Municipal Solid Waste Management and Waste-to-Energy Potential from Rajshahi City Corporation in Bangladesh

Abstract

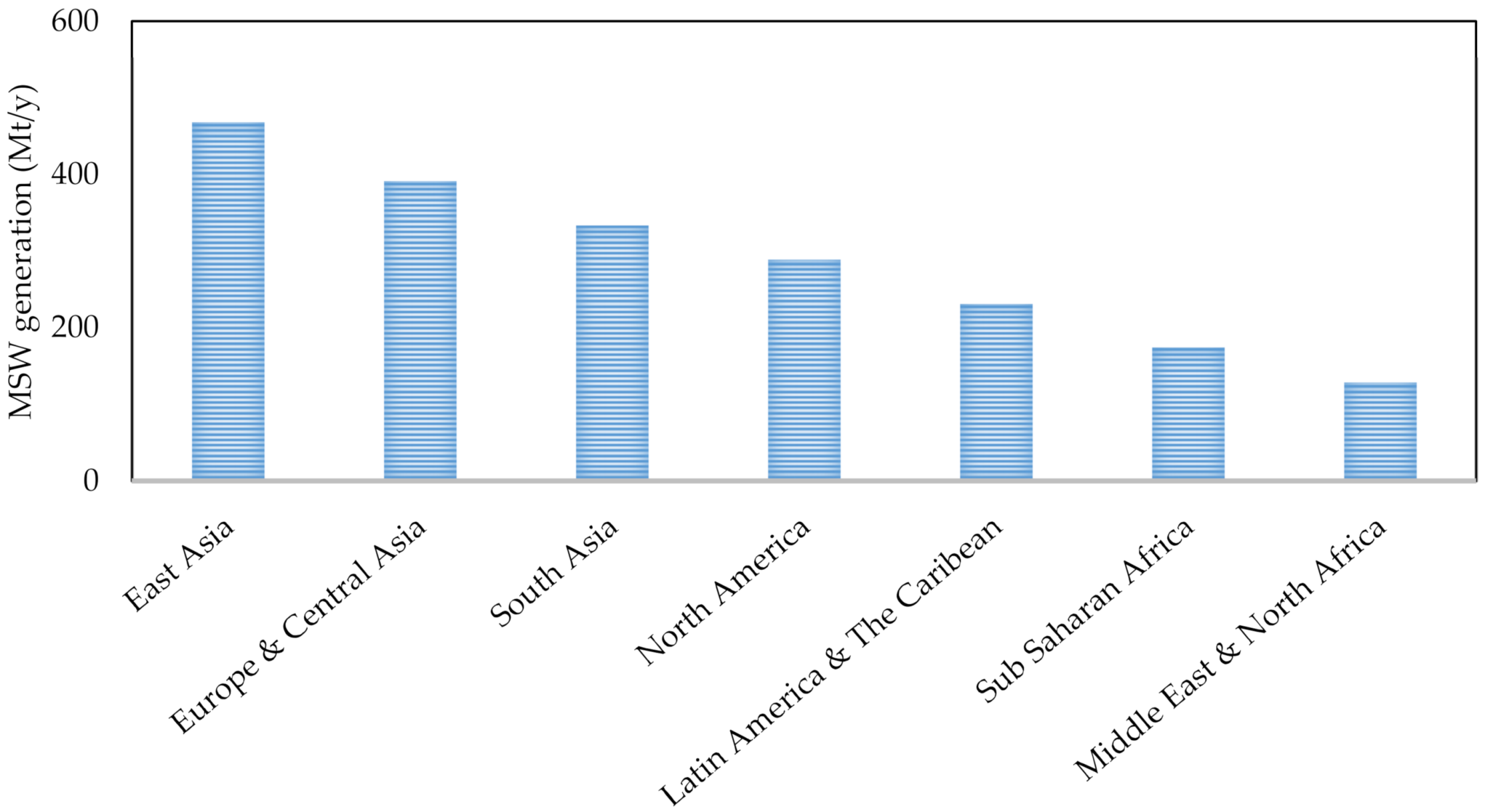

1. Introduction

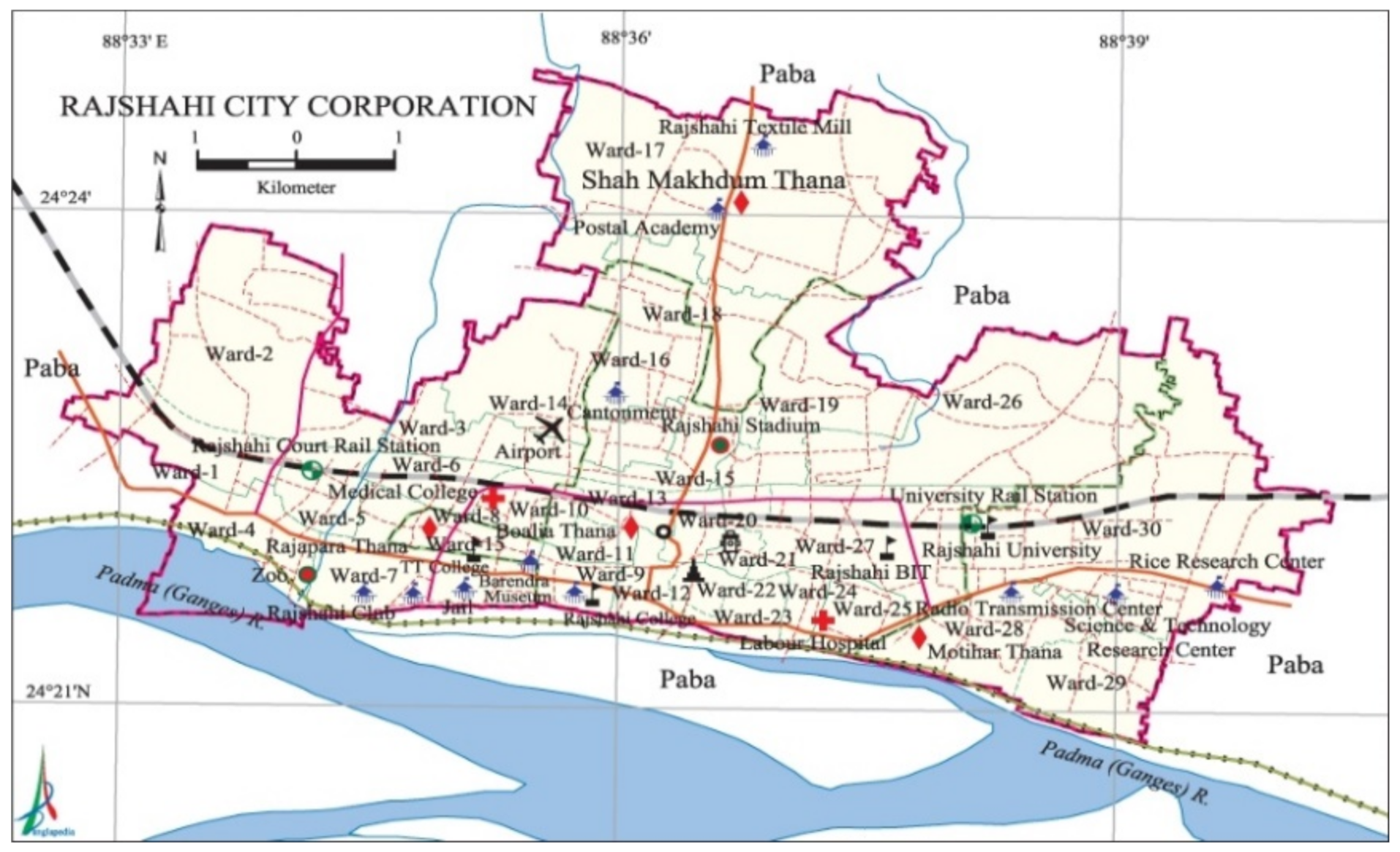

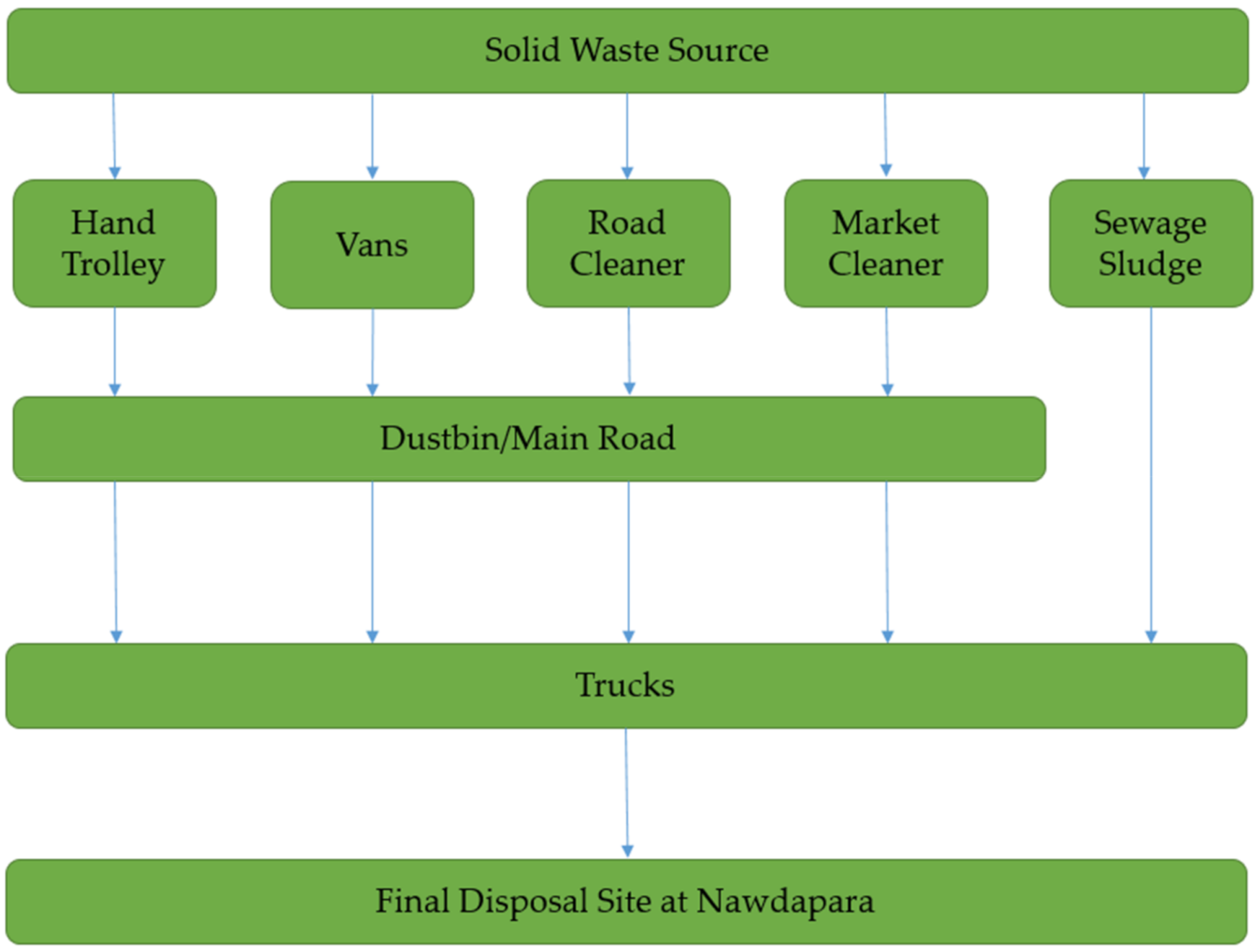

2. Present Status of MSW Management in RCC, Bangladesh

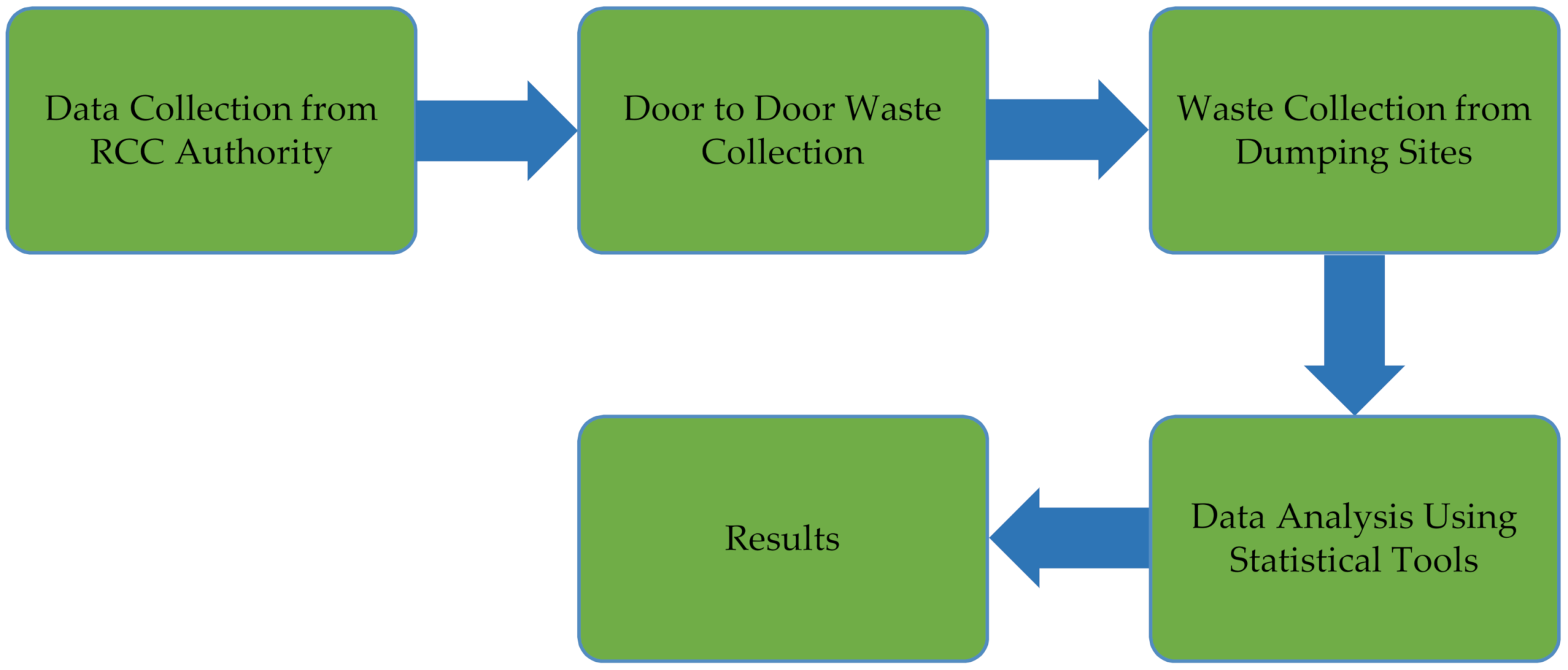

3. Research Methodology

3.1. Data Collection

3.2. Calorific Value and Potential Power Generation from MSW

- = Net electrical power.

- = Electrical power = Steam power/11,395 (kWh/kg).

- = Station service allowance = 0.06 ∗ .

4. Results and Discussions

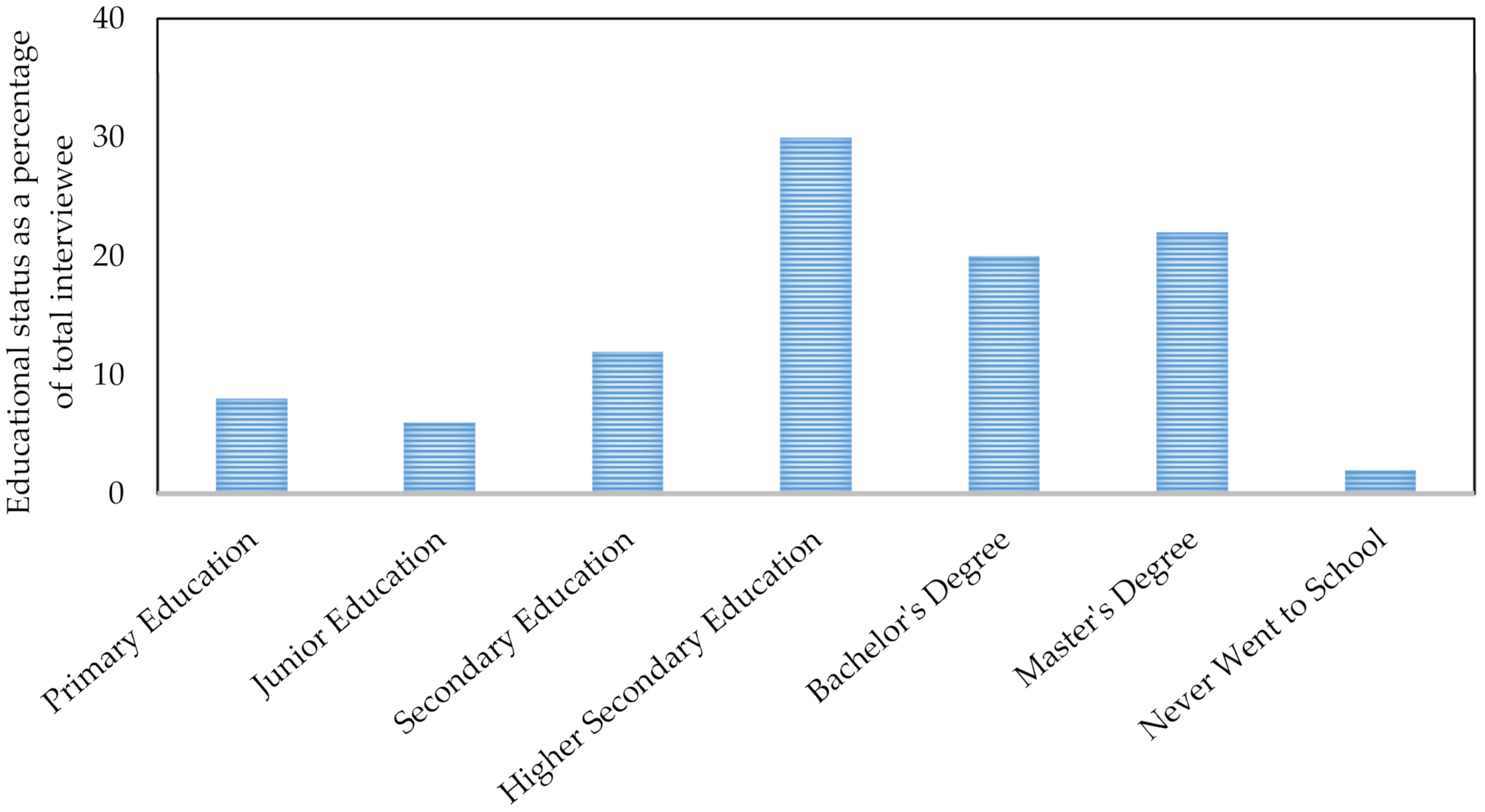

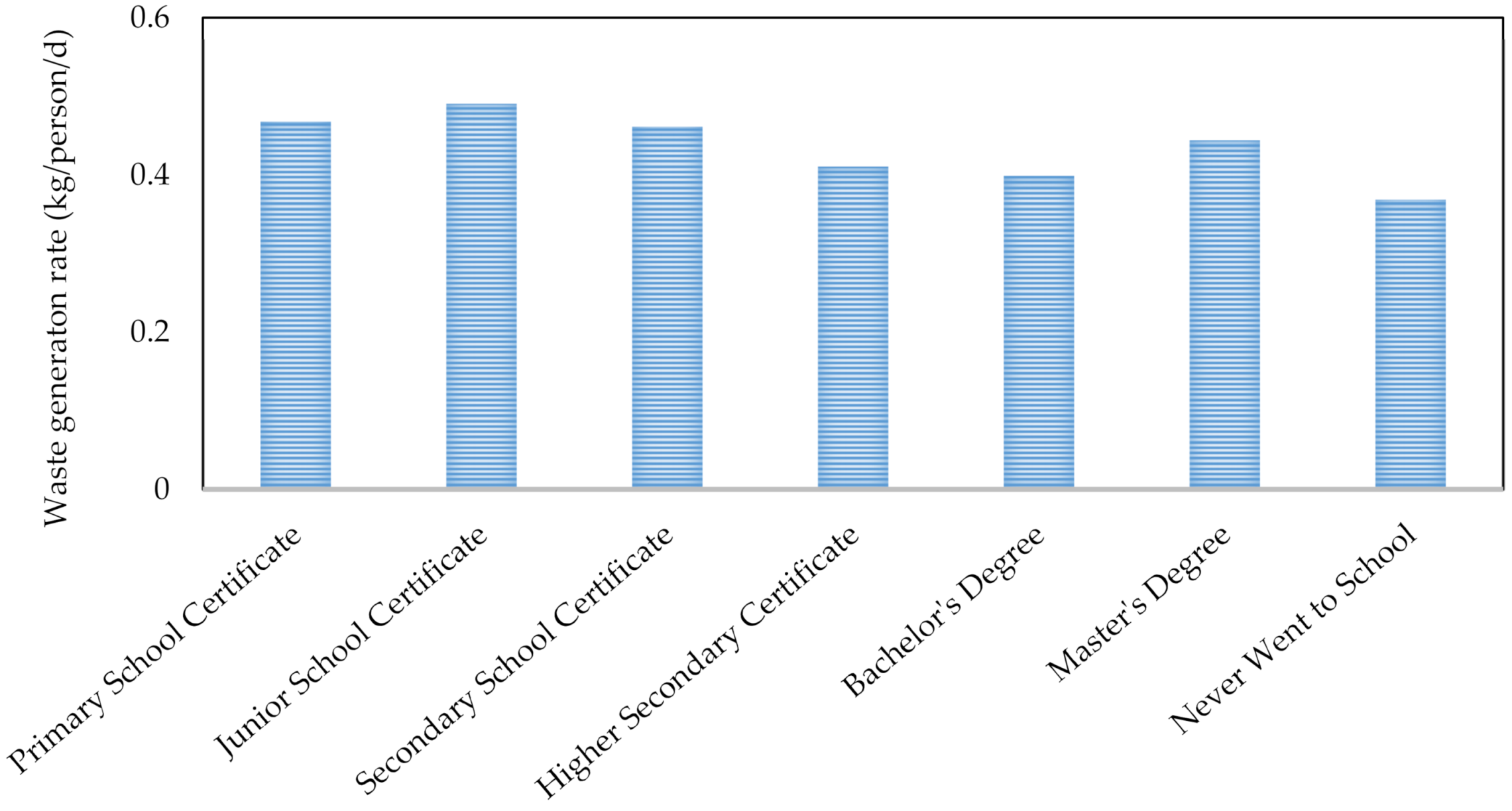

4.1. Estimation of MSW Generation

4.2. Calorific Value and Possible Electricity Generation

4.2.1. Physical Composition of MSW in RCC

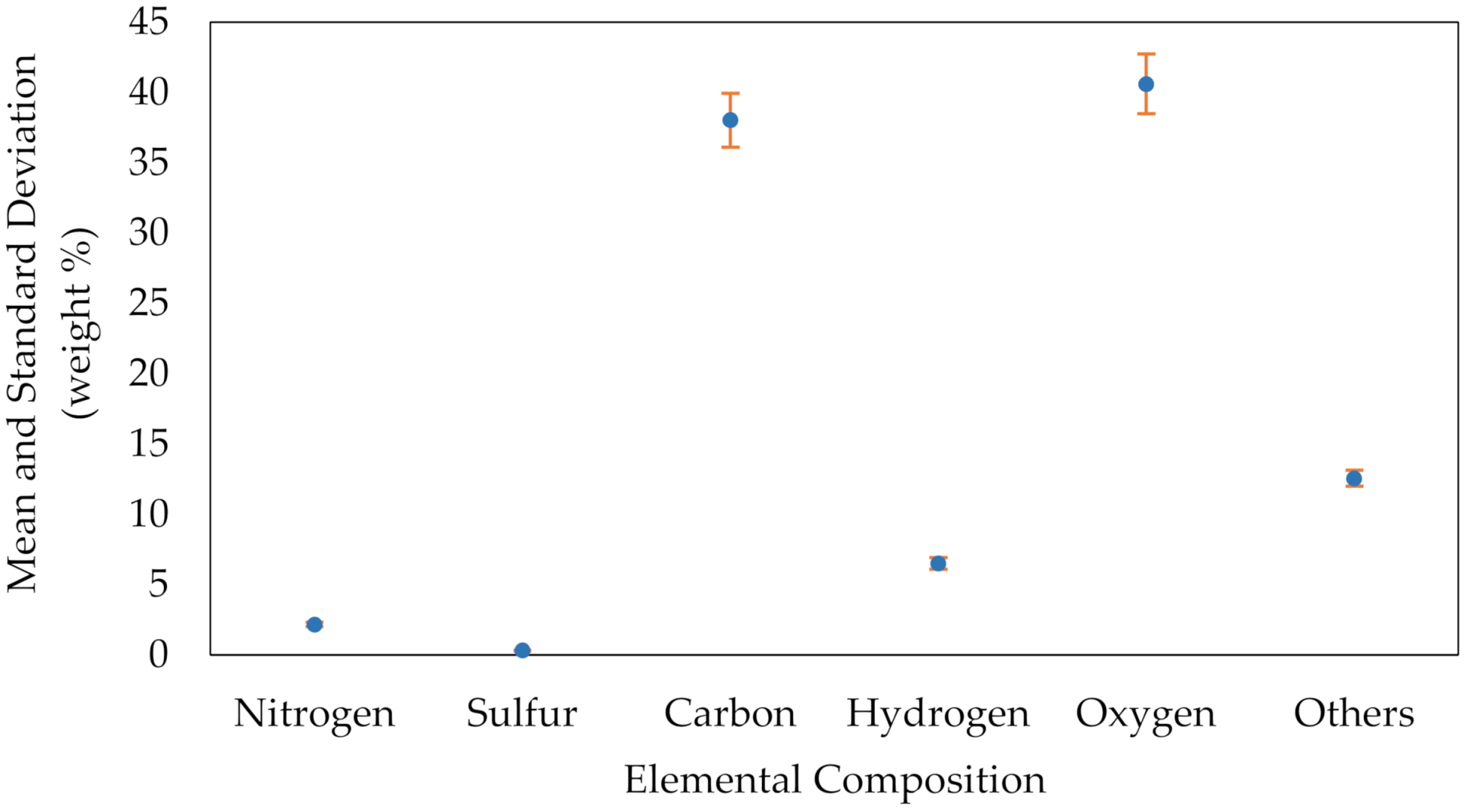

4.2.2. Chemical Composition (Dry) of MSW at RCC

4.2.3. Determination of Calorific Value and Potential Electrical Energy

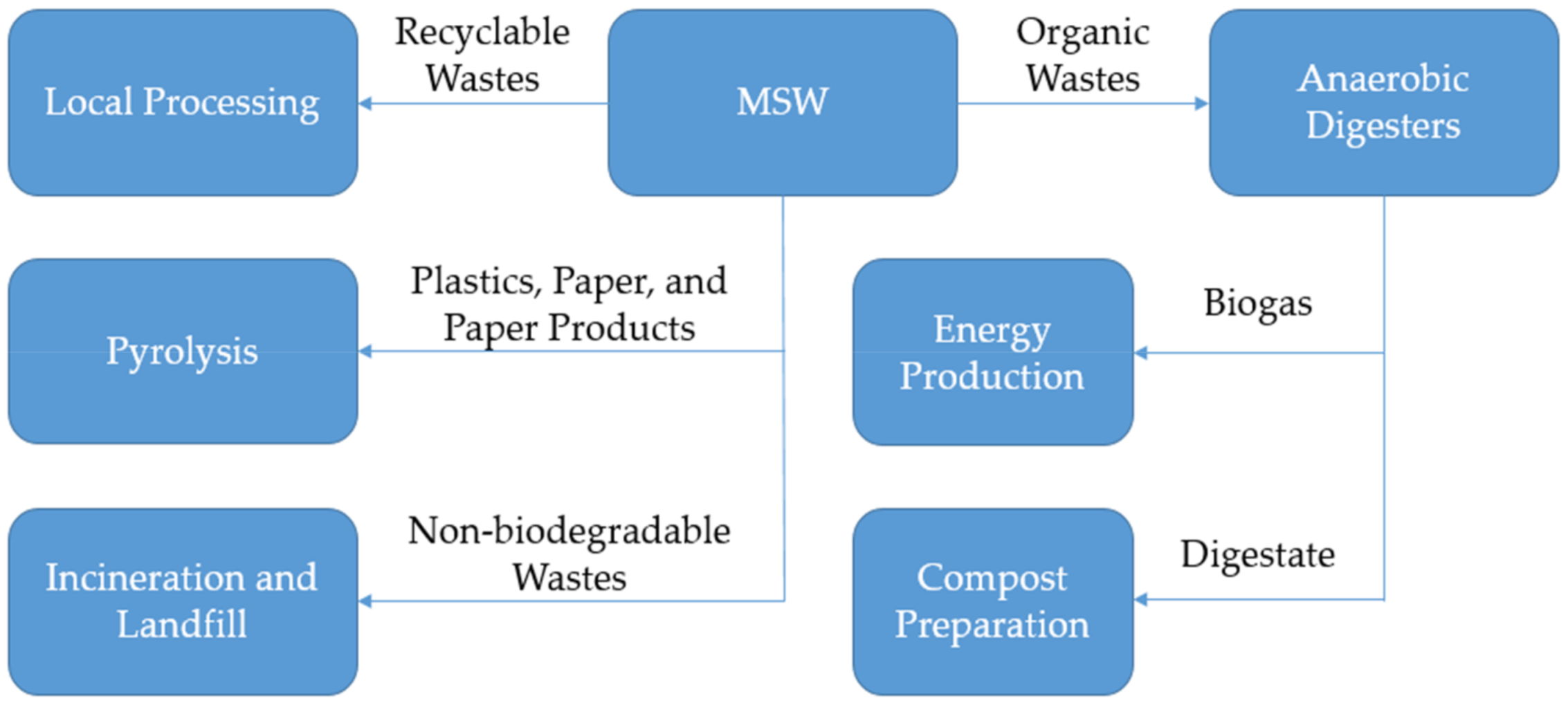

5. Potential Treatment of Conversion Technologies

5.1. Landfill Gas Recovery

5.2. Waste Recycling

5.3. Incineration

5.4. Composting

5.5. Anaerobic Digestion

5.6. Pyrolysis

5.7. Gasification

5.8. Depolymerization

5.9. Refuse-Derived Fuel (RDF)

6. Proposed WTE Conversion Technology

7. Techno-Economic Analysis of the Proposed AD Plant

8. Future Recommendations

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharholy, M.; Ahmad, K.; Vaishya, R.; Gupta, R.D. Municipal solid waste characteristics and management in Allahabad, India. Waste Manag. 2007, 27, 490–496. [Google Scholar] [CrossRef] [PubMed]

- Kum, V.; Sharp, A.; Harnpornchai, N. Improving the solid waste management in Phnom Penh city: A strategic approach. Waste Manag. 2005, 25, 101–109. [Google Scholar] [CrossRef] [PubMed]

- Alamgir, M.; McDonald, C.; Roehl, K.; Ahsan, A. Integrated Management and Safe Disposal of Municipal Solid Waste in Least Developed Asian Countries and Technology, Bangladesh; Final Report of ‘Waste Safe’, A feasibility project under the Asia Pro Eco Programmed of the EC; Khulna University of Engineering & Technology: Khulna, Bangladesh, 2005. [Google Scholar]

- Farzana, F.; Kabir, M.A. Development of An Integrated GIS Based Methodology for the Selection of Solid Waste Disposal Sites for Khulna City. Khulna Univ. Stud. 2004, 4, 725–731. [Google Scholar]

- Rana, M.S. Feasibility of Study Waste to Energy and Power Generation of Dhaka City. Master’s Thesis, University of Dhaka, Dhaka, Bangladesh, 2016. [Google Scholar]

- Sujauddin, M.; Huda, S.M.; Hoque, A.T.M.R. Household solid waste characteristics and management in Chittagong, Bangladesh. Waste Manag. 2008, 28, 1688–1695. [Google Scholar] [CrossRef]

- Bari, Q.H.; Hassan, K.M.; Haque, M.E. Solid waste recycling in Rajshahi city of Bangladesh. Waste Manag. 2012, 32, 2029–2036. [Google Scholar] [CrossRef]

- Hossain, H.M.Z.; Hasna, Q.; Uddin, M.; Ahmed, T. Municipal solid waste (MSW) as a source of renewable energy in Bangladesh: Revisited. Renew. Sustain. Energy Rev. 2014, 39, 35–41. [Google Scholar] [CrossRef]

- Halder, P.K.; Paul, N.; Hoque, M.E.; Hoque, A.S.M.; Parvez, M.S.; Rahman, M.H.; Ali, M. Municipal Solid Waste and its Management in Rajshahi City, Bangladesh: A Source of Energy. Int. J. Renew. Energy Res. 2014, 4, 1. [Google Scholar]

- Islam, D.; Saifullah, A.Z.A. Solid Waste and Sugarcane Bagasse-A Renewable Source of Energy in Rajshahi City, Bangladesh. In Proceedings of the 4th International Conference on Mechanical Engineering, Dhaka, Bangladesh, 26–28 December 2001; pp. 33–38. [Google Scholar]

- Das, B.K. Energy Recovery Potential from Municipal Solid Waste in Rajshahi City by Landfill Technique. Int. J. Renew. Energy Res. 2014, 4, 2. [Google Scholar]

- Miezah, K.; Obiri-danso, K.; Kádár, Z.; Fei-baffoe, B.; Mensah, M.Y. Municipal solid waste characterization and quantification as a measure towards effective waste management in Ghana. Waste Manag. 2015, 46, 15–27. [Google Scholar] [CrossRef]

- Tai, J.; Zhang, W.; Che, Y.; Feng, D. Municipal solid waste source-separated collection in China: A comparative analysis. Waste Manag. 2011, 31, 1673–1682. [Google Scholar] [CrossRef]

- Rahman, M.N. Case Study on the Recent Solid Waste Management Scenario in Rajshahi City, Bangladesh. Am. J. Environ. Prot. 2013, 2, 58. [Google Scholar] [CrossRef][Green Version]

- Imran, M.A.; Islam, M.T. Case Study on the Solid Waste Management of Rajshahi, an Idea to It’s Recycling & Probable Measures for Its Management. In Proceedings of the Waste Safe 2015—4th International Conference on Solid Waste Management in the Developing Countries, Khulna, Bangladesh, 15–17 February 2015. [Google Scholar]

- Saifullah, A.Z.A. Electrical Energy Potential from Municipal Solid Waste in Rajshahi City Corporation, Bangladesh. Am. J. Eng. Res. 2015, 4, 69–85. [Google Scholar]

- Das, P.; Islam, M.S.; Huda, N. Feasibility analysis of municipal solid waste (MSW) for energy production in Rajshahi City Corporation. AIP Conf. Proc. 2019, 2121, 120004. [Google Scholar]

- World Bank Annual Report 2018; World Bank Group: Washington, DC, USA, 2018; Available online: http://documents.worldbank.org/curated/en/630671538158537244/The-World-Bank-Annual-Report-2018 (accessed on 17 April 2021).

- Bangladesh Population (2021)—Worldometer. Available online: https://www.worldometers.info/world-population/bangladesh-population/ (accessed on 25 March 2021).

- Sebastian, R.M.; Alappat, B. Thermal Properties of Indian Municipal Solid Waste over the Past, Present and Future Years and Its Effect on Thermal Waste to Energy Facilities. Civ. Eng. Urban Plan. Int. J. 2016, 3, 2. [Google Scholar] [CrossRef]

- Rajshahi City Corporation—Banglapedia. Available online: http://en.banglapedia.org/index.php?title=Rajshahi_City_Corporation (accessed on 24 March 2021).

- Islam, M.; Uddin, M.N.; Rahman, M.M. A GIS-based approach to explore the factors contributing towards Urban residential land development and re-development (LDR): A case of Rajshahi City Corporation area. Geol. Ecol. Landsc. 2020, 1–12. [Google Scholar] [CrossRef]

- Alamgir, M.; Bidlingmaier, W.; Glawe, U.; Martens, J.; Sharif, L.A.; Visvanathan, C.; Stepniewski, W. Safe and Sustainable Management of Municipal Solid Waste in Khulna City of Bangladesh. In Proceedings of the Sardinia 2007, Eleventh International Waste Management and Landfill Symposium, S. Margherita di Pula, Cagliary, Italy, 1–5 October 2007; Volume 1, p. 5. [Google Scholar]

- Islam, F.A.S. Solid Waste Management System in Dhaka City of Bangladesh. J. Mod. Sci. Technol. 2016, 4, 192–209. [Google Scholar]

- Khurmi, R.S.; Gupta, J.K. A Textbook of Thermal Engineering; S. Chand & Company Pvt. Ltd.: Ram Nagar, New Delhi, India, 2016. [Google Scholar]

- Themelis, N.J.; Kim, Y.H. Material and energy balances in a large-scale aerobic bioconversion cell. Waste Manag. Res. 2002, 20, 234–242. [Google Scholar] [CrossRef]

- Kirunda, M.P. A Case of Kira Town Council, Uganda: Public Participation in Solid Waste Management: Challenges and Prospects. Master’s Thesis, The University of Agder, Kristiansand, Norway, 2009. [Google Scholar]

- Zhu, J.; Chow, M.Y. A review of emerging techniques on generation expansion planning. IEEE Trans. Power Syst. 1997, 12, 1722–1728. [Google Scholar]

- Abd Kadir, S.A.S.; Yin, C.; Sulaiman, M.R.; Chen, X.; El-Harbawi, M. Incineration of municipal solid waste in Malaysia: Salient issues, policies and waste-to-energy initiatives. Renew. Sustain. Energy Rev. 2013, 24, 181–186. [Google Scholar] [CrossRef]

- Sabbas, T.; Polettini, A.; Pomi, R.; Astrup, T.; Hjelmar, O.; Mostbauer, P.; Cappai, G.; Magel, G.; Salhofer, S.; Speiser, C.; et al. Management of municipal solid waste incineration residues. Waste Manag. 2003, 23, 61–88. [Google Scholar] [CrossRef]

- Gajalakshmi, S.; Abbasi, S.A. Solid waste management by composting: State of the art. Crit. Rev. Environ. Sci. Technol. 2008, 38, 311–400. [Google Scholar] [CrossRef]

- Rao, M.S.; Singh, S.P. Bioenergy conversion studies of organic fraction of MSW: Kinetic studies and gas yield-organic loading relationships for process optimization. Bioresour. Technol. 2004, 95, 173–185. [Google Scholar] [CrossRef] [PubMed]

- Kapoor, R.; Ghosh, P.; Kumar, M.; Vijay, V.K. Evaluation of biogas upgrading technologies and future perspectives: A review. Environ. Sci. Pollut. Res. 2019, 26, 11631–11661. [Google Scholar] [CrossRef]

- Constantinescu, M.; Bucura, F.; Ionete, R.; Ion-ebrasu, D.; Sandru, C.; Zaharioiu, A.; Marin, F.; Miricioiu, M.G.; Niculescu, V.; Oancea, S.; et al. From Plastic to Fuel—New Challenges. Mater. Plast. 2019, 56, 721–729. [Google Scholar] [CrossRef]

- Constantinescu, M.; Bucura, F.; Ionete, R.; Niculescu, V. Comparative Study on Plastic Materials as a New Source of Energy. Mater. Plast. 2019, 56, 41–46. [Google Scholar] [CrossRef]

- Belgiorno, V.; De Feo, G.; Rocca, C.D.; Napoli, R.M.A. Energy from gasification of solid wastes. Waste Manag. 2003, 23, 1–15. [Google Scholar] [CrossRef]

- Wolosiewicz-Glab, M.; Pieta, P.; Sas, S.; Grabowski, L. Plastic waste depolymerization as a source of energetic heating oils. E3S Web Conf. 2017, 14, 02044. [Google Scholar] [CrossRef]

- Brás, I.; Silva, M.; Lobo, G.; Cordeiro, A.; Faria, M.; De Lemos, L.T. Refuse Derived Fuel from Municipal Solid Waste rejected fractions- a Case Study. Energy Procedia 2017, 120, 349–356. [Google Scholar] [CrossRef]

- Yuan, K.; Xiao, H.; Li, X. Development and application of municipal solid waste incineration in China. Nengyuan Gongcheng 2008, 5, 43–46. [Google Scholar]

- Purnomo, C.W.; Kurniawan, W.; Aziz, M. Technological review on thermochemical conversion of COVID-19-related medical wastes. Resour. Conserv. Recycl. 2021, 167, 105429. [Google Scholar] [CrossRef]

- Melville, L.; Weger, A.; Wiesgickl, S.; Franke, M. Anaerobic Digestion; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2014. [Google Scholar]

- Hadidi, L.A.; Omer, M.M. A financial feasibility model of gasification and anaerobic digestion waste-to-energy (WTE) plants in Saudi Arabia. Waste Manag. 2017, 59, 90–101. [Google Scholar] [CrossRef] [PubMed]

- International Renewable Energy Agency (IRENA). Biomass for Power Generation. 2012. Available online: https://www.irena.org/DocumentDownloads/Publications/RE_Technologies_Cost_Analysis-BIOMASS.pdf (accessed on 7 April 2021).

- Banks, C.; Zhang, Y. Technical Report: Optimising Inputs and Outputs from Anaerobic Digestion Processes. 2010. Available online: http://randd.defra.gov.uk/Document.aspx?Document=WR0212_8889_TRP.pdf (accessed on 7 April 2021).

- International Renewable Energy Agency. Renewable Power Generation Costs in 2014. 2015. Available online: http://www.irena.org/menu/index.aspx?mnu=Subcat&PriMenuID=36&CatID=141&SubcatID=494 (accessed on 7 April 2021).

| Sources (%) | Rajshahi | Khulna | Sylhet | Barishal | Chattogram | Dhaka |

|---|---|---|---|---|---|---|

| Institutional | 1.22 | 1.02 | 1.29 | 1.46 | 1.14 | 1.17 |

| Municipal services | 1.24 | 0.55 | 0.80 | 1.15 | 0.51 | 0.53 |

| Residential | 77.18 | 85.87 | 78.04 | 79.55 | 83.83 | 75.86 |

| Commercial | 18.59 | 11.60 | 18.48 | 15.52 | 13.92 | 22.07 |

| Others | 1.77 | 0.96 | 1.40 | 2.32 | 0.60 | 0.37 |

| MSW Composition (wt%) | Rajshahi | Khulna | Sylhet | Barishal | Chattogram | Dhaka | Average |

|---|---|---|---|---|---|---|---|

| Paper and paper products | 8.90 | 9.50 | 8.40 | 7.20 | 9.90 | 10.70 | 9.10 |

| Textiles and wood | 1.90 | 1.30 | 2.10 | 1.90 | 2.10 | 2.20 | 1.90 |

| Food and vegetables | 71.10 | 78.90 | 73.80 | 81.10 | 73.60 | 68.30 | 74.50 |

| Rubber and leather | 1.10 | 0.50 | 0.60 | 0.10 | 1.00 | 1.40 | 0.80 |

| Dust, ash and mud products | 6.50 | 3.70 | 5.30 | 3.10 | 5.10 | 6.70 | 5.10 |

| Glass and ceramics | 1.10 | 0.50 | 0.70 | 0.50 | 1.00 | 0.70 | 0.80 |

| Polyethylene | 4.00 | 3.10 | 3.40 | 3.50 | 2.80 | 4.30 | 3.50 |

| Metal | 1.10 | 1.10 | 1.10 | 1.20 | 2.20 | 2.00 | 1.40 |

| Brick, concrete and stone | 2.90 | 0.10 | 1.80 | 0.10 | 1.10 | 1.80 | 1.30 |

| Others | 1.90 | 1.20 | 1.20 | 1.30 | 1.30 | 2.80 | 1.60 |

| Total | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Year | Total Population | Urban Population (% Total) | MSW Generation Rate (kg/capita/d) | Total MSW Generation (t/d) |

|---|---|---|---|---|

| 1991 | 20,872,204 | 20.15 | 0.49 | 9873.50 |

| 2001 | 28,808,477 | 23.39 | 0.50 | 11,695.00 |

| 2004 | 32,765,152 | 25.08 | 0.50 | 16,382.00 |

| 2025 | 78,440,000 | 40.00 | 0.60 | 47,064.00 |

| Means of Transportation | Number of Vehicles/Manpower |

|---|---|

| Truck | 14 |

| Wheel bars | 150 |

| Manpower | 1073 |

| Van | 210 |

| Residence Type | No. of People | Amount of Waste (kg) | Educational Status of Interviewees | Amount Being Paid for Waste Collection (BDT) | Condition of Residence |

|---|---|---|---|---|---|

| Family (O) | 7 | 3.55 | PE | 0 | SP |

| Family (R) | 5 | 2.74 | HE | 30 | SP |

| Family (O) | 4 | 2.32 | JE | 30 | SP |

| Family (R) | 4 | 2.20 | JE | 30 | SP |

| Family (R) | 5 | 1.98 | PE | 0 | P |

| Family (O) | 4 | 1.45 | BD | 31–60 | P |

| Family (O) | 3 | 2.55 | BD | 21–30 | P |

| Family (O) | 6 | 2.82 | HE | 31–60 | P |

| Family (O) | 5 | 3.44 | MD | 0 | P |

| Family (R) | 4 | 2.25 | BD | 30 | P |

| Family (O) | 6 | 3.05 | BD | 30 | P |

| Family (R) | 3 | 1.95 | HE | 30 | P |

| Family (R) | 5 | 2.95 | HE | 30 | P |

| Family (O) | 6 | 5.10 | HE | 40 | P |

| Family (R) | 4 | 1.33 | HE | 21–30 | SP |

| Family (R) | 4 | 1.15 | HE | 0 | SP |

| Family (O) | 5 | 2.08 | SE | 31–60 | P |

| Family (R) | 4 | 2.64 | HE | 0 | P |

| Family (O) | 8 | 3.34 | JE | 30 | P |

| Family (O) | 3 | 1.85 | MD | 30–40 | P |

| Family (O) | 6 | 3.75 | SE | 0 | P |

| Family (O) | 3 | 1.65 | BD | 30 | P |

| Family (O) | 4 | 2.74 | JE | 30 | SP |

| Family (O) | 3 | 3.12 | MD | 40 | SP |

| Family (R) | 4 | 2.58 | PE | 0 | P |

| Family (O) | 8 | 2.95 | N/A | 0 | SP |

| Family (O) | 4 | 1.80 | MD | 0 | P |

| Family (O) | 7 | 3.14 | BD | 30 | P |

| Family (R) | 3 | 2.36 | HE | 30–40 | P |

| Family (O) | 7 | 2.56 | HE | 30 | P |

| Family (R) | 3 | 1.63 | MD | 30 | SP |

| Family (R) | 3 | 1.32 | MD | 0 | P |

| Family (R) | 4 | 2.46 | SE | 0 | P |

| Family (O) | 3 | 2.15 | HE | 0 | P |

| Family (O) | 5 | 1.72 | PE | 30 | SP |

| Family (R) | 3 | 2.07 | MD | 30–40 | P |

| Large Family (O) | 26 | 11.52 | SE | 40 | SP |

| Large Family (O) | 28 | 14.96 | MD | 40 | P |

| Large Family (O) | 52 | 16.65 | MD | 40 | P |

| Large Family (O) | 94 | 36.00 | BD | 40 | P |

| Large Family (O) | 49 | 21.54 | HE | 40 | P |

| Large Family (O) | 24 | 11.96 | HE | 40 | P |

| Large Family (O) | 32 | 17.12 | BD | 30 | P |

| Large Family (O) | 45 | 19.06 | SE | 35 | P |

| Large Family (O) | 20 | 9.73 | HE | 30 | P |

| Large Family (O) | 32 | 11.86 | BD | 30 | P |

| Large Family (O) | 15 | 5.97 | MD | 30 | SP |

| Large Family (O) | 81 | 26.96 | BD | 40 | P |

| Large Family (O) | 92 | 25.53 | HE | 40 | P |

| Large Family (O) | 17 | 7.72 | MD | 30 | SP |

| Total | 772 | 325.32 |

| MSW Composition | Family 1 | Family 2 | Family 3 | Family 4 (%) | Family 5 | Family 6 | Family 7 | Average MSW Composition (%) |

|---|---|---|---|---|---|---|---|---|

| Vegetables and food | 70.12 | 65.35 | 69.45 | 80.70 | 69.12 | 71.12 | 80.21 | 72.29 |

| Paper and paper products | 7.29 | 7.32 | 5.73 | 2.02 | 7.29 | 7.29 | 3.65 | 5.79 |

| Polyethylene | 4.10 | 7.99 | 4.31 | 4.10 | 4.10 | 4.60 | 3.98 | 4.74 |

| Textiles and wood | 4.68 | 3.30 | 4.95 | 5.08 | 4.69 | 4.52 | 2.56 | 4.25 |

| Leather and rubber | 1.08 | 0.38 | 0.60 | 1.38 | 1.08 | 0.87 | 0.39 | 0.82 |

| Metals | 1.23 | 0.90 | 3.14 | 0.17 | 2.14 | 1.13 | 0 | 1.24 |

| Glass and ceramics | 0.12 | 0.50 | 0.58 | 0.61 | 0.22 | 0.12 | 1.27 | 0.48 |

| Brick, concrete and stones | 3.48 | 4.18 | 4.35 | 0.27 | 3.46 | 3.07 | 2.76 | 3.08 |

| Dust, ash and mud products | 6.43 | 7.00 | 6.12 | 3.43 | 6.44 | 5.43 | 3.22 | 5.43 |

| Others | 1.80 | 2.75 | 1.80 | 1.60 | 1.70 | 1.70 | 1.87 | 1.88 |

| Total | 100 |

| MSW Composition | Weight before Drying (kg) | Weight after Drying (kg) | Weight Percentage (dry) | Moisture Content (%) |

|---|---|---|---|---|

| Food and vegetables | 45.47 | 16.65 | 26.33 | 63.38 |

| Paper and paper products | 3.66 | 3.31 | 5.24 | 9.56 |

| Polyethylene | 3.00 | 2.79 | 4.42 | 7.00 |

| Textiles and wood | 2.69 | 2.62 | 4.15 | 2.60 |

| Rubber and leather | 0.52 | 0.47 | 0.74 | 9.62 |

| Metal and tins | 0.78 | 0.77 | 1.21 | 1.28 |

| Glass and ceramics | 0.30 | 0.29 | 0.47 | 3.33 |

| Brick, concrete and stone | 1.95 | 1.90 | 3.00 | 2.56 |

| Dust, ash and mud products | 3.43 | 2.74 | 4.33 | 20.12 |

| Others | 1.19 | 1.16 | 1.83 | 2.52 |

| Total | 63.23 | 32.70 | 48.28 |

| Heat Energy (MJ/kg) | Steam Energy (MJ/kg) | Electrical Power, EP (kWh/kg) | Station Service Allowance, SA (kWh/kg) | Net electrical Power ENP (kWh/kg) |

|---|---|---|---|---|

| 14.90 | 10.43 | 0.9153 | 0.0549 | 0.8604 |

| Treatment Technique | Category of Solid Waste | Percentage of Total Waste |

|---|---|---|

| Composting/anaerobic digestion/incineration | Vegetable and food wastes | 72.29% |

| Landfilling | Dust, ash, mud, brick, concrete, stone, glass, ceramic, etc. | 10.87% |

| Pyrolysis/gasification | Paper, paper product, polyethylene, wood, rubber, etc. | 10.53–15.6% |

| Recycling | Metals | 1.24% |

| Total MSW Generation | 358.19 tons/day |

|---|---|

| Food and Vegetables | 259 tons/day (72.29%) |

| Total Biogas Generation * | 38,850 m3 |

| Compost Fertilizer ** | 65 tons/day |

| Input Parameters | Values |

|---|---|

| Beginning design year | 2021 |

| Construction duration | 3 years |

| Year of the beginning of operation | 2024 |

| Lifetime | 25 years |

| Year of the end of operation | 2049 |

| Electricity generation from 1 ton of organic waste [42,44] | 0.992 MWh |

| Operating days in a year | 365 |

| Operating hours in a year | 7446 |

| Waste capacity per year | (259 ∗ 365) or 94,535 tons |

| Plant capacity factor [42,43] | 85% |

| Facility annual throughput per year | (94,535 ∗ 85%) or 80,355 tons |

| Electricity generation efficiency [42,45] | 36% |

| Electricity production per year | (80,355 ∗ 0.992 ∗ 36%) or 28,696 MWh |

| Plant capacity | (28,696/7446) or 3.85 MW |

| Capital expenditure per MW [42,45] | USD 4,339,000 or BDT 369 million |

| Capital expenditure (CAPEX) | (369 ∗ 3.85) or BDT 1421 million |

| Fixed operating cost (% of CAPEX/year) [42,45] | 3 |

| Fixed operating cost | (1421 ∗ 3%) or BDT 42.6 million |

| Variable operating cost (USD 4.4*MWh) [42,43] | (4.4 ∗ 28,696) or USD 126,262.2 or BDT 10.7 million |

| Revenue from compost per day | BDT 0.39 million |

| Revenue from compost per year | BDT 142 million |

| Cost of electricity (assumed) | BDT 7 per kWh (generally varies in between BDT 6 and 8) |

| Annual revenue from electricity | (7 ∗ 28,696 ∗ 1000) or BDT 201 million |

| Annual net cash inflow | (201 + 142 − 42.6 − 10.7) or BDT 290 million |

| Payback period (CAPEX/annual net cash inflow) | (1421/290) or 4.9 years |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habib, M.A.; Ahmed, M.M.; Aziz, M.; Beg, M.R.A.; Hoque, M.E. Municipal Solid Waste Management and Waste-to-Energy Potential from Rajshahi City Corporation in Bangladesh. Appl. Sci. 2021, 11, 3744. https://doi.org/10.3390/app11093744

Habib MA, Ahmed MM, Aziz M, Beg MRA, Hoque ME. Municipal Solid Waste Management and Waste-to-Energy Potential from Rajshahi City Corporation in Bangladesh. Applied Sciences. 2021; 11(9):3744. https://doi.org/10.3390/app11093744

Chicago/Turabian StyleHabib, Md. Ahasan, Mim Mashrur Ahmed, Muhammad Aziz, Mohd. Rafiqul Alam Beg, and Md. Emdadul Hoque. 2021. "Municipal Solid Waste Management and Waste-to-Energy Potential from Rajshahi City Corporation in Bangladesh" Applied Sciences 11, no. 9: 3744. https://doi.org/10.3390/app11093744

APA StyleHabib, M. A., Ahmed, M. M., Aziz, M., Beg, M. R. A., & Hoque, M. E. (2021). Municipal Solid Waste Management and Waste-to-Energy Potential from Rajshahi City Corporation in Bangladesh. Applied Sciences, 11(9), 3744. https://doi.org/10.3390/app11093744