Analysis of Healthcare Push and Pull Task via JACK: Predicted Joint Accuracy during Full-Body Simulation

Abstract

:1. Introduction

2. Materials and Methods

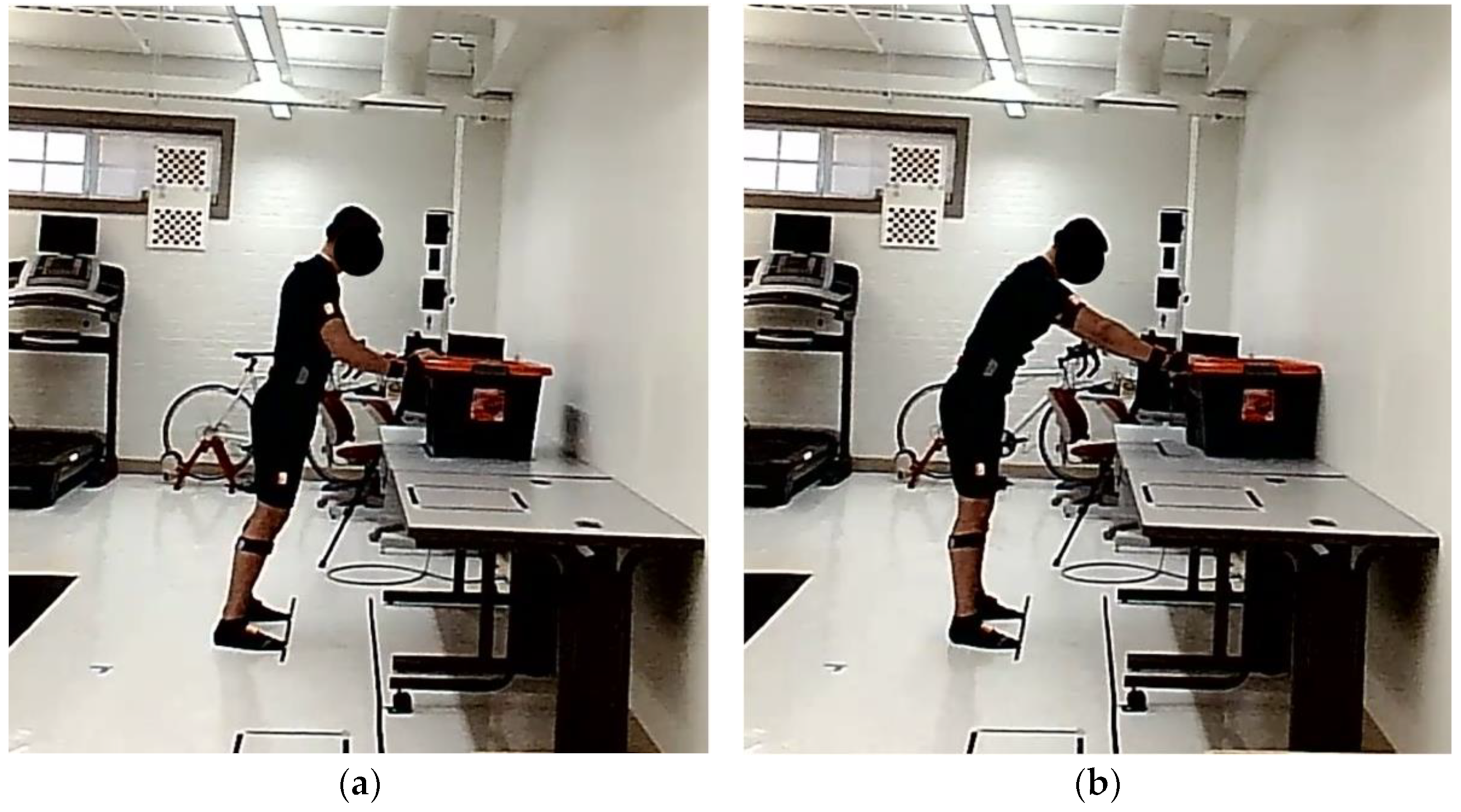

2.1. Participants and System Set-Up

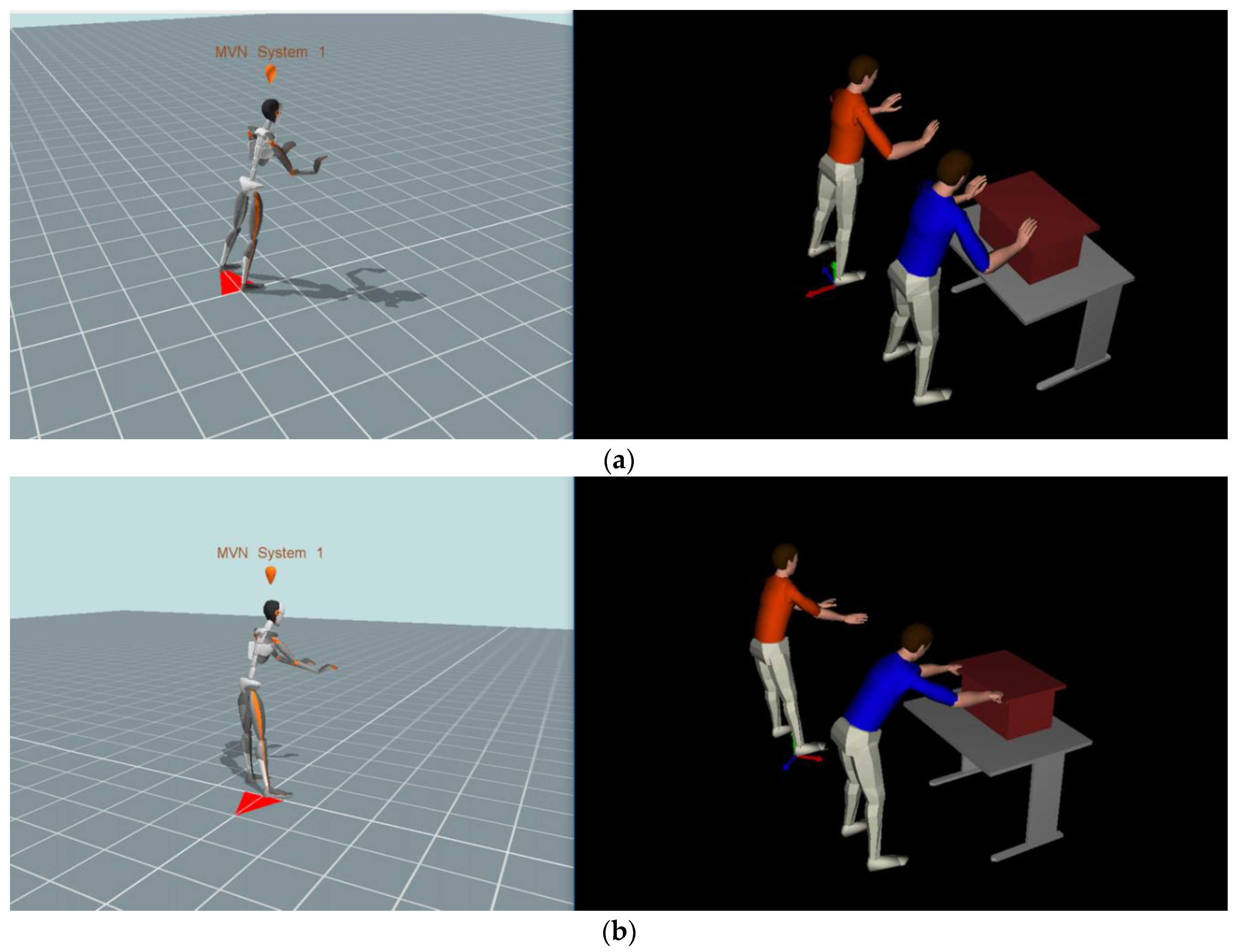

2.2. Operation Tasks

2.3. Data Collection

2.4. Data Analysis

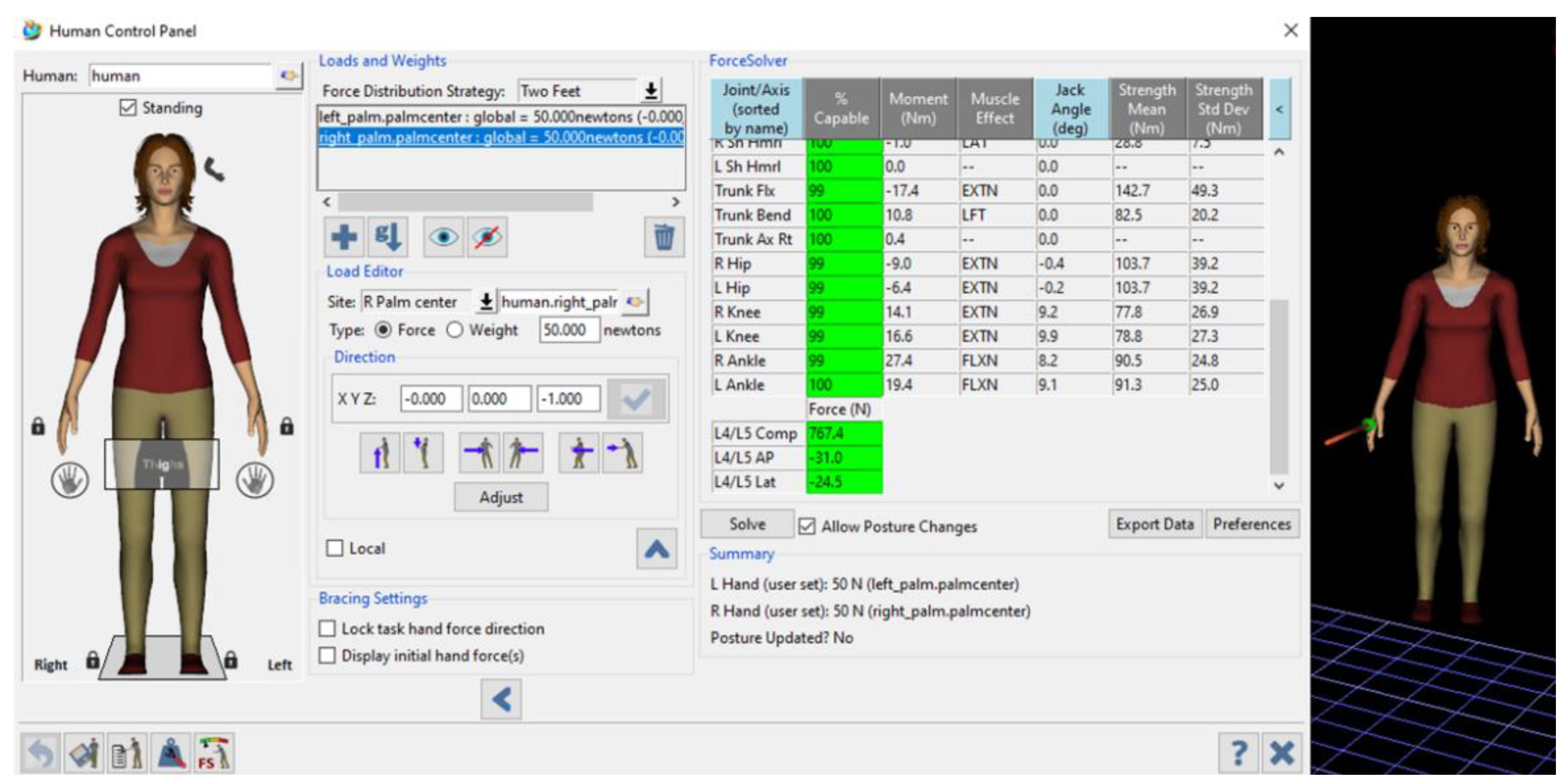

2.4.1. Force Settings in Tasks

2.4.2. Lower Back Analysis

2.4.3. Joint Angle Comparison

2.4.4. Statistical Analysis

3. Results

3.1. Lower Back Analysis

3.1.1. Push Task

3.1.2. Pull Task

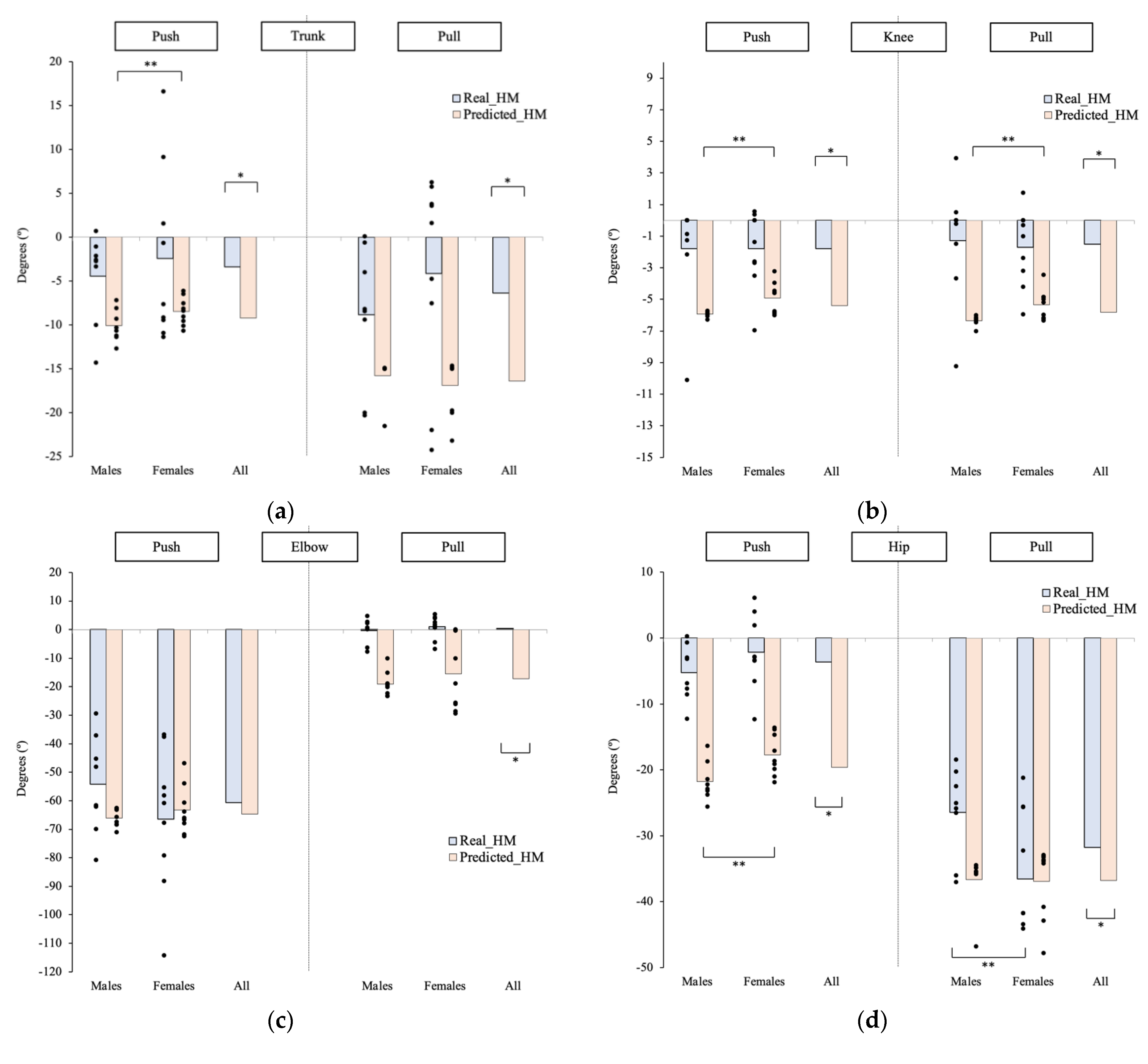

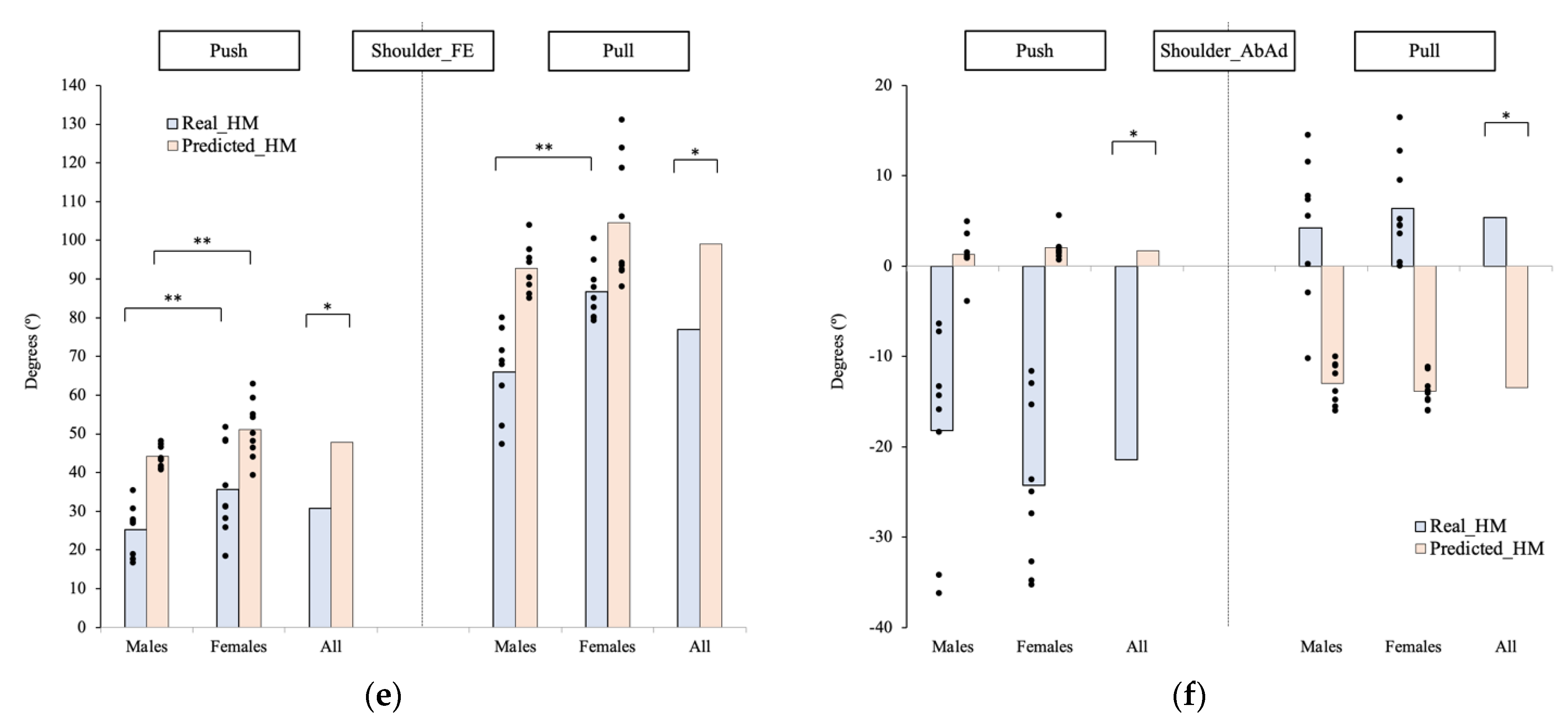

3.2. Joint Angle Analysis

3.2.1. Push Task

3.2.2. Pull Task

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Bureal of Labour Statistics, U.S. Department of Labor. Employer-Reported Workplace Injuries and Illnesses—2020. Available online: https://www.bls.gov/news.release/pdf/osh.pdf (accessed on 3 November 2021).

- National Institute of Neurological Disorders and Stroke (NIH). Low Back Pain. Available online: https://www.ninds.nih.gov/health-information/disorders/back-pain (accessed on 3 May 2022).

- Freburger, J.K.; Holmes, G.M.; Agans, R.P.; Jackman, A.M.; Darter, J.D.; Wallace, A.S.; Castel, L.D.; Kalsbeek, W.D.; Carey, T.S. The rising prevalence of chronic low back pain. Arch. Intern. Med. 2009, 169, 251–258. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Michigan Municipal Workers’ Compensation Fund Safety and Health Resource Manual (MML). Michigan Municipal League: A Basic Plan for Preventing Back Injuries. Available online: https://www.mml.org/insurance/risk_resources/publications/s_and_h_manual/13A.PDF (accessed on 18 April 2022).

- Insurance Information Institute (III). Steps to Reduce Workplace Injuries. Available online: https://www.iii.org/article/steps-to-reduce-workplace-injuries (accessed on 2 March 2022).

- Occupational Safety and Health Administration (OSHA); United States Department of Labor. Training Requirements in OSHA Standards. Available online: https://www.osha.gov/sites/default/files/publications/osha2254.pdf (accessed on 26 May 2022).

- Schall, M.C., Jr.; Fethke, N.B.; Roemig, V. Digital human modeling in the occupational safety and health process: An application in manufacturing. IISE Trans. Occup. Ergon. Hum. Factors 2018, 6, 64–75. [Google Scholar] [CrossRef] [PubMed]

- Grobelny, J.; Michalski, R. Preventing work-related musculoskeletal disorders in manufacturing by digital human modeling. Int. J. Environ. Res. Public Health 2020, 17, 8676. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.; Hernandez, J.; Schweitzer, E.; Littman, A. The Accuracy of Dynamic Simulation with the Use of TSB within JACK Siemens PLM software. In Proceedings of the 6th North American International Conference on Industrial Engineering and Operations Management, Monterrey, Mexico, 3–5 November 2021. [Google Scholar]

- Chaffin, D.B. Improving digital human modelling for proactive ergonomics in design. Ergonomics 2005, 48, 478–491. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.; Piovesan, D.; Conley, K. The Effect of Pulling Effort on Lumbar Spine via Applying Digital Human Modeling Technology. In Proceedings of the Institute of Industrial and Systems Engineers (IISE) Annual Conference, Seattle, WA, USA, 21–24 May 2022. [Google Scholar]

- Kajaks, T.; Stephens, A.; Potvin, J.R. The effect of manikin anthropometrics and posturing guidelines on proactive ergonomic assessments using digital human models. Int. J. Hum. Factors Model. Simul. 2011, 2, 236–253. [Google Scholar] [CrossRef]

- Zhao, W.; Madhavan, V.; Fernandez, J. Study of the Accuracy of Postures Obtained by Immersive Virtual Reality for Use in Ergonomic Analysis. In Proceedings of the 13th Annual International Conference on Industrial Engineering Theory, Applications and Practice, Las Vegas, NV, USA, 7–10 September 2008. [Google Scholar]

- Park, J.; Jung, K.; Chang, J.; Kwon, J.; You, H. Evaluation of driving posture prediction in digital human simulation using RAMSIS®. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting; Sage: Los Angeles, CA, USA, 2011; pp. 1711–1715. [Google Scholar]

- Piovesan, D.; Pierobon, A.; DiZio, P.; Lackner, J.R. Comparative analysis of methods for estimating arm segment parameters and joint torques from inverse dynamics. J. Biomech. Eng. 2011, 133, 031003. [Google Scholar] [CrossRef] [PubMed]

- Xsens. Xsens 3D Motion Tracking. Available online: https://tutorial.xsens.com/?_ga=2.191254569.2072040727.1649269985-1839686643.1648751945 (accessed on 9 June 2022).

- Waters, T.R.; Putz-Anderson, V.; Garg, A. Applications Manual for the Revised NIOSH Lifting Equation; U.S. Department of Health and Human Services: Cincinnati, OH, USA, 1994.

- Watson, K. What’s an Average Shoulder Width? Available online: https://www.healthline.com/health/average-shoulder-width (accessed on 26 October 2018).

- Dempster, L. Patterns of Human Motion; Prentice-Hall, Inc.: Englewood Cliffs, NJ, USA, 1971. [Google Scholar]

- Mount Nittany Health (MNH). Back Safety: Pushing and Pulling. Available online: https://www.mountnittany.org/wellness-article/pushing-and-pulling-back-safety (accessed on 7 May 2021).

- University of Rochester Medical Center (UoRMC). The Right Way to Push and Pull. Available online: https://www.urmc.rochester.edu/encyclopedia/content.aspx?contenttypeid=1&contentid=4458 (accessed on 25 February 2022).

- Chen, G.; Liu, L.; Yu, J. A comparative study on strength between American college male and female students in Caucasian and Asian populations. Sport Sci. Rev. 2012, 21, 153. [Google Scholar] [CrossRef]

- Han, K.-S.; Rohlmann, A.; Zander, T.; Taylor, W.R. Lumbar spinal loads vary with body height and weight. Med. Eng. Phys. 2013, 35, 969–977. [Google Scholar] [CrossRef] [PubMed]

- Rohlmann, A.; Bauer, L.; Zander, T.; Bergmann, G.; Wilke, H.-J. Determination of trunk muscle forces for flexion and extension by using a validated finite element model of the lumbar spine and measured in vivo data. J. Biomech. 2006, 39, 981–989. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, X.; Piovesan, D.; Arenas, M.; Liu, H. Analysis of Healthcare Push and Pull Task via JACK: Predicted Joint Accuracy during Full-Body Simulation. Appl. Sci. 2022, 12, 6450. https://doi.org/10.3390/app12136450

Ji X, Piovesan D, Arenas M, Liu H. Analysis of Healthcare Push and Pull Task via JACK: Predicted Joint Accuracy during Full-Body Simulation. Applied Sciences. 2022; 12(13):6450. https://doi.org/10.3390/app12136450

Chicago/Turabian StyleJi, Xiaoxu, Davide Piovesan, Maria Arenas, and He Liu. 2022. "Analysis of Healthcare Push and Pull Task via JACK: Predicted Joint Accuracy during Full-Body Simulation" Applied Sciences 12, no. 13: 6450. https://doi.org/10.3390/app12136450

APA StyleJi, X., Piovesan, D., Arenas, M., & Liu, H. (2022). Analysis of Healthcare Push and Pull Task via JACK: Predicted Joint Accuracy during Full-Body Simulation. Applied Sciences, 12(13), 6450. https://doi.org/10.3390/app12136450