Evaluation of the Mechanical Properties of Normal Concrete Containing Nano-MgO under Freeze–Thaw Conditions by Evolutionary Intelligence

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

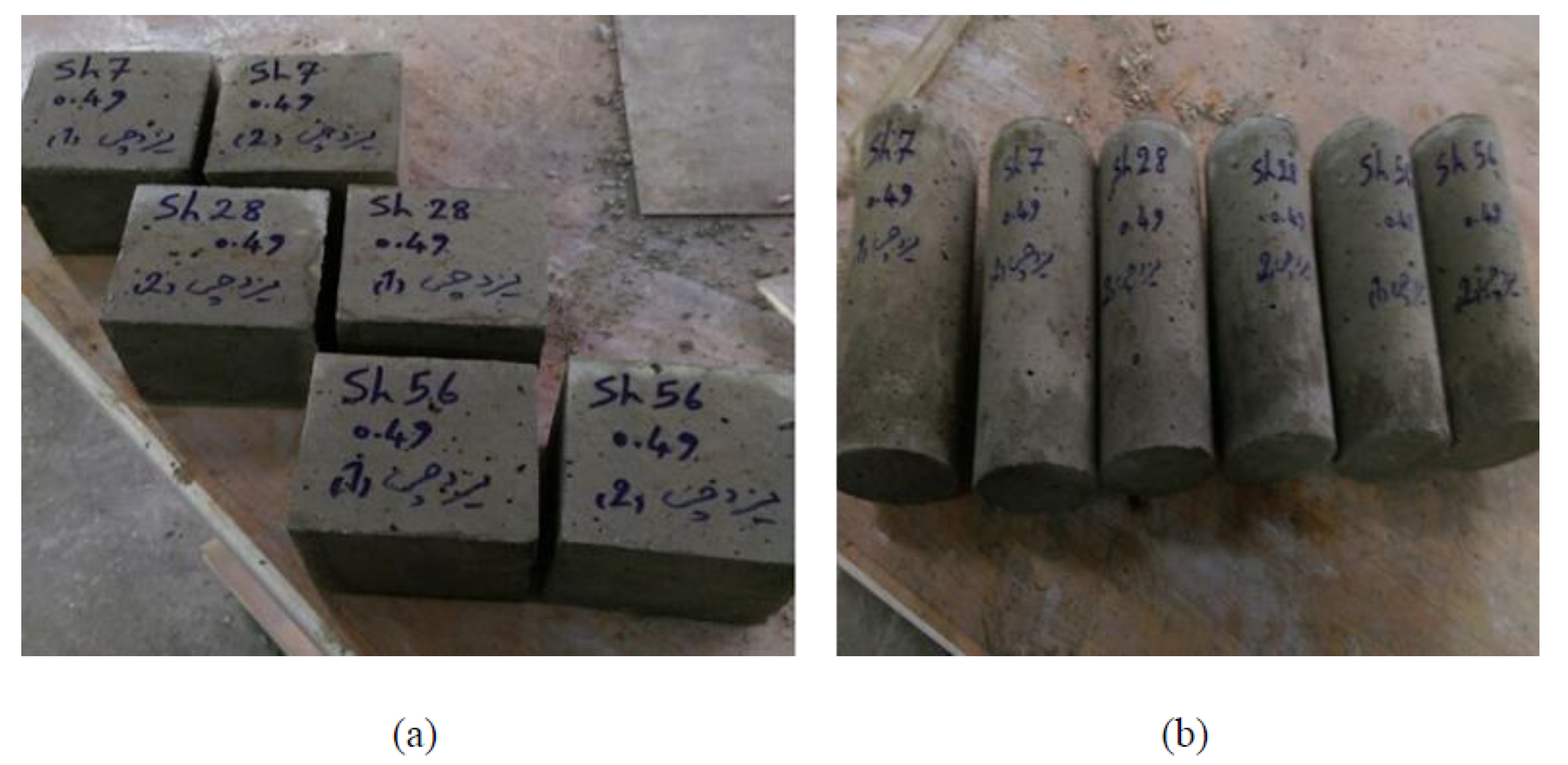

2.2. Mixture and Sample Preparation

2.3. Experimental Tests

2.3.1. Freeze–Thaw Test

2.3.2. Compressive Test

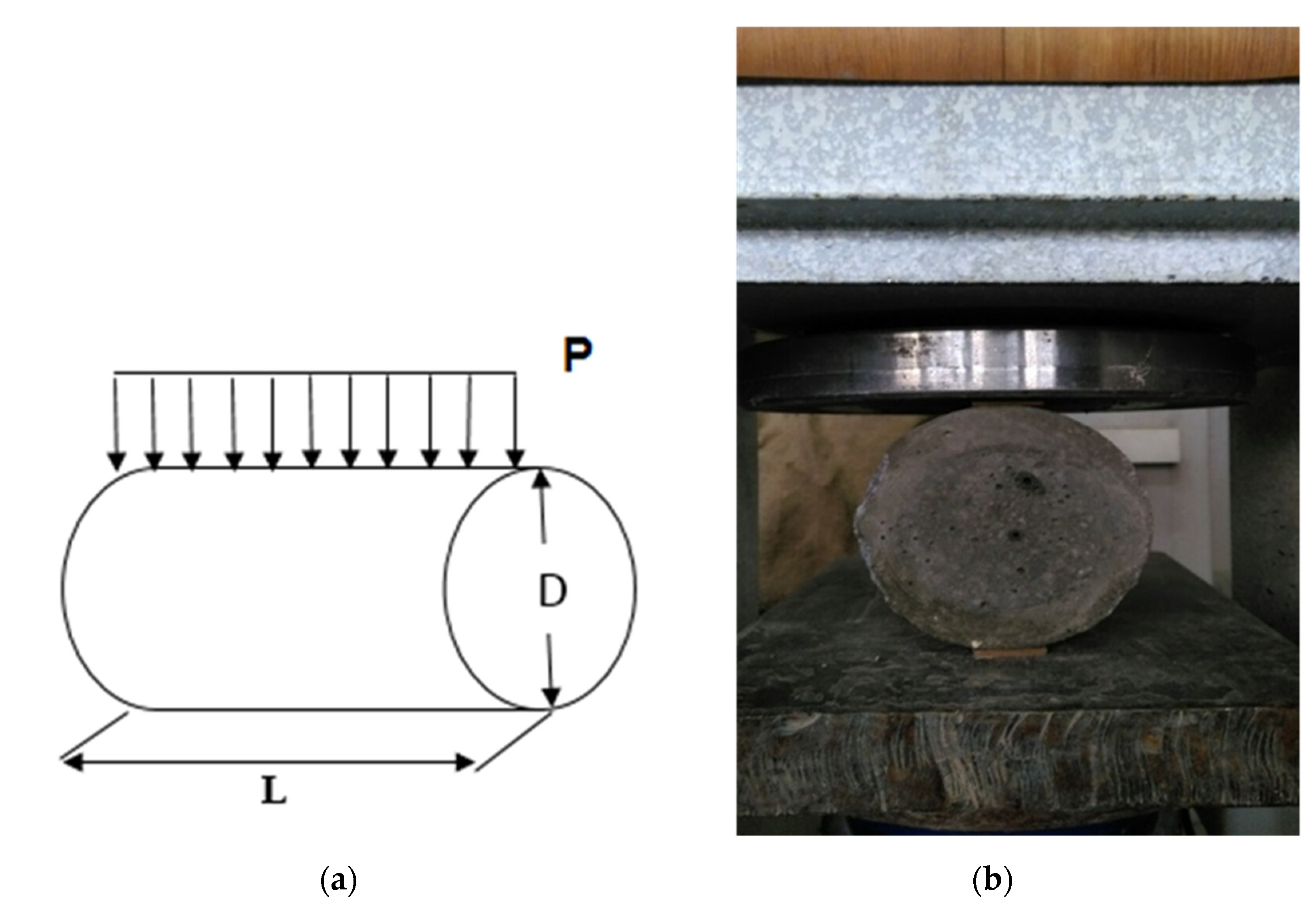

2.3.3. Tensile Test

2.3.4. Permeability Test

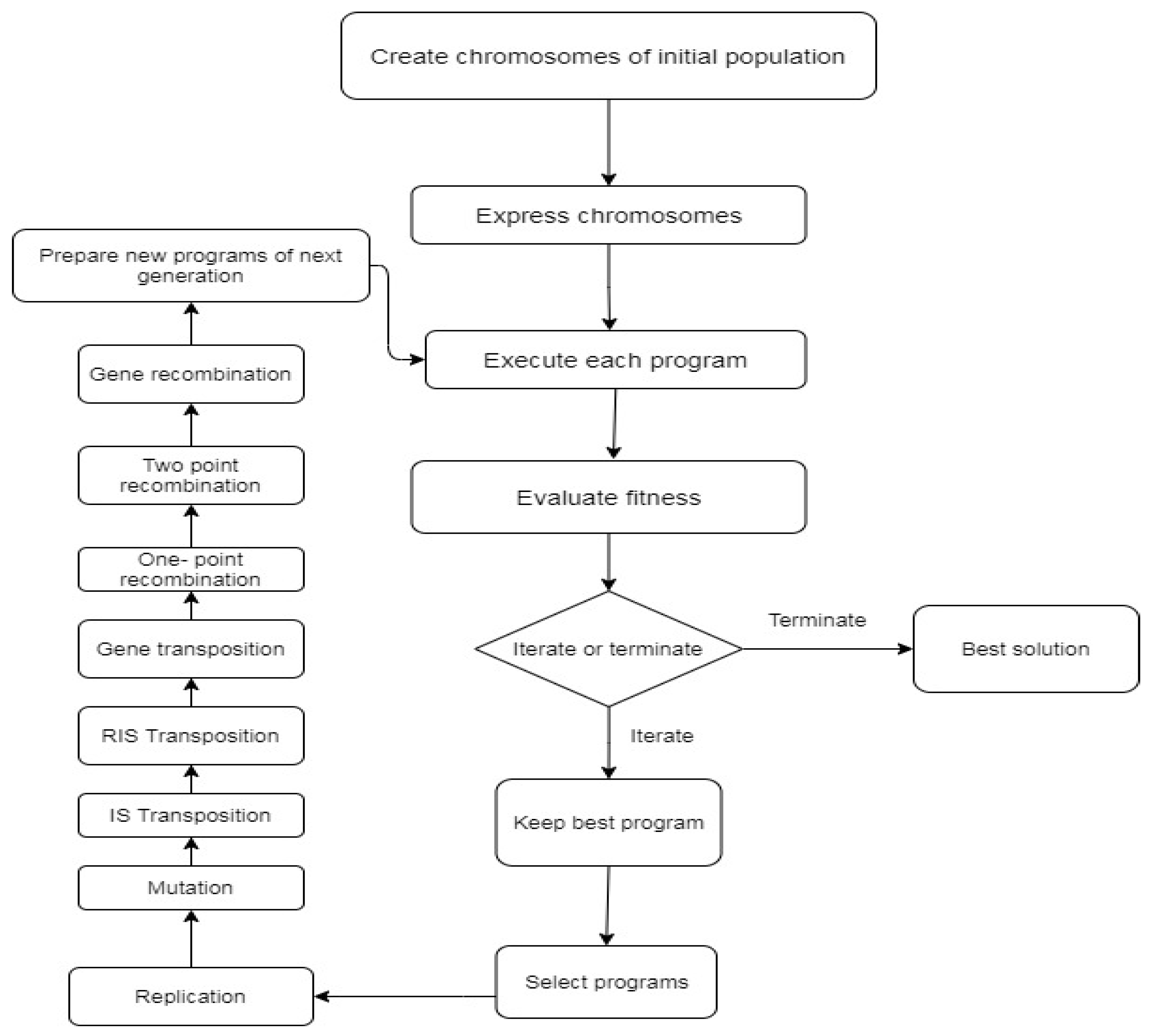

3. Evolutionary Intelligence Method

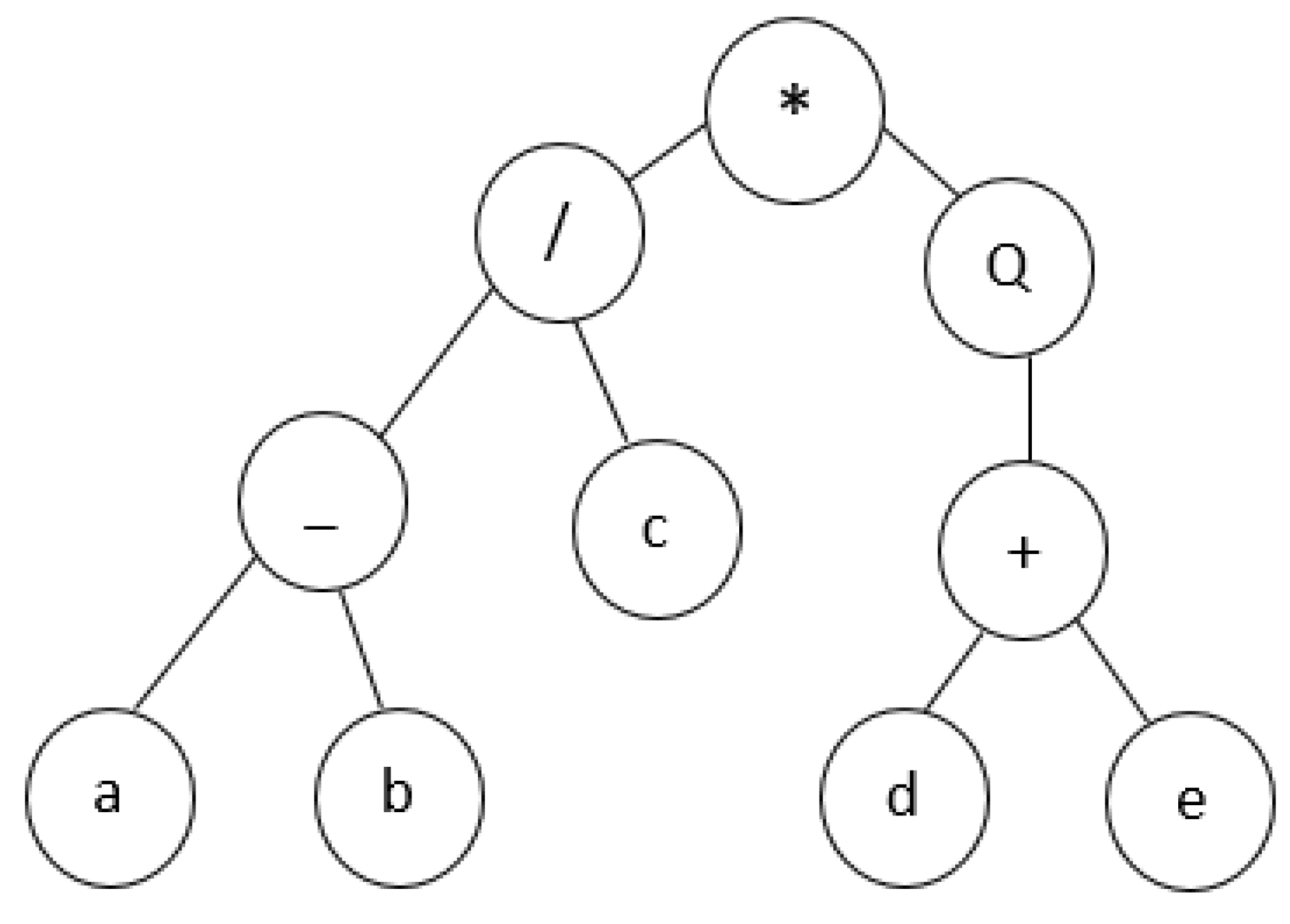

3.1. Gene Expression Programming

- 0123456789

- */Q-c+abde.

- 012345678901234567890

- *ba-Qbaa+babbabaabbab.

3.2. Required Data for Modeling

4. Results and Discussion

4.1. Compressive Strength

4.2. Tensile Strength

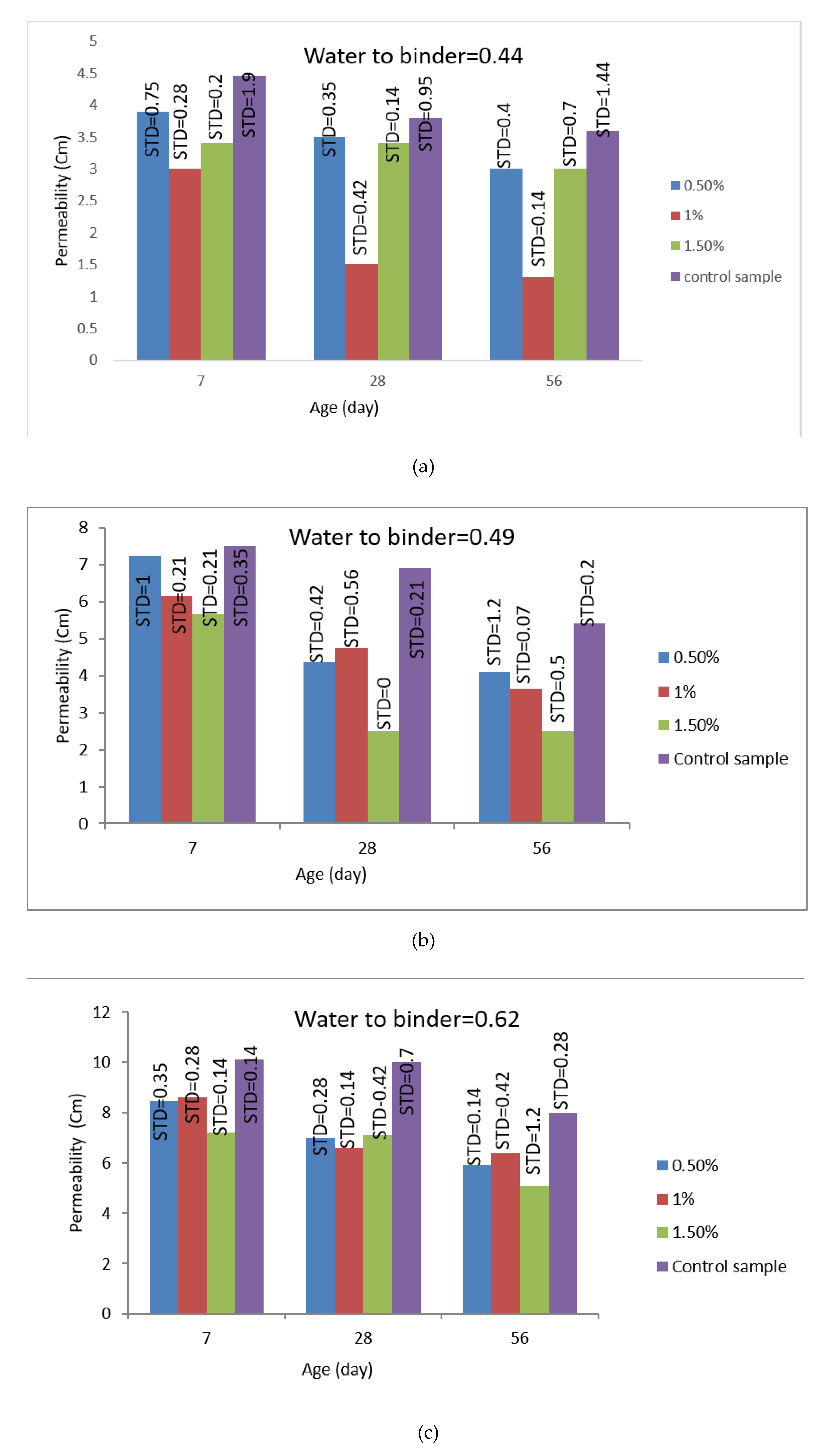

4.3. Permeability Test

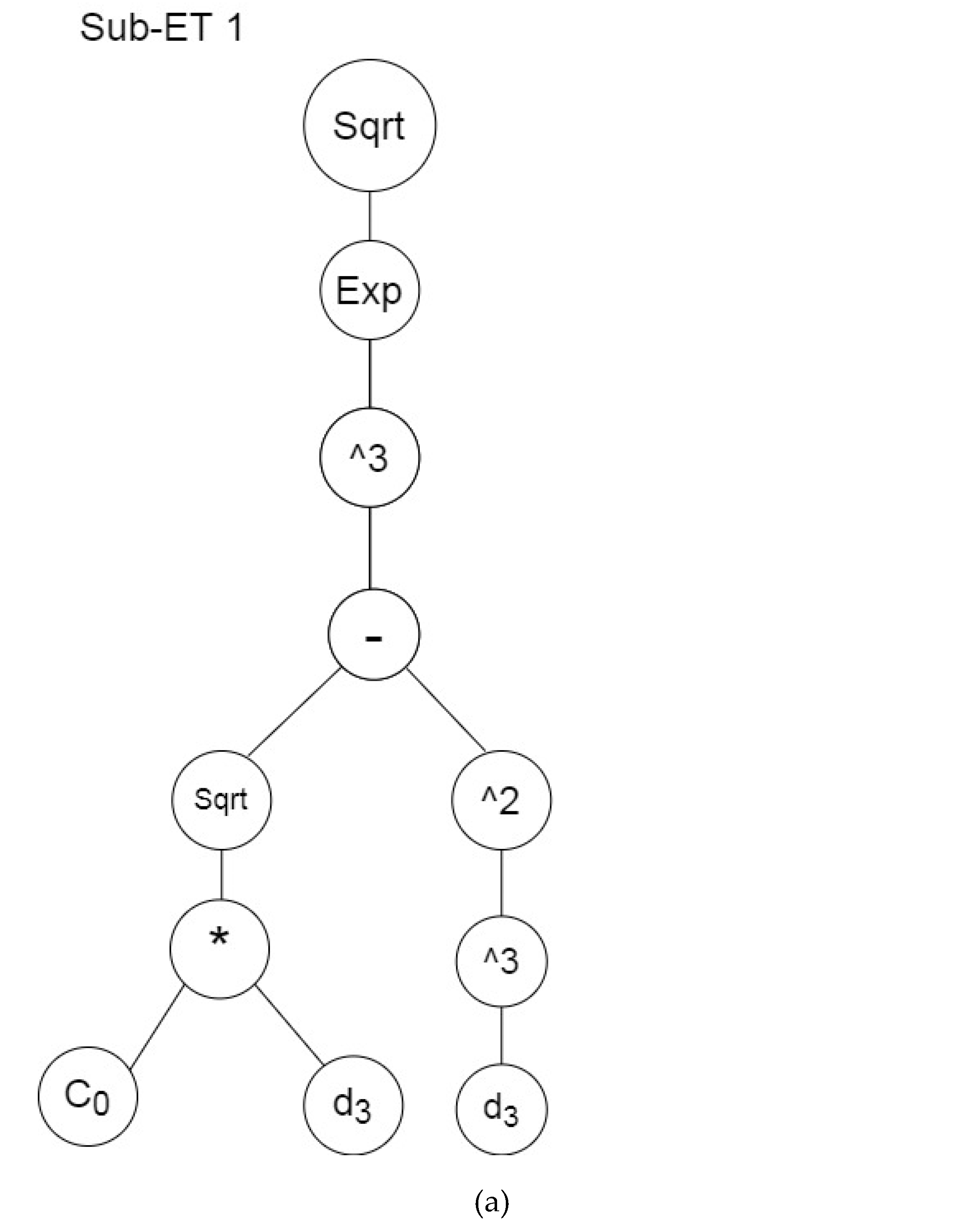

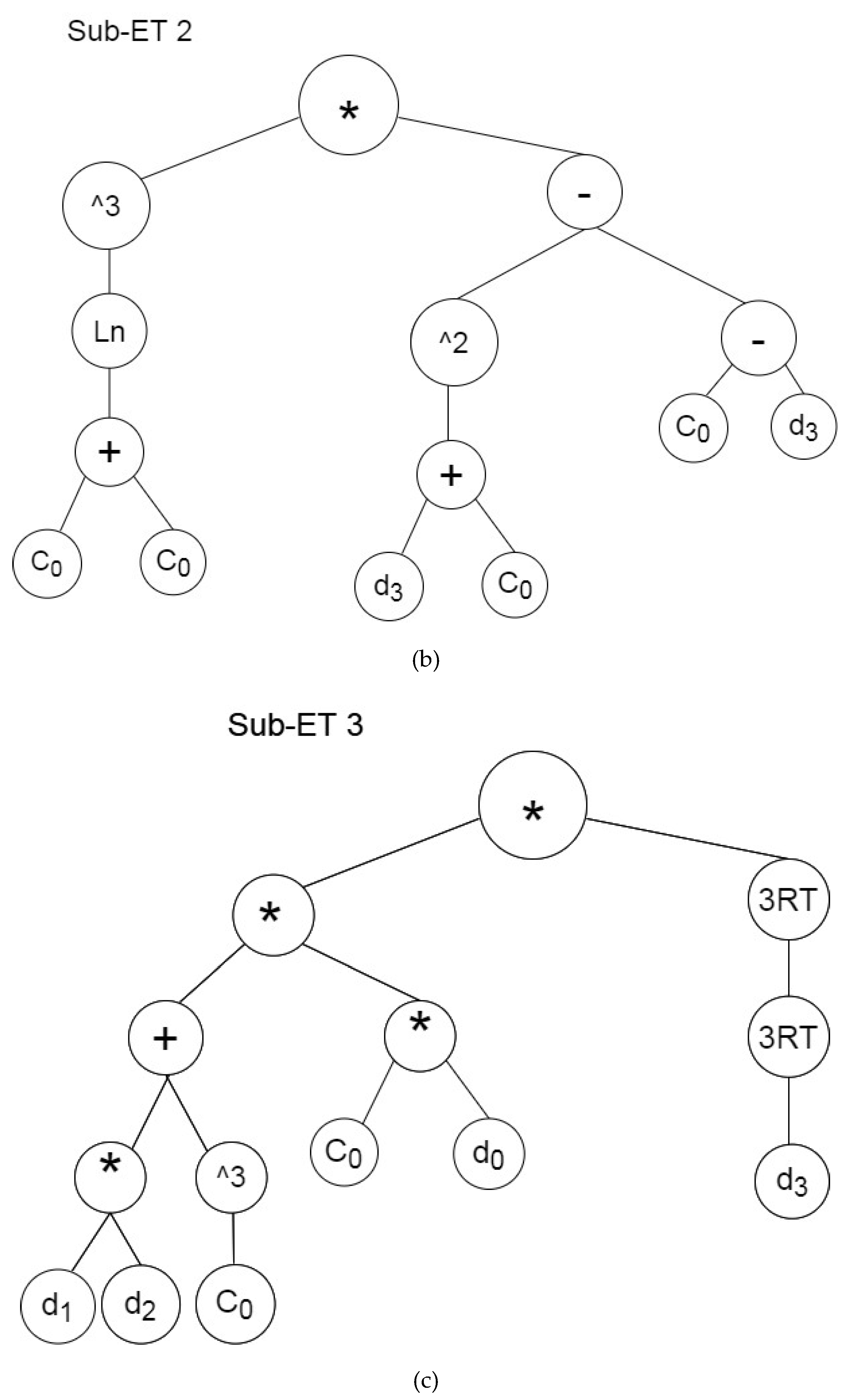

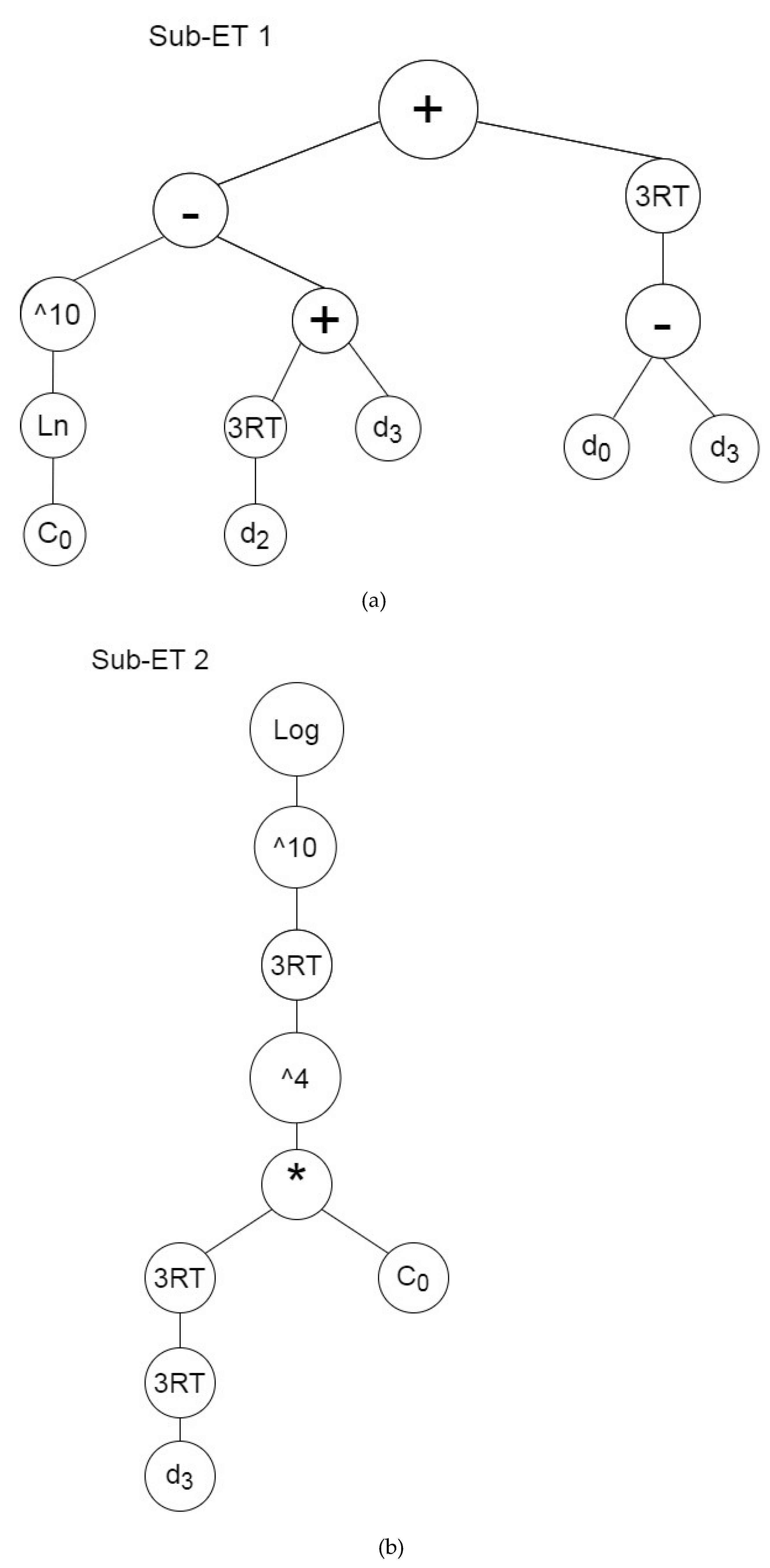

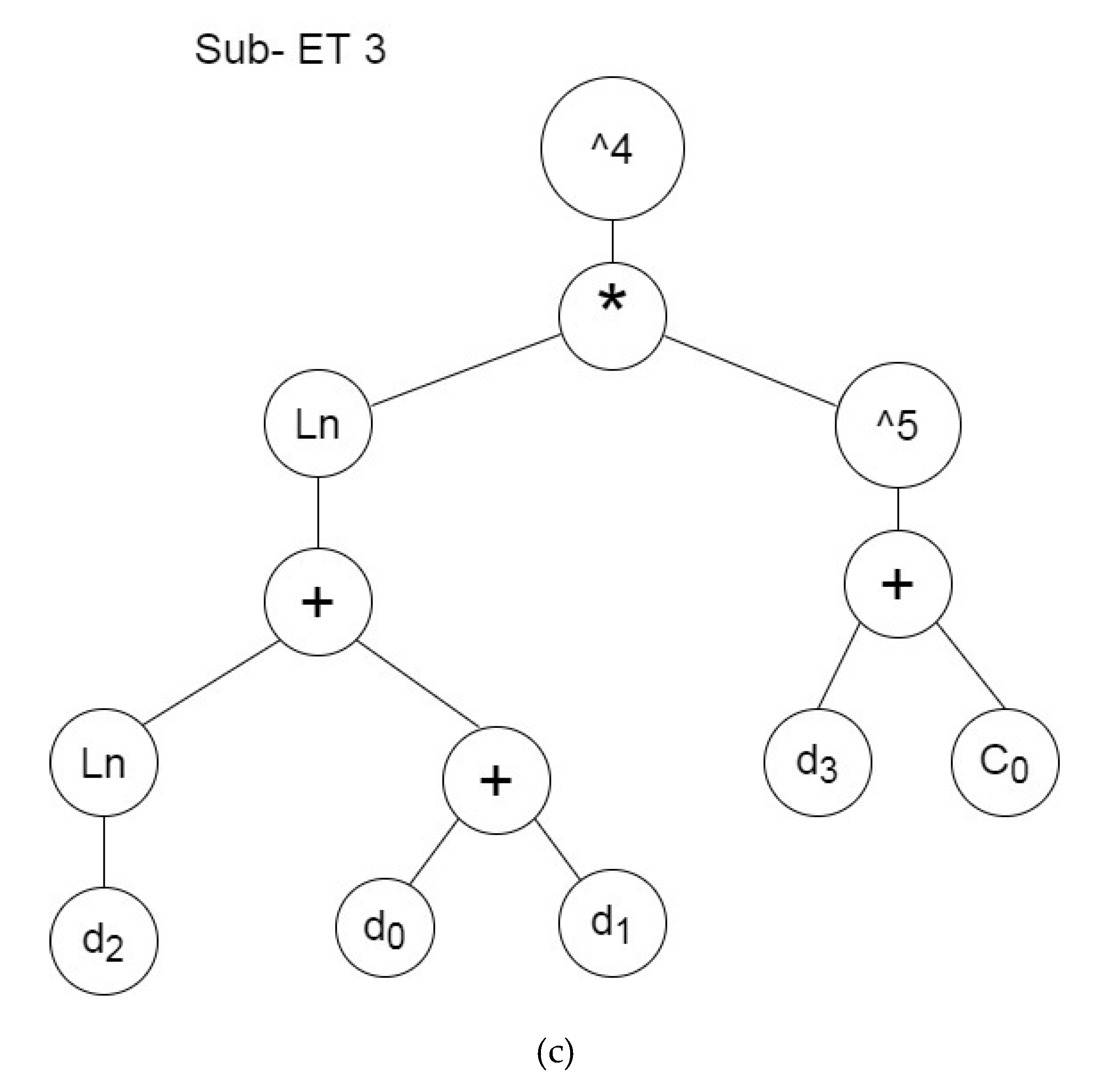

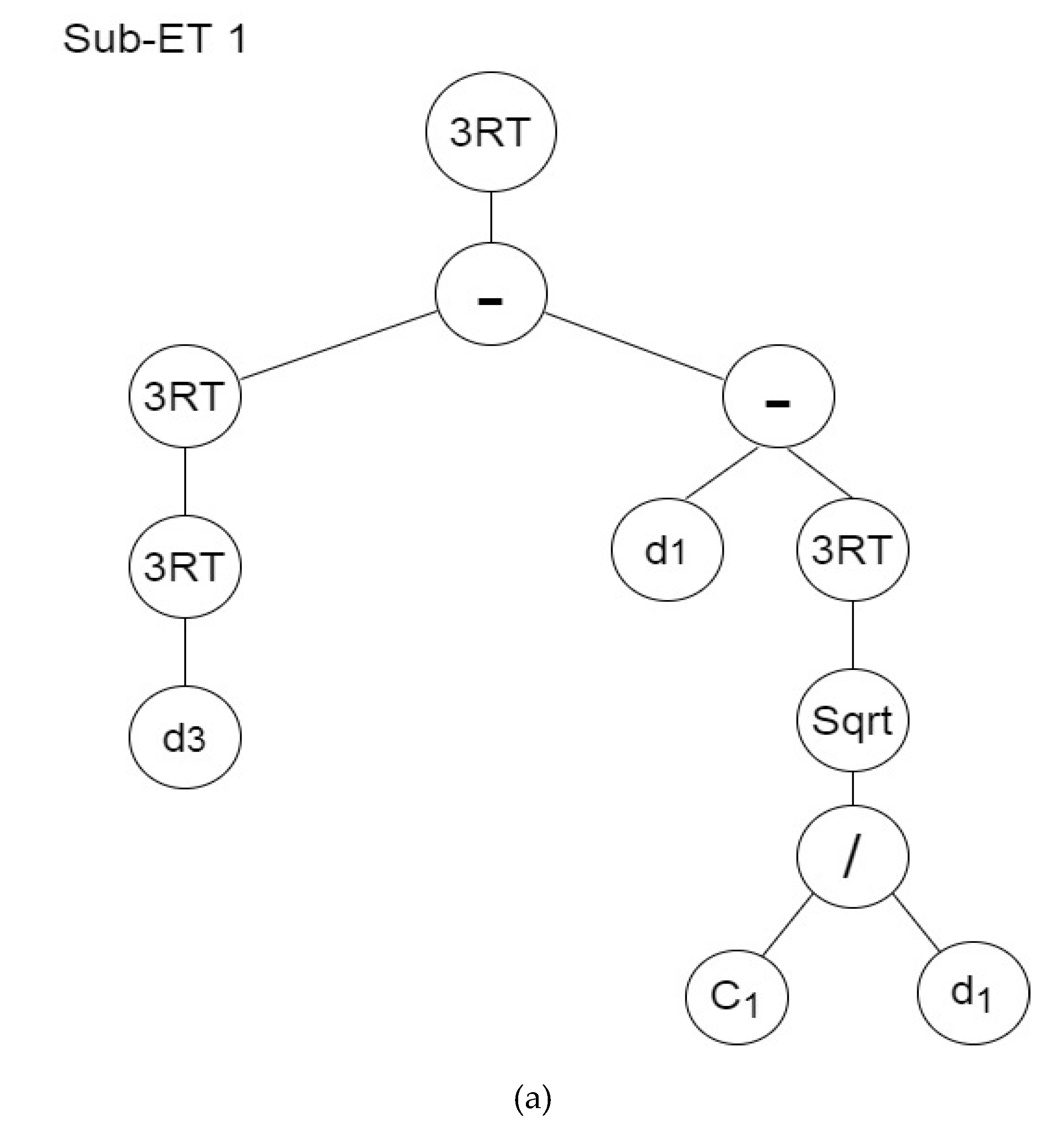

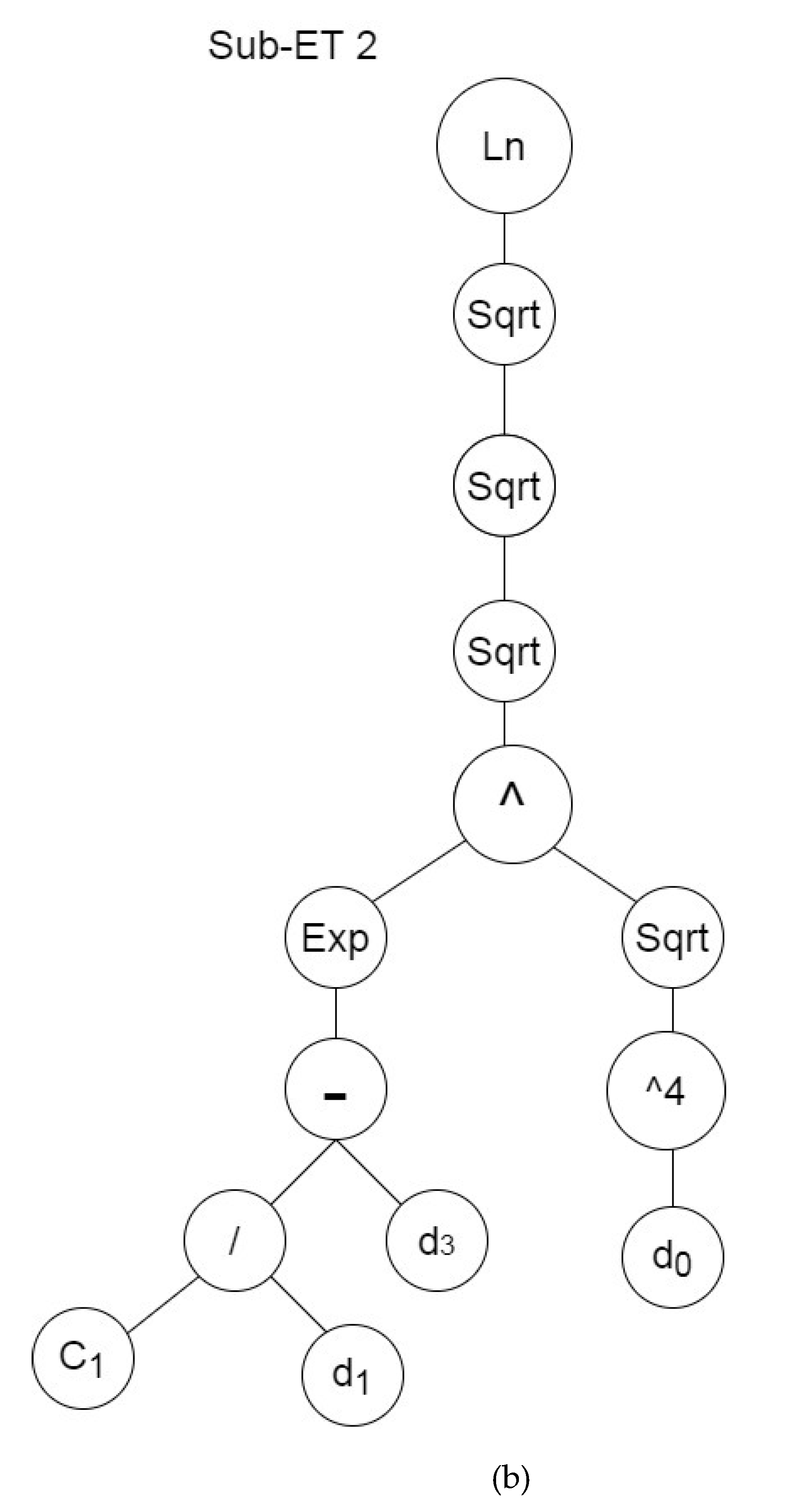

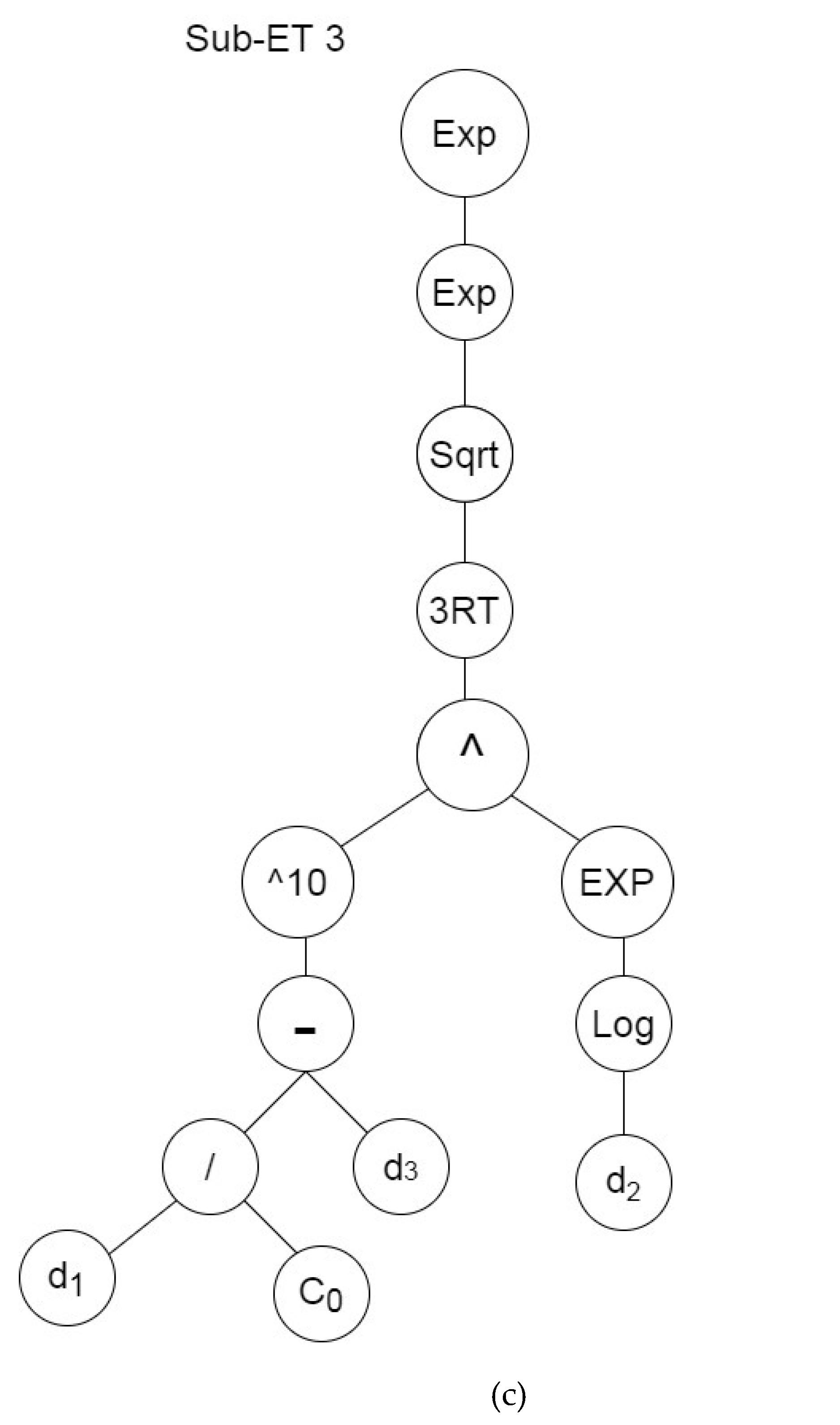

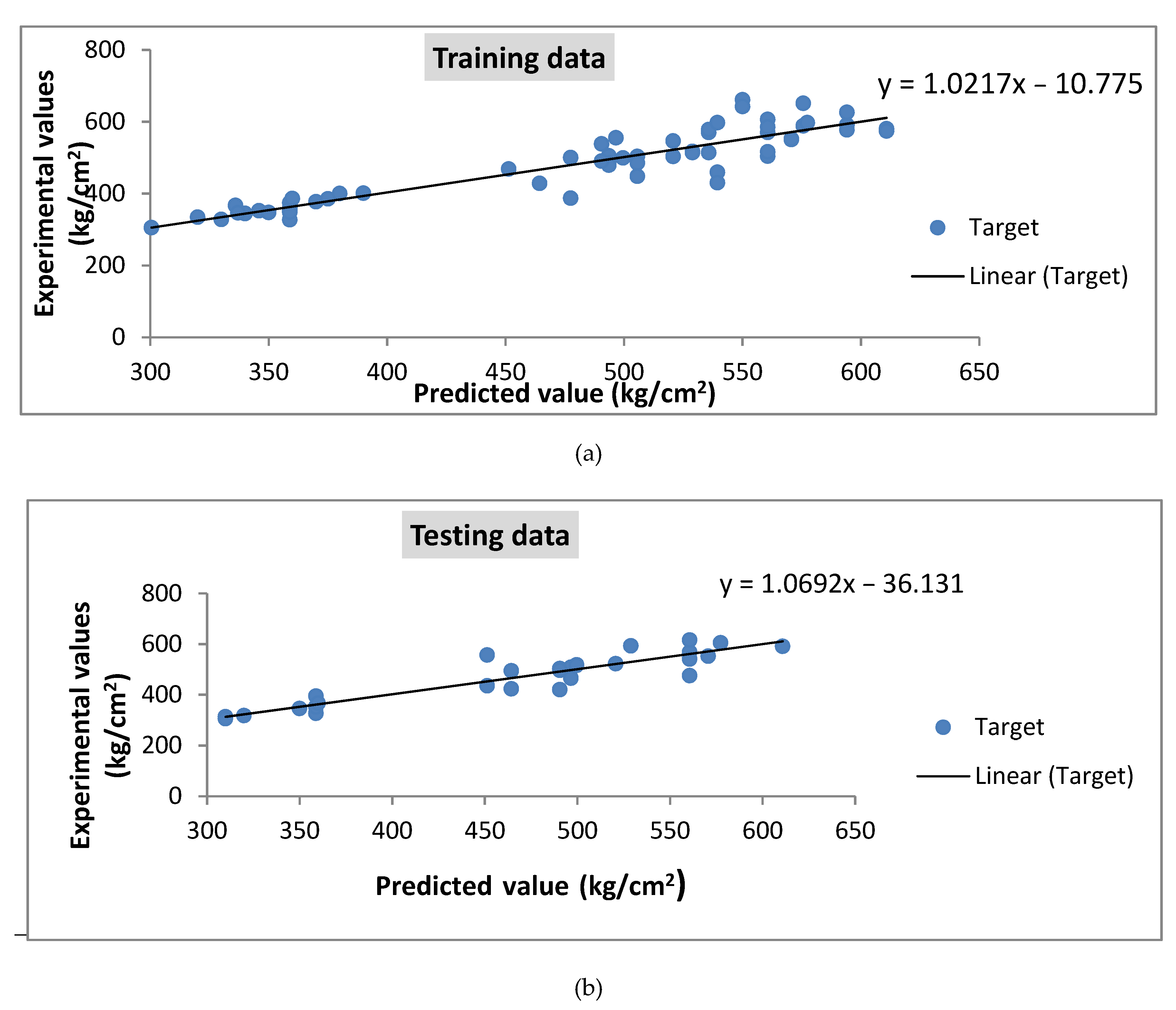

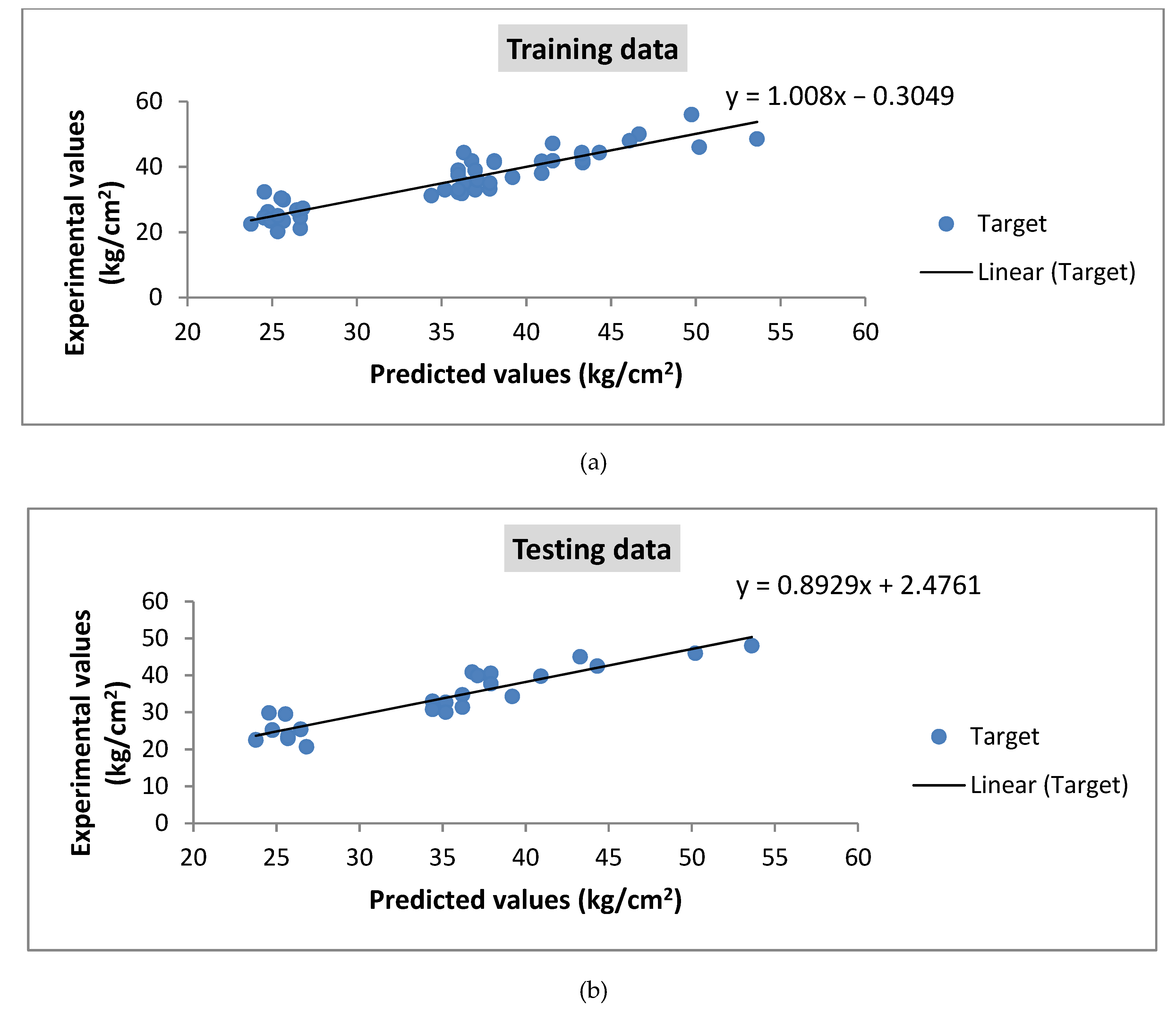

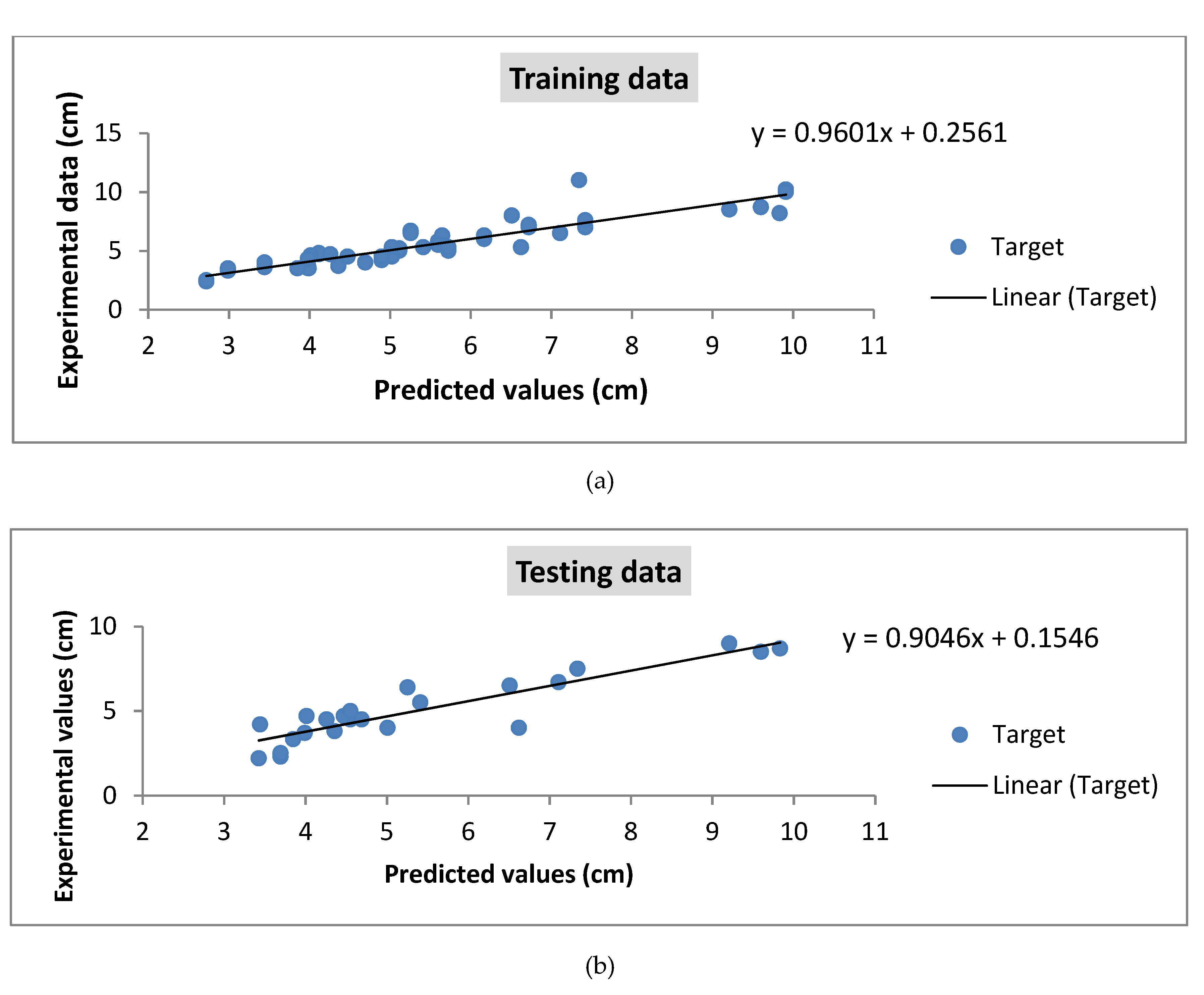

4.4. Modeling and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbols | |

| C(i,j) | Value obtained by chromosome i for fitness case j |

| CP | Curing period of concrete samples |

| D | Diameter of specimen (mm) |

| ei | Experimental value |

| Fi | Fitness function |

| h | Head length of chromosome |

| L | Length of specimen (mm) |

| M | Selection range |

| n | Number of arguments |

| NMgO | Percentage of nano-MgO |

| P | Maximum force indicated by the testing machine (N) |

| Pi | Prediction value |

| R2 | Statistical error value |

| RMSE | Root mean square error |

| SP | Percentage of super plasticizer |

| t | Tail length of chromosome |

| T | Tensile strength of cylindrical sample (MPa) |

| Tj | The target value for fitness case j |

| W/C | Water-to-cement ratio |

References

- Powers, T.C. A Working Hypothesis for Further Studies of Frost Resistance of Concrete. J. Am. Concr. Inst. 1945, 16, 245–272. [Google Scholar]

- Ebrahimi, K.H.; Daiezadeh, M.J.; Zakertabrizi, M.; Zahmatkesh, F.; Habibnejad Korayem, A. A review of the impact of micro- and nanoparticles on freeze-thaw durability of hardened concrete: Mechanism perspective. Constr. Build. Mater. 2018, 186, 1105–1113. [Google Scholar] [CrossRef]

- Du, L.; Folliard, K.J. Mechanisms of air entrainment in concrete. Cem. Concr. Res. 2005, 35, 1463–1471. [Google Scholar] [CrossRef]

- Halbiniak, J.; Langier, B. Research on the frost resistance of concretes modified with fly ash. Teka Kom. Motoryz. Energetyki Rolnictwa. 2014, 14, 23–30. [Google Scholar]

- Chung, C.W.; Shon, C.S.; Kim, Y.S. Chloride ion diffusivity of fly ash and silica fume concretes exposed to freeze–thaw cycles. Constr. Build. Mater. 2010, 24, 1739–1745. [Google Scholar] [CrossRef]

- Cwirzen, A.; Habermehl-Cwirzen, K. The Effect of Carbon Nano- and Microfibers on Strength and Residual Cumulative Strain of Mortars Subjected to Freeze-Thaw Cycles. J. Adv. Concr. Tech. 2013, 11, 80–88. [Google Scholar] [CrossRef]

- Wong, H.S.; Barakat, R.; Alhilali, A.; Saleh, M.; Cheeseman, C.R. Hydrophobic concrete using waste paper sludge ash. Cem. Concr. Res. 2015, 70, 9–20. [Google Scholar] [CrossRef]

- Du, H.; Du, S.; Liu, X. Durability performances of concrete with nano-silica. Constr. Build. Mater. 2014, 73, 705–712. [Google Scholar] [CrossRef]

- Wang, B.; Wang, L.; Lai, F. Freezing resistance of HPC with nano-SiO2. J. Wuhan Univ. Technol. Mater. Sci. 2008, 23, 85–88. [Google Scholar] [CrossRef]

- Fan, Y.; Zhang, S.; Wang, Q.; Shah, S.P. Effects of nano-kaolinite clay on the freeze–thaw resistance of concrete. Cem. Concr. Compos. 2015, 62, 1–12. [Google Scholar] [CrossRef]

- Gonzalez, M.; Tighe, S.L.; Hui, K.; Rahman, S.; Lima, A.O. Evaluation of freeze-thaw and scaling response of nano concrete for Portland Cement Concrete (PCC) pavements. Constr. Build. Mater. 2016, 120, 465–472. [Google Scholar] [CrossRef]

- Yanturina, R.A.; Trofimov, B.Y.; Ahmedjanov, R.M. The Influence of Graphite-Containing Nano-Additives on Thermo-Frost Resistance of Concrete. Proc. Eng. 2017, 206, 869–874. [Google Scholar] [CrossRef]

- Shahrajabian, F.; Behfarnia, K. The effects of nano particles on freeze and thaw resistance of alkali-activated slag concrete. Constr. Build. Mater. 2018, 176, 172–178. [Google Scholar] [CrossRef]

- Kalhori, H.; Bagherzadeh, B.; Bagherpour, R.; Akhlaghi, M.A. Experimental study on the influence of the different percentage of nanoparticles on strength and freeze–thaw durability of shotcrete. Constr. Build. Mater. 2020, 256, 119470. [Google Scholar] [CrossRef]

- Nobre, J.; Hawreen, A.; Evangelista, L.; Bravo, M. Magnesia (MgO) Production and Characterization, and Its Influence on the Performance of Cementitious Materials: A Review. Materials 2020, 13, 4752. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Tang, M.; Al Tabbaa, A. MgO expansive cement and concrete in China: Past, present and future. Cem. Concr. Res. 2014, 57, 1–12. [Google Scholar] [CrossRef]

- Moradpour, R.; Taheri-Nassaj, E.; Parhizkar, T.; Ghodsian, M. The effects of nanoscale expansive agents on the mechanical properties of non-shrink cement-based composites: The influence of nano-MgO addition. Compos. Part B 2013, 5, 193–202. [Google Scholar] [CrossRef]

- Dung, N.; Unluer, C. Improving the performance of reactive MgO cement-based concrete. Constr. Build. Mater. 2016, 126, 747–758. [Google Scholar] [CrossRef]

- Kabir, H.; Hooton, R. Evaluating soundness of concrete containing shrinkage-compensating MgO admixtures. Constr. Build. Mater. 2020, 253, 119141. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Alavi, A.H.; Ryan, C. Handbook of Genetic Programming Applications; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Ferreira, C. Gene expression programming: A new adaptive algorithm for solving problems. Complex. Syst. 2011, 13, 87–129. [Google Scholar]

- Ferreira, C. Gene Expression Programming in Problem Solving. In Soft Computing and Industry; Roy, R., Köppen, M., Ovaska, S., Furuhashi, T., Hoffmann, F., Eds.; Springer: London, UK, 2002. [Google Scholar] [CrossRef]

- Ferreira, C. Gene Expression Programming: Mathematical Modeling by an Artificial Intelligence, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Gandomi, A.H.; Alavi, A.H.; Mirzahosseini, M.R.; Moghadasnejad, F. Nonlinear Genetic-Based Models for Prediction of Flow Number of Asphalt Mixtures. J. Mater. Civil. Eng. 2011, 23, 248–263. [Google Scholar] [CrossRef]

- Ozcan, F. Gene expression programming based formulations for splitting tensile strength of concrete. Constr. Build. Mater. 2012, 26, 404–410. [Google Scholar] [CrossRef]

- Gandomi, A.H.; ASCE, S.M.; Karim Babanajad, S.; Alavi, A.H.; Farnam, Y. Novel Approach to Strength Modeling of Concrete under Triaxial Compression. J. Mater. Civil. Eng. 2012, 24, 1132–1143. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Alavi, A.H.; Kazemi, S.; Gandomi, M. Formulation of shear strength of slender RC beams using gene expression programming, part I: Without shear reinforcement. Auto. Constr. 2014, 42, 112–121. [Google Scholar] [CrossRef]

- Alkroosh, I.; Ammash, H. Soft computing for modeling punching shear of reinforced concrete flat slabs. Ain. Shams. Eng. J. 2015, 6, 439–448. [Google Scholar] [CrossRef]

- Mahdinia, S.; Eskandari-Naddaf, H.; Shadnia, R. Effect of cement strength class on the prediction of compressive strength of cement mortar using GEP method. Constr. Build. Mater. 2019, 198, 27–41. [Google Scholar] [CrossRef]

- Shahmansouri, A.A.; Akbarzadeh Bengar, H.; Jahani, E. Predicting compressive strength and electrical resistivity of eco-friendly concrete containing natural zeolite via GEP algorithm. Constr. Build. Mater. 2019, 223, 116883. [Google Scholar] [CrossRef]

- Farjad Iqbal, M.; Liu, Q.F.; Azim, I.; Zhu, X.; Yang, J.; Javed, M.F.; Rauf, M. Prediction of mechanical properties of green concrete incorporating waste foundry sand based on gene expression programming. J. Hazard. Mater. 2020, 384, 121322. [Google Scholar] [CrossRef] [PubMed]

- Behnia, D.; Behnia, M.; Shahriar, K.; Goshtasbi, K. A New Predictive Model for Rock Strength Parameters Utilizing GEP Method. Proc. Eng. 2017, 191, 591–599. [Google Scholar] [CrossRef]

- Yeddula, B.S.R.; Karthiyaini, S. Experimental investigations and GEP modelling of compressive strength of ferrosialate based geopolymer mortars. Constr. Build. Mater. 2020, 236, 117602. [Google Scholar] [CrossRef]

- ASTM C150. Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM C33/C33M-18. Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Baghdadi, Y.; Youssef, L.Y.; Bouhadir, K.; Harb, M.; Mustapha, S.; Tehrani-Bagha, A. The effects of modified zinc oxide nanoparticles on the mechanical/thermal properties of epoxy resin. J. Appl. Polym. Sci. 2020, 137, 43–49330. [Google Scholar] [CrossRef]

- ASTM C666/C666M-15. Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar] [CrossRef]

- ASTM C496/C496M-17. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- DIN 1048 (Part-5): German Standard for determination of Permeability of Concrete. Available online: https://www.mystandards.biz/standard/din-1048-5-1.6.1991.html (accessed on 1 January 1991).

- Ferreira, C. Automatically Defined Functions in Gene Expression Programming. In Genetic Systems Programming. Studies in Computational Intelligence; Nedjah, N., Mourelle, L.M., Abraham, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar] [CrossRef]

- GEPSOFT, GeneXproTools. Version 5.0. 2013. Available online: https://www.gepsoft.com/ (accessed on 1 May 2013).

| Chemical Analysis (%) | Cement Type 2 Portland |

|---|---|

| CaO | 63.35 |

| SiO2 | 21.32 |

| Fe2O3 | 3.77 |

| MgO | 2.44 |

| SO32− | 1.98 |

| Na2O | 0.24 |

| K2O | 0.63 |

| Cl− | 0.01 |

| Blaine (cm2/g) | 3210 |

| Sieve No. (BS) | Remaining Mass on Sieve (gr) | Remaining Mass on Sieve (%) | Cumulative Fraction Passing (%) | Cumulative Fraction Remaining (%) |

|---|---|---|---|---|

| 1” | 0 | 0 | 100 | 0 |

| 3/4” | 150 | 5 | 95 | 5 |

| 1/2” | 1000 | 33.4 | 61.6 | 38.4 |

| 3/8” | 870 | 29 | 32.6 | 67.4 |

| #4 | 930 | 31.1 | 1.5 | 98.5 |

| Pan | 40 | 1.3 | 0 | 100 |

| Sieve No. | Remaining Mass (gr) | Remaining Mass (%) | Cumulative Fraction Remaining |

|---|---|---|---|

| #4 | 170 | 17 | 17 |

| #8 | 280 | 28.5 | 45.5 |

| #16 | 140 | 14.2 | 59.7 |

| #30 | 180 | 18.3 | 78 |

| #50 | 130 | 13.2 | 91.2 |

| #100 | 70 | 7.1 | 98.3 |

| #200 | 10 | 1.02 | 99.3 |

| Magnesium Oxide Nano-Powder (MgO) Certificate of Analysis | |||

|---|---|---|---|

| MgO | Na | K | Ca |

| >99% | <750 ppm | <218 | <760 |

| Type of Samples | Water-to-Binder Ratio | Percentage of Nano-MgO | Super Plasticizer | Curing Period |

|---|---|---|---|---|

| Cubic samples (10 × 10 × 10) | 0.44 0.49 0.62 | 0%, 0.5%, 1%, 1.5% | 0%, 0.5%, 1% | 7, 28, 56 days |

| Cylinder samples (10 × 20) |

| Input Variables | Range of Variation | Output Variables | Range of Variables |

|---|---|---|---|

| Water-to-binder ratio | 0.44–0.62 | Compressive strength (kg/cm2) | 305–661 |

| Curing Age (day) | 7–56 | Tensile strength (kg/cm2) | 20–56 |

| Nano-MgO % | 0–1.5 | Permeability (cm) | 2.4–11 |

| Super Plasticizer % | 0–1 |

| Model’s Properties | GEP 1 | GEP 2 | GEP 3 | GEP 4 | GEP 5 | GEP6 | GEP 7 | GEP 8 |

|---|---|---|---|---|---|---|---|---|

| Number of chromosomes | 30 | 30 | 30 | 30 | 35 | 35 | 35 | 35 |

| Number of head size | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 |

| Number of genes | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Linking function | Addition | Addition | Multiplication | Multiplication | Addition | Addition | Multiplication | Multiplication |

| Constant per gene | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 |

| GEP Model | Predictive Equation of GEP for Compressive Strength |

|---|---|

| GEP 1 | |

| GEP Model | Predictive Equation of GEP for Tensile Strength |

|---|---|

| GEP 1 | |

| GEP Model | Predictive Equation of GEP for Permeability |

|---|---|

| GEP 6 | |

| GEP Model | R2 | Root Mean Square Error (RMSE) (Fitness Value) |

|---|---|---|

| GEP1 for compressive strength | Training = 0.98 Testing = 0.98 | Training = 24.16 Testing = 24.28 |

| GEP1 for tensile strength | Training = 0.97 Testing = 0.96 | Training = 227.1 Testing = 225.25 |

| GEP6 for permeability | Training = 0.96 Testing = 0.95 | Training = 558.14 Testing = 528.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yazdchi, M.; Foroughi Asl, A.; Talatahari, S.; Gandomi, A.H. Evaluation of the Mechanical Properties of Normal Concrete Containing Nano-MgO under Freeze–Thaw Conditions by Evolutionary Intelligence. Appl. Sci. 2021, 11, 2529. https://doi.org/10.3390/app11062529

Yazdchi M, Foroughi Asl A, Talatahari S, Gandomi AH. Evaluation of the Mechanical Properties of Normal Concrete Containing Nano-MgO under Freeze–Thaw Conditions by Evolutionary Intelligence. Applied Sciences. 2021; 11(6):2529. https://doi.org/10.3390/app11062529

Chicago/Turabian StyleYazdchi, Mehdi, Ali Foroughi Asl, Siamak Talatahari, and Amir H. Gandomi. 2021. "Evaluation of the Mechanical Properties of Normal Concrete Containing Nano-MgO under Freeze–Thaw Conditions by Evolutionary Intelligence" Applied Sciences 11, no. 6: 2529. https://doi.org/10.3390/app11062529

APA StyleYazdchi, M., Foroughi Asl, A., Talatahari, S., & Gandomi, A. H. (2021). Evaluation of the Mechanical Properties of Normal Concrete Containing Nano-MgO under Freeze–Thaw Conditions by Evolutionary Intelligence. Applied Sciences, 11(6), 2529. https://doi.org/10.3390/app11062529