A Sliding Surface for Controlling a Semi-Bridgeless Boost Converter with Power Factor Correction and Adaptive Hysteresis Band

Abstract

1. Introduction

2. Sliding Mode Control Design

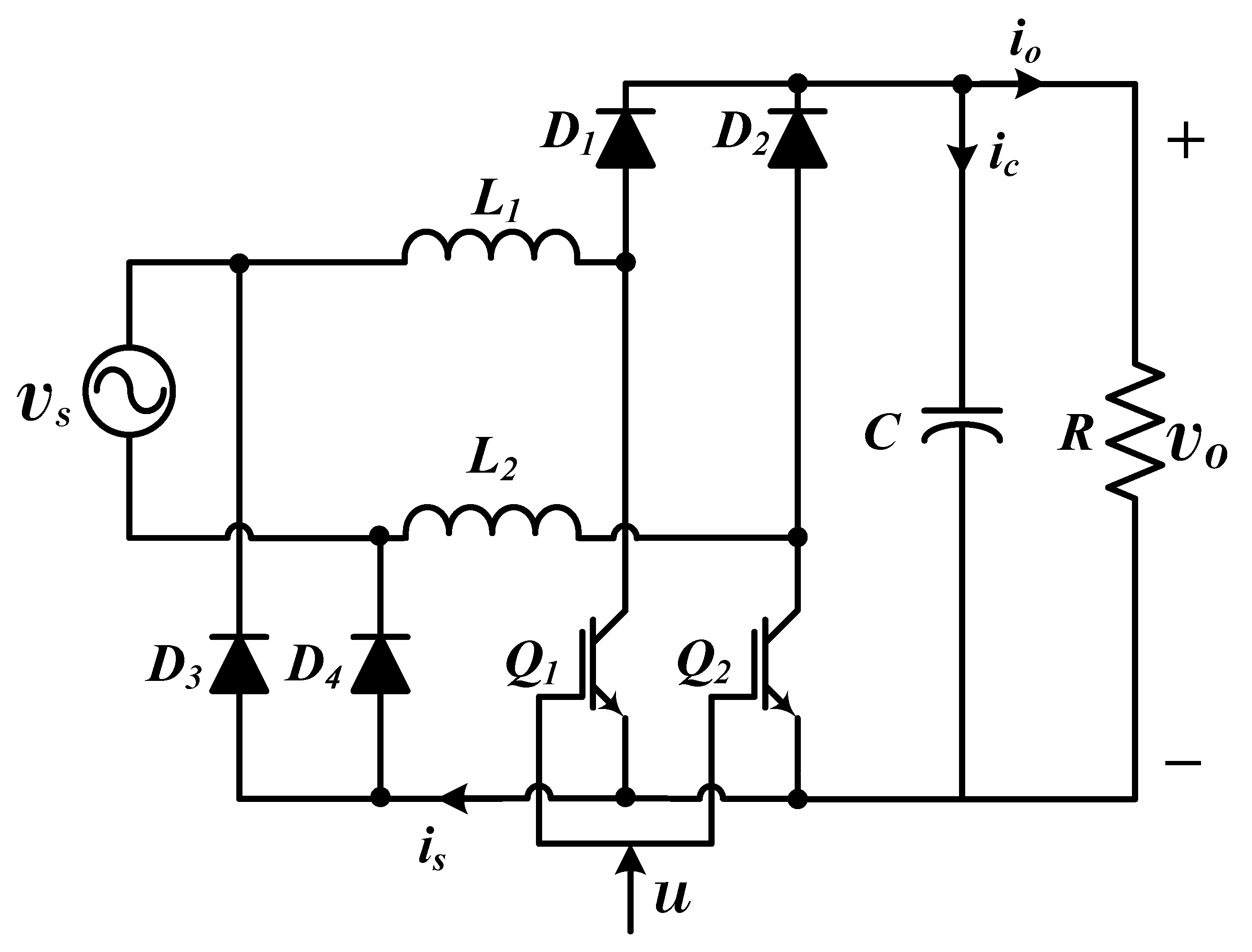

2.1. First Step: SBBC Mathematical Modeling

2.2. Second Step: Sliding Surface Proposal

2.3. Third Step: Validation of Transversality Condition

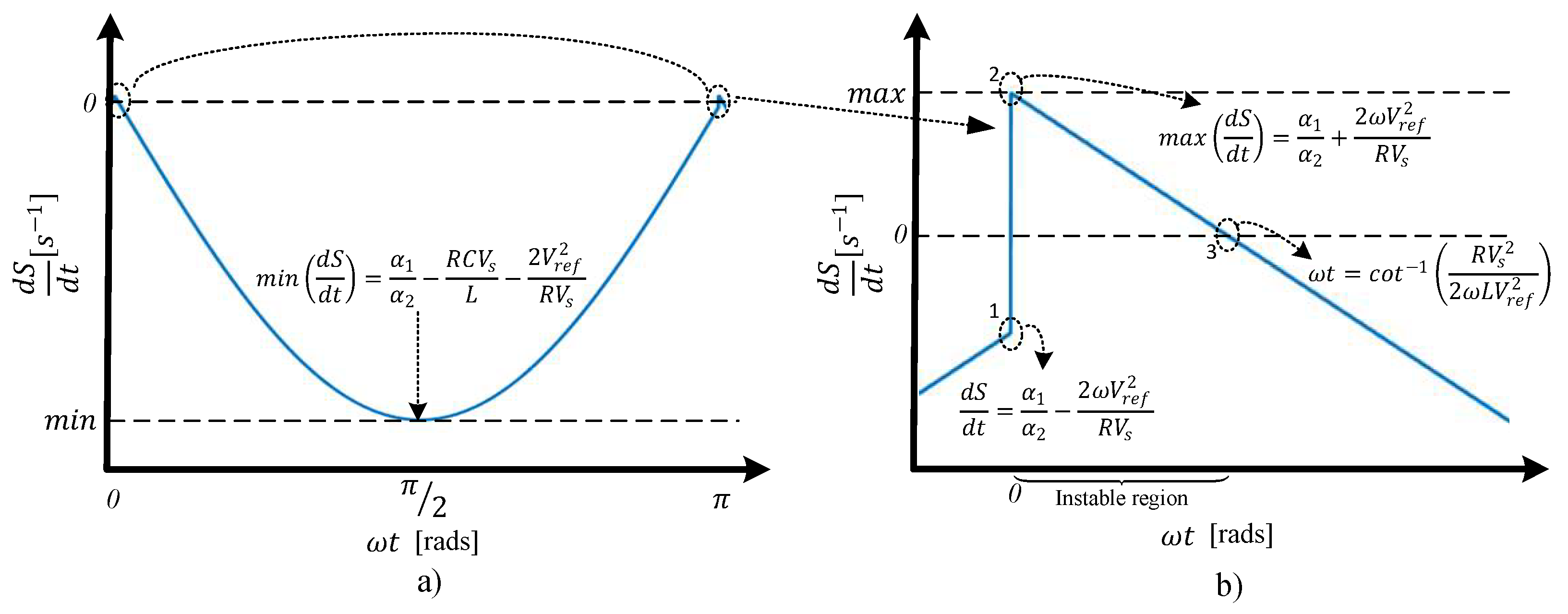

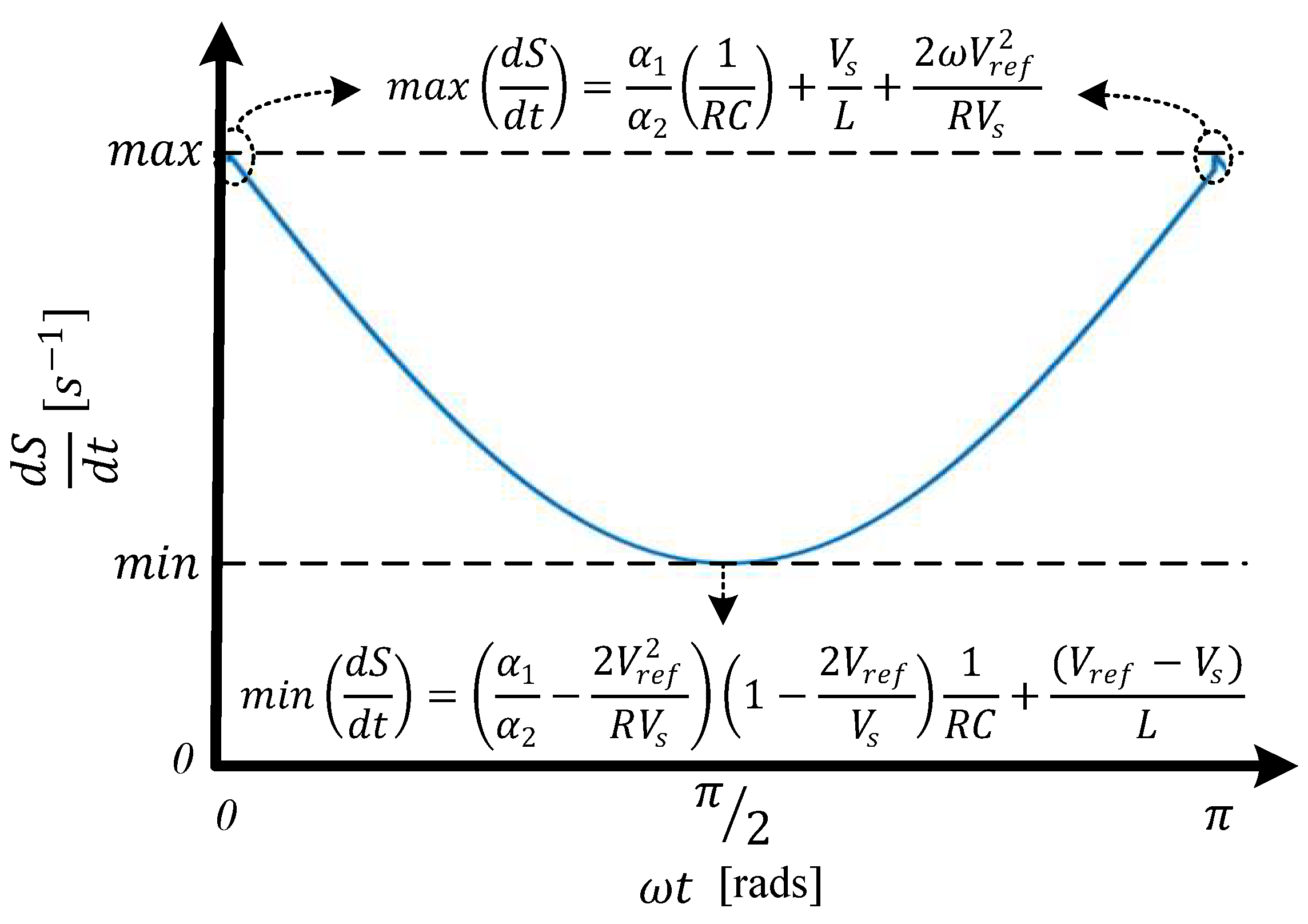

2.4. Fourth Step: Validation of Existence Condition

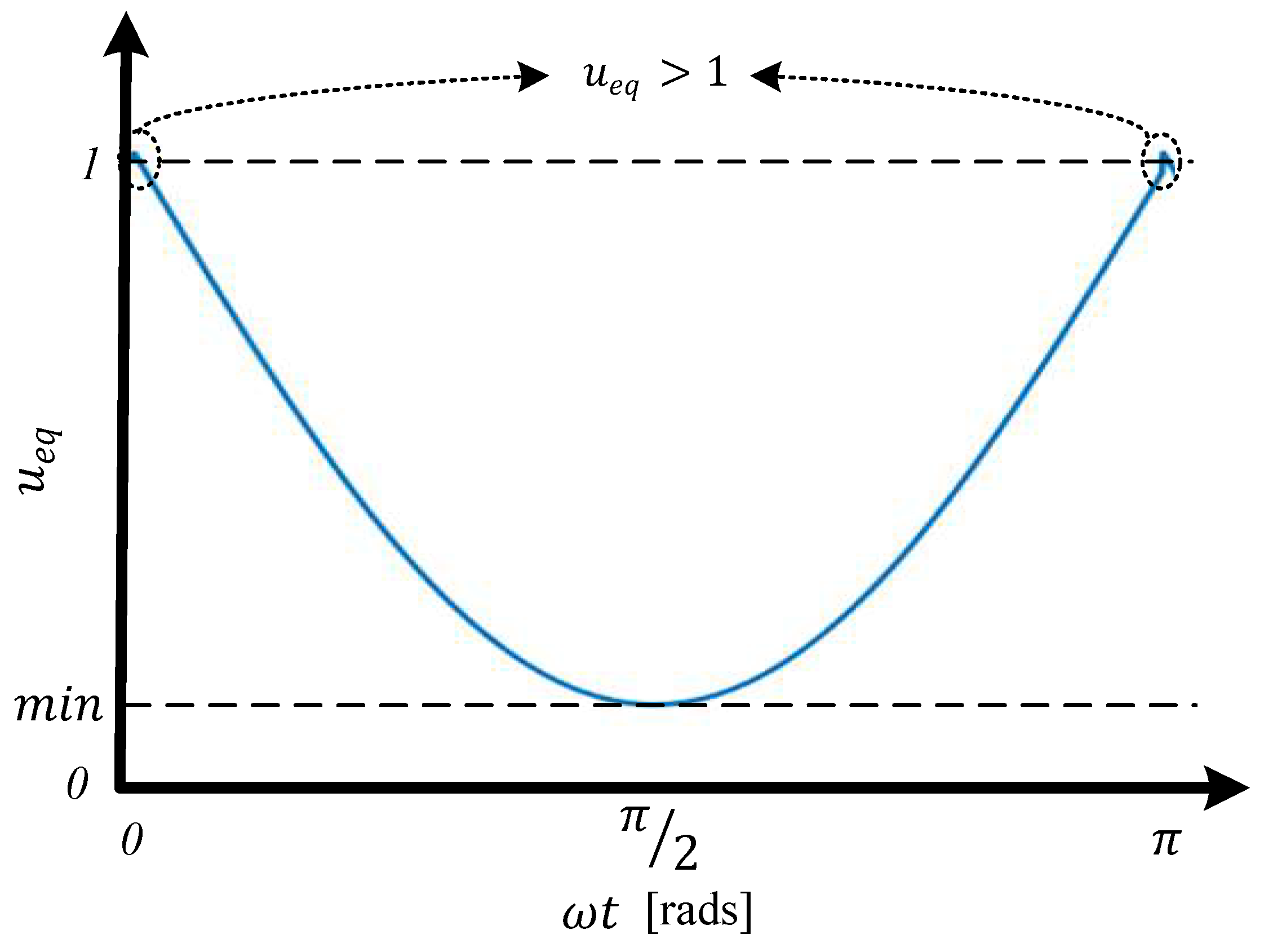

2.5. Fifth Step: Validation of Equivalent Control

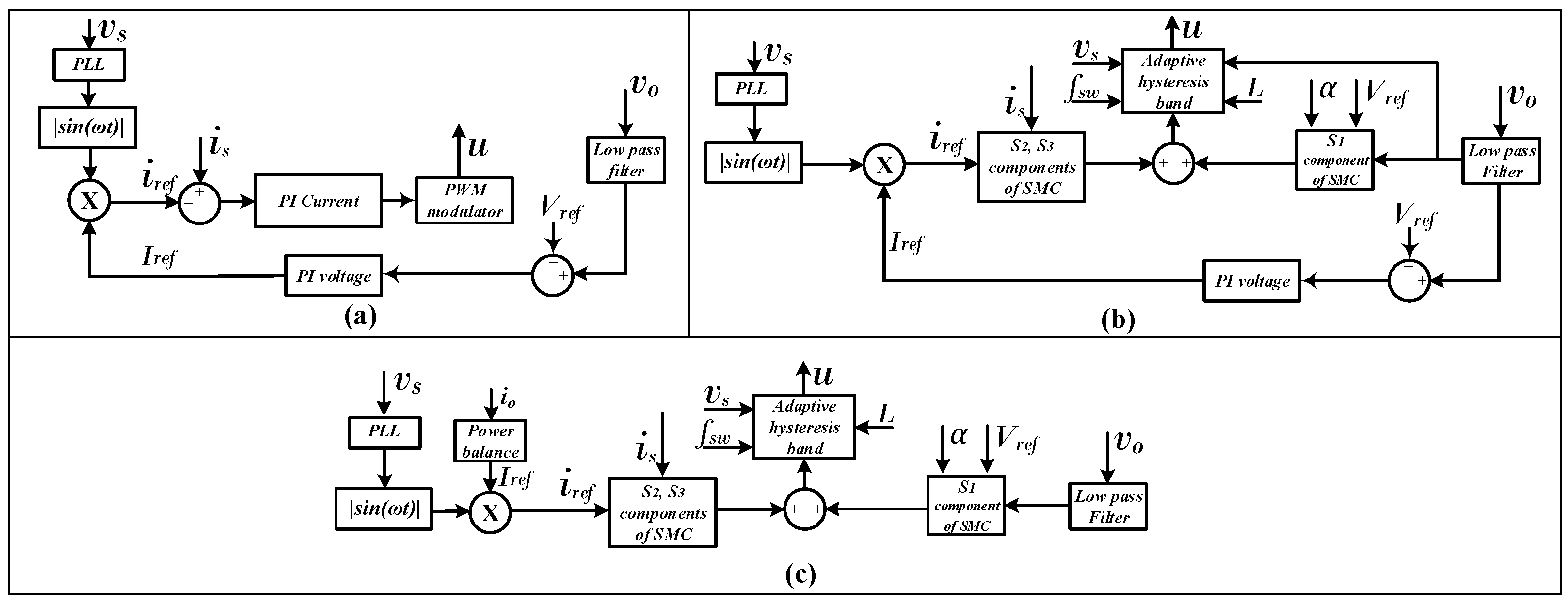

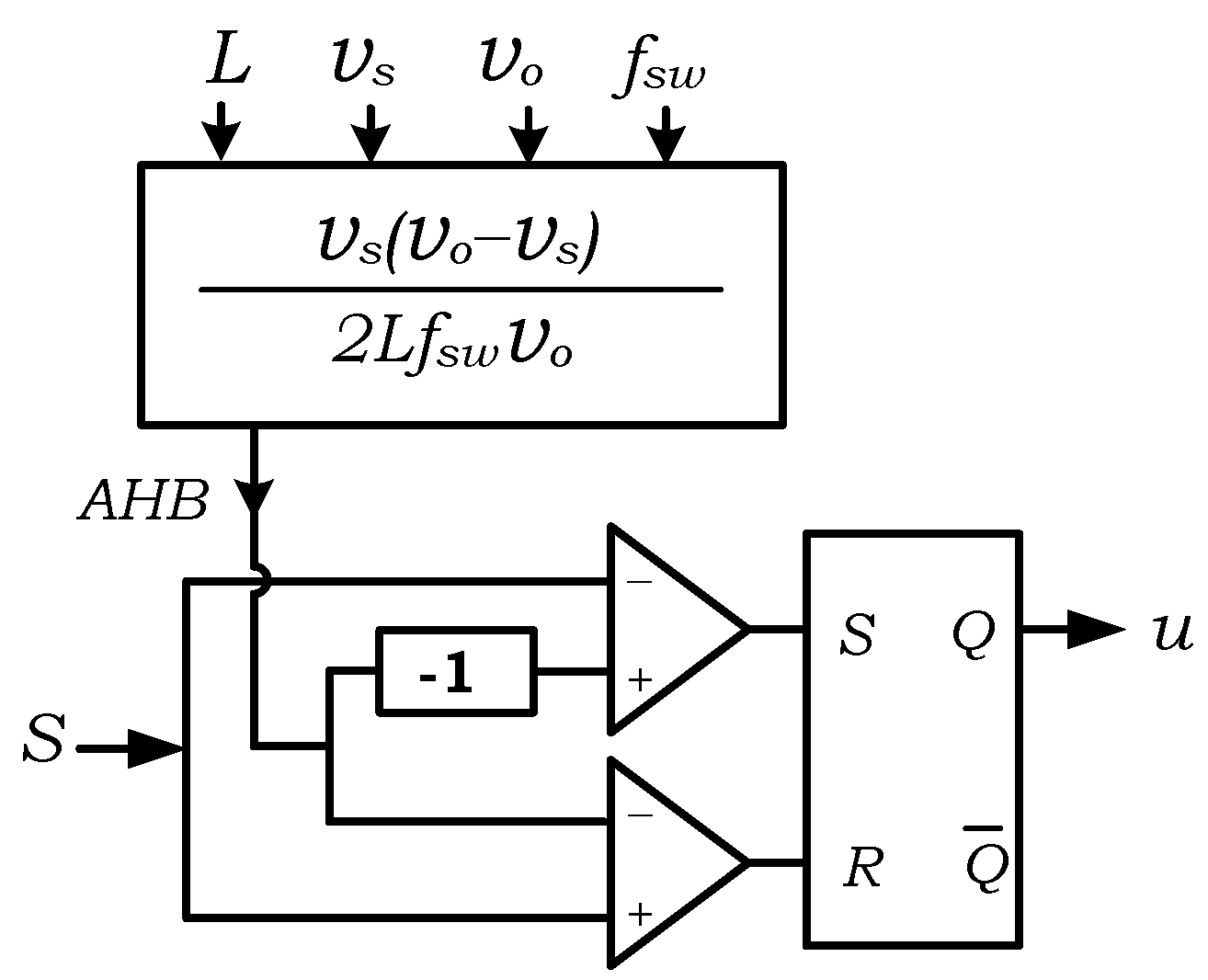

3. Control Schemes

4. Simulation Results

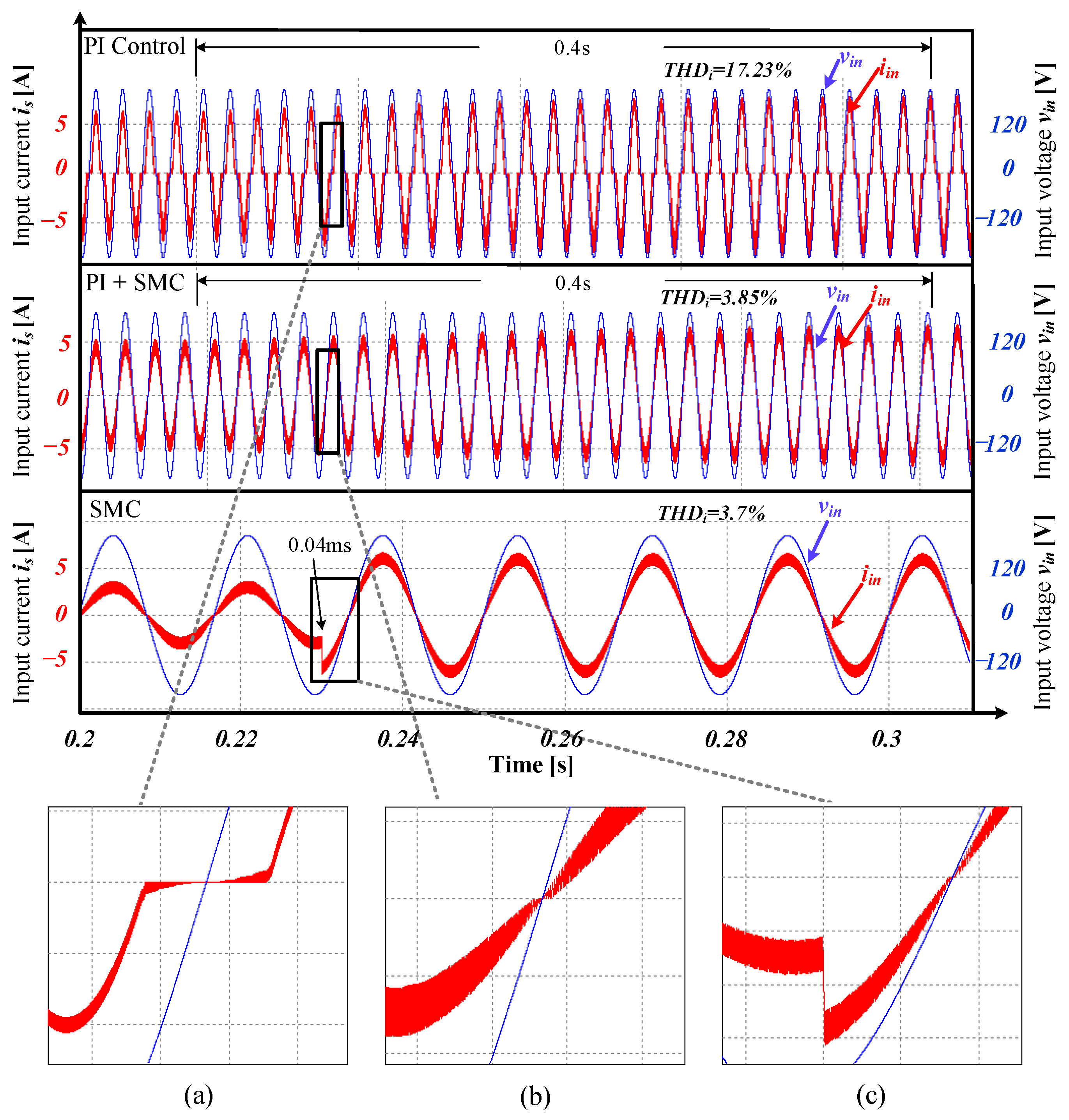

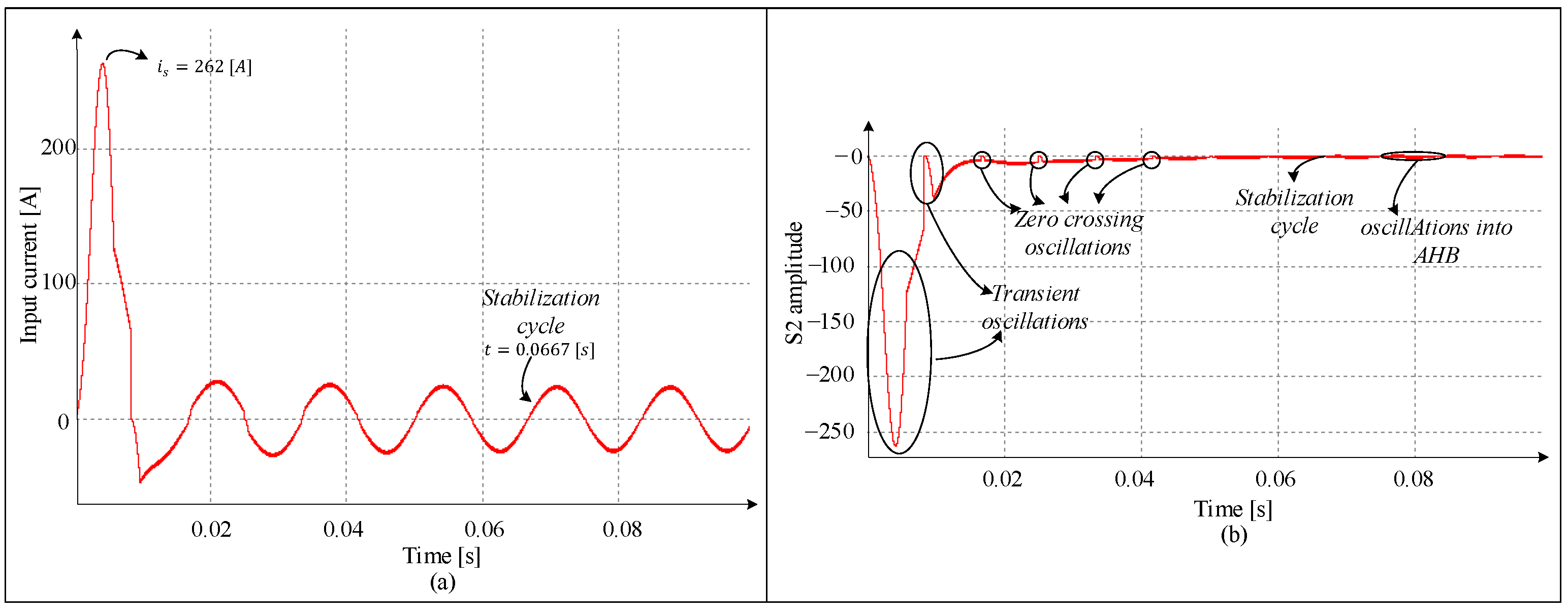

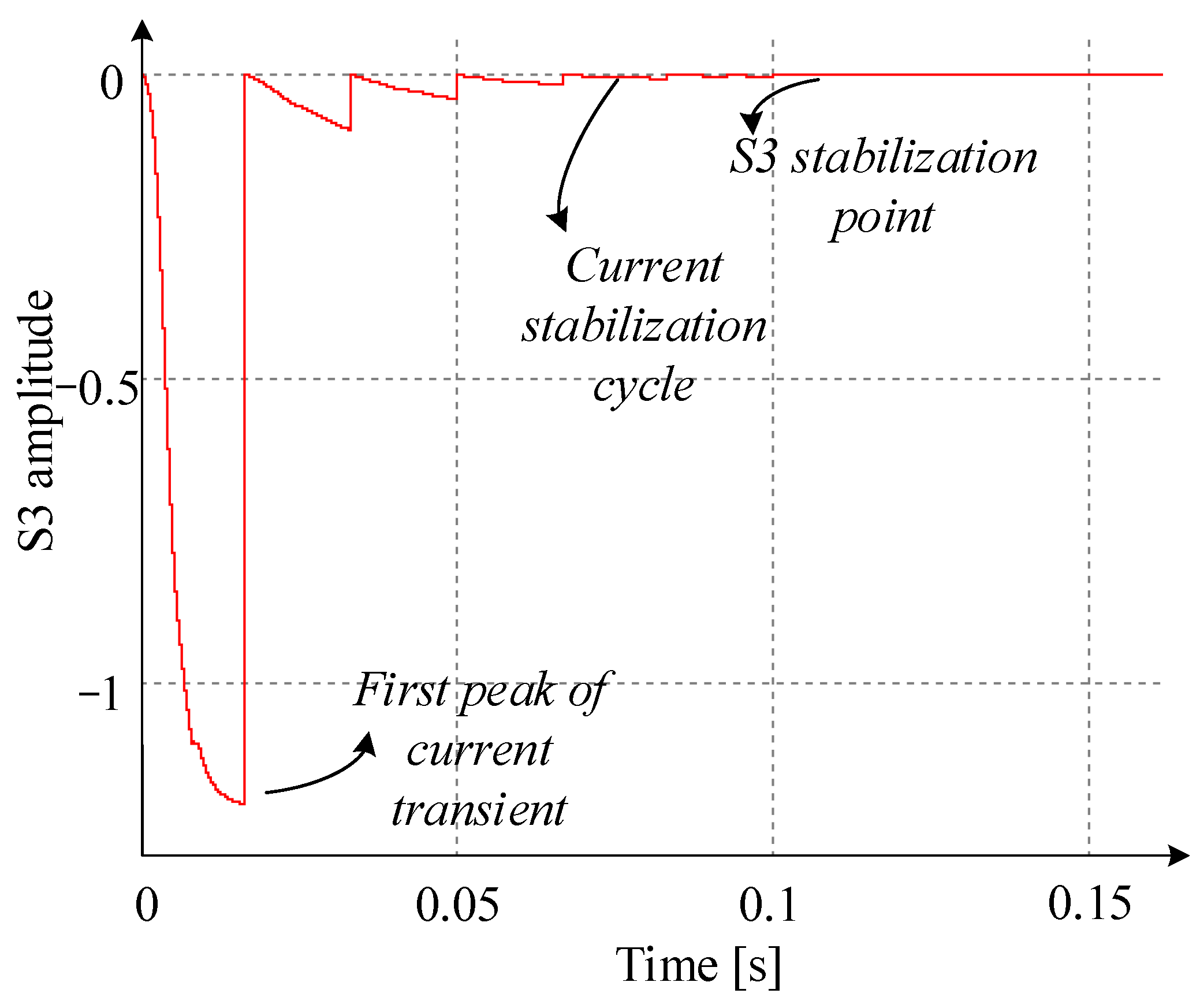

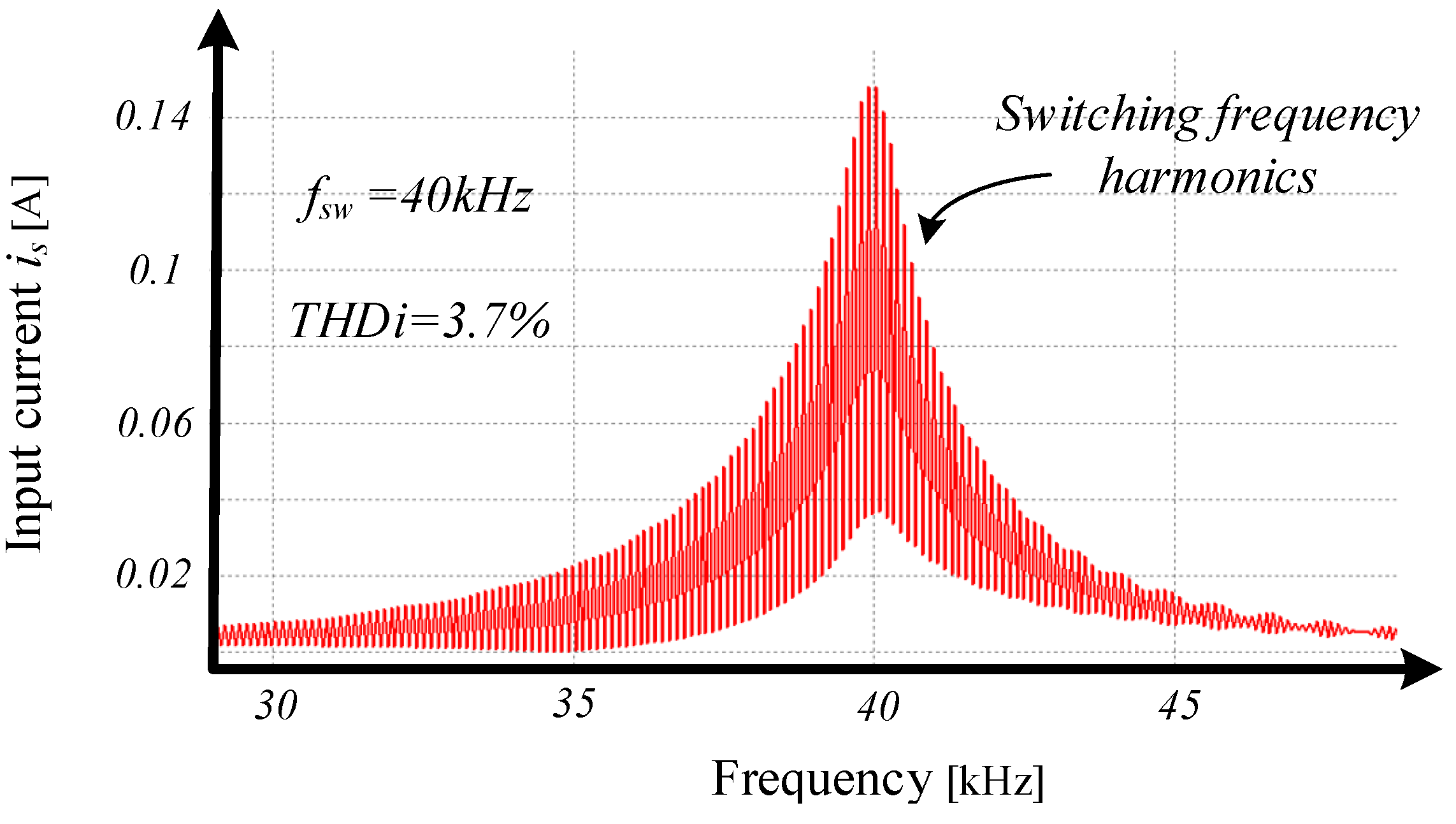

4.1. Comparative Analysis for PI, PI-SMC and SMC

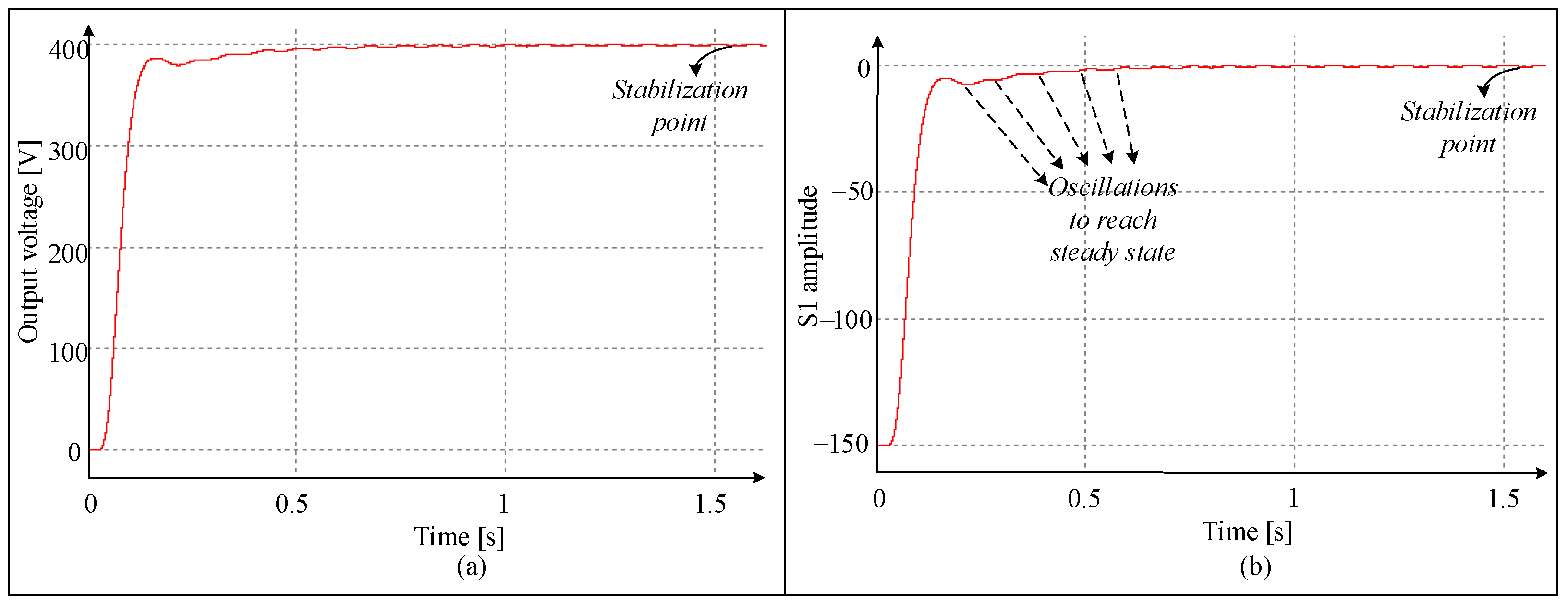

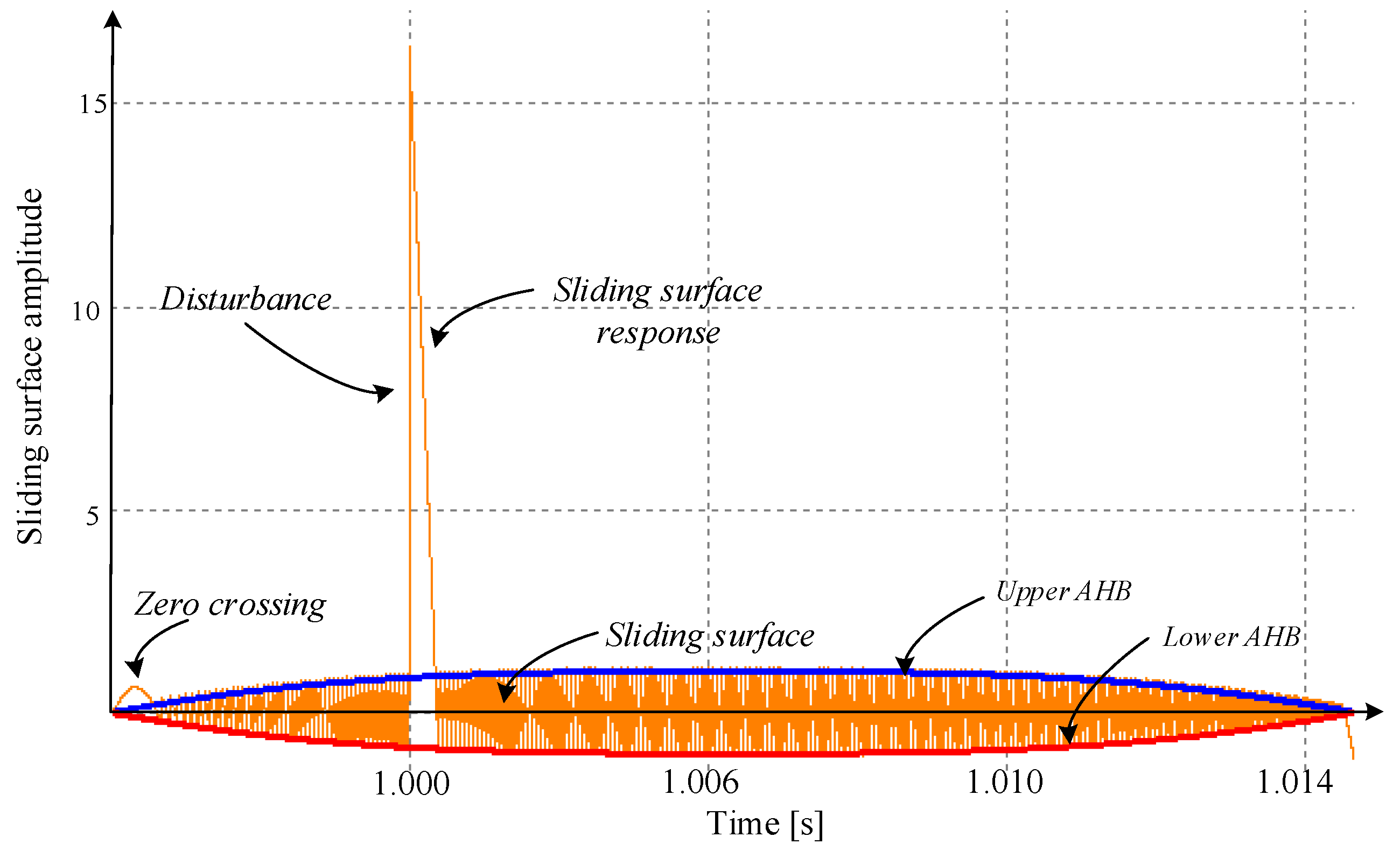

4.2. Sliding Mode Control Behavior

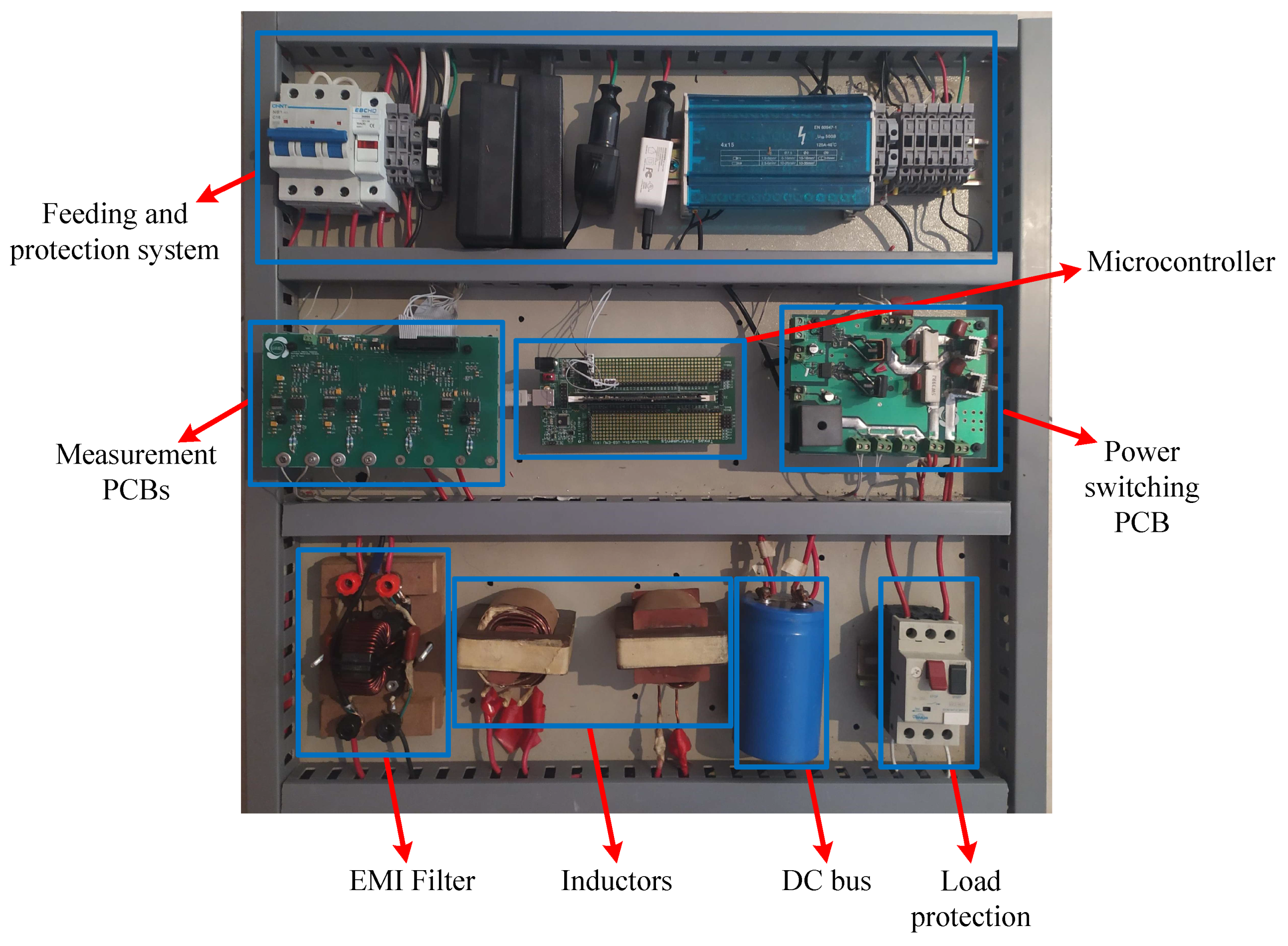

5. Experimental Results

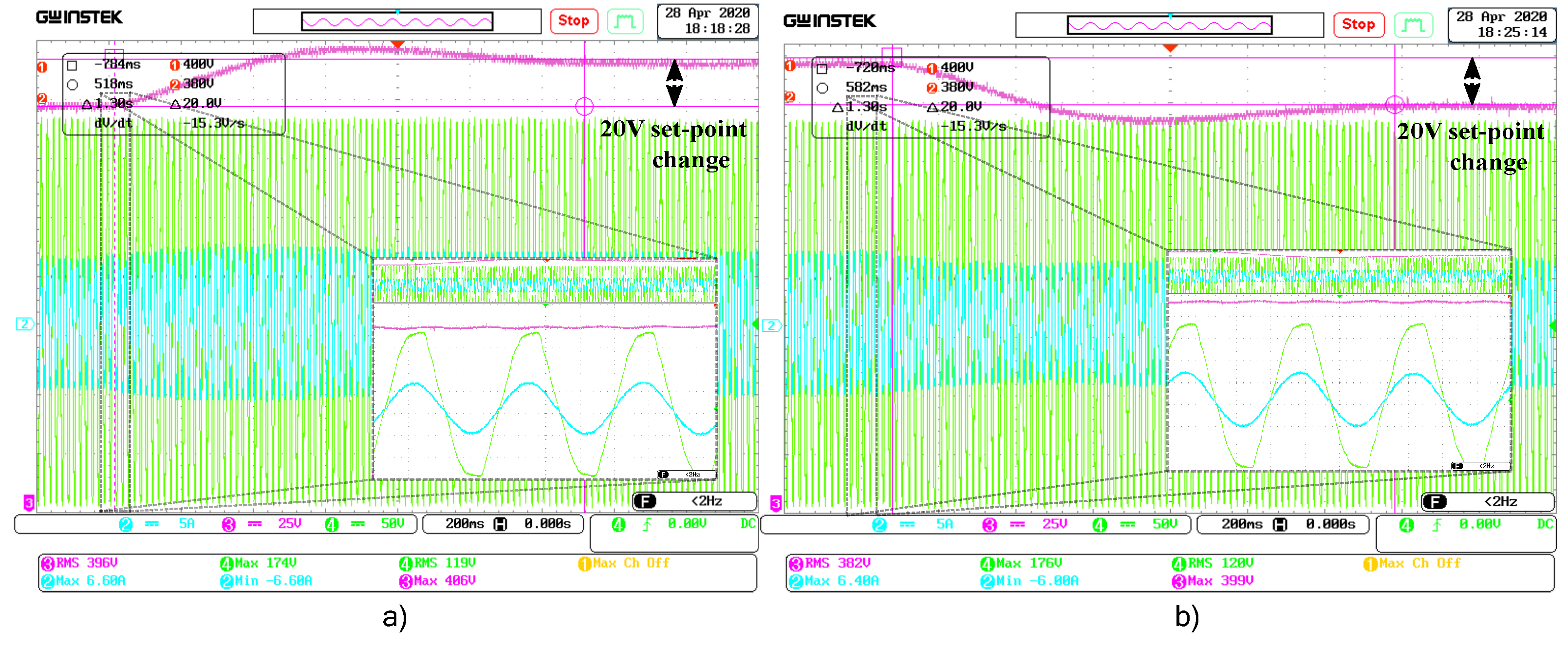

5.1. Results for PI-SMC Controller

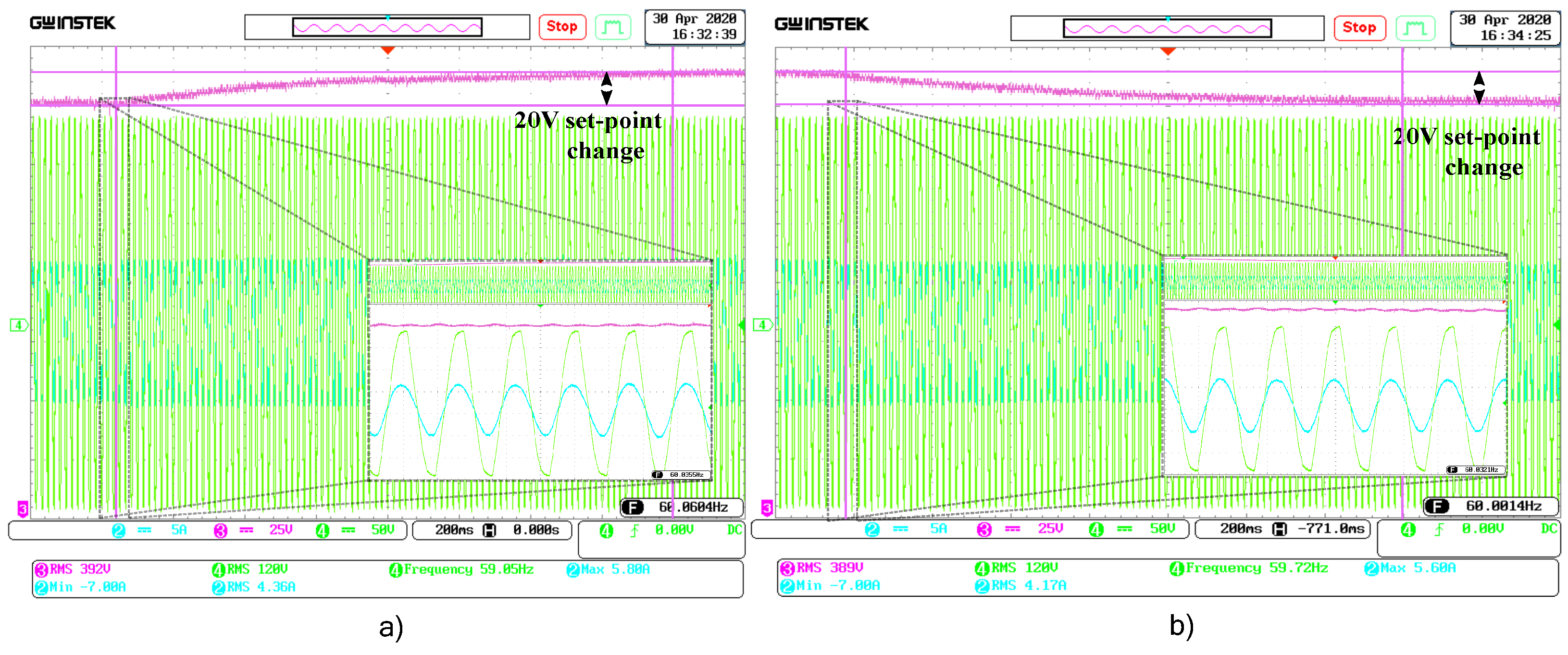

5.2. Results for the Proposed SMC Controller

5.3. Zero Crossing Comparison

5.4. Experimental vs. Simulation Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baek, J.; Kim, J.; Lee, J.; Park, M.; Moon, G. A New Standby Structure Integrated With Boost PFC Converter for Server Power Supply. IEEE Trans. Power Electron. 2019, 34, 5283–5293. [Google Scholar] [CrossRef]

- Xu, H.; Chen, D.; Xue, F.; Li, X. Optimal Design Method of Interleaved Boost PFC for Improving Efficiency from Switching Frequency, Boost Inductor, and Output Voltage. IEEE Trans. Power Electron. 2019, 34, 6088–6107. [Google Scholar] [CrossRef]

- Bist, V.; Singh, B. An Adjustable-Speed PFC Bridgeless Buck–Boost Converter-Fed BLDC Motor Drive. IEEE Trans. Ind. Electron. 2014, 61, 2665–2677. [Google Scholar] [CrossRef]

- Cho, K.S.; Lee, B.K.; Kim, J.S. CRM PFC Converter with New Valley Detection Method for Improving Power System Quality. Electronics 2020, 9, 38. [Google Scholar] [CrossRef]

- Zhang, R.; Ma, W.; Wang, L.; Hu, M.; Cao, L.; Zhou, H.; Zhang, Y. Line Frequency Instability of One-Cycle-Controlled Boost Power Factor Correction Converter. Electronics 2018, 7, 203. [Google Scholar] [CrossRef]

- IEEE. Recommended Practice and Requirements for Harmonic Control in Electric Power Systems (IEEE Std 519-2014 (Revision of IEEE Std 519-1992)); IEEE: Piscataway, NJ, USA, 2014; pp. 1–29. [Google Scholar]

- IEEE. IEEE Recommended Practice—Adoption of IEC 61000-4-15:2010, Electromagnetic Compatibility (EMC)—Testing and Measurement Techniques—Flickermeter-Functional and Design Specifications (IEEE Std 1453-2011); IEEE: Piscataway, NJ, USA, 2011; pp. 1–58. [Google Scholar]

- Huang, Q.; Huang, A.Q. Review of GaN totem-pole bridgeless PFC. CPSS Trans. Power Electron. Appl. 2017, 2, 187–196. [Google Scholar] [CrossRef]

- Huber, L.; Jang, Y.; Jovanovic, M.M. Performance Evaluation of Bridgeless PFC Boost Rectifiers. IEEE Trans. Power Electron. 2008, 23, 1381–1390. [Google Scholar] [CrossRef]

- Musavi, F.; Edington, M.; Eberle, W.; Dunford, W.G. Evaluation and Efficiency Comparison of Front End AC-DC Plug-in Hybrid Charger Topologies. IEEE Trans. Smart Grid 2012, 3, 413–421. [Google Scholar] [CrossRef]

- Alam, M.; Eberle, W.; Gautam, D.S.; Botting, C. A Soft-Switching Bridgeless AC–DC Power Factor Correction Converter. IEEE Trans. Power Electron. 2017, 32, 7716–7726. [Google Scholar] [CrossRef]

- Marcos-Pastor, A.; Vidal-Idiarte, E.; Cid-Pastor, A.; Martínez-Salamero, L. Loss-Free Resistor-Based Power Factor Correction Using a Semi-Bridgeless Boost Rectifier in Sliding-Mode Control. IEEE Trans. Power Electron. 2015, 30, 5842–5853. [Google Scholar] [CrossRef]

- Tan, F.D.; Ramshaw, R.S. Instabilities of a boost converter system under large parameter variations. IEEE Trans. Power Electron. 1989, 4, 442–449. [Google Scholar] [CrossRef]

- Fan, J.W.; Yeung, R.S.; Chung, H.S. Optimized Hybrid PWM Scheme for Mitigating Zero-Crossing Distortion in Totem-Pole Bridgeless PFC. IEEE Trans. Power Electron. 2019, 34, 928–942. [Google Scholar] [CrossRef]

- Kessal, A.; Rahmani, L. Ga-Optimized Parameters of Sliding-Mode Controller Based on Both Output voltage and Input Current With an Application in the PFC of AC/DC Converters. IEEE Trans. Power Electron. 2014, 29, 3159–3165. [Google Scholar] [CrossRef]

- Musavi, F.; Eberle, W.; Dunford, W.G. A Phase-Shifted Gating Technique With Simplified Current Sensing for the Semi-Bridgeless AC–DC Converter. IEEE Trans. Veh. Technol. 2013, 62, 1568–1576. [Google Scholar] [CrossRef]

- Kim, Y.; Sung, W.; Lee, B. Comparative Performance Analysis of High Density and Efficiency PFC Topologies. IEEE Trans. Power Electron. 2014, 29, 2666–2679. [Google Scholar] [CrossRef]

- Mohanty, P.R.; Panda, A.K. Fixed-Frequency Sliding-Mode Control Scheme Based on Current Control Manifold for Improved Dynamic Performance of Boost PFC Converter. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 576–586. [Google Scholar] [CrossRef]

- Alsmadi, Y.M.; Utkin, V.; Haj-ahmed, M.A.; Xu, L. Sliding mode control of power converters: DC/DC converters. Int. J. Control 2018, 91, 2472–2493. [Google Scholar] [CrossRef]

- Montoya, D.G.; Ramos-Paja, C.A.; Giral, R. Maximum power point tracking of photovoltaic systems based on the sliding mode control of the module admittance. Electr. Power Syst. Res. 2016, 136, 125–134. [Google Scholar] [CrossRef]

- Sira-Ramirez, H. Nonlinear variable structure systems in sliding mode: the general case. IEEE Trans. Autom. Control 1989, 34, 1186–1188. [Google Scholar] [CrossRef]

- Utkin, V. Variable structure systems with sliding modes. IEEE Trans. Autom. Control 1977, 22, 212–222. [Google Scholar] [CrossRef]

- Mallik, A.; Lu, J.; Khaligh, A. Sliding Mode Control of Single-Phase Interleaved Totem-Pole PFC for Electric Vehicle Onboard Chargers. IEEE Trans. Veh. Technol. 2018, 67, 8100–8109. [Google Scholar] [CrossRef]

- El Aroudi, A.; Martínez-Treviño, B.A.; Vidal-Idiarte, E.; Cid-Pastor, A. Fixed Switching Frequency Digital Sliding-Mode Control of DC-DC Power Supplies Loaded by Constant Power Loads with Inrush Current Limitation Capability. Energies 2019, 12, 1055. [Google Scholar] [CrossRef]

- Rathore, N.; Fulwani, D.; Rathore, A.K.; Gautam, A.R. Adaptive Sliding Mode Based Loss-Free Resistor for Power-Factor Correction Application. IEEE Trans. Ind. Appl. 2019, 55, 4332–4343. [Google Scholar] [CrossRef]

- Harirchi, F.; Rahmati, A.; Abrishamifar, A. Boost PFC converters with integral and double integral sliding mode control. In Proceedings of the 2011 19th Iranian Conference on Electrical Engineering, Tehran, Iran, 17–19 May 2011; pp. 1–6. [Google Scholar]

- Sudalaimani, M.; Revathi, L.V.; Senthilkumar, N. Direct Power based Sliding Mode Control of AC-DC Converter with Reduced THD. Tehnički Vjesnik 2018, 25, 72–79. [Google Scholar]

- Shieh, H.J.; Chen, Y.Z. A Sliding Surface-Regulated Current-Mode Pulse-Width Modulation Controller for a Digital Signal Processor-Based Single Ended Primary Inductor Converter-Type Power Factor Correction Rectifier. Energies 2017, 10, 1175. [Google Scholar] [CrossRef]

- Chincholkar, S.H.; Jiang, W.; Chan, C. A Normalized Output Error-Based Sliding-Mode Controller for the DC–DC Cascade Boost Converter. IEEE Trans. Circuits Syst. II Express Briefs 2020, 67, 92–96. [Google Scholar] [CrossRef]

- Sira-Ramirez, H. Sliding motions in bilinear switched networks. IEEE Trans. Circuits Syst. 1987, 34, 919–933. [Google Scholar] [CrossRef]

- Sira-Ramirez, H.; Rios-Bolivar, M. Sliding mode control of DC-to-DC power converters via extended linearization. IEEE Trans. Circuits Syst. I Fundam. Theory Appl. 1994, 41, 652–661. [Google Scholar] [CrossRef]

- Mejía-Ruiz, G.E.; Muñoz-Galeano, N.; López-Lezama, J.M. Modeling and development of a bridgeless PFC Boost rectifier. Rev. Fac. Ing. Univ. Antioq. 2017, 82, 9–21. [Google Scholar] [CrossRef]

- Tan, S.; Lai, Y.M.; Tse, C.K.; Martinez-Salamero, L.; Wu, C. A Fast-Response Sliding-Mode Controller for Boost-Type Converters With a Wide Range of Operating Conditions. IEEE Trans. Ind. Electron. 2007, 54, 3276–3286. [Google Scholar] [CrossRef]

- Siew-Chong Tan. ; Lai, Y.M.; Tse, C.K. A unified approach to the design of PWM-based sliding-mode voltage controllers for basic DC-DC converters in continuous conduction mode. IEEE Trans. Circuits Syst. I Regul. Pap. 2006, 53, 1816–1827. [Google Scholar] [CrossRef]

- Mejía-Ruiz, G.E.; Muñoz-Galeano, N.; Ortiz-Castrillón, J.R. Banda de Histéresis Adaptativa para un Convertidor AC-DC Elevador sin Puente, con Correccion del Factor de Potencia y Control por Modos Deslizantes. Inf. Tecnol. 2019, 30, 283–292. [Google Scholar] [CrossRef][Green Version]

| Ref. | Contributions | Drawbacks |

|---|---|---|

| [12,25] | Hybrid PI-SMC with constant hysteresis band. | 1. Variable switching frequency. |

| 2. DC voltage not considered in the SS. | ||

| [15] | GA hybrid PI-SMC | 1. DC voltage oscillations. |

| 2. High DC overvoltages. | ||

| 3. High near zero crossings. | ||

| [18] | Hybrid PI-SMC controller (fixed frequency). | 1. DC voltage oscillations. |

| 2. Slow linear control. | ||

| [23] | Hybrid PI-SMC controller (Totem-pole topology). | 1. Protection external limiter required. |

| 2. DC voltage over peaks. | ||

| [26] | Integral and double integral SMC. | 1. Integral: high |

| 2. Doble integral: DC current components. | ||

| 3. DC voltage not considered in the SS. | ||

| 4. DC voltage control was not implemented. | ||

| [27,28] | Hybrid PI-SMC for current error reduction. | 1. AC-current and DC-voltage slow responses. |

| Parameter | Value |

|---|---|

| Grid voltage | 120 Vrms |

| Grid frequency | 60 Hz |

| DC bus capacitor | 2.2 mF |

| DC bus voltage | 400 V |

| Inductors | 2.2 mH |

| Switching frequency | 40 kHz |

| Rated power | 500 W |

| Rated Load | 320 Ω |

| Criteria | Hybrid SMC-PI (Load 25%) | Proposed SMC (Load 50%) | ||

|---|---|---|---|---|

| Simulation | Experimental | Simulation | Experimental | |

| Stabilization time | 1.6 s | 1.53 s | 0.03 s | 0 s |

| Undervoltage | 15.5 v | 18 v | 0.4 v | 0 v |

| Cycles to reach steady state | 24 | 27 | less than 1 | less than to 1 |

| 4.25% | 4.82% | 3.7% | 2.67% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortiz-Castrillón, J.R.; Mejía-Ruiz, G.E.; Muñoz-Galeano, N.; López-Lezama, J.M.; Cano-Quintero, J.B. A Sliding Surface for Controlling a Semi-Bridgeless Boost Converter with Power Factor Correction and Adaptive Hysteresis Band. Appl. Sci. 2021, 11, 1873. https://doi.org/10.3390/app11041873

Ortiz-Castrillón JR, Mejía-Ruiz GE, Muñoz-Galeano N, López-Lezama JM, Cano-Quintero JB. A Sliding Surface for Controlling a Semi-Bridgeless Boost Converter with Power Factor Correction and Adaptive Hysteresis Band. Applied Sciences. 2021; 11(4):1873. https://doi.org/10.3390/app11041873

Chicago/Turabian StyleOrtiz-Castrillón, José Robinson, Gabriel Eduardo Mejía-Ruiz, Nicolás Muñoz-Galeano, Jesús María López-Lezama, and Juan Bernardo Cano-Quintero. 2021. "A Sliding Surface for Controlling a Semi-Bridgeless Boost Converter with Power Factor Correction and Adaptive Hysteresis Band" Applied Sciences 11, no. 4: 1873. https://doi.org/10.3390/app11041873

APA StyleOrtiz-Castrillón, J. R., Mejía-Ruiz, G. E., Muñoz-Galeano, N., López-Lezama, J. M., & Cano-Quintero, J. B. (2021). A Sliding Surface for Controlling a Semi-Bridgeless Boost Converter with Power Factor Correction and Adaptive Hysteresis Band. Applied Sciences, 11(4), 1873. https://doi.org/10.3390/app11041873