Driven Pile Effects on Nearby Cylindrical and Semi-Tapered Pile in Sandy Clay

Abstract

1. Introduction

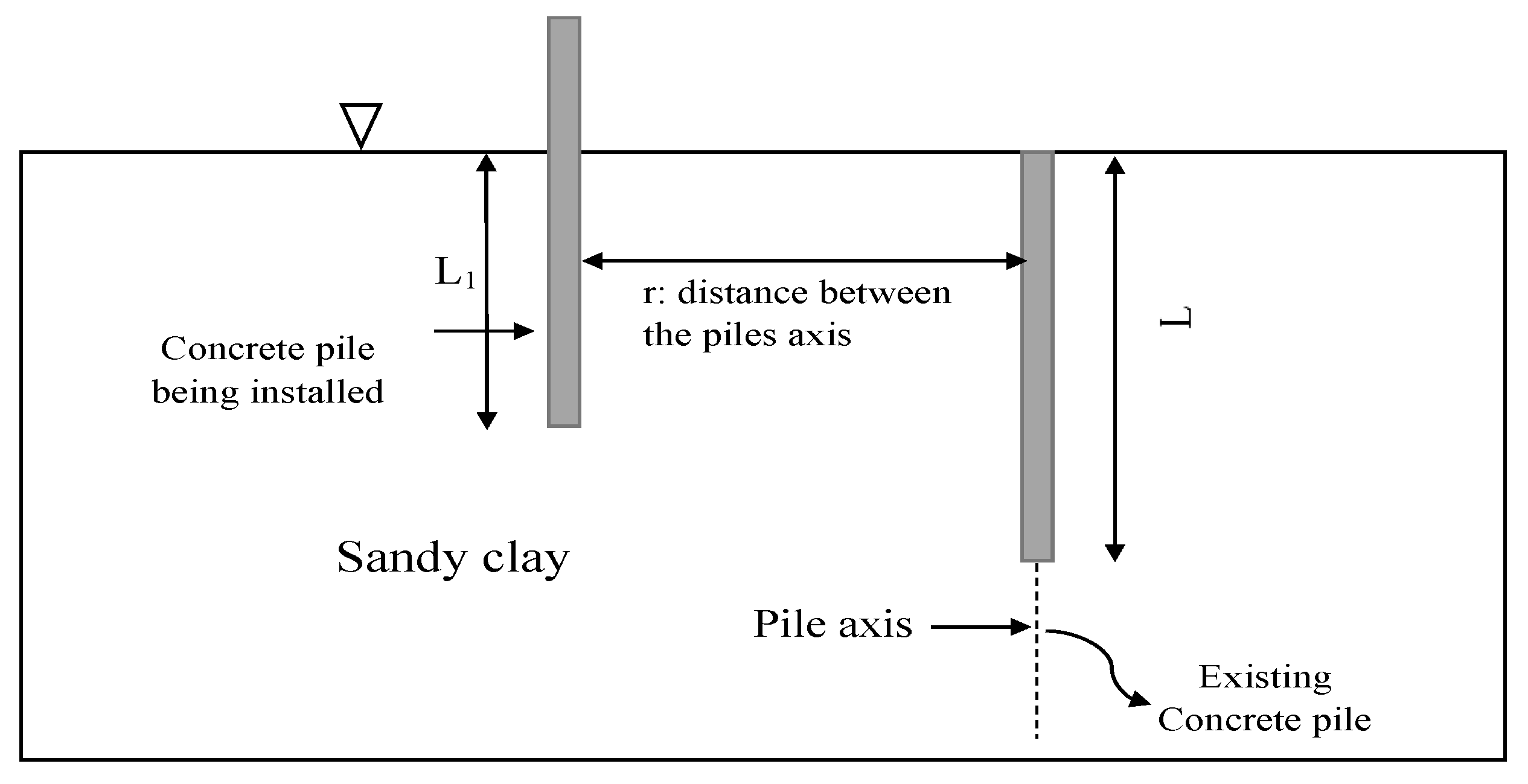

2. Basic Concepts

2.1. Factors for Ground Vibration Estimation

2.2. Wave Propagation and Determination of Soil Damping Ratio

2.3. Soil–Pile Interaction

2.4. Evaluation of Pile Axial Ultimate Capacity

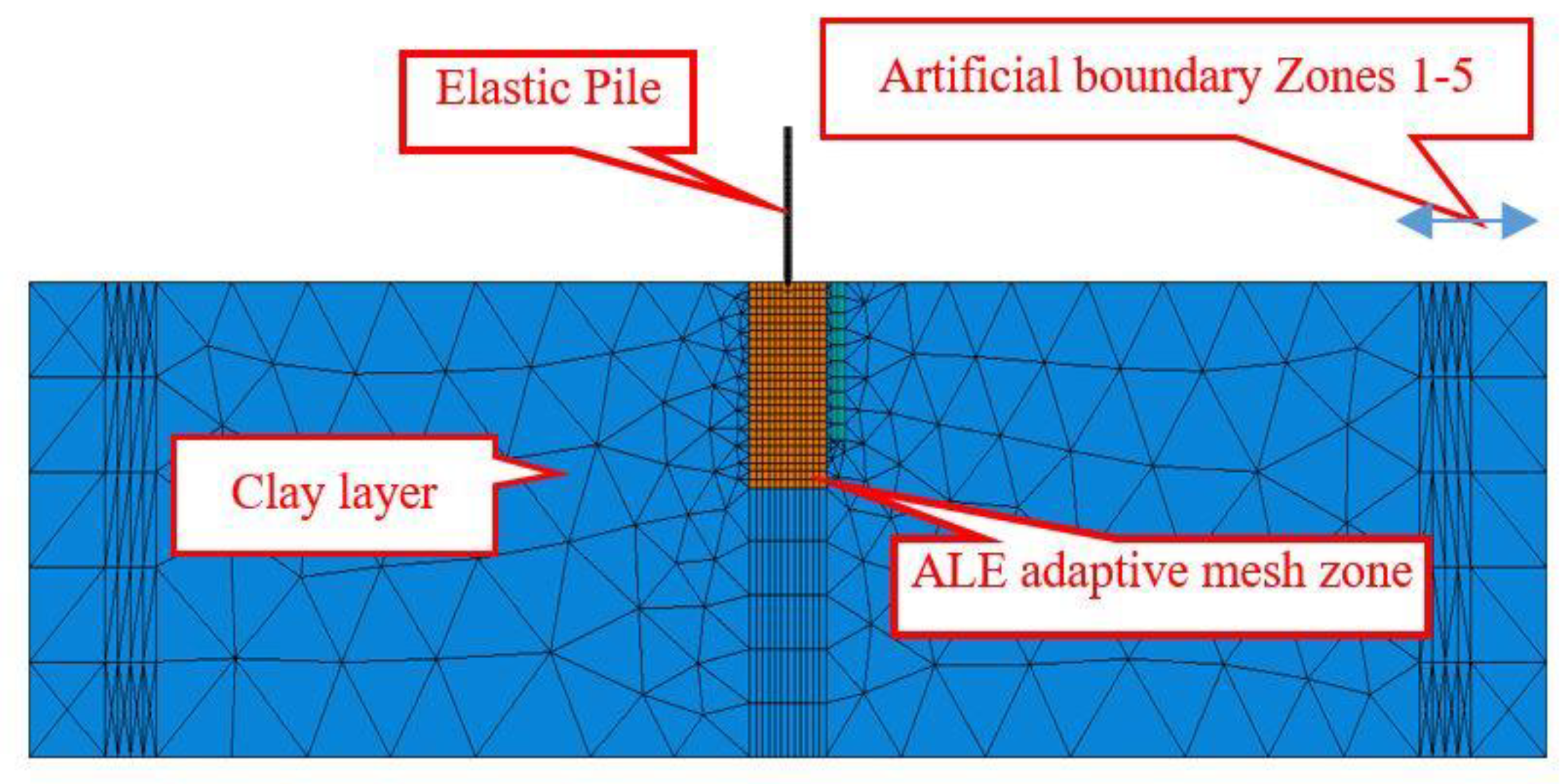

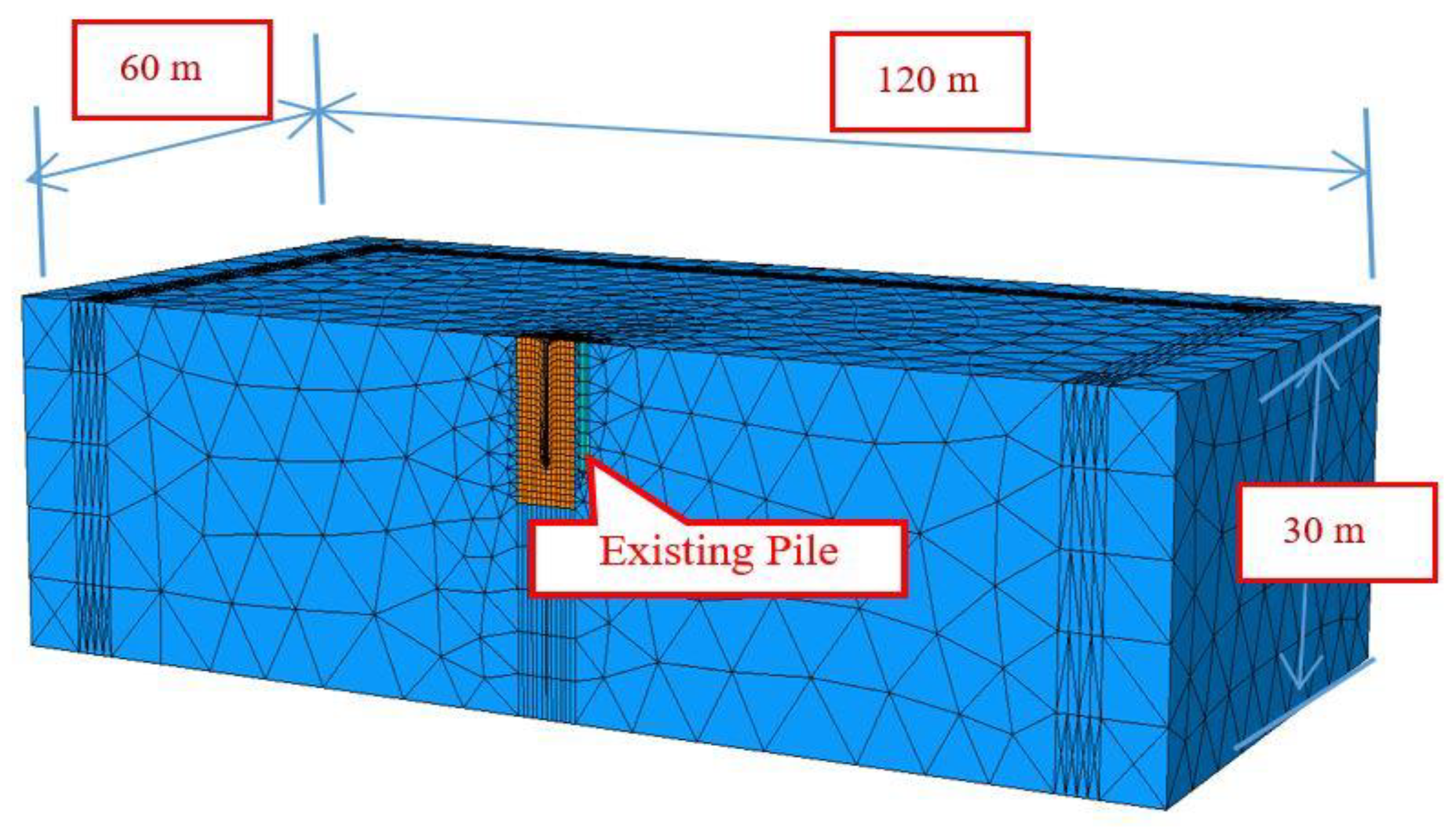

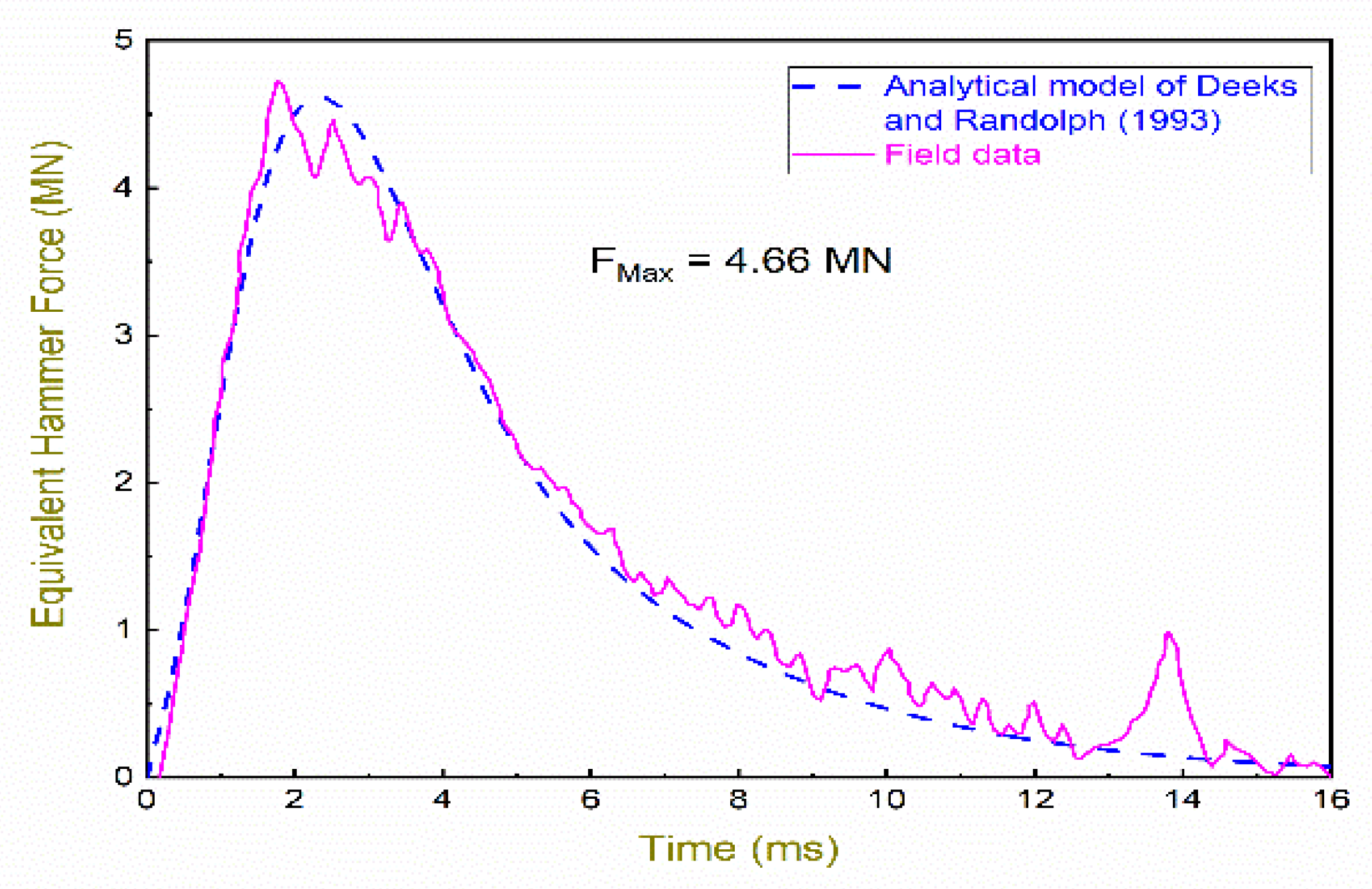

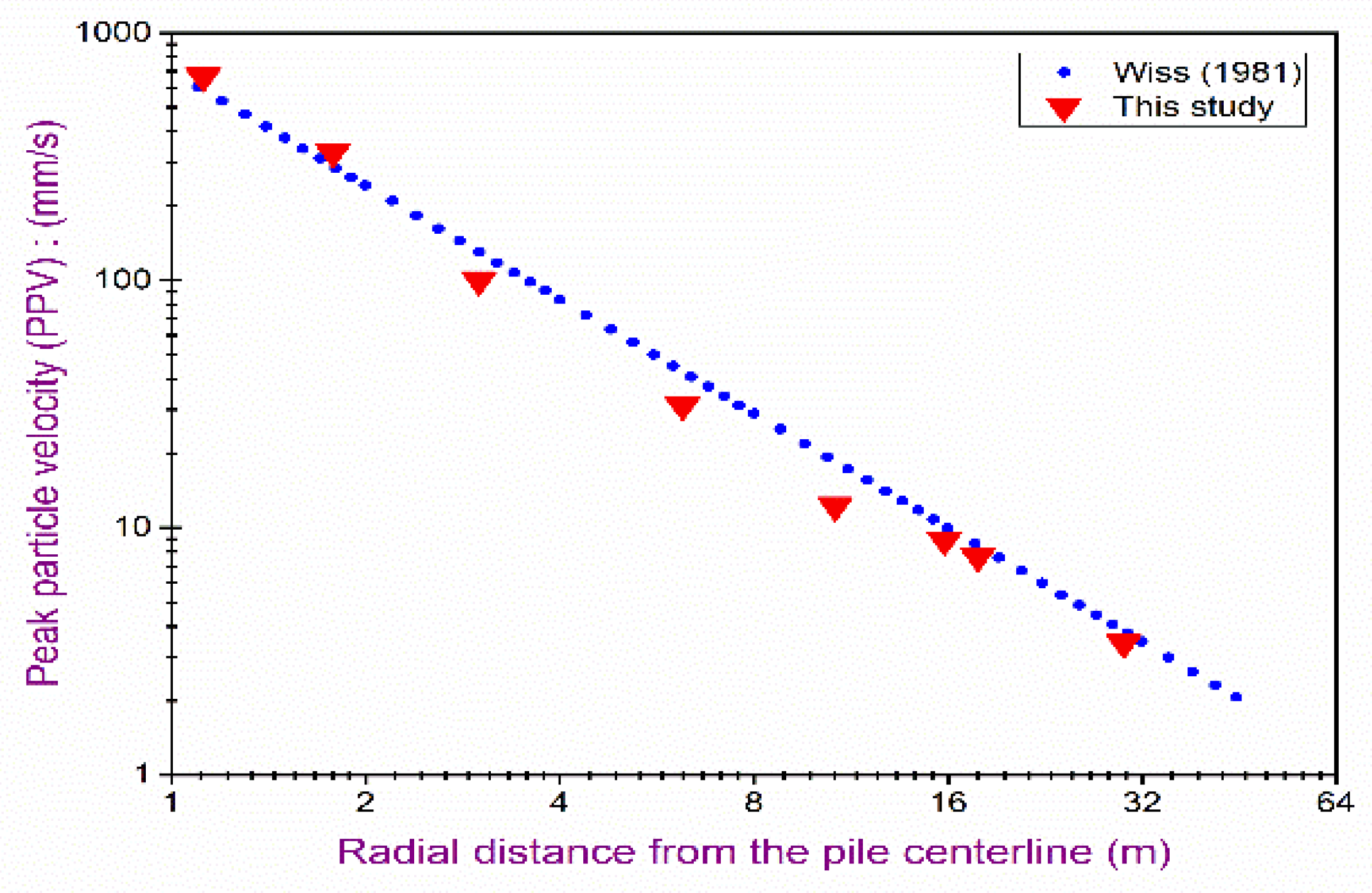

3. Numerical Model and Verification

- Divide the side and bottom part of the finite element mesh into subzones

- Increase the damping gradually in these subzones

4. Pile Response Analysis Due to Ground

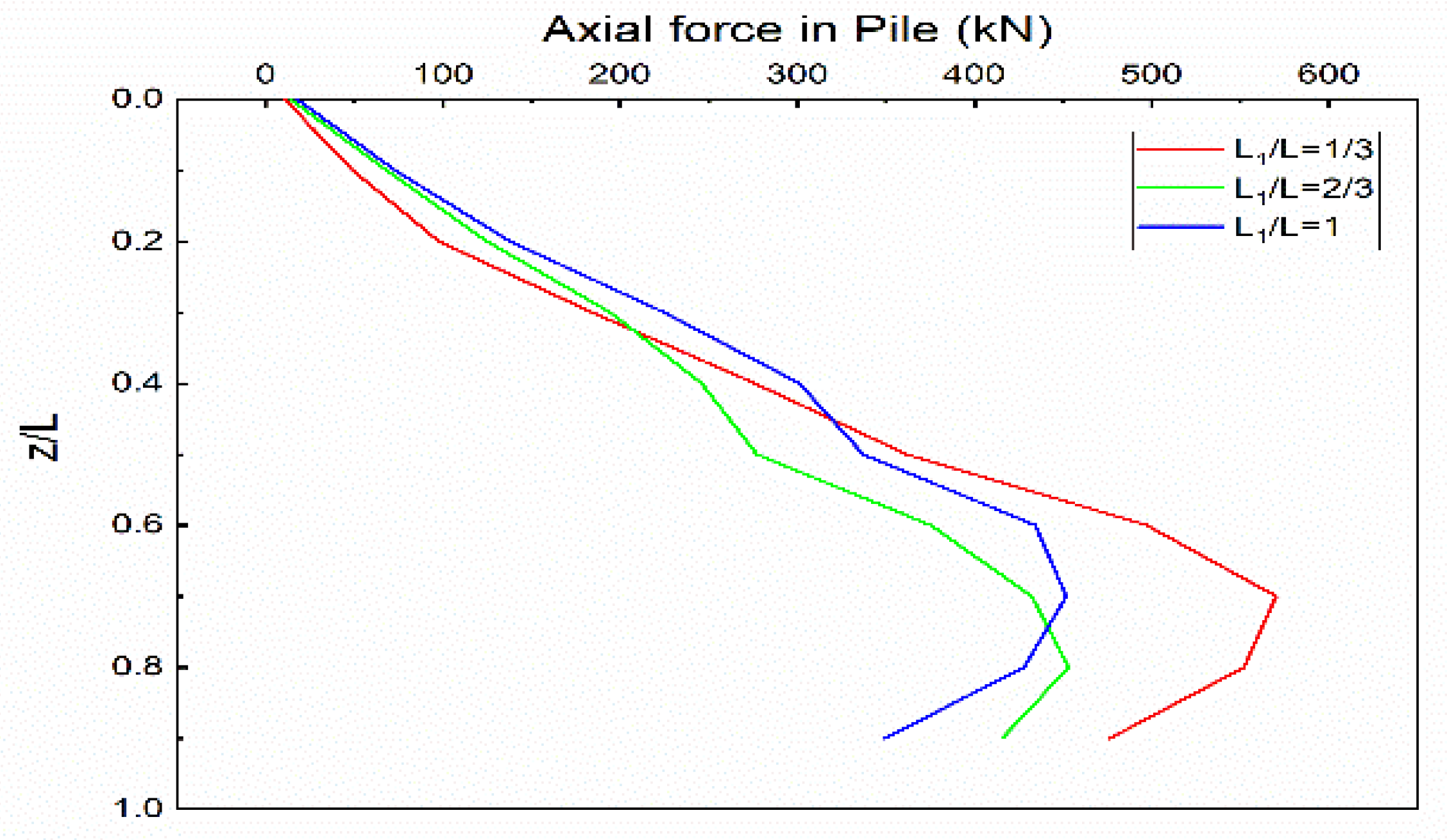

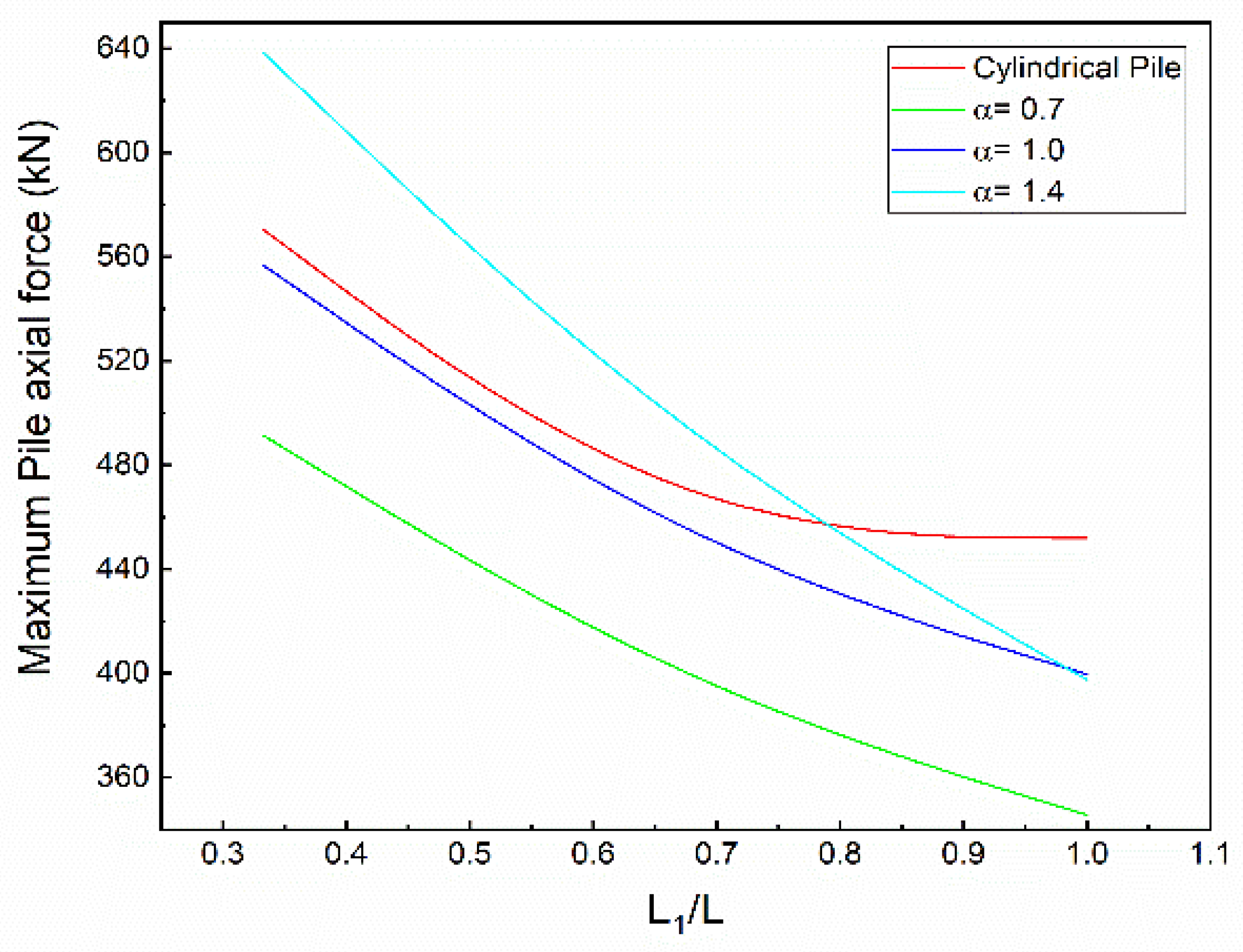

4.1. Axial Reaction

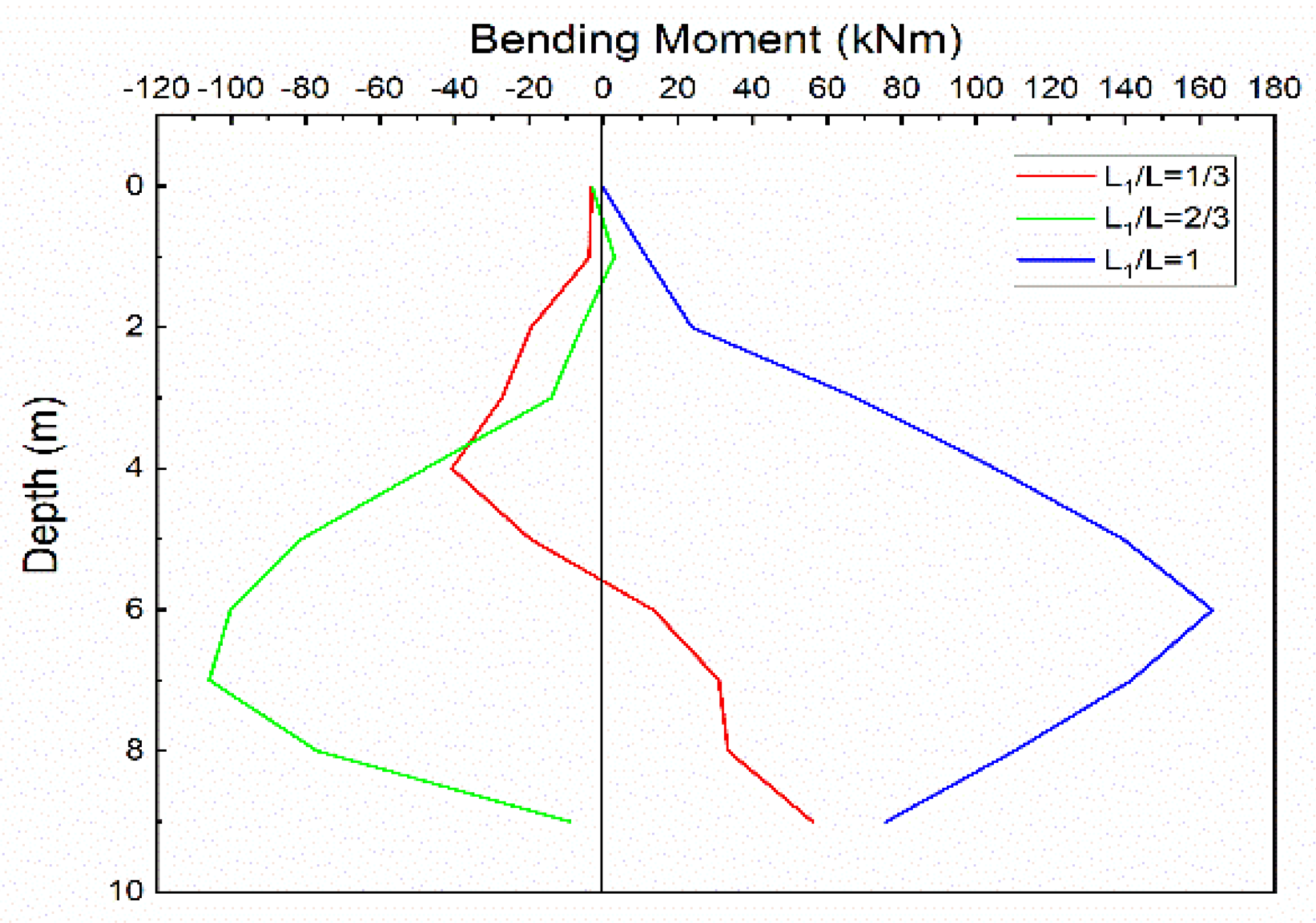

4.2. Bending Moment Analysis

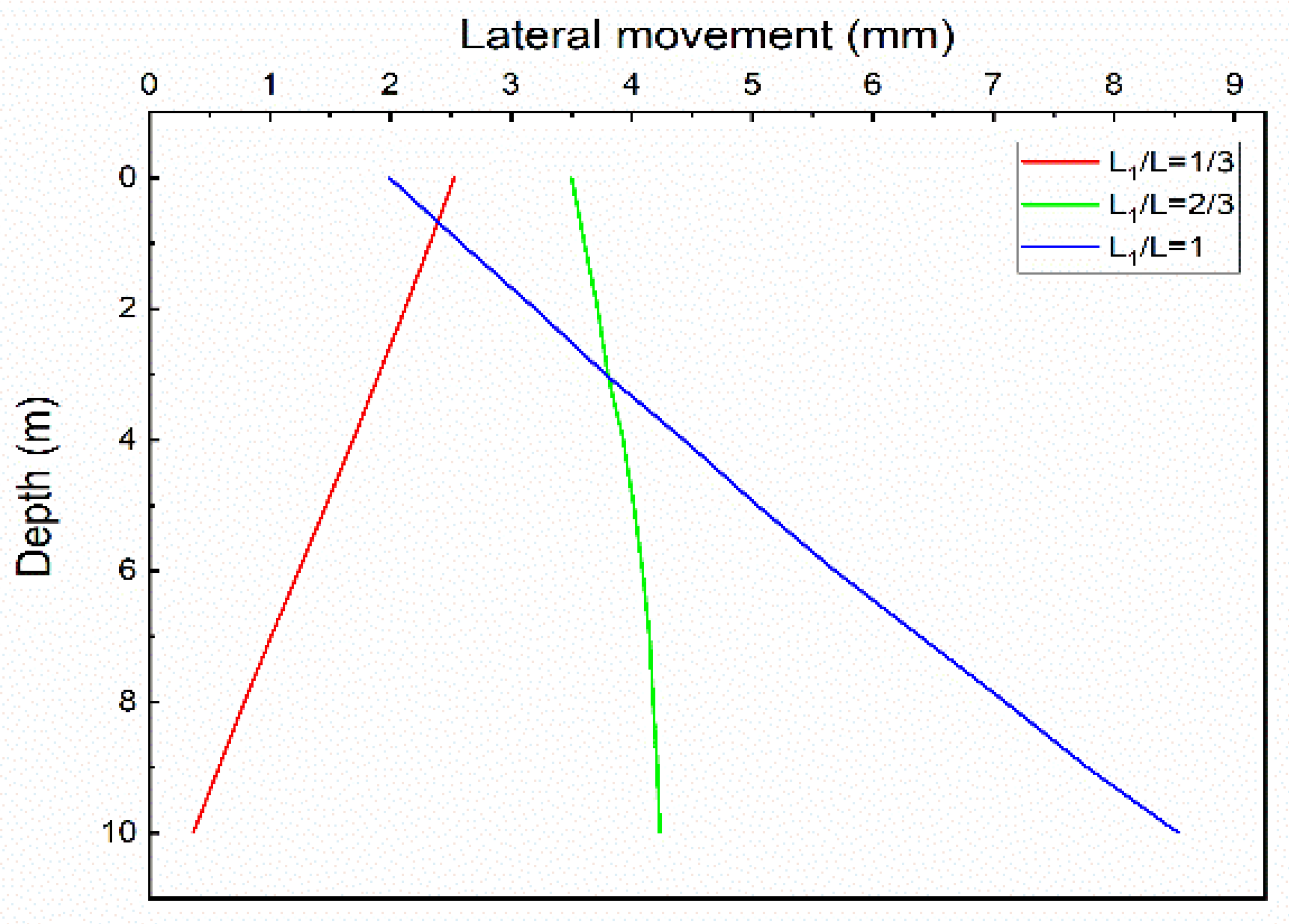

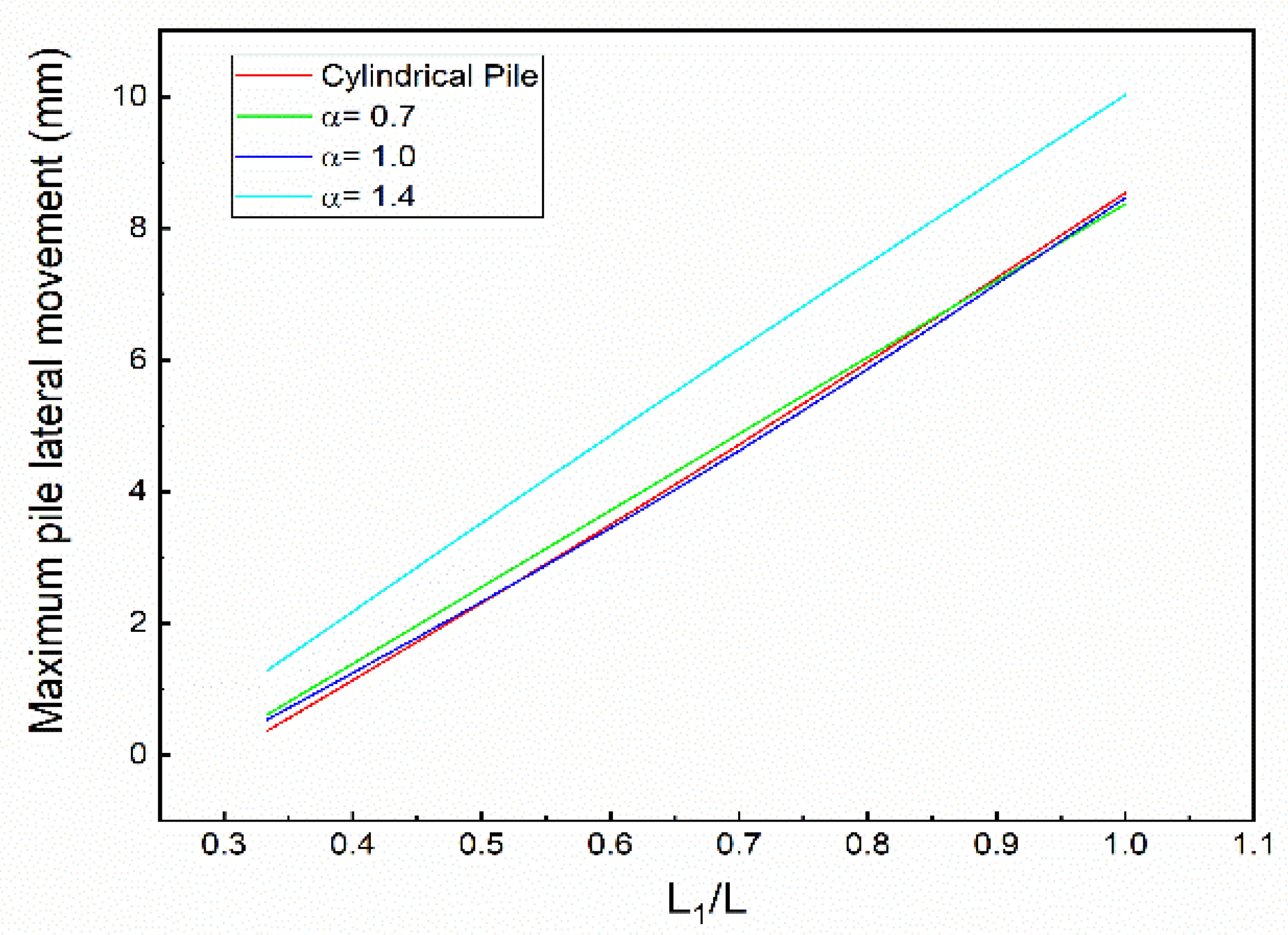

4.3. Lateral Movement Analysis

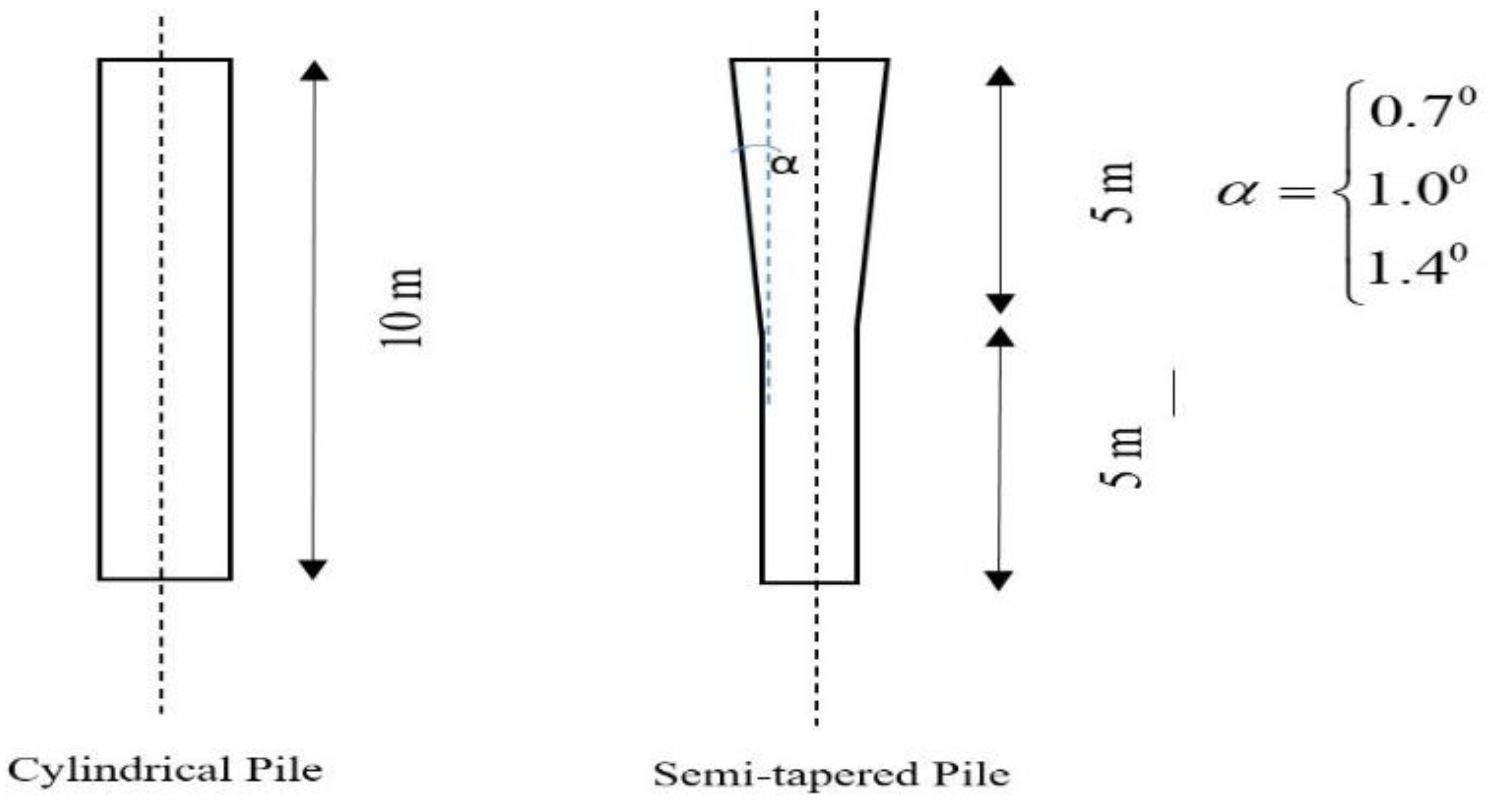

4.4. Effect of the Pile Shape

5. Conclusions

- In this paper, a reliable method to complete the driving of a pile was proposed. This involved combining the element deletion and arbitrary Lagrangian–Eulerian (ALE) mesh method.

- The adjacent semi-tapered pile was subjected to less axial and lateral movement than the cylindrical one with the same length and volume for a taper angle smaller than 1.0°, and vice versa for a taper angle greater than 1.4°.

- Moreover, the influence of the driven pile on the existing pile’s responses was significant, the bending moment and axial force were not negligible, and the coupling effect in the case of the loaded pile should be factually considered. In fact, the pile’s design subjected to lateral and axial load was usually treated as a separate problem.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bhattacharya, S.; Dash, S.; Mitra, N.; Adhikari, S.; Blakeborough, A. Investigation of Bending–Buckling Interaction of Piles in Liquefiable Soils. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008. [Google Scholar]

- Meyerhof, G.G. Closure to “Bearing Capacity and Settlement of Pile Foundations”. J. Geotech. Eng. Div. 1977, 103, 1023–1025. [Google Scholar] [CrossRef]

- O’Neill, M.W. Review of augered pile practice outside the United States. In Transportation Research Record1447; Transportation Research Board: Washington, DC, USA, 1994; pp. 3–9. [Google Scholar]

- Thiyyakkandi, S.; McVay, M.; Bloomquist, D.; Lai, P. Measured and Predicted Response of a New Jetted and Grouted Precast Pile with Membranes in Cohesionless Soils. J. Geotech. Geo Environ. Eng. 2013, 139, 1334–1345. [Google Scholar] [CrossRef]

- Poulos, H. The influence of construction “side effects” on existing pile foundations. Geotech. Eng. 2005, 36, 51–67. [Google Scholar]

- Lombardi, D.; Dash, S.; Bhattacharya, S. Inclusion of axial load on bending response of pile in liquefiable soils. In Proceedings of the 8th International Conference on Urban Earthquake Engineering, Tokyo, Japan, 7–8 March 2011. [Google Scholar]

- Tavasoli, O.; Ghazavi, M. Wave propagation and ground vibrations due to non-uniform cross-sections piles driving. Comput. Geotech. 2018, 104, 13–21. [Google Scholar] [CrossRef]

- Sormeie, A.; Ghazavi, M. Analysis of non-uniform piles driven into cohesive soils. Soil Dyn. Earthq. Eng. 2018, 109, 282–285. [Google Scholar] [CrossRef]

- Ghazavi, M. Response of tapered piles to axial harmonic loading. Can. Geotech. J. 2008, 45, 1622–1628. [Google Scholar] [CrossRef]

- El Naggar, M.H.; Wei, J.Q. Response of tapered piles subjected to lateral loading. Can. Geotech. J. 1999, 36, 52–71. [Google Scholar] [CrossRef]

- Ghazavi, M. Analysis of kinematic seismic response of tapered piles. Geotech. Geol. Eng. 2006, 25, 37–44. [Google Scholar] [CrossRef]

- Shanker, K.; Basudhar, P.; Patra, N. Flexural Response of Tapered Piles in Liquefied Soils. In Proceedings of the 12th International Conference of International Association for Computer Methods and Advances in Geomechanics, Goa, India, 1–6 October 2008. [Google Scholar]

- Musir, A.A. A study of pile driving effects on nearby building. Int. J. Geomate 2014, 6, 806–810. [Google Scholar] [CrossRef]

- Yang, Z.X.; Jardine, R.J.; Zhu, B.T.; Rimoy, S. Stresses Developed around Displacement Piles Penetration in Sand. J. Geotech. Geo Environ. Eng. 2014, 140, 04013027. [Google Scholar] [CrossRef]

- Rooz, A.F.H.; Hamidi, A. A numerical model for continuous impact pile driving using ALE adaptive mesh method. Soil Dyn. Earthq. Eng. 2019, 118, 134–143. [Google Scholar] [CrossRef]

- Rooz, A.F.H.; Hamidi, A. Numerical Analysis of Factors Affecting Ground Vibrations due to Continuous Impact Pile Driving. Int. J. Géoméch. 2017, 17, 04017107. [Google Scholar] [CrossRef]

- Rezaei, M.; Hamidi, A.; Rooz, F.H.A. Investigation of Peak Particle Velocity Variations during Impact Pile Driving Process. Civ. Eng. Infrastruct. J. 2016, 49, 59–69. [Google Scholar] [CrossRef]

- Sheng, D.; Eigenbrod, K.D.; Wriggers, P. Finite element analysis of pile installation using large-slip frictional contact. Comput. Geotech. 2005, 32, 17–26. [Google Scholar] [CrossRef]

- Masoumi, H.R.; François, S.; Degrande, G. A non-linear coupled finite element-boundary element model for the prediction of vibrations due to vibratory and impact pile driving. Int. J. Numer. Anal. Methods Géoméch. 2009, 33, 245–274. [Google Scholar] [CrossRef]

- Khoubani, A.; Ahmadi, M.M. Numerical study of ground vibration due to impact pile driving. Proc. Inst. Civ. Eng. Geotech. Eng. 2014, 167, 28–39. [Google Scholar] [CrossRef]

- Dijkstra, J.; Broere, W.; Heeres, O. Numerical simulation of pile installation. Comput. Geotech. 2011, 38, 612–622. [Google Scholar] [CrossRef]

- Grabe, J.; Henke, S. Simulation of pile driving by 3-dimensional Finite-Element analysis. In Proceedings of the 17th European Young Geotechnical Engineers’ Conference, Croatia, Zagreb, 19–23 July 2006; pp. 215–233. [Google Scholar]

- Mabsout, M.E.; Tassoulas, J.L. A finite element model for the simulation of pile driving. Int. J. Numer. Methods Eng. 1994, 37, 257–278. [Google Scholar] [CrossRef]

- Ramshaw, C.L.; Selby, A.R.; Bettess, P. Ground Waves Generated by Pile Driving, and Structural Interaction. In Proceedings of the Fourth International Conference on Recent Advances in Geotechnical Earthquake Engineering and Soil Dynamic, St. Louis, MO, USA, 26–31 March 2001. [Google Scholar]

- Masoumi, H.; Degrande, G.; Lombaert, G. Prediction of free field vibrations due to pile driving using a dynamic soil–structure interaction formulation. Soil Dyn. Earthq. Eng. 2007, 27, 126–143. [Google Scholar] [CrossRef]

- Masouleh, S.F.; Fakharian, K. Application of a continuum numerical model for pile driving analysis and comparison with a real case. Comput. Geotech. 2008, 35, 406–418. [Google Scholar] [CrossRef]

- Liyanapathirana, D.; Ekanayake, S. Application of EPS geofoam in attenuating ground vibrations during vibratory pile driving. Geotext. Geomembranes 2016, 44, 59–69. [Google Scholar] [CrossRef]

- Lupiezowiec, M. Fem Model of Vibration Propagation in the Soil Caused by Prefabricated Driven Piles. In Proceedings of the 14th SGEM GeoConference on Science and Technologies in Geology, Exploration and Mining, Albena, Bulgaria, 17–26 June 2014; Volume 2, pp. 363–368. [Google Scholar] [CrossRef]

- Goh, A.T.C.; Wong, K.S.; Teh, C.I.; Wen, D. Pile Response Adjacent to Braced Excavation. J. Geotech. Geoenviron. Eng. 2003, 129, 383–386. [Google Scholar] [CrossRef]

- Korff, M.; Mair, R.J.; Van Tol, F.A.F. Pile-Soil Interaction and Settlement Effects Induced by Deep Excavations. J. Geotech. Geo Environ. Eng. 2016, 142, 04016034. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Wei, J.; Poulos, H.; Liu, H. Effects of Multipropped Excavation on an Adjacent Floating Pile. J. Geotech. Geoenviron. Eng. 2017, 143, 04017021. [Google Scholar] [CrossRef]

- Liyanapathirana, D.; Nishanthan, R. Influence of deep excavation induced ground movements on adjacent piles. Tunn. Undergr. Space Technol. 2016, 52, 168–181. [Google Scholar] [CrossRef]

- Soomro, M.A.; Brohi, A.S.; Bangwar, D.K.; Bhatti, S.A. 3D Numerical Modeling of Pile Group Responses to Excavation-Induced Stress Release in Silty Clay. Eng. Technol. Appl. Sci. Res. 2018, 8, 2577–2584. [Google Scholar] [CrossRef]

- Soomro, M.A.; Mangnejo, D.A.; Bhanbhro, R.; Memon, N.A.; Memon, M.A. 3D finite element analysis of pile responses to adjacent excavation in soft clay: Effects of different excavation depths systems relative to a floating pile. Tunn. Undergr. Space Technol. 2019, 86, 138–155. [Google Scholar] [CrossRef]

- Wang, L.; Chen, K.; Hong, Y.; Ng, C. Effect of consolidation on responses of a single pile subjected to lateral soil movement. Can. Geotech. J. 2015, 52, 769–782. [Google Scholar] [CrossRef]

- Basile, F. Effects of tunnelling on pile foundations. Soils Found. 2014, 54, 280–295. [Google Scholar] [CrossRef]

- Mu, L.; Huang, M.; Finno, R.J. Tunnelling effects on lateral behavior of pile rafts in layered soil. Tunn. Undergr. Space Technol. 2012, 28, 192–201. [Google Scholar] [CrossRef]

- Abaqus 6.14-3 [Computer Software]; SIMULIA: Providence, RI, USA, 2019.

- Svinkin, M.R. Minimizing Construction Vibration Effects. Pr. Period. Struct. Des. Constr. 2004, 9, 108–115. [Google Scholar] [CrossRef]

- Elseman, I.; Abdel, R.; Mostafa, T.M. Measurement and Evaluation of Blasting ground Vibrations and Airblasts at the Limestone Quarries of Assiut Cement Company (CEMEX). J. Eng. Sci. 2006, 34, 1293–1309. [Google Scholar]

- Athanasopoulos, G.; Pelekis, P. Ground vibrations from sheetpile driving in urban environment: Measurements, analysis and effects on buildings and occupants. Soil Dyn. Earthq. Eng. 2000, 19, 371–387. [Google Scholar] [CrossRef]

- Grizi, A.; Athanasopoulos-Zekkos, A.; Woods, R.D. Ground Vibration Measurements near Impact Pile Driving. J. Geotech. Geo Environ. Eng. 2016, 142, 04016035. [Google Scholar] [CrossRef]

- Serdaroglu, M.S. Nonlinear Analysis of Pile Driving and Ground Vibrations in Saturated Cohesive Soils Using the Finite Element Method. Ph.D. Thesis, University of Iowa, Iowa City, IA, USA, 2010. [Google Scholar]

- Schümann, B.; Grabe, J. FE-based modelling of pile driving in saturated soils. In Proceedings of the 8th International Conference on Structural Dynamics, Leuven, Belgium, 4–6 July 2011; European Association for Structural Dynamics (EASD) KUL, Technological Institute of the Royal Flemish Society of Engineers, Eds.; Katholieke Universiteit Leuven: Leuven, Belgium, 2011. [Google Scholar]

- Zhao, G.Y.; Chen, J. Dynamic property identification of soil used in shaking table test: A comparison of several methods. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008. [Google Scholar]

- Madheswaran, C.K.; Natarajan, K.; Sundaravadivelu, R.; Boominathan, A. Effect of Trenches on Attenuation of Ground Vibration during Pile Driving. Springer Proc. Phys. 2008, 2007, 231–238. [Google Scholar] [CrossRef]

- Masoumi, H.; Degrande, G. Numerical modeling of free field vibrations due to pile driving using a dynamic soil-structure interaction formulation. J. Comput. Appl. Math. 2008, 215, 503–511. [Google Scholar] [CrossRef]

- Hamidi, A.; Rooz, A.F.H.; Pourjenabi, M. Allowable Distance from Impact Pile Driving to Prevent Structural Damage Considering Limits in Different Standards. Pr. Period. Struct. Des. Constr. 2018, 23, 04017029. [Google Scholar] [CrossRef]

- McCarron, W.O. Deepwater Foundations and Pipeline Geomechanics; McCarron, W.O., Ed.; J. Ross Publishing: Plantation, FL, USA, 2011. [Google Scholar]

- Golpasand, M.R.; Do, N.A.; Dias, D.; Nikudel, M. Effect of the lateral earth pressure coefficient on settlements during mechanized tunneling. Geomech. Eng. 2018. [Google Scholar] [CrossRef]

- Wiss, J.F. Construction vibrations: State-of-the-art. J. Geotech. Eng. 1981, 107, 167–181. [Google Scholar]

- Zhang, M.; Tao, M. A Parametric Study on Factors Affecting Ground Vibrations during Pile Driving through Finite Element Simulations. In Proceedings of the GeoRisk, Atlanta, Georgia, 26–28 June 2011; pp. 931–938. [Google Scholar]

- Liu, G.; Jerry, S.Q. A non-reflecting boundary for analyzing wave propagation using the finite element method. Finite Elements Anal. Des. 2003, 39, 403–417. [Google Scholar] [CrossRef]

- Deeks, A.J.; Randolph, M.F. Analytical modelling of hammer impact for pile driving. Int. J. Numer. Anal. Methods Géoméch. 1993, 17, 279–302. [Google Scholar] [CrossRef]

- Ni, Q.; Hird, C.; Guymer, I. Physical modelling of pile penetration in clay using transparent soil and particle image velocimetry. Géotechnique 2010, 60, 121–132. [Google Scholar] [CrossRef]

- Manandhar, S.; Yasufuku, N. Vertical bearing capacity of tapered piles in sands using cavity expansion theory. Soils Found. 2013, 53, 853–867. [Google Scholar] [CrossRef]

| Elastic Pile | ||||

|---|---|---|---|---|

| Diameter 0.5 m | Length 10 m | Density 2500 kg/m3 | Young’s modulus 40,000 MPa | Poisson’s ratio 0.25 |

| Sandy Clay | ||||

| Friction angle 25 degrees | Cohesion 15 kPa | Density 2000 kg/m3 | Young’s modulus 80 MPa | Poisson’s ratio 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fall, M.; Gao, Z.; Ndiaye, B.C. Driven Pile Effects on Nearby Cylindrical and Semi-Tapered Pile in Sandy Clay. Appl. Sci. 2021, 11, 2919. https://doi.org/10.3390/app11072919

Fall M, Gao Z, Ndiaye BC. Driven Pile Effects on Nearby Cylindrical and Semi-Tapered Pile in Sandy Clay. Applied Sciences. 2021; 11(7):2919. https://doi.org/10.3390/app11072919

Chicago/Turabian StyleFall, Massamba, Zhengguo Gao, and Becaye Cissokho Ndiaye. 2021. "Driven Pile Effects on Nearby Cylindrical and Semi-Tapered Pile in Sandy Clay" Applied Sciences 11, no. 7: 2919. https://doi.org/10.3390/app11072919

APA StyleFall, M., Gao, Z., & Ndiaye, B. C. (2021). Driven Pile Effects on Nearby Cylindrical and Semi-Tapered Pile in Sandy Clay. Applied Sciences, 11(7), 2919. https://doi.org/10.3390/app11072919