Effect of pH on the Economic Potential of Dark Fermentation Products from Used Disposable Nappies and Expired Food Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Inoculum

2.2. Substrates

2.3. Experimental Set-Up and Procedure

3. Results and Discussion

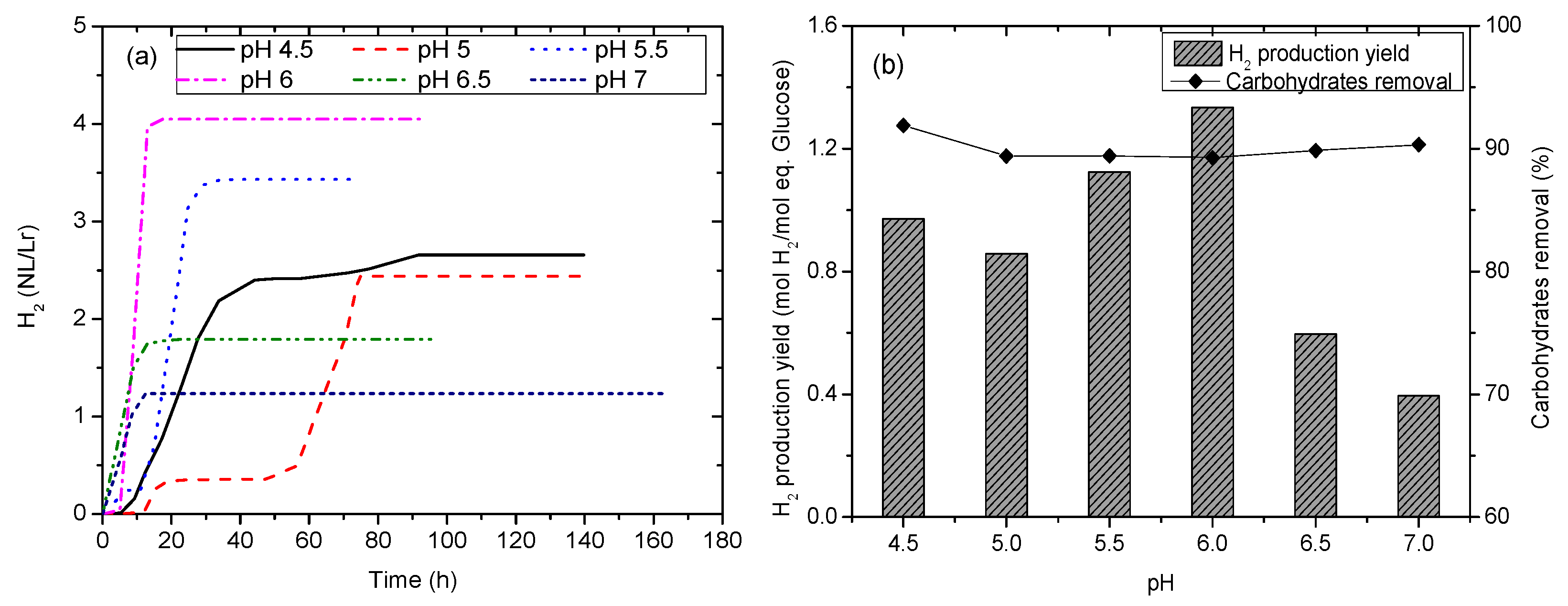

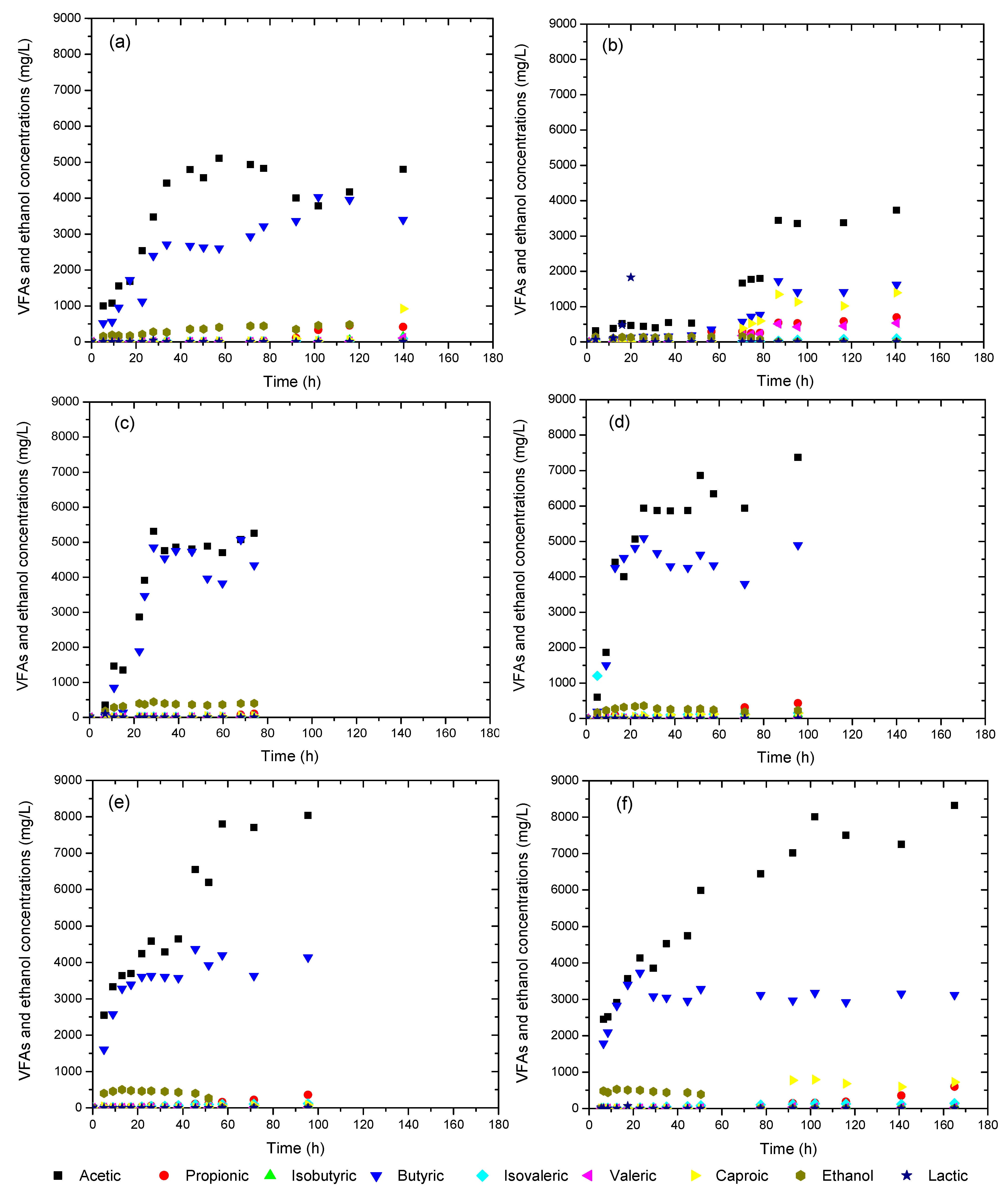

3.1. Effect of pH

3.2. Uses of Produced VFAs

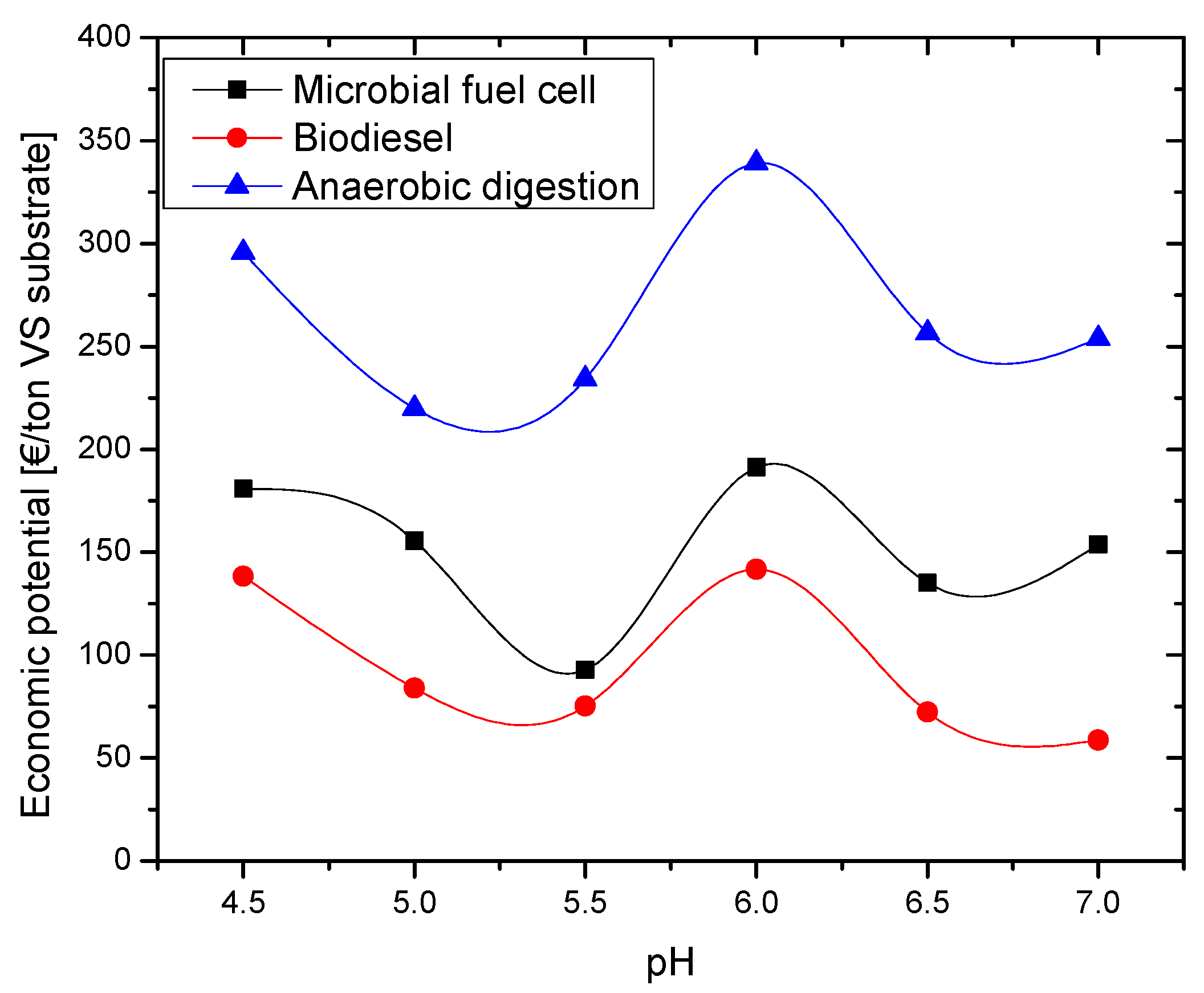

3.2.1. Microbial Fuel Cells

3.2.2. Biodiesel Production

3.2.3. Anaerobic Digestion Process

3.3. Comparison of Different VFAs Exploitation Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Colón, J.; Ruggieri, L.; Sánchez, A.; González, A.; Puig, I. Possibilities of composting disposable diapers with municipal solid wastes. Waste Manag. Res. 2011, 29, 249–259. [Google Scholar] [CrossRef] [PubMed]

- Stevens, G.; Tuncki, C. Sustainability Report, 5th ed.; EDANA: Brussels, Belgium, 2019; Available online: https://www.edana.org/docs/default-source/sustainability/sustainability-report.pdf?sfvrsn=4a926b0_18 (accessed on 20 March 2020).

- Anastopoulos, I.; Milojković, J.V.; Tsigkou, K.; Zafiri, C.; Lopičić, Z.R.; Kornaros, M.; Pashalidis, I. A nappies management by-product for the treatment of uranium-contaminated waters. J. Hazard. Mater. 2021, 404, 124147. [Google Scholar] [CrossRef] [PubMed]

- Tsigkou, K.; Tsafrakidou, P.; Kopsahelis, A.; Zagklis, D.; Zafiri, C.; Kornaros, M. Used disposable nappies and expired food products valorisation through one-& two-stage anaerobic co-digestion. Renew. Energy 2020, 147, 610–619. [Google Scholar] [CrossRef]

- Tsigkou, K.; Tsafrakidou, P.; Athanasopoulou, S.; Zafiri, C.; Kornaros, M. Effect of pH on the Anaerobic Fermentation of Fruit/Vegetables and Disposable Nappies Hydrolysate for Bio-hydrogen Production. Waste Biomass Valorization 2020, 11, 539–551. [Google Scholar] [CrossRef]

- Tsigkou, K.; Tsafrakidou, P.; Zafiri, C.; Soto Beobide, A.; Kornaros, M. Pretreatment of used disposable nappies: Super absorbent polymer deswelling. Waste Manag. 2020, 112, 20–29. [Google Scholar] [CrossRef]

- Guo, X.M.; Trably, E.; Latrille, E.; Carrere, H.; Steyer, J.-P. Hydrogen production from agricultural waste by dark fermentation: A review. Int. J. Hydrog. Energy 2010, 35, 10660–10673. [Google Scholar] [CrossRef]

- Lee, W.S.; Chua, A.S.M.; Yeoh, H.K.; Ngoh, G.C. A review of the production and applications of waste-derived volatile fatty acids. Chem. Eng. J. 2014, 235, 83–99. [Google Scholar] [CrossRef]

- Ucar, D.; Zhang, Y.; Angelidaki, I. An overview of electron acceptors in microbial fuel cells. Front. Microbiol. 2017, 8, 643. [Google Scholar] [CrossRef]

- Park, G.W.; Fei, Q.; Jung, K.; Chang, H.N.; Kim, Y.-C.; Kim, N.; Choi, J.; Kim, S.; Cho, J. Volatile fatty acids derived from waste organics provide an economical carbon source for microbial lipids/biodiesel production. Biotechnol. J. 2014, 9, 1536–1546. [Google Scholar] [CrossRef]

- Meng, X.; Yang, J.; Xu, X.; Zhang, L.; Nie, Q.; Xian, M. Biodiesel production from oleaginous microorganisms. Renew. Energy 2009, 34, 1–5. [Google Scholar] [CrossRef]

- Conway, M.E.; Jooste, F.; Smith, M.D. Treatment of Absorbent Sanitary Paper Products. Patent Number: ES2098375T3, 1 May 1997. [Google Scholar]

- Torrijos, M.; Sousbie, P.; Rouez, M.; Lemunier, M.; Lessard, Y.; Galtier, L.; Simao, A.; Steyer, J.P. Treatment of the biodegradable fraction of used disposable diapers by co-digestion with waste activated sludge. Waste Manag. 2014, 34, 669–675. [Google Scholar] [CrossRef] [PubMed]

- Khoo, S.C.; Phang, X.Y.; Ng, C.M.; Lim, K.L.; Lam, S.S.; Ma, N.L. Recent technologies for treatment and recycling of used disposable baby diapers. Process Saf. Environ. Prot. 2019, 123, 116–129. [Google Scholar] [CrossRef]

- Knowaste Home Page. Available online: https://www.knowaste.com/ (accessed on 20 March 2020).

- Fater Sustainability Page. Available online: https://fatergroup.com/ww/value#sustainability (accessed on 15 March 2020).

- Diaper Recycling Technology Home Page. Available online: https://diaperrecycling.technology/ (accessed on 26 March 2020).

- Super Faiths Inc., Home Page. Available online: http://superfaiths.com/english/ (accessed on 29 March 2020).

- Tsigkou, K.; Zagklis, D.; Tsafrakidou, P.; Zapanti, P.; Manthos, G.; Karamitou, K.; Zafiri, C.; Kornaros, M. Expired food products and used disposable adult nappies mesophilic anaerobic co-digestion: Biochemical methane potential, feedstock pretreatment and two-stage system performance. Renew. Energy 2021, 168, 309–318. [Google Scholar] [CrossRef]

- Kan, E. Effects of pretreatments of anaerobic sludge and culture conditions on hydrogen productivity in dark anaerobic fermentation. Renew. Energy 2013, 49, 227–231. [Google Scholar] [CrossRef]

- Gan, S.; Zakaria, S.; Ng, P.; Chia, C.H.; Chen, R.S. Effect of acid hydrolysis and thermal hydrolysis on solubility and properties of oil palm empty fruit bunch fiber cellulose hydrogel. BioResources 2016, 11, 126–139. [Google Scholar] [CrossRef]

- European Commission Commission Regulation (EU) No 142/2011 of 25 February 2011 implementing Regulation (EC) No 1069/2009 of the European Parliament and of the Council laying down health rules as regards animal by-products and derived products not intended for human consumpti. Off. J. 2011, 54, 1–254.

- Kirchmann, H.; Pettersson, S. Human urine-chemical composition and fertilizer use efficiency. Fertil. Res. 1994, 40, 149–154. [Google Scholar] [CrossRef]

- Carrel, G.; Egli, L.; Tran, C.; Schneiter, P.; Giusti, V.; D’Alessio, D.; Tappy, L. Contributions of fat and protein to the incretin effect of a mixed meal. Am. J. Clin. Nutr. 2011, 94, 997–1003. [Google Scholar] [CrossRef]

- Elbeshbishy, E.; Dhar, B.R.; Nakhla, G.; Lee, H.-S. A critical review on inhibition of dark biohydrogen fermentation. Renew. Sustain. Energy Rev. 2017, 79, 656–668. [Google Scholar] [CrossRef]

- Marzialetti, T.; Valenzuela Olarte, M.B.; Sievers, C.; Hoskins, T.J.C.; Agrawal, P.K.; Jones, C.W. Dilute Acid Hydrolysis of Loblolly Pine: A Comprehensive Approach. Ind. Eng. Chem. Res. 2008, 47, 7131–7140. [Google Scholar] [CrossRef]

- Eaton, A.D.; Clesceri, L.S.; Greenberg, A.E.; Franson, M.A.H. Standard Methods for the Examination of Water and Wastewater, 22nd ed.; American Water Works Association: Denver, CO, USA, 2012. [Google Scholar]

- Joseffson, B. Rapid spectrophotometric determination of total carbohydrates. In Methods of Seawater Analysis; Grasshoff, K., Ehrhardt, M., Kremling, K., Eds.; Wiley-VCH: Weinheim, Germany, 1983. [Google Scholar]

- Dareioti, M.A.; Vavouraki, A.I.; Kornaros, M. Effect of pH on the anaerobic acidogenesis of agroindustrial wastewaters for maximization of bio-hydrogen production: A lab-scale evaluation using batch tests. Bioresour. Technol. 2014, 162, 218–227. [Google Scholar] [CrossRef] [PubMed]

- Hubbe, M.A.; Ayoub, A.; Daystar, J.S.; Venditti, R.A.; Pawlak, J.J. Enhanced absorbent products incorporating cellulose and its derivatives: A review. BioResources 2013, 8, 6556–6629. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S. Composition, properties and health benefits of indigestible carbohydrate polymers as dietary fiber: A review. Int. J. Biol. Macromol. 2013, 61, 1–6. [Google Scholar] [CrossRef]

- Chatellard, L.; Trably, E.; Carrère, H. The type of carbohydrates specifically selects microbial community structures and fermentation patterns. Bioresour. Technol. 2016, 221, 541–549. [Google Scholar] [CrossRef]

- Lee, C.; Lee, S.; Han, S.-K.; Hwang, S. Effect of operational pH on biohydrogen production from food waste using anaerobic batch reactors. Water Sci. Technol. 2014, 69, 1886–1893. [Google Scholar] [CrossRef]

- Sivagurunathan, P.; Kumar, G.; Bakonyi, P.; Kim, S.-H.; Kobayashi, T.; Xu, K.Q.; Lakner, G.; Tóth, G.; Nemestóthy, N.; Bélafi-Bakó, K. A critical review on issues and overcoming strategies for the enhancement of dark fermentative hydrogen production in continuous systems. Int. J. Hydrog. Energy 2016, 41, 3820–3836. [Google Scholar] [CrossRef]

- Teng, S.-X.; Tong, Z.-H.; Li, W.-W.; Wang, S.-G.; Sheng, G.-P.; Shi, X.-Y.; Liu, X.-W.; Yu, H.-Q. Electricity generation from mixed volatile fatty acids using microbial fuel cells. Appl. Microbiol. Biotechnol. 2010, 87, 2365–2372. [Google Scholar] [CrossRef]

- Ishii, S.; Watanabe, K.; Yabuki, S.; Logan, B.E.; Sekiguchi, Y. Comparison of electrode reduction activities of Geobacter sulfurreducens and an enriched consortium in an air-cathode microbial fuel cell. Appl. Environ. Microbiol. 2008, 74, 7348–7355. [Google Scholar] [CrossRef]

- Fei, Q.; Chang, H.N.; Shang, L.; Kim, N.; Kang, J. The effect of volatile fatty acids as a sole carbon source on lipid accumulation by Cryptococcus albidus for biodiesel production. Bioresour. Technol. 2011, 102, 2695–2701. [Google Scholar] [CrossRef]

- Karmee, S.K.; Linardi, D.; Lee, J.; Lin, C.S.K. Conversion of lipid from food waste to biodiesel. Waste Manag. 2015, 41, 169–173. [Google Scholar] [CrossRef] [PubMed]

- Scaglione, D.; Caffaz, S.; Ficara, E.; Malpei, F.; Lubello, C. A simple method to evaluate the short-term biogas yield in anaerobic codigestion of WAS and organic wastes. Water Sci. Technol. 2008, 58, 1615–1622. [Google Scholar] [CrossRef] [PubMed]

- Kemcore. Available online: https://www.kemcore.com/ (accessed on 10 March 2020).

- Neste. Biodiesel Prices (SME&FAME). Available online: https://www.neste.com/corporate-info/investors/market-data/biodiesel-prices-sme-fame (accessed on 2 March 2020).

- Eurostat. Electricity Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Electricity_price_statistics (accessed on 16 March 2020).

- Eurostat. Natural Gas Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Natural_gas_price_statistics (accessed on 16 March 2020).

| Parameter | Used DN Hydrolysate (g/L) | EFPs (g/kg) | Mixture after Hydrolysis (g/L) | |||

|---|---|---|---|---|---|---|

| pH | 7.40 | ±0.01 | N/A | 4.21 | ±0.03 | |

| t-Carbohydrates | 3.50 | ±1.70 | 183.80 | ±37.20 | 31.59 | ±8.42 |

| d-Carbohydrates | 0.06 | ±0.01 | N/A | 12.24 | ±0.18 | |

| t-COD | 5.01 | ±1.68 | 663.27 | ±86.59 | 49.95 | ±6.41 |

| d-COD | 0.40 | ±0.01 | N/A | 20.42 | ±1.45 | |

| TS | 8.17 | ±0.52 | 554.51 | ±58.60 | 42.37 | ±0.85 |

| VS | 6.51 | ±0.55 | 509.20 | ±7.13 | 32.95 | ±0.95 |

| TSS | 6.70 | ±0.01 | N/A | 22.03 | ±0.35 | |

| VSS | 6.16 | ±0.31 | N/A | 22.00 | ±0.30 | |

| TKN | 0.07 | ±0.02 | 3.92 | ±0.42 | 0.91 | ±0.06 |

| NH3-N | 0.07 | ±0.01 | 2.65 | ±0.06 | 0.25 | ±0.02 |

| Oil & Grease | 0.02 | ±0.01 | 47.00 | ±1.38 | 3.14 | ±0.14 |

| t-P | 0.05 | ±0.01 | 1.24 | ±0.25 | 2.16 | ±0.07 |

| d-P | 0.02 | ±0.01 | N/A | 0.87 | ±0.01 | |

| VFA | Reaction | ΔG° (MJ/Mole) |

|---|---|---|

| Acetic Acid | C2H4O2 + 2 O2 → 2 CO2 + 2 H2O | −0.873 |

| Propionic Acid | C3H6O2 + 3.5 O2 → 3 CO2 + 3 H2O | −1.603 |

| Butyric Acid | C4H8O2 + 5 O2 → 4 CO2 + 4 H2O | −2.243 |

| Valeric Acid | C5H10O2 + 6.5 O2 → 5 CO2 + 5 H2O | −2.883 |

| Caproic Acid | C6H12O2 + 8 O2 → 6 CO2 + 6 H2O | −3.523 |

| pH | CE (%) | Chemical Energy from VFAs Oxidation (MJ/kg VS) |

|---|---|---|

| 4.5 | 26.20 | 8.51 |

| 5.0 | 33.44 | 7.22 |

| 5.5 | 22.64 | 8.04 |

| 6.0 | 26.84 | 10.65 |

| 6.5 | 30.12 | 10.01 |

| 7.0 | 34.31 | 10.55 |

| pH | NaOH (kg/kgVS) | H2 (MJ/kgVS) | VFAs (kg/kgVS) | Eq. Electric Energy (MJ/kgVS) | Eq. Biodiesel (kg/kgVS) | Eq. CH4 (MJ/kgVS) |

|---|---|---|---|---|---|---|

| 4.5 | 0.022 | 1.41 | 0.41 | 2.23 | 0.124 | 7.26 |

| 5 | 0.085 | 1.30 | 0.34 | 2.41 | 0.102 | 6.16 |

| 5.5 | 0.169 | 1.83 | 0.41 | 1.82 | 0.123 | 7.27 |

| 6 | 0.129 | 2.15 | 0.55 | 2.86 | 0.165 | 9.32 |

| 6.5 | 0.175 | 0.95 | 0.54 | 3.02 | 0.162 | 8.86 |

| 7 | 0.192 | 0.66 | 0.56 | 3.62 | 0.169 | 9.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zagklis, D.; Papadionysiou, M.; Tsigkou, K.; Tsafrakidou, P.; Zafiri, C.; Kornaros, M. Effect of pH on the Economic Potential of Dark Fermentation Products from Used Disposable Nappies and Expired Food Products. Appl. Sci. 2021, 11, 4099. https://doi.org/10.3390/app11094099

Zagklis D, Papadionysiou M, Tsigkou K, Tsafrakidou P, Zafiri C, Kornaros M. Effect of pH on the Economic Potential of Dark Fermentation Products from Used Disposable Nappies and Expired Food Products. Applied Sciences. 2021; 11(9):4099. https://doi.org/10.3390/app11094099

Chicago/Turabian StyleZagklis, Dimitris, Marina Papadionysiou, Konstantina Tsigkou, Panagiota Tsafrakidou, Constantina Zafiri, and Michael Kornaros. 2021. "Effect of pH on the Economic Potential of Dark Fermentation Products from Used Disposable Nappies and Expired Food Products" Applied Sciences 11, no. 9: 4099. https://doi.org/10.3390/app11094099

APA StyleZagklis, D., Papadionysiou, M., Tsigkou, K., Tsafrakidou, P., Zafiri, C., & Kornaros, M. (2021). Effect of pH on the Economic Potential of Dark Fermentation Products from Used Disposable Nappies and Expired Food Products. Applied Sciences, 11(9), 4099. https://doi.org/10.3390/app11094099