An Attempt to Model the Surface Pressures of Apples Using the Finite Element Method

Abstract

1. Introduction

1.1. Impact Loads on Biological Material

1.2. FEM Load Assessment of Biological Material

2. Materials and Methods

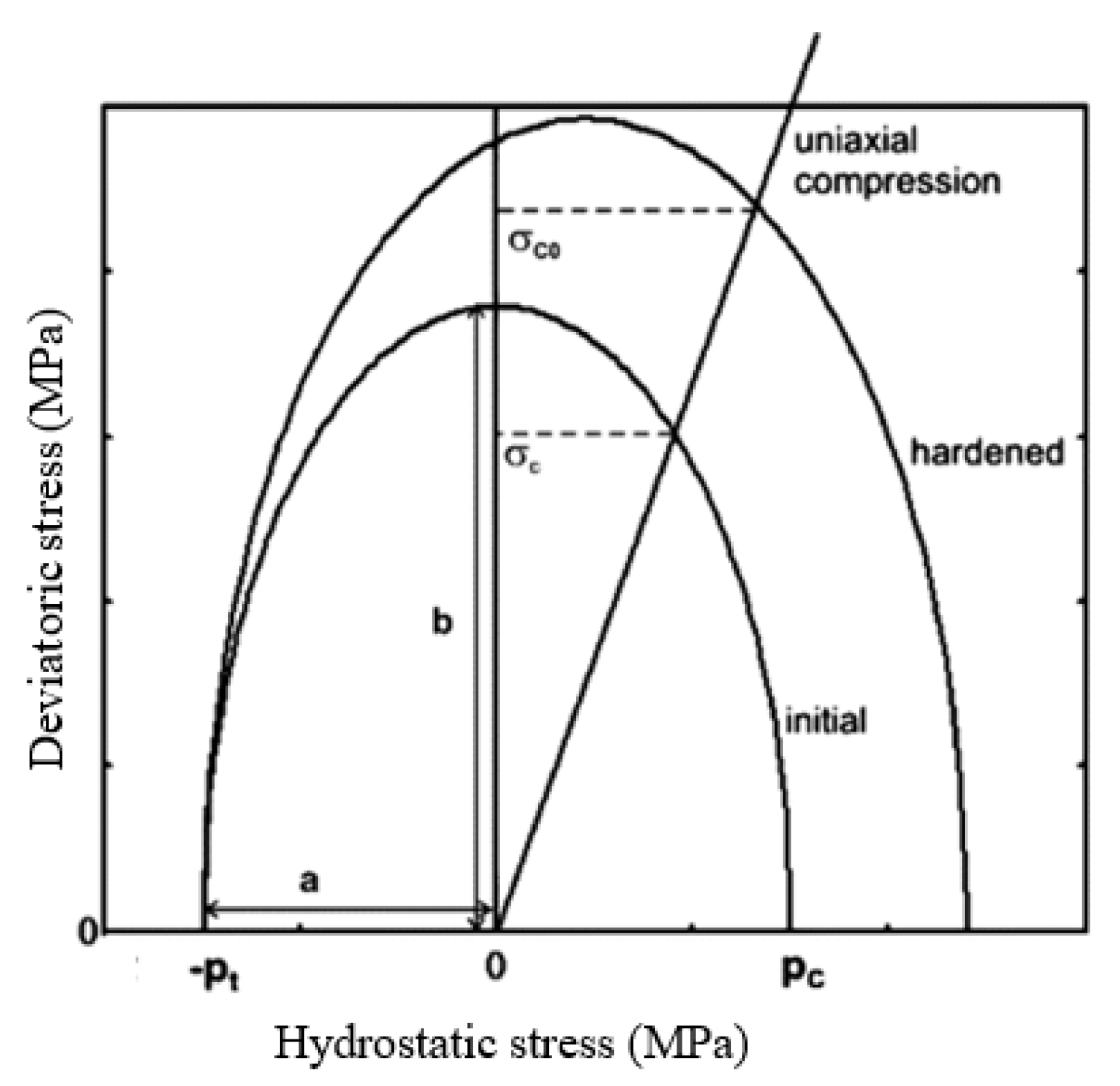

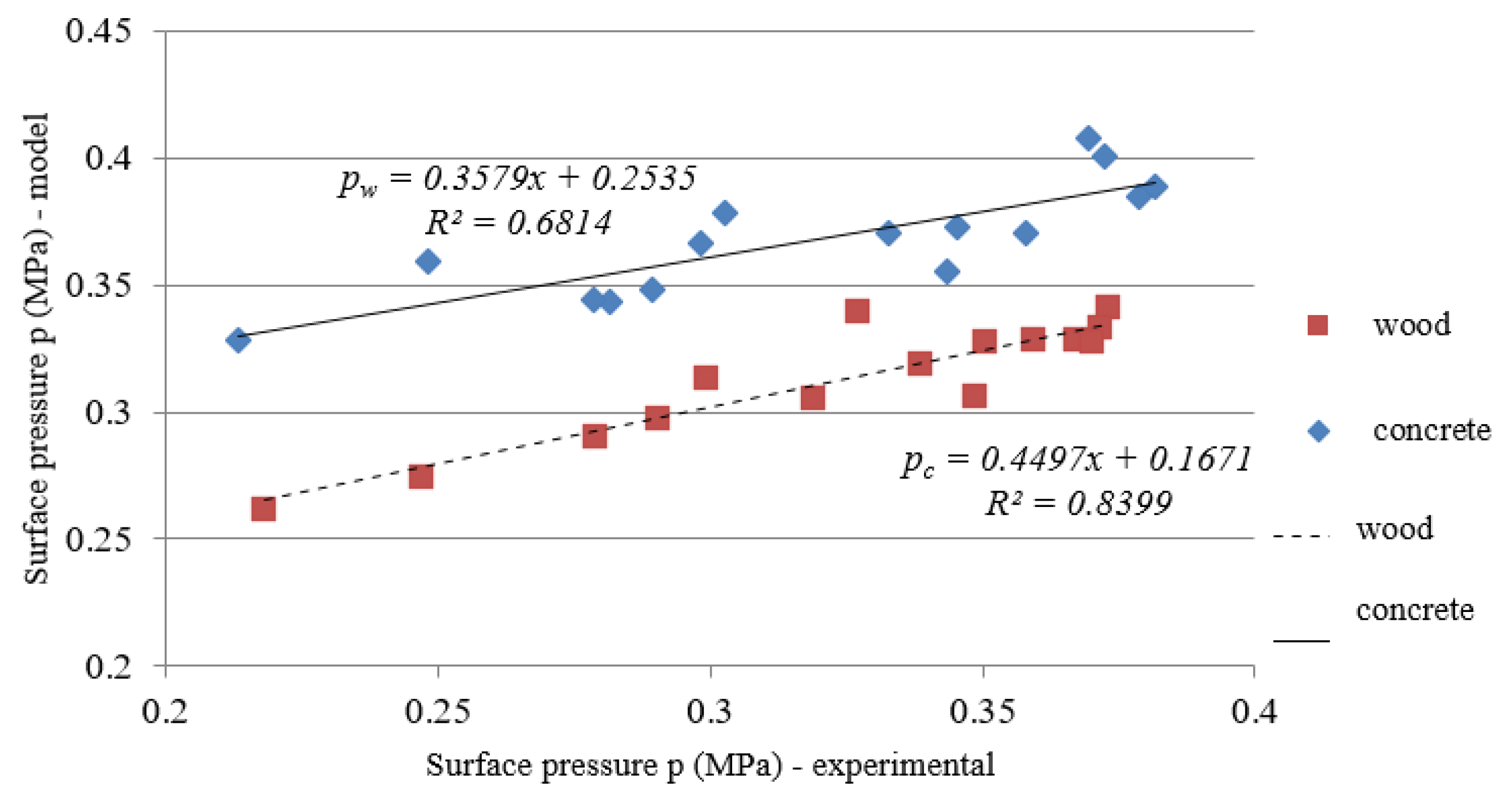

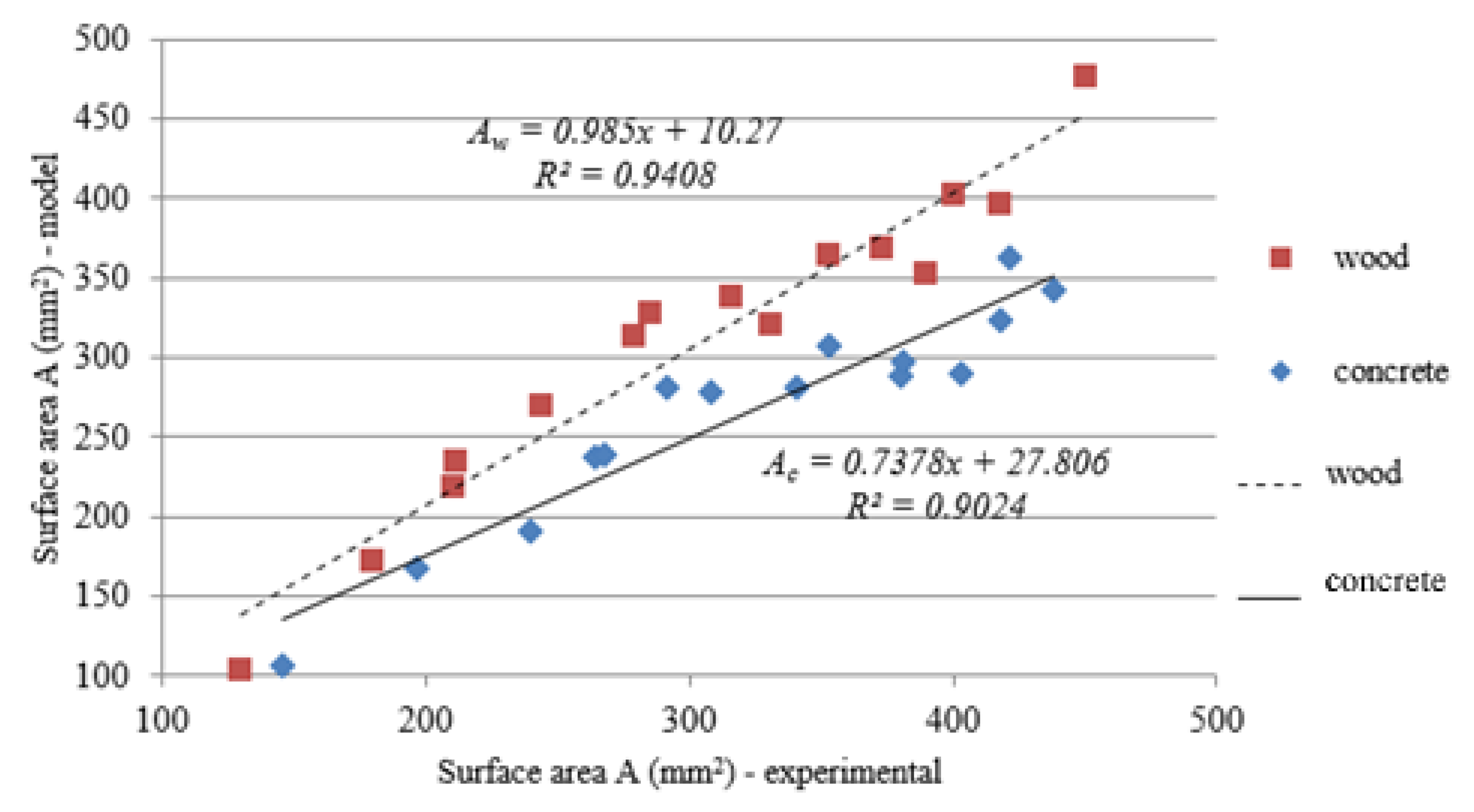

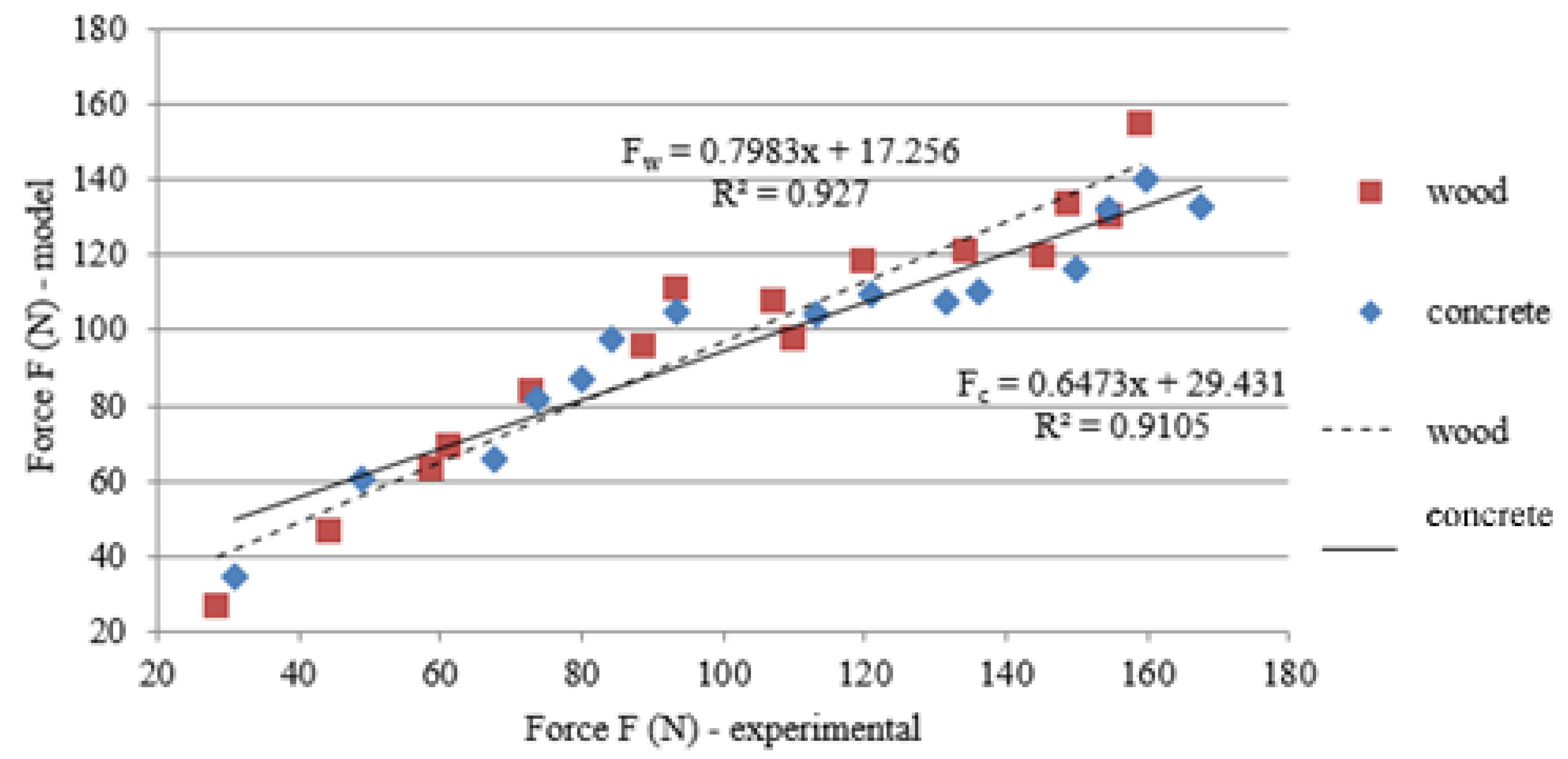

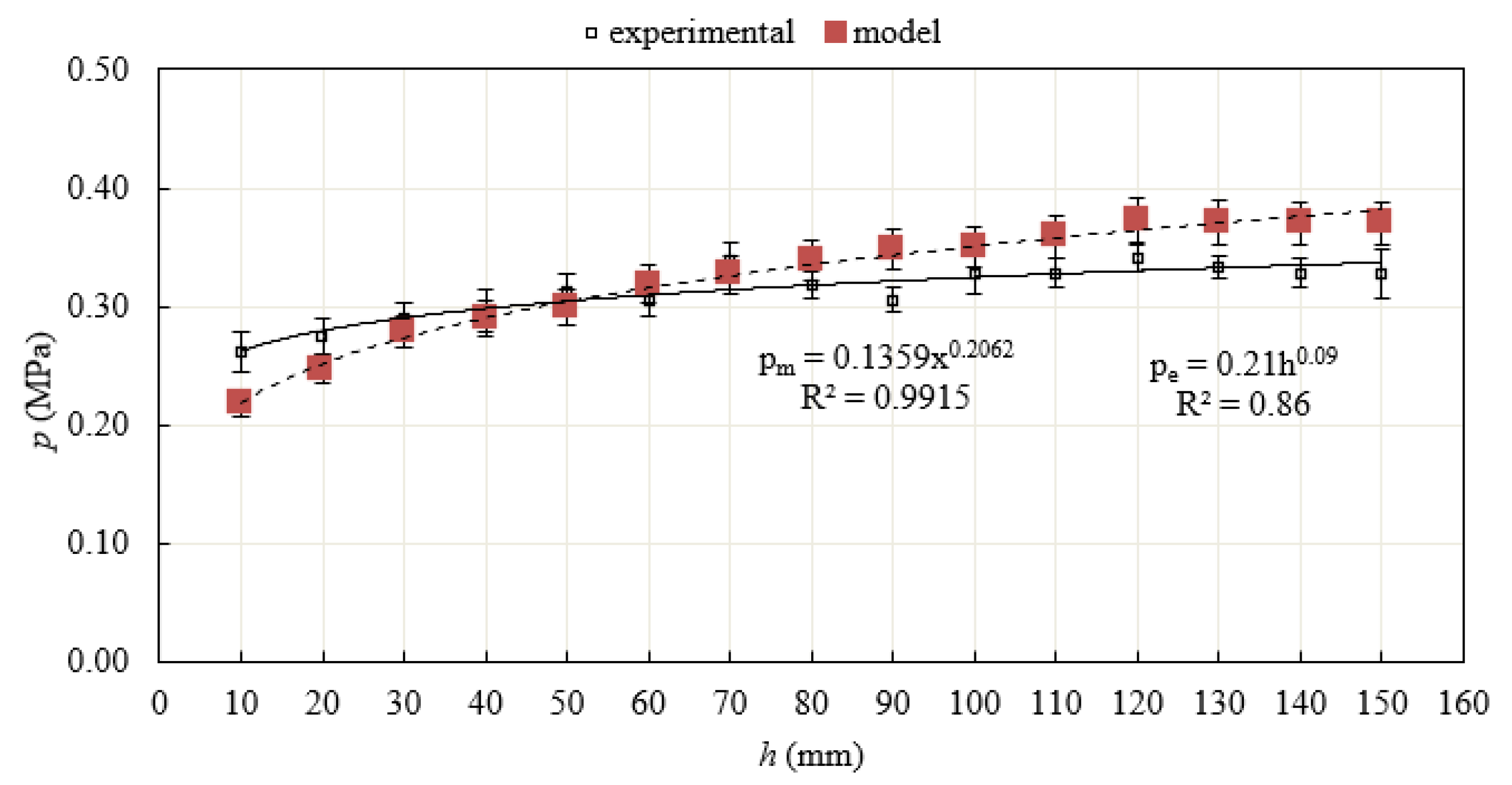

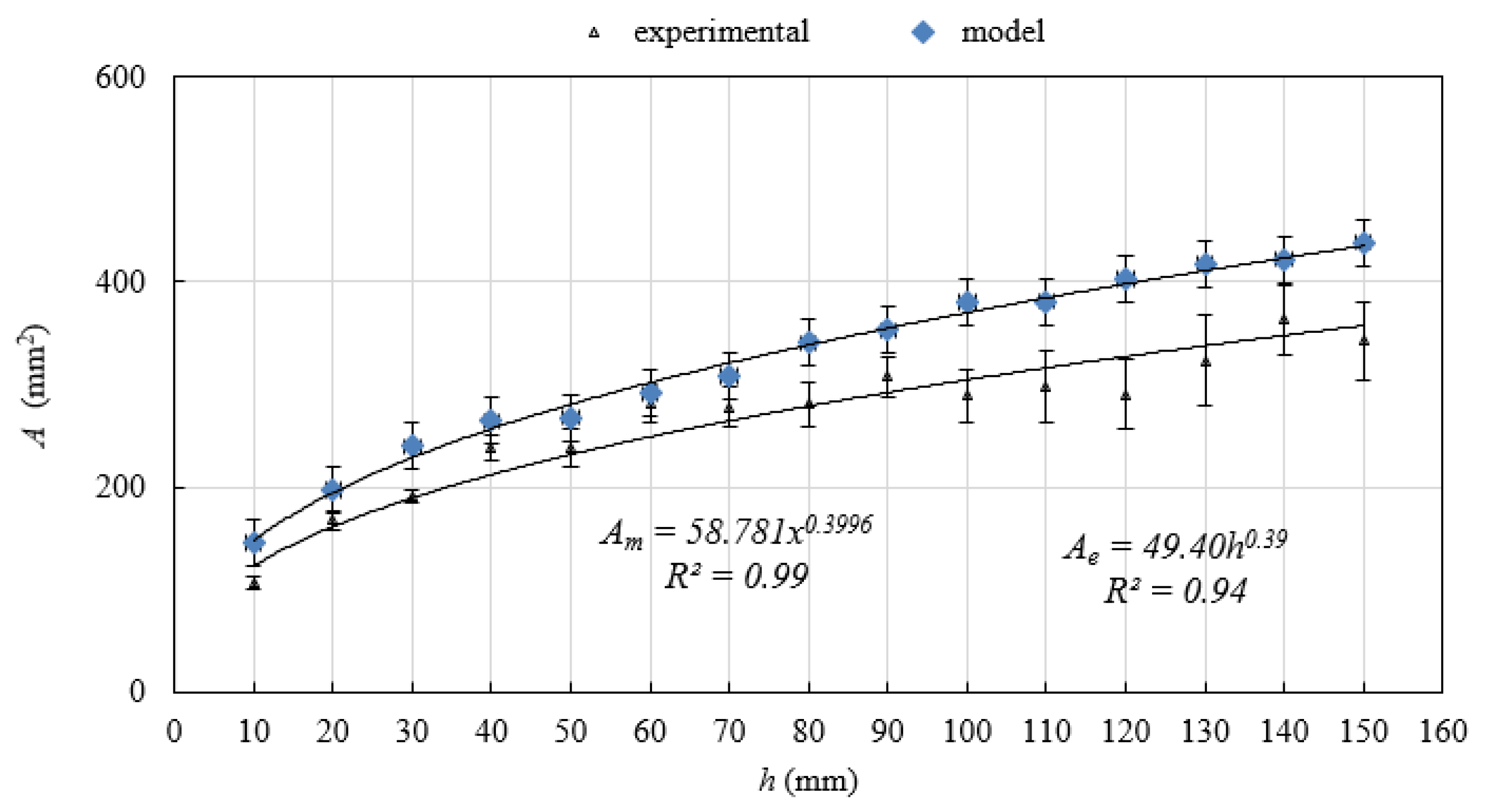

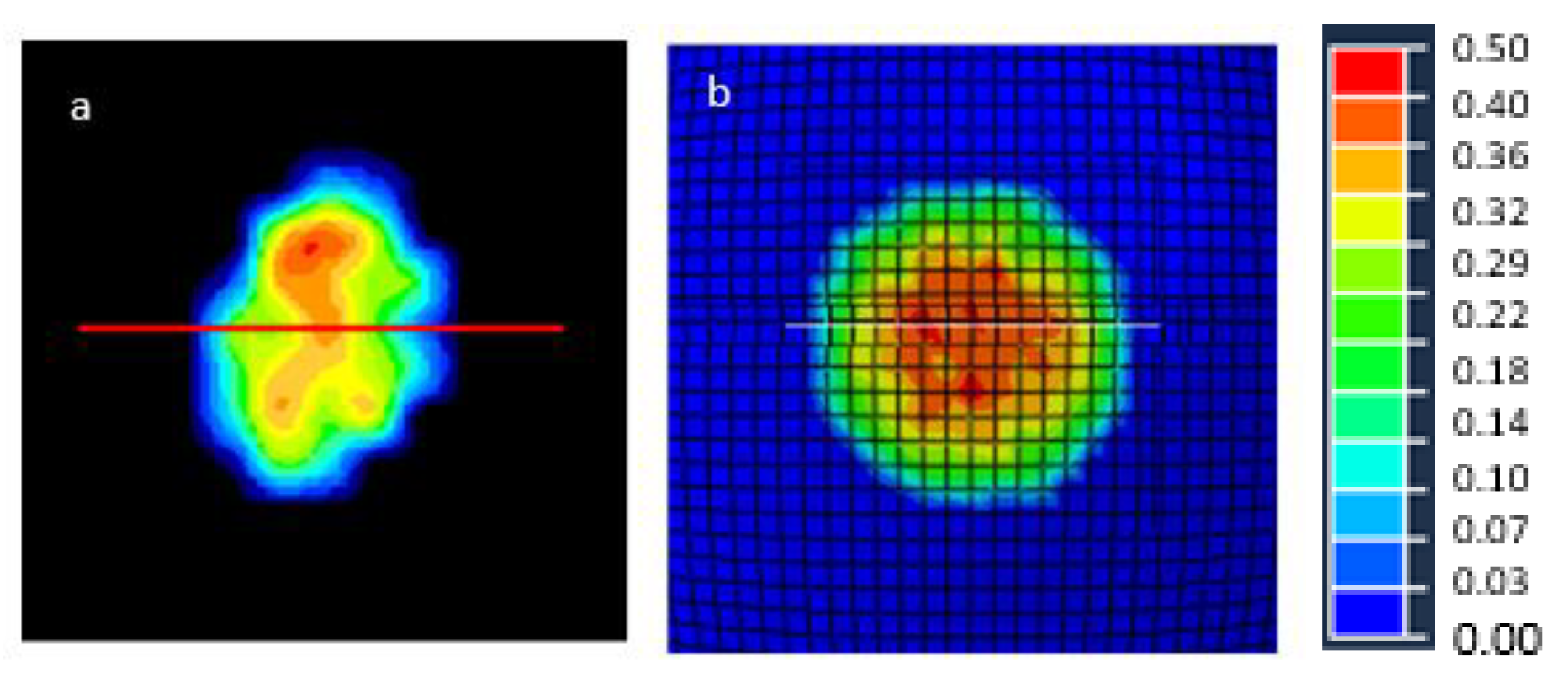

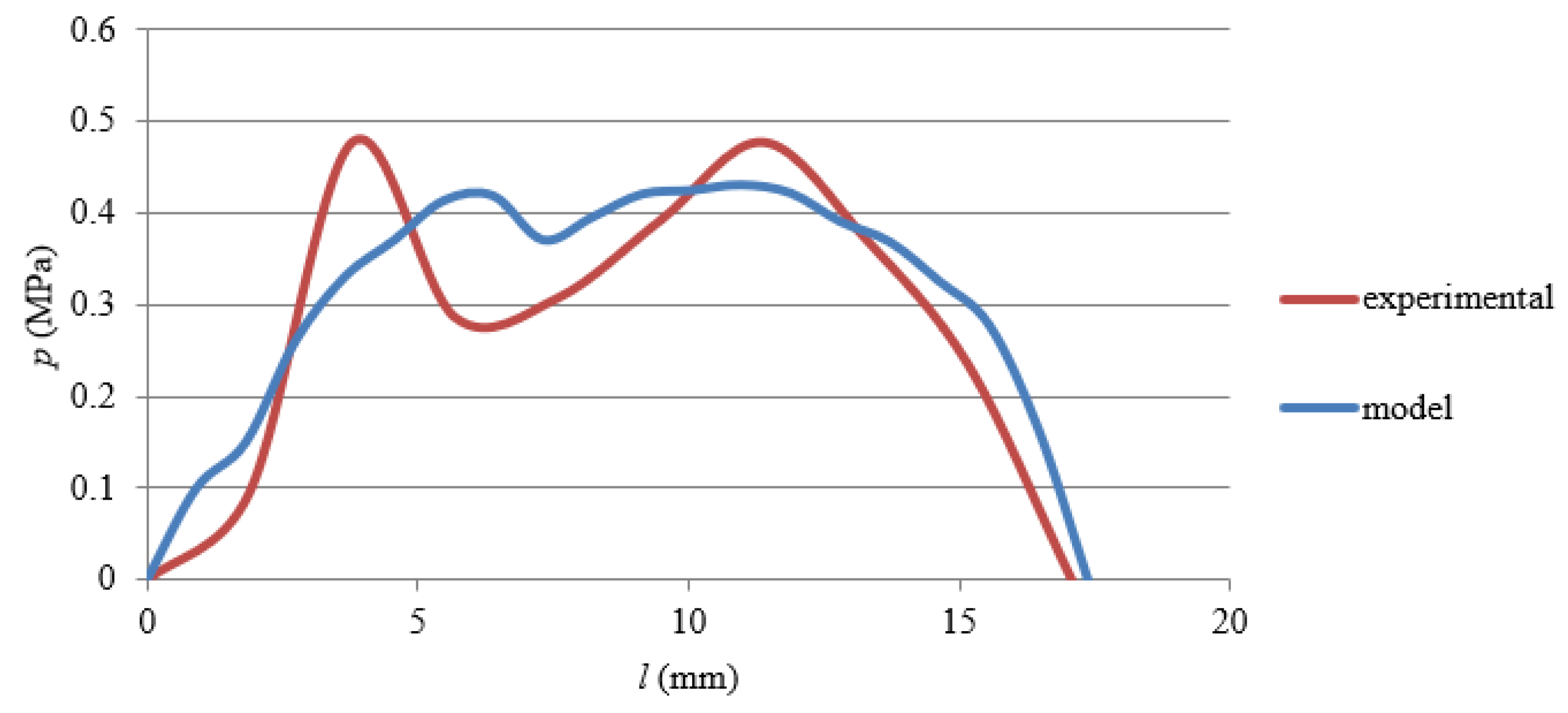

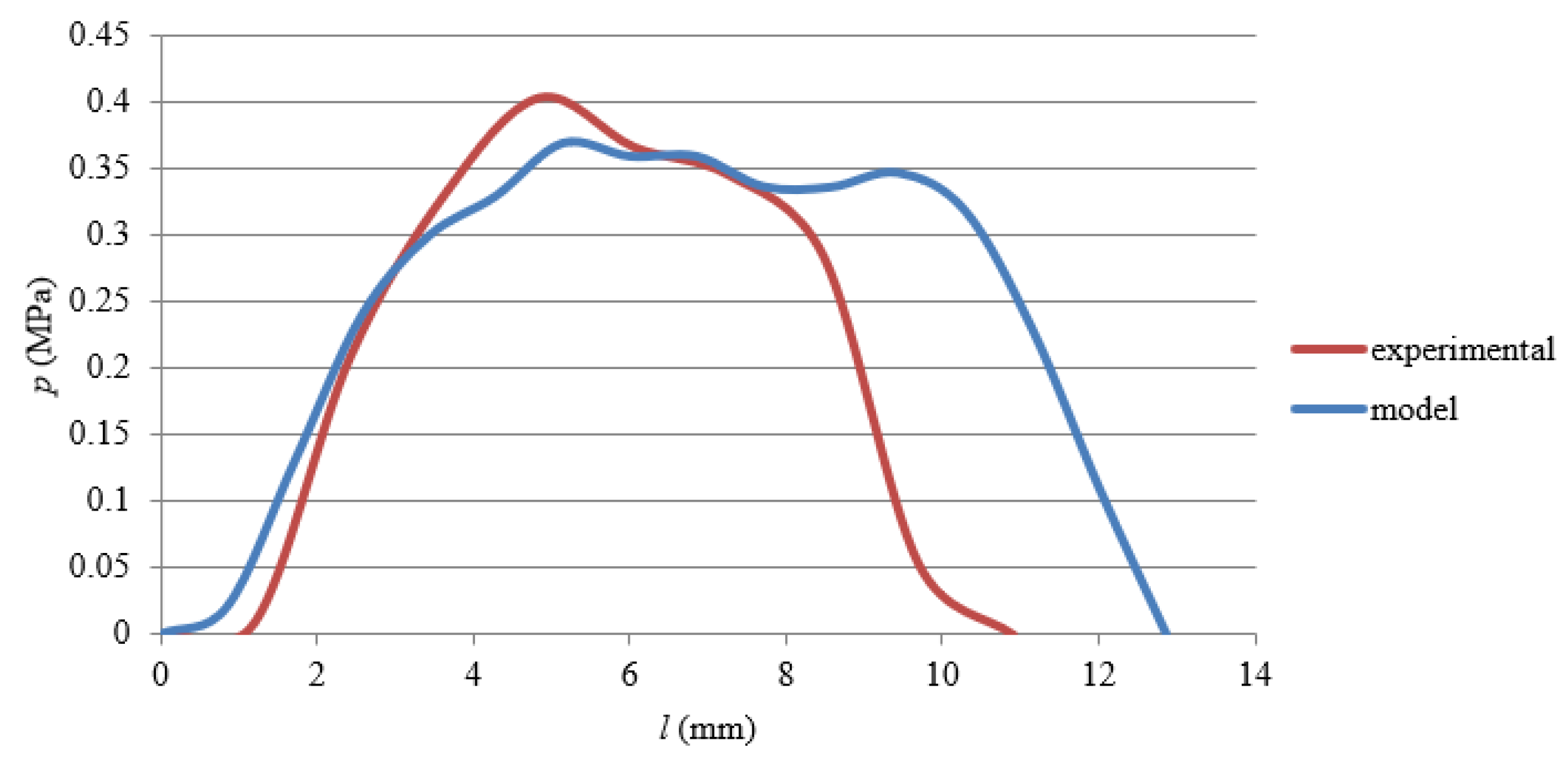

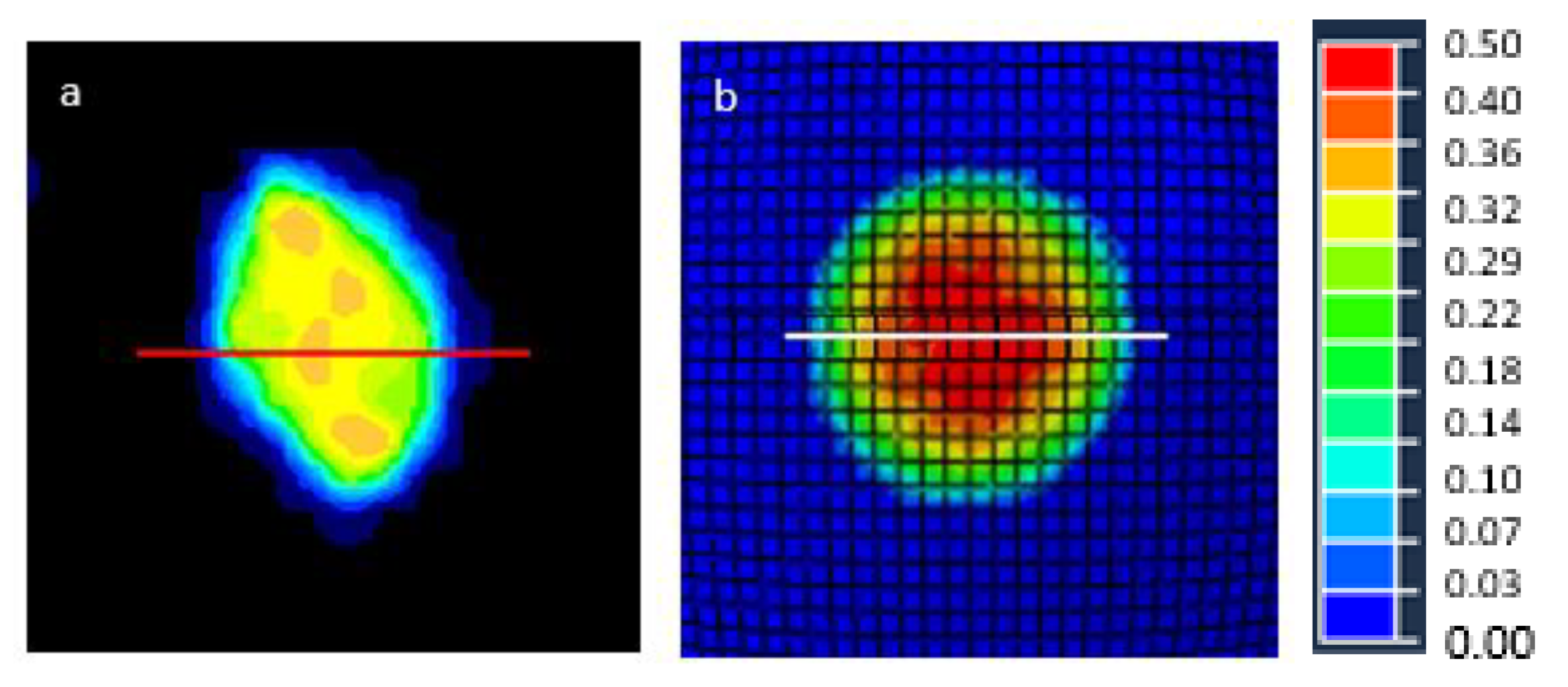

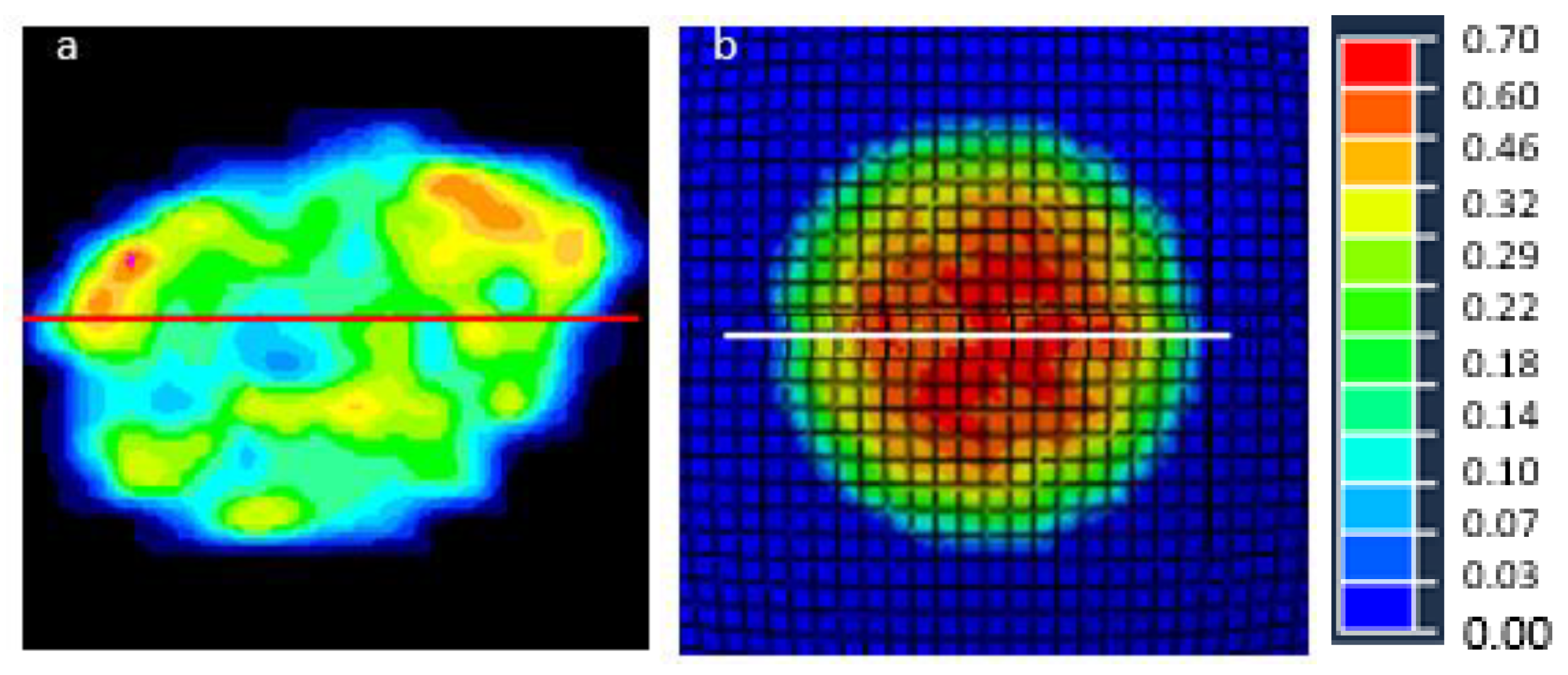

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Poland Statistics, Wynikowy Szacunek Głównych Ziemiopłodów Rolnych Iogrodniczych w 2020r. Available online: Stat.gov.pl/obszary-tematyczne/rolnictwo-lesnictwo/uprawy-rolne-i-ogrodnicze/produkcja-upraw-rolnych-i-ogrodniczych-w-2019-roku,9,18.html (accessed on 14 December 2020).

- Commission Implementing Regulation (EU). No 543/2011 of 7 June 2011 laying down detailed rules for the application of Council Regulation (EC) No 1234/2007 in respect of the fruit and vegetables and processed fruit and vegetables sectors. Off. J. Eur. Union Legis. 2011, 54. [Google Scholar] [CrossRef]

- Komarnicki, P.; Stopa, R.; Szyjewicz, D.; Młotek, M. Evaluation of bruise resistance of pears to impact load. Postharvest Biol. Technol. 2016, 114, 36–44. [Google Scholar] [CrossRef]

- Konopacka, D.; Rutkowski, K.; Jabłek, C.Z.J., II. Hasło Ogrodnicze. Available online: http://www.ho.haslo.pl/article.php?id=662&rok=2001&numer=05 (accessed on 10 December 2019).

- Nadulski, R. Wpływ czasu i warunków przechowywania jabłek na ich wybrane właściwości mechaniczne. Inżynieria Rol. 2009, 2, 107–116. [Google Scholar]

- Bollen, A.F.; Rue, B.T.D. Handling Impacts for Kiwifruit, Asian Pears and Apples. Am. Soc. Agric. Eng. 1990, 5, 14. [Google Scholar]

- Barchi, G.L.; Berardinelli, A.; Guarnieri, A.; Ragni, L.; Totaro, C. Fila Damage to Loquats by Vibration-simulating Intra-state Transport. Biosyst. Eng. 2002, 82, 305–312. [Google Scholar] [CrossRef]

- Stropek, Z.; Gołacki, K. A new method for measuring impact related bruises in fruits. Postharvest Biol. Technol. 2015, 110, 131–139. [Google Scholar] [CrossRef]

- Sitkei, G. Mechanics of Agricultural Materials; Elsevier: Sopran, Hungary, 1987. [Google Scholar]

- Opara, U.L.; Pathare, P.B. Bruise damage measurement and analysis of fresh horticultural produce—A review. Postharvest Biol. Technol. 2014, 91, 9–24. [Google Scholar] [CrossRef]

- Gołacki, K. Prędkość i energia w procesie deformacji materiału roślinnego na przykładzie korzeni marchwi. Zeszyty Problemowe Postępów Nauk Rolniczych 1996, 425, 61–66. [Google Scholar]

- Gołacki, K. Test relaksacji naprężeń dla korzeni marchwi. Zeszyty Problemowe Postępów Nauk Rolniczych 1996, 433, 347–351. [Google Scholar]

- Gołacki, K.; Bobin, G.; Stropek, Z. Bruise resistance of apples (Melrose variety). Teka Komisji Motoryzacji i Energetyki Rolnictwa 2009, 9, 40–47. [Google Scholar]

- Blahovec, J. A simple model of the processes of compression and mechanical damage of pulps (In Czech). Zemed. Technol. 1985, 31, 349–364. [Google Scholar]

- Gharaghani, B.N.; Maghsoudi, H. Free fall analysis of orange fruit using numerical and experimental methods. Int. J. Food Prop. 2018, 21, 484–495. [Google Scholar] [CrossRef]

- Van Zeebroeck, M.; Van Linden, V.; Darius, P.; De Ketelaere, B.; Ramon, H.; Tijskens, E. The effect of fruit factors on the bruise susceptibility of apples. Postharvest Biol. Technol. 2007, 46, 10–19. [Google Scholar] [CrossRef]

- Blahovec, J. Role of water content in food and product texture. Int. Agrophys. 2007, 21, 209–215. [Google Scholar]

- Balasubramanian, S.; Singh, K.; Kumar, R. Physical properties of coriander seeds at different moisture content. Int. Agrophys. 2012, 26, 419–422. [Google Scholar] [CrossRef]

- Guillermin, N.; Dupont, C.; Le Morvan, J.M.; Langlais, C.; Mauget, J.C. Rheological and technological properties of two cider apple cultivars. LWT Food Sci. Technol. 2006, 39, 995–1000. [Google Scholar] [CrossRef]

- Stopa, R.; Szyjewicz, D.; Komarnicki, P.; Kuta, Ł. Limit values of impact energy determined from contours and surface pressure distribution of apples under impact loads. Comput. Electron. Agric. 2018, 154, 1–9. [Google Scholar] [CrossRef]

- Macek, R.; Silling, S. Peridynamics via finite element analysis. Finite Elem. Anal. Des. 2007, 43, 1169–1178. [Google Scholar] [CrossRef]

- Petru, M.; Novak, O.; Herak, D.; Simanjuntak, S. Finite element method model of the mechanical behaviour of Jatropha cur-cas L. seed under compression loading. Biosyst. Eng. 2012, 111, 412–421. [Google Scholar] [CrossRef]

- Herak, D.; Kabutey, A.; Divisova, M.; Simanjuntak, S. Mathematical model of mechanical behaviour of Jatropha curcas L. seeds under compression loading. Biosyst. Eng. 2013, 114, 279–288. [Google Scholar] [CrossRef]

- Güner, M.; Dursun, E.; Dursun, I. Mechanical Behaviour of Hazelnut under Compression Loading. Biosyst. Eng. 2003, 85, 485–491. [Google Scholar] [CrossRef]

- Herak, D.; Kabutey, A.; Sedlacek, A.; Gurdil, G. Mechanical behaviour of several layers of selected plant seeds under com-pression loading. Res. Agric. Eng. 2012, 58, 24–29. [Google Scholar] [CrossRef]

- Akangbe, O.; Herak, D. Mechanical behaviour of selected bulk oilseeds under compression loading. Agron. Res. 2017, 15, 941–951. [Google Scholar]

- Munjiza, A.; Rougier, E.; Knight, E. Large Strain Finite Element Method: A Practical Course; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Cardenas-Weber, M.; Stroshine, R.L.; Haghighi, K.; Edan, Y. Melon material properties and finite element analysis of melon compression with application to robot gripping. Trans. ASAE 1991, 34, 920–929. [Google Scholar] [CrossRef]

- Celik, H.K. Determination of bruise susceptibility of pears (Ankara variety) to impact load by means of FEM-based explicit dynamics simulation. Postharvest Biol. Technol. 2017, 128, 83–97. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Chen, L.; Chukwu, O.; Opara, U.L. Susceptibility of apples to bruising inside ventilated corrugated paperboard packages during simulated transport damage. Postharvest Biol. Technol. 2016, 118, 111–119. [Google Scholar] [CrossRef]

- Li, Z.; Li, P.; Liu, J. Effect of Mechanical Damage on Mass Loss and Water Content in Tomato Fruits. Int. Agrophys. 2011, 25, 77–83. [Google Scholar]

- Lu, R.; Abbott, J.A. Finite element analysis of modes of vibration in apples. J. Texture Stud. 1996, 27, 265–286. [Google Scholar] [CrossRef]

- Topakci, M.; Celik, H.K.; Canakci, M.; Rennie, A.; Akinci, I.; Karayel, D. Deep Tillage Tool Optimization by Means of Finite Element Method: Case Study for a Subsoiler Tine. J. Food Agric. Environ. 2010, 8, 531–536. [Google Scholar]

- Zhang, S.; Wu, X.; Zhang, S.; Cheng, Q.; Tan, Z. An effective method to inspect and classify the bruising degree of apples based on the optical properties. Postharvest Biol. Technol. 2017, 127, 44–52. [Google Scholar] [CrossRef]

- Celik, H.K.; Rennie, A.E.; Akinci, I. Deformation behaviour simulation of an apple under drop case by finite element method. J. Food Eng. 2011, 104, 293–298. [Google Scholar] [CrossRef]

- Komarnicki, P.; Stopa, R.; Szyjewicz, D.; Kuta, Ł.; Klimza, T. Influence of Contact Surface Type on the Mechanical Damages of Apples Under Impact Loads. Food Bioprocess. Technol. 2017, 10, 1479–1494. [Google Scholar] [CrossRef][Green Version]

- Masso-Moreu, Y.; Mills, N. Impact compression of polystyrene foam pyramids. Int. J. Impact Eng. 2003, 28, 653–676. [Google Scholar] [CrossRef]

- Unuigbe, O.M.; Onuoha, S.N. Assessment of impact damage to apple fruits. Niger. J. Technol. 2013, 32, 137–141. [Google Scholar]

- ANSYS Doc. 2016. Available online: https://ansyshelp.ansys.com (accessed on 10 February 2020).

- Lee, J.; Lee, B. Modal analysis of carbon nanotubes and nanocones using FEM. Comput. Mater. Sci. 2012, 51, 30–42. [Google Scholar] [CrossRef]

- SolidWorks Doc. 2010. Available online: https://help.solidworks.com (accessed on 10 February 2020).

- Wakabayashi, N.; Ona, M.; Suzuki, T.; Igarashi, Y. Nonlinear finite element analyses: Advances and challenges in dental applications. J. Dent. 2008, 36, 463–471. [Google Scholar] [CrossRef] [PubMed]

- Du, C.-J.; Sun, D.-W. Learning techniques used in computer vision for food quality evaluation: A review. J. Food Eng. 2006, 72, 39–55. [Google Scholar] [CrossRef]

- Stopa, R.; Komarnicki, P.; Szyjewicz, D.; Kuta, Ł. Modeling of carrot root radial press process for different shapes of loading elements using the finite element method. Int. J. Food Prop. 2017, 20, S340–S352. [Google Scholar] [CrossRef]

| Foam Hardening | Rate Dependent | ||

|---|---|---|---|

| Yield Stress | Uniaxial Plastic Strain | Yield Stress Ratio | Equivalent Plastic Strain Rate |

| 0.3 | 0 | 0.1 | 0 |

| 3 | 1 | 0.5 | 1 |

| Density (kg·m−3) | Elastic Properties | ||||||

|---|---|---|---|---|---|---|---|

| Young’s Modulus (MPa) | Poisson’s Ratio | ||||||

| Concrete | 2400 | 14,000 | 0.2 | ||||

| Wood | 1000 | E1 | E2 | E3 | ν12 | ν13 | ν23 |

| 12,500 | 830 | 830 | 0.467 | 0.372 | 0.435 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szyjewicz, D.; Kuta, Ł.; Działak, P.; Stopa, R. An Attempt to Model the Surface Pressures of Apples Using the Finite Element Method. Appl. Sci. 2021, 11, 7579. https://doi.org/10.3390/app11167579

Szyjewicz D, Kuta Ł, Działak P, Stopa R. An Attempt to Model the Surface Pressures of Apples Using the Finite Element Method. Applied Sciences. 2021; 11(16):7579. https://doi.org/10.3390/app11167579

Chicago/Turabian StyleSzyjewicz, Daniel, Łukasz Kuta, Paulina Działak, and Roman Stopa. 2021. "An Attempt to Model the Surface Pressures of Apples Using the Finite Element Method" Applied Sciences 11, no. 16: 7579. https://doi.org/10.3390/app11167579

APA StyleSzyjewicz, D., Kuta, Ł., Działak, P., & Stopa, R. (2021). An Attempt to Model the Surface Pressures of Apples Using the Finite Element Method. Applied Sciences, 11(16), 7579. https://doi.org/10.3390/app11167579