Abstract

One-sided surface charred European beech wood (Fagus sylvatica L.) was studied. Radial and tangential specimens of dimensions of 50 × 25 × 350 mm were one-sided surface charred at 200, 250, 300, 350, and 400 °C for various times using a contact heating system. Specimens of dimensions of 50 × 25 × 50 mm3 were prepared for treatment intensity analysis and its effect on surface wettability. Density profiles of the radial and tangential charred specimens were determined using X-ray densitography with a resolution of 0.05 mm. The wettability of the one-sided surface charred wood specimens was analyzed via contact angle, measured using the sessile drop method and determined over 10 to 150 s. The oven-dried specimens were partially submerged in water and water uptake was recorded after 2, 4, 6, 8, 10, 48, and 72 h according to EN-927-5. The surface density of the radial specimen groups charred at 200 °C for 6 min and 250 °C for 4 min decreased by about 4.5 to 8.2%. With increasingly severe charring, the surface density decreased by about 15.5 to 33.5%. A mild charring process produced a surface charred layer of approx. 2 mm, while higher temperatures and longer times affected the density up to 4–6 mm beneath the surface. Differences were found between the water uptake of the radial and tangential charred beech specimens. The most significant decrease of 56% in water uptake was recorded for the radial group prepared at 200 °C for 20 min after floating in water for 72 h. Water uptake in the radial groups modified at 250 °C for 4 and 6 min after 72 h decreased by 38% and 36%, respectively. The tangential groups did not show any statistically significant decrease. The average water uptake of the groups charred at 200 °C for 20 min, 350 °C for 2 min and 400 °C for 1 min was greater than that of the reference; the variability of the measured data was significantly greater due to the highly anisotropic character of the tangential specimens. Micro cracks were also visible on the surface. Concluding from the results of this study, one-sided surface charred beech wood exhibits increased potential in terms of wood–water related properties when a temperature range of 200–400 °C is applied.

1. Introduction

The growing interest in ecological construction has increased the demand for renewable and easily recyclable materials. Wood is a sustainable, ecological, low-cost choice for exterior building elements [1]. Wood products with a long service life can make a significant contribution to climate change mitigation [2]. Therefore, there is a scientific effort to enhance wood in order to obtain materials that maintain advantages over their service life and, at the same time, reduce their disadvantages, such as natural variability, dimensional instability, and biological degradability [3,4]. The resistance of natural wood species to biological degradation is closely associated with a higher moisture content in timber structures (above 20%), and the chemical composition of wood, e.g., presence of extractives, etc. Water uptake and water release into the environment may cause surface cracking of wooden structures as a result of the internal stresses caused by swelling and shrinkage. The damaged surface and high moisture content of wood can favor the risk of biological degradation [5]. Hygroscopicity of wood, which is one of the main characteristics increasing the risk of rot decay, can be temporarily or permanently eliminated using modification methods, such as chemical, thermal, and mechanical treatments [6,7,8]. The thermal modification of wood at elevated temperatures (160–260 °C), as one of the most commonly used commercial methods, decreases the equilibrium moisture content (EMC) and improves its dimensional stability and biological durability [9]. An alternative to traditional thermal modification is to modify only the exposed surfaces, saving time and costs, and preserving the material properties of the interior of the wood [10,11,12,13]. Recent scientific work shows that wood can be one-sided surface charred using a hot plate under controlled conditions—i.e., temperature and time—leaving the structural properties of the wood relatively unchanged [11,12,13]. It is well known that wood undergoes a number of overlapping chemical reactions as a result of thermal degradation when high temperatures are applied. At lower temperatures (180–250 °C), wood undergoes important chemical transformations that result in the decomposition of non-crystalline carbohydrates [14,15,16,17,18,19], while lignin and cellulose degradation occurs somewhat above 280 °C [20,21]. Heating to 300 °C results in the depolymerization of cellulose, the production of volatile compounds, the formation of oxidation products (carbonyl and carboxyl compounds), and finally charring, causing extensive mass loss [22]. Most of the hemicelluloses have decomposed at 300 °C and the most rapid rates of decomposition of cellulose and lignin take place at approx. 360 °C, while the remaining lignin continues to decompose above 400 °C [12,23]. Even though there has recently been interest in this topic, one-sided surface charring using a contact heating system at a temperature range of 200–400 °C has not yet been tested.

Beech is the most widespread broadleaf species in forests of the Czech Republic and there is strong demand to find new and alternative ways to commercially use this traditional timber, especially for outdoor conditions. It is hypothesized that by applying an appropriate combination of charring parameters, i.e., time and temperature, the optimum treatment intensity can be determined, decreasing the surface wettability properties of beech wood when compared with untreated material.

2. Materials and Methods

European beech (Fagus sylvatica L.) wood from a Czech forest enterprise was studied. Specimens of dimensions 50 × 20 × 350 mm were made from one tree and cut from sawn boards with an average oven-dry density of 631 kg/m3 (standard deviation 53 kg/m3) for radial and 658 kg/m3 (standard deviation 35 kg/m3) for tangential specimens (Table 1). The specimens were sorted into two main groups according to the orientation of the surface (radial or tangential) to be charred. The radial and tangential specimens were sorted into groups with an as similar average density as possible, with 10 specimens in each group. Specimens were one-sided surface charred by contact heating using a laboratory hot plate (CERAN 33SR) with a built-in NiCrNi sensor and electronic temperature controller on the radial and tangential surfaces. The specimens were first dried to 0% MC (103 ± 2°C), then immediately charred in order to avoid any shape deformation during contact heating. No additional pressure was applied during the charring process. The time–temperature regimes of the processes are shown in Table 1.

Table 1.

Time–temperature regimes of one-sided surface charring.

The radial and tangential references and the one-sided surface charred specimens of dimensions 50 × 20 × 50 mm were analyzed for their density profiles to determine the intensity of the charring process. The oven-dried specimens (103 ± 2 °C for 24 h) were measured using an X-ray density profile analyzer—DPX3000 (Imal s.r.l., San Damaso, Italy)—with a measuring step of 0.05 mm. Five specimens from each group were measured.

The wettability of the one-sided surface charred specimens was determined using contact angle measurements, as well as by surface water uptake according to EN-927-5. Initially, the specimens were placed in a climate chamber at 20 °C and 65% RH for one week until a constant mass was achieved (less than 2% of variation). The specimens were then transferred one by one to the laboratory, where individual measurements were carried out. The contact angle at the contact line of advancing sessile drops was analyzed using the surface energy evaluation system—the “See System” (Advex Instruments, Brno, Czech Republic). The specimens were placed on a movable stage in front of a CCD camera while drops of distilled water (with a volume of 1 μL) were put onto the charred surface. Images were recorded with the camera over 10 to 150 s. The surface was measured repeatedly (at least five times) and always at a different position. The analysis was performed at room temperature (20 °C).

The specimens of dimensions of 50 × 20 × 50 mm3 were also measured for water uptake. The sides of the wood were sealed with two-component epoxy varnish EPOLEX S1300 mixed with the hardener EPOLEX S7300 and dried to 0% moisture content. The mass gain (water uptake) of partially submerged specimens was recorded after 2, 4, 6, 8, 10, 24, 48, and 72 h.

The data recorded were processed using Statistica 13 software (StatSoft Inc., Tulsa, OK, USA) and evaluated using one-factor analysis of variance (ANOVA), completed with Tukey’s honest significance test (HSD test).

3. Results and Discussion

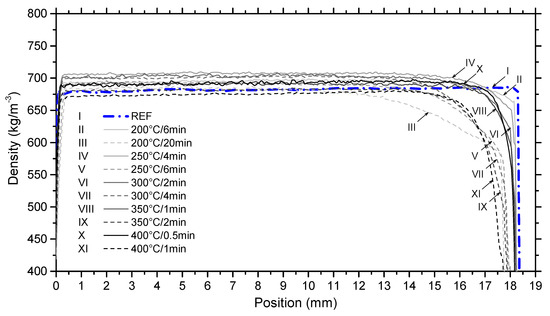

The intensity of one-sided surface charring of the radial and tangential specimens was determined using X-ray density profile analysis and compared to the reference (Figure 1 and Figure 2). The density profile of the reference radial and tangential specimens varied due to the different annual ring orientations in their cross sections and consequently earlywood and latewood proportions in the longitudinal sides. The average density of the reference radial specimens showed uniform distribution, while one-sided charred specimens tended to decrease in their density profile according to the time–temperature regime applied. Application of mild temperature–time regimes (200/6 and 250/4) led to only minor changes in the surface density profile, which decreased by about 4.5 to 8.2%. With increasingly severe charring, the surface density decreased by about 15.5 to 33.5%. According to the results, the mild charring processes produced a surface charred layer of approx. 2 mm, while a higher temperature and longer time affected density up to 4 mm. A significantly greater difference was found when a temperature of 200 °C was applied for 20 min. As a result of the longer time, the density profile was affected up to 6 mm beneath the surface of the specimen.

Figure 1.

Density profiles of charred specimens compared to the reference—radial.

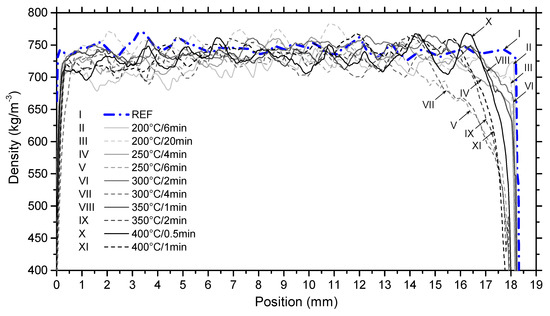

Figure 2.

Density profiles of charred specimens compared to the reference—tangential.

The decrease in density during one-sided surface charring is associated with a number of overlapping thermal degradation reactions as previously presented by several authors [21,24]. Hemicelluloses are decomposed at temperature up to 250–300 °C, followed by lignin and cellulose degradation above 280 °C. The depolymerization of cellulose, production of volatile compounds, formation of oxidation products, and charring result at a temperature of approx. 300 °C. As the temperature increase, the degree of polymerization of cellulose decrease and the crystallinity increase [25]. This might be due to a preferred degradation of the less ordered molecules during the thermal treatment [26,27]. Further decomposition of cellulose and lignin takes place at approx. 360 °C, while at 400 °C the remaining lignin continues to decompose [23].

The density profiles of the tangential specimens showed greater variability and therefore evaluation is not as straightforward as with the radial specimens. According to the results, most of the charring processes produced a surface charred layer of only approx. 2 mm, while greater thermal degradation was found in specimens undergoing 250/6 and 300/4 regimes. These differences can be partially explained by the different densities of the radial and tangential specimens and partially due to the different thermal conductivity of wood in the radial and tangential directions (λR > λT). These differences can be attributed to the significant number of wood rays in hardwoods and their orientation [28,29]. In addition, in the tangential section reasonably the ratio of earlywood and latewood is different, depending by the position if close to the pith or far from the pith [3].

The contact angle (CA) evolution with time is given for charred radial and tangential specimens as well as for an untreated sample at different temperatures (Figure 3). The highest values were measured for the lowest temperature (200/20R—68.2°; 200/20T—70.0°), the higher the temperature was used, the worse CA, which is in line with previous results [11], where contact heating was also used for the preparation. As a rule, the wettability of heat-treated wood decreases [7,21,30]. Heat treatment of beech blocks were performed by Hakkou et al. (2005) in France, in a reactor placed in an oven, the wood surface started to be hydrophobic (CA > 90°) after 120 °C [21]. CA characterized on heat-treated beech wood at 240 °C in an industrial oven showed that the variation after and before processing (∆θa = 16.2°) was low compared with other species (spruce = 44.7°, pine = 62.4° poplar = 85.8°) [28]. The value of ∆θa for beech processed by contact heating for radial specimens (∆θa = 200/20R—REFR) was 24.0° and 5.6° for tangential (∆θa = 200/20T—REFT). The average value of ∆θa corresponded to 14.8°, which was more or less in the good agreement previous results [31]. The effect of processing direction is obvious. Characteristics of dynamic wetting process for two different heat-treated (max. 205 °C) North American wood species, white ash and soft maple, in axial, radial and tangential directions were studied and CA values were in all cases were higher for heat-treated wood than for untreated [32], this is in line with our results. Nevertheless, these results suggest that the difference between the CA in radial and tangential directions are not significant. In contrast, the behavior of CA in tangential and radial beech samples shows large differences.

Figure 3.

Contact angle of the radial (A) and tangential (B) one-sided charred specimens.

The lowest contact angles were measured on the surfaces that were charred at the highest temperatures (400 °C). The charring increased the hydrophobic behavior more in radial specimens. The exception was sample 400/1R, where CA decreased much faster than in the others; after 7 s its CA results were worse than the reference. Tangential specimens showed better values of CA than REFT at 200/20T, 250/4T and 250/6T. The rest have CA values that are the same as the reference (300/4T and 350/1T), or even worse (300/2T, 350/2T, 400/1T and 400/0.5T). The sample REFT had a relatively high CA on average, but the standard deviation was 14.11 after 10 s and 16.04 after 150 s (the highest initial measured CA is 87° and the lowest 32°). The results suggest that the surface properties of the tangential samples varied considerably. Principally, the values of radial standard deviation increased quite steadily with increasing observation time; the higher the temperature and time of charring, the greater the increase in deviation (250/4R = 0.30; 400/1R = 10.32). In contrast, tangential samples (except REFT) show standard deviation values that are very similar, regardless of the treatment method (250/4T = 0.55; 400/1T = 2.69).

In general, polymeric materials are semi-crystalline with co-existing amorphous and crystalline phases. They show a certain degree of structural order, expressed by a degree of crystallinity from 40% to 90% (100% is never possible in processing conditions). Most wood-derived cellulose is crystalline [3]; due to the effect of pyrolysis, the crystallinity increases. The higher hydrophobicity of heat-treated wood can be explained by degradation of the amorphous region and an increase in cellulose crystallinity with temperature since the sorption of water by amorphous region is higher than for crystalline cellulose. It has been demonstrated using 13C nuclear magnetic resonance and X-ray analyses that heat-treated wood has a higher crystallinity, leading to a more hydrophobic material [26,31,33]. The fiber alignment and degree of crystallinity can also affect the hydrophobicity of the samples, the larger the alignment of the fiber, the higher the degree of crystallinity [34].

In addition, higher amounts of non-polar components on the surface of samples exposed to higher temperatures cause an increase in hydrophobicity, which is attributed to extractive migrations and deposition of volatile organic compound substances [33]. Moreover, the hydrophobic character is correlated with low values of electron-donating components. After heat treatment, the lignin content increased, while carboxylic acid functions that are mainly present in hemicelluloses decreased significantly; an important decrease in wood acidity was noted [35]. The dehydration reactions of hemicelluloses that are ongoing during heat-treatment are able to degrade OH-groups, which cause a decrease in water penetration into the wood surface [36]. The heat treatment causes a greater gas permeability and an increase in porosity and decrease in gravimetric density [37,38,39]. Finally, extensive charring (more than 400 °C) leads to intensive cracking and an increase in the capillary absorption of water, which is related to the high standard deviation values measured for wood charred at 400 °C.

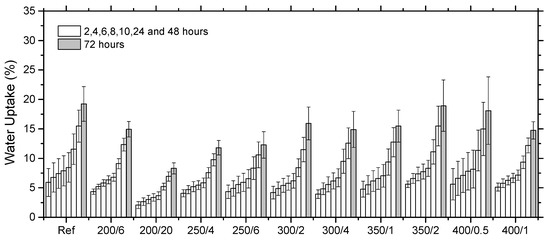

The results of wettability of the one-sided surface charred specimens were determined by surface water uptake and are presented in Figure 4 and Figure 5. Similar to the contact-angle measurements, varying results of water uptake were found for the radial and tangential specimens. The average water uptake of the radial specimens after 72 h was statistically (p = 0.000207) lower than the reference. The most significant decrease of 56% in water uptake was found in the 200/20 group after 72 h of floating in water. The reduced water absorption is likely to be due to a reduction in the number of hydroxyl groups (-OH) in the celluloses and hemicelluloses as a result of high temperature treatment. Furthermore, the decreased accessibility of water molecules to cellulose hydroxyl groups due to the increase in cellulose crystallinity and cross-linking in lignin can also play an important role [40,41,42]. The water uptake of the 250/4 and 250/6 specimens after 72 h decreased by about 38% and 36%, respectively. With increasingly severe charring, specimens exhibited only minor differences, though the standard deviation increased more than with the others.

Figure 4.

Water uptake (%) of the radial reference and one-sided surface charred specimens over 72 h.

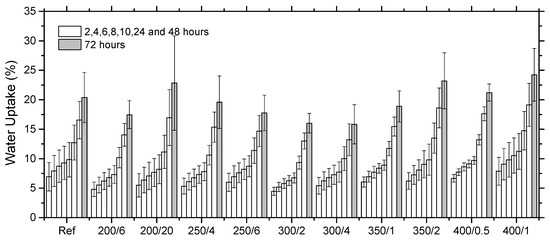

Figure 5.

Water uptake (%) of the tangential reference and one-sided surface charred specimens over 72 h.

There was no statistically significant difference between the water uptake of the tangential specimens (Figure 5). The average water uptake in 200/20, 350/2, and 400/1 samples increased when compared to the reference. The variability of measured data was also significantly greater than those of the radial specimens. The main reason can be found in the highly anisotropic character of the tangential specimens, which undergo more severe dimensional changes (swelling) during water soaking than the radial specimens [43]. The charred surface layer is hydrophobic, cross-linked and aromatic, but also porous and brittle, especially at temperatures above 300 °C.

When capillary absorption takes place and water molecules penetrate into the cell wall, wood starts to swell and change its transverse dimensions. As a result of the surface micro cracks in the charred layers, water uptake is increased and causes additional surface damage due to the different internal stresses of the charred surface and untreated inner wood.

The results indicate that the most important factors influencing the performance of one-sided surface charred beech wood are, not only the process parameters, i.e., temperature and time, but also the orientation of annual rings towards the heat flow, which may play a major role during a product’s life [13,44,45,46]. Density profile measurements can potentially be used as an efficient tool to verify the charring process intensity and further optimize the process according to specific requirements.

4. Conclusions

One-sided surface charred beech wood (Fagus sylvatica L.) was studied. The density profile of the studied specimens varied due to the different annual ring orientations in the specimens. The gravimetric density of charred specimens tended to decrease according to the time–temperature regime applied. Differences in water uptake between the radial and tangential one-sided charred specimens were found. A statistically significant decrease in water uptake was recorded only in the radial groups. The tangential groups did not show any statistically significant decrease. The statistically insignificant change in water uptake of charred tangential groups can be attributed to the anisotropic character and higher dimensional instability of tangential specimens, which can lead to cracking of the modified surface, as well as to the different depths of the charred layer when compared to the radial specimens. In addition, there was high data variability with the tangential specimens, and therefore further testing should be carried out to avoid the effects of natural wood variability, and other influencing factors. Concluding from the results of this study, one-sided surface charred beech wood exhibits increased potential in terms of wood–water related properties when temperatures in the range of 200–400 °C are applied. However, in-depth studies focused on the stabilization of the surface charred layer should be performed to fully exploit its potential.

Author Contributions

Measuring water uptake, writing the manuscript—V.Š.; measuring contact angle, data analysis, writing the manuscript—D.M.; specimen preparation, charring process and optimization—J.D. (Jakub Dohnal); specimen preparation, measuring density profiles—J.D. (Jakub Dömény); measuring contact angle, statistical analysis—L.Z.; data analysis; writing the manuscript—A.O.; specimens preparation, data and statistical analysis, graphics—V.V.; conceptualization, research project administration, supervising and manuscript writing—review and editing—P.Č. All authors have read and agreed to the published version of the manuscript.

Funding

This project has received funding from the Internal Grant Agency of the Faculty of Forestry and Wood Technology at Mendel University in Brno, Czech Republic, project No. LDF_VP_2020040, from the European Union’s Horizon 2020 research and innovation programme under grant agreement N°952314 and from the Czech Academy of Sciences, Institute of Theoretical and Applied Mechanics (RVO 68378297).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jones, D.; Brischke, C. Performance of Bio-Based Building Materials; Woodhead Publishing: Cambridge, UK, 2017; p. 650. [Google Scholar]

- Werner, F.; Taverna, R.; Hofer, P.; Richter, K. Greenhouse Gas Dynamics of an Increased Use of Wood in Buildings in Switzerland. Clim. Chang. 2006, 74, 319–347. [Google Scholar] [CrossRef]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2005; p. 487. [Google Scholar]

- Kutnar, A.; Muthu, S.S. Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts; Springer: Berlin/Heidelberg, Germany, 2016; p. 248. [Google Scholar]

- Eaton, R.A.; Hale, M.D.C. Wood: Decay, Pests and Protection; Chapman and Hall Ltd.: New York, NY, USA, 1993; p. 546. [Google Scholar]

- Militz, H. Thermal Treatment of Wood: European Processes and Their Background; Document no. IRG/WP 02-40241; International Research Group on Wood Preservation: Stockholm, Sweden, 2002. [Google Scholar]

- Esteves, B.; Pereira, H. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Hill, C. Wood modification: An update. BioResources 2011, 6, 918–919. [Google Scholar]

- Čermák, P.; Vahtikari, K.; Rautkari, L.; Laine, K.; Horáček, P.; Baar, J. The effect of wetting cycles on moisture behaviour of thermally modified Scots pine (Pinus sylvestris L.) wood. J. Mater. Sci. 2016, 51, 1504–1511. [Google Scholar] [CrossRef]

- Gosselink, R.J.A.; Krosse, A.M.A.; van der Putten, J.C.; van der Kolk, J.C.; de Klerk-Engels, B.; van Dam, J.E.G. Wood preservation by low-temperature carbonization. Ind. Crops Prod. 2004, 19, 3–12. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Hautamäki, S.; Lillqvist, K.; Segerholm, K.; Rautkari, L. Surface modification of solid wood by charring. J. Mater. Sci. 2017, 52, 6111–6119. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Turunen, H.; Čermák, P.; Hautamäki, S.; Rautkari, L. Surface-related characteristics of surface-charred spruce wood. Materials 2018, 11, 2083. [Google Scholar] [CrossRef]

- Čermák, P.; Dejmal, A.; Paschová, Z.; Kymäläinen, M.; Dömény, J.; Brabec, M.; Hess, D.; Rautkari, L. One-sided surface charring of beech wood. J. Mater. Sci. 2019, 54, 9497–9506. [Google Scholar] [CrossRef]

- Viitaniemi, P. Thermowood—Modified Wood for Improved Performance. In Proceedings of the 4th Eurowood Symposium ‘Wood—The Ecological Material’, Stockholm, Sweden, 22–23 September 1997; Trätek Rapport No. P9709084. pp. 67–69. [Google Scholar]

- Jämsä, S.; Ahola, P.; Viitaniemi, P. Performance of coated heat-treated wood. Surf. Coat. Int. 1999, 6, 297–300. [Google Scholar] [CrossRef]

- Jämsä, S.; Ahola, P.; Viitaniemi, P. Long-term natural weathering of coated ThermoWood. Pigment Resin Technol. 2000, 29, 68–74. [Google Scholar] [CrossRef]

- Santos, J.A. Mechanical behaviour of eucalyptus wood modified by heat. Wood Sci. Technol. 2000, 34, 39–43. [Google Scholar] [CrossRef]

- Kamdem, D.P.; Pizzi, A.; Jermannaud, A. Durability of heat-treated wood. Holz als Roh Werkstoff 2002, 60, 1–6. [Google Scholar] [CrossRef]

- Repellin, V.; Guyonnet, R. Evaluation of heat-treated wood swelling by differential scanning calorimetry in relation to chemical composition. Holzforschung 2005, 59, 28–34. [Google Scholar] [CrossRef]

- Fuwape, J.A. Effects of carbonization temperature on charcoal from some tropical trees. Bioresour. Technol. 1996, 57, 91–94. [Google Scholar] [CrossRef]

- Hakkou, M.; Pétrissans, M.; Zoulalian, A.; Gérardin, P. Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym. Degrad. Stab. 2005, 89, 1–5. [Google Scholar] [CrossRef]

- Frangi, A.; Fontana, M. Charring rates and temperature profiles of wood sections. Fire Mater. 2003, 27, 91–102. [Google Scholar] [CrossRef]

- Byrne, C.E.; Nagle, D.C. Carbonization of wood for advanced materials applications. Carbon 1997, 35, 259–266. [Google Scholar] [CrossRef]

- Weiland, J.J.; Guyonnet, R. Study of chemical modifications and fungi degradation of thermally modified wood using DRIFT spectroscopy. Holz als Roh Werkstoff 2003, 61, 216–220. [Google Scholar] [CrossRef]

- Romagnoli, M.; Vittorio, V.; Alessandra, S. Heat treatment effect on lignin and carbohydrates in Corsican pine earlywood and latewood studied by PY–GC–MS technique. J. Wood Chem. Technol. 2018, 38, 57–70. [Google Scholar] [CrossRef]

- Sivonen, H.; Maunu, S.L.; Sundholm, F.; Jämsä, S.; Viitaniemi, P. Magnetic Resonance Studies of Thermally Modified Wood. Holzforschung 2002, 56, 648–654. [Google Scholar] [CrossRef]

- Bhuiyan, M.T.R.; Hirai, N.; Sobue, N. Changes of crystallinity in wood cellulose by heat treatment under dried and moist conditions. J. Wood Sci. 2000, 46, 431–436. [Google Scholar] [CrossRef]

- Sonderegger, W.; Vecellio, M.; Zwicker, P.; Niemz, P. Combined bound water and water vapour diffusion of Norway spruce and European beech in and between the principal anatomical directions. Holzforschung 2011, 65, 819–828. [Google Scholar] [CrossRef]

- Steinhagen, P.H. Thermal conductive properties of wood, green or dry, from −40 °C to +100 °C: A literature review. In USDA Forest Service General Technical Report FPL-9; Forest Products Laboratory: Madison, WI, USA, 1977. [Google Scholar]

- Wang, W.; Zhu, Y.; Cao, J.; Sun, W. Correlation between Dynamic Wetting Behavior and Chemical Components of Thermally Modified Wood. Appl. Surf. Sci. 2015, 324, 332–338. [Google Scholar] [CrossRef]

- Pétrissans, M.; Gérardin, P.; El Bakali, I.; Serraj, M. Wettability of Heat-Treated Wood. Holzforschung 2003, 57, 301–307. [Google Scholar] [CrossRef]

- Kocaefe, D.; Poncsak, S.; Doré, G.; Younsi, R. Effect of Heat Treatment on the Wettability of White Ash and Soft Maple by Water. Holz als Roh und Werkstoff 2008, 66, 355–361. [Google Scholar] [CrossRef]

- Šernek, M.; Kamke, F.A.; Glasser, W.G. Comparative Analysis of Inactivated Wood Surface. Holzforschung 2004, 58, 22–31. [Google Scholar] [CrossRef]

- Areias, A.C.; Ribeiro, C.; Sencadas, V.; Garcia-Giralt, N.; Diez-Perez, A.; Gómez Ribelles, J.L.; Lanceros-Méndez, S. Influence of Crystallinity and Fiber Orientation on Hydrophobicity and Biological Response of Poly(l-Lactide) Electrospun Mats. Soft Matter 2012, 8, 5818–5825. [Google Scholar] [CrossRef]

- Gérardin, P.; Petrič, M.; Petrissans, M.; Lambert, J.; Ehrhrardt, J.J. Evolution of Wood Surface Free Energy after Heat Treatment. Polym. Degrad. Stab. 2007, 92, 653–657. [Google Scholar] [CrossRef]

- Lopes, J. de O.; Garcia, R.A.; do Nascimento, A.M. Wettability of the Surface of Heat-Treated Juvenile Teak Wood Assessed by Drop Shape Analyzer. Maderas Ciencia y Tecnología 2018, 20, 249–256. [Google Scholar]

- Kymäläinen, M.; Rautkari, L.; Hill, C.A.S. Sorption Behaviour of Torrefied Wood and Charcoal Determined by Dynamic Vapour Sorption. J. Mater. Sci. 2015, 50, 7673–7680. [Google Scholar] [CrossRef]

- Jang, E.S.; Kang, C.W. Changes in Gas Permeability and Pore Structure of Wood under Heat Treating Temperature Conditions. J. Wood Sci. 2019, 65, 37. [Google Scholar] [CrossRef]

- Romagnoli, M.; Cavalli, D.; Pernarella, R.; Zanuttini, R.; Togni, M. Physical and mechanical characteristics of poor-quality wood after heat treatment. iForest-Biogeosci. For. 2015, 8, 884. [Google Scholar] [CrossRef]

- Virta, J. Cupping of wooden cladding boards in cyclic conditions—a study of heat-treated and non-heat-treated boards. Build. Environ. 2005, 40, 1395–1399. [Google Scholar] [CrossRef]

- Boonstra, M.; Tjeerdsma, B. Chemical analysis of heat treated softwoods. Holz Roh-Werkstoff 2006, 64, 204–211. [Google Scholar] [CrossRef]

- Hill, C. Wood Modification Chemical, Thermal and other Processes; Wiley: Hoboken, NJ, USA, 2006; p. 239. [Google Scholar]

- Kúdela, J.; Čunderlík, I. Beech Wood—Structure, Properties, Use (Bukové Drevo—Štruktúra, Vlastnosti, Použitie); Technická univerzita vo Zvolene: Zvolen, Slovakia, 2012; p. 152. [Google Scholar]

- Bryden, K.M.; Ragland, K.W.; Rutland, C.J. Modeling thermally thick pyrolysis of wood. Biomass Bioenergy 2002, 22, 41–53. [Google Scholar] [CrossRef]

- Metsä-Kortelainen, S.; Antikainen, T.; Viitaniemi, P. The water absorption of sapwood and heartwood of Scots pine and Norway spruce heat-treated at 170, 190, 210 and 230 °C. Holz als Roh Werkstoff 2006, 64, 192–197. [Google Scholar] [CrossRef]

- Fortino, S.; Genoese, A.; Genoese, A.; Rautkari, L. FEM simulation of the hygro-thermal behaviour of wood under surface densification at high temperature. J. Mater. Sci. 2013, 48, 7603–7612. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).