Microstructure, Mechanical and Ignition Characteristics of Si3N4 Reinforced Magnesium Matrix Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

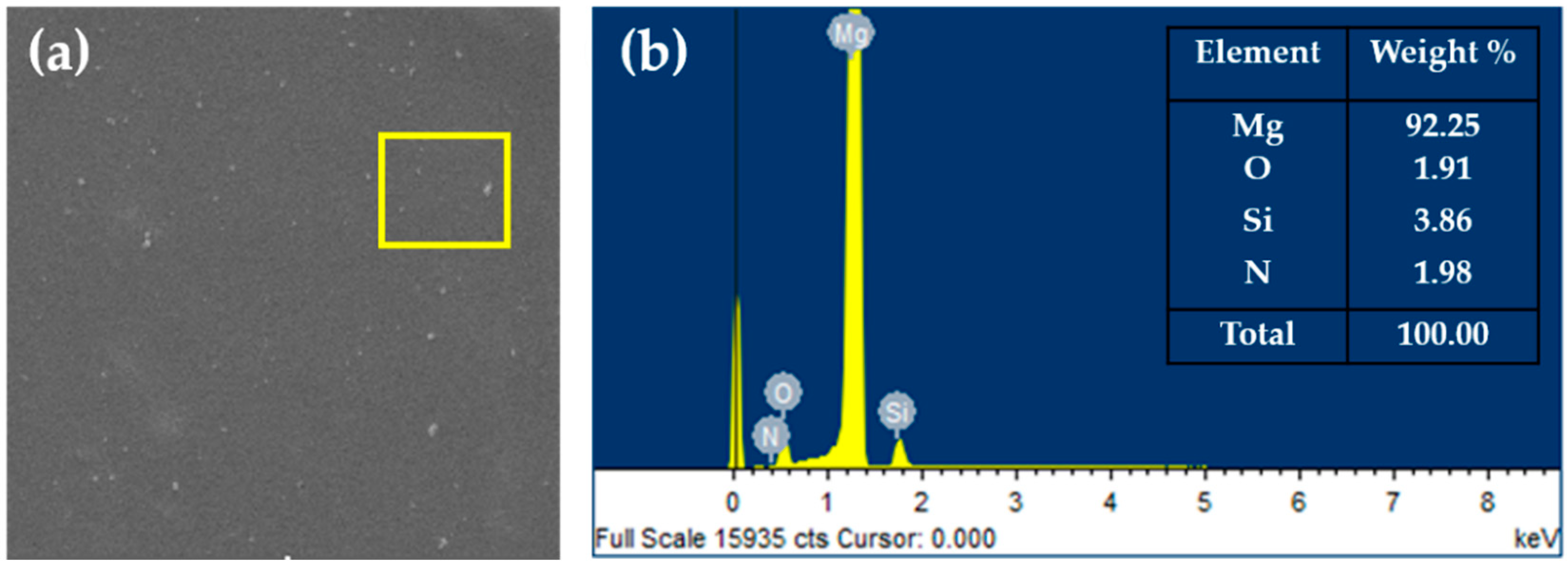

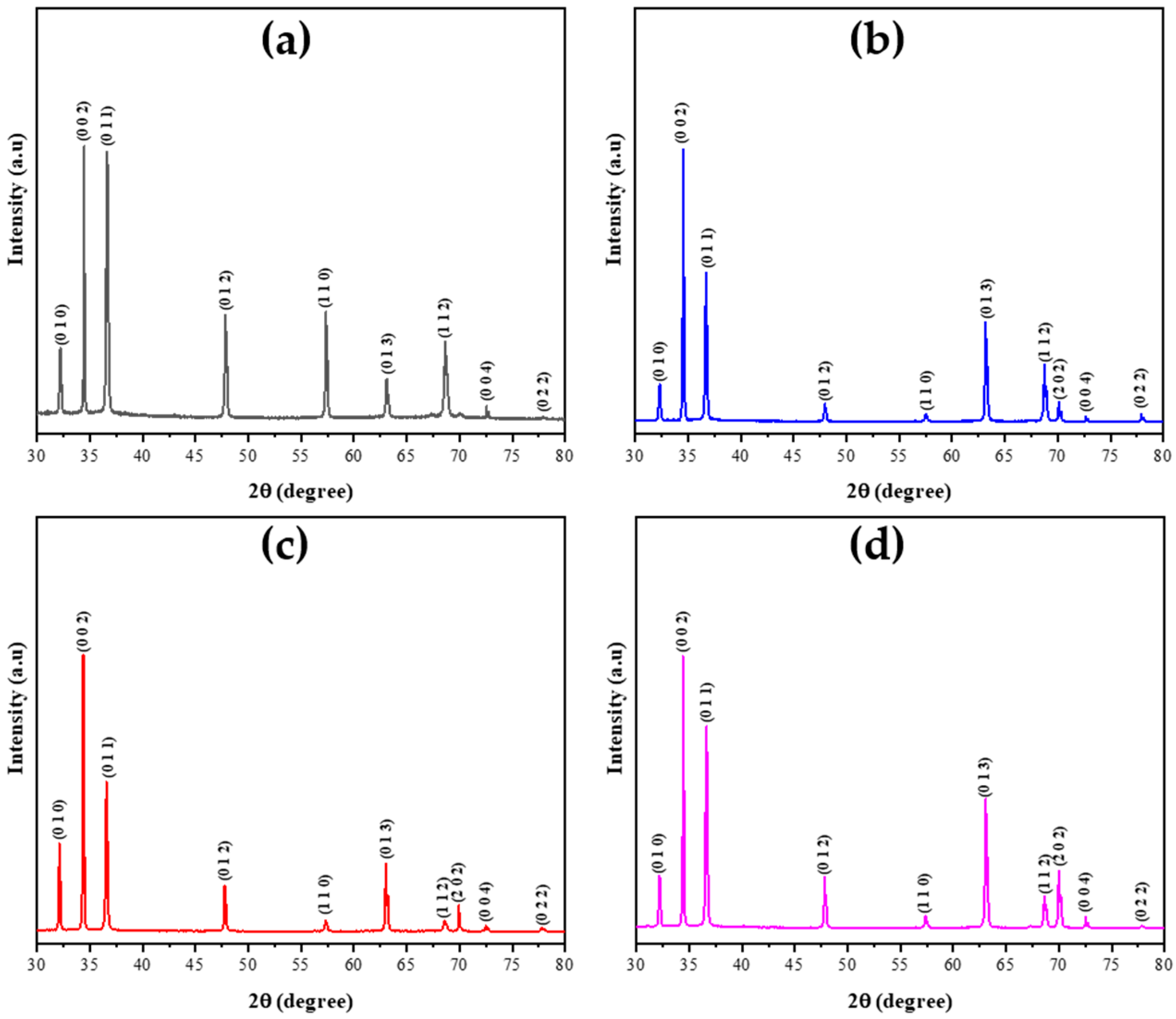

3.1. Microstructural Characterization

3.2. Density and Porosity

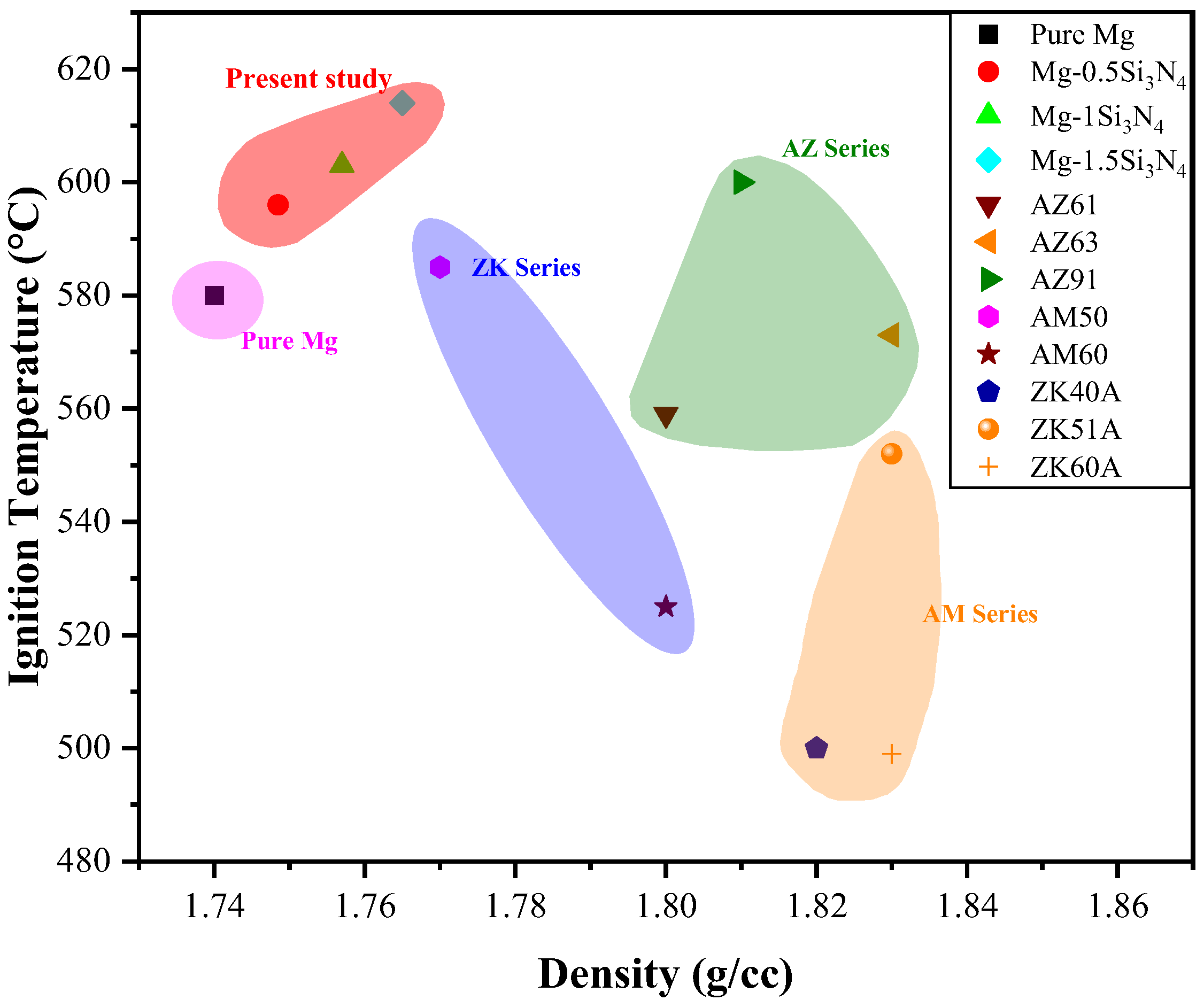

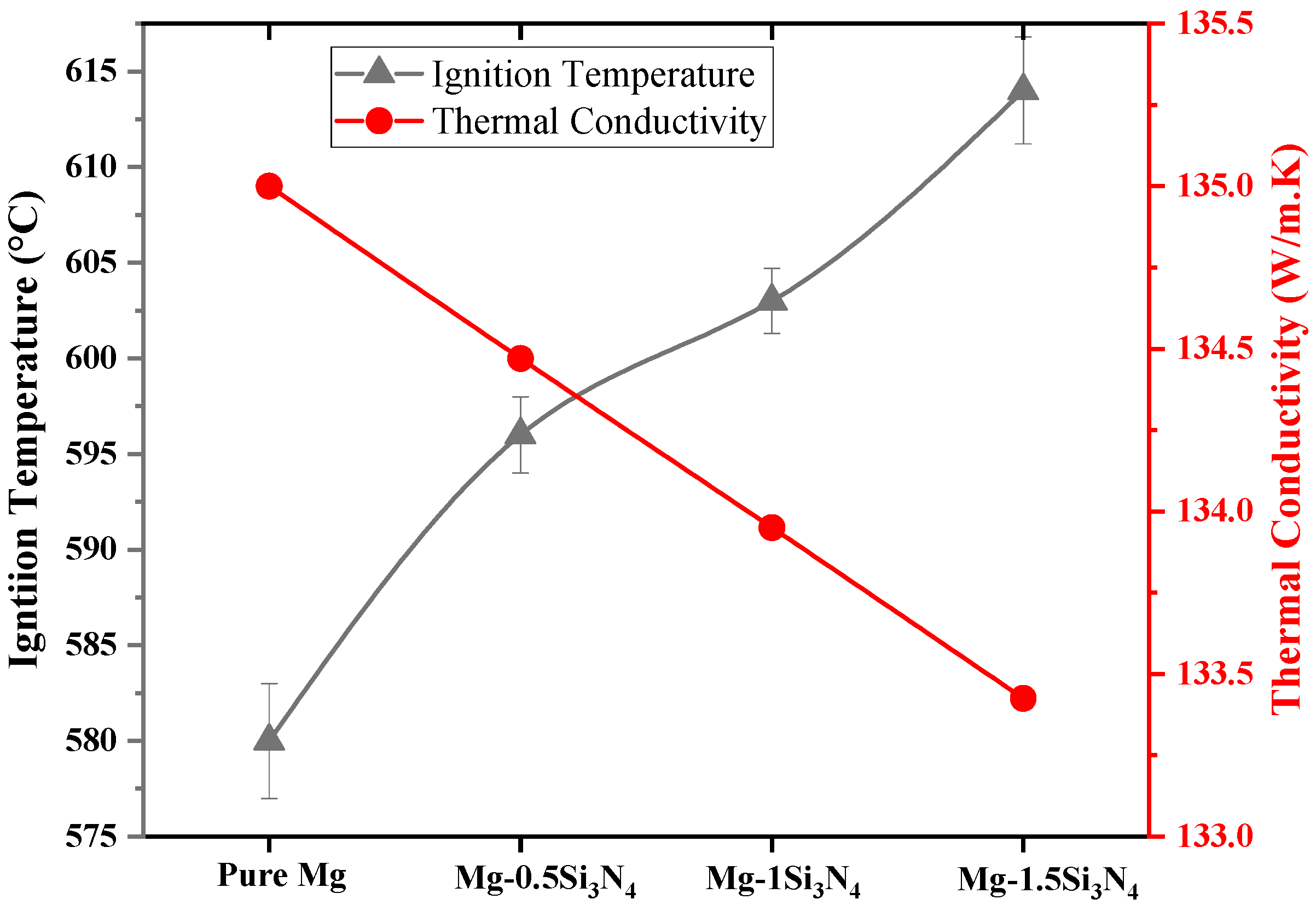

3.3. Igntion Response

3.4. Compression Test

4. Conclusions

- The ultrasonic vibration during the fabrication process resulted in a uniform distribution of Si3N4 nanoparticles in the Mg matrix. The distribution is more homogeneous in the 0.5 and 1 vol% Mg/Si3N4 nanocomposites compared to the 1.5 vol% Si3N4 nanoparticles, as the latter had some clustered nanoparticles when observed under SEM;

- Similar to the EDS analysis, the XRD results revealed the presence of Mg and Si3N4. Moreover, the XRD analysis showed no evidence of interfacial reaction products;

- The porosity of the samples increased with the increasing vol% of the Si3N4 nanoparticles, with Mg-1.5 Si3N4 showing a higher porosity (1.3%) compared to the remaining samples;

- The ignition temperature of the nanocomposites is enhanced by increasing the amount of the Si3N4 nanoparticles by forming a dense and more stable oxide layer on the surface. The nanocomposite with 1.5 vol% Si3N4 nanoparticles showed the highest ignition temperature of 614 °C, ~6% more than pure Mg;

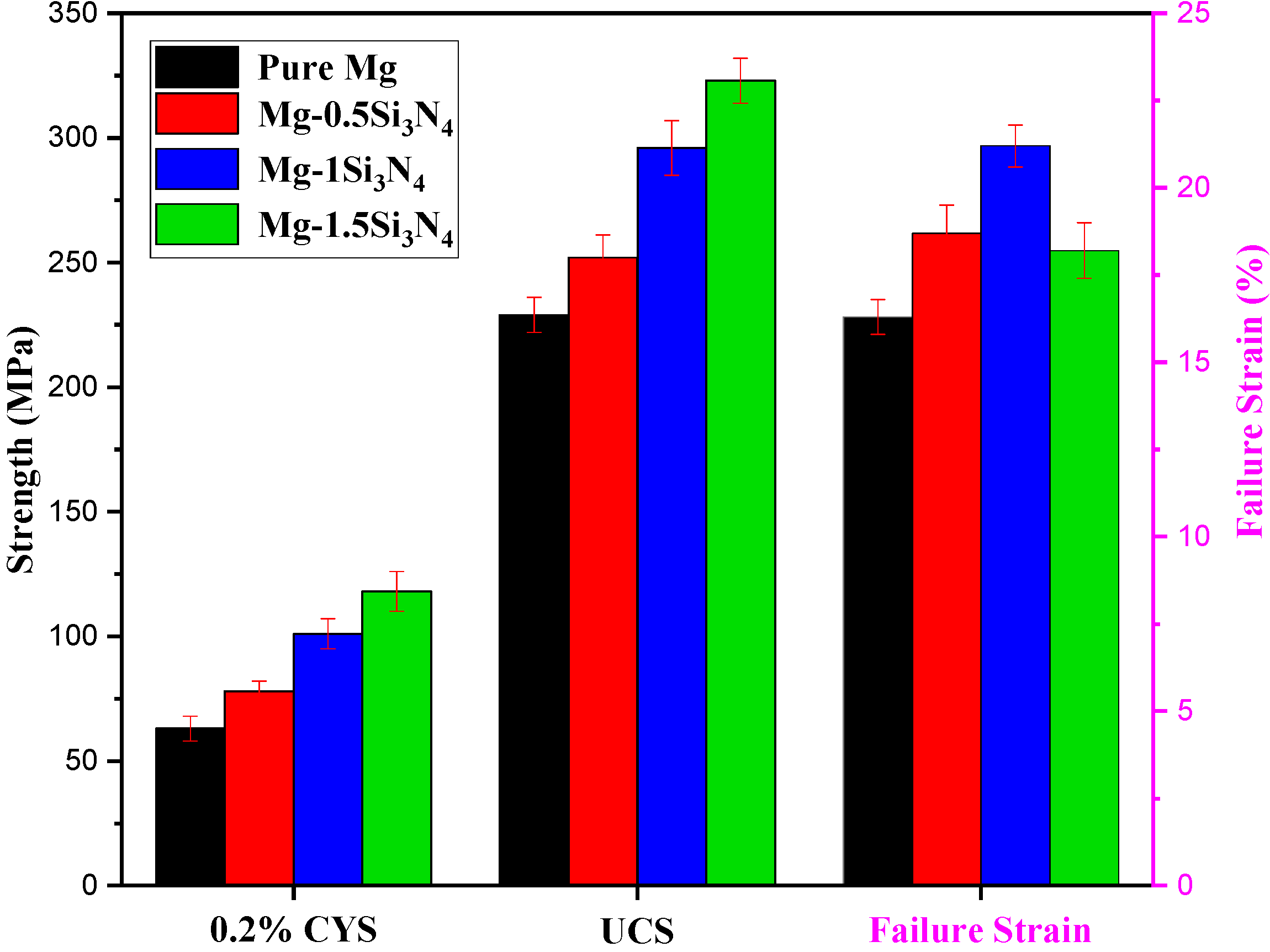

- Adding Si3N4 nanoparticles gradually improved the compressive yield strength and ultimate strength, with 1.5 vol% Si3N4 nanocomposites having a maximum yield strength of 118 MPa and an ultimate strength of 323 MPa. The failure strain improved with the addition of Si3N4 nanoparticles, with 1 vol% Si3N4 nanocomposites displaying a maximum failure strain of 21.2%, ~30% greater than pure Mg.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Tokarska, K.B.; Gillett, N.P.; Weaver, A.J.; Arora, V.K.; Eby, M. The Climate Response to Five Trillion Tonnes of Carbon. Nat. Clim. Chang. 2016, 6, 851–855. [Google Scholar] [CrossRef]

- Meinshausen, M.; Meinshausen, N.; Hare, W.; Raper, S.C.B.; Frieler, K.; Knutti, R.; Frame, D.J.; Allen, M.R. Greenhouse-Gas Emission Targets for Limiting Global Warming to 2 °C. Nature 2009, 458, 1158–1162. [Google Scholar] [CrossRef] [PubMed]

- Joost, W.J. Reducing Vehicle Weight and Improving U.S. Energy Efficiency Using Integrated Computational Materials Engineering. Jom 2012, 64, 1032–1038. [Google Scholar] [CrossRef] [Green Version]

- Esmaily, M.; Svensson, J.E.; Fajardo, S.; Birbilis, N.; Frankel, G.S.; Virtanen, S.; Arrabal, R.; Thomas, S.; Johansson, L.G. Fundamentals and Advances in Magnesium Alloy Corrosion. Prog. Mater. Sci. 2017, 89, 92–193. [Google Scholar] [CrossRef]

- Hirsch, J.; Al-Samman, T. Superior Light Metals by Texture Engineering: Optimized Aluminum and Magnesium Alloys for Automotive Applications. Acta Mater. 2013, 61, 818–843. [Google Scholar] [CrossRef]

- Tun, K.S.; Brendan, T.Y.S.; Tekumalla, S.; Gupta, M. Development from Alloys to Nanocomposite for an Enhanced Mechanical and Ignition Response in Magnesium. Metals 2021, 11, 1792. [Google Scholar] [CrossRef]

- Tekumalla, S.; Gupta, N.; Gupta, M. Influence of Turning Speed on the Microstructure and Properties of Magnesium ZK60 Alloy Pre-Processed via Turning-Induced-Deformation. J. Alloys Compd. 2020, 831, 154840. [Google Scholar] [CrossRef]

- Aydin, D.S.; Bayindir, Z.; Hoseini, M.; Pekguleryuz, M.O. The High Temperature Oxidation and Ignition Behavior of Mg-Nd Alloys Part I: The Oxidation of Dilute Alloys. J. Alloys Compd. 2013, 569, 35–44. [Google Scholar] [CrossRef]

- Pu, D.; Pan, Y. First-Principles Investigation of Solution Mechanism of C in TM-Si-C Matrix as the Potential High-Temperature Ceramics. J. Am. Ceram. Soc. 2021, 105, 2858–2868. [Google Scholar]

- Pan, Y.; Chen, S. Influence of Alloying Elements on the Mechanical and Thermodynamic Properties of ZrB2 Boride. Vacuum 2022, 198, 110898. [Google Scholar] [CrossRef]

- Pu, D.; Pan, Y. New Insight into the Structural Stability, Ductility and Melting Point of Mo5SiB2 under High-Pressure Environment. Vacuum 2022, 196, 110727. [Google Scholar] [CrossRef]

- Mittal, M. Explosion Characteristics of Micron- and Nano-Size Magnesium Powders. J. Loss Prev. Process Ind. 2014, 27, 55–64. [Google Scholar] [CrossRef]

- Choi, K.; Sakasai, H.; Nishimura, K. Minimum Ignition Energies of Pure Magnesium Powders Due to Electrostatic Discharges and Nitrogen’s Effect. J. Loss Prev. Process Ind. 2016, 41, 144–146. [Google Scholar] [CrossRef]

- Boris, P. A Study of the Flammability of Magnesium; Federal Aviation Administration: Washington, DC, USA, 1964; Volume 41.

- Gupta, M.; Wong, W.L.E. Magnesium-Based Nanocomposites: Lightweight Materials of the Future. Mater. Charact. 2015, 105, 30–46. [Google Scholar] [CrossRef]

- Pu, D.; Pan, Y. First-Principles Prediction of Structure and Mechanical Properties of TM5SiC2 Ternary Silicides. Vacuum 2022, 199, 110981. [Google Scholar] [CrossRef]

- Pu, D.; Pan, Y. First-Principles Investigation of Oxidation Mechanism of Al-Doped Mo5Si3 Silicide. Ceram. Int. 2022, 48, 11518–11526. [Google Scholar] [CrossRef]

- Han, D.; Zhang, J.; Huang, J.; Lian, Y.; He, G. A Review on Ignition Mechanisms and Characteristics of Magnesium Alloys. J. Magnes. Alloy. 2020, 8, 329–344. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Lee, D.B. Oxidation of AM60B Mg Alloys Containing Dispersed SiC Particles in Air at Temperatures between 400 and 550 °C. Oxid. Met. 2010, 73, 183–192. [Google Scholar] [CrossRef]

- Parande, G.; Manakari, V.; Meenashisundaram, G.K.; Gupta, M. Enhancing the Tensile and Ignition Response of Monolithic Magnesium by Reinforcing with Silica Nanoparticulates. J. Mater. Res. 2017, 32, 2169–2178. [Google Scholar] [CrossRef]

- Kujur, M.S.; Mallick, A.; Manakari, V.; Parande, G.; Tun, K.; Gupta, M. Significantly Enhancing the Ignition/Compression/Damping Response of Monolithic Magnesium by Addition of Sm2O3 Nanoparticles. Metals 2017, 7, 357. [Google Scholar] [CrossRef] [Green Version]

- Kujur, M.S.; Manakari, V.; Parande, G.; Tun, K.S.; Mallick, A.; Gupta, M. Enhancement of Thermal, Mechanical, Ignition and Damping Response of Magnesium Using Nano-Ceria Particles. Ceram. Int. 2018, 44, 15035–15043. [Google Scholar] [CrossRef]

- Manakari, V.; Parande, G.; Doddamani, M.; Gupta, M. Enhancing the Ignition, Hardness and Compressive Response of Magnesium by Reinforcing with Hollow Glass Microballoons. Materials 2017, 10, 997. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marker, T.R. Development of a Laboratory- Scale Flammability Test for Magnesium Alloys Used in Aircraft Seat Construction; Federal Aviation Administration William J. Hughes Technical Center: Egg Harbor Township, NJ, USA, 2014.

- Krstic, Z.; Krstic, V.D. Silicon Nitride: The Engineering Material of the Future. J. Mater. Sci. 2012, 47, 535–552. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Sabat, R.K.; Jayalakshmi, S.; Suwas, S.; Almajid, A.; Gupta, M. Mg/BN Nanocomposites: Nano-BN Addition for Enhanced Room Temperature Tensile and Compressive Response. J. Compos. Mater. 2015, 49, 3045–3055. [Google Scholar] [CrossRef]

- Tekumalla, S.; Yang, C.; Seetharaman, S.; Wong, W.L.E.; Goh, C.S.; Shabadi, R.; Gupta, M. Enhancing Overall Static/Dynamic/Damping/Ignition Response of Magnesium through the Addition of Lower Amounts (<2%) of Yttrium. J. Alloys Compd. 2016, 689, 350–358. [Google Scholar] [CrossRef]

- Pan, Y. First-Principles Investigation of Structural Stability, Electronic and Optical Properties of Suboxide (Zr3O). Mater. Sci. Eng. B 2022, 281, 115746. [Google Scholar] [CrossRef]

- Tekumalla, S.; Gupta, M. An Insight into Ignition Factors and Mechanisms of Magnesium Based Materials: A Review. Mater. Des. 2017, 113, 84–98. [Google Scholar] [CrossRef]

- Kim, Y.M.; Yim, C.D.; Kim, H.S.; You, B.S. Key Factor Influencing the Ignition Resistance of Magnesium Alloys at Elevated Temperatures. Scr. Mater. 2011, 65, 958–961. [Google Scholar] [CrossRef]

- Pu, D.; Pan, Y. First-Principles Investigation of Equilibrium Phase, Mechanical and Thermodynamic Properties of the Nowotny TM5Si3C Ternary Phase. Ceram. Int. 2022, 48, 20438–20445. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Habibi, M.K.; Jayalakshmi, S.; Jia Ai, K.; Almajid, A.; Gupta, M. Nano-AlN Particle Reinforced Mg Composites: Microstructural and Mechanical Properties. Mater. Sci. Technol. 2015, 31, 1122–1130. [Google Scholar] [CrossRef]

- Meenashisundaram, G.K.; Nai, M.H.; Almajid, A.; Gupta, M. Development of High Performance Mg-TiO2 Nanocomposites Targeting for Biomedical/Structural Applications. Mater. Des. 2015, 65, 104–114. [Google Scholar] [CrossRef]

- Parande, G.; Manakari, V.; Meenashisundaram, G.K.; Gupta, M. Enhancing the Hardness/Compression/Damping Response of Magnesium by Reinforcing with Biocompatible Silica Nanoparticulates. Int. J. Mater. Res. 2016, 107, 1091–1099. [Google Scholar] [CrossRef]

| Sample | 0.2% CYS (MPa) | UCS (MPa) | Failure Strain (%) |

|---|---|---|---|

| Pure Mg | 63 ± 5 | 229 ± 7 | 16.3 ± 0.5 |

| Mg-0.5Si3N4 | 78 ± 4 | 252 ± 9 | 18.7 ± 0.8 |

| Mg-1.0Si3N4 | 101 ± 6 | 296 ± 11 | 21.2 ± 0.6 |

| Mg-1.5 Si3N4 | 118 ± 8 | 323 ± 9 | 18.2 ± 0.8 |

| Mg-0.4AlN [32] | 72 ± 5 | 314 ± 20 | 17.5 ± 0.6 |

| Mg-1.2BN [26] | 109 ± 4 | 307 ± 6 | 17.6 ± 2 |

| Mg-2.5TiO2 [33] | 101 ± 9 | 305.5 ± 11 | 22 ± 2 |

| Mg-2SiO2 [34] | 89 ± 1 | 207 ± 3 | 21.87 ± 2.1 |

| Mg-1.5CeO2 [22] | 111 ± 2 | 329 ± 7 | 19.7 ± 0.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pasha, M.B.; Rao, R.N.; Ismail, S.; Gupta, M. Microstructure, Mechanical and Ignition Characteristics of Si3N4 Reinforced Magnesium Matrix Nanocomposites. Appl. Sci. 2022, 12, 6138. https://doi.org/10.3390/app12126138

Pasha MB, Rao RN, Ismail S, Gupta M. Microstructure, Mechanical and Ignition Characteristics of Si3N4 Reinforced Magnesium Matrix Nanocomposites. Applied Sciences. 2022; 12(12):6138. https://doi.org/10.3390/app12126138

Chicago/Turabian StylePasha, Mahammod Babar, Rajamalla Narasimha Rao, Syed Ismail, and Manoj Gupta. 2022. "Microstructure, Mechanical and Ignition Characteristics of Si3N4 Reinforced Magnesium Matrix Nanocomposites" Applied Sciences 12, no. 12: 6138. https://doi.org/10.3390/app12126138

APA StylePasha, M. B., Rao, R. N., Ismail, S., & Gupta, M. (2022). Microstructure, Mechanical and Ignition Characteristics of Si3N4 Reinforced Magnesium Matrix Nanocomposites. Applied Sciences, 12(12), 6138. https://doi.org/10.3390/app12126138