Structural Design and Dynamic Simulation Optimization of the Triggering Device in a Pressure-Holding Controller for Deep in Situ Coring

Abstract

:1. Introduction

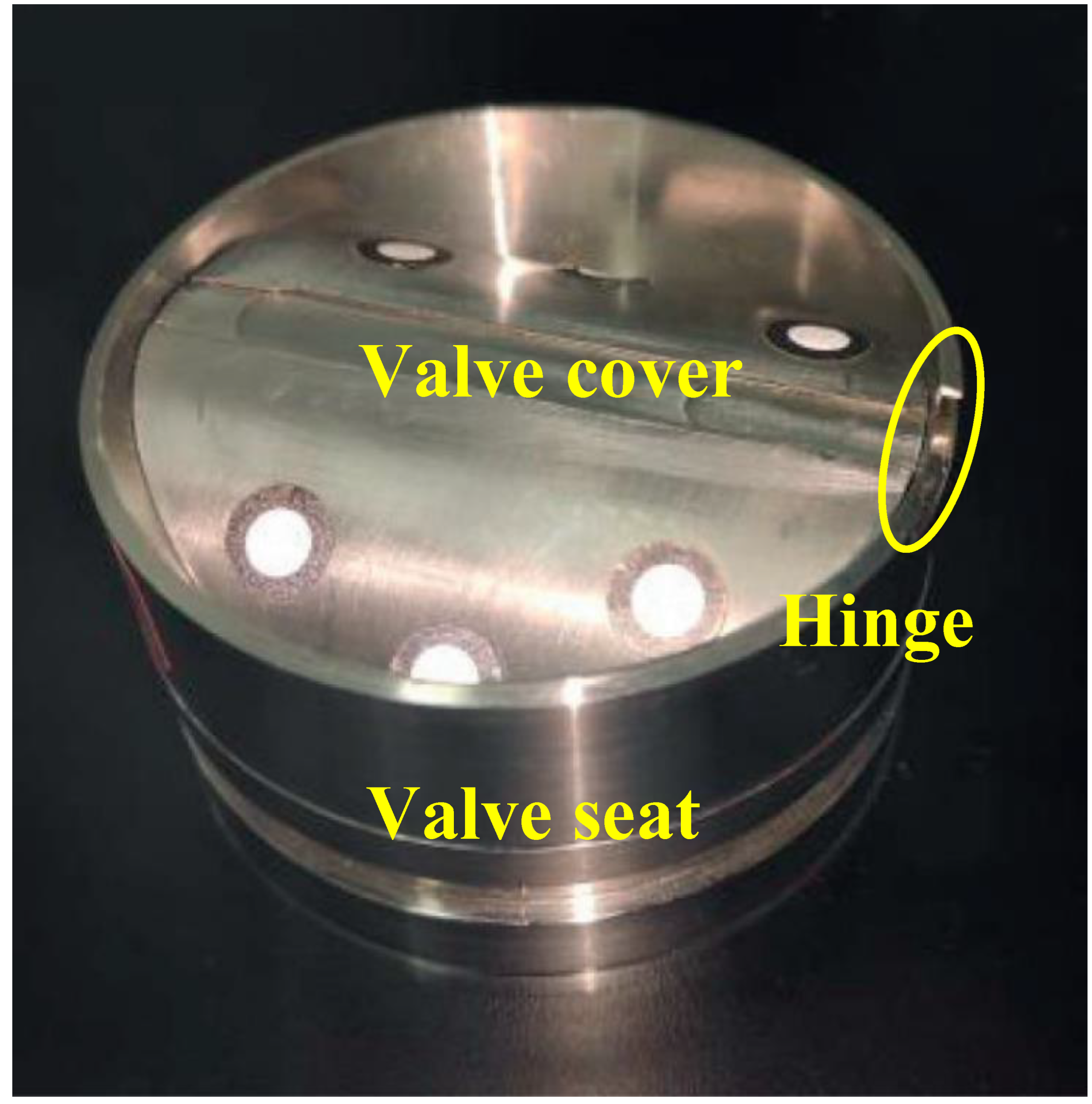

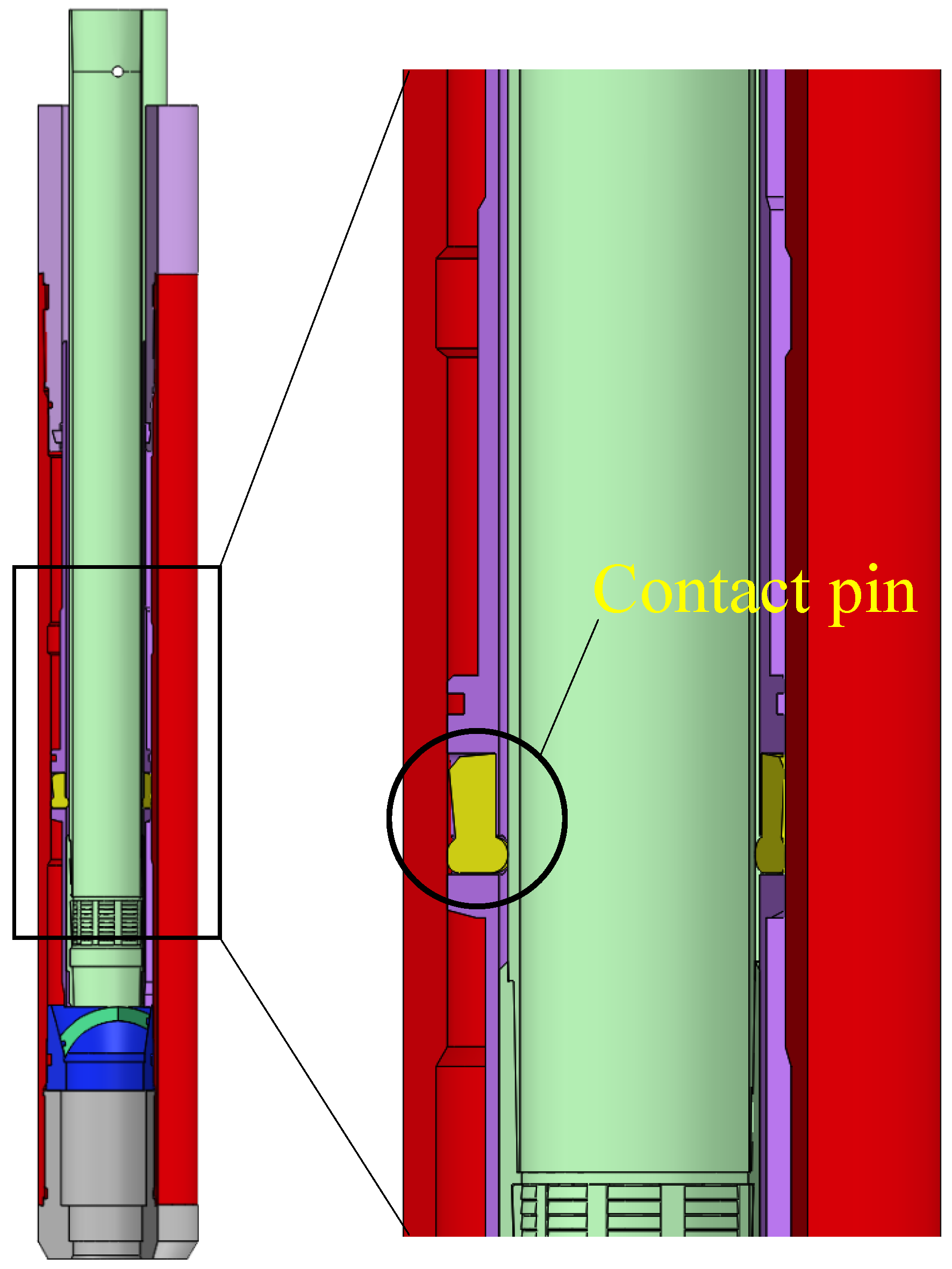

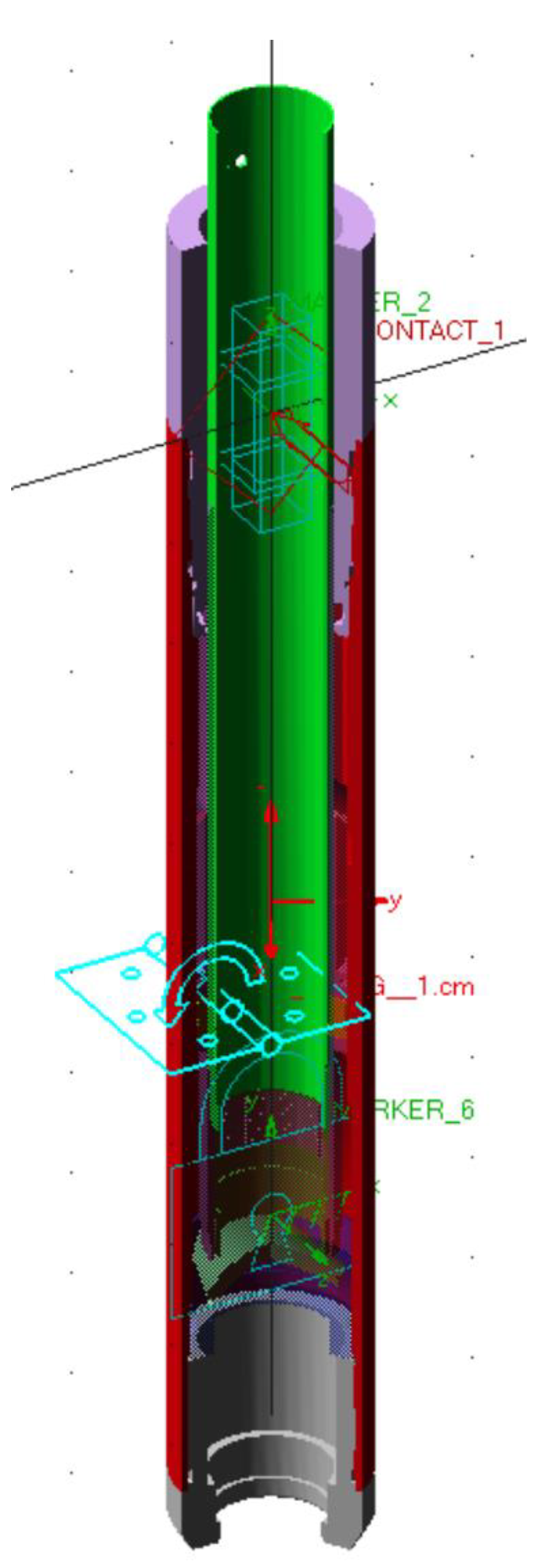

2. Trigger Mechanism Structural Design

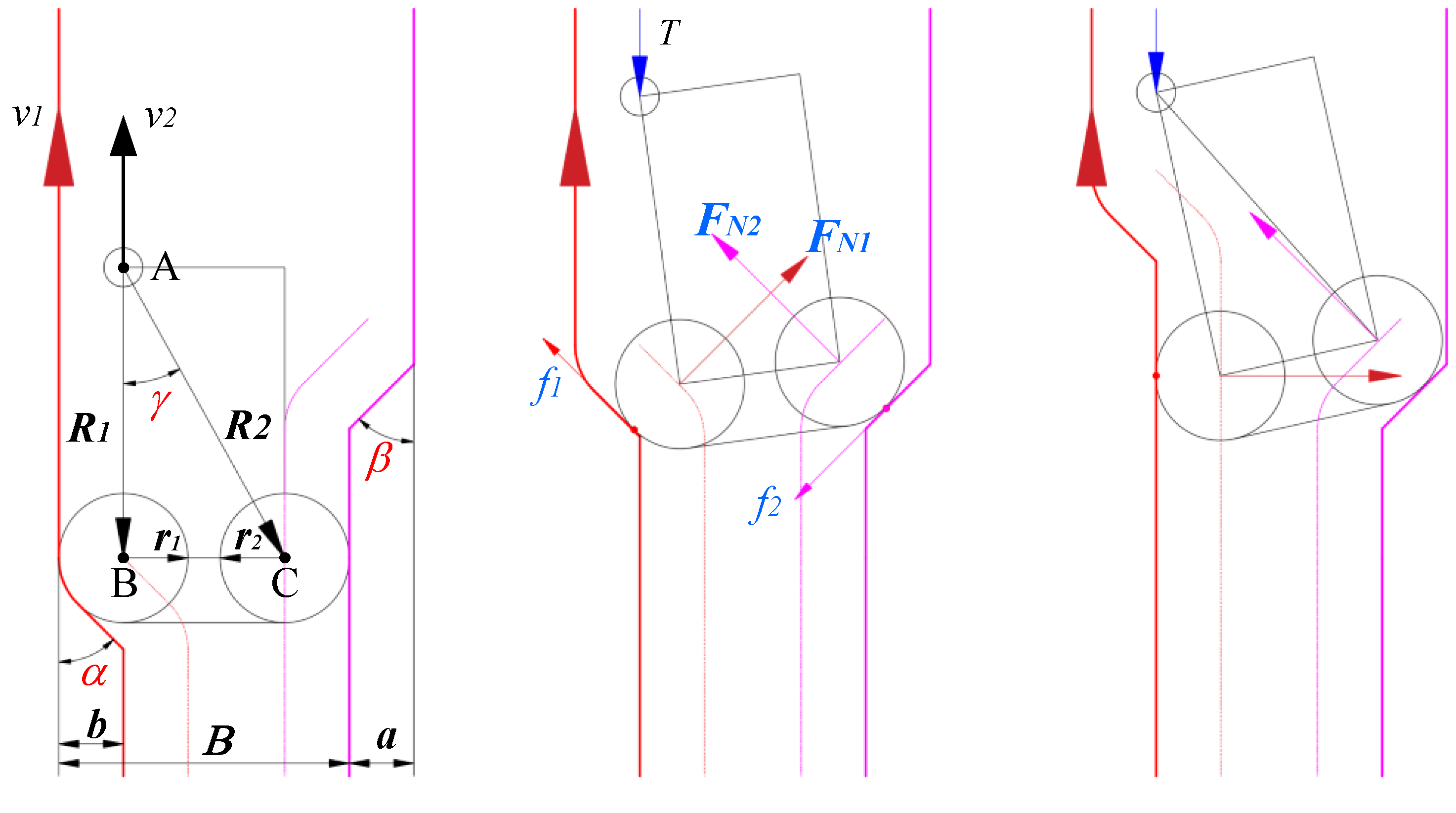

3. Kinetic Model of Trigger Mechanism

3.1. Dynamic Model of Closing and Sealing Mechanism of Pressure-Holding Controller

3.2. Contact Mechanics Modelling of Contact Pins

4. Simulation Result Analysis

5. Conclusions

- (1)

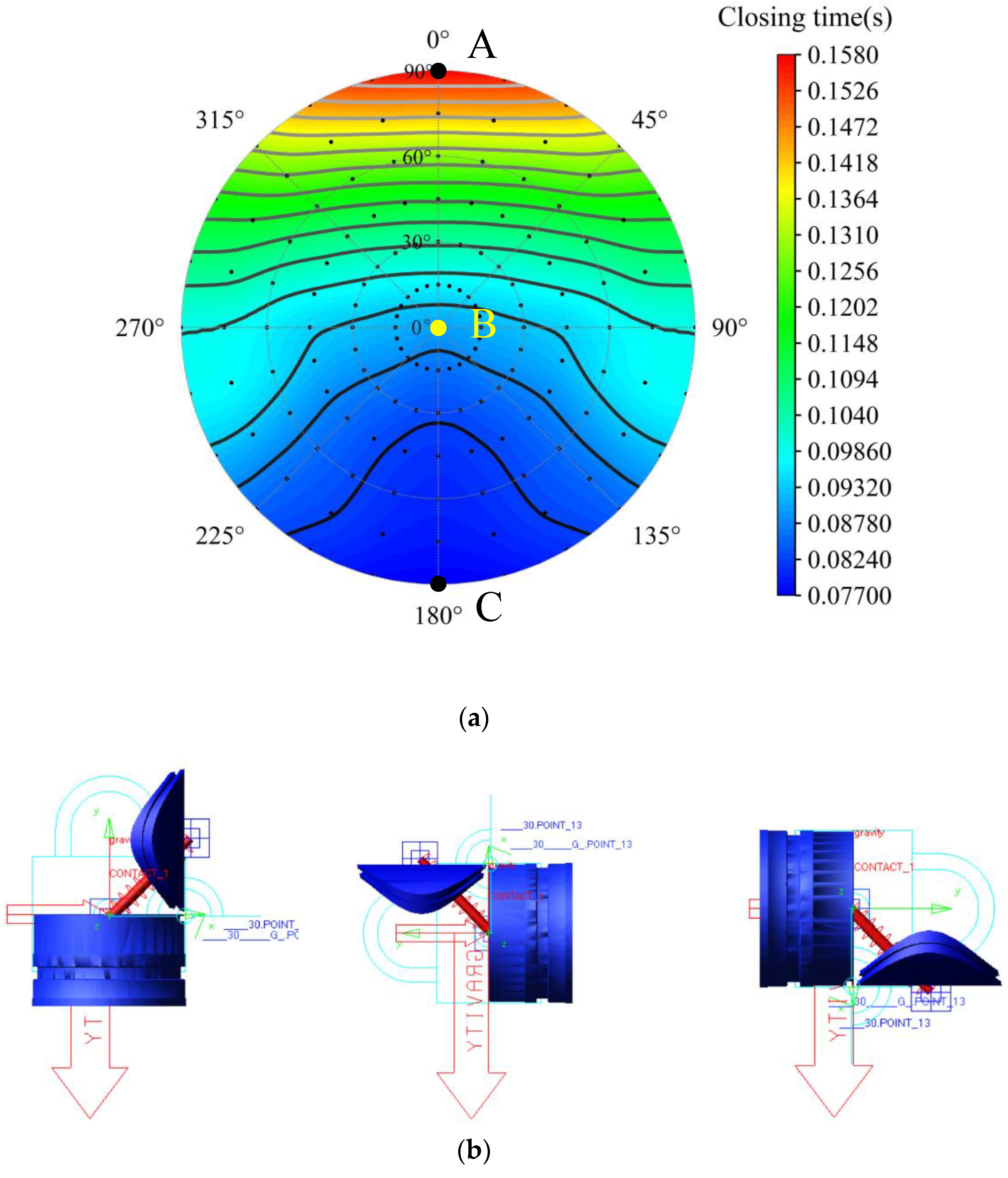

- The pressure-holding controller mechanism driven by the elastic force had different closing times at different angles in space, and the closing rules of the valve cover at different azimuth angles were obtained. The two extreme positions with the longest and shortest closing times of the valve cover occurred when the coring device performed horizontal coring, the closing time was the shortest when the pressure-holding controller hinge was at the top, and the closing time was the longest when the pressure-holding controller hinge was at the bottom.

- (2)

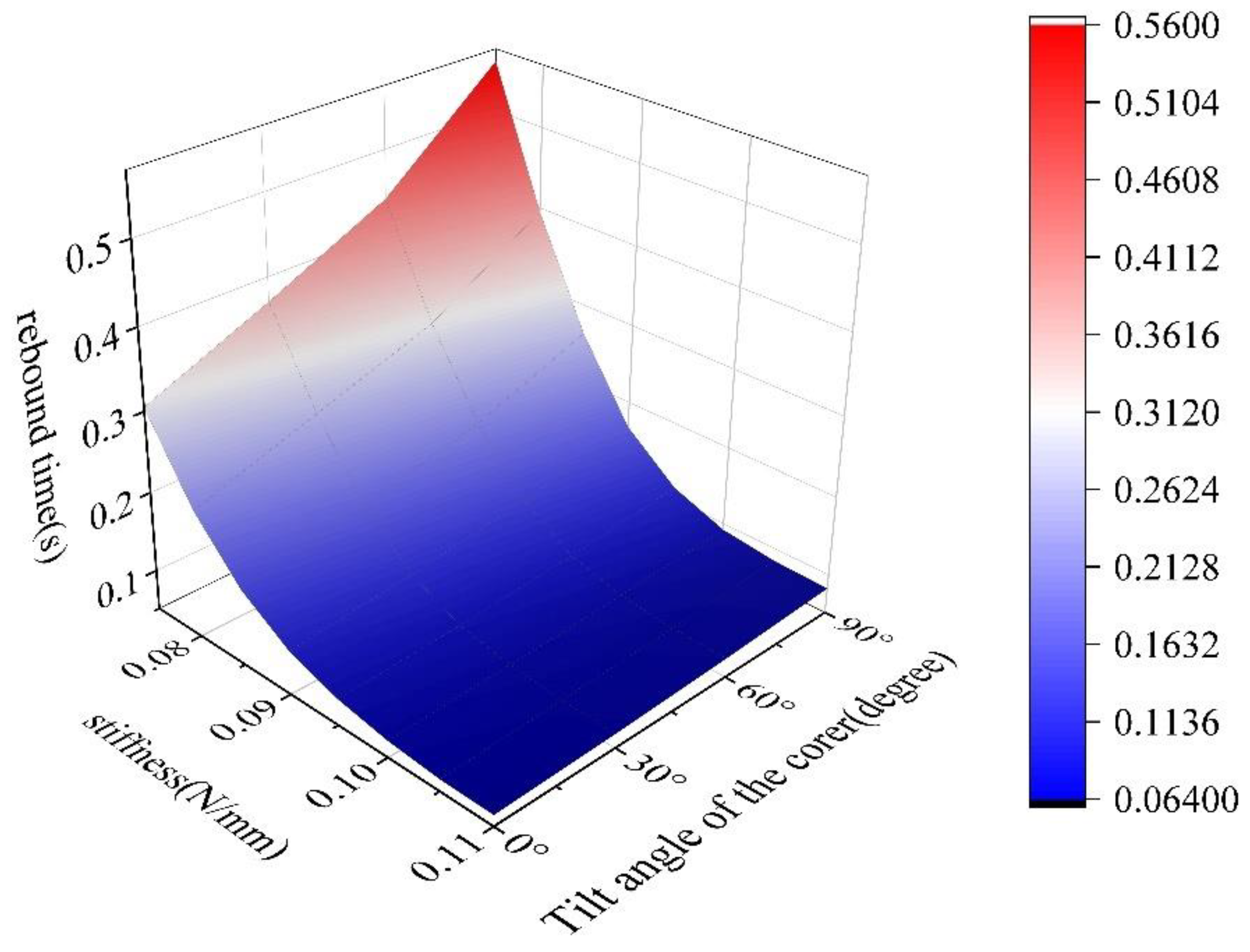

- According to the simulation experiments of the spring sleeve springback at several different angles, the selection range of the spring stiffness was determined. In the case of applying fixed initial pressure to the valve cover of the pressure-holding controller, a spring with a small stiffness value should be used. According to the simulation test results, the optimal solution of 0.08 N/mm was obtained.

- (3)

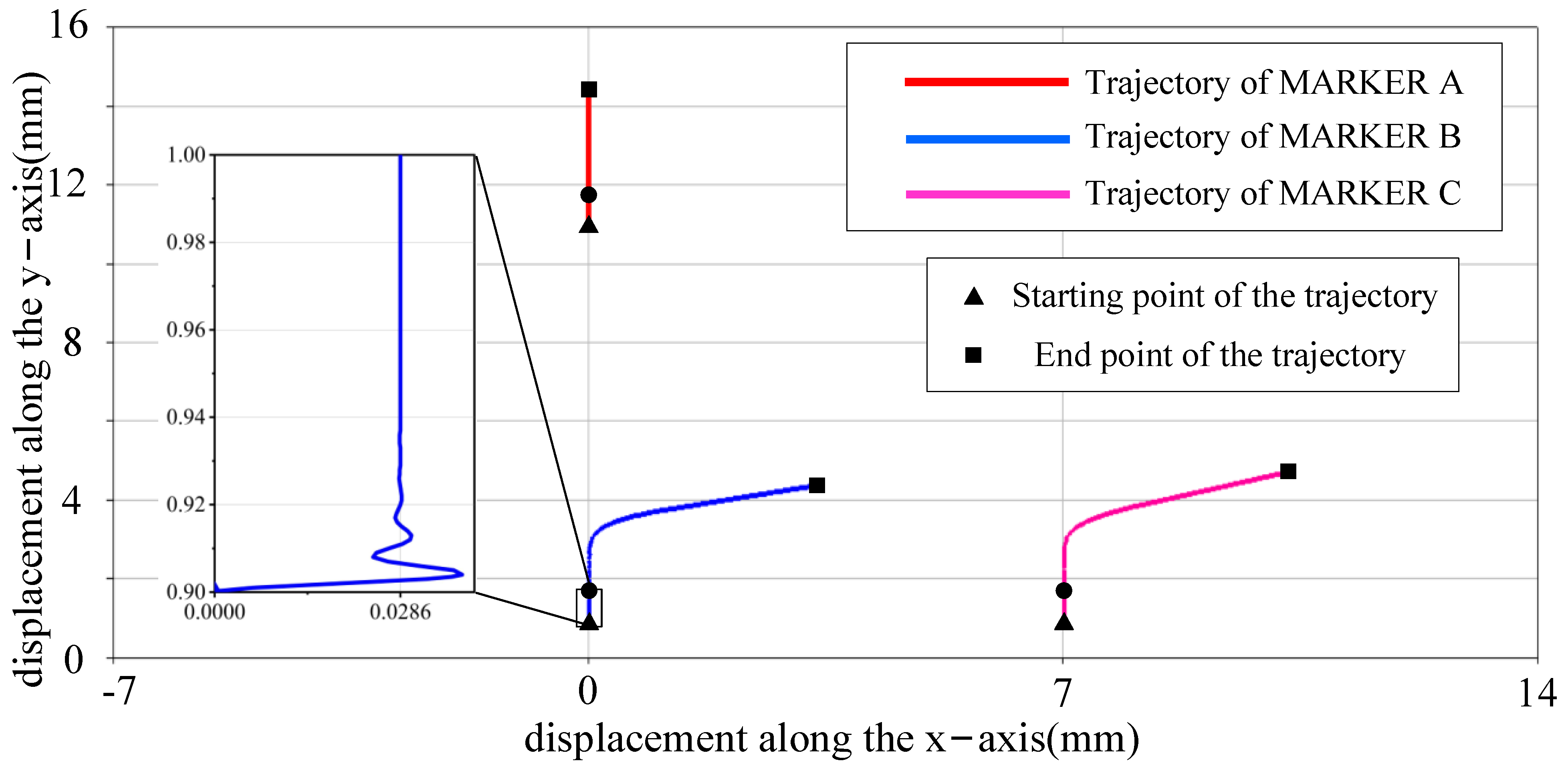

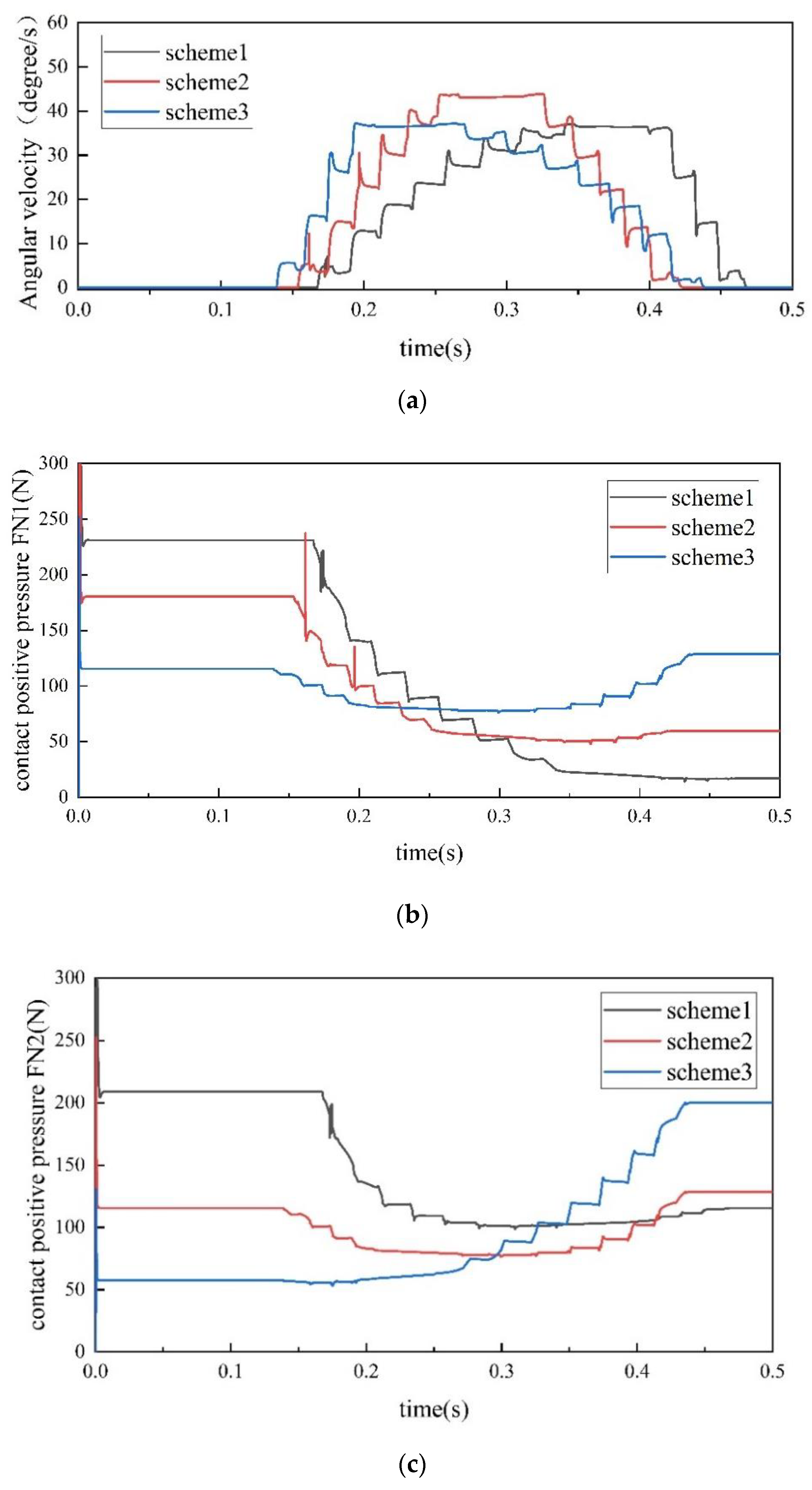

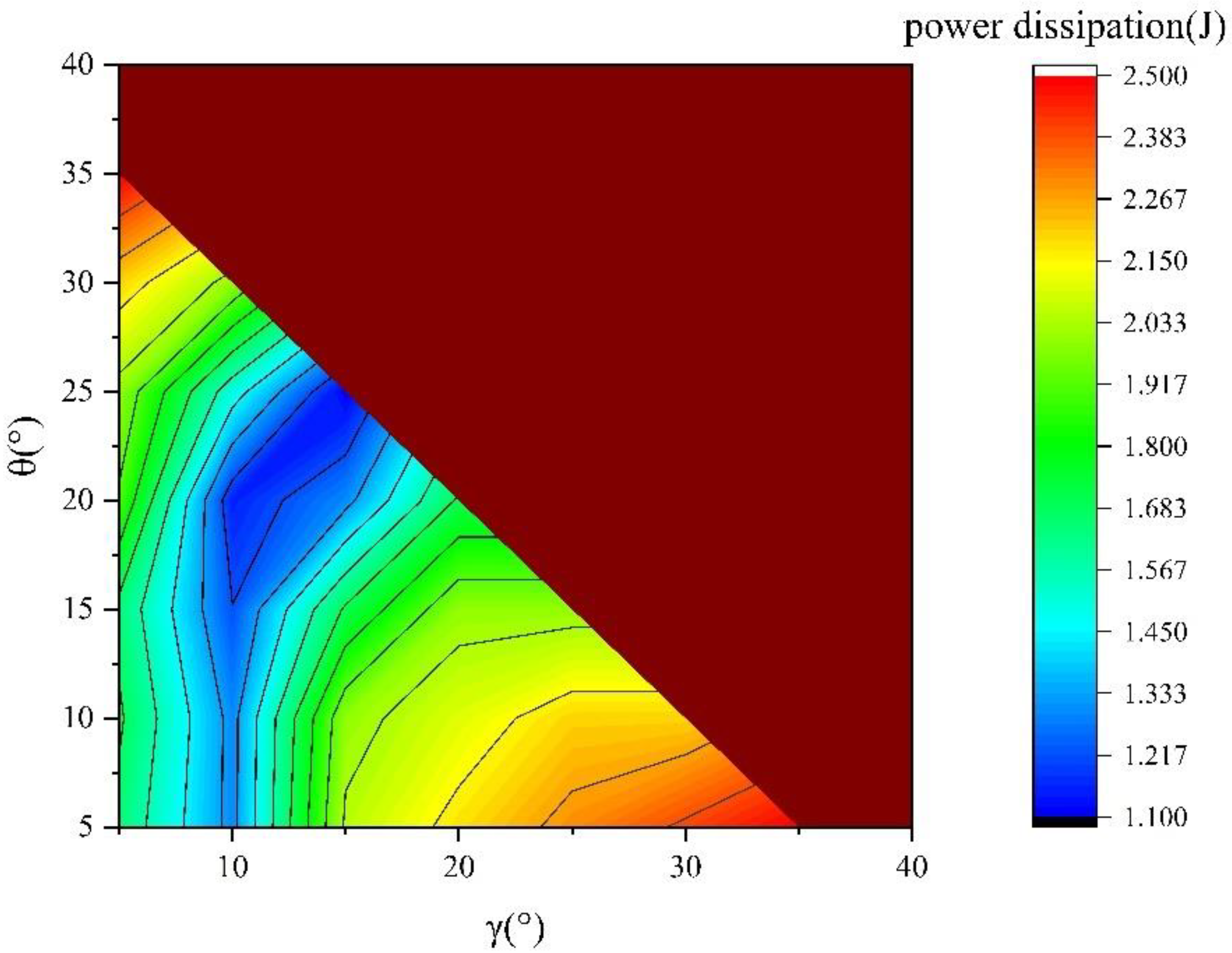

- The surface contact mechanics of the trigger mechanism was modeled, the dynamic contact force and dynamic friction force between components under different angle schemes were calculated through numerical simulation, and the energy efficiency of the mechanical system was compared in the three schemes from the perspective of energy input and consumption. scheme 2 was more suitable, and the kinetics was verified and optimized. On this basis, by comparing different combinations of α and β angles, the best set of angle values for γ and θ was optimized, and the key parameters of the contact pin were determined.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, H.-P.; Gao, F.; Ju, Y. Research and development of rock mechanics in deep ground engineering. Chin. J. Rock Mech. Eng. 2015, 34, 2161–2178. [Google Scholar]

- Xie, H.P.; Gao, F.; Ju, Y.; Ge, S.R.; Wang, G.F.; Zhang, R.; Gao, M.Z.; Wu, G.; Liu, J.Z. Theoretical and technological conception of the fluidization mining for deep coal resources. J. China Coal. Soc. 2017, 42, 547–556. [Google Scholar]

- Gao, M.; Xie, J.; Guo, J.; Lu, Y.; He, Z.; Li, C. Fractal evoluti on and connectivity characteristics of mining-induced crack networks in coal masses at different depths. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 1. [Google Scholar]

- Xie, H.; Ju, Y.; Gao, F.; Gao, M.; Zhang, R. Groundbreaking theoretical and technical conceptualization of fluidized mining of deep underground solid mineral resources. Tunn. Undergr. Space Technol. 2017, 67, 68–70. [Google Scholar] [CrossRef]

- Xie, H.; Ju, Y.; Ren, S.; Gao, F.; Liu, J.; Zhu, Y. Theoretical and technological exploration of deep In situ fluidized coal mining. Front. Energy 2019, 13, 603–611. [Google Scholar] [CrossRef]

- Xie, H. Research review of the state key research development program of China: Deep rock mechanics and mining theory. J. China Coal Soc. 2019, 44, 1283–1305. [Google Scholar]

- Gao, M.-Z.; Wang, M.-Y.; Xie, J. In-situ disturbed mechanical behavior of deep coal rock. J. China Coal Soc. 2020, 45, 2691–2703. [Google Scholar]

- Gao, M.; Hao, H.; Xue, S.; Lu, T.; Cui, P.; Gao, Y.; Xie, J.; Yang, B.; Xie, H. Discing behavior and mechanism of cores extracted from Songke-2 well at depths below 4500 m. Int. J. Rock Mech. Min. Sci. 2022, 149, 104976. [Google Scholar]

- Gao, M.; Xie, J.; Gao, Y.; Wang, W.; Li, C.; Yang, B.; Liu, J.; Xie, H. Mechanical behavior of coal under different mining rates: A case study from laboratory experiments to field testing. Int. J. Min. Sci. Technol. 2021, 31, 825–841. [Google Scholar] [CrossRef]

- Gao, M.Z.; Yang, B.G.; Xie, J.; Ye, S.Q.; Liu, J.J.; Liu, Y.T.; Tang, R.F.; Hao, H.C.; Wang, X.; Wen, X.Y.; et al. The mechanism of microwave rock breaking and its potential application to rock-breaking technology in drilling. Pet. Sci. 2022. [Google Scholar] [CrossRef]

- Kvenvolden, K.A.; Cameron, D. Pressure core barrel; Application to the study of gas hydrates. Deep Sea Drilling Project Site 533, Leg 76. Initial. Rep. DSDP 1983, 76, 367–375. [Google Scholar]

- Milkov, A.V.; Dickens, G.R.; Claypool, G.E.; Lee, Y.J.; Borowski, W.S.; Torres, M.E.; Xu, W.; Tomaru, H.; Tréhu, A.M.; Schultheiss, P. Co-existence of gas hydrate, free gas, and brine within the regional gas hydrate stability zone at Hydrate Ridge (Oregon margin): Evidence from prolonged degassing of a pressurized core. Earth Planet. Sci. Lett. 2004, 222, 829–843. [Google Scholar] [CrossRef]

- Dickens, G.R.; Wallace, P.J.; Paull, C.K.; Borowski, W.S. Detection of methane gas hydrate in the pressure core sampler (PCS): Volume-pressure-time relations during controlled degassing experiments. In Proceedings of the Ocean Drilling Program: Scientific Results; Texas A&M University: College Station, TX, USA, 2000; Volume 164, pp. 113–126. [Google Scholar]

- Amann, H.; Hohnberg, H.; Reinelt, R. HYACE-a novel autoclave coring equipment for systematic offshore gashydrate sampling. In Proceedings of the Conference on gas hydrates—noxious substances or resources, Tagung: Gashydrate—Problemstoff/Resource, Clausthal-Zellerfeld, Germany, 6–7 November 1997. [Google Scholar]

- Schultheiss, P.; Holland, M.; Humphrey, G. Wireline coring and analysis under pressure: Recent use and future developments of the HYACINTH system. Sci. Drill. 2009, 7, 44–50. [Google Scholar] [CrossRef]

- Abegg, F.; Hohnberg, H.J.; Pape, T.; Bohrmann, G.; Freitag, J. Development and application of pressure-core-sampling systems for the investigation of gas-and gas-hydrate-bearing sediments. Deep. Sea Res. Part I Oceanogr. Res. Pap. 2008, 55, 1590–1599. [Google Scholar] [CrossRef]

- Qin, H. Research on Low-Disturbing Sampling Theory and Truth-Preserving Technique of Deep-Sea Surface Layer Sediment; Zhejiang University: Hangzhou, China, 2005. [Google Scholar]

- Zhu, H.Y.; Liu, Q.Y.; Wong, G.R.; Xiao, X.H.; Zhu, X.H.; Jiang, Z.L.; Zhang, D.Y. A pressure and temperature preservation system for gas-hydrate-bearing sediments sampler. Pet. Sci. Technol. 2013, 31, 652–662. [Google Scholar] [CrossRef]

- Luo, Y.; Peng, J.; Sun, M.; Sun, Q.; Ji, T.; Bo, K. An ice-valve-based pressure-coring system for sampling natural hydrate-bearing sediments: Proof-of-concept laboratory studies. J. Nat. Gas Sci. Eng. 2015, 27, 1462–1469. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, J.; Sun, M.; Gao, Q.; Wu, D. Development of applicable ice valves for ice-valve-based pressure corer employed in offshore pressure coring of gas hydrate-bearing sediments. Chem. Eng. Res. Des. 2016, 111, 117–126. [Google Scholar] [CrossRef]

- Qin, Y.; Yuan, L.; Hu, Q.T.; Ye, J.P.; Hu, A.M.; Shen, B.H.; Cheng, Y.P.; He, X.Q.; Zhang, S.A.; Li, G.F.; et al. Status and development orientation of coal bed methane exploration and development technology in China. Coal Sci. Technol. 2012, 40, 1–6. [Google Scholar]

- Wang, X.; Zou, D.; Yang, L.; Liu, A. Design of a pressure preservation coring tool for deep and ultra-deep coalbed methane samples. China Pet. Mach. 2020, 48, 40–45. [Google Scholar]

- Wang, F.; Luo, Y.; Liang, Y.; Peng, J.; Li, B. Sampling methane-bearing coal seams by freezing method: Coalbed methane desorption and inhibition characteristics under freezing temperature. Nat. Resour. Res. 2020, 29, 1351–1360. [Google Scholar] [CrossRef]

- Gao, M.Z.; Chen, L.; Fan, D.; Yang, M.Q.; Liu, C.; Li, J.N.; Zhao, L.; Tian, D.Z.; Li, C.; Wang, R.Z.; et al. Principle and technology of coring with in-situ pressure and gas maintaining in deep coal mine. J. China Coal Soc. 2021, 46, 885–897. [Google Scholar]

- Xie, H.P.; Liu, T.; Gao, M.Z.; Chen, L.; Zhou, H.W.; Ju, Y.; Gao, F.; Peng, X.B.; Li, X.J.; Peng, R.D.; et al. Research on in-situ condition preserved coring and testing systems. Pet. Sci. 2021, 18, 1840–1859. [Google Scholar] [CrossRef]

- Li, C.; Xie, H.; Gao, M.; Chen, L.; Zhao, L.; Li, C.; Wu, N.; He, Z.; Li, J. Novel designs of pressure controllers to enhance the upper pressure limit for gas-hydrate-bearing sediment sampling. Energy 2021, 227, 120405. [Google Scholar] [CrossRef]

- Xie, H.; Gao, M.; Zhang, R.; Peng, G.; Wang, W.; Li, A. Study on the Mechanical Properties and Mechanical Response of Coal Mining at 1000 m or Deeper. Rock Mech. Rock Eng. 2018, 52, 1475–1490. [Google Scholar] [CrossRef]

- Gao, M.Z.; Zhang, J.G.; Li, S.W.; Wang, M.; Wang, Y.W.; Cui, P.F. Calculating changes in fractal dimension of surface cracks to quantify how the dynamic loading rate affects rock failure in deep mining. J. Cent. South Univ. 2020, 27, 3013–3024. [Google Scholar] [CrossRef]

- Xie, J.; Gao, M.; Zhang, S.; Fu, C.; Peng, G.; Liu, J. Experimental study on triaxial fracture behavior and energy release law of deep coal under the effect of loading rates. J. Cent. South Univ. (Sci. Technol.) 2021, 52, 2713–2724. [Google Scholar]

- Wu, N.; Xie, H.; Chen, L.; Gao, M.; Li, C. Sealing Form and Failure Mechanism of Deep In Situ Rock Core Pressure-Maintaining Controller. Geofluids 2020, 2020, 8892720. [Google Scholar] [CrossRef]

- Liu, P.; Song, W.; Jiang, Q.; Li, X. Sealing performance of O-ring in deep sea high pressure environment. Chin. Hydraul. Pneum. 2017, 66–70. [Google Scholar] [CrossRef]

- Ji, J. Research on Sealing and Friction Characteristics of O-Seal Ring. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2015. [Google Scholar]

- Zheng, E.; Zhu, R.; Zhu, S.; Lu, X. A study on dynamics of flexible multi-link mechanism including joints with clearance and lubrication for ultra-precision presses. Nonlinear Dyn. 2016, 83, 137–159. [Google Scholar] [CrossRef]

- Li, J.; Yan, S.; Guo, F.; Guo, P. Effects of damping, friction, gravity, and flexibility on the dynamic performance of a deployable mechanism with clearance. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2013, 227, 1791–1803. [Google Scholar] [CrossRef]

- Zheng, E.; Zhou, X. Modeling and simulation of flexible slider-crank mechanism with clearance for a closed high speed press system. Mech. Mach. Theory 2014, 74, 10–30. [Google Scholar] [CrossRef]

- Rong, X.; Li, Y.; Ruan, J.; Li, B. Design and simulation for a hydraulic actuated quadruped robot. J. Mech. Sci. Technol. 2012, 26, 1171–1177. [Google Scholar] [CrossRef]

- Khemili, I.; Romdhane, L. Dynamic analysis of a flexible slider–crank mechanism with clearance. Eur. J. Mech. A/Solids 2008, 27, 882–898. [Google Scholar] [CrossRef]

- Sharf, I.; Zhang, Y.N. A contact force solution for non-colliding contact dynamics simulation. Multibody Syst. Dyn. 2006, 16, 263–290. [Google Scholar] [CrossRef]

| Component | Core Barrel Boot | Sleeve | Contact Pin | Outer Tube |

|---|---|---|---|---|

| Core barrel boot | ||||

| Sleeve | Translational joint | |||

| Contact pin | Contact force | Revolute joint, Contact force | ||

| Outer tube | None | Translational joint (with friction), spring force | Contact force (with Coulomb friction) |

| Elastic modulus (GPa) | 220 |

| Poisson’s ratio | 0.27 |

| Static friction coefficient | 0.3 |

| Coefficient of kinetic friction | 0.18 |

| Contact stiffness (N/mm) | |

| Contact stiffness (N/mm) | |

| Drive speed (mm/s) | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, M.; Li, Y.; Chen, L.; Yang, X.; Duan, Z.; Fu, C.; Wang, D. Structural Design and Dynamic Simulation Optimization of the Triggering Device in a Pressure-Holding Controller for Deep in Situ Coring. Appl. Sci. 2022, 12, 4961. https://doi.org/10.3390/app12104961

Xu M, Li Y, Chen L, Yang X, Duan Z, Fu C, Wang D. Structural Design and Dynamic Simulation Optimization of the Triggering Device in a Pressure-Holding Controller for Deep in Situ Coring. Applied Sciences. 2022; 12(10):4961. https://doi.org/10.3390/app12104961

Chicago/Turabian StyleXu, Meng, Yanyan Li, Ling Chen, Xun Yang, Zengfeng Duan, Chenghang Fu, and Dingming Wang. 2022. "Structural Design and Dynamic Simulation Optimization of the Triggering Device in a Pressure-Holding Controller for Deep in Situ Coring" Applied Sciences 12, no. 10: 4961. https://doi.org/10.3390/app12104961

APA StyleXu, M., Li, Y., Chen, L., Yang, X., Duan, Z., Fu, C., & Wang, D. (2022). Structural Design and Dynamic Simulation Optimization of the Triggering Device in a Pressure-Holding Controller for Deep in Situ Coring. Applied Sciences, 12(10), 4961. https://doi.org/10.3390/app12104961