Abstract

In the digital transformation era in the Architecture, Engineering, and Construction (AEC) industry, Cognitive Digital Twins (CDT) are introduced as part of the next level of process automation and control towards Construction 4.0. CDT incorporates cognitive abilities to detect complex and unpredictable actions and reason about dynamic process optimization strategies to support decision-making in building lifecycle management (BLM). Nevertheless, there is a lack of understanding of the real impact of CDT integration, Machine Learning (ML), Cyber-Physical Systems (CPS), Big Data, Artificial Intelligence (AI), and Internet of Things (IoT), all connected to self-learning hybrid models with proactive cognitive capabilities for different phases of the building asset lifecycle. This study investigates the applicability, interoperability, and integrability of an adapted model of CDT for BLM to identify and close this gap. Surveys of industry experts were performed focusing on life cycle-centric applicability, interoperability, and the CDT model’s integration in practice besides decision support capabilities and AEC industry insights. The evaluation of the adapted model of CDT model support approaching the development of CDT for process optimization and decision-making purposes, as well as integrability enablers confirms progression towards Construction 4.0.

1. Introduction

Computerization and digitization are beginning to significantly affect how physical/engineering properties are handled during their life cycles [1,2]. The capture, exchange, use, and control of data and information during an asset’s entire life (design, construction, Operation and Maintenance (O&M), and disposal/renewal) are among the most challenging aspects of implementing Building Information Modeling (BIM), so-called BIM in asset management [3]. Intelligent, innovative asset life cycle management has arisen during the last years in the Architecture, Engineering, and Construction (AEC) industry [2]. Digital twins (DT), the blockchains, and the Internet of Things (IoT) draw interest because of their synergistic and information management functionality [4].

Cognitive computing is machines’ ability to mimic the human capacity to sense, think, and make optimal decisions in a given situation [5]. While the path reaching fully cognitive systems is still in its early stage, there are several application areas where the technology has already been implemented in many applications such as chatbots by the service sector to provide optimal responses to customer feedback [6].

The DT is already in the early stages, mainly used for prototyping, and includes modeling, simulation, verification, evaluation, and confirmation of the physical artifact using a simulated replica [7]. Analysis emphasis has been heavily placed on simulations and what-if analyses to advise implementation and eventual physical product refinement by continuous monitoring and data assimilation. According to Zhang et al. [8], encompassing intelligence and cognition in a DT is a requirement to realize disruptive technology’s potential accurately and to produce integration, calibration, and symbiotic connectivity in the environments, the physical and virtual replica. According to intelligence and cognition, mental abilities and mechanisms that utilize complex information management and synergy across physical and digital settings will manipulate and strengthen the “twining” structure. Dimensions can be listed as stimuli, interaction, aims, time, and situation switching. The main goal is to foster self-adaptive assessment and smart, proactive decision-making through the two realms in an info-symbiotic way and work on the more wealthy and finer-grained information base. Cyber-Physical Systems (CPS) and socio-technical environments, for example, may benefit from this view because their activities are marked by ambiguity, dynamism, and confusion. Cyber Foraging will represent intelligent analysis and planning simulation difficult and costly computational to achieve this in reality with limited computing resources.

In the digital transformation era in the AEC industry, Cognitive Digital Twins (CDT) are introduced as part of the next level of process automation and control towards Construction 4.0 [9]. CDT incorporates cognitive abilities to detect complex and unpredictable actions and reason about dynamic process optimization strategies to support decision-making in building lifecycle management (BLM). Nevertheless, there is a lack of awareness of the real impact of CDT integration, Machine Learning (ML), CPS, Big Data, Artificial Intelligence (AI), and Internet of Things (IoT), all connected to self-learning hybrid models with proactive cognitive capabilities for different phases of the building asset lifecycle. This study investigates the applicability, interoperability, and integrability of an adapted model of CDT for BLM to identify and close this gap. Four research questions are raised in line with the study’s goals:

- (1)

- What functionalities do industry professionals allocate a CDT for BLM?

- (2)

- What are achievable interoperability levels between CDT, IoT, Big data, and AI with current BLM technologies?

- (3)

- What integrability enablers are necessary for implementing the CDT for BLM?

- (4)

- How and what information should be retrievable and assignable to CDT?

As the immense contribution, the knowledge domain understands how a CDT model operates and how it connects to most BLM fields. Besides, the study of integrability enablers and professionals’ perceptions of the technical ecosystem’s accessibility is facilitated by synthesizing industry professionals’ questionnaire perspectives. Understanding DT’s interoperability value, IoT, AI, big data, and sophisticated building management systems could also help build life cycle management.

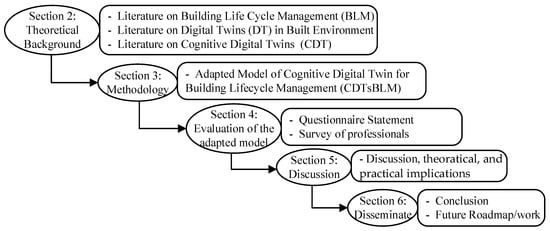

As shown in Figure 1, this article is structured as follows: in section two (theoretical background), BLM’s essential concepts and CDT are depicted. Section three describes the adapted model of CDT for BLM. In section four, an evaluation of the CDTsBLM model is presented. Section five offers the discussions on decision support capabilities, integrability enablement, and practical implications. In section six, the conclusions, recommendations, and future road map are presented.

Figure 1.

Research framework of the adapted model of Cognitive Digital Twins for Building Lifecycle Management.

2. Theoretical Background

This section outlines key related works in the three main areas relevant to this article: (1) Building Lifecycle Management (BLM)’s essential concepts; (2) Digital Twins (DTs) in build environment and; (3) Cognitive Digital Twins (CDT) are presented.

2.1. Building Lifecycle Management (BLM)

The building lifecycle mainly includes the design, construction, operation, maintenance, and end-of-life stages. Each step can be separated into superimposed information layers that entail efficient data/information exchange strategies for interoperability throughout all lifecycle phases [10]. BLM refers to a method of integrating and handling the different stages of a construction project’s lifecycle [11]. BLM is a strategic planning process that supports the development, operation, and maintenance of buildings and their associated infrastructure, including building planning, design, construction, operation, and maintenance. It aims to reduce costs and improve efficiency by ensuring that buildings are built, operated, maintained, and replaced in the most cost-effective and timely manner. The BLM is an integrated approach to building management that considers all the building activities, the building’s surroundings, and the impact of these activities on the environment. The BLM, directly and indirectly, affects many aspects, such as buildings or infrastructures’ operation and efficiency, operational risks, the environmental impact of buildings, people’s quality of life, safety, and businesses. Such a complex and complicated process needs to be real-time, accurate, intelligent, and automated to monitor, detect, learn, analyze, simulate, validate, and operate. There are disintegrated data and information in every phase of the construction project, which contains a significant amount of design and cost information in the design process and decision-making steps; in the implementation step, a considerable amount of material consumption beyond the data generated during the design process and decision-making steps; and a vast data and information in operation and maintenance step.

As a result, to enforce BLM, a management mechanism must be developed that communicates each participant’s expertise and phase of the development project to avoid a lack of sufficient and timely information connection and dissemination at different life cycle stages [12]. BLM sometimes starts with a physical analysis of the structure to generate a numerical representation (e.g., CAD documents). In this sense, at the beginning of its lifecycle, developing an effective BLM system is more than enough to avoid data loss during the building’s construction, use/maintenance, and disposal [13]. By offering an interactive IT environment to handle the whole construction lifecycle, BLM seeks to migrate and enhance knowledge exchange in all phases of the building process [14]. Energy management, facilities management, maintenance management, and product/information traceability management are part of a scalable BLM scheme that allows users to incorporate and reuse building knowledge, domain expertise across a building’s life cycle [13,14,15,16]. A scalable networking infrastructure that offers uniform interfaces for sharing all forms of data consumed or generated by the participants, corporations, or information systems, in general, participating in the building lifecycle is a vital component of a functional BLM framework. BLM must interact with any intelligent items/systems that are part of the building lifecycle (sensors, actuators, RFID, databases) [10]. According to BIM, a technique that seeks to manage a building’s entire life cycle in a particular data environment, proper data digitalization may optimize knowledge management and share within the multidisciplinary team [17].

2.2. Digital Twins (DTs) in the Built Environment

The CPS is realized through the DT for visualization, modeling, simulation, analysis, prediction, and optimization. DT contains three main components to create a practical loop: a physical entity, a virtual entity, and a data link [18]. Usually, there are two approaches to dynamic mapping in the DT. Inspection data are gathered in the physical world and subsequently transmitted to the virtual world for further analysis. Simulation, prediction, and optimization are achieved in the virtual model by learning data from multiple sources, offering prompt solutions to guide the realistic process and adapt to the changing context.

Based on Alizadehsalehi and Yitmen [19], DTs have various features in the AEC industry such as Real-time (gather and present real-time data of physical assets), Analytics (store data, run continuous analytics from historical data, and provide helpful insight), Simulations (utilize to run various data-driven simulations), visualization (overlay real-life and live 3D BIM models, images, and videos of the physical asset and also the foundation for immersive visualizations), Automation (a bi-directional system that can manage the behavior of physical assets), and Predictions (provide predictions of assets’ future behaviors using historical data and analytics of various scenarios assets). As a comprehensive summary, Table 1 presents DT applications in the AEC industry that appeared in the recent literature (2019–2021).

Table 1.

Digital Twins applications in the AEC industry that appeared in the recent literature.

2.3. Cognitive Digital Twins (CDT)

The DT concept allows the physical equivalent to be mirrored in virtual space, including exchanging data between them [7]. CDT expresses an evolution of the DT concept. It has been crafted to fit the requirement of monitoring complex industrial processes and apply the same trade model, shadow, and thread of DTs [6]. The balance between rapidity, resolution, and exception handling is crucial from any industry’s economic perspective [44]. Virtualization in a dynamic, run-time process allows the digital counterpart’s behavioral model to be constantly modified to mimic the physical element’s actions, resulting in the CDT [45]. Virtualization is a dynamic design-time process involving computational approaches to model the physical feature, evolving into the complex, run-time process that allows the digital counterpart’s behavioral model to be constantly adjusted to mirror the physical element’s actions, resulting in the CDT. The CDT is a DT with cognitive abilities, including detecting anomaly and behavioral learning, and the power to determine physical twin actions to improve measures defining its state or function [46]. Therefore, a CDT uses optimization approaches to aid decision-making and data from the physical twin analyzed using analytics or ML.

To put it another way, the CDT is envisioned as a robust monitoring and control mechanism and an essential part of the decision-making action that leads to system optimization. Using optimization techniques inside the heart of the cognitive twin and its impact is the primary crucial differentiating point instead of currently available DT solutions [46]. To make the transition from physical assets in the form of digital replicas to cognitive advancement, Abburu et al. [6] used a three-layer structure to describe the types of twins needed: digital, hybrid, and cognitive. The need to build isolated models of systems for anomaly detection, connect the models for predicting unusual behavior, and problem-solving skills to deal with uncertain situations constitutes the three-layer separation. CDT is characterized in DT through advanced semantic abilities to detect the mechanisms of virtual model evolution, enhance DT-based decision-making, and foster the interpretation of virtual model interrelationships [47]. The CDT ensures that assets are adequately managed and that problems outside technical stakeholders are resolved by implementing Internet of Things (IoT) systems [48].

CDTs may have a high degree of intelligence, allowing them to mimic human cognitive processes and perform conscious acts with little or no human intervention [8]. The Knowledge Core of CDT has semantic-driven recognition, learning, inference, estimation, and decision qualifications consisting of a series of prediction and ML models developed using the data from multiple sources such as physical equivalents and sensors from all aspects of operational conditions of the industrial systems. Besides, it incorporates temporal supply chain data and processes as well as experts’ domain knowledge. As a result, the CDT can train and improve to represent and depict the physical asset’s current state and operating conditions in real-time. Furthermore, in both the digital and physical worlds, the CDT can identify, analyze, deduce, forecast the twinned physical system’s present and potential actions, and produce decisions by interrelating machines and humans.

Lu et al. [49] suggested a new cognitive twins so-called CT definition and a knowledge graph-centric framework for the CT process. Du et al. [50] explored how to build individualized information systems for future smart cities using a human-centered DT simulation approach of cognitive behaviors. Eirinakis et al. [46] suggested an Enhanced Cognitive Twin so-called ECT introducing advanced cognitive skills to the DT asset that allow assisting choices to allow DTs to respond to internal or external stimulation in the context of process industries. The ECT can be used at varying levels of the supply chain hierarchy, including sensor, device, process, workforce, and manufacturing stages, and can be integrated to allow lateral and vertical interaction.

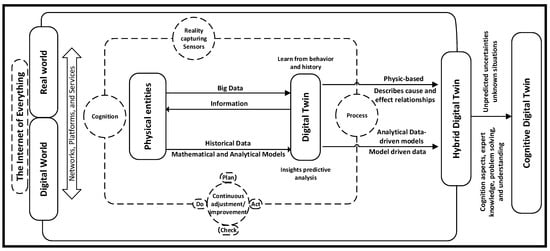

The concepts of the Hybrid and Cognitive Digital Twin (COGNITWIN) toolbox were developed by Abburu et al. [6] to cover cognitive skills for efficient management and operation of processing equipment, for lowering production costs, and efficiency improvements in the process industry. A sensor network can constantly track and capture data from different plant processes and properties stored in a standard setup database. The COGNITWIN project mainly aims at adding the cognitive component to process control systems, thus enabling them to self-organize and provide solutions in case of unexpected behaviors. Figure 2 shows the different stages of DT to CDT. A DT is a formal digital representation of an asset, process, or system that captures any systems’ attributes and behaviors through IoT-based various reality capturing sensors suitable for communication, storage, interpolation, and processing to measure, simulate, and experiment with the digital replica to understand its physical counterpart. A DT for monitoring, diagnostics, and prognostics to optimize asset performance and utilization uses sensory data combined with historical data, human expertise, and fleet and simulation learning to improve prognostic outcomes. A DT gets data from physical entities and applies them to the model.

Figure 2.

Different stages of Digital Twins to Cognitive Digital Twins.

A Hybrid Digital Twin is usually defined as the DT comprised of combined multiple models. A Hybrid Twin (HT) extends the DT by intertwining different models to take advantage of both physics space and data-driven modeling. HT gets the data from the physical entities and uses them in several models jointly. The way to increase the degree of influence and scope of DT is to have cognitive features, such as reasoning, planning, and learning. Digital twins based on data analytics require immense amounts of data for accuracy, and while physics-based simulation models are highly accurate, they take an incredible amount of time to run. New hybrid systems are combining the best of both worlds for a digital twin that is both quick and exact.

Although HT has a lot of different models, there are so many parameters that influence the processes that, in some situations, are not covered by existing models. CDT represents the next step in evolving the DT concept in the AI era, incorporating cognition aspects to deal with unforeseen situations effectively. Revolutionary DTs will arise as a result of intertwining distinct models to accomplish advanced predictive capabilities and finding solutions to problems to be encountered by integrating expert knowledge. CDT gets data from physical entities and compares them with models, including models of expert knowledge.

Table 2, as a comprehensive summary, exhibites diverse CDT applications in various fields of industry based on the latest research (2019–2021).

Table 2.

Diverse Cognitive Digital Twins applications in various fields of industry.

3. Methodology

3.1. Adapted Model of aCognitive Digital Twin for Building Lifecycle Management (CDTsBLM)

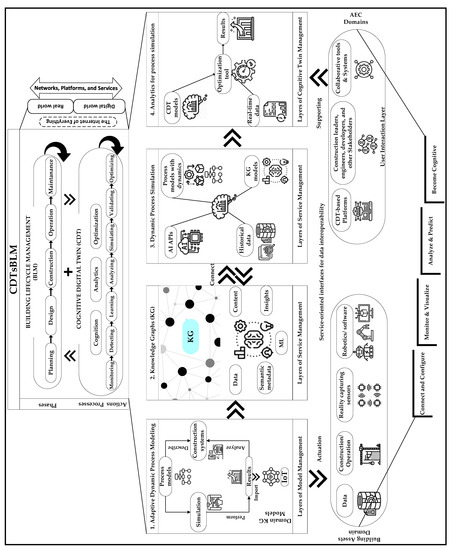

This paper reviews previous work on BLM, DT in the built environment, and CDT and presents an adapted framework developed by Lu et al. [48] and Abburu et al. [6] to improve BLM with CDT in the AEC industry. The adapted framework in this research is referred to as the CDTsBLM Model of the framework. This framework’s processes, as shown in Figure 3, are discussed in detail in this section. The CDT is a capabilities-driven digital representation of its physical twin. It should be a capability augmentation and an intelligent digital companion cycle and evolution phases. CDT facilitates cognition towards improving the behavior of the complex process systems inherent in planning, design, construction, and operations. An ML pipeline automates the ML workflow by facilitating data to be converted and associated into a model that can be processed to automate the ML model’s outputs and input data completely. As shown in Figure 3, the conceptual framework facilitates the implementation and evaluation of consistent CDT in BLM by integrating various pipelines of ML and analytical tools at various stages from planning to the whole operations through the processing phases during operations.

Figure 3.

Knowledge Graph-centric Conceptual Framework of Cognitive Digital Twin for Building Lifecycle Management (CDTsBLM) (adapted from the developed framework by Lu et al. [48] and Abburu et al. [6]).

3.1.1. CDTsBLM Framework

The first section of CDTsBLM is CDT and adaptive dynamic process modeling. In this section, all IoT-based systems, consisting of reality capturing sensors, other construction-related technologies, networks, and computational composition, are considered hybrid systems, including continuous systems and discrete systems. DT is an incorporated structure of mathematical models and data ensuring that real physical systems and their virtual entities are synchronized in real-time. Such a method can be characterized as whole workflows where the computing composition and other plant nodes are connected. A process modeling and simulation approach is applied to enact these workflows and simulate the hybrid system behaviors in this arrangement.

Knowledge Graph (KG) helps to represent the data that can achieve cognitive learning by machines. Knowledge is awareness or familiarity, someone or something gained by the experience of a fact or situation. On the other side, a Graph represents how any data are stored in the form of associations. KG is a term of how the engine builds relationships between people, technology, and facts. The KG models are focused on topological relationships between physical and cognitive entities. Ontologies for KG models are created before designing KG models to describe semantics and syntax. KGs will serve as the core mechanism for ML flows, extending data manipulation to enable practical consumption through CDTsBLM. KGs and ML techniques provide the required abstraction layer to clarify better (a) the context of each method and (b) the complex interactions that represent machine-understandable data and ML algorithms to make it easier for data and information extraction tools to communicate.

Artificial Intelligence (AI) APIs, historical data, process models with dynamics, and KG models are integrated to produce CDT models. CDT models aim to support decision-making for dynamic processes of physical entities. The use of dynamic process simulation has been developed as a reliable and effective tool to examine the transient behavior of process systems.

In the CDT and analytics for the process simulation stage, optimization tools will support process optimization through real-time data and CDT models. The result of this optimization is implemented to make decisions for physical entities manipulating.

A service-oriented interface for the data interoperability approach is offered to develop interfaces for heterogeneous data, and for that reason, all the assets and business domain data should be converted into integrated formats through the established interfaces. It means that all generated and captured data at any stage of projects need to be converted to a common data environment.

3.1.2. Layers in CDT

The architecture of CDTsBLM has essentially four layers with each of them providing a set of services as follows.

Model Management Layer is in charge of three different kinds of models: (1) first-principle models for processes based on underlying physics; (2) analytical models based on various AI methods and ML; and (3) information-driven models focused mainly on their detailed work experience based on tacit knowledge of the domain and human operating experts. This Layer’s primary role is to ensure that various services, including modeling, data-driven, and human experts, provide efficient storage and access for multiple models.

The Service Management Layer makes effective use of all available services to solve the fundamental domain issues. It is focused on a complicated organization of services, combining data-driven model-based services to create value-added pipelines. It contains a registry service, enabling the rapid discovery of the orchestral services required. Service results should be made public, and practical and scalable communication of service can be ensured.

The User Interaction Layer is a digital definition of a physical device simulating its actions. It’s critical to assist a user in discovering a CDT’s data and models, as well as its characteristics. To put it another way, intuitive yet exploratory user interaction should be possible.

A twin represents a dynamic framework that should be handled effectively, and the Cognitive Twin Management Layer models a physical system’s behavior. A Twin can define the system’s actions as a digital description of a physical system by offering a standard behavior model. Contrarily, a Twin is a digital entity whose life cycle is affected by a physical system; in other words, physical design behavior changes should be replicated in double structure models as soon as the physical environment’s corresponding data become apparent.

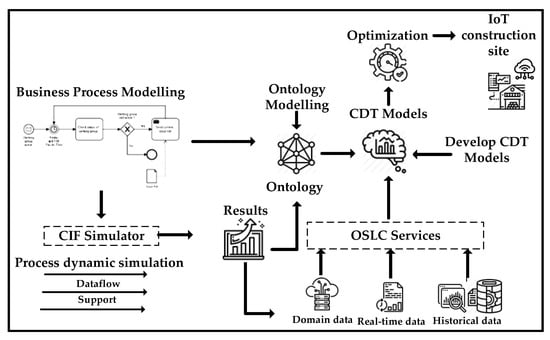

3.1.3. CDT realization within Cognitive Building Lifecycle Environment (CBLE)

Figure 4 depicts the CDTsBLM conceptual architecture built on service pipelines from which accessible data flow. The use of data streams implements the cognitive center of the CDT through one pipeline, which provides learning, event identification, and prediction and reasoning skills. A second pipeline for each CDT allows analysis and justification of vast quantities of raw data from different sources. A meta-structure improves the CDT by allowing multi-source data flow interoperability, higher reasoning, cognition pipelines since they interconnect through KGs.

Figure 4.

Outline of the process flow of Cognitive Digital Twin for Building Lifecycle Management (CDTsBLM) (adapted from the developed framework by Lu et al. [48]).

KGs enrich and direct the relationship between these two data-driven modeling approaches. ML algorithms, data analytics, and KGs form the foundation of a robust cognitive computing framework that allows for fine-tuned outcomes and increased process and reasoning abilities. The semantic models augment a set of data with features that enable cognitive processes to be far more agile. Combining quantitative-driven ML, qualitative KGs, and data analytics combines machines’ computing power with the human intuition and experiences needed to solve various Construction 4.0 use cases. Optimization can be exploited, related to the scope of the activity, the time horizon, providing CDTs with the capability to resolve optimized production issues, such as short-term real-time reorganization and reconfiguration of entire systems, mid-term timing, and lots for individual activities or whole construction and long-term capacity planning.

In the transition from CDTsBLM Conceptual Architecture to Technical Architecture, there is a data communication framework for collecting, processing, integrating, and managing multi-source, multi-scale, and multivariate data from production assets. CDT module interaction and API-based communication with the business domain can also be supported by a messaging and operation bus.

Actuators can be implemented to execute real-time decisions dynamically and communicate them directly from CDT to physical twin. Several enablers must characterize the CDT definition: (1) A profile describes the twinned asset and descriptive details, as well as models; (2) the connections between CDT and other CDT construction, as a network of linked CDTs, a factory or process or different architecture; (3) facets of cognition such as thinking, modeling, estimation, and optimization; (4) aspects of confidence to ensure correct knowledge transmission; (5) status and future notification visualization for end-users; (6) computation requirements as well as implementation aspects; (7) Identifying the CDT lifecycle.

These enablers tackle various stages of a cognitive factory model. The first is to simulate the construction or even other development contexts as a network of interconnected CDTs, for example, the workstation, process, and machine. Data from different sources, including ERP, Physical Twins, Human Operators, were initially added. Detection services (CEP), which are combined with Simulation and Optimization Services in the Cognitive Core functionality, use data-driven process models to allow CDTs to (1) detect a natural anomaly, such as an impending system malfunction, (2) forecast possible response steps with ideal outcomes, (3) simulate the optimized outputs and future consequences gradually, (4) return a well-thought-out proposal for the future course of action, which will be submitted to the appropriate stakeholders or actuaries for approval or denial.

3.1.4. CDT and Cognition

The definition, which is data-oriented, resides at the heart of the CDT. Construction 4.0 needs a greater cognitive increase in assets to allow continuous improvement of the data-driven process. CDTsBLM uses a modern architecture for generation construction data analytics to integrate cognition into DTs and as a meta-platform to help create and implement a range of building applications, such as quality management and predictive maintenance. The CDTsBLM approach depends on a new DT data analytics, in which an innovative CDT-driven metaphor represents a system model, improving the DT base and the integrated CDT structures to understand and solve situations that cannot be modeled, for example, by design allowed in numerical models or experience in the context of numeric models. Based on the current process data in real-time, this integrated approach will explain the issue, including tool deterioration for each particular machine and product type. This cognitive function is assisted in rare cases by the just-in-time process status simulation to measure an anomaly’s assurance that needs to be resolved in an extraordinary circumstance. This data-driven simulation would also indicate whether an anomaly is triggered by a particular scenario, meaning how long current process settings will remain unchanged. This novel approach describes data-driven model simulations from twins using novel predictive clustering methods and advanced inductive database mining rules.

3.1.5. CDT and Data

For the analytical models implemented in CDTsBLM, extensive data sources are required. The well-known critical issue in developing analytical models is processing and modeling various types of data in real-time. A complex architecture must adhere to the other methods to construct a universal analytical structure in Construction 4.0 for real-time data stream processing. It is also possible to synchronize and optimize data until they are fed into the analysis models. CDTsBLM seeks to provide an exhaustive and modern, multi-level model of uncertainties and causal relationships that include the following sub-models at multiple levels: model content fluxes, statistical capability models, technological process models, deviation models between optimal technical simulations, observations, and logistics demand projects. Material flow pattern models consider the lead time of input materials and generate uncertainties for understanding product transport and logistics and the various technical procedures to be used. Machinery availability, breakdown model, and models for employee insecurity will be considered for statistical capability models. Models of technical processes can incorporate domain awareness. Due to its state-of-the-art data-guided online processing algorithms for broad re-in-time data streams, the CDTsBLM uses the framework as its analytical tool to handle data requirements for CDTs. It aims to address multimodal data fusion, data preparation, optimization, and the analytical design of a manufacturing process as an entity that generates a typical analytical structural model for intrinsic, interrelated process variables. The architecture allows CDTs, when introduced, to seamlessly use many multimodal data types.

3.1.6. CDT and Optimization

When converting a DT to a CDT, the implemented optimization that allows the CDT to generate optimization functions is a critical enabler and differentiator. The vast majority of batch processing, construction planning optimization issues are NP-hard, which applies to Construction 4.0. Consequently, using conventional algorithmic and mathematical programming approaches to generate a proper solution to a real-life issue is computationally intractable. It is not always possible to have precise values of optimization criteria such as inventory supply, production times, costs, human resource efficiency, equipment durability, and construction industry specifications, or to be mindful of future diversities in material order preference, equipment failures due to a lack of information or the changing existence of actual construction sites. As a result, an optimum solution for approximate parameters could be inadequate until the parameters are realized. This complexity is present, especially in the process industries, where the quality of a given material inside a construction cannot be calculated with certainty before the component is processed. As a result, dealing with complexity is almost as critical as making the model itself, as it can be used to verify mathematical models and maintain production viability during operations.

The proposed solution dealing with decision circumstances involving complexity treats all potential realizations of parameters as part of the feedback. This collection is referred to as a scenario set, and each parameter completion is referred to as a scenario. As a result, a scheme reflects a possible condition of the universe. Since the cost of a solution is determined by a situation, its value is therefore unknown. Ex-post research compares a solution to an optimal solution that might have been obtained if the parameters had been realized in their original form. Decision-makers who do not want to take risks are more interested in avoiding the worst situations in the real world. A robust optimization methodology, under a discrete or intermittent uncertainty and the regret criteria of max–min or min–max, is a critical modeling approach for meeting the above requirements.

Another important aspect is the manufacturing process’s performance. Its capability primarily determines the control system’s capability to adjust schedules to changing conditions, especially at the short-term decision support level for real-time adaptive optimizing. These dynamic problems with re-optimization can be handled via reactive and proactive frames, in which the optimization process is progressively conducted at some intervals and dynamically evolves into integrated new or old knowledge. These methods can address complex optimization problems effectively with input parameters and variables that have not been completed, uncertain or unknown, that are modified simultaneously by the development of the real-time solution process. A suggested architecture for this path utilizes vigorous optimizations of different models (1) builds on well-established concepts such as negligence in which unique input parameters are not known to provide a universal solution which is efficient to optimize the worst-case solution and optimize overall actuality in all realizations of hidden parameters, (2) implements the adaptive, efficient, multi-stage optimization technique for planning where optimized decisions on unknown criteria and action on recourse depend on the realization of insecurity.

CDTsBLM is designed to deliver a complete CDT optimization toolkit based on a local hybrid search, evolutionary calculation, and data-driven techniques to scalable resource-aware planning and optimization algorithms that can be utilized to solve complicated planning issues with a variety of constraints, including utilities, renewable resources, and machinery service restraints. They also possess the potential to hierarchically address various schedule targets, including time and energy-conscious combinations. They often have a high degree of precision by strengthening their forecasting capabilities by utilizing (1) multiple design processes as decision variables to help monitor construction site factors such as efficiency and length while controlling several scheduling parameters such as processing time, energy usage, and operational expense, (2) a variety of execution types, including, for example, alternate routings and resource demand variations for each construction operation. A modified algorithm is designed to complement the prior algorithm set in the Optimization toolkit to endorse the CDT for rigorous online preparation problems, easily extended to resource-conscious purpose multifunctional optimization alternatives.

4. Evaluation of the Proposed CDTsBLM Model

Testing the proposed CDTsBLM model aims to recognize its effectiveness in practice and thus validate it. In this assessment, a digital survey was established with the literature review as a basis and distributed to industry professionals across countries. The survey’s core theme was to provide practitioners with an insight into the life cycle-centric applicability and integrality of CDTs with existing BLM practices.

4.1. Sampling

AEC increasingly involves multiple stakeholders ranging from Design Manager to Design Coordinator, Designer, BIM Manager, BIM Coordinator, Digitalization specialist, Project Manager, Construction Manager, Asset Manager, Asset Administrator, and Asset Controller. The longevity of assets may mean that the stakeholders or even the type of usage may change over time; this poses challenges in how these assets are managed over their life and specific challenges to the way data and information about them are handled. Therefore, the study focused on private organizations dealing with building projects operating in the United States (USA), United Kingdom (UK), and Sweden. The sample includes only large firms.

4.2. Data Collection

The data collection was confined to actors that have vital roles in capturing, delivering, and using the information in the building life cycle and technology domain innovation projects. Design, project management, contracting, and facilities management firms were compiled by searching for geographic position cataloging enterprises. The survey included owners and consultants for asset management. The national inclusions improve the validity of questions as they represent the different cultures, experiences, and ways of working of corporate and national groups. The proportions of company positions, sizes, and regions are shown in Table 3.

Table 3.

Company region, size, and role in percentage.

LinkedIn contacted 271 businesses, and a single representative from each was requested to participate in the questionnaire. Contributors were apprised about the search’s aims, and their answers were kept private and anonymous. A total of 45 percent of completed queries were collected. Experts were asked to talk regarding their work, observations, and organizations. Participant experts used a five-point Likert scale to rate their agreement with BLM digitalization-central statements, with one being the most disagreeable and five being the most agreeable.

4.3. Descriptive Statistics

Descriptive statistics reporting the mean values and standard deviations of questionnaire responses are presented in Table 4. The summarized statistics speficies interesting comprehensions as an overview of the AEC industry’s perception of the concepts. According to the results, the mean scores for 16 of the 20 questions were higher than 3.65 out of 5.00. The proposed model’s overall mean rating was 4.06, which means that industry professionals support approaching CDT development for process optimization and decision-making purposes and that integrability enablers confirm progression towards Construction 4.0.

Table 4.

Descriptive statistics, factor analysis and reliability test.

The argument that sought respondents’ opinions on real-time analytics for data-driven models enhanced with cognitive resources was conducted to support decision-making and aid learning, optimization, and reasoning had the highest mean of 4.45 in the relative importance of the variables. Through reason, learning, and optimization, CDTs can monitor, project, modify, and make better choices in real-time. CDT is a robust monitoring and tracking method, and the overall system is optimized with a mean value of 4.38. CDT covers existing process control systems with cognitive elements that allow them to organize themselves and provide a so-called indication of unanticipated actions at an average of 4.34. Overall, respondents agree that CDT should provide cognitive features that enable it to sense complex and unpredictable movements and reason about dynamic process optimization strategies to aid decision-making in BLM.

4.4. Factor Analysis

Functionalities of the BLM, CDT, IoT, and Process optimization and achievable levels of interoperability ad integrability of the proposed model as rated by the industry professionals are presented in Table 4. Confirmatory factor analysis boosts trust in the assessment’s precision and quality. Table 4 lists the items that were used to calculate each element. A five-point Likert scale was applied to measure all objects, and they were found perceptual. All factor loadings between 0.703 and 0.892, as well as all Cronbach’s coefficients less than 0.70, were considered to be adequate.

According to Table 4, CDT was ranked as the highest, Process Optimization as the second, IoT as the third, Self-learning as the fourth, and BLM as the fifth factor for life cycle-centric applicability and integrability of CDTs with current BLM practice, exploring decision support capabilities and AEC industry insights.

4.5. Correlation Analysis

Spearman’s rank-order correlation was used to validate the relationships, and the evaluation of the matrix shows a correlation. A positive linear relationship exists within BLM for improved productivity and sustainability, CDT for enhanced decision-making, IoT for real-time connectivity, and self-learning by applying new knowledge on the existing data, models, methods, and optimization simulation decision support. The highest correlation occurs between CDT for improved decision making and IoT for real-time connectivity in ρ < 0.01 (r = 0.812). The second significant positive correlation exists between CDT for enhanced decision making and optimization and simulation for decision support in ρ < 0.01 (r = 0.799). The correlation calculations of respondents’ perception of CDT decision support abilities are depicted in Table 5.

Table 5.

Correlational analysis of Cognitive Digital Twins’ perception of decision support capabilities.

5. Discussion

The motivation for this research came from the novelty of the DT concept and its future applications, which will establish the adaption of CDTs in the AEC industry. Besides, the lack of attention paid in the literature to CDT in AEC project management led the authors to investigate this research. The adapted model in this study provides a viable solution to the identified problem. Process modeling has been used to explain the steps and significant aspects of the CDTsBLM framework. This study presents a novel adapted model that integrates CDT and BLM concepts and allows all project stakeholders to identify and collect the right data sets and implement them properly to optimize the system. The proposed model attempts to improve the BLM performance compared to the traditional and current methods.

In BLM, the CDT can be used to represent any physical unit. Buildings, process phases, total procedures, and ultimately an entire construction operation can be virtualized using CDT. CDTs can be elicited at various hierarchical levels, with CDTs combining horizontally and vertically to form an aggregated structure. The Cognitive Building Lifecycle Environment (CBLE), built by combining CDTs, shares significant knowledge horizontally. Only important decision-making material, on the other hand, is transmitted vertically to upper levels. A mission-critical building’s CDT (monitoring and managing its condition and actions) supplying input to a particular process phase that feeds the building design process’s CDT is an example. These CDTs will act and respond when sharing data with the various exchanged data sets and their semantics. Hence, the respective CDTs must be coordinated by a supervisory check, resulting in the CBLE, with market requirements, time horizons, and the essence of various activities that must be processed at any given time determined. This study examined the implementation, integrability, and interoperability of CDT in existing BLM practices in the life cycle, exploring decision-making skills and AEC industry insights. It is anticipated that the CDTsBLM model will promote the qualifications mentioned to allow better knowledge, analysis, optimization, and decision-making, which will concentrate on evaluation. The CDTsBLM model will enable re-evaluation, projection, and re-evaluation in a dynamic and complex world, with the possible planning, design, structuring, and operating. The operational processes’ environmental effect must be reduced in the AEC industry by optimizing the building lifecycle processes by the CDTsBLM model.

One path forward to achieving new operational efficiencies depends on the reality that much of the human-dependent work activity can be significantly reduced by automating repetitive activities such as data acquisition, base data analysis, and the need for physical presence at physical locations, yielding a faster and safer approach to gathering data as well as reducing the time it takes to correlate and analyze that information. This rich collection of information is accessed, maintained, and controlled by humans for three primary activity streams. Analytics involves various analytical models, technologies, and approaches providing historical, current, and predictive insights from the data gathered. The workflow requires information about and procedures to inspect, maintain, modify and repair the physical asset. Visualization involves information, including the spatial geometry used for primarily planning and engineering.

The cognition, interpretation, and optimization of decision-making skills are fundamental to CDTsBLM. The connections between the ecosystem capacity perceived as a collective framework and all of the capabilities contribute to establishing a crucial cycle-centric application with inclusive aspects that contribute to explain the value of technology integrity from a professional inducible usability perspective. The CDTsBLM uses its models to evaluate data from the current framework to provide feedback and support decision-making. Depending on the study, the data and intelligence displayed are performed by the CDTsBLM.

The quantitative analysis of the data collected from Design Managers, Design Coordinators, Designers, BIM Managers, BIM Coordinators, Digitalization specialists, Project Managers, Construction Managers, Asset Managers, Asset Administrators, and Asset Controllers indicated that there is a willingness to use this type of CDT technology and related models. This analysis justified that the CDTsBLM model framework helps to provide a real-time analysis for data-driven models augmented by cognitive resources, which was conducted to facilitate decision-making and improve understanding, optimization, and thinking. Further, it shows that CDTsBLM is a valuable monitoring and control mechanism that helps in overall device optimization. It helps managerial levels of projects self-organize and respond to unpredictable activities and aid in decision-making for complex systems, including physical actors. The AEC industry can revolutionize how to design, build truly, and operate in a complex project environment. The AEC industry will inevitably adapt cognition, analytics, self-learning, and optimization techniques due to the emergence of DT, Cognitive computing, AI, ML, and cloud-based systems. Table 6 shows such a system’s process, opportunities, and challenges. This research indicates that the CDTsBLM is an intelligent system that seamlessly connects engineering operational data, information, and models utilized over the whole building asset lifecycle with self-learning and predictive capabilities. It then makes the results readily available in real-time and the proper context for all related stakeholders to prevent or solve potential issues proactively. The findings from this research could serve as a base to pave the way for promoting progression towards Construction 4.0.

Table 6.

Sample of Cognitive Digital Twins cognition, analytics, and optimization processes in Building Lifecycle Management.

6. Conclusions

Construction projects and their data from the first stage to the last day of AEC projects are becoming huge and more complex to gather and manage. It is becoming exceedingly difficult, if not impossible, to identify and collect the right data sets and put them in the proper context to enable the optimization of the system. However, with help from a DT that can sense, reason, and act, such intelligent systems will help projects’ stakeholders make the right decisions or autonomously trigger the right actions in the digital or physical world. Increasing complexity in terms of the DT becomes apparent when looking at the various application streams and their need for precise and real-time data. The DTs’ highest level is the CDT connected with the top-level cognitive engineering maturity, including AI and ML. This article introduced the newly adapted CDT paradigm, including BLM’s capabilities in cognition, analytics, and optimization for construction 4.0. The most significant advantage of cognition is the ability to solve problems preventively unknown. The CDT provides a toolkit for optimizing based on its cognitive components that enables CDT to carry out optimization tasks and delivers valuable results that other CDTs or process actors consume. Industry practitioners have examined the technical framework of CDTsBLM and taken full advantage of additional CDT capabilities, including construction schedules, preventive maintenance, and other goals, in the traditional DT sense. The benefits of implementing the CDT concept in the construction industry are intended by opening the optimization tool kit inside the CDT and enhancing real-time or almost real-time choices by interplaying optimization and simulation. Finally, the CDT description and conceptualization formalities will be further evolved alongside this implementation and assessment by tailoring every application scenario specific to the technology, ability, and KPIs that show this CDT effect.

The findings demonstrate the applicability of the CDTsBLM integration for a variety of AEC analysis scenarios. Future research directions could focus on investigating the processes and sub-processes of CDTsBLM applications in various AEC projects. Utilizing this system’s legal and financial aspects will also lead to future research opportunities of CDTsBLM. Researchers might want to explore the processes and integrability of various construction technologies with CDT for various purposes.

Author Contributions

Conceptualization, I.Y., S.A.; methodology, I.Y., S.A., İ.A., M.E.A.; software, I.Y., S.A.; validation, I.Y., S.A., İ.A., M.E.A.; formal analysis, I.Y., S.A., İ.A., M.E.A.; investigation, I.Y., S.A., İ.A., M.E.A.; resources, I.Y., S.A., İ.A., M.E.A.; data curation, I.Y., S.A., İ.A., M.E.A.; writing—original draft preparation, I.Y., S.A., İ.A., M.E.A.; writing—review and editing, I.Y., S.A., İ.A., M.E.A.; visualization, I.Y., S.A., İ.A., M.E.A.; supervision, I.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

not applicable.

Informed Consent Statement

not applicable.

Data Availability Statement

not applicable.

Acknowledgments

The authors would like to thank all the survey respondents in the AEC industry.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Alizadehsalehi, S.; Yitmen, I. A Concept for Automated Construction Progress Monitoring: Technologies Adoption for Benchmarking Project Performance Control. Arab. J. Sci. Eng. 2018, 44, 4993–5008. [Google Scholar] [CrossRef]

- Salehi, S.A.; Yitmen, I. Modeling and analysis of the impact of BIM-based field data capturing technologies on automated construction progress monitoring. Int. J. Civ. Eng. 2018, 16, 1669–1685. [Google Scholar] [CrossRef]

- Pärn, E.; Edwards, D.; Sing, M. The building information modelling trajectory in facilities management: A review. Autom. Constr. 2017, 75, 45–55. [Google Scholar] [CrossRef]

- Götz, C.S.; Karlsson, P.; Yitmen, I. Exploring applicability, interoperability and integrability of Blockchain-based digital twins for asset life cycle management. Smart Sustain. Built Environ. 2020. [Google Scholar] [CrossRef]

- Lytras, M.; Visvizi, A. Artificial Intelligence and Cognitive Computing: Methods, Technologies, Systems, Applications and Policy Making. Sustainability 2021, 13, 3598. [Google Scholar] [CrossRef]

- Abburu, S.; Berre, A.J.; Jacoby, M.; Roman, D.; Stojanovic, L.; Stojanovic, N. Cognitive Digital Twins for the Process Industry. In Proceedings of the The Twelfth International Conference on Advanced Cognitive Technologies and Applications (COGNITIVE 2020), Nice, France, 25–29 October 2020. [Google Scholar]

- Hartmann, D.; Van der Auweraer, H. Digital Twins. In Progress in Industrial Mathematics: Success Stories: The Industry and the Academia Points of View; Springer International Publishing: Cham, Switzerland, 2021; pp. 3–17. [Google Scholar]

- Zhang, N.; Bahsoon, R.; Theodoropoulos, G. Towards Engineering Cognitive Digital Twins with Self-Awareness. In Proceedings of the 2020 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Toronto, ON, Canada, 11–14 October 2020; p. 3891. [Google Scholar]

- Alizadehsalehi, S.; Hadavi, A.; Huang, J.C. From BIM to extended reality in AEC industry. Autom. Constr. 2020, 116, 103254. [Google Scholar] [CrossRef]

- Vanlande, R.; Nicolle, C.; Cruz, C. IFC and building lifecycle management. Autom. Constr. 2008, 18, 70–78. [Google Scholar] [CrossRef]

- Di Biccari, C.; Mangialardi, G.; Lazoi, M.; Corallo, A. Configuration Views from PLM to Building Lifecycle Management. In IFIP International Conference on Product Lifecycle Management; Springer: Berlin/Heidelberg, Germany, 2018; pp. 69–79. [Google Scholar]

- Wu, S.; Liu, Q. Analysis on the Application of BIM and RFID in Life Cycle Management of Prefabricated Building. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Chengdu, China, 13–15 December 2019; Volume 780. [Google Scholar]

- Kubler, S.; Madhikermi, M.; Buda, A.; Främling, K.; Derigent, W.; Thomas, A.; Thomas, A. Towards data exchange interoperability in building lifecycle management. In Proceedings of the Proceedings of the 2014 IEEE Emerging Technology and Factory Automation (ETFA), Barcelona, Spain, 16–19 September 2014; pp. 1–8. [Google Scholar]

- Ustinovičius, L.; Rasiulis, R.; Nazarko, L.; Vilutienė, T.; Reizgevicius, M. Innovative research projects in the field of Building Lifecycle Management. Procedia Eng. 2015, 122, 166–171. [Google Scholar] [CrossRef]

- Puķīte, I.; Geipele, I. Different Approaches to Building Management and Maintenance Meaning Explanation. Procedia Eng. 2017, 172, 905–912. [Google Scholar] [CrossRef]

- Kubler, S.; Buda, A.; Robert, J.; Främling, K.; Le Traon, Y. Building lifecycle management system for enhanced closed loop collaboration. In IFIP International Conference on Product Lifecycle Management; Springer: Cham, Switzerland, 2016; pp. 423–432. [Google Scholar]

- Malagnino, A.; Mangialardi, G.; Zavarise, G.; Corallo, A. Business process management and building information modeling for the innovation of cultural heritage restoration process. In Proceedings of the IMEKO International Conference on Metrology for Archaeology and Cultural Heritage, Lecce, Italy, 23–25 October 2017. [Google Scholar]

- Pan, Y.; Zhang, L. A BIM-data mining integrated digital twin framework for advanced project management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I. Digital twin-based progress monitoring management model through reality capture to extended reality technologies (DRX). Smart Sustain. Built Environ. 2021. [Google Scholar] [CrossRef]

- Deng, M.; Menassa, C.C.; Kamat, V.R. From BIM to digital twins: A systematic review of the evolution of intelligent building representations in the AEC-FM industry. J. Inf. Technol. Constr. 2021, 26, 58–83. [Google Scholar] [CrossRef]

- Bosch-Sijtsema, P.; Claeson-Jonsson, C.; Johansson, M.; Roupe, M. The hype factor of digital technologies in AEC. Constr. Innov. 2021. [Google Scholar] [CrossRef]

- Hasan, S.M.; Lee, K.; Moon, D.; Kwon, S.; Jinwoo, S.; Lee, S. Augmented reality and digital twin system for interaction with construction machinery. J. Asian Arch. Build. Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Camposano, J.C.; Smolander, K.; Ruippo, T. Seven Metaphors to Understand Digital Twins of Built Assets. IEEE Access 2021, 9, 27167–27181. [Google Scholar] [CrossRef]

- Meža, S.; Pranjić, A.M.; Vezočnik, R.; Osmokrović, I.; Lenart, S. Digital Twins and Road Construction Using Secondary Raw Materials. J. Adv. Transp. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Hou, L.; Wu, S.; Zhang, G.; Tan, Y.; Wang, X. Literature Review of Digital Twins Applications in Construction Workforce Safety. Appl. Sci. 2020, 11, 339. [Google Scholar] [CrossRef]

- Borowski, P. Digitization, Digital Twins, Blockchain, and Industry 4.0 as Elements of Management Process in Enterprises in the Energy Sector. Energies 2021, 14, 1885. [Google Scholar] [CrossRef]

- Del Giudice, M.; Osello, A. Handbook of Research on Developing Smart Cities Based on Digital Twins; IGI Global: Hershey, PA, USA, 2021. [Google Scholar]

- Tagliabue, L.; Cecconi, F.; Maltese, S.; Rinaldi, S.; Ciribini, A.; Flammini, A. Leveraging Digital Twin for Sustainability Assessment of an Educational Building. Sustainability 2021, 13, 480. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, A.; Wang, W. A Framework for an Indoor Safety Management System Based on Digital Twin. Sensors 2020, 20, 5771. [Google Scholar] [CrossRef] [PubMed]

- Austin, M.; Delgoshaei, P.; Coelho, M.; Heidarinejad, M. Architecting Smart City Digital Twins: Combined Semantic Model and Machine Learning Approach. J. Manag. Eng. 2020, 36, 04020026. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital twin-enabled anomaly detection for built asset monitoring in operation and maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Greif, T.; Stein, N.; Flath, C.M. Peeking into the void: Digital twins for construction site logistics. Comput. Ind. 2020, 121, 103264. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M.; Konstantinou, E. Moving from Building Information Models to Digital Twins for Operation and Maintenance. In Proceedings of the Institution of Civil Engineers—Smart Infrastructure and Construction; Thomas Telford Ltd.: London, Greater London, UK, 2020; pp. 1–9. [Google Scholar]

- Rausch, C.; Sanchez, B.; Esfahani, M.E.; Haas, C. Computational Algorithms for Digital Twin Support in Construction. In Construction Research Congress 2020; American Society of Civil Engineers (ASCE): Tempe, AZ, USA, 2020; pp. 191–200. [Google Scholar]

- Dawood, N.; Rahimian, F.; Seyedzadeh, S.; Sheikhkhoshkar, M. Enabling the Development and Implementation of Digital Twins. In Proceedings of the 20th International Conference on Construction Applications of Virtual Reality; Tesside University Press: Middlesbrough, UK, 2020. [Google Scholar]

- Alonso, R.; Borras, M.; Koppelaar, R.H.E.M.; Lodigiani, A.; Loscos, E.; Yöntem, E. SPHERE: BIM Digital Twin Platform. proceedings 2019, 20, 9. [Google Scholar] [CrossRef]

- Mathot, M.; Hohrath, B.; Rolvink, A.; Coenders, J. Design Modelling with Next Generation Parametric System Packhunt.io. In Impact: Design With All Senses; Springer: Cham, Switzerland, 2019; pp. 277–287. [Google Scholar]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmstrom, J. Digital Twin: Vision, Benefits, Boundaries, and Creation for Buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Kan, C.; Anumba, C.J. Digital Twins as the Next Phase of Cyber-Physical Systems in Construction. In Computing in Civil. Engineering 2019: Data, Sensing, and Analytics; American Society of Civil Engineers (ASCE): Atlanta, GA, USA, 2019; pp. 256–264. [Google Scholar]

- Lu, Q.; Xie, X.; Heaton, J.; Parlikad, A.K.; Schooling, J. From BIM Towards Digital Twin: Strategy and Future Development for Smart Asset Management. In International Workshop on Service Orientation in Holonic and Multi-Agent Manufacturing; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Kaewunruen, S.; Lian, Q. Digital twin aided sustainability-based lifecycle management for railway turnout systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar] [CrossRef]

- Lydon, G.; Caranovic, S.; Hischier, I.; Schlueter, A. Coupled simulation of thermally active building systems to support a digital twin. Energy Build. 2019, 202, 109298. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I. The Impact of Field Data Capturing Technologies on Automated Construction Project Progress Monitoring. Procedia Eng. 2016, 161, 97–103. [Google Scholar] [CrossRef]

- Rozanec, J.M.; Jinzhi, L. Towards actionable cognitive digital twins for manufacturing. In Proceedings of the International Workshop on Semantic Digital Twins, co-located with ESWC, Heraklion, Greece, July 2020. [Google Scholar]

- Eirinakis, P.; Kalaboukas, K.; Lounis, S.; Mourtos, I.; Rozanec, J.M.; Stojanovic, N.; Zois, G. Enhancing Cognition for Digital Twins. In Proceedings of the 2020 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, 15–17 June 2020; pp. 1–7. [Google Scholar]

- Kalaboukas, K.; Rožanec, J.; Košmerlj, A.; Kiritsis, D.; Arampatzis, G. Implementation of Cognitive Digital Twins in Connected and Agile Supply Networks—An Operational Model. Appl. Sci. 2021, 11, 4103. [Google Scholar] [CrossRef]

- Lu, J.; Zheng, X.; Gharaei, A.; Kalaboukas, K.; Kiritsis, D. Cognitive Twins for Supporting Decision-Makings of Internet of Things Systems. In Proceedings of the 5th International Conference on the Industry 4.0 Model for Advanced Manufacturing; Springer International Publishing: Cham, Switzerland, 2020; pp. 105–115. [Google Scholar]

- Lu, V.Q.; Parlikad, A.K.; Woodall, P.; Ranasinghe, G.D.; Heaton, J. Developing a Dynamic Digital Twin at a Building Level: Using Cambridge Campus as Case Study. In International Conference on Smart Infrastructure and Construction 2019 (ICSIC) Driving Data-Informed Decision-Making; ICE Publishing: London, UK, 2019. [Google Scholar]

- Du, J.; Zhu, Q.; Shi, Y.; Wang, Q.; Lin, Y.; Zhao, D. Cognition Digital Twins for Personalized Information Systems of Smart Cities: Proof of Concept. J. Manag. Eng. 2020, 36, 04019052. [Google Scholar] [CrossRef]

- Rožanec, J.M.; Lu, J.; Rupnik, J.; Škrjanc, M.; Mladenić, D.; Fortuna, B.; Kiritsis, D. Actionable Cognitive Twins for Decision Making in Manufacturing. arXiv 2021, arXiv:2103.12854. [Google Scholar]

- Berlanga, R.; Museros, L.; Llidó, D.M.; Sanz, I.; Aramburu, M.J. Towards Semantic DigitalTwins for Social Networks. 2021. [Google Scholar]

- Albayrak, Ö.; Ünal, P. Smart Steel Pipe Production Plant via Cognitive Digital Twins: A Case Study on Digitalization of Spiral Welded Pipe Machinery. In Cybersecurity Workshop by European Steel Technology Platform; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Abburu, S.; Berre, A.J.; Jacoby, M.; Roman, D.; Stojanovic, L.; Stojanovic, N. COGNITWIN—Hybrid and cognitive digital twins for the process industry. In Proceedings of the 2020 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, 15–17 June 2020. [Google Scholar]

- Essa, E.; Hossain, M.S.; Tolba, A.S.; Raafat, H.M.; Elmogy, S.; Muahmmad, G. Toward cognitive support for automated defect detection. Neural Comput. Appl. 2019, 32, 4325–4333. [Google Scholar] [CrossRef]

- Saracco, R. Digital Twins: Bridging Physical Space and Cyberspace. Computer 2019, 52, 58–64. [Google Scholar] [CrossRef]

- Fernández, F.; Sánchez, Á.; Vélez, J.F.; Moreno, A.B. Symbiotic Autonomous Systems with Consciousness Using Digital Twins. In International Work-Conference on the Interplay Between Natural and Artificial Computation; Springer: Cham, Switzerland, 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).