Micromagnetic Characterization of Operation-Induced Damage in Charpy Specimens of RPV Steels

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Mechanical Tests

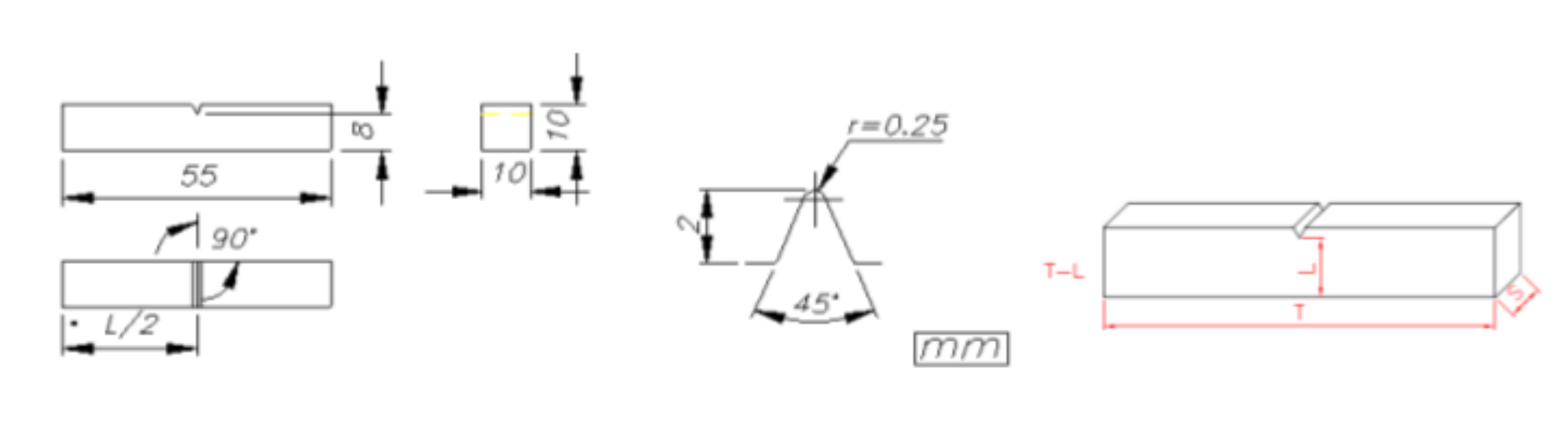

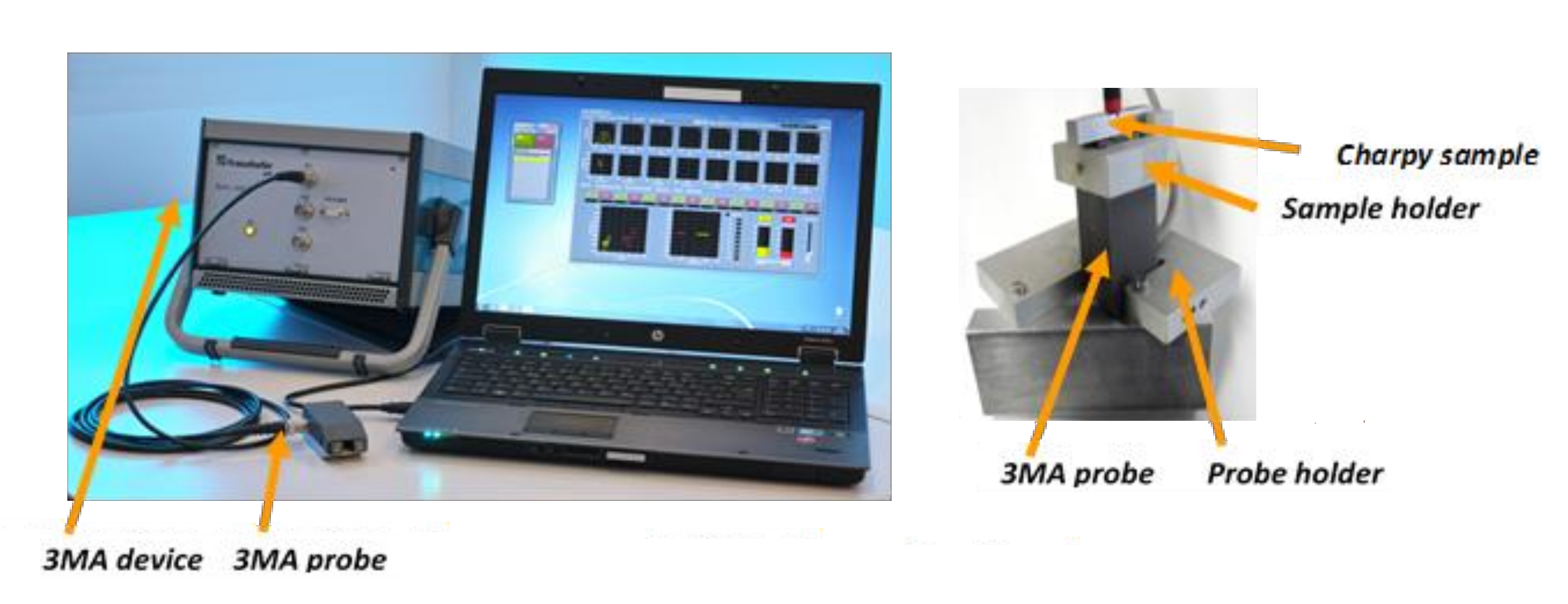

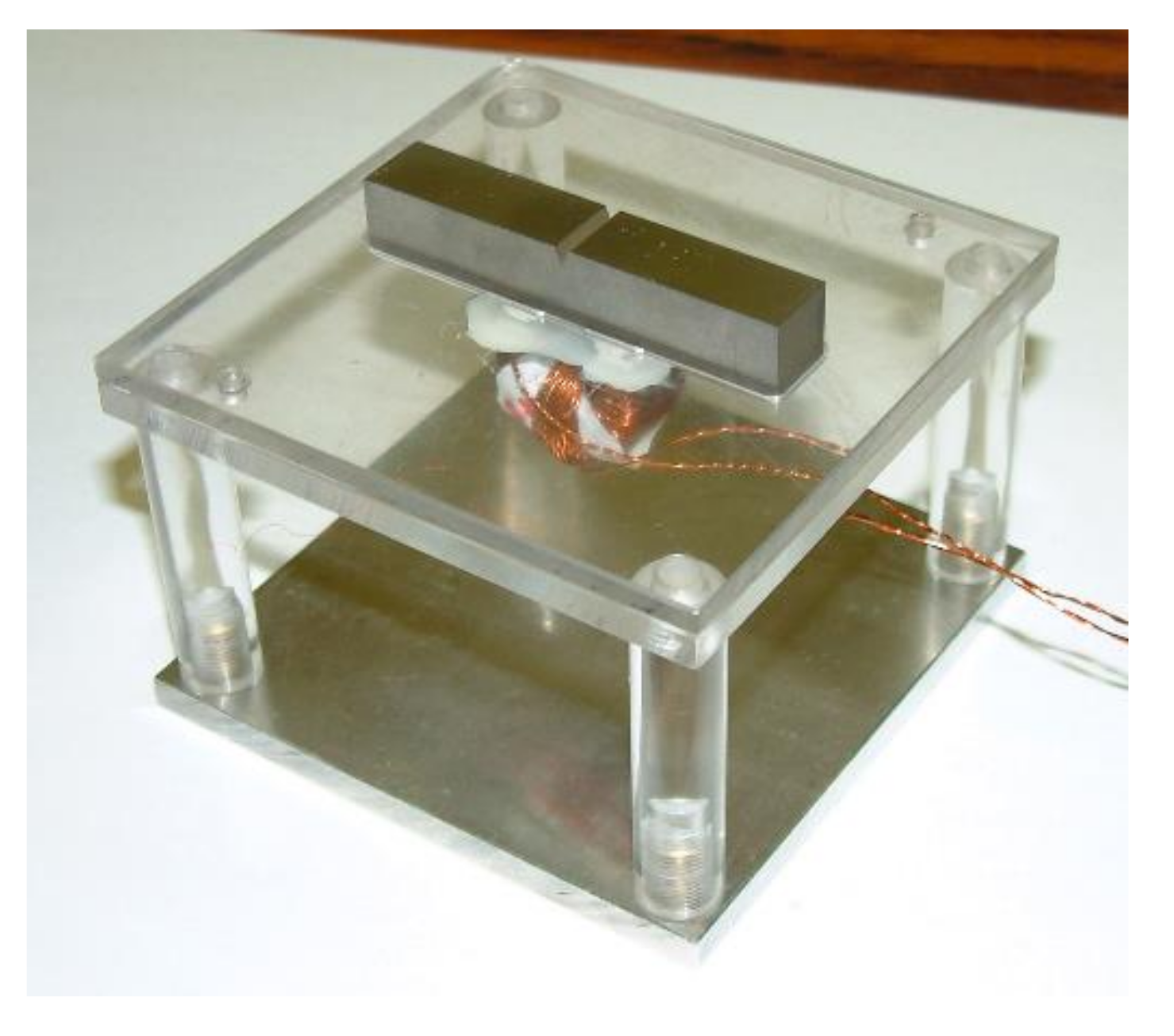

2.2. Micromagnetic Methods

- I.

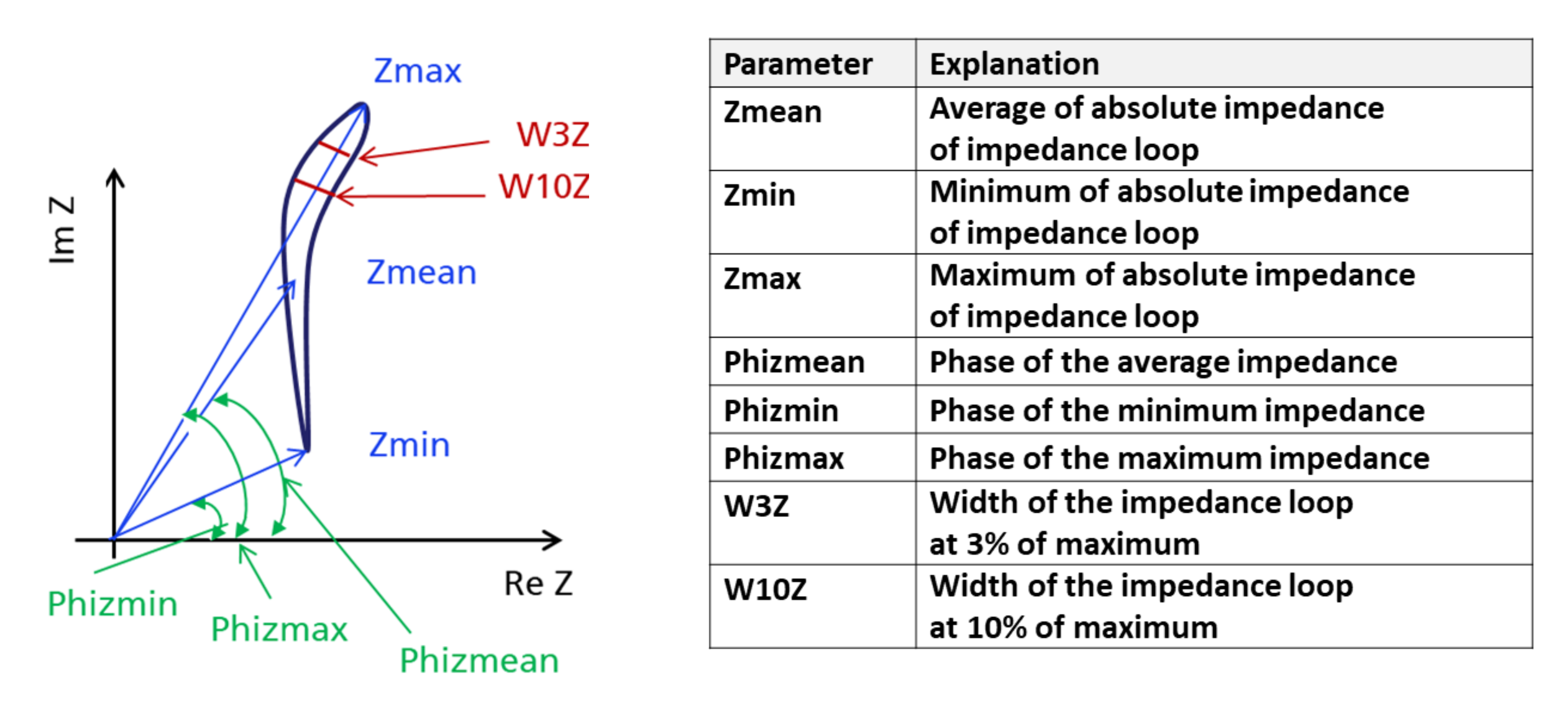

- Eddy currents (ECs) arise in a material if it is exposed to an alternating magnetic field and depend on the electrical conductivity σ and the magnetic permeability µ of the material [16,17]. The higher-frequency EC-affected impedance (Z) is not constant throughout the rather low-frequency hysteresis loop. Therefore, Z describes a loop in the impedance plane throughout one hysteresis cycle [19]. Figure 2 illustrates the parameters derived from this loop.

- II.

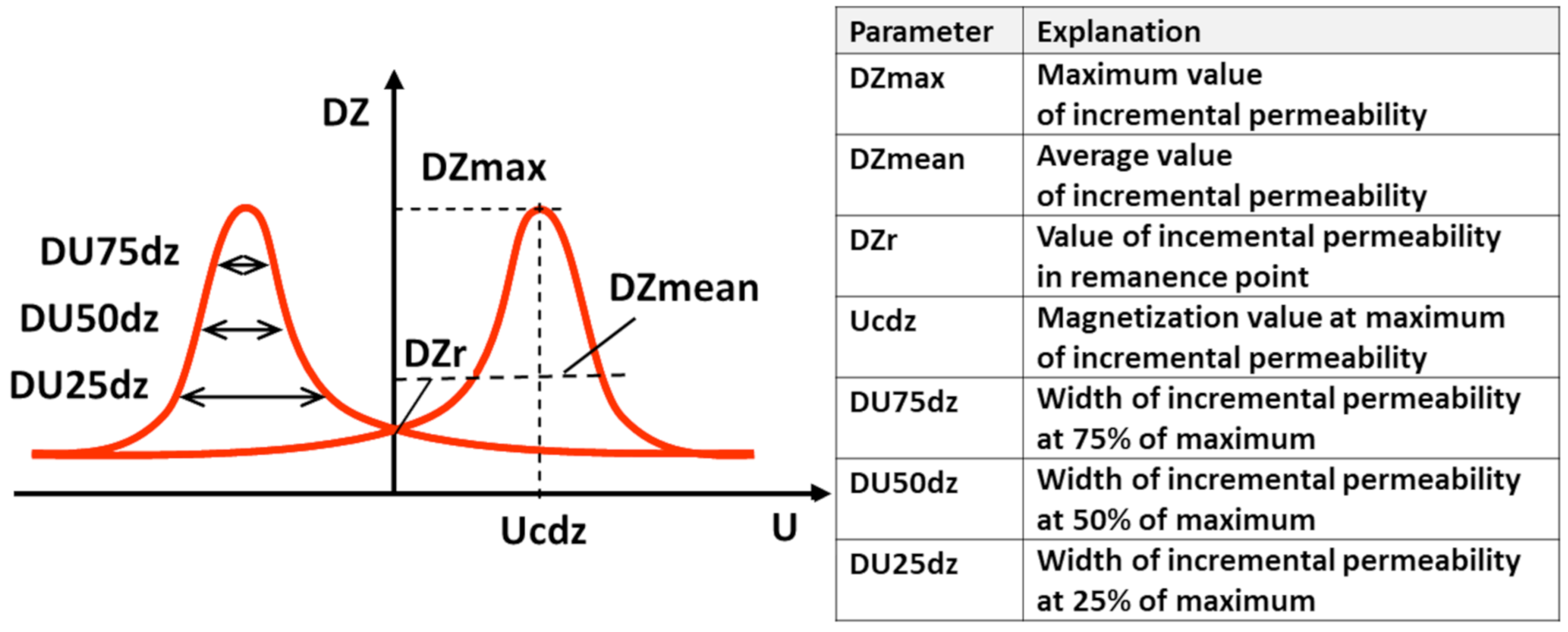

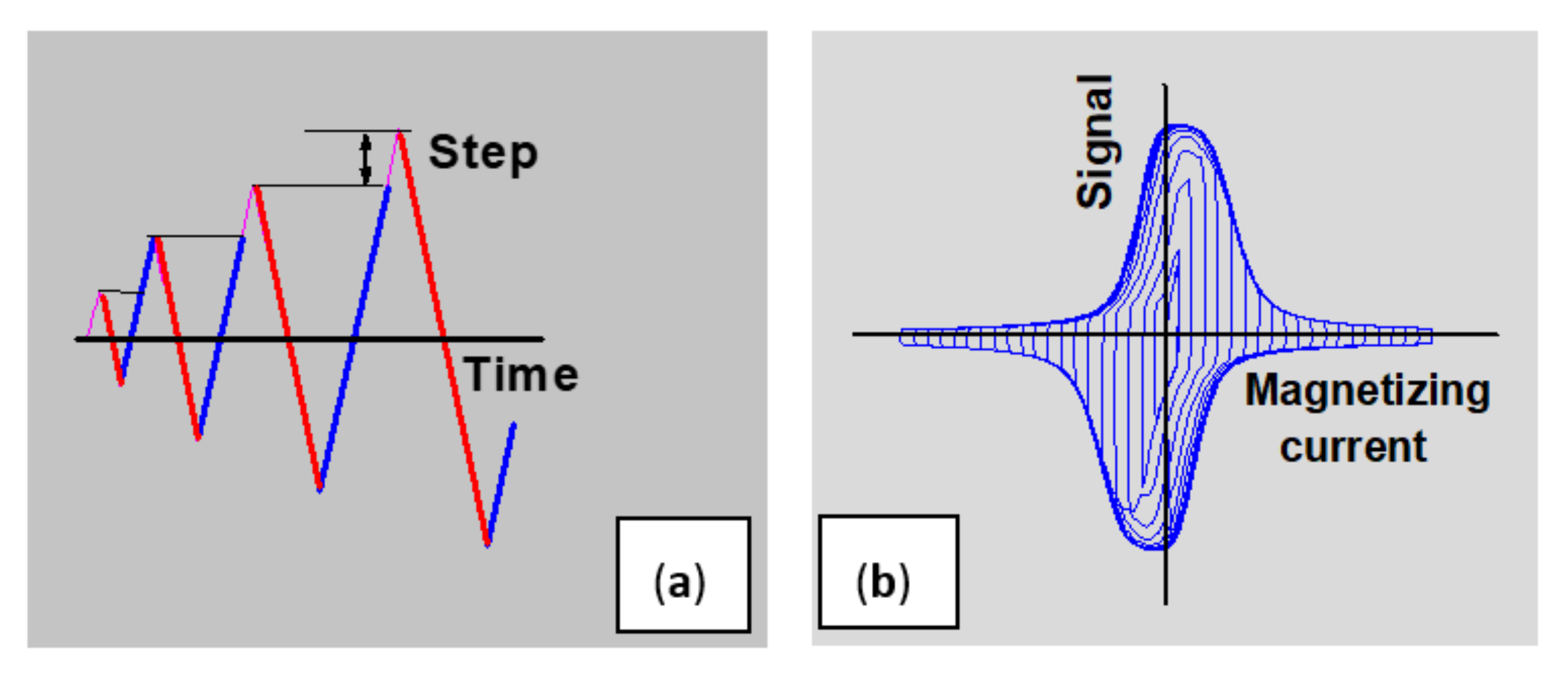

- Incremental permeability (IP) analysis is a method of separating magnetic permeability information from electrical conductivity information in EC analysis [16,17]. Plotting the change in EC coil impedance (DZ) against drive voltage U lecads to an incremental permeability plot (Figure 3, left) [19]. Several parameters are derived from the incremental permeability curve (Figure 3).

- III.

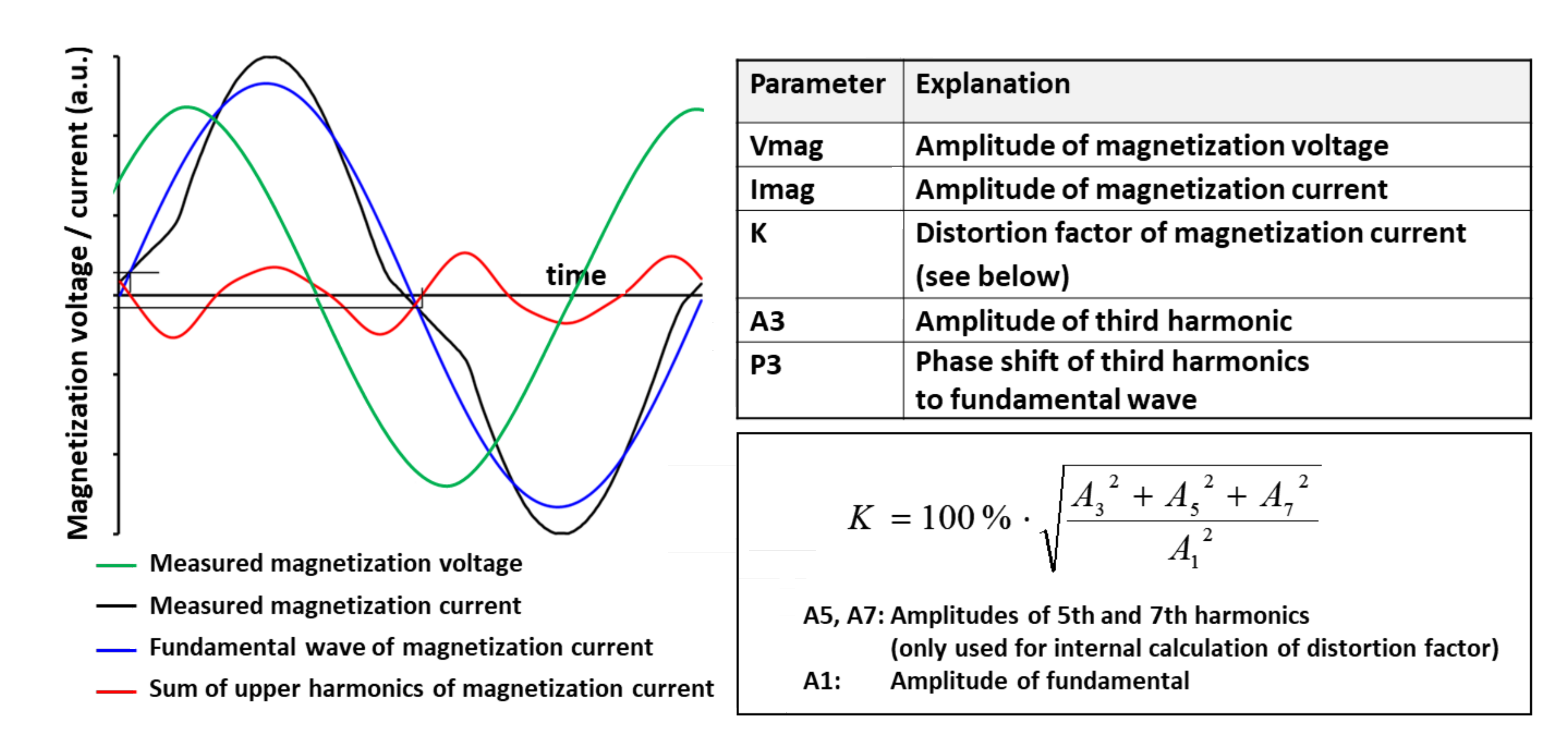

- The measured magnetizing current exhibits a low-frequency distortion due to hysteresis in the magnetic circuit. The fundamental and harmonic components can be determined numerically using a fast Fourier transform; thus, the distortions of the magnetizing current are quantified. The harmonic components determined through this procedure allow for the determination of material properties (Figure 4) [19].

3. Results

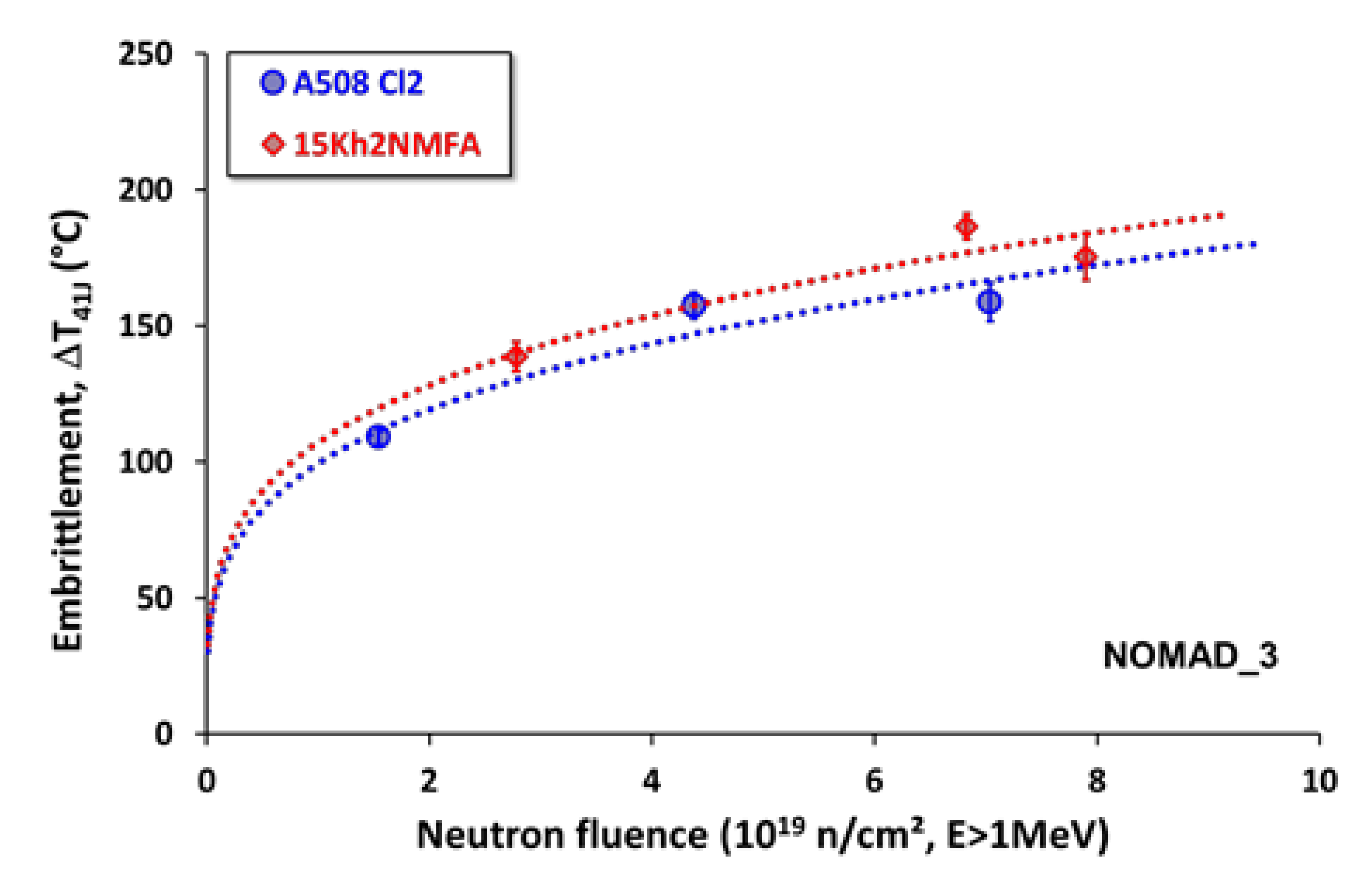

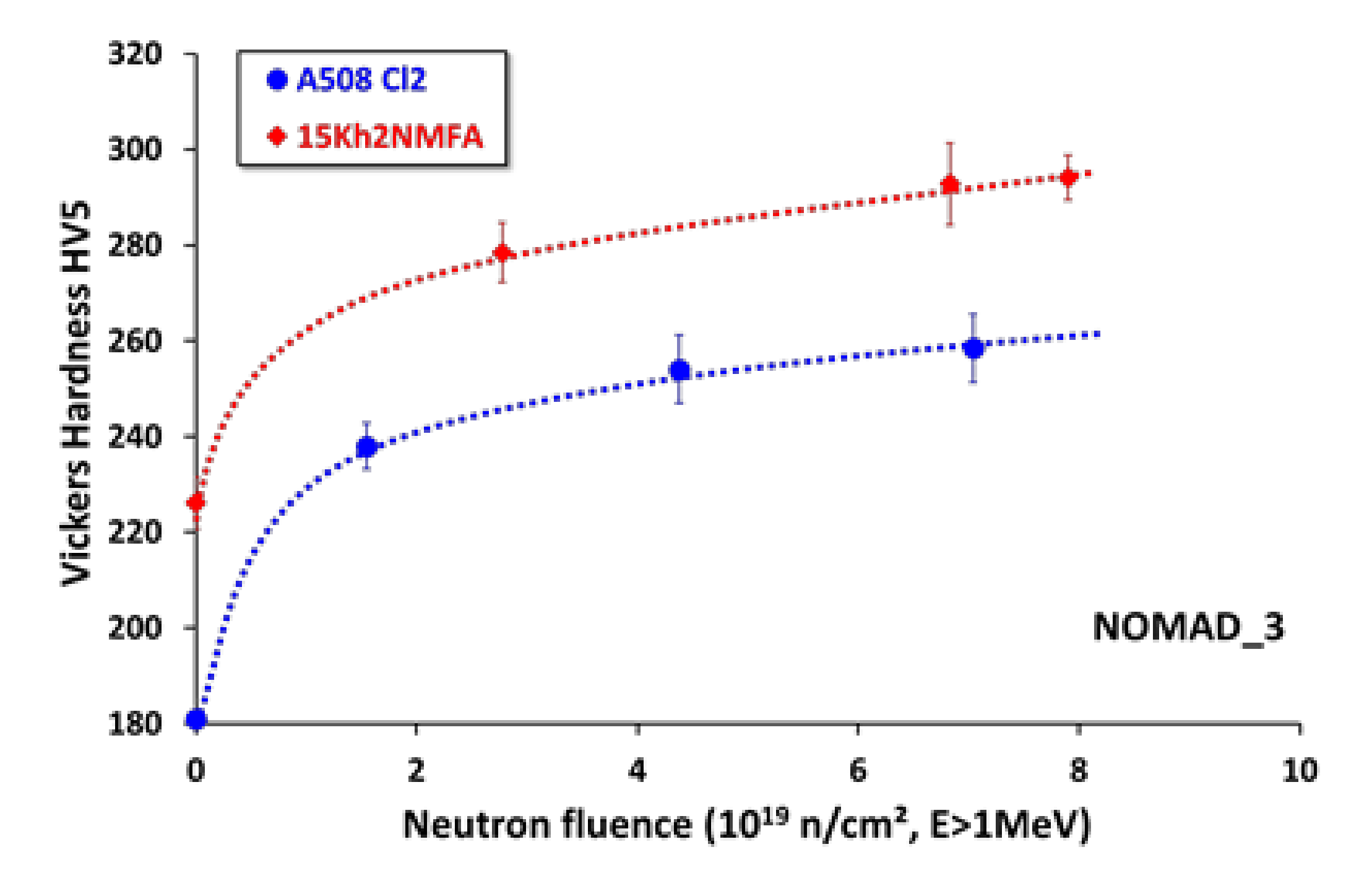

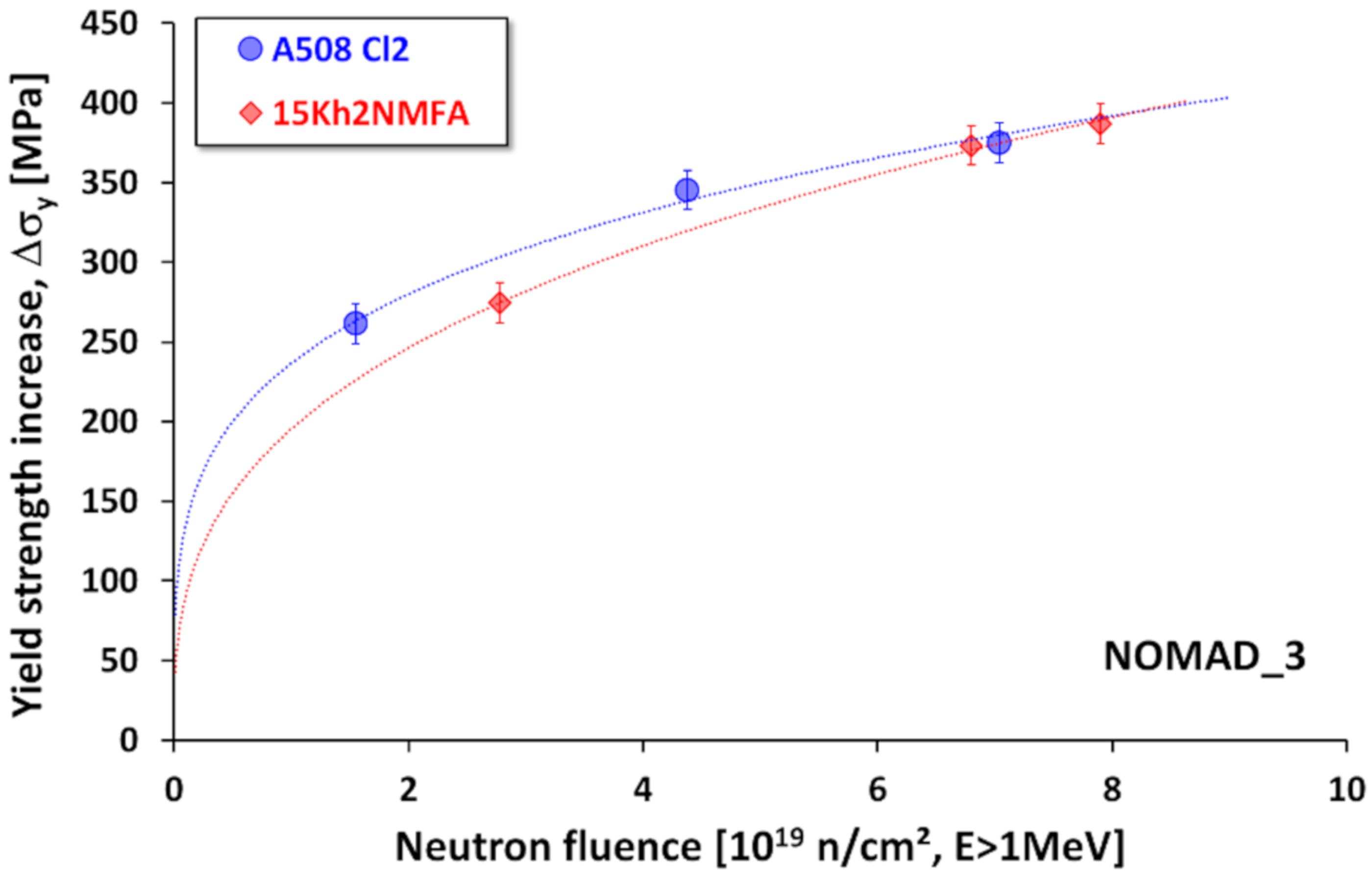

3.1. Mechanical Properties

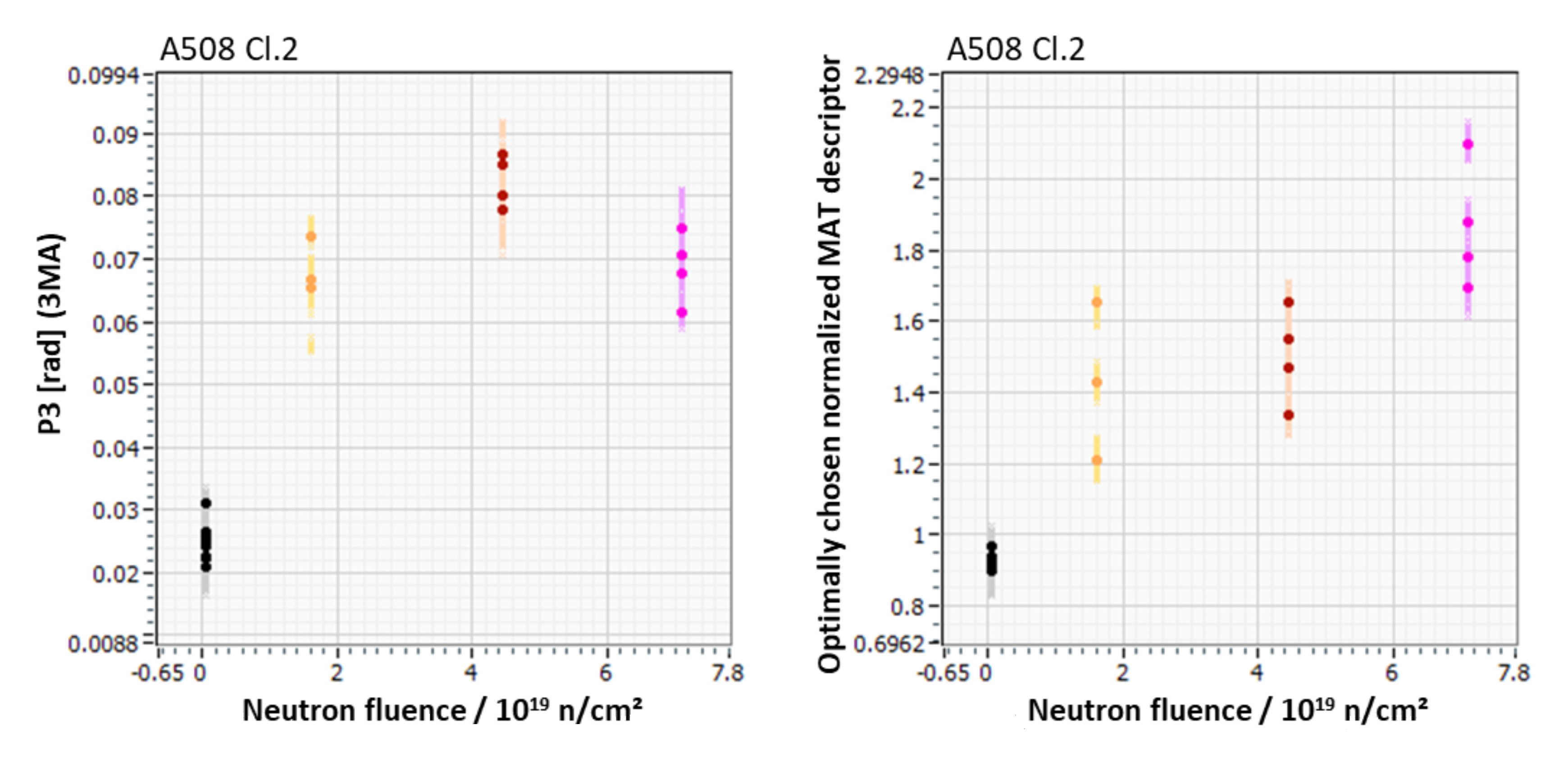

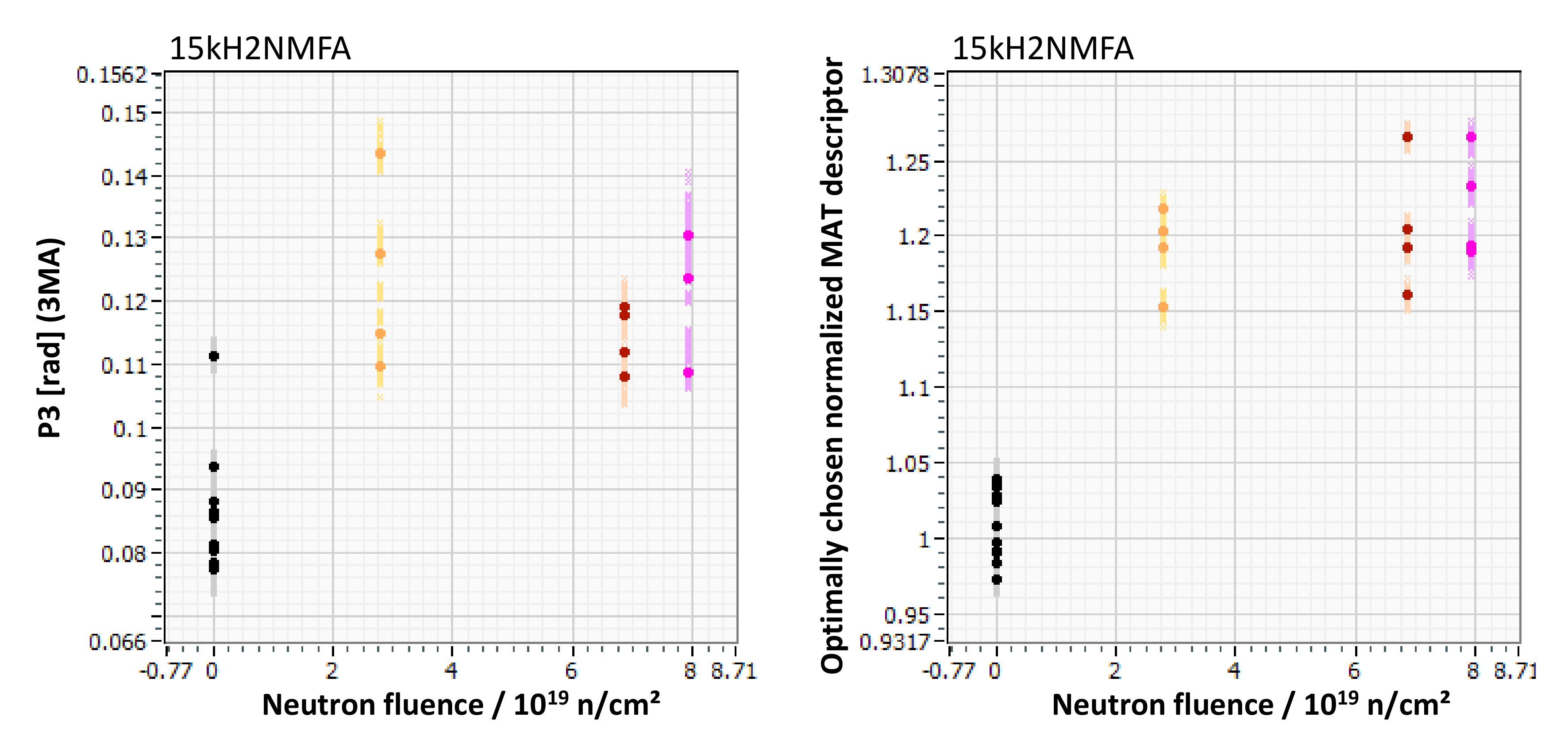

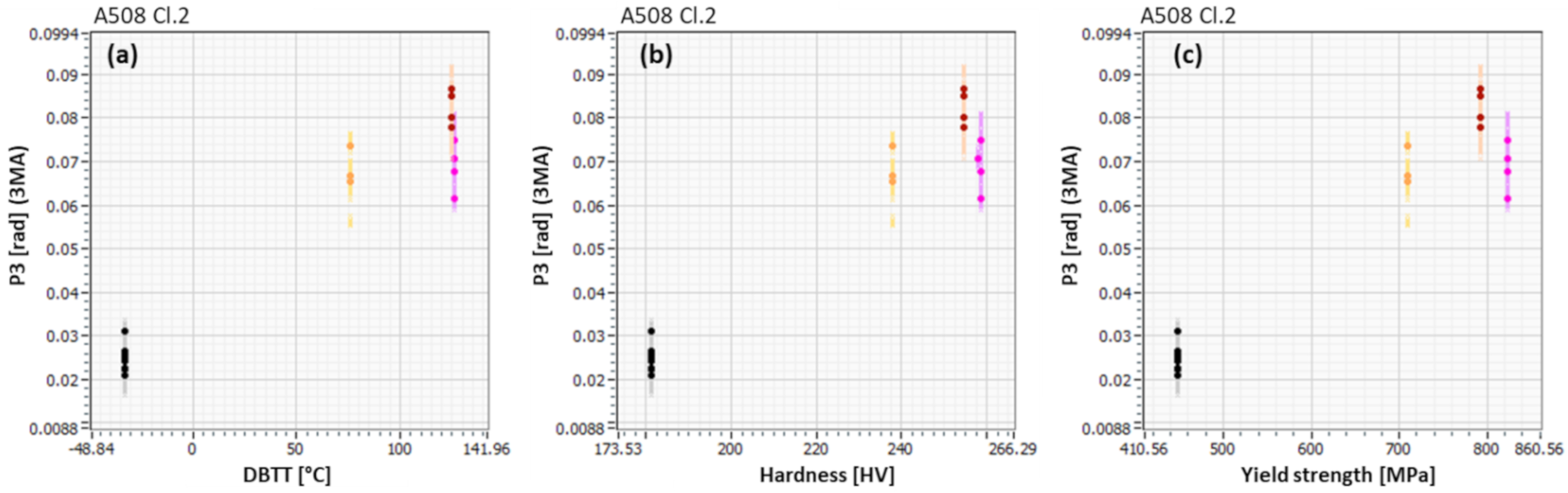

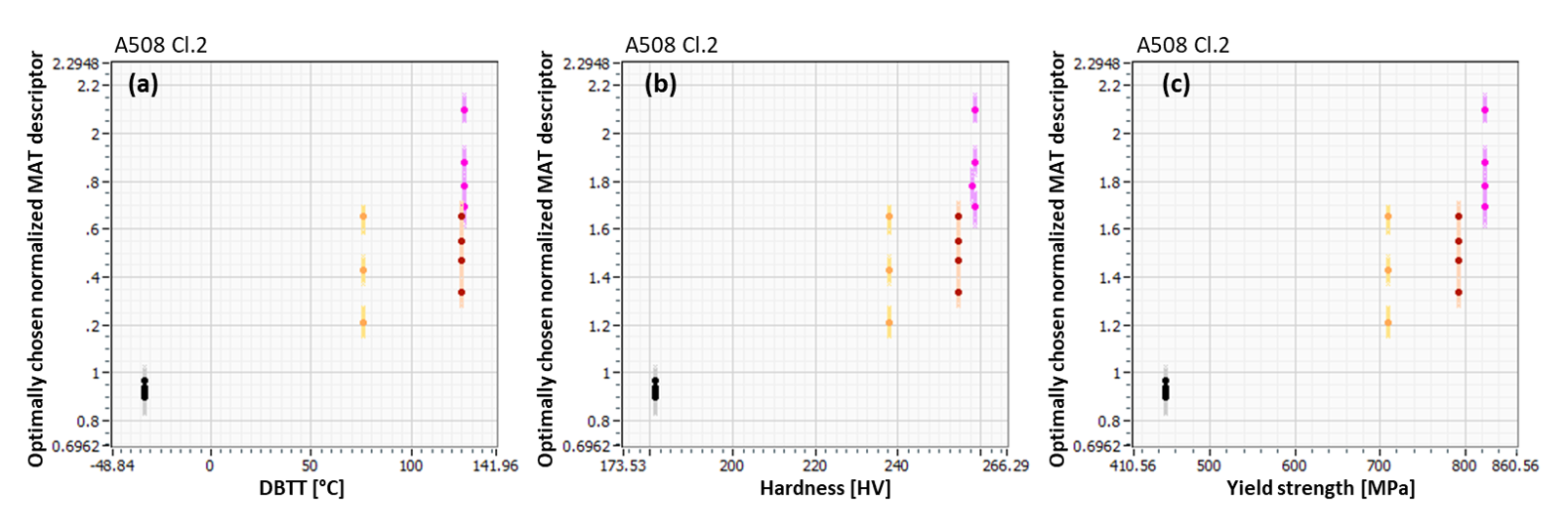

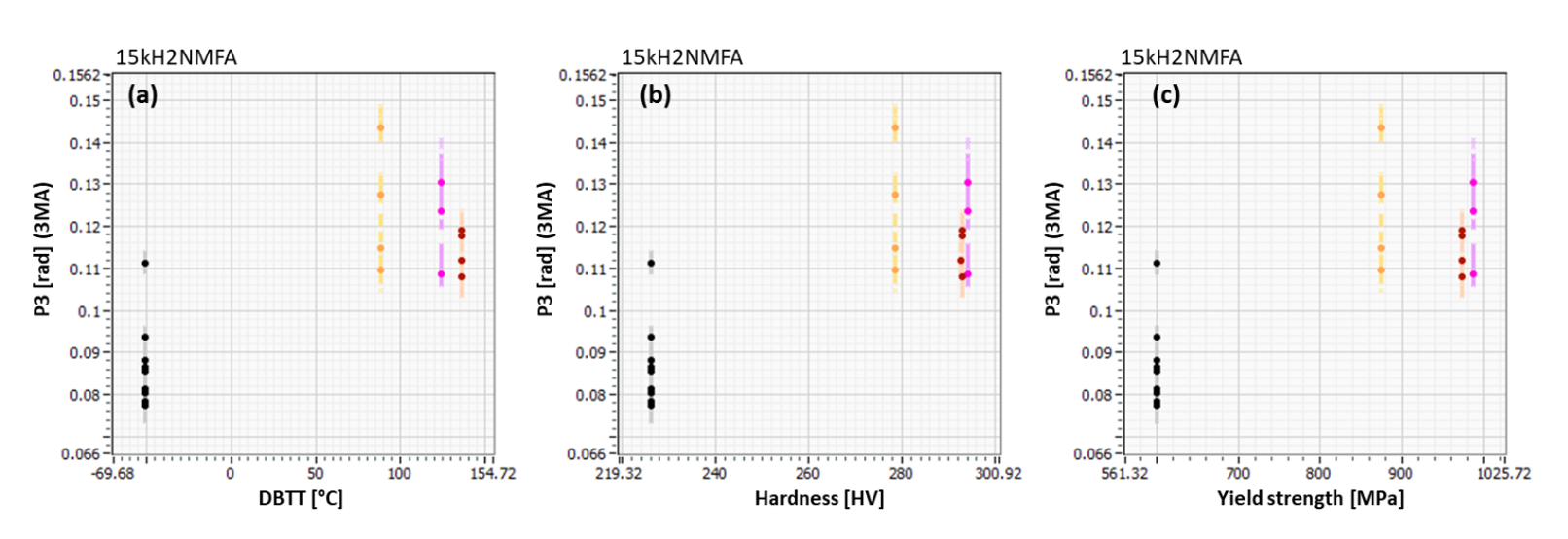

3.2. Micromagnetics Results

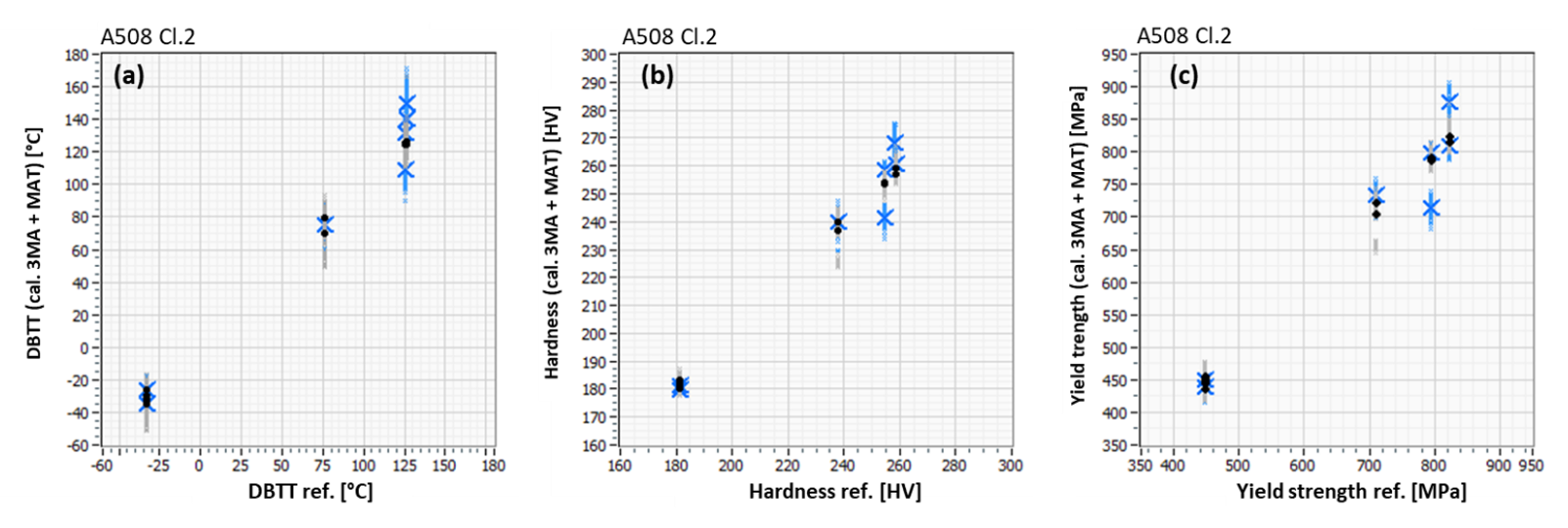

3.3. Nondestructive Prediction of Embrittlement and Hardening

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ferreño, D.; Gorrochategui, I.; Gutiérrez-Solana, F. Degradation due to neutron embrittlement of nuclear vessel steels: A critical review about the current experimental and analytical techniques to characterise the material, with particular emphasis on alternative methodologies. In Nuclear Power—Control, Reliability and Human Factors; Tsvetkov, P., Ed.; IntechOpen Limited: London, UK, 2011; Available online: http://www.intechopen.com/articles/show/title/non-destructive-testing-for-ageing-management-of-nuclear-power-components (accessed on 14 May 2020)ISBN 978-9-53307-599-0.

- Niffenegger, M.; Leber, H.J. Monitoring the embrittlement of reactor pressure vessel steels by using the Seebeck coefficient. J. Nucl. Mater. 2009, 389, 62. [Google Scholar] [CrossRef]

- Niffenegger, M.; Reichlin, K.; Kalkhof, D. Application of the Seebeck effect for monitoring of neutron embrittlement and low-cycle fatigue in nuclear reactor steel. Nucl. Eng. Des. 2005, 235, 1777–1788. [Google Scholar] [CrossRef]

- Seiler, G. Early detection of fatigue at elevated temperature in austenitic steel using electromagnetic ultrasound transducers. In Proceedings of the Seventh International Conference on Low Cycle Fatigue: LCF7, Deutscher Verband für Materialforschung und-Prüfung e.V. (DVM), Aachen, Germany, 9–11 September 2013; pp. S359–S364. [Google Scholar]

- Smith, R.L.; Rusbridge, K.L.; Reynolds, W.N.; Hudson, B. Ultrasonic attenuation, microstructure and ductile to brittle transition temperature in Fe-C alloys. Mater. Eval. 1993, 41, 219–222. [Google Scholar]

- Dobmann, G.; Kröning, M.; Theiner, W.; Willems, H.; Fiedler, U. Nondestructive characterization of materials (ultrasonic and magnetic techniques) for strength and toughness prediction and the detection early creep damage. Nucl. Eng. Des. 1995, 157, 137–158. [Google Scholar] [CrossRef]

- Jiles, D.C. Magnetic methods in nondestructive testing. In Encyclopedia of Materials Science and Technology; Buschow, K.H.J., Ed.; Elsevier Press: Oxford, UK, 2001; p. 6021. [Google Scholar]

- Blitz, J. Electrical and Magnetic Methods of Nondestructive Testing; Adam Hilger IOP Publishing, Ltd.: Bristol, UK, 1991. [Google Scholar]

- Lo, C.C.H.; Jakubovics, J.P.; Scrub, C.B. Non-destructive evaluation of spheroidized steel using magnetoacoustic and Barkhausen emission. IEEE Trans. Magn. 1997, 33, 4035–4037. [Google Scholar] [CrossRef]

- Kikuchi, H.; Ara, K.; Kamada, Y.; Kobayashi, S. Effect of microstructure changes on Barkhausen noise properties and hysteresis loop in cold rolled low carbon steel. IEEE Trans. Magn. 2009, 45, 2744–2747. [Google Scholar] [CrossRef]

- Hartmann, K.; Moses, A.J.; Meydan, T. A system for measurement of AC Barkhausen noise in electrical steels. J. Magn. Magn. Mater. 2003, 254–255, 318–320. [Google Scholar] [CrossRef]

- Pirfo Barroso, S.; Horváth, M.; Horváth, Á. Magnetic measurements for evaluation of radiation damage on nuclear reactor materials. Nucl. Eng. Des. 2010, 240, 722–725. [Google Scholar] [CrossRef]

- Augustyniak, B.; Chmielewski, M.; Piotrowski, L.; Kowalewski, Z. Comparison of properties of magnetoacoustic emission and mechanical barkhausen effects for P91 steel after plastic flow and creep. IEEE Trans. Magn. 2008, 44, 3273–3276. [Google Scholar] [CrossRef]

- Devine, M.K. Magnetic detection of material properties. J. Min. Met. Mater. JOM 1992, 44, 24–30. [Google Scholar] [CrossRef]

- Kronmüller, H.; Fähnle, M. Micromagnetism and the Microstructure of Ferromagnetic Solids; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Szielasko, K.; Tschuncky, R.; Rabung, M.; Seiler, G.; Altpeter, I.; Dobmann, G.; Herrmann, H.G.; Boller, C. Early Detection of Critical Material Degradation by Means of Electromagnetic Multi-Parametric NDE. AIP Conf. Proc. 2014, 1581. [Google Scholar] [CrossRef]

- Dobmann, G.; Altpeter, I.; Kopp, M.; Rabung, M.; Hubschen, G. ND-materials characterization of neutron induced embrittlement in German nuclear reactor pressure vessel material by micromagnetic NDT techniques. In Electromagnetic Nondestructive Evaluation (XI); IOS Press: Amsterdam, The Netherlands, 2008; p. 54. ISBN 978-1-58603-896-0. [Google Scholar]

- Altpeter, I.; Becker, R.G.; Dobmann, R.; Kern, W.A.; Theiner, A. Yashan: Robust Solutions of Inverse Problems in Eletromagnetic Non-Destructive Evaluation. Inverse Probl. 2002, 18, 1907–1921. [Google Scholar] [CrossRef]

- Szielasko, K.; Wolter, B.; Tschuncky, R.; Youssef, S. Micromagnetic materials characterization using maschin learning—Progress in Nondestructive Prediction of Mechanical Properties of Steel and Iron. Tech. Mess. 2020, 87, 428–437. [Google Scholar] [CrossRef]

- Takahashi, S.; Kobayashi, S.; Kikuchi, H.; Kamada, Y. Relationship between mechanical and magnetic properties in cold rolled low carbon steel. J. Appl. Phys. 2006, 100, 113908. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, S.; Gillemot, F.; Horváth, Á.; Székely, R. Magnetic properties of a highly neutron-irradiated nuclear reactor pressure vessel steel. J. Nucl. Mater. 2012, 421, 112–116. [Google Scholar] [CrossRef]

- Tomáš, I. Non-destructive Magnetic Adaptive Testing of ferromagnetic materials. J. Mag. Mag. Mat. 2004, 268, 178–185. [Google Scholar] [CrossRef]

- Tomáš, I.; Vértesy, G. Magnetic Adaptive Testing. In Nondestructive Testing Methods and New Applications; Omar, M., Ed.; IntechOpen Limited: London, UK, 2012; Available online: http://www.intechopen.com/articles/show/title/magnetic-adaptive-testing (accessed on 8 November 2020)ISBN 978-953-51-0108-6.

- Tomáš, I.; Vértesy, G.; Pirfo Barroso, S.; Kobayashi, S. Comparison of four NDT methods for indication of reactor steel degradation by high fluences of neutron irradiation. Nucl. Eng. Des. 2013, 265, 201–209. [Google Scholar] [CrossRef]

- Uytdenhouwen, I.; Chaouadi, R.; Other NOMAD Consortium Members. NOMAD: Non-destructive Evaluation (NDE) system for the inspection of operation-induced material degradation in nuclear power plants—Overview of the neutron irradiation campaigns. In ASME 2020 Pressure Vessels & Piping Conference; Non-Destructive Examination, V007T07A003, PVP2020-21512; ASME: New York, NY, USA, 2020; Volume 7. [Google Scholar]

- Uytdenhouwen, I.; Chaouadi, R. Effect of neutron irradiation on the mechanical properties of an A508 Cl.2 forging irradiated in a BAMI capsule. In Pressure Vessels and Piping Conference; Codes and Standards, V001T01A060, PVP2020-21513; ASME: New York, NY, USA, 2020; Volume 1. [Google Scholar]

- Uytdenhouwen, I.; Chaouadi, R. Accepted to be Published in the ASME 2021 Proceedings PVP2021-61969 Paper: Effect of Neutron Irradiation on the Mechanical Properties of an A508 Cl.2 and 15Kh2NMFA Irradiated in the NOMAD_3 rig in the BR2 Cooling Water. Available online: https://proceedings.asmedigitalcollection.asme.org/PVP/ (accessed on 2 March 2021).

- Tomáš, I.; Perevertov, O. Permeameter for Preisach approach to materials testing. In JSAEM Studies in Applied Electromagnetics and Mechanics, 9th ed.; Takagi, T., Ueasaka, M., Eds.; IOS Press: Amsterdam, The Netherlands, 2001; pp. 5–15. [Google Scholar]

- Vértesy, G.; Gasparics, A.; Uytdenhouwen, I.; Szenthe, I.; Gillemot, F.; Chaouadi, R. Nondestructive investigation of neutron irradiation generated structural changes of reactor steel material by magnetic hysteresis method. Metals 2009, 10, 642. [Google Scholar] [CrossRef]

- Vértesy, G.; Gasparics, A.; Griffin, J.M.; Mathew, J.; Fitzpatrick, M.E.; Uytdenhouwen, I. Analysis of surface roughness influence in non-destructive magnetic measurements applied to reactor pressure vessel steels. Appl. Sci. 2020, 10, 8938. [Google Scholar] [CrossRef]

- Integrity of Reactor Pressure Vessels in Nuclear Power Plants: Assessment of Irradiation Embrittlement Effects in Reactor Pressure Vessel Steels; IAEA Nuclear Energy Series No.NP-T-3.11; Atomic Energy Agency: Vienna, Austria, 2009.

- Seeger, A. Moderne Probleme der Metallphysik; Springer: Berlin/Heidelberg, Germany, 1966; p. 232. [Google Scholar]

| C | Mn | Si | S | P | Cr | Ni | Mo | Cu |

|---|---|---|---|---|---|---|---|---|

| 0.201 | 0.578 | 0.27 | 0.0085 | 0.0091 | 0.372 | 0.668 | 0.599 | 0.0472 |

| C | Mn | Si | S | P | Cr | Ni | Mo | V | Cu |

|---|---|---|---|---|---|---|---|---|---|

| 0.16 | 0.42 | 0.29 | 0.008 | 0.012 | 1.97 | 1.29 | 0.52 | 0.12 | 0.12 |

| A508 Cl.2. | Fast Fluence (E > 1 MeV) (×1019 n/cm2) | Vickers Hardness HV5 (ΔHV) | Yield Strength @RT (MPa) (Δσy) | DBTT T41J (°C) (ΔT41J) |

|---|---|---|---|---|

| Baseline | 0 | 181.2 ± 2.8 | 448 | −33 ± 9 |

| Low fluence | 1.55 | 237.9 ± 2.8 (56.7) | 710 (262) | 76 ± 15 (109) |

| Medium fluence | 4.38 | 254.4 ± 1.5 (73.2) | 793 (345) | 125 ± 15 (158) |

| High fluence | 7.04 | 258.5 ± 3.1 (77.3) | 823 (375) | 126 ± 15 (159) |

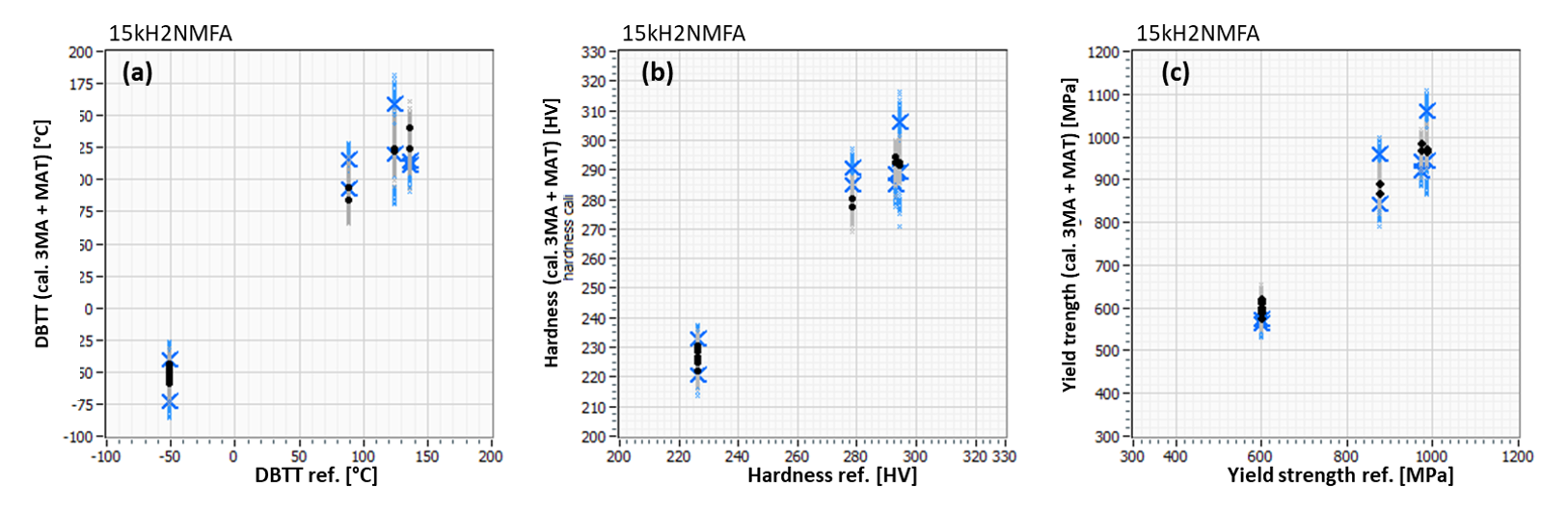

| 15Kh2NMFA | Fast Fluence (E > 1 MeV) (×1019 n/cm2) | Vickers Hardness HV5 (ΔHV) | Yield Strength @RT (MPa) (Δσy) | DBTT T41J (°C) (ΔT41J) |

|---|---|---|---|---|

| Baseline | 0 | 226.1 ± 5.5 | 600 | −51 ± 12 |

| Low fluence | 2.78 | 278.5 ± 3.4 (52.4) | 875 (275) | 88 ± 15 (139) |

| Medium fluence | 6.83 | 292.8 ± 3.1 (66.7) | 973 (373) | 136 ± 15 (187) |

| High fluence | 7.9 | 294.1 ± 4.5 (68.0) | 987 (387) | 124 ± 15 (175) |

| Parameter | R2 | RMSE | ||

|---|---|---|---|---|

| Training | Test | Training | Test | |

| DBTT | 99.8% | 97.5% | 2.9 °C | 12.5 °C |

| Yield strength | 99.9% | 94.5% | 6.2 MPa | 38.0 MPa |

| Hardness | 99.9% | 96.4% | 1.1 HV | 6.6 HV |

| Parameter | R2 | RMSE | ||

|---|---|---|---|---|

| Training | Test | Training | Test | |

| DBTT | 99.6% | 92.5% | 5.2 °C | 21.4 °C |

| Yield strength | 99.4% | 91.5% | 13.2 MPa | 51.6 MPa |

| Hardness | 99.5% | 92.8% | 2.1 HV | 7.9 HV |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rabung, M.; Kopp, M.; Gasparics, A.; Vértesy, G.; Szenthe, I.; Uytdenhouwen, I.; Szielasko, K. Micromagnetic Characterization of Operation-Induced Damage in Charpy Specimens of RPV Steels. Appl. Sci. 2021, 11, 2917. https://doi.org/10.3390/app11072917

Rabung M, Kopp M, Gasparics A, Vértesy G, Szenthe I, Uytdenhouwen I, Szielasko K. Micromagnetic Characterization of Operation-Induced Damage in Charpy Specimens of RPV Steels. Applied Sciences. 2021; 11(7):2917. https://doi.org/10.3390/app11072917

Chicago/Turabian StyleRabung, Madalina, Melanie Kopp, Antal Gasparics, Gábor Vértesy, Ildikó Szenthe, Inge Uytdenhouwen, and Klaus Szielasko. 2021. "Micromagnetic Characterization of Operation-Induced Damage in Charpy Specimens of RPV Steels" Applied Sciences 11, no. 7: 2917. https://doi.org/10.3390/app11072917

APA StyleRabung, M., Kopp, M., Gasparics, A., Vértesy, G., Szenthe, I., Uytdenhouwen, I., & Szielasko, K. (2021). Micromagnetic Characterization of Operation-Induced Damage in Charpy Specimens of RPV Steels. Applied Sciences, 11(7), 2917. https://doi.org/10.3390/app11072917