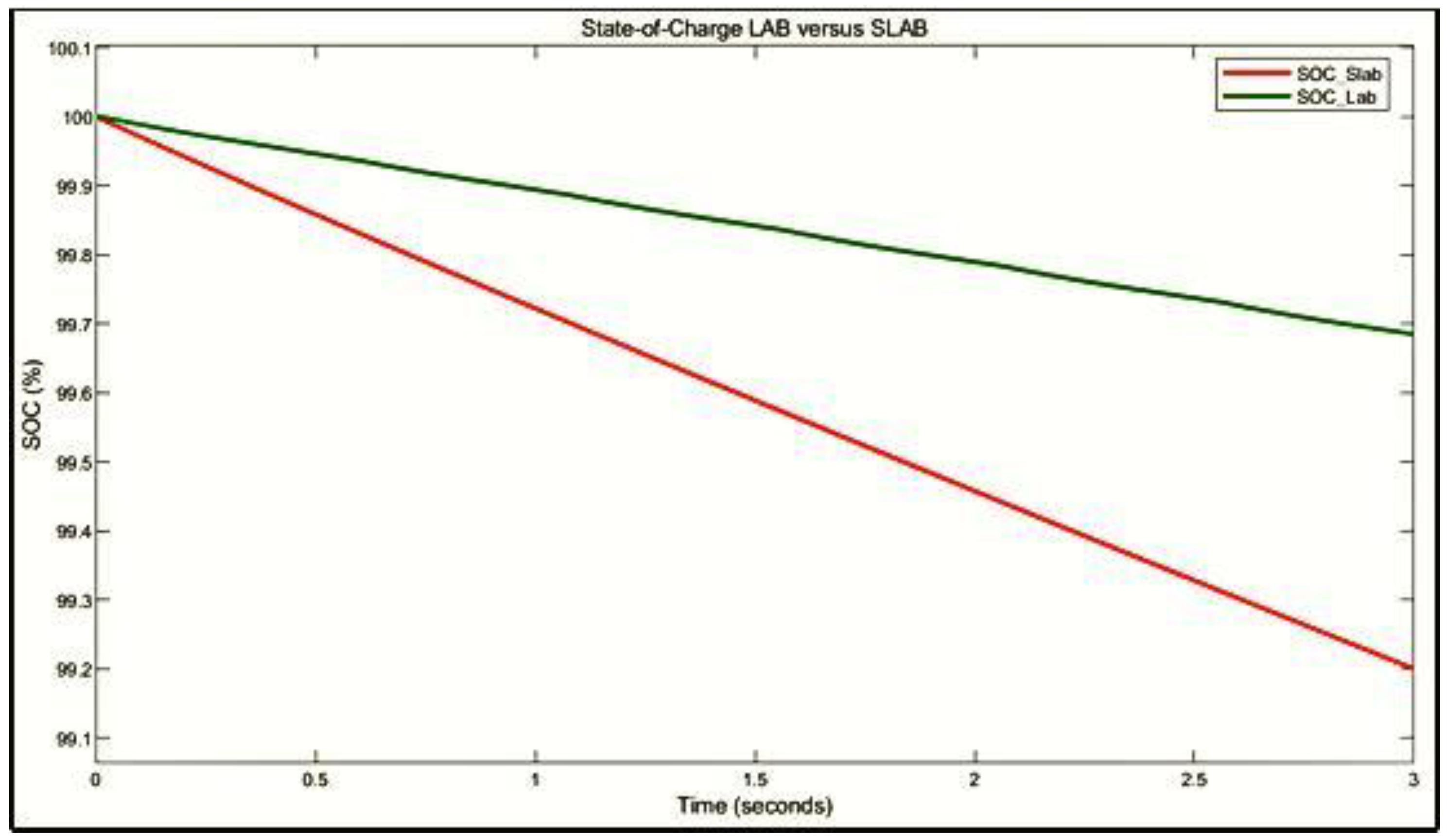

4.1. Case Two (12 V-70 Ah HESS Capacity)

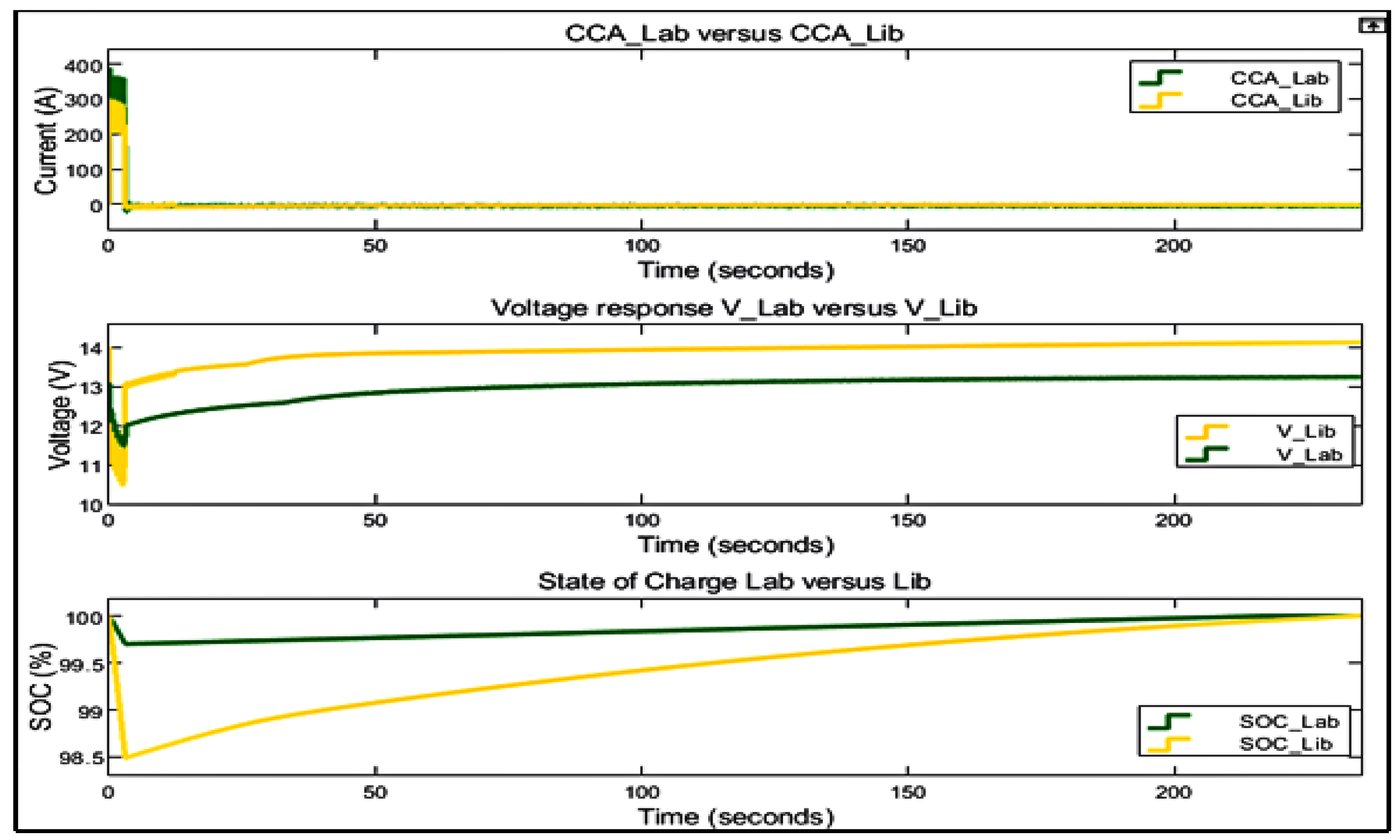

4.2. Case Three (12 V-90 Ah HESS Capacity)

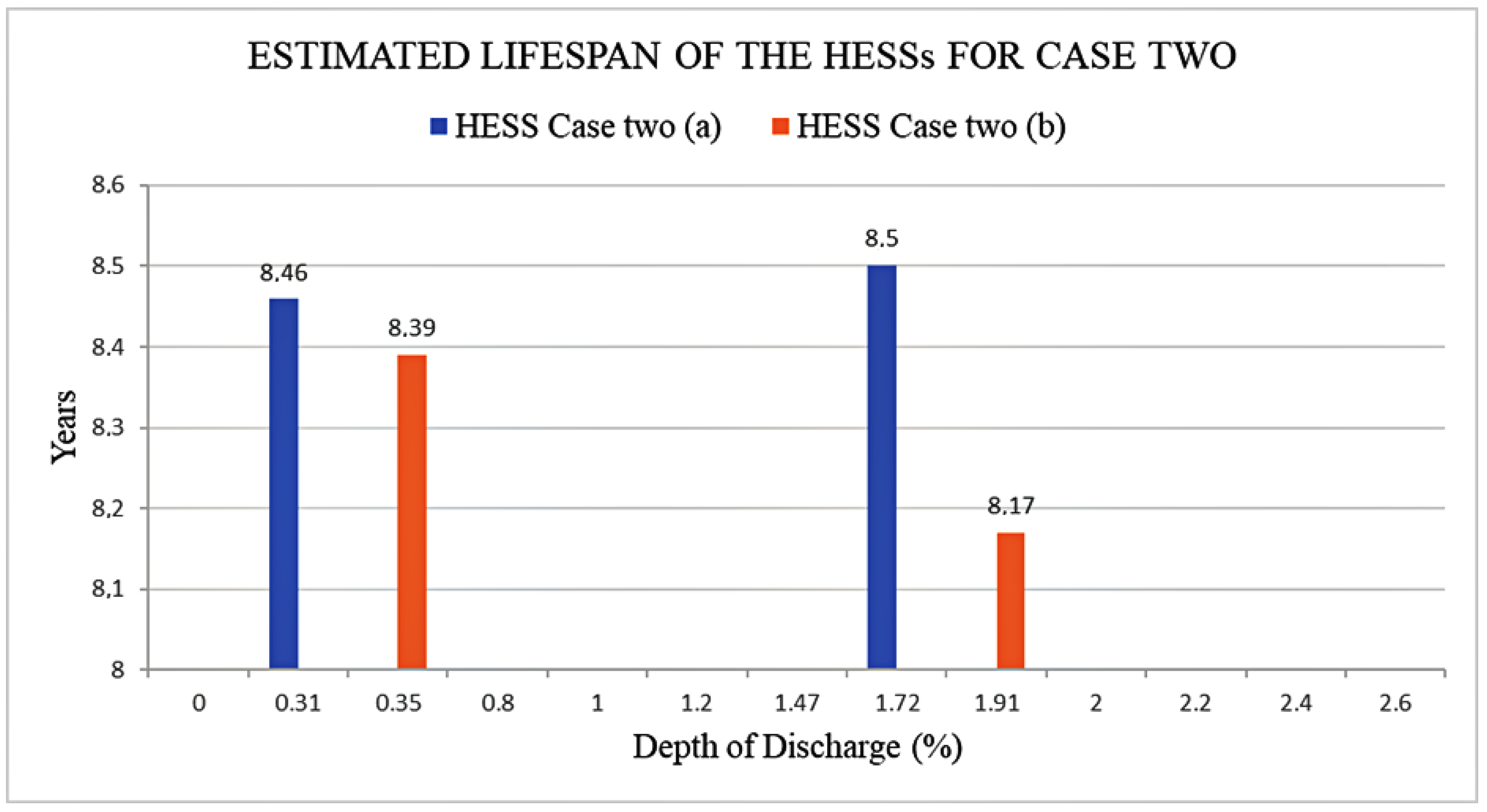

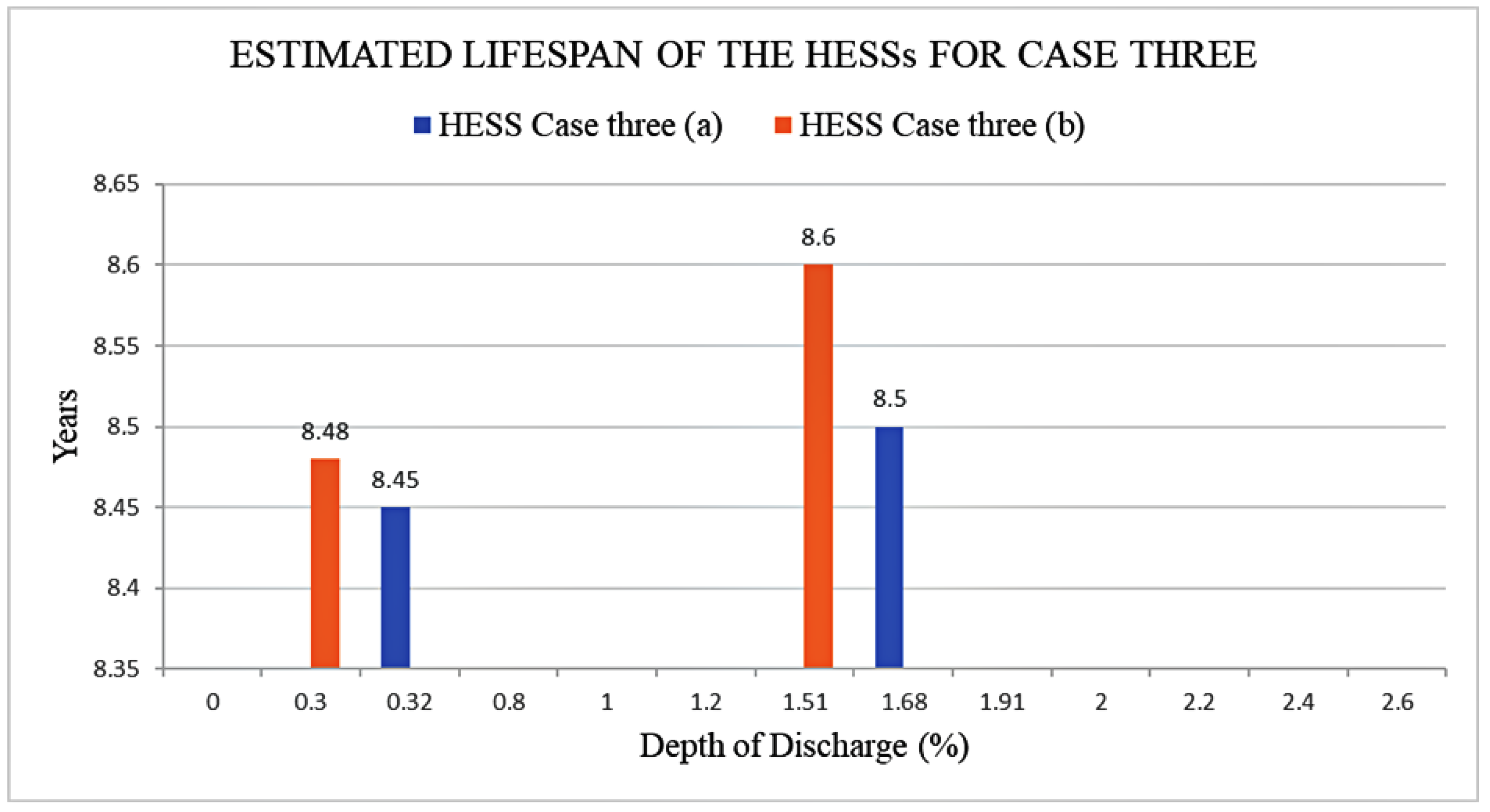

4.3. Lifespan Estimation Results

- On the battery datasheet, the curve showing the number of cycles as a function of DoD until the battery reaches EoL is used;

- The curve shows the battery lifespan in days as a function of float charging voltage and temperature.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Parallel branch capacitances. | |

| Cold-cranking current/ampere. | |

| Hybrid energy storage system cold cranking current. | |

| Lead-acid battery cold cranking current. | |

| Li-ion battery cold cranking current. | |

| Minimum converter output capacitance. | |

| Duty cycle. | |

| Depth of discharge. | |

| End of life. | |

| Switching frequency. | |

| Reference cold cranking current of a hybrid energy storage system. | |

| Alternator current. | |

| Required auxiliary components current. | |

| Battery charging current. | |

| Battery circulating current. | |

| Reference charging current. | |

| Demanded output current. | |

| Inductor current. | |

| Change in minimum inductor current. | |

| Converter output cold cranking current. | |

| Battery depth of discharge. | |

| Minimum inductor value. | |

| Loss of battery life. | |

| The number of cycles performed at instant . | |

| The maximum number of cycles to failure. | |

| The maximum number of battery services. | |

| The number of operations. | |

| Open circuit voltage. | |

| PI control compensation factor. | |

| Actual battery capacity. | |

| Stored battery capacity. | |

| Parallel branch resistances. | |

| Internal battery series resistance. | |

| Single lead-acid battery. | |

| State of charge. | |

| Hybrid energy storage system state of charge. | |

| Initial battery state of charge. | |

| Lead-acid battery state of charge. | |

| Li-ion battery state of charge. | |

| Minimum lead-acid battery state of charge. | |

| Maximum lead-acid battery state of charge. | |

| Minimum li-ion battery state of charge. | |

| Maximum li-ion battery state of charge. | |

| Change in lead-acid battery state of charge. | |

| Change in li-ion battery state of charge. | |

| Sampling time. | |

| Total voltage drops in the RC parallel branch. | |

| Battery voltage. | |

| Charging battery reference voltage. | |

| DC bus voltage link. | |

| High inductor voltage. | |

| Low inductor voltage. | |

| Minimum inductor voltage. | |

| Converter output voltage. | |

| Change in converter output voltage. | |

| Reference voltage. | |

| Battery internal resistance voltage drop. |

References

- Leach, F.; Kalghatgi, G.; Stone, R.; Miles, P. The Scope for Improving the Efficiency and Environmental Impact of Internal Combustion Engines. Transp. Eng. 2020, 1, 100005. [Google Scholar] [CrossRef]

- Electric Cars Fend off Supply Challenges to More than Double Global Sales—Analysis. Available online: https://www.iea.org/commentaries/electric-cars-fend-off-supply-challenges-to-more-than-double-global-sales (accessed on 7 February 2022).

- Balali, Y.; Stegen, S. Review of Energy Storage Systems for Vehicles Based on Technology, Environmental Impacts, and Costs. Renew. Sustain. Energy Rev. 2021, 135, 110185. [Google Scholar] [CrossRef]

- Kollmeyer, P.J.; Jahns, T.M. Aging and Performance Comparison of Absorbed Glass Matte, Enhanced Flooded, PbC, NiZn, and LiFePO4 12 V Start Stop Vehicle Batteries. J. Power Sources 2019, 441, 227139. [Google Scholar] [CrossRef]

- Ferg, E.E.; Schuldt, F.; Schmidt, J. The Challenges of a Li-Ion Starter Lighting and Ignition Battery: A Review from Cradle to Grave. J. Power Sources 2019, 423, 380–403. [Google Scholar] [CrossRef]

- Albers, J.; Meissner, E. 6—Automotive Absorptive Glass-Mat Lead–Acid Batteries: State of the Art. In Lead-Acid Batteries for Future Automobiles; Garche, J., Karden, E., Moseley, P.T., Rand, D.A.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 185–211. ISBN 978-0-444-63700-0. [Google Scholar]

- Dehghani-Sanij, A.R.; Tharumalingam, E.; Dusseault, M.B.; Fraser, R. Study of Energy Storage Systems and Environmental Challenges of Batteries. Renew. Sustain. Energy Rev. 2019, 104, 192–208. [Google Scholar] [CrossRef]

- Moseley, P.T.; Rand, D.A.J.; Garche, J. Study of Energy Storage Systems and Environmental Challenges of Batteries. In Lead-Acid Batteries for Future Automobiles; Garche, J., Karden, E., Moseley, P.T., Rand, D.A.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 601–618. ISBN 978-0-444-63700-0. [Google Scholar]

- Srinivas, S.; Hiremath, N.; Reddy, K.C. Energy Requirement of Hybrid Vehicles. Mater. Today Proc. 2021, 54, 282–287. [Google Scholar] [CrossRef]

- Mandal, S.; Thangarasu, S.; Thong, P.T.; Kim, S.-C.; Shim, J.-Y.; Jung, H.Y. Positive Electrode Active Material Development Opportunities through Carbon Addition in the Lead-Acid Batteries: A Recent Progress. J. Power Sources 2021, 485, 229336. [Google Scholar] [CrossRef]

- Shi, M.; Yuan, J.; Dong, L.; Zhang, D.; Li, A.; Zhang, J. Combining Physicochemical Model with the Equivalent Circuit Model for Performance Prediction and Optimization of Lead-Acid Batteries. Electrochim. Acta 2020, 353, 136567. [Google Scholar] [CrossRef]

- Hu, X.; Zou, C.; Zhang, C.; Li, Y. Technological Developments in Batteries: A Survey of Principal Roles, Types, and Management Needs. IEEE Power Energy Mag. 2017, 15, 20–31. [Google Scholar] [CrossRef]

- Lencwe, M.J.; Chowdhury, S.P.D.; Olwal, T.O. Performance Studies of Lead Acid Batteries for Transport Vehicles. In Proceedings of the 2017 IEEE PES PowerAfrica, Accra, Ghana, 27–30 June 2017; pp. 528–532. [Google Scholar]

- Zhang, Y.; Zhou, C.; Yang, J.; Xue, S.; Gao, H.; Yan, X.; Huo, Q.; Wang, S.; Cao, Y.; Yan, J.; et al. Advances and Challenges in Improvement of the Electrochemical Performance for Lead-Acid Batteries: A Comprehensive Review. J. Power Sources 2022, 520, 230800. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Y.; Chen, Y.; Li, X.; Cheng, J.; Chen, S.; Lin, J.; Zhang, X.; Zhang, Y. Effect of Polyaniline-Modified Lignosulfonate Added to the Negative Active Material on the Performance of Lead-Acid Battery. Electrochim. Acta 2020, 338, 135859. [Google Scholar] [CrossRef]

- Zhang, Y.; Ali, A.; Li, J.; Xie, J.; Shen, P.K. Stereotaxically Constructed Graphene/Nano Lead Composite for Enhanced Cycling Performance of Lead-Acid Batteries. J. Energy Storage 2021, 35, 102192. [Google Scholar] [CrossRef]

- Calborean, A.; Murariu, T.; Morari, C. Optimized Lead-Acid Grid Architectures for Automotive Lead-Acid Batteries: An Electrochemical Analysis. Electrochim. Acta 2021, 372, 137880. [Google Scholar] [CrossRef]

- Fichtner, M. Recent Research and Progress in Batteries for Electric Vehicles. Batter. Supercaps 2022, 5, e202100224. [Google Scholar] [CrossRef]

- Ding, Y.; Cano, Z.P.; Yu, A.; Lu, J.; Chen, Z. Automotive Li-Ion Batteries: Current Status and Future Perspectives. Electrochem. Energy Rev. 2019, 2, 1–28. [Google Scholar] [CrossRef]

- Chen, W.; Liang, J.; Yang, Z.; Li, G. A Review of Lithium-Ion Battery for Electric Vehicle Applications and Beyond. Energy Procedia 2019, 158, 4363–4368. [Google Scholar] [CrossRef]

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A Review on Electric Vehicles: Technologies and Challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Kebede, A.A.; Coosemans, T.; Messagie, M.; Jemal, T.; Behabtu, H.A.; Van Mierlo, J.; Berecibar, M. Techno-Economic Analysis of Lithium-Ion and Lead-Acid Batteries in Stationary Energy Storage Application. J. Energy Storage 2021, 40, 102748. [Google Scholar] [CrossRef]

- Cano, Z.P.; Banham, D.; Ye, S.; Hintennach, A.; Lu, J.; Fowler, M.; Chen, Z. Batteries and Fuel Cells for Emerging Electric Vehicle Markets. Nat. Energy 2018, 3, 279–289. [Google Scholar] [CrossRef]

- Deng, J.; Bae, C.; Denlinger, A.; Miller, T. Electric Vehicles Batteries: Requirements and Challenges. Joule 2020, 4, 511–515. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Hussain, A.; Yusof, Y.; Ker, P.J. State-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications: Issues and Recommendations. IEEE Access 2018, 6, 19362–19378. [Google Scholar] [CrossRef]

- Omariba, Z.B.; Zhang, L.; Sun, D. Review on Health Management System for Lithium-Ion Batteries of Electric Vehicles. Electronics 2018, 7, 72. [Google Scholar] [CrossRef] [Green Version]

- Trahey, L.; Brushett, F.R.; Balsara, N.P.; Ceder, G.; Cheng, L.; Chiang, Y.-M.; Hahn, N.T.; Ingram, B.J.; Minteer, S.D.; Moore, J.S.; et al. Energy Storage Emerging: A Perspective from the Joint Center for Energy Storage Research. Proc. Natl. Acad. Sci. USA 2020, 117, 12550–12557. [Google Scholar] [CrossRef] [PubMed]

- Lencwe, M.J.; Chowdhury, S.P.D.; Olwal, T.O. Hybrid Energy Storage System Topology Approaches for Use in Transport Vehicles: A Review. Energy Sci. Eng. 2022, 10, 1449–1477. [Google Scholar] [CrossRef]

- Nizam, M.; Maghfiroh, H.; Nur Kuncoro, F.; Adriyanto, F. Dual Battery Control System of Lead Acid and Lithium Ferro Phosphate with Switching Technique. World Electr. Veh. J. 2021, 12, 4. [Google Scholar] [CrossRef]

- Yu, X.; Sandhu, N.S.; Yang, Z.; Zheng, M. Suitability of Energy Sources for Automotive Application—A Review. Appl. Energy 2020, 271, 115169. [Google Scholar] [CrossRef]

- Kalghatgi, G. Development of Fuel/Engine Systems—The Way Forward to Sustainable Transport. Engineering 2019, 5, 510–518. [Google Scholar] [CrossRef]

- Singh, A.; Karandikar, P.B.; Kulkarni, N.R. Mitigation of Sulfation in Lead Acid Battery towards Life Time Extension Using Ultra Capacitor in Hybrid Electric Vehicle. J. Energy Storage 2021, 34, 102219. [Google Scholar] [CrossRef]

- Farjah, A.; Ghanbari, T.; Seifi, A.R. Contribution Management of Lead-acid Battery, Li-ion Battery, and Supercapacitor to Handle Different Functions in EVs. Int. Trans. Electr. Energy Syst. 2020, 30, e12155. [Google Scholar] [CrossRef]

- Lencwe, M.J.; Chowdhury, S.P.; Olwal, T.O. A Multi-Stage Approach to a Hybrid Lead Acid Battery and Supercapacitor System for Transport Vehicles. Energies 2018, 11, 2888. [Google Scholar] [CrossRef] [Green Version]

- Lencwe, M.J.; Chowdhury, S.P.D.; Olwal, T.O. An Effective Control for Lead-Acid Performance Enhancement in a Hybrid Battery-Supercapacitor System Used in Transport Vehicles. Sustainability 2021, 13, 13971. [Google Scholar] [CrossRef]

- Madani, S.S.; Schaltz, E.; Knudsen Kær, S. An Electrical Equivalent Circuit Model of a Lithium Titanate Oxide Battery. Batteries 2019, 5, 31. [Google Scholar] [CrossRef] [Green Version]

- Zau, A.T.P.; Lencwe, M.J.; Chowdhury, S.P.D.; Olwal, T.O. A Battery Management Strategy in a Lead-Acid and Lithium-Ion Hybrid Battery Energy Storage System for Conventional Transport Vehicles. Energies 2022, 15, 2577. [Google Scholar] [CrossRef]

- Fiorenti, S.; Guanetti, J.; Onori, S.; Guezennec, Y.; Madella, N.; Saletti, A.; Bovo, S. Modeling and Experimental Validation of PbA Battery-Supercapacitor Energy Storage System. IFAC Proc. Vol. 2013, 46, 307–312. [Google Scholar] [CrossRef]

- Iskak, C.A.; Windarko, N.A.; Rakhmawati, R. Design and Implementation Bidirectional DC-DC Converter for Load Sharing and Charging Battery. In Proceedings of the 2019 International Seminar on Application for Technology of Information and Communication (iSemantic), Semarang, Indonesia, 21–22 September 2019; pp. 455–459. [Google Scholar]

- Chao, K.H.; Tseng, M.C.; Huang, C.H.; Liu, Y.G.; Huang, L.C. Design and Implementation of a Bidirectional DC-DC Converter for Stand-Alone Photovoltaic Systems. Int. J. Comput. Consum. Control IJ3C 2013, 2, 44–55. [Google Scholar]

- Ceraolo, M.; Huria, T.; Pede, G.; Vellucci, F. Lithium-Ion Starting-Lighting-Ignition Batteries: Examining the Feasibility. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011; pp. 1–6. [Google Scholar]

- Bai, Y.; Wang, D. Fundamentals of Fuzzy Logic Control—Fuzzy Sets, Fuzzy Rules and Defuzzifications. In Advanced Fuzzy Logic Technologies in Industrial Applications; Springer: Berlin/Heidelberg, Germany, 2006; pp. 17–36. [Google Scholar]

- Jadhav, A.D.; Nair, S. Battery Management Using Fuzzy Logic Controller. J. Phys. Conf. Ser. 2019, 1172, 012093. [Google Scholar] [CrossRef]

- Ross, T.J. Fuzzy Logic with Engineering Applications; John Wiley & Sons: Hoboken, NJ, USA, 2005; ISBN 0-470-86076-6. [Google Scholar]

- Sun, Q.; Xing, D.; Yang, Q.; Zhang, H.; Patel, J. A New Design of Fuzzy Logic Control for SMES and Battery Hybrid Storage System. In Proceedings of the 8th International Conference on Applied Energy—ICAE2016, Beijing, China, 8–11 October 2016. [Google Scholar] [CrossRef]

- Andrenacci, N.; Chiodo, E.; Lauria, D.; Mottola, F. Life Cycle Estimation of Battery Energy Storage Systems for Primary Frequency Regulation. Energies 2018, 11, 3320. [Google Scholar] [CrossRef] [Green Version]

- Jeong, S.; Jang, Y.J.; Kum, D. Economic Analysis of the Dynamic Charging Electric Vehicle. IEEE Trans. Power Electron. 2015, 30, 6368–6377. [Google Scholar] [CrossRef]

- Sauer, D.U.; Wenzl, H. Comparison of Different Approaches for Lifetime Prediction of Electrochemical Systems—Using Lead-Acid Batteries as Example. J. Power Sources 2008, 176, 534–546. [Google Scholar] [CrossRef]

- Schaltz, E.; Khaligh, A.; Rasmussen, P.O. Influence of Battery/Ultracapacitor Energy-Storage Sizing on Battery Lifetime in a Fuel Cell Hybrid Electric Vehicle. IEEE Trans. Veh. Technol. 2009, 58, 3882–3891. [Google Scholar] [CrossRef]

- ForbattSA. Forbatt 12 V VRLA 70 AH FB12-70. 2021. Available online: https://forbatt.co/shop/uncategorized/forbatt-installations-accessories/intrusion-accessories-forbatt-installations-accessories/motorcylce-batteries/forbatt12v-vrla-70ahfb12-70/ (accessed on 24 January 2022).

- Meissner, E.; Richter, G. The Challenge to the Automotive Battery Industry: The Battery Has to Become an Increasingly Integrated Component within the Vehicle Electric Power System. J. Power Sources 2005, 144, 438–460. [Google Scholar] [CrossRef]

- Noh, T.-W.; Ahn, J.-H.; Lee, B.K. Cranking Capability Estimation Algorithm Based on Modeling and Online Update of Model Parameters for Li-Ion SLI Batteries. Energies 2019, 12, 3365. [Google Scholar] [CrossRef] [Green Version]

| 12 V-70 Ah Battery | ||||||||

| Battery Type | Boost Mode | Buck Mode | ||||||

| Vbatt (V) | VDC_OUT (V) | Lmin (nH) | Cmin | Dboost | Dbuck | Vbus (V) | Vchar (V) | |

| LAB | 12.2733 | 13 | 58.41 | 2.2 mF | 0.056 | 0.9 | 14.5 | 13.1 |

| LIB | 12.7954 | 13 | 11.38 | 871 µF | 0.016 | 0.97 | 14.5 | 14.2 |

| 12 V-90 Ah Battery | ||||||||

| LAB | 12.2733 | 13 | 53.02 | 2.4 mF | 0.056 | 0.9 | 14.5 | 13.1 |

| LIB | 12.7954 | 13 | 1.03 | 960 µF | 0.016 | 0.97 | 14.5 | 14.2 |

| Case No. | Battey Type | Capacity (Ah) | CCC (A) | Load Share (%) | |

|---|---|---|---|---|---|

| Two | a | HESS | 70.4 | 599.1 | 100 |

| LAB | 60 | 326.9 | 53 | ||

| LIB | 7.8 | 290.3 | 47 | ||

| b | HESS | 69.8 | 596.2 | 100 | |

| LAB | 62 | 378.5 | 62.9 | ||

| LIB | 10.4 | 222.9 | 37.1 | ||

| Three | a | HESS | 90.4 | 653.2 | - |

| LAB | 80 | 386.7 | 59.7 | ||

| LIB | 10.4 | 260.5 | 40.3 | ||

| b | HESS | 90 | 665.5 | 100 | |

| LAB | 77 | 379.1 | 56.1 | ||

| LIB | 13 | 293.4 | 43.9 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lencwe, M.J.; Zau, A.T.P.; Chowdhury, S.P.D.; Olwal, T.O. Integrated Fuzzy-Logic and Triple-Loop PI-Based Management Strategy for a Lead-Acid/Lithium-Ion Hybrid Battery Energy Storage System. Appl. Sci. 2022, 12, 6910. https://doi.org/10.3390/app12146910

Lencwe MJ, Zau ATP, Chowdhury SPD, Olwal TO. Integrated Fuzzy-Logic and Triple-Loop PI-Based Management Strategy for a Lead-Acid/Lithium-Ion Hybrid Battery Energy Storage System. Applied Sciences. 2022; 12(14):6910. https://doi.org/10.3390/app12146910

Chicago/Turabian StyleLencwe, Mpho J., Andre T. Puati Zau, S. P. Daniel Chowdhury, and Thomas O. Olwal. 2022. "Integrated Fuzzy-Logic and Triple-Loop PI-Based Management Strategy for a Lead-Acid/Lithium-Ion Hybrid Battery Energy Storage System" Applied Sciences 12, no. 14: 6910. https://doi.org/10.3390/app12146910

APA StyleLencwe, M. J., Zau, A. T. P., Chowdhury, S. P. D., & Olwal, T. O. (2022). Integrated Fuzzy-Logic and Triple-Loop PI-Based Management Strategy for a Lead-Acid/Lithium-Ion Hybrid Battery Energy Storage System. Applied Sciences, 12(14), 6910. https://doi.org/10.3390/app12146910