Effect of Nano Hydrotalcite on the Aging Resistance of a High Binder Content Stone Mastic Asphalt

Abstract

:1. Introduction

2. Materials and Methods

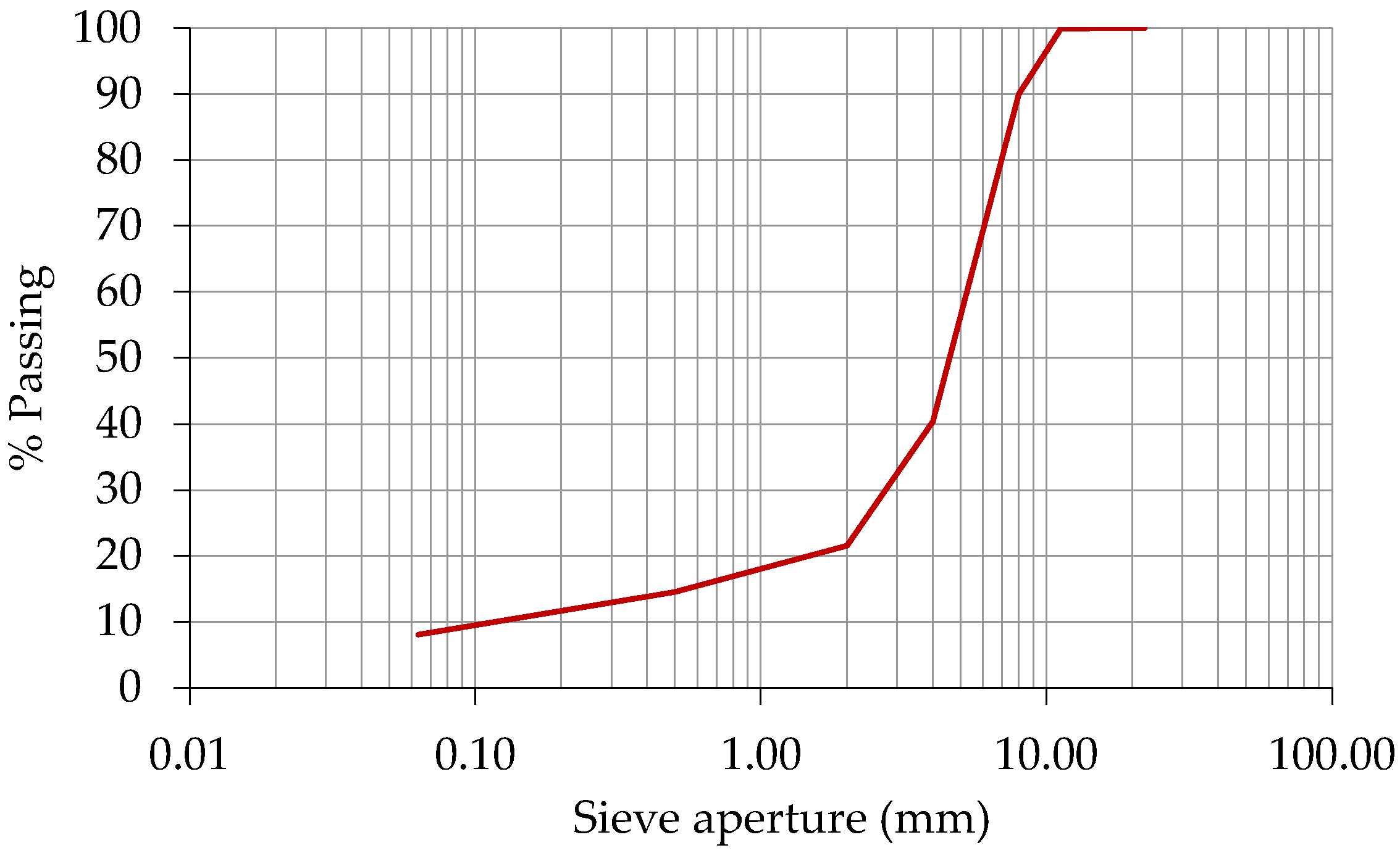

2.1. Materials

2.2. Methods

3. Results and Discussion

3.1. Surface Characteristics

3.2. Mechanical Performance

3.2.1. Indirect Tensile Strength and Water Sensitivity

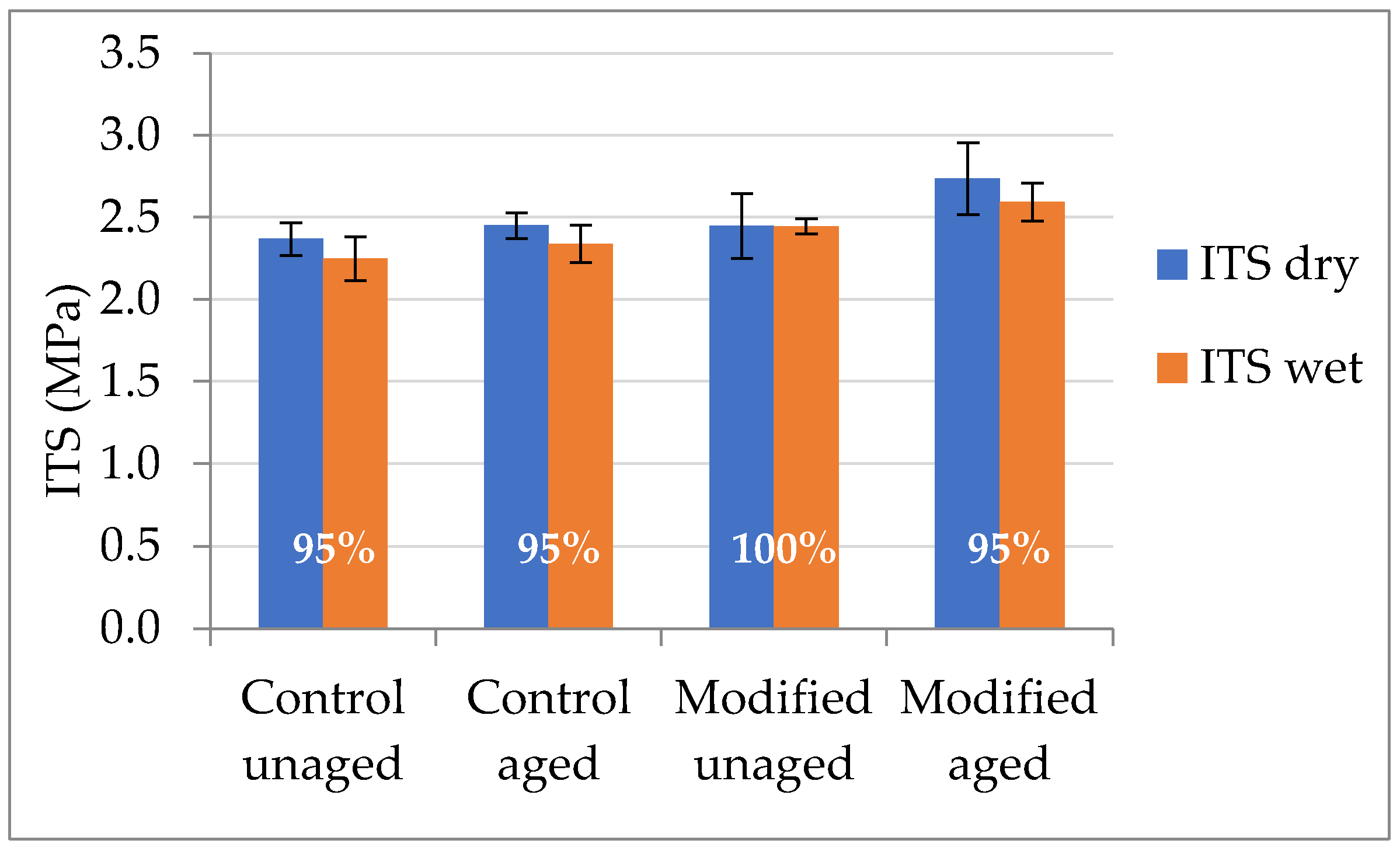

3.2.2. Stiffness

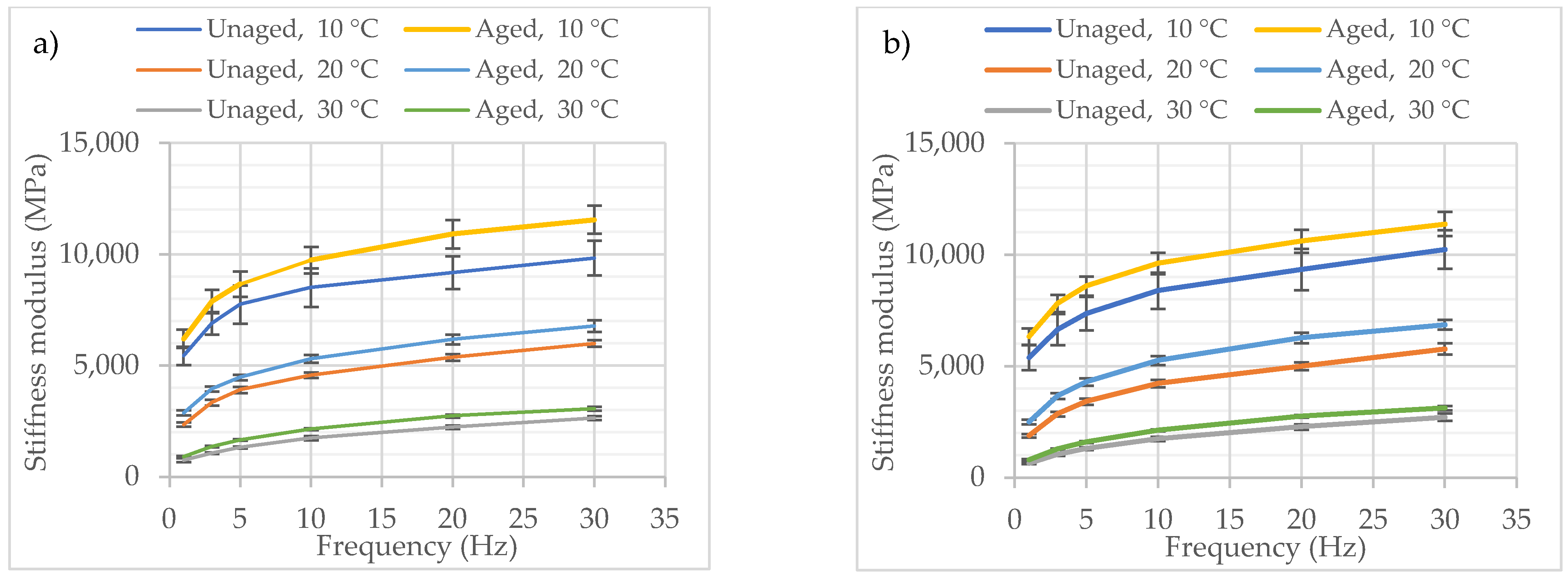

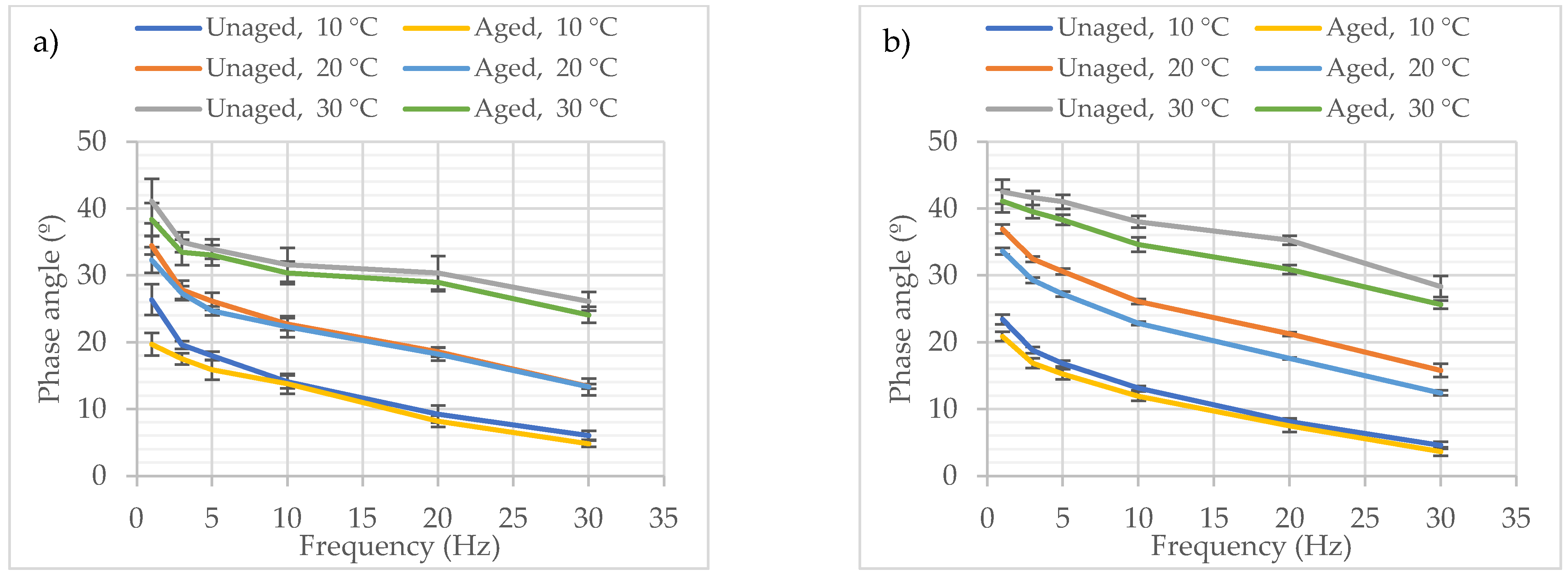

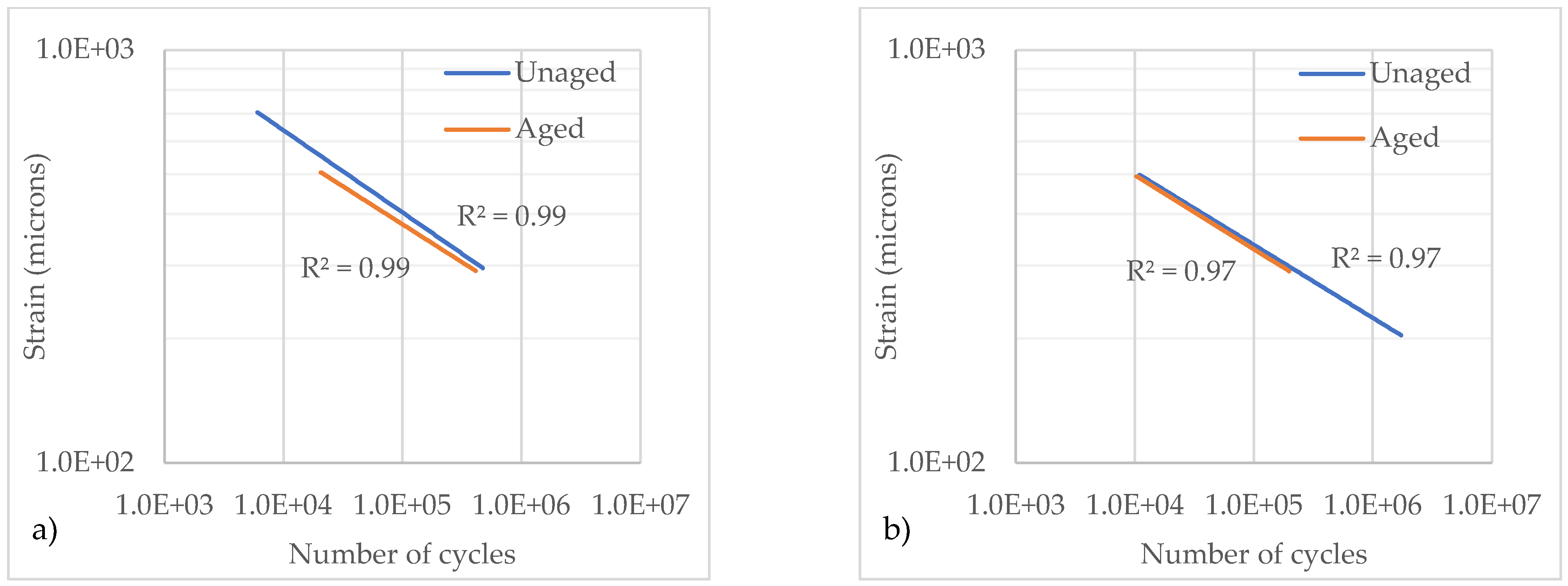

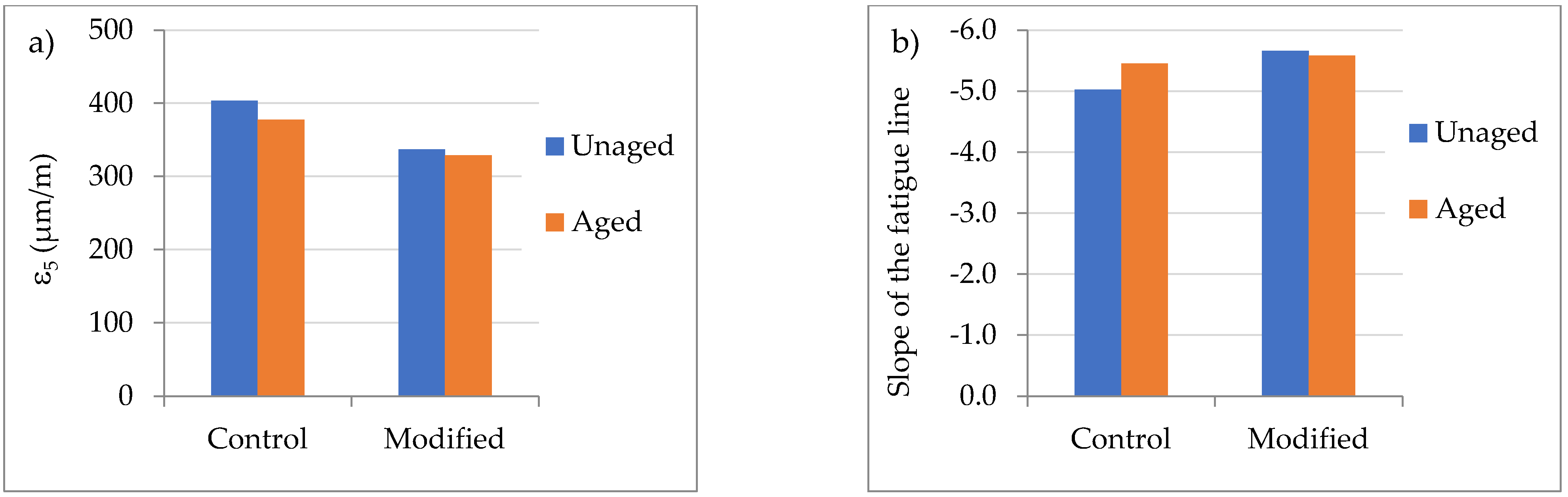

3.2.3. Resistance to Fatigue

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Miranda, H.M.B.; Batista, F.A.; Neves, J.; Antunes, M.D.L. Influence of the aggregate skeleton matrix and volumetric composition on the resistance of stone mastic asphalt to permanent deformation. Road Mater. Pavement Des. 2020, 1–14. [Google Scholar] [CrossRef]

- Polaczyk, P.; Ma, Y.; Xiao, R.; Hu, W.; Jiang, X.; Huang, B. Characterization of aggregate interlocking in hot mix asphalt by mechanistic performance tests. Road Mater. Pavement Des. 2021, 22, S498–S513. [Google Scholar] [CrossRef]

- White, G.; Almutairi, H. Laboratory and field performance comparison of dense graded and stone mastic asphalt as a runway surface. Int. J. Pavement Eng. 2020, 1–13. [Google Scholar] [CrossRef]

- Sirin, O.; Paul, D.K.; Kassem, E. State of the Art Study on Aging of Asphalt Mixtures and Use of Antioxidant Additives. Adv. Civ. Eng. 2018, 2018, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Habbouche, J.; Hajj, E.Y.; Sebaaly, P.E.; Piratheepan, M. A critical review of high polymer-modified asphalt binders and mixtures. Int. J. Pavement Eng. 2018, 21, 686–702. [Google Scholar] [CrossRef]

- Behnood, A. A review of the warm mix asphalt (WMA) technologies: Effects on thermo-mechanical and rheological properties. J. Clean. Prod. 2020, 259, 120817. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Caputo, P.; Abe, A.A.; Loise, V.; Porto, M.; Calandra, P.; Angelico, R.; Rossi, C.O. The Role of Additives in Warm Mix Asphalt Technology: An Insight into Their Mechanisms of Improving an Emerging Technology. Nanomaterials 2020, 10, 1202. [Google Scholar] [CrossRef]

- Gupta, A.; Rodriguez-Hernandez, J.; Castro-Fresno, D. Incorporation of Additives and Fibers in Porous Asphalt Mixtures: A Review. Materials 2019, 12, 3156. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Picado-Santos, L.G.; Capitão, S.D.; Neves, J.M. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Rossi, C.O.; Teltayev, B.; Angelico, R. Adhesion Promoters in Bituminous Road Materials: A Review. Appl. Sci. 2017, 7, 524. [Google Scholar] [CrossRef] [Green Version]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Pascual-Muñoz, P.; Castro-Fresno, D. Mechanical performance of fibers in hot mix asphalt: A review. Constr. Build. Mater. 2019, 200, 756–769. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J.; Capitão, S. A Review of Nanomaterials’ Effect on Mechanical Performance and Aging of Asphalt Mixtures. Appl. Sci. 2019, 9, 3657. [Google Scholar] [CrossRef] [Green Version]

- Tabaković, A.; Schlangen, E. Self-Healing Technology for Asphalt Pavements. In Self-Healing Materials; Hager, M.D., van der Zwaag, S., Schubert, U.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 285–306. [Google Scholar]

- Vo, H.V.; Park, D.-W.; Seo, J.-W.; Le, T.H.M. Effects of asphalt types and aging on healing performance of asphalt mixtures using induction heating method. J. Traffic Transp. Eng. (Engl. Ed.) 2019, 7, 227–236. [Google Scholar] [CrossRef]

- Pasupunuri, S.K.; Tiwari, D.; Jain, S.; Kumar, P. Self-healing pavements: A revolution in pavement materials. In Proceedings of the IRF World Road Meeting, New Delhi, India, 14–17 November 2017; p. 739. [Google Scholar]

- Gulisano, F.; Crucho, J.; Gallego, J.; Picado-Santos, L. Microwave Healing Performance of Asphalt Mixture Containing Electric Arc Furnace (EAF) Slag and Graphene Nanoplatelets (GNPs). Appl. Sci. 2020, 10, 1428. [Google Scholar] [CrossRef] [Green Version]

- Martinho, F.C.G.; Farinha, J.P.S. An overview of the use of nanoclay modified bitumen in asphalt mixtures for enhanced flexible pavement performances. Road Mater. Pavement Des. 2017, 20, 671–701. [Google Scholar] [CrossRef]

- Yang, J.; Tighe, S. A Review of Advances of Nanotechnology in Asphalt Mixtures. Procedia-Soc. Behav. Sci. 2013, 96, 1269–1276. [Google Scholar] [CrossRef] [Green Version]

- Crucho, J.; Neves, J.; Capitão, S.; Picado-Santos, L. Mechanical performance of asphalt concrete modified with nanoparticles: Nanosilica, zero-valent iron and nanoclay. Constr. Build. Mater. 2018, 181, 309–318. [Google Scholar] [CrossRef]

- Filippi, S.; Cappello, M.; Merce, M.; Polacco, G. Effect of Nanoadditives on Bitumen Aging Resistance: A Critical Review. J. Nanomater. 2018, 2018, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Evans, D.G.; Slade, R.C.T. Structural Aspects of Layered Double Hydroxides. In Layered Double Hydroxides; Duan, X., Evans, D.G., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 1–87. [Google Scholar]

- Wang, Q.; O’Hare, D. Recent Advances in the Synthesis and Application of Layered Double Hydroxide (LDH) Nanosheets. Chem. Rev. 2012, 112, 4124–4155. [Google Scholar] [CrossRef]

- Xu, S.; Chen, Z.; Zhang, B.; Yu, J.; Zhang, F.; Evans, D.G. Facile preparation of pure CaAl-layered double hydroxides and their application as a hardening accelerator in concrete. Chem. Eng. J. 2009, 155, 881–885. [Google Scholar] [CrossRef]

- Duan, P.; Chen, W.; Ma, J.; Shui, Z. Influence of layered double hydroxides on microstructure and carbonation resistance of sulphoaluminate cement concrete. Constr. Build. Mater. 2013, 48, 601–609. [Google Scholar] [CrossRef]

- Cui, P.; Zhou, H.; Li, C.; Wu, S.; Xiao, Y. Characteristics of using layered double hydroxides to reduce the VOCs from bituminous materials. Constr. Build. Mater. 2016, 123, 69–77. [Google Scholar] [CrossRef]

- Liu, X.; Wu, S.; Pang, L.; Xiao, Y.; Pan, P. Fatigue Properties of Layered Double Hydroxides Modified Asphalt and Its Mixture. Adv. Mater. Sci. Eng. 2014, 2014, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Pang, L.; Liu, K.; Wu, S.; Lei, M.; Chen, Z. Effect of LDHs on the aging resistance of crumb rubber modified asphalt. Constr. Build. Mater. 2014, 67, 239–243. [Google Scholar] [CrossRef]

- Peng, C.; Yu, J.; Zhao, Z.; Fu, J.; Zhao, M.; Wang, W.; Dai, J. Preparation and properties of a layered double hydroxide deicing additive for asphalt mixture. Cold Reg. Sci. Technol. 2014, 110, 70–76. [Google Scholar] [CrossRef]

- Xu, S.; Li, L.; Yu, J.; Zhang, C.; Zhou, J.; Sun, Y. Investigation of the ultraviolet aging resistance of organic layered double hydroxides modified bitumen. Constr. Build. Mater. 2015, 96, 127–134. [Google Scholar] [CrossRef]

- Xu, S.; Yu, J.; Zhang, C.; Yao, T.; Sun, Y. Effect of salicylic acid intercalated layered double hydroxides on ultraviolet aging properties of bitumen. Mater. Struct. 2015, 49, 1235–1244. [Google Scholar] [CrossRef]

- Xu, S.; Yu, J.; Hu, C.; Jia, L.; Xue, L. Performance evaluation of asphalt containing layered double hydroxides with different zinc ratio in the host layer. Pet. Sci. Technol. 2017, 35, 127–133. [Google Scholar] [CrossRef]

- Zhao, Z.J.; Xu, S.; Wu, W.F.; Yu, J.Y.; Wu, S.P. The Aging Resistance of Asphalt Containing a Compound of LDHs and Antioxidant. Pet. Sci. Technol. 2015, 33, 787–793. [Google Scholar] [CrossRef]

- Zhu, K.; Wang, Y.; Tang, D.; Wang, Q.; Li, H.; Huang, Y.; Huang, Z.; Wu, K. Flame-Retardant Mechanism of Layered Double Hydroxides in Asphalt Binder. Materials 2019, 12, 801. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, H.; Li, L.; Yu, J.; Xu, S.; Xie, D. Effect of layered double hydroxides on ultraviolet aging properties of different bitumens. Constr. Build. Mater. 2016, 111, 565–570. [Google Scholar] [CrossRef]

- Huang, Y.; Feng, Z.; Zhang, H.; Yu, J. Effect of Layered Double Hydroxides (LDHs) on Aging Properties of Bitumen. J. Test. Eval. 2012, 40, 734–739. [Google Scholar] [CrossRef]

- Bao, S.; Liu, Q.; Norambuena-Contreras, J.; Wang, Z.; Wu, S. Effect of layered double hydroxides addition on the ageing and self-healing properties of asphalt binder. Mater. Res. Express 2019, 6, 075704. [Google Scholar] [CrossRef]

- Shen, A.; Wu, H.; Guo, Y.; Yang, X.; He, Z.; Li, Y. Effect of Layered Double Hydroxide on Rheological and Flame-Retardant Properties of Styrene-Butadiene-Styrene–Modified Asphalt. J. Mater. Civ. Eng. 2021, 33, 04020454. [Google Scholar] [CrossRef]

- CEN. EN13108-5:2006, Bituminous Mixtures-Material Specifications-Part 5: Stone Mastic Asphalt; European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- CEN. EN12697-35:2004+A1:2007, Bituminous Mixtures-Test Methods for Hot Mix Asphalt-Part 35: Laboratory Mixing; European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- CEN. EN12697-30:2012, Bituminous Mixtures-Test Methods for Hot Mix Asphalt-Part 30: Specimen Prepared by Impact Compactor; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- CEN. EN12697-33:2003+A1:2007, Bituminous Mixtures-Test Methods for Hot Mix Asphalt-Part 33: Specimen Prepared by Roller Compactor; European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- CEN. EN13036-4:2011, Road and Airfield Surface Characteristics-Test Methods-Part 4: Method for Measurement of Slip/Skid Resistance of a Surface: The Pendulum Test; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- CEN. EN13036-1:2010, Road and Airfield Surface Characteristics-Test Methods-Part 1: Measurement of Pavement Surface Macrotexture Depth Using a Volumetric Patch Technique; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- AASHTO. R30-02(2010), Standard Practice for Mixture Conditioning of Hot Mix Asphalt; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2010. [Google Scholar]

- CEN. EN12697-23:2003, Bituminous Mixtures-Test Methods for Hot Mix Asphalt-Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens; European Committee for Standardization: Brussels, Belgium, 2003. [Google Scholar]

- CEN. EN12697-12:2008, Bituminous Mixtures-Test Methods for Hot Mix Asphalt-Part 12: Determination of the Water Sensitivity of Bituminous Specimens; European Committee for Standardization: Brussels, Belgium, 2008. [Google Scholar]

- IP. Specifications; Portuguese Infrastructure Agency: Almada, Portugal, 2014. [Google Scholar]

- CEN. EN12697-26:2012, Bituminous Mixtures-Test Methods for Hot Mix Asphalt-Part 26: Stiffness; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- CEN. EN12697-24:2012, Bituminous Mixtures-Test Methods for Hot Mix Asphalt-Part 24: Resistance to Fatigue; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- Crucho, J.; Picado-Santos, L.; Neves, J.; Capitão, S.; Al-Qadi, I.L. Tecnico accelerated ageing (TEAGE)—A new laboratory approach for bituminous mixture ageing simulation. Int. J. Pavement Eng. 2018, 21, 753–765. [Google Scholar] [CrossRef]

- Islam, R.; Hossain, M.I.; Tarefder, R.A. A study of asphalt aging using Indirect Tensile Strength test. Constr. Build. Mater. 2015, 95, 218–223. [Google Scholar] [CrossRef]

| Property/Type of Test | Test Standard | Parameter | Unit | Value |

|---|---|---|---|---|

| Marshall method | EN 12697-34 | Binder content | % | 7.5 |

| Stability | kN | 6.7 | ||

| Flow | mm | 3.2 | ||

| Marshall Quotient | kN/mm | 2.1 | ||

| Porosity | % | 4.9 | ||

| Skid resistance | EN 13036-4 | Pendulum test value (PTV) | n.a. | 58 |

| Surface macrotexture | EN 13036-1 | Mean texture depth (MTD) | mm | 1.2 |

| Permanent deformation | EN 12697-22 | Rut depth in air (RDair) | mm | 3.9 |

| Proportional rut depth in air (PRDair) | % | 7.5 | ||

| Wheel-tracking slope in air (WTSair) | mm/103 cycles | 0.286 | ||

| Indirect tensile strength | EN 12697-23 | Indirect tensile strength (ITS) | MPa | 2.368 |

| Water sensitivity | EN 12697-12 | Indirect tensile strength ratio (ITSR) | % | 95 |

| Stiffness (at 20 °C, 10 Hz) | EN 12697-26 | Stiffness modulus | MPa | 4565 |

| Phase angle | ° | 22.7 | ||

| Resistance to fatigue (at 20 °C, 10 Hz) | EN 12697-24 | µm/m | 403 | |

| Slope of the fatigue line | n.a. | −5.02 |

| Binder | Penetration | Softening Point |

|---|---|---|

| × 10−1 mm | °C | |

| Control | 52.5 | 90.0 |

| Modified | 47.1 | 93.0 |

| Property | Test Standard | Parameters | Mixture Conditioning | |

|---|---|---|---|---|

| Unaged | Aged | |||

| Skid resistance | EN 13036-4 | Pendulum test value (PTV) | √ | × |

| Surface macrotexture | EN 13036-1 | Mean texture depth (MTD) | √ | × |

| Indirect tensile strength | EN 12697-23 | Indirect tensile strength (ITS) | √ | √ |

| Water sensitivity | EN 12697-12 | Indirect tensile strength ratio (ITSR) | √ | √ |

| Stiffness | EN 12697-26 | Stiffness modulus Phase angle | √ | √ |

| Resistance to fatigue | EN 12697-24 | Fatigue lines | √ | √ |

| Asphalt Mixture | PTV | MTD |

|---|---|---|

| mm | ||

| Control | 58 (4.3) | 1.2 (0.12) |

| Modified | 65 (5.2) | 1.0 (0.09) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Crucho, J.; Neves, J. Effect of Nano Hydrotalcite on the Aging Resistance of a High Binder Content Stone Mastic Asphalt. Appl. Sci. 2021, 11, 9971. https://doi.org/10.3390/app11219971

Crucho J, Neves J. Effect of Nano Hydrotalcite on the Aging Resistance of a High Binder Content Stone Mastic Asphalt. Applied Sciences. 2021; 11(21):9971. https://doi.org/10.3390/app11219971

Chicago/Turabian StyleCrucho, João, and José Neves. 2021. "Effect of Nano Hydrotalcite on the Aging Resistance of a High Binder Content Stone Mastic Asphalt" Applied Sciences 11, no. 21: 9971. https://doi.org/10.3390/app11219971

APA StyleCrucho, J., & Neves, J. (2021). Effect of Nano Hydrotalcite on the Aging Resistance of a High Binder Content Stone Mastic Asphalt. Applied Sciences, 11(21), 9971. https://doi.org/10.3390/app11219971