Bead Geometry Prediction in Laser-Wire Additive Manufacturing Process Using Machine Learning: Case of Study

Abstract

:Featured Application

Abstract

1. Introduction

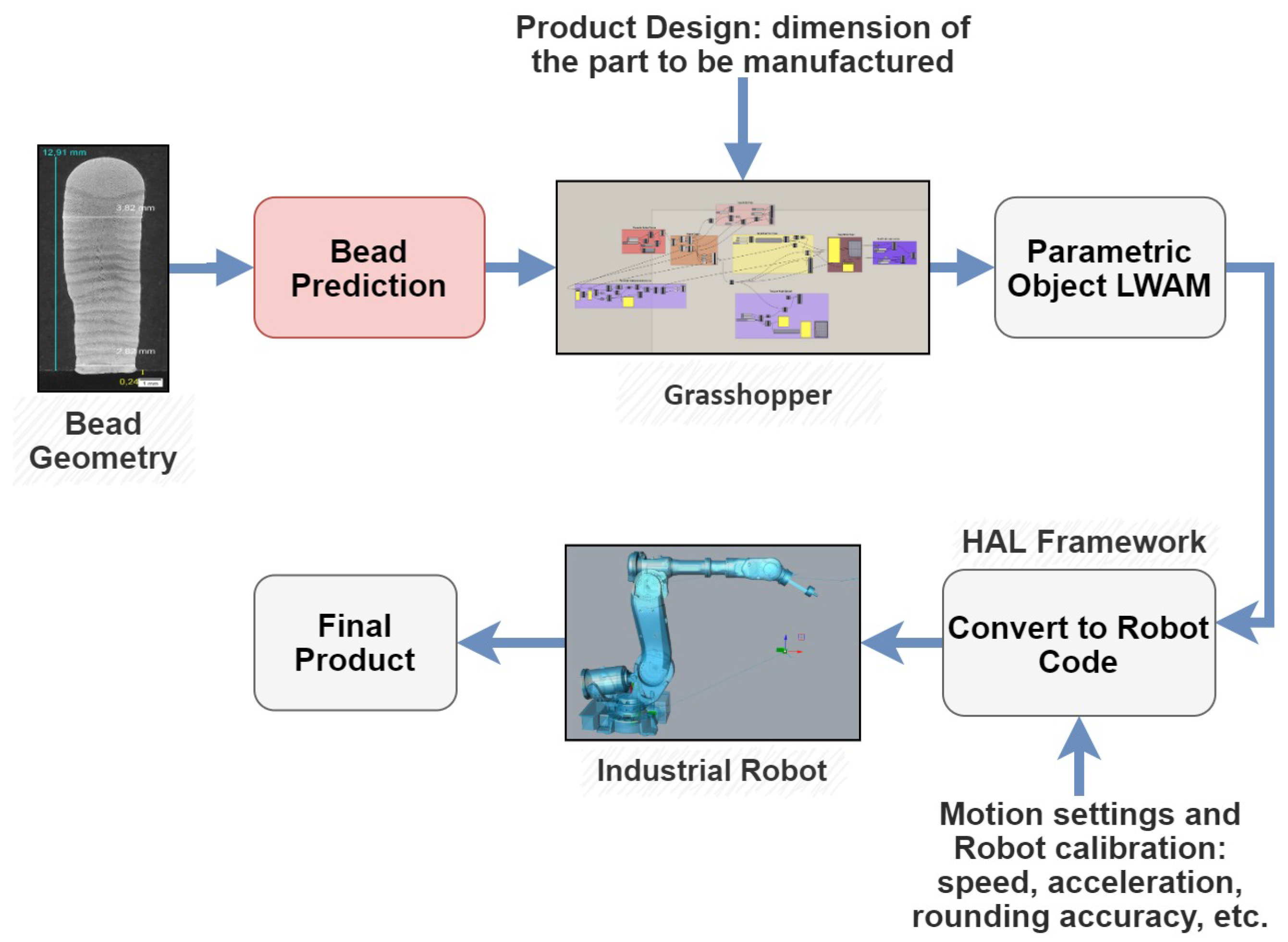

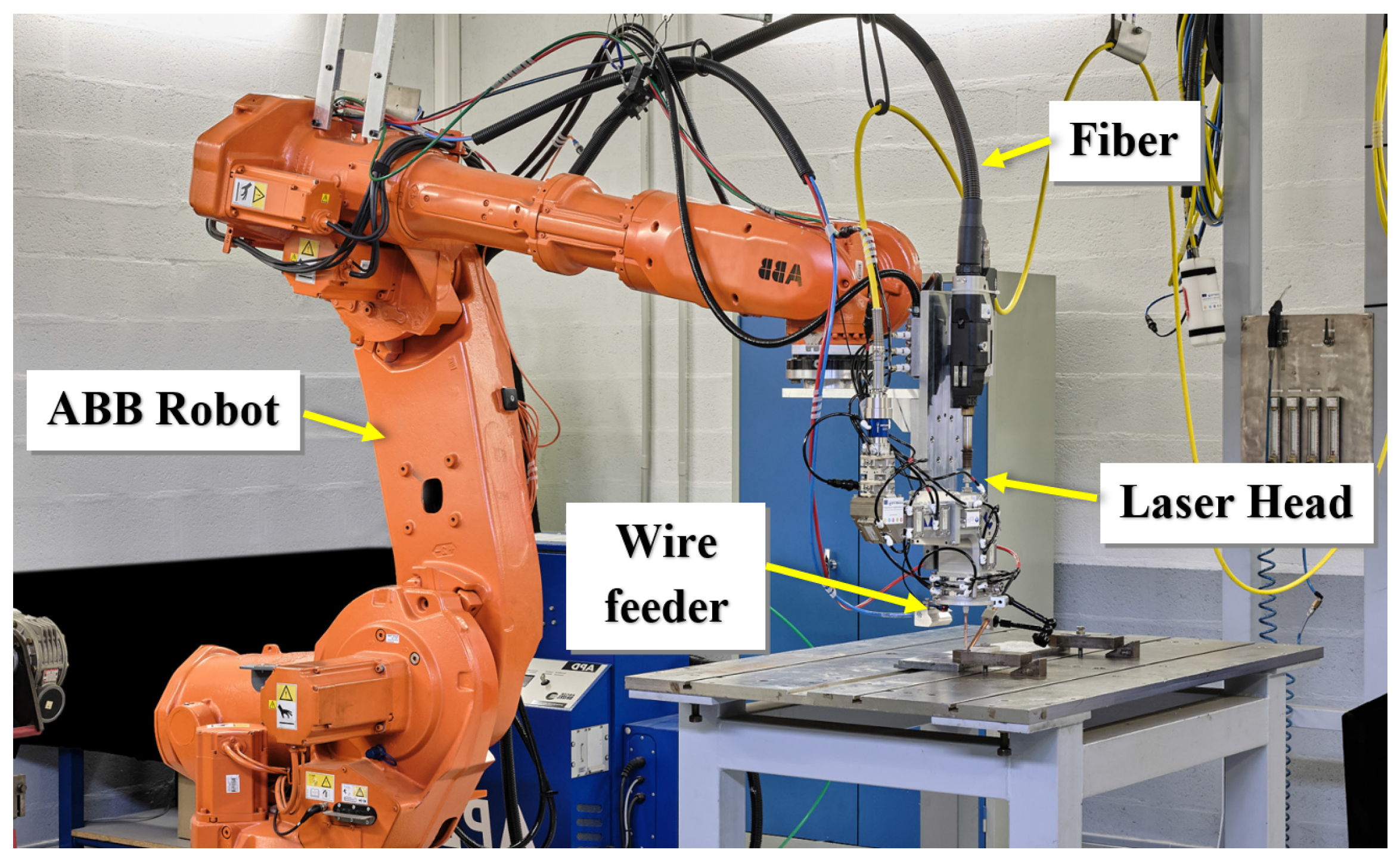

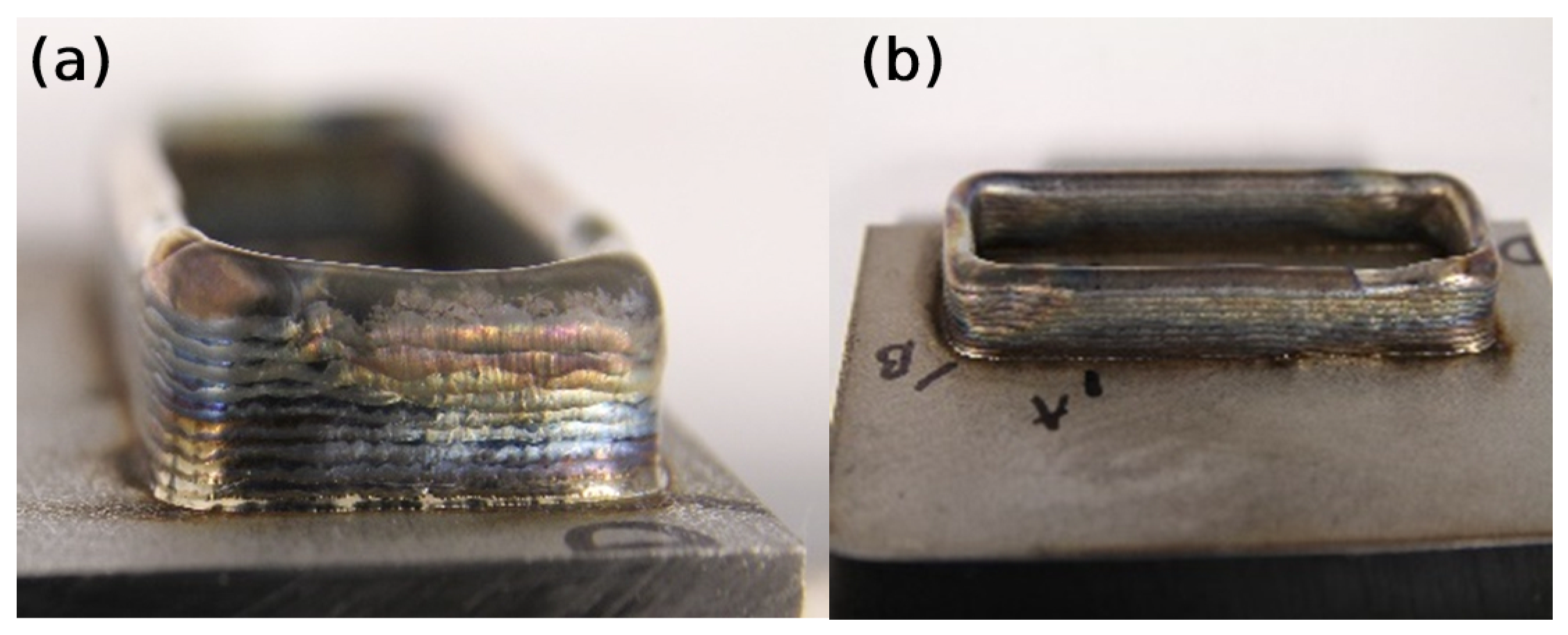

2. Methodology

- Parametric surface creation: In this step, mathematical tools are used to create a 2D model surface. Alternatively, a CAD part could be imported directly and changed to a parametric CAD part using Grasshoppers tools.

- Pattern creation: In this step, patterns (zigzag, spiral tool path, etc.) are designed and added to the 2D surface. The zigzag pattern is advised for its simplicity of implementation, robustness, and surface roughness [40].

- Layer-to-layer deposition strategy: After depositing the first layer, a suitable travel strategy is required to reach the next layer, and successively. The travel strategy depends on some deposition parameters, such as the laser power, wire feed rate, and robot travel speed. Therefore, the travel strategy should be carefully chosen as it can influence the cooling of the previous layer as well as the bonding between layers. For more details see e.g., [41,42].

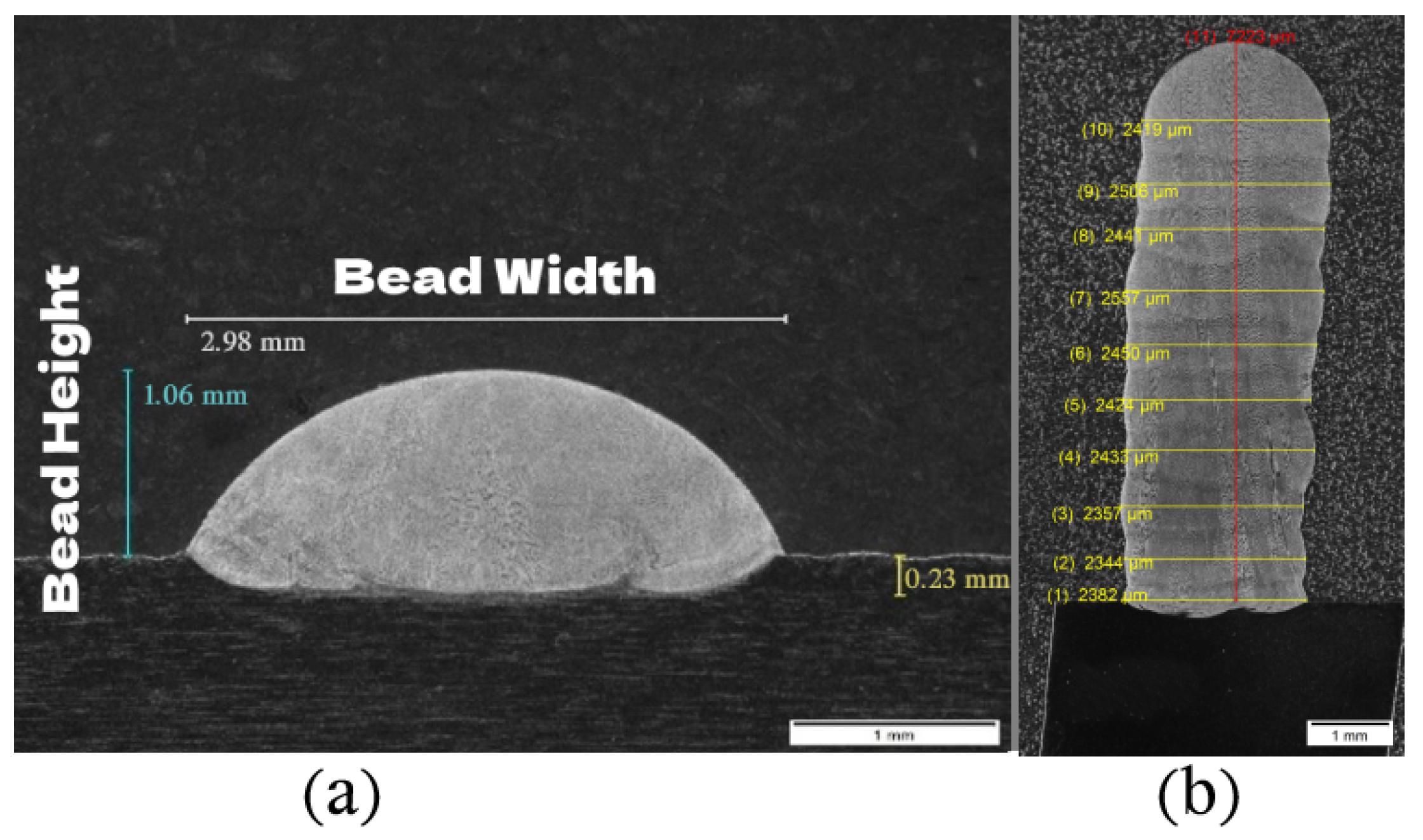

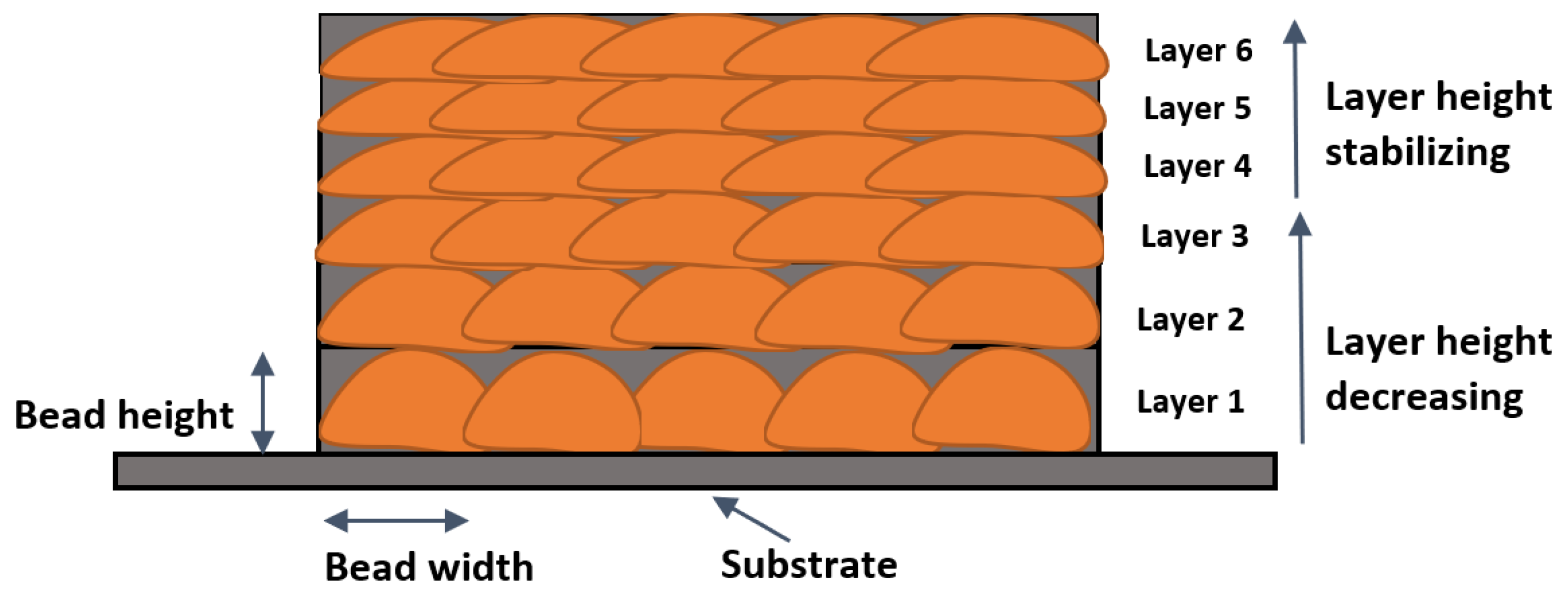

- Bead geometry measurements: Finally, a laser scanner was used to obtain the measurements data of the bead geometry during the LWAM process. The laser scanner was mounted on the welding robot’s arm to directly measure the bead geometry for each layer deposition. A measurement for a single bead geometry and layer deposition is shown in Figure 3.

3. Prediction Model

3.1. Bead Height Prediction Model

3.2. Neural Network Prediction

4. Experimental Results and Discussion

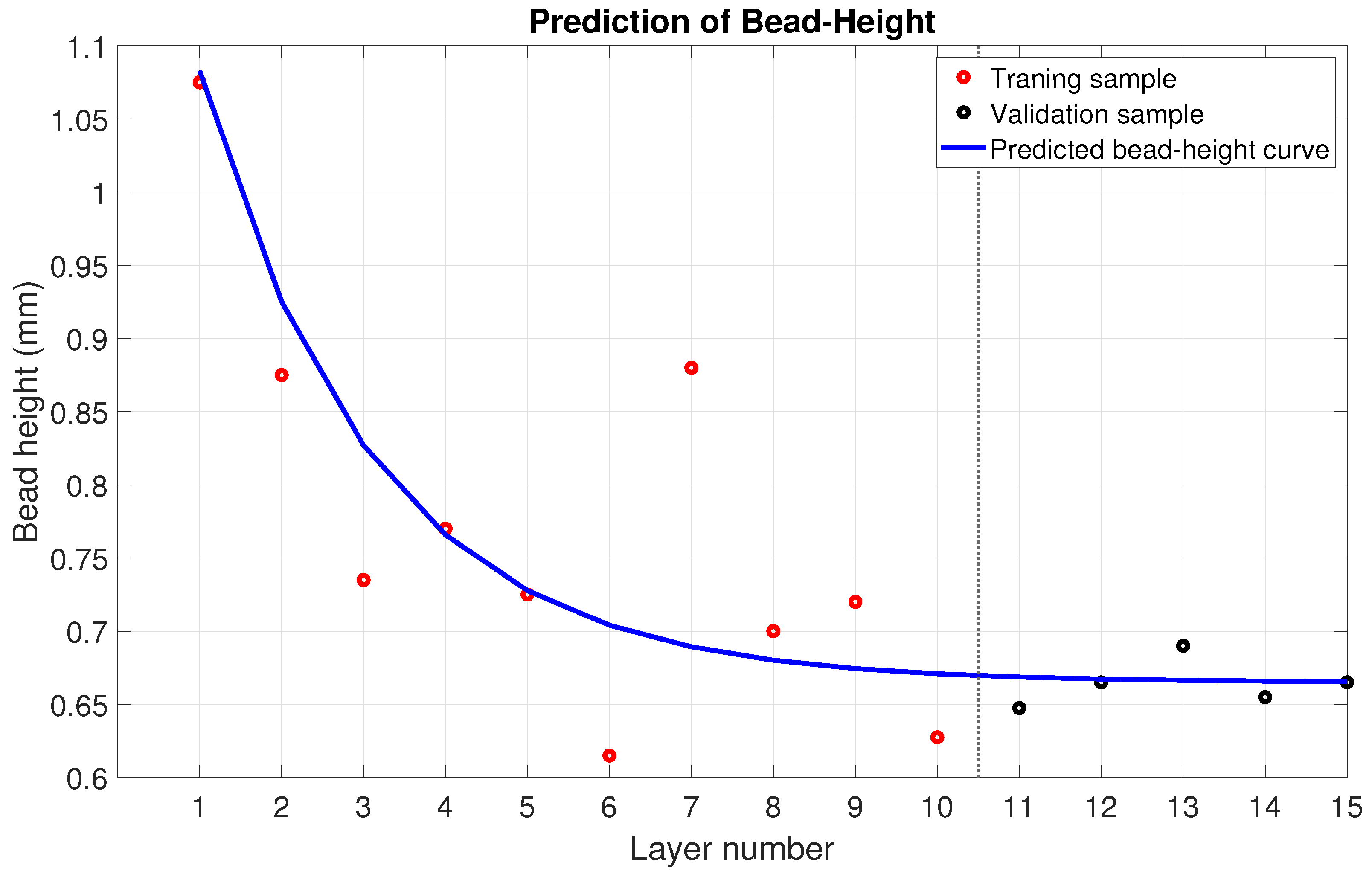

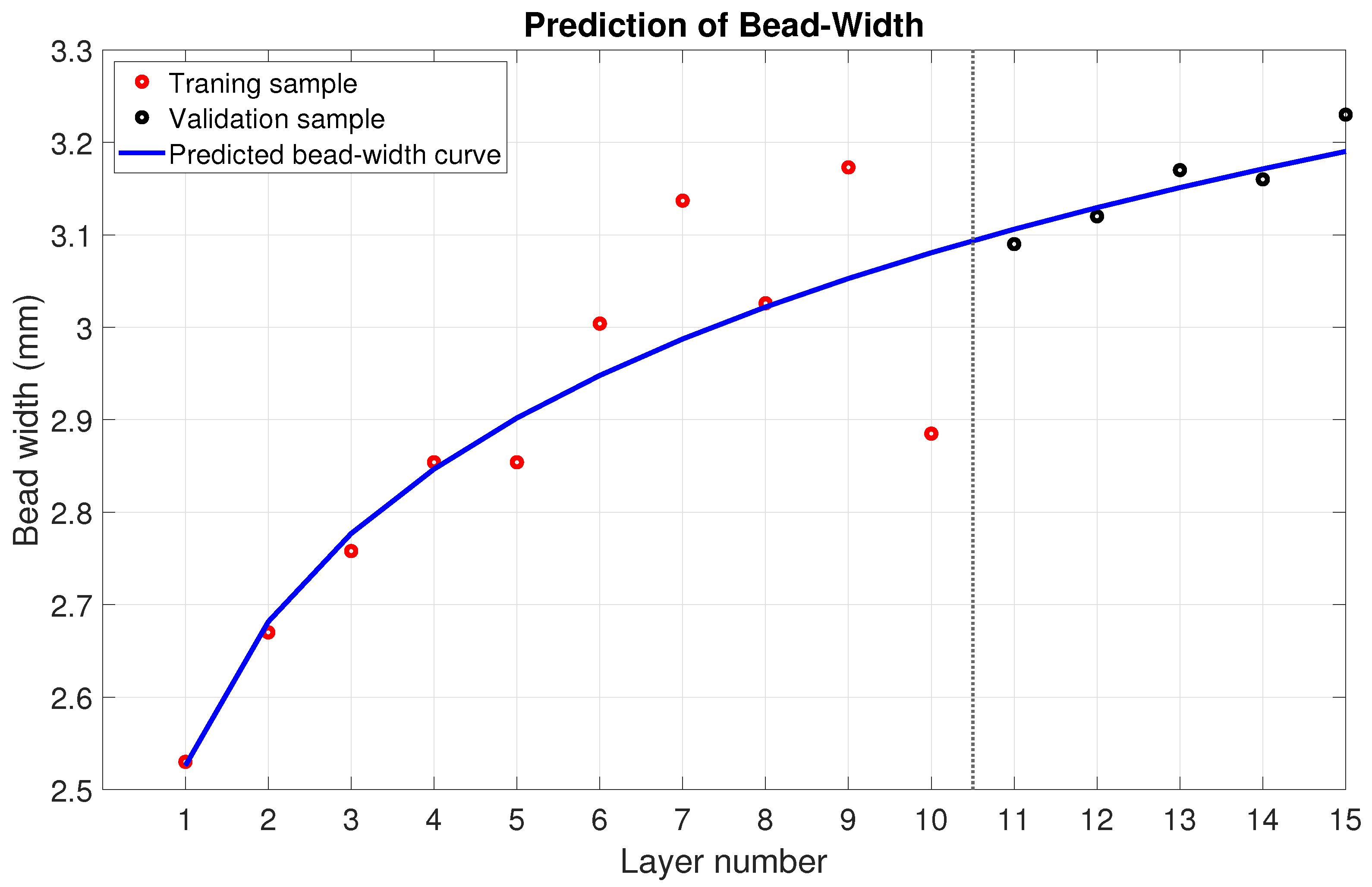

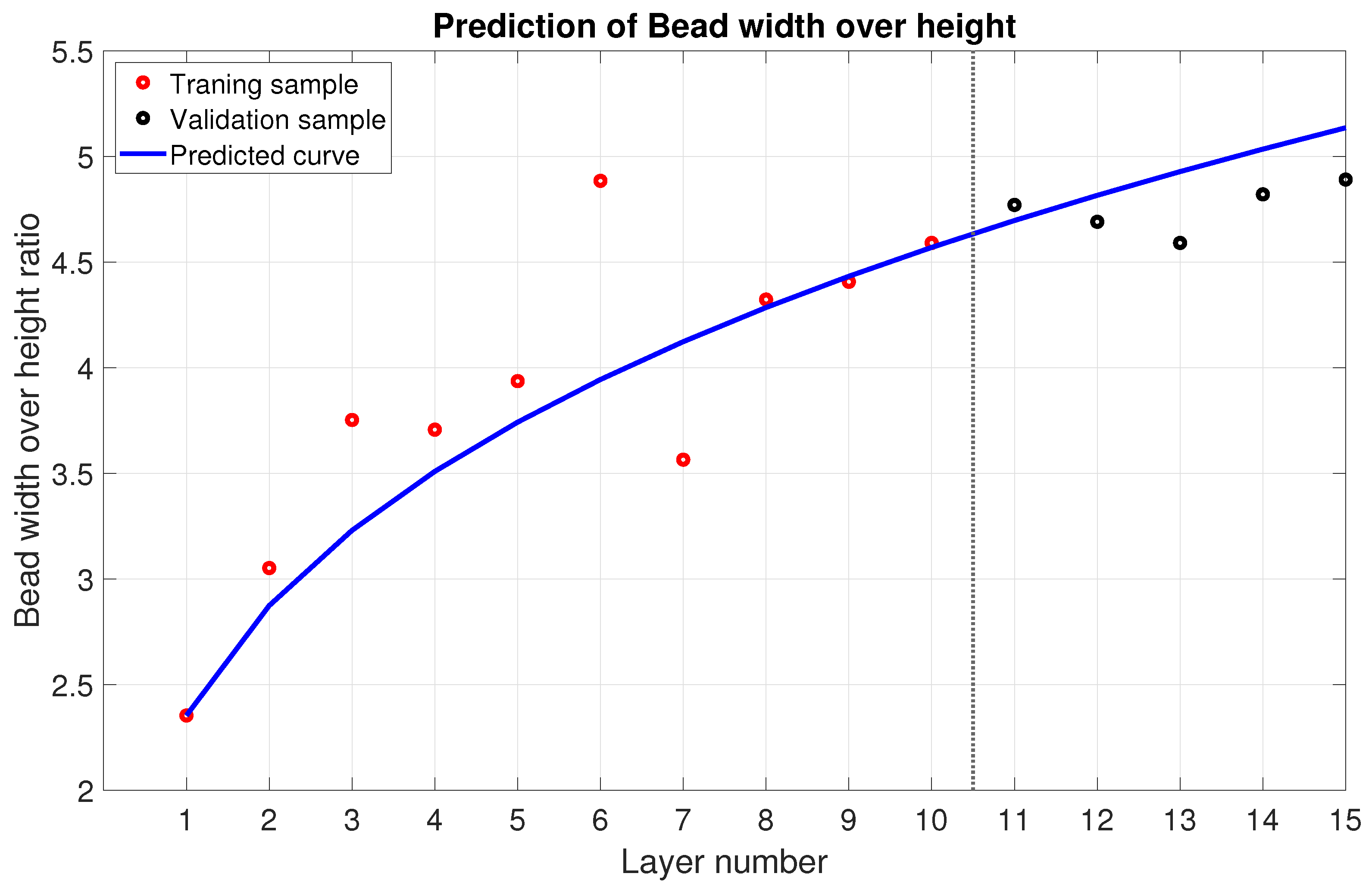

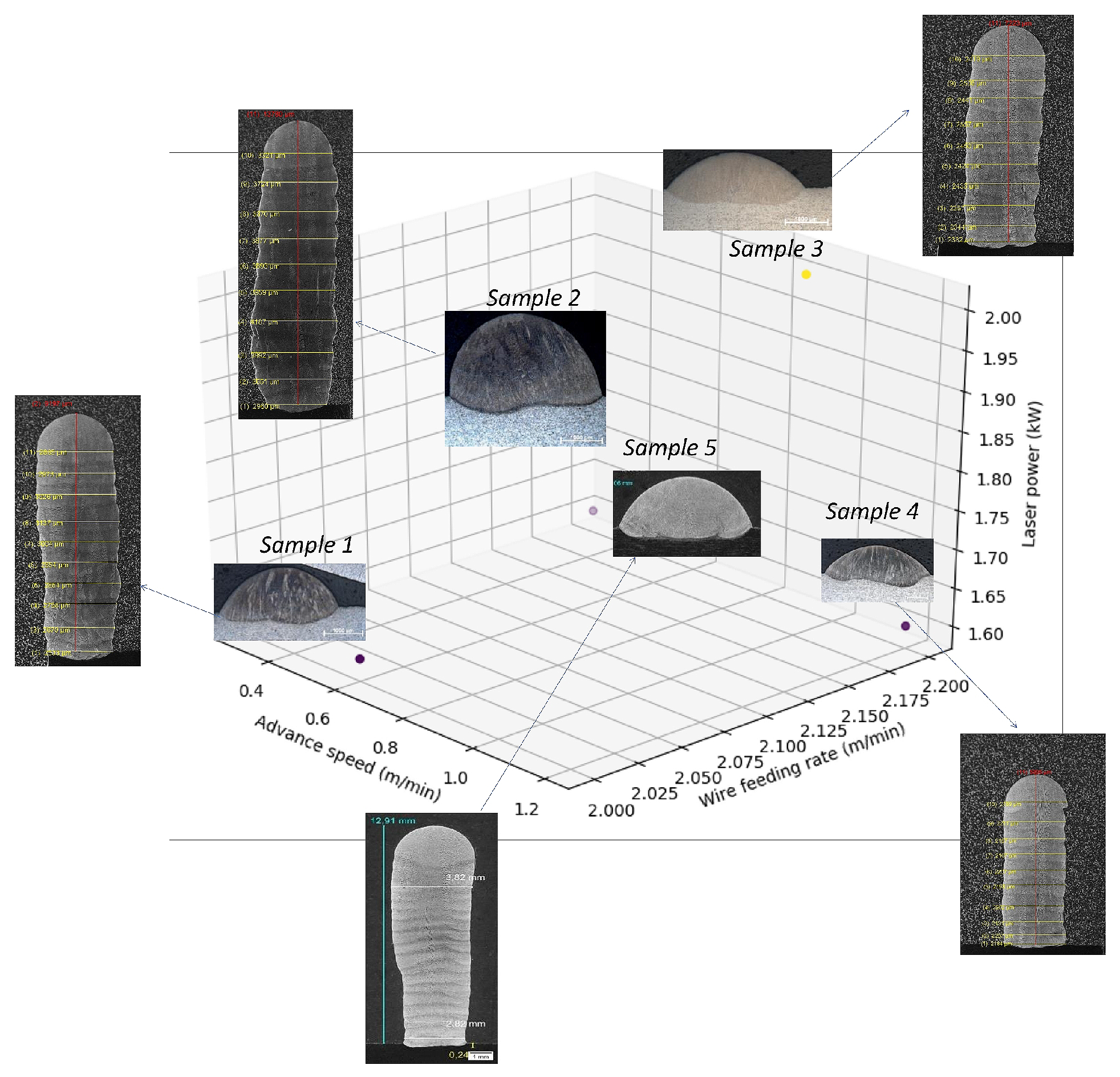

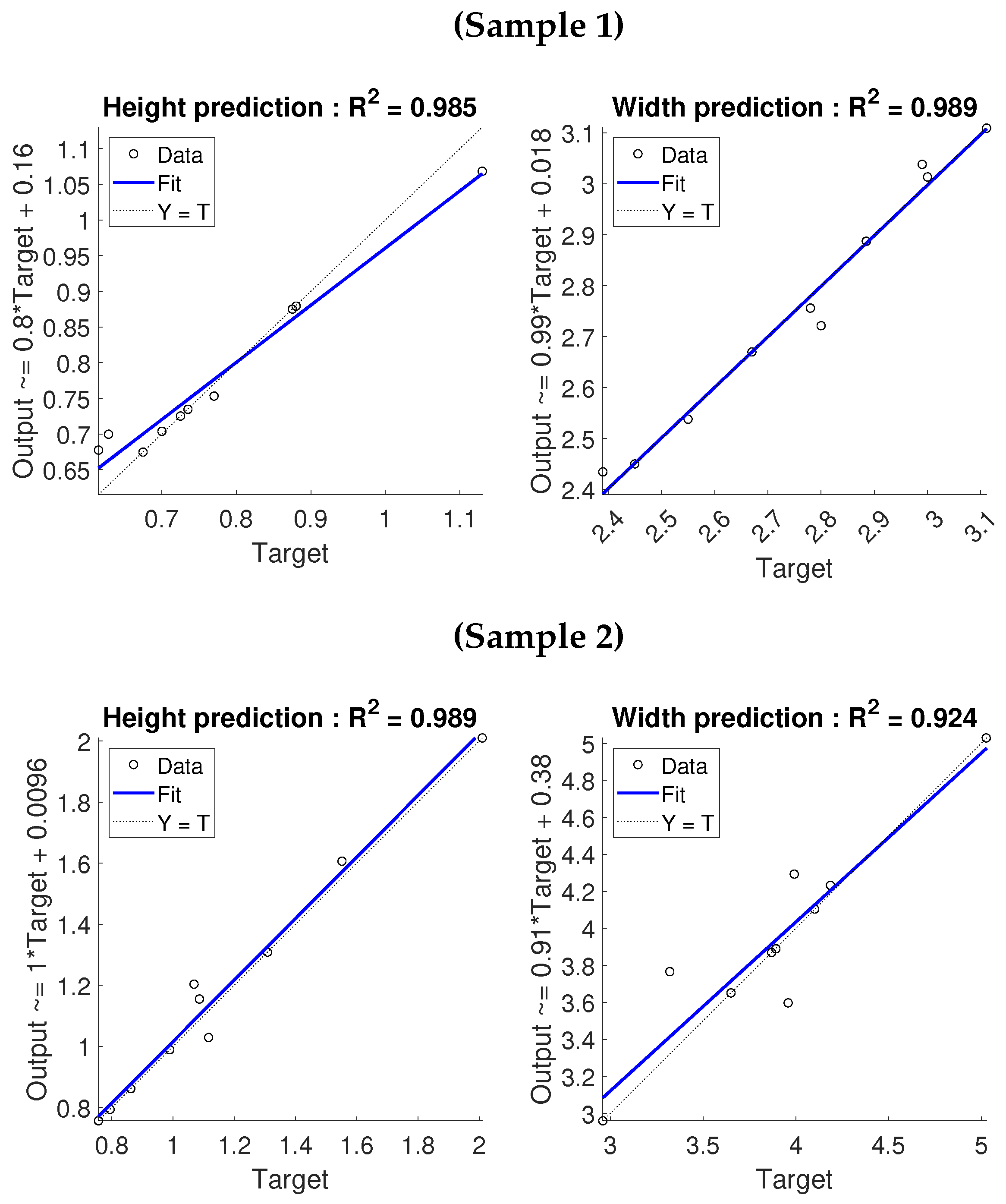

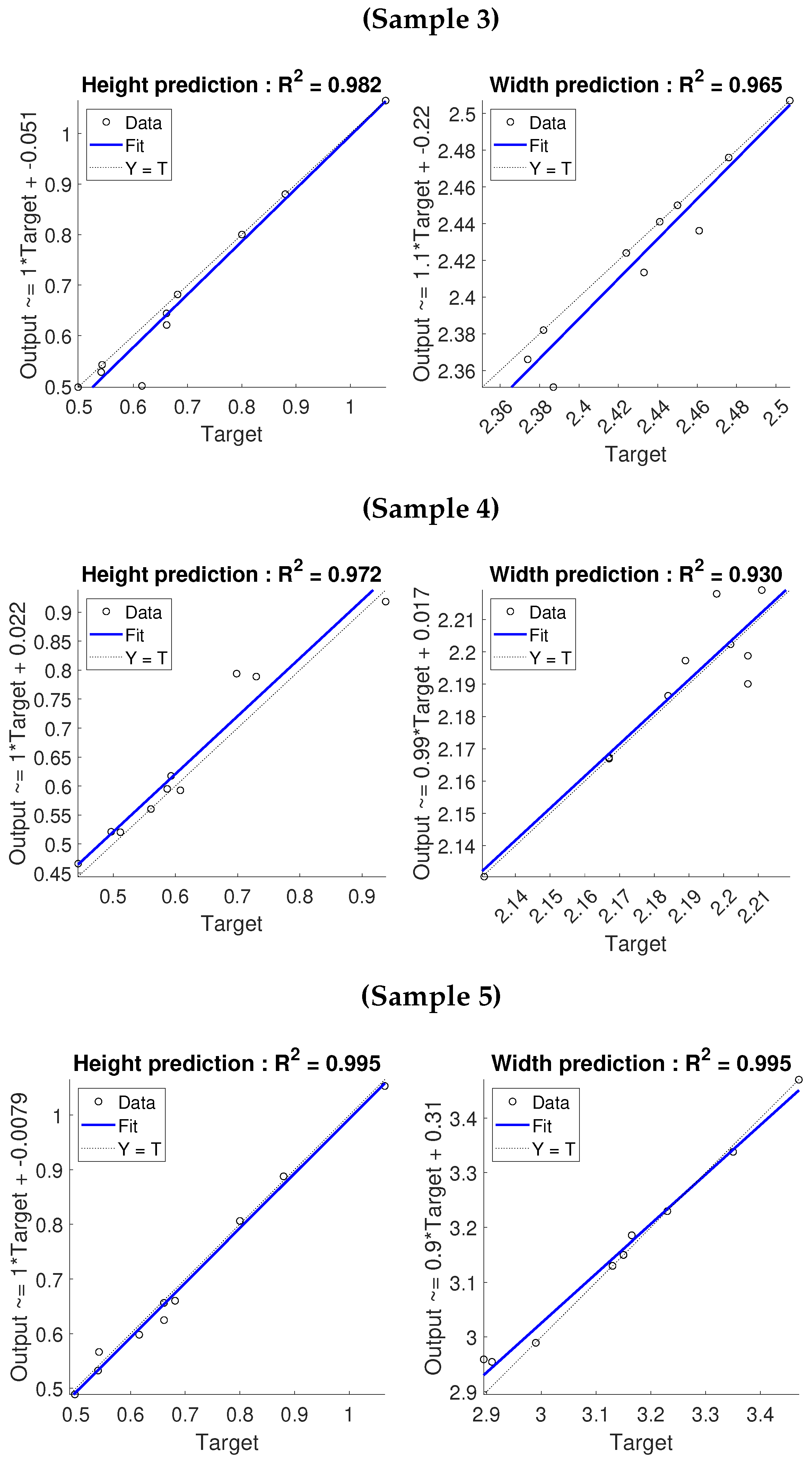

4.1. Bead Geometry Prediction

4.2. First-Order Deposition Parameters

5. Conclusions

- Regression algorithms can be used for prediction tasks related to the LWAM process, including for supervision tasks;

- There exists a power decay in correlating process parameters to bead thickness.

- The experimental results showed an increase of width-to-height ratio as a function of layer progression due to the heat conducted from the laser–matter interaction.

- Satisfying prediction models were obtained and could be used to predict the geometry of beads as part of LWAM control programming for horizontal and vertical robot movement.

- In this case, acceptable bead prediction with good layer deposition was obtained when P, V, and F were kW, m/min, and m/min, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shaqour, B.; Abuabiah, M.; Abdel-Fattah, S.; Juaidi, A.; Abdallah, R.; Abuzaina, W.; Qarout, M.; Verleije, B.; Cos, P. Gaining a better understanding of the extrusion process in fused filament fabrication 3D printing: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 1279–1291. [Google Scholar] [CrossRef]

- Zenou, M.; Grainger, L. Additive manufacturing of metallic materials. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 53–103. [Google Scholar]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot. Comput.-Integr. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef] [Green Version]

- Frostevarg, J. Comparison of three different arc modes for laser-arc hybrid welding steel. J. Laser Appl. 2016, 28, 022407. [Google Scholar] [CrossRef]

- Brooks, H.; Molony, S. Design and evaluation of additively manufactured parts with three dimensional continuous fibre reinforcement. Mater. Des. 2016, 90, 276–283. [Google Scholar] [CrossRef] [Green Version]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S. Modelling and prediction of surface roughness in wire arc additive manufacturing using machine learning. J. Intell. Manuf. 2021, 1–16. [Google Scholar] [CrossRef]

- Muscato, G.; Spampinato, G.; Cantelli, L. A closed loop welding controller for a rapid manufacturing process. In Proceedings of the 2008 IEEE International Conference on Emerging Technologies and Factory Automation, Hamburg, Germany, 15–18 September 2008; pp. 1080–1083. [Google Scholar]

- Ding, Y.; Warton, J.; Kovacevic, R. Development of sensing and control system for robotized laser-based direct metal addition system. Addit. Manuf. 2016, 10, 24–35. [Google Scholar] [CrossRef] [Green Version]

- Bi, G.; Gasser, A.; Wissenbach, K.; Drenker, A.; Poprawe, R. Characterization of the process control for the direct laser metallic powder deposition. Surf. Coat. Technol. 2006, 201, 2676–2683. [Google Scholar] [CrossRef]

- Song, L.; Bagavath-Singh, V.; Dutta, B.; Mazumder, J. Control of melt pool temperature and deposition height during direct metal deposition process. Int. J. Adv. Manuf. Technol. 2012, 58, 247–256. [Google Scholar] [CrossRef]

- Meriaudeau, F.; Truchetet, F. Control and optimization of the laser cladding process using matrix cameras and image processing. J. Laser Appl. 1996, 8, 317–324. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A. A mechatronics approach to laser powder deposition process. Mechatronics 2006, 16, 631–641. [Google Scholar] [CrossRef]

- Hu, D.; Kovacevic, R. Sensing, modeling and control for laser-based additive manufacturing. Int. J. Mach. Tools Manuf. 2003, 43, 51–60. [Google Scholar] [CrossRef]

- Koch, J.; Mazumder, J. Apparatus and Methods for Monitoring and Controlling Multi-Layer Laser Cladding. U.S. Patent 6,122,564, 19 September 2000. [Google Scholar]

- Fox, M.D.; Hand, D.P.; Su, D.; Jones, J.D.; Morgan, S.A.; McLean, M.A.; Steen, W.M. Optical sensor to monitor and control temperature and build height of the laser direct-casting process. Appl. Opt. 1998, 37, 8429–8433. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.M.; Yang, Y.P.; Zhang, W.; Na, S.J. Advanced welding manufacturing: A brief analysis and review of challenges and solutions. J. Manuf. Sci. Eng. 2020, 142, 110816. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Gao, M.; Zeng, X. Layer thickness dependence of performance in high-power selective laser melting of 1Cr18Ni9Ti stainless steel. J. Mater. Process. Technol. 2015, 215, 142–150. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Selective laser melting technology: From the single laser melted track stability to 3D parts of complex shape. Phys. Procedia 2010, 5, 551–560. [Google Scholar] [CrossRef] [Green Version]

- Guan, K.; Wang, Z.; Gao, M.; Li, X.; Zeng, X. Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel. Mater. Des. 2013, 50, 581–586. [Google Scholar] [CrossRef]

- Averyanova, M.; Cicala, E.; Bertrand, P.; Grevey, D. Experimental design approach to optimize selective laser melting of martensitic 17-4 PH powder: Part I–single laser tracks and first layer. Rapid Prototyp. J. 2012, 18, 28–37. [Google Scholar] [CrossRef]

- Dai, K.; Shaw, L. Parametric studies of multi-material laser densification. Mater. Sci. Eng. A 2006, 430, 221–229. [Google Scholar] [CrossRef]

- Mbodj, N.G.; Plapper, P. Bead Width Prediction in Laser Wire Additive Manufacturing Process. In Recent Advances in Manufacturing Engineering and Processes; Springer: Berlin, Germany, 2022; pp. 33–40. [Google Scholar]

- Zhu, G.; Li, D.; Zhang, A.; Pi, G.; Tang, Y. The influence of laser and powder defocusing characteristics on the surface quality in laser direct metal deposition. Opt. Laser Technol. 2012, 44, 349–356. [Google Scholar] [CrossRef]

- Donadello, S.; Motta, M.; Demir, A.G.; Previtali, B. Monitoring of laser metal deposition height by means of coaxial laser triangulation. Opt. Lasers Eng. 2019, 112, 136–144. [Google Scholar] [CrossRef] [Green Version]

- Simeone, O. A brief introduction to machine learning for engineers. Found. Trends Signal Process. 2018, 12, 200–431. [Google Scholar] [CrossRef]

- Parisi, G.I.; Kemker, R.; Part, J.L.; Kanan, C.; Wermter, S. Continual lifelong learning with neural networks: A review. Neural Netw. 2019, 113, 54–71. [Google Scholar] [CrossRef]

- Khatir, S.; Tiachacht, S.; Le Thanh, C.; Ghandourah, E.; Mirjalili, S.; Wahab, M.A. An improved Artificial Neural Network using Arithmetic Optimization Algorithm for damage assessment in FGM composite plates. Compos. Struct. 2021, 273, 114287. [Google Scholar] [CrossRef]

- Tran-Ngoc, H.; Khatir, S.; Ho-Khac, H.; De Roeck, G.; Bui-Tien, T.; Wahab, M.A. Efficient Artificial neural networks based on a hybrid metaheuristic optimization algorithm for damage detection in laminated composite structures. Compos. Struct. 2021, 262, 113339. [Google Scholar] [CrossRef]

- Zenzen, R.; Khatir, S.; Belaidi, I.; Le Thanh, C.; Wahab, M.A. A modified transmissibility indicator and Artificial Neural Network for damage identification and quantification in laminated composite structures. Compos. Struct. 2020, 248, 112497. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Hu, J.; Wu, L. Bead geometry prediction for robotic GMAW-based rapid manufacturing through a neural network and a second-order regression analysis. J. Intell. Manuf. 2014, 25, 157–163. [Google Scholar] [CrossRef]

- Nagesh, D.; Datta, G. Genetic algorithm for optimization of welding variables for height to width ratio and application of ANN for prediction of bead geometry for TIG welding process. Appl. Soft Comput. 2010, 10, 897–907. [Google Scholar] [CrossRef]

- Milhomme, S.; Lartigau, J.; Brugger, C.; Froustey, C. Bead geometry prediction using multiple linear regression analysis. Int. J. Adv. Manuf. Technol. 2021, 117, 607–620. [Google Scholar] [CrossRef]

- Karmuhilan, M.; Kumarsood, A. Intelligent process model for bead geometry prediction in WAAM. Mater. Today Proc. 2018, 5, 24005–24013. [Google Scholar] [CrossRef]

- Wacker, C.; Köhler, M.; David, M.; Aschersleben, F.; Gabriel, F.; Hensel, J.; Dilger, K.; Dröder, K. Geometry and Distortion Prediction of Multiple Layers for Wire Arc Additive Manufacturing with Artificial Neural Networks. Appl. Sci. 2021, 11, 4694. [Google Scholar] [CrossRef]

- Ayed, A.; Bras, G.; Bernard, H.; Michaud, P.; Balcaen, Y.; Alexis, J. Study of Arc-wire and Laser-wire processes for the realization of Ti-6Al-4V alloy parts. MATEC Web Conf. EDP Sci. 2020, 321, 03002. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Valentine, P.J.; Piker, D.; Austin, S.A.; De Kestelier, X. Modelling curved-layered printing paths for fabricating large-scale construction components. Addit. Manuf. 2016, 12, 216–230. [Google Scholar] [CrossRef] [Green Version]

- Nilsson, D. G-Code to RAPID Translator for Robot-Studio. Master’s Thesis, University West, Trollhattan, Sweden, 2016. [Google Scholar]

- Schwartz, T. Extension of a visual programming language to support teaching and research on robotics applied to construction. In Rob|Arch 2012; Springer: Berlin, Germany, 2013; pp. 92–101. [Google Scholar]

- Misra, D.; Sundararajan, V.; Wright, P.K. Zig-zag tool path generation for sculptured surface. In Geometric and Algorithmic Aspects of Computer-Aided Design and Manufacturing; American Mathematical Society: Piscataway, NJ, USA, 2005; p. 265. [Google Scholar]

- Ren, K.; Chew, Y.; Liu, N.; Zhang, Y.; Fuh, J.; Bi, G. Integrated numerical modelling and deep learning for multi-layer cube deposition planning in laser aided additive manufacturing. Virtual Phys. Prototyp. 2021, 16, 318–332. [Google Scholar] [CrossRef]

- Liu, F.; Wei, L.; Shi, S.; Wei, H. On the varieties of build features during multi-layer laser directed energy deposition. Addit. Manuf. 2020, 36, 101491. [Google Scholar] [CrossRef]

- Ranganathan, A. The levenberg-marquardt algorithm. Tutoral LM Algorithm 2004, 11, 101–110. [Google Scholar]

- Farber, R. CUDA Application Design and Development; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Cazic, I.; Zollinger, J.; Mathieu, S.; El Kandaoui, M.; Plapper, P.; Appolaire, B. New insights into the origin of fine equiaxed microstructures in additively manufactured Inconel 718. Scr. Mater. 2021, 195, 113740. [Google Scholar] [CrossRef]

| Test Trial | P (kW) | F (m/min) | V (m/min) |

|---|---|---|---|

| Sample 1 | 1.6 | 0.6 | 2.0 |

| Sample 2 | 1.6 | 0.3 | 2.2 |

| Sample 3 | 2.0 | 0.9 | 2.2 |

| Sample 4 | 1.6 | 1.2 | 2.2 |

| Sample 5 | 1.4 | 1.4 | 0.45 |

| Sample | RMSE | MAE | MAPE | |||||

|---|---|---|---|---|---|---|---|---|

| Height | Width | Height | Width | Height | Width | Height | Width | |

| 1 | 0.0361 | 0.0337 | 0.9847 | 0.9894 | 0.0282 | 0.0082 | 2.8151% | 0.8235% |

| 2 | 0.0580 | 0.2053 | 0.9888 | 0.9242 | 0.0291 | 0.0301 | 2.9098% | 3.0145% |

| 3 | 0.0392 | 0.0154 | 0.9818 | 0.9652 | 0.0345 | 0.0037 | 3.4547% | 0.3704% |

| 4 | 0.0388 | 0.0094 | 0.9717 | 0.9300 | 0.0408 | 0.0030 | 4.0777% | 0.2951% |

| 5 | 0.0176 | 0.0258 | 0.9954 | 0.9947 | 0.0232 | 0.0047 | 2.3192% | 0.4720% |

| P | V | F | |

|---|---|---|---|

| Acceptable bead Prediction | Low | Low | High |

| Good layer Deposition | Low | Low | High |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mbodj, N.G.; Abuabiah, M.; Plapper, P.; El Kandaoui, M.; Yaacoubi, S. Bead Geometry Prediction in Laser-Wire Additive Manufacturing Process Using Machine Learning: Case of Study. Appl. Sci. 2021, 11, 11949. https://doi.org/10.3390/app112411949

Mbodj NG, Abuabiah M, Plapper P, El Kandaoui M, Yaacoubi S. Bead Geometry Prediction in Laser-Wire Additive Manufacturing Process Using Machine Learning: Case of Study. Applied Sciences. 2021; 11(24):11949. https://doi.org/10.3390/app112411949

Chicago/Turabian StyleMbodj, Natago Guilé, Mohammad Abuabiah, Peter Plapper, Maxime El Kandaoui, and Slah Yaacoubi. 2021. "Bead Geometry Prediction in Laser-Wire Additive Manufacturing Process Using Machine Learning: Case of Study" Applied Sciences 11, no. 24: 11949. https://doi.org/10.3390/app112411949

APA StyleMbodj, N. G., Abuabiah, M., Plapper, P., El Kandaoui, M., & Yaacoubi, S. (2021). Bead Geometry Prediction in Laser-Wire Additive Manufacturing Process Using Machine Learning: Case of Study. Applied Sciences, 11(24), 11949. https://doi.org/10.3390/app112411949