Variability in the Solid Particle Density and Its Influence on the Corresponding Void Ratio and Dry Density: A Case Study Conducted on the MBT Reject Waste Stream from the MBT Plant in Marišćina, Croatia

Abstract

:1. Introduction

2. Materials and Methods

2.1. Origin of Waste Specimens

2.2. Experimental Program

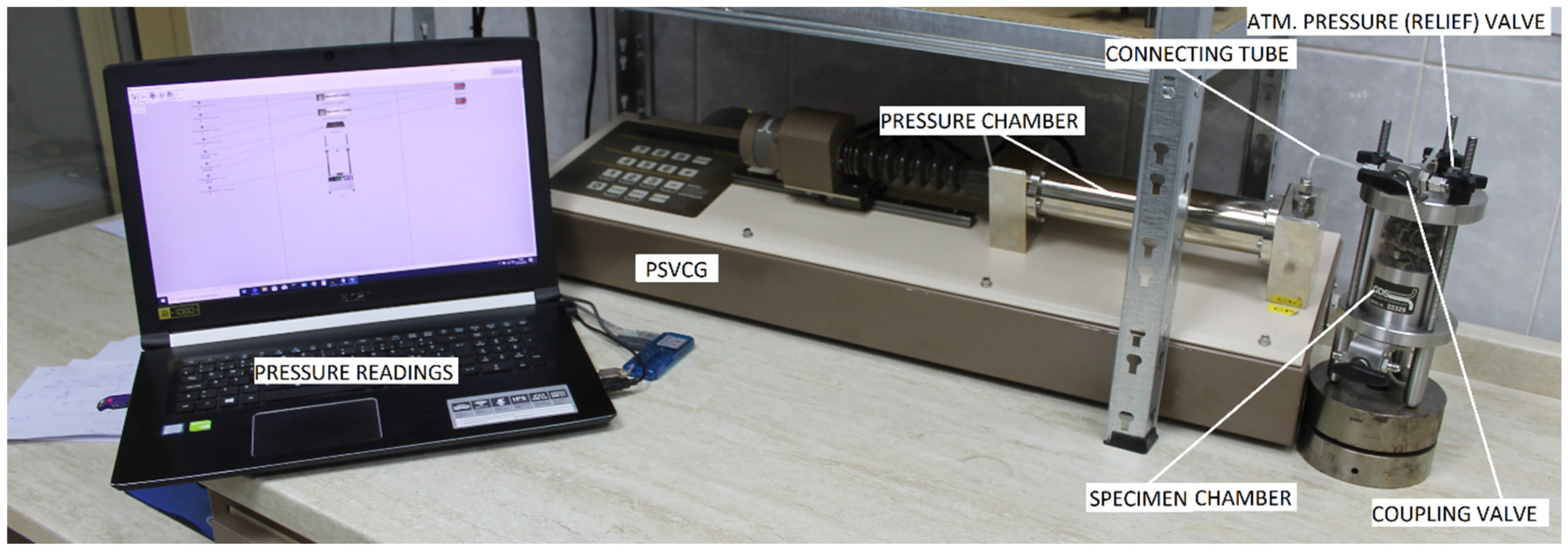

2.2.1. Air Pycnometry Method

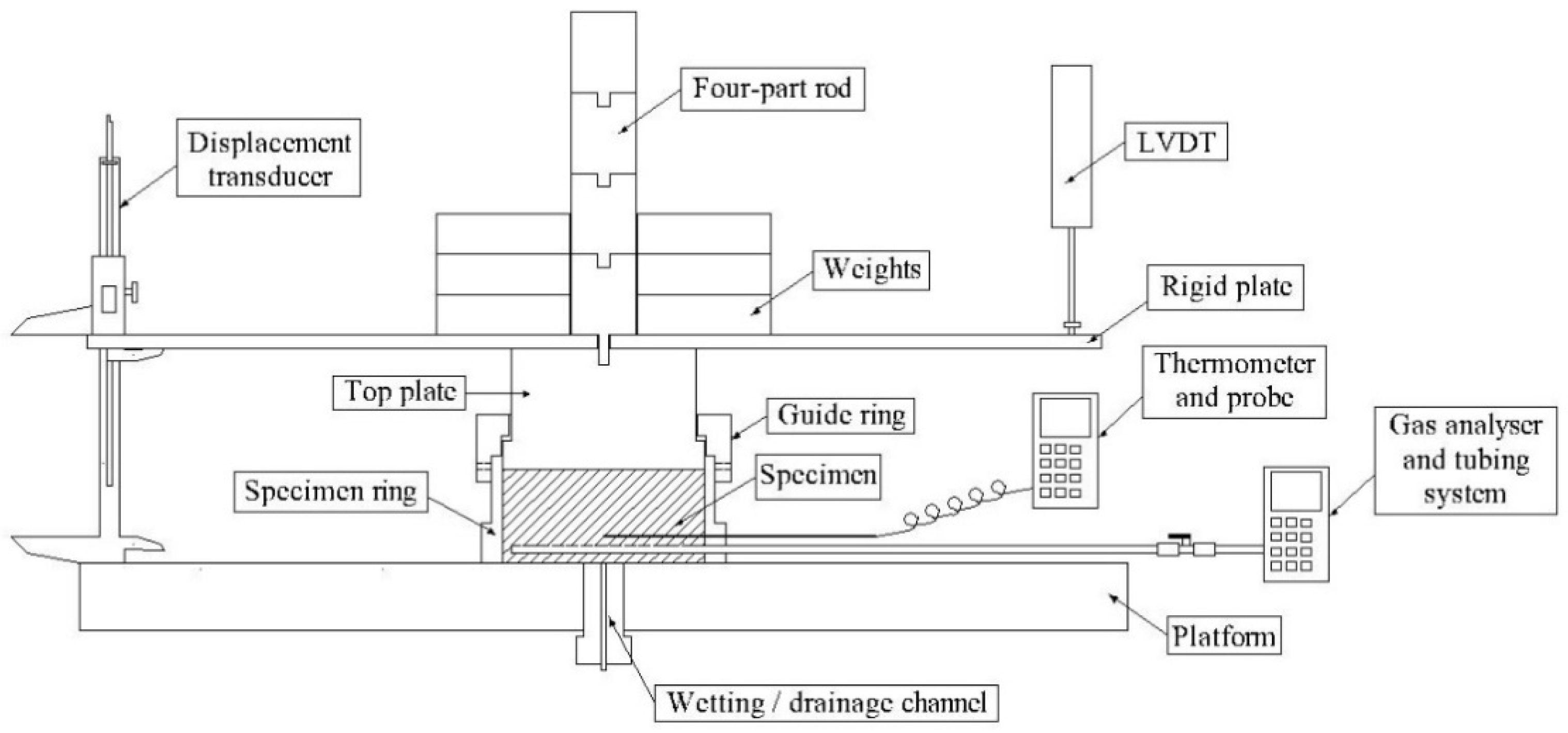

2.2.2. Oedometer Method

3. Results and Discussion

3.1. Basic Geotechnical Properties of the Tested Waste Material

3.2. Air Pycnometer Test Results

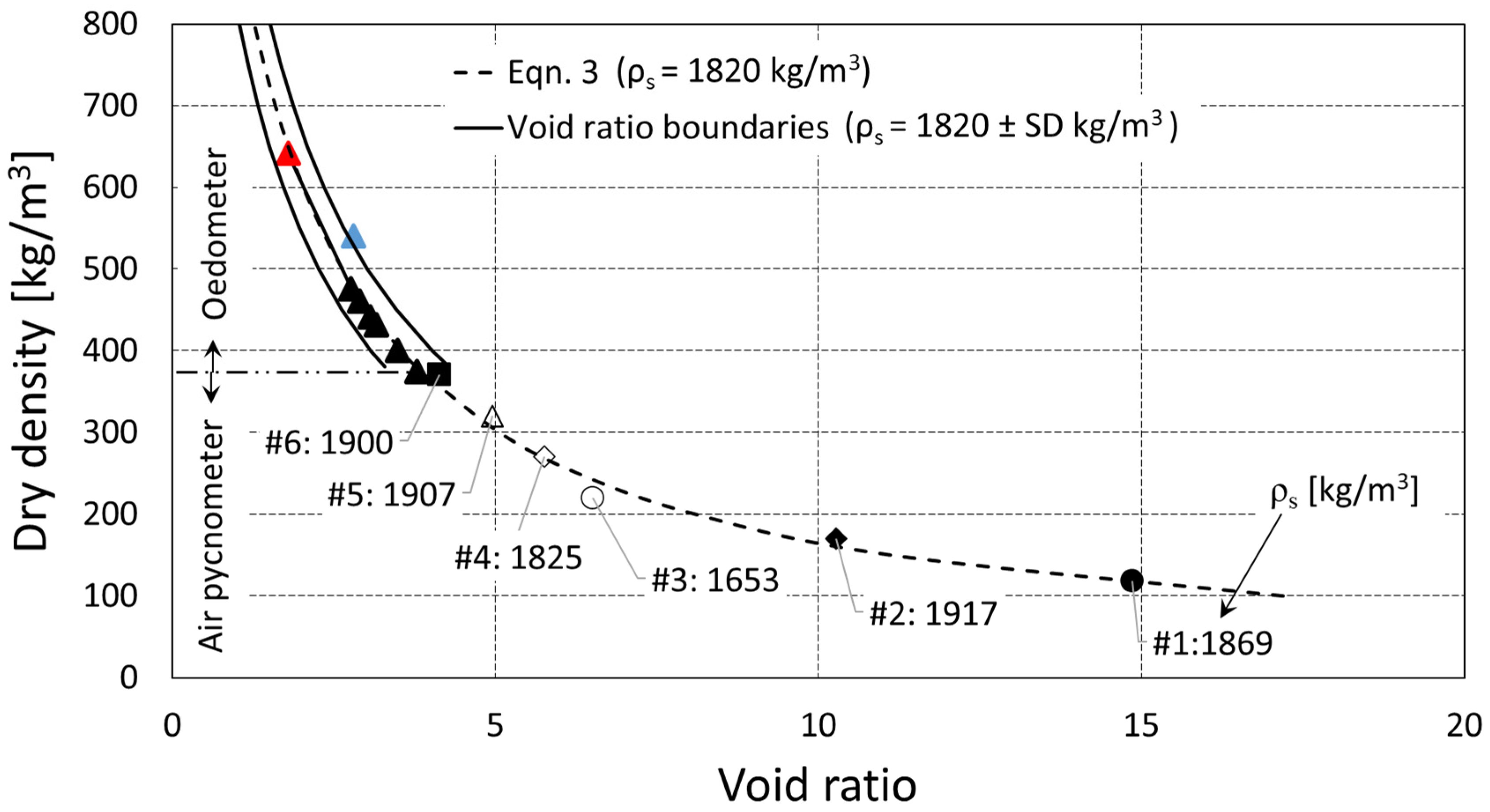

Variability in the Solid Particle Density Caused by Waste Heterogeneity and Its Influence on the Estimation of The Initial Void Ratio

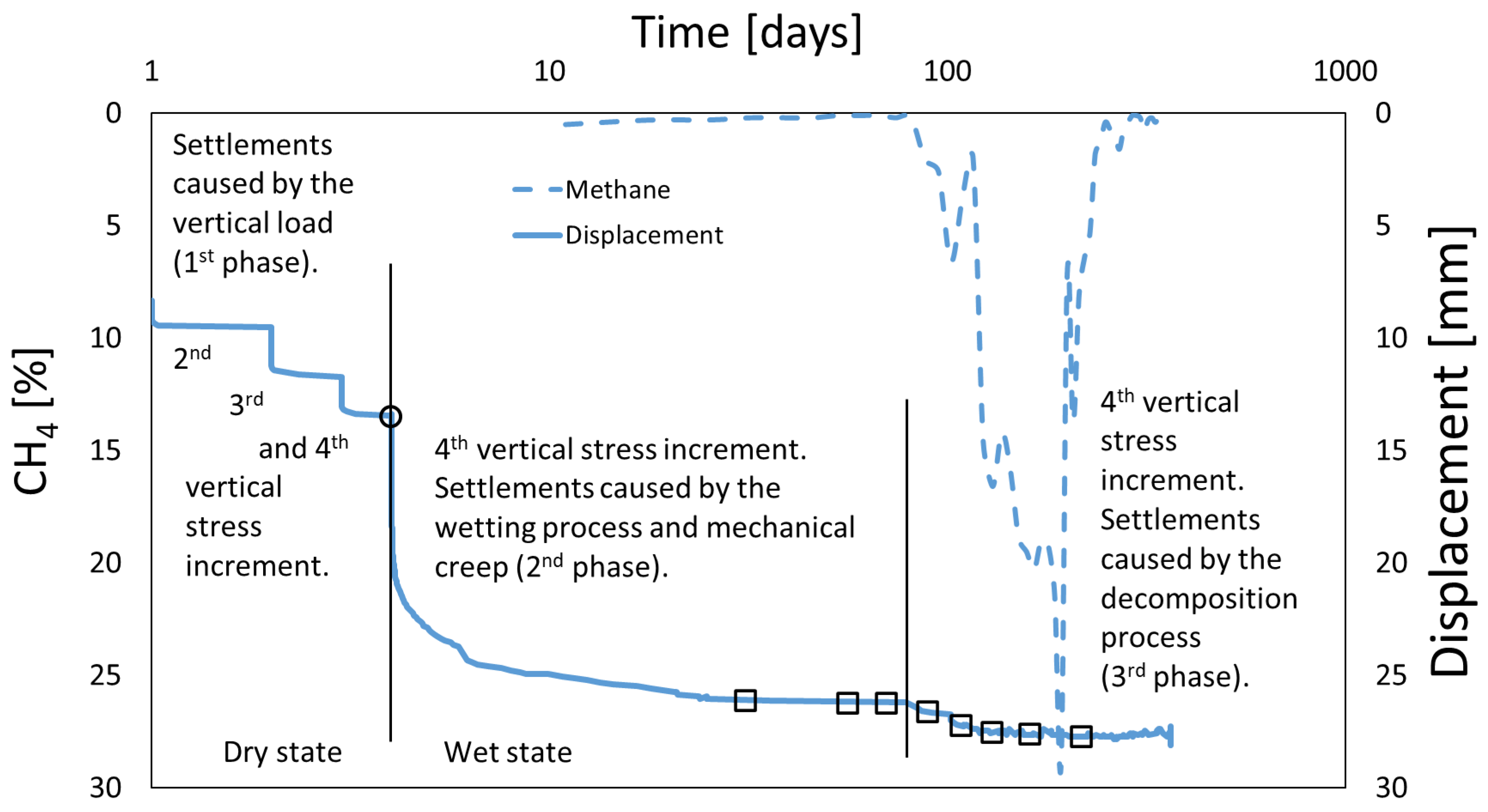

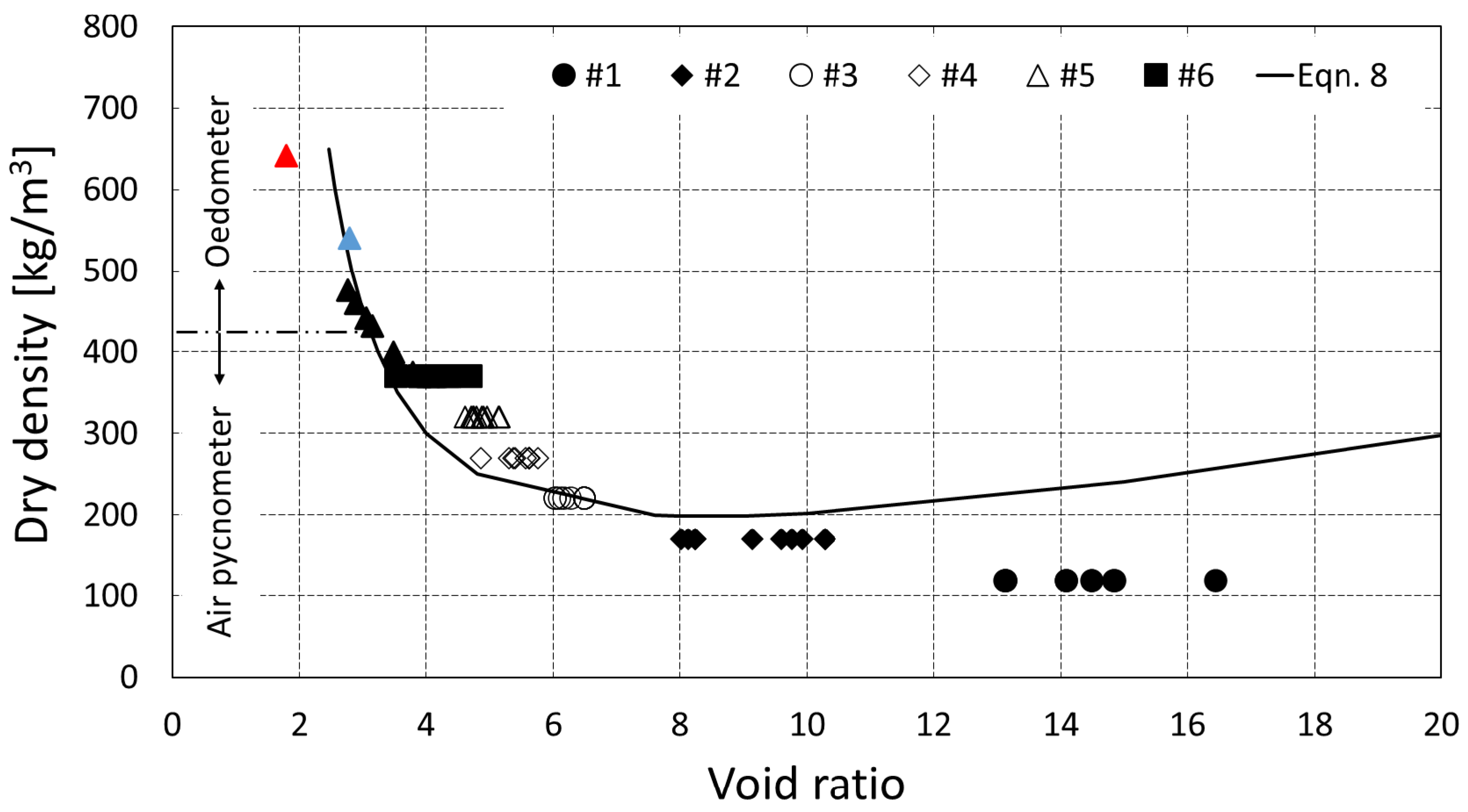

3.3. Oedometer Test Results

Variability in the Solid Particle Density Caused by the Decomposition Process and Its Influence on the Final Void Ratio and Dry Density Values

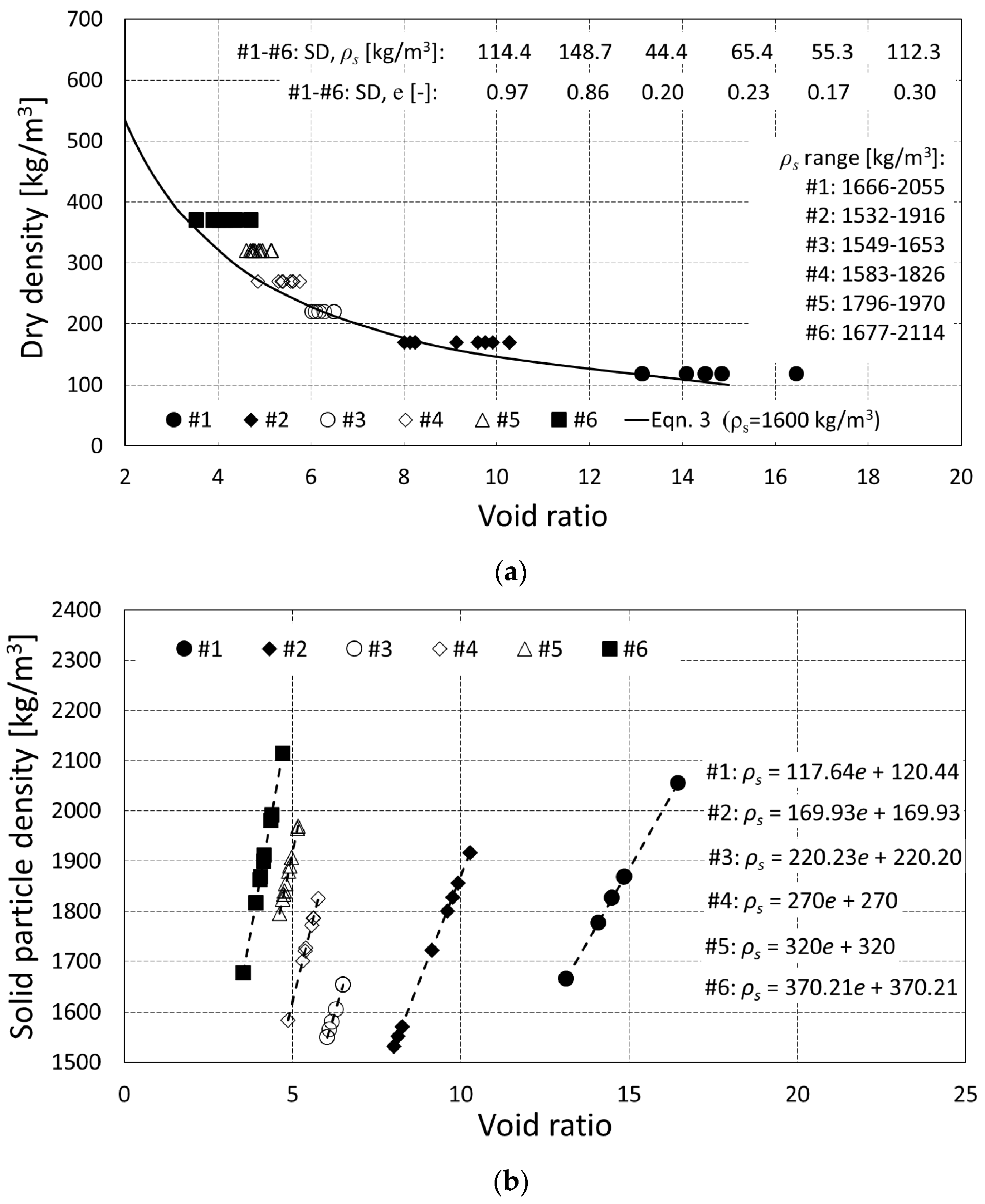

3.4. Empirical Correlations between the Solid Particle Density, Dry Density, and Void Ratio

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qian, X.; Koerner, R.M.; Gray, D.H. Geotechnical Aspects of Landfill Design and Construction, 1st ed.; Prentice-Hall Inc.: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Stoltz, G.; Gourc, J.-P.; Oxarango, L. Characterization of the physico-mechanical properties of MSW. Waste Manag. 2010, 30, 1439–1449. [Google Scholar] [CrossRef] [PubMed]

- Yesiller, N.; Hanson, J.L.; Cox, J.T.; Noce, D.E. Determination of specific gravity of municipal solid waste. Waste Manag. 2014, 345, 848–858. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bareither, C.A.; Benson, C.H.; Edil, T.B. Compression Behavior of municipal solid waste: Immediate compression. J. Geotech. Geoenviron. Eng. 2012, 138, 1047–1062. [Google Scholar] [CrossRef]

- Volume and Density Determinations for Particle Technologists. Available online: https://www.micromeritics.com/Repository/Files/Volume_and_Density_determinations_for_Particle_Technologists_0.pdf (accessed on 24 April 2022).

- Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer (D854-14); ASTM International: West Conshohocken, PA, USA, 2016.

- Agnew, J.M.; Leonard, J.J.; Feddes, J.; Feng, Y. A modified air pycnometer for compost volume and density determination. Can. Biosyst. Eng. 2003, 45, 27–34. [Google Scholar]

- Reddy, K.R.; Hettiarachchi, H.; Gangathulasi, J.; Bogner, J.E. Geotechnical properties of municipal solid waste at different phases of biodegradation. Waste Manag. 2011, 31, 2275–2286. [Google Scholar] [CrossRef] [PubMed]

- Entenmann, W.; Wendt, P. Placement and compaction of treated municipal solid waste in modern landfills, results of geotechnical and hydraulic tests and monitoring. In Proceedings of the 11th International Waste Management and Landfill Symposium, Cagliary, Italy, 1–5 October 2007. [Google Scholar]

- Pulat, H.F.; Yukselen-Aksoy, Y. Factors affecting the shear strength behaviour of municipal solid wastes. Waste Manag. 2017, 69, 215–224. [Google Scholar] [CrossRef] [PubMed]

- The Environmental Protection and Energy Efficiency Fund. Available online: https://www.fzoeu.hr/en/wmc-mariscina/7765 (accessed on 24 April 2022).

- Kaniski, N.; Gavez, B.; Hrncic, N.; Petrovic, I. Shear strength of biodried municipal solid waste. In Proceedings of the 18th International Symposium on Waste Management and Sustainable Landfilling, Cagliary, Italy, 11–15 October 2021. [Google Scholar]

- Ruggieri, L.; Gea, T.; Artola, A.; Sanchez, A. Air filled porosity measurements by air pycnometry in the composting process: A review and a correlation analysis. Bioresour. Technol. 2009, 100, 2655–2666. [Google Scholar] [CrossRef] [PubMed]

- GDS Instruments. Available online: https://www.gdsinstruments.com/gds-products/toxic-interface-unit (accessed on 24 April 2022).

- Petrovic, I.; Kaniski, N.; Hrncic, N.; Hip, I. Correlations between field capacity, porosity, solid particle density and dry density of a mechanically and biologically (biodried) treated reject waste stream. Bioresour. Technol. Rep. 2022, 17, 100996. [Google Scholar] [CrossRef]

- Heiss-Ziegler, C.; Fehrer, K. Geotechnical behaviour of mechanically-biologically pretreated municipal solid waste (MSW). In Proceedings of the 9th International Waste Management and Landfill Symposium (CD-ROM), Cagliari, Italy, 6–10 October 2003. [Google Scholar]

- Hudson, A.P.; White, J.K.; Beaven, R.P.; Powrie, W. Modelling the compression behaviour of landfilled domestic waste. Waste Manag. 2004, 24, 259–269. [Google Scholar] [CrossRef] [PubMed]

- Rose, J.L.; Izzo, R.L.S.; Mahler, C.F. Effect of MSW compost-soil mixtures in compaction and permeability tests. In Proceedings of the 12th International Waste Management and Landfill Symposium, Cagliary, Italy, 5–9 October 2009. [Google Scholar]

- Fernando, V.I.; Sudarshana, C.K. Strength Characteristics of Mechanically Biologically Treated (MBT) Waste. Ph.D. Thesis, University of Southampton, Southampton, UK, November 2011. [Google Scholar]

- Velkushanova, K. Characterization of Wastes towards Sustainable LandfiLling by Some Physical and Mechanical Properties with an Emphasis on Solid Particles Compressibility. Ph.D. Thesis, University of Southampton, Southampton, UK, November 2011. [Google Scholar]

- Petrovic, I.; Stuhec, D.; Kovacic, D. Large oedometer for measuring stiffness of MBT waste. Geotech. Test. J. 2014, 37, 296–310. [Google Scholar] [CrossRef]

- Sivakumar Babu, G.L.; Lakshmikanthan, P.; Santhosh, L.G. Shear strength characteristics of mechanically biologically treated municipal solid waste (MBT-MSW) from Bangalore. Waste Manag. 2015, 39, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Fang, Y.; Wang, Y.; Xu, H. Compression behaviors of mechanically biologically treated wastes of Tianziling landfill in Hangzhou, China. Environ. Sci. Pollut. Res. 2020, 27, 43970–43986. [Google Scholar] [CrossRef] [PubMed]

- The Engineering Toolbox. Available online: https://www.engineeringtoolbox.com/density-solids-d_1265.html (accessed on 24 April 2022).

- Beaven, P.R. The Hydrogeological and Geotechnical Properties of Household Waste in Relation to Sustainable Landfilling. Ph.D. Thesis, University of London, London, UK, May 1999. [Google Scholar]

- Powrie, W.; Beaven, R.P. Hydraulic properties of household waste and implications for landfills. Proc. Inst. Civ. Eng. Geotech. Eng. 1999, 137, 235–247. [Google Scholar] [CrossRef]

| Ref. | [kg/m3] | Measurement Method | Additional Information |

|---|---|---|---|

| [9] | 1580–1980 | Capillary pycnometer | Various waste mixtures |

| [16] | 2210 | - | Particle size ≤ 25 mm; waste was treated together with sewage sludge in a two-step process over a period of >20 weeks. |

| [17] | 880–1300 | - | The waste was processed using the DANO technique prior to testing. The evolution of the solid particle density with the vertical load. The vertical stress range went from 34 to 463 kPa. |

| [18] | 1900 | Water pycnometry | MSW compost, test method NBR 7181/1984 (ABNT (a), 1984). |

| [19] | 1690 | Gas jar method | 0–10 mm fraction size, average value. |

| 1930 | Gas jar method | 0–20 mm fraction size, average value. | |

| [20] | 1630 | Gas jar method | BS1377-2 |

| [21] | 2150 | Water pycnometry | D 854-02, maximum particle size was 4.75 mm. |

| [22] | 1260 | Density bottle method and pycnometer method | Mechanically and biologically treated compost reject collected from the Mavallipura landfill site. |

| [23] | 1580 ± 60 | Water pycnometry | MBT waste, Tianziling landfill, Hangzhou, China—winter specimen. |

| 1380 ± 80 | MBT waste, Tianziling landfill, Hangzhou, China—summer specimen. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrovic, I.; Kaniski, N.; Hrncic, N.; Bosilj, D. Variability in the Solid Particle Density and Its Influence on the Corresponding Void Ratio and Dry Density: A Case Study Conducted on the MBT Reject Waste Stream from the MBT Plant in Marišćina, Croatia. Appl. Sci. 2022, 12, 6136. https://doi.org/10.3390/app12126136

Petrovic I, Kaniski N, Hrncic N, Bosilj D. Variability in the Solid Particle Density and Its Influence on the Corresponding Void Ratio and Dry Density: A Case Study Conducted on the MBT Reject Waste Stream from the MBT Plant in Marišćina, Croatia. Applied Sciences. 2022; 12(12):6136. https://doi.org/10.3390/app12126136

Chicago/Turabian StylePetrovic, Igor, Nikola Kaniski, Nikola Hrncic, and Dino Bosilj. 2022. "Variability in the Solid Particle Density and Its Influence on the Corresponding Void Ratio and Dry Density: A Case Study Conducted on the MBT Reject Waste Stream from the MBT Plant in Marišćina, Croatia" Applied Sciences 12, no. 12: 6136. https://doi.org/10.3390/app12126136

APA StylePetrovic, I., Kaniski, N., Hrncic, N., & Bosilj, D. (2022). Variability in the Solid Particle Density and Its Influence on the Corresponding Void Ratio and Dry Density: A Case Study Conducted on the MBT Reject Waste Stream from the MBT Plant in Marišćina, Croatia. Applied Sciences, 12(12), 6136. https://doi.org/10.3390/app12126136