Feasibility of Application of Near Infrared Reflectance (NIR) Spectroscopy for the Prediction of the Chemical Composition of Traditional Sausages

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Sampling

2.1.1. Samples for the Development of the Calibration Model

2.1.2. Samples for Validation of the Calibration Model

2.2. Preparation of Samples for Proximate Analysis

2.3. Proximate Analysis (Reference Methods)

2.4. NIR Spectroscopy

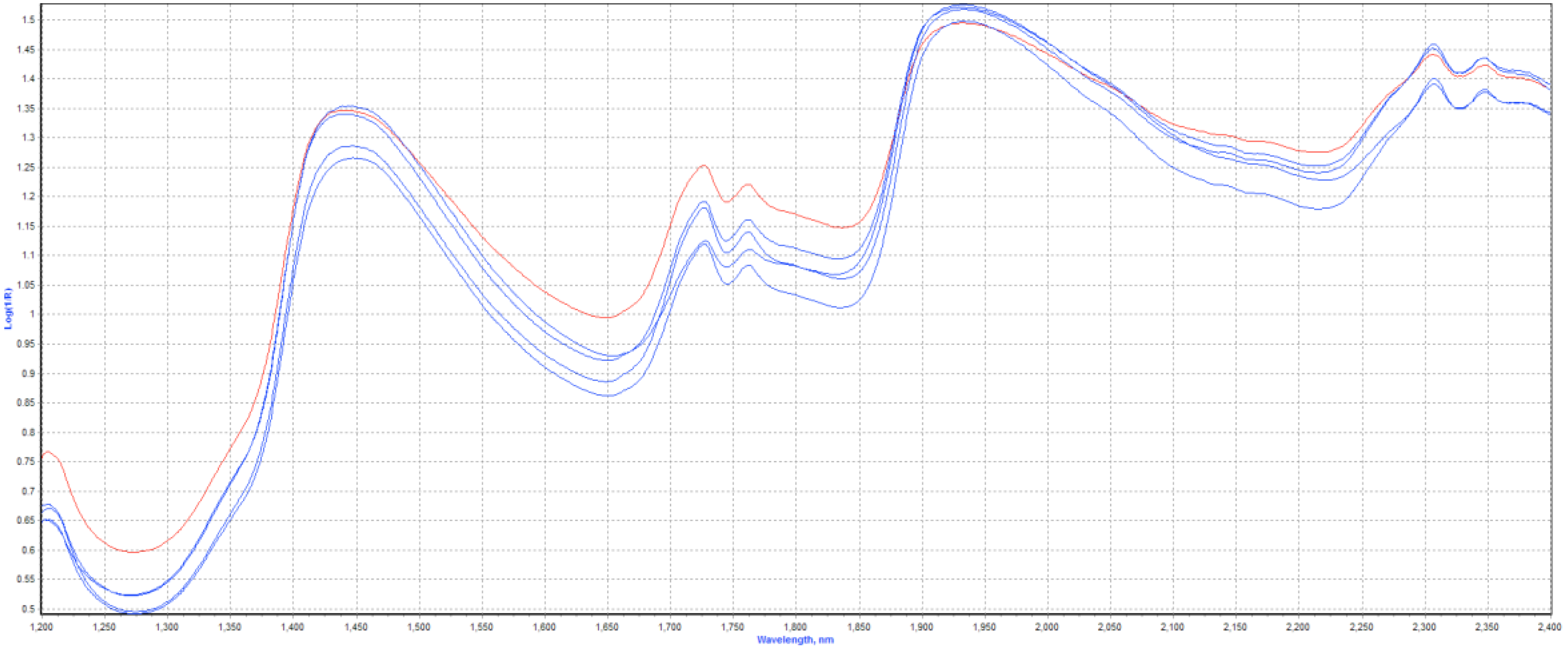

2.4.1. Spectra Acquisition

2.4.2. Spectra Analysis

2.4.3. Regression Analysis

3. Results and Discussion

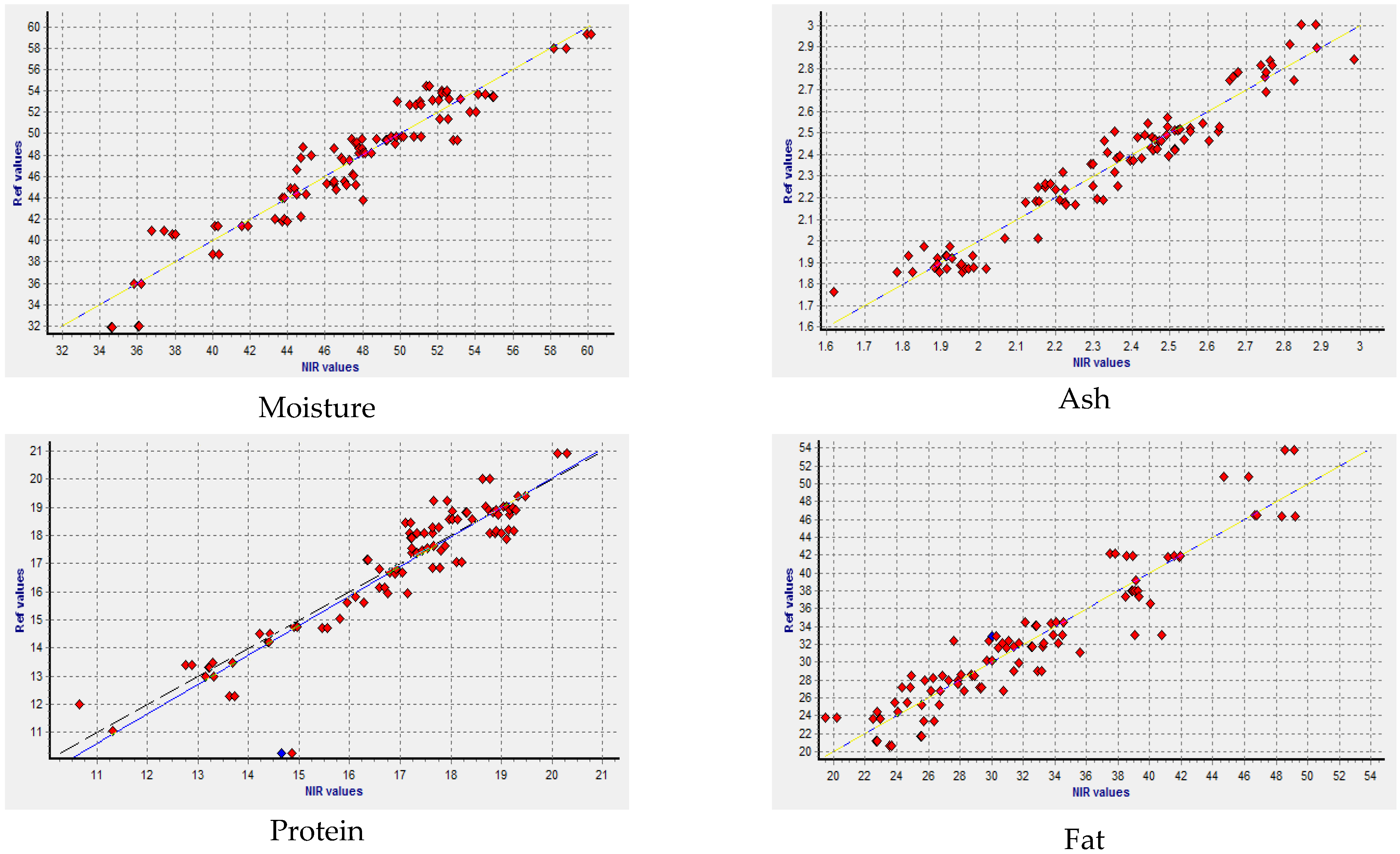

3.1. Development of the Calibration Model

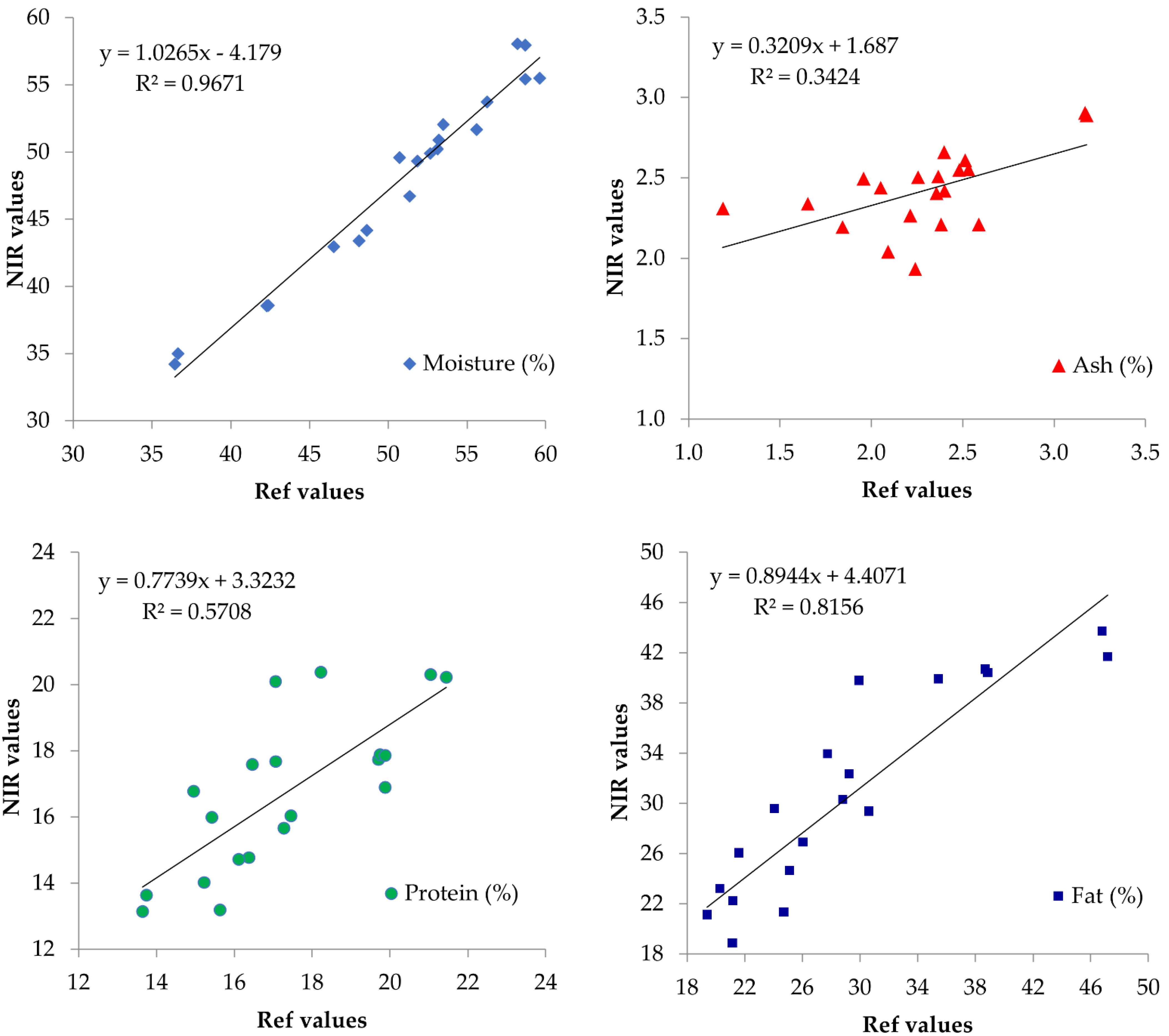

3.2. Validation of the Calibration Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Papagianni, M.; Ambrosiadis, I.; Filiousis, G. Mould growth on traditional Greek sausages and penicillin production by Penicillium isolates. Meat Sci. 2007, 76, 653–657. [Google Scholar] [CrossRef] [PubMed]

- Greek state. Code of Foodstuffs, Beverages and Objects of Common Use—Part A: Foodstuffs and beverages (Classification, specifications and definitions of meat products and meat preparations). Gov. Gaz 2014, 91. (In Greek) [Google Scholar]

- Papadima, S.N.; Arvanitoyannis, I.; Bloukas, J.G.; Fournitzis, G.C. Chemometric model for describing Greek traditional sausages. Meat Sci. 1999, 51, 271–277. [Google Scholar] [CrossRef]

- Ambrosiadis, J.; Soultos, N.; Abrahim, A.; Bloukas, J.G. Physicochemical, microbiological and sensory attributes for the characterization of Greek traditional sausages. Meat Sci. 2004, 66, 279–287. [Google Scholar] [CrossRef]

- Konstandinidis, K.; Kasapidou, E.; Govaris, A.; Mitlianga, P. Evaluation of the chemical composition and the nutritional quality of traditional (village) style Greek Sausages. In Proceedings of the 59th International Congress of Meat Science and Technology, Izmir, Turkey, 18–23 August 2013; p. 129. [Google Scholar]

- Parasoglou, V.-K.; Tzemou, M.; Mitlianga, P.; Kasapidou, E. Variation in the chemical composition of traditional sausages per production batch. In Proceedings of the 4th Panhellenic Conference of Production Animals and Food Hygiene, Volos, Greece, 12–14 May 2017. [Google Scholar]

- Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the Provision of Food Information to Consumers, Amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and Repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004. Available online: https://eur-lex.europa.eu/eli/reg/2011/1169/2018-01-01 (accessed on 25 January 2021).

- Sheard, P.R.; Hope, E.; Hughes, S.I.; Baker, A.; Nute, G.R. Eating quality of UK-style sausages varying in price, meat content, fat level and salt content. Meat Sci. 2010, 85, 40–46. [Google Scholar] [CrossRef]

- Dixit, Y.; Casado-Gavalda, M.P.; Cama-Moncunill, R.; Cama-Moncunill, X.; Markiewicz-Keszycka, M.; Cullen, P.J.; Sullivan, C. Developments and challenges in online NIR spectroscopy for meat processing. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1172–1187. [Google Scholar] [CrossRef]

- Prieto, N.; Roehe, R.; Lavín, P.; Batten, G.; Andrés, S. Application of near infrared reflectance spectroscopy to predict meat and meat products quality: A review. Meat Sci. 2009, 83, 175–186. [Google Scholar] [CrossRef] [PubMed]

- Ortiz-Somovilla, V.; España-España, F.; Gaitán-Jurado, A.J.; Pérez-Aparicio, J.; de Pedro-Sanz, E.J. Proximate analysis of homogenized and minced mass of pork sausages by NIRS. Food Chem. 2007, 101, 1031–1040. [Google Scholar] [CrossRef]

- Gaitán-Jurado, A.J.; Ortiz-Somovilla, V.; España-España, F.; Pérez-Aparicio, J.; De Pedro-Sanz, E.J. Quantitative analysis of pork dry-cured sausages to quality control by NIR spectroscopy. Meat Sci. 2008, 78, 391–399. [Google Scholar] [CrossRef]

- Zamora-Rojas, E.; Pérez-Marín, D.; de Pedro-Sanz, E.; Guerrero-Ginel, J.E.; Garrido-Varo, A. Handheld NIRS analysis for routine meat quality control: Database transfer from at-line instruments. Chemom. Intell. Lab. Syst. 2012, 114, 30–35. [Google Scholar] [CrossRef]

- González-Mohino, A.; Pérez-Palacios, T.; Antequera, T.; Ruiz-Carrascal, J.; Olegario, L.S.; Grassi, S. Monitoring the Processing of Dry Fermented Sausages with a Portable NIRS Device. Foods 2020, 9, 1294. [Google Scholar] [CrossRef] [PubMed]

- Greek state. Regulation of operation subjects for the production of meat products in the premises of butcher shops. Gov. Gaz 2014. (In Greek) [Google Scholar]

- Harrington, P.D.B. Multiple versus single set validation of multivariate models to avoid mistakes. Crit. Rev. Anal. Chem. 2018, 48, 33–46. [Google Scholar] [CrossRef] [PubMed]

- Ritthiruangdej, P.; Ritthiron, R.; Shinzawa, H.; Ozaki, Y. Non-destructive and rapid analysis of chemical compositions in thai steamed pork sausages by near-infrared spectroscopy. Food Chem. 2011, 129, 684–692. [Google Scholar] [CrossRef] [PubMed]

- Anderson, S. Determination of fat, moisture, and protein in meat and meat products by using the FOSS FoodScan near-infrared spectrophotometer with FOSS artificial neural network calibration model and associated database: Collaborative study. J. AOAC Int. 2007, 90, 1073–1083. [Google Scholar] [CrossRef]

- Workman, J.J. NIR spectroscopy calibration basics. In Handbook of Near-Infrared Analysis, 3rd ed.; Burns, D.A., Ciurczak, E.W., Eds.; CRC Press: Boca Raton, FL, USA, 2008; pp. 123–150. [Google Scholar]

- Cozzolino, D.; Murray, I. Effect of sample presentation and animal muscle species on the analysis of meat by near infrared reflectance spectroscopy. J. Near Infrared Spectrosc. 2002, 10, 37–44. [Google Scholar] [CrossRef]

- Williams, P. Sampling, sample preparation, and sample selection. In Handbook of Near-Infrared Analysis, 3rd ed.; Burns, D.A., Ciurczak, E.W., Eds.; CRC Press: Boca Raton, FL, USA, 2008; pp. 267–295. [Google Scholar]

- Association of Analytical Communities International. Official Methods of Analysis of AOAC International, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2003. [Google Scholar]

- Greenfield, H.; Southgate, D.A.T. Food Composition Data—Production, Management and Use, 2nd ed.; Food and Agriculture Organization of the United Nations: Rome, Italy, 2003. [Google Scholar]

- Prevolnik, M.; Candek-Potokar, M.; Skorjanc, D. Ability of NIR spectroscopy to predict meat chemical composition and quality: A review. Czech J. Anim. Sci. 2004, 49, 500–510. [Google Scholar] [CrossRef]

- Prieto, N.; Pawluczyk, O.; Dugan, M.E.R.; Aalhus, J.L. A review of the principles and applications of near-infrared spectroscopy to characterize meat, fat, and meat products. Appl. Spectrosc. 2017, 71, 1403–1426. [Google Scholar] [CrossRef] [Green Version]

- Shenk, J.S.; Westerhaus, M.O. Calibration the ISI Way. In Near Infrared Spectroscopy: The Future Waves; Davies, A.M.C., Williams, P.C., Eds.; NIR Publications: Chichester, UK, 1996; pp. 198–202. [Google Scholar]

- Porep, J.U.; Kammerer, D.R.; Carle, R. On-line application of near infrared (NIR) spectroscopy in food production. Trends Food Sci. Technol. 2015, 46, 211–230. [Google Scholar] [CrossRef]

- Su, H.; Sha, K.; Zhang, L.; Zhang, Q.; Xu, Y.; Zhang, R.; Li, H.; Sun, B. Development of near infrared reflectance spectroscopy to predict chemical composition with a wide range of variability in beef. Meat Sci. 2014, 98, 110–114. [Google Scholar] [CrossRef]

- Alomar, D.; Gallo, C.; Castaneda, M.; Fuchslocher, R. Chemical and discriminant analysis of bovine meat by near infrared reflectance spectroscopy (NIRS). Meat Sci. 2003, 63, 441–450. [Google Scholar] [CrossRef]

- Weeranantanaphan, J.; Downey, G.; Allen, P.; Sun, D.W. A review of near infrared spectroscopy in muscle food analysis: 2005–2010. J. Near Infrared Spectrosc. 2011, 19, 61–104. [Google Scholar] [CrossRef]

- Collell, C.; Gou, P.; Picouet, P.; Arnau, J.; Comaposada, J. Feasibility of near-infrared spectroscopy to predict aw and moisture and NaCl contents of fermented pork sausages. Meat Sci. 2010, 85, 325–330. [Google Scholar] [CrossRef] [PubMed]

- Tzemou, M.; Parasoglou, V.K.; Ioannidou, T.; Papadopoulos, V.; Mitlianga, P.; Kasapidou, E. Prediction of chemical composition of Greek traditional sausages by near-infrared reflectance spectroscopy. In Proceedings of the 3rd IMEKO Foods Conference: Metrology Promoting Harmonization and Standardization in Food and Nutrition, Thessaloniki, Greece, 1–4 October 2017; P27. pp. 236–239. [Google Scholar]

- European Commission. Guidance Document for Competent Authorities for the Control of Compliance with EU Legislation on: Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the Provision of Food Information to Consumers, Amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and Repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004 and Council Directive 90/496/EEC of 24 September 1990 on Nutrition Labelling of Foodstuffs and Directive 2002/46/EC of the European Parliament and of the Council of 10 June 2002 on the Approximation of the Laws of the Member States Relating to Food Supplements with Regard to the Setting of Tolerances for Nutrient Values Declared on a Label. 2012. Available online: https://ec.europa.eu/food/sites/food/files/safety/docs/labelling_nutrition-vitamins_minerals-guidance_tolerances_1212_en.pdf (accessed on 10 February 2021).

| Parameter | Mean Values | Standard Deviation | Range |

|---|---|---|---|

| Reference Methods | |||

| Moisture (%) | 47.73 | 5.215 | 31.87–59.24 |

| Ash (%) | 2.49 | 0.369 | 1.85–3.28 |

| Protein (%) | 17.61 | 2.222 | 11.08–22.41 |

| Fat (%) | 31.41 | 6.888 | 20.72–53.76 |

| NIR Spectroscopy | |||

| Moisture (%) | 47.21 | 4.865 | 34.65–59.94 |

| Ash (%) | 2.41 | 0.305 | 1.62–3.09 |

| Protein (%) | 17.82 | 2.412 | 10.65–21.88 |

| Fat (%) | 31.33 | 6.320 | 19.48–49.32 |

| Parameter | SEC | RMSEC | SECV | RMSECV |

|---|---|---|---|---|

| Moisture (%) | 1.58 | 0.92 | 2.13 | 0.86 |

| Ash (%) | 0.18 | 0.77 | 0.26 | 0.56 |

| Protein (%) | 0.89 | 0.87 | 1.17 | 0.78 |

| Fat (%) | 1.73 | 0.93 | 2.17 | 0.88 |

| Parameter | Mean Values | Standard Deviation | Range |

|---|---|---|---|

| Reference Methods | |||

| Moisture (%) | 50.73 | 6.934 | 36.46–59.62 |

| Ash (%) | 2.29 | 0.452 | 1.19–3.18 |

| Protein (%) | 17.32 | 2.321 | 13.64–21.45 |

| Fat (%) | 28.83 | 8.513 | 19.38–47.18 |

| NIR Spectroscopy | |||

| Moisture (%) | 47.90 | 7.238 | 34.21–58.06 |

| Ash (%) | 2.42 | 0.248 | 1.94–2.91 |

| Protein (%) | 16.73 | 2.377 | 13.14–20.37 |

| Fat (%) | 30.20 | 8.431 | 17.84–43.72 |

| Deviations between NIR spectroscopy values and reference methods values | |||

| Moisture (%) | −2.83 | 1.326 | −4.73–−0.15 |

| Ash (%) | 0.13 | 0.367 | −0.38–1.12 |

| Protein (%) | −0.59 | 1.643 | −2.99–3.04 |

| Fat (%) | 1.36 | 3.730 | −5.48–9.87 |

| Parameter | Correlation Coefficient | Significance |

|---|---|---|

| Moisture (%) | 0.983 | *** |

| Ash (%) | 0.585 | ** |

| Protein (%) | 0.756 | *** |

| Fat (%) | 0.903 | *** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kasapidou, E.; Papadopoulos, V.; Mitlianga, P. Feasibility of Application of Near Infrared Reflectance (NIR) Spectroscopy for the Prediction of the Chemical Composition of Traditional Sausages. Appl. Sci. 2021, 11, 11282. https://doi.org/10.3390/app112311282

Kasapidou E, Papadopoulos V, Mitlianga P. Feasibility of Application of Near Infrared Reflectance (NIR) Spectroscopy for the Prediction of the Chemical Composition of Traditional Sausages. Applied Sciences. 2021; 11(23):11282. https://doi.org/10.3390/app112311282

Chicago/Turabian StyleKasapidou, Eleni, Vasileios Papadopoulos, and Paraskevi Mitlianga. 2021. "Feasibility of Application of Near Infrared Reflectance (NIR) Spectroscopy for the Prediction of the Chemical Composition of Traditional Sausages" Applied Sciences 11, no. 23: 11282. https://doi.org/10.3390/app112311282

APA StyleKasapidou, E., Papadopoulos, V., & Mitlianga, P. (2021). Feasibility of Application of Near Infrared Reflectance (NIR) Spectroscopy for the Prediction of the Chemical Composition of Traditional Sausages. Applied Sciences, 11(23), 11282. https://doi.org/10.3390/app112311282