Seismic Performance of Grille-Type Steel Plate Concrete Composite Walls with Application in a Super-High-Rise Building

Abstract

:Featured Application

Abstract

1. Introduction

2. Numerical Modeling and Validation

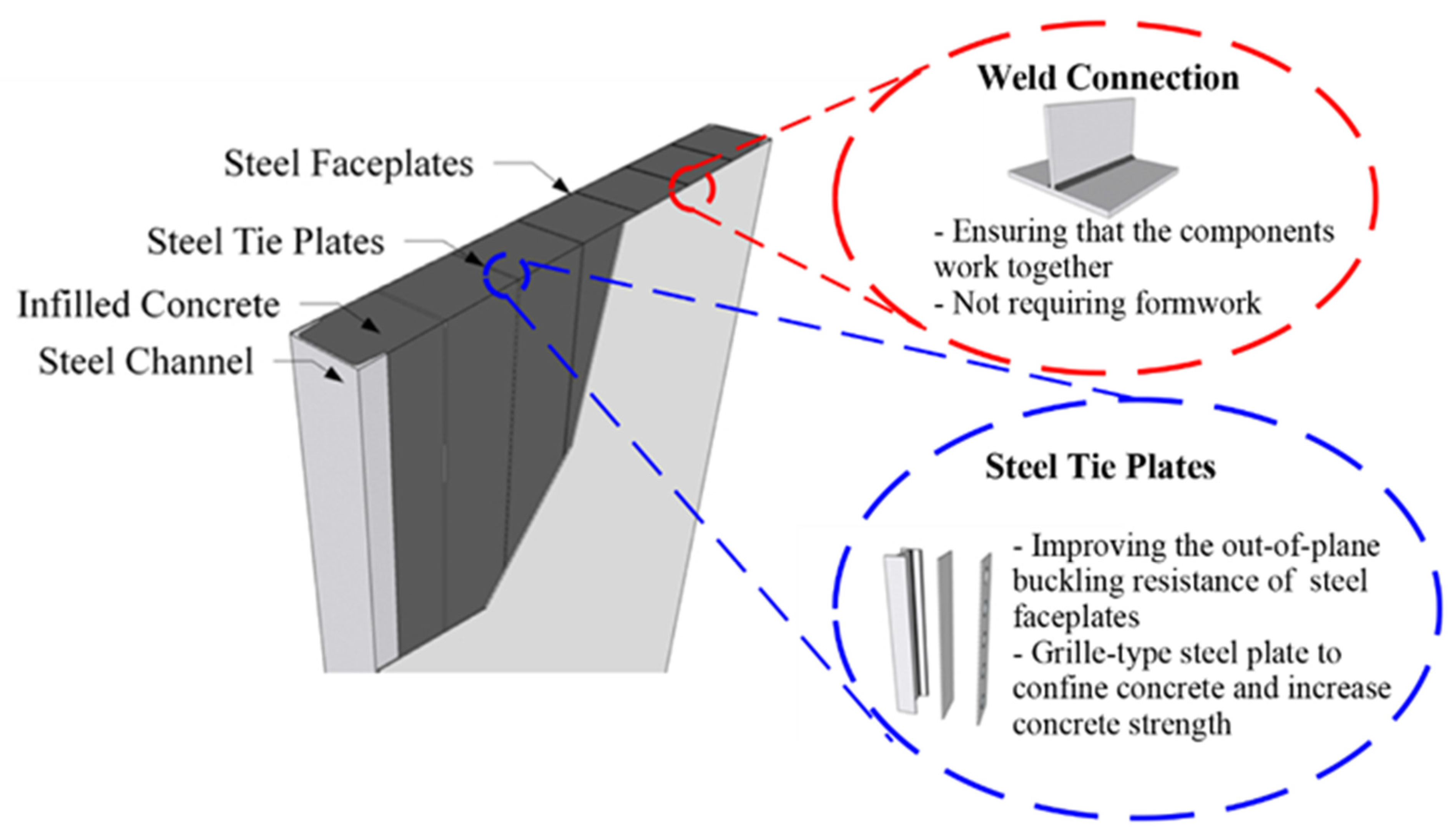

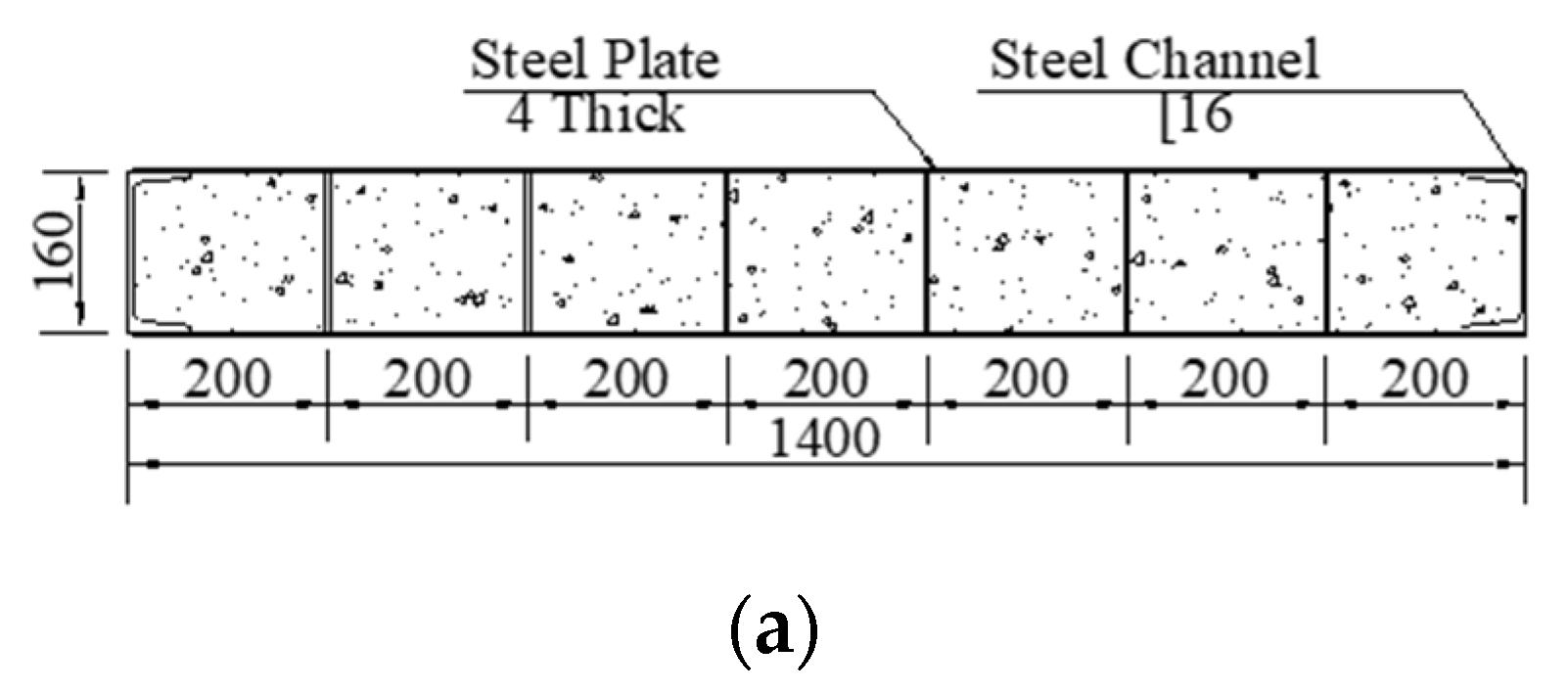

2.1. Literature Tests for GSPCW Walls

2.2. Numerical Models

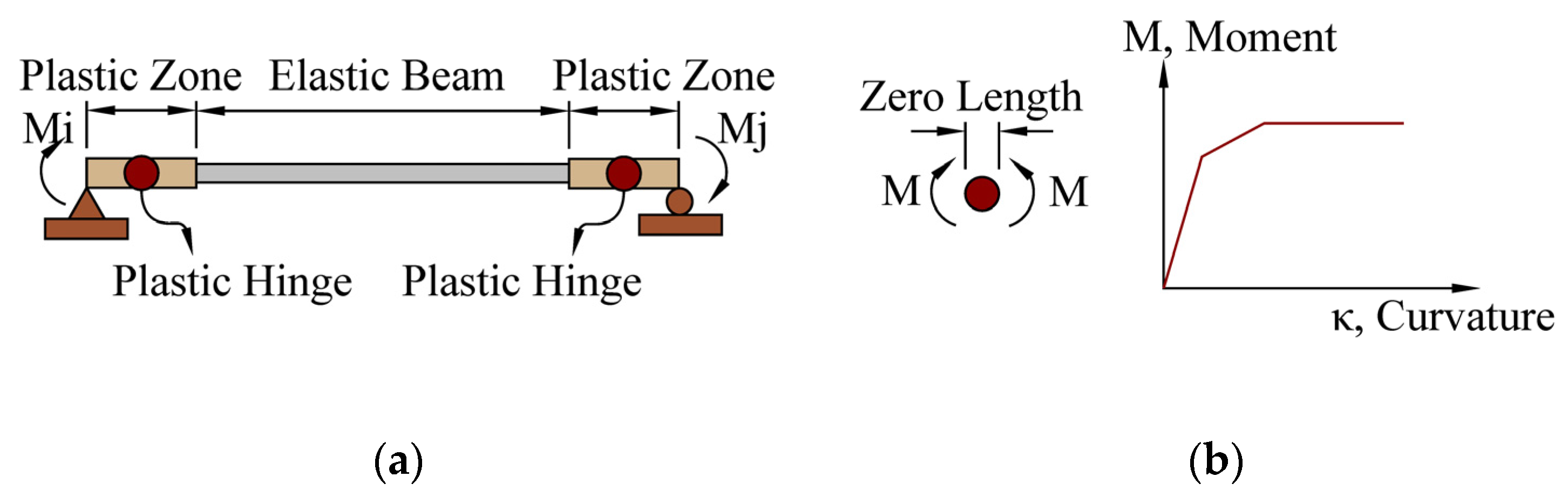

2.2.1. Modeling Assumptions

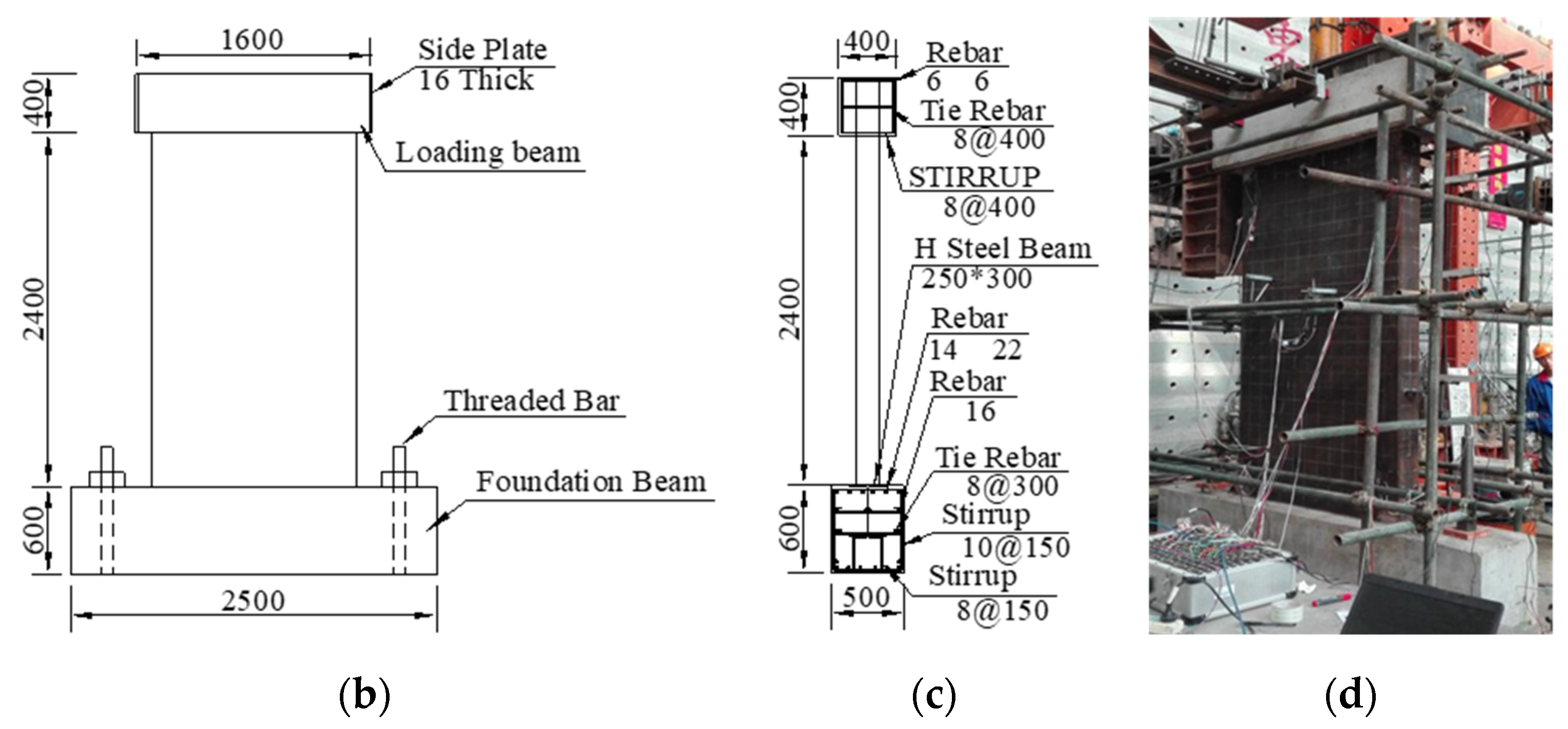

2.2.2. Material Models

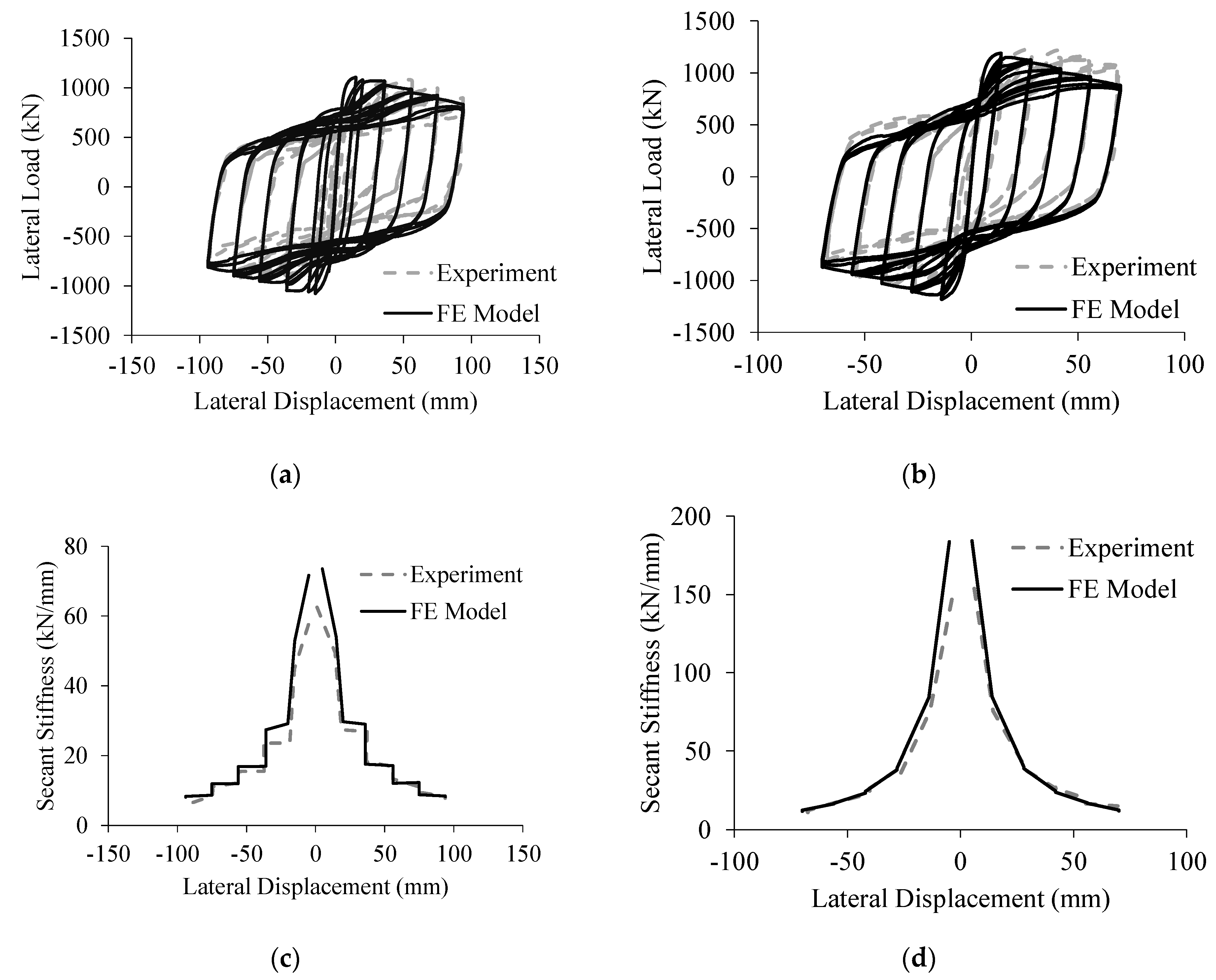

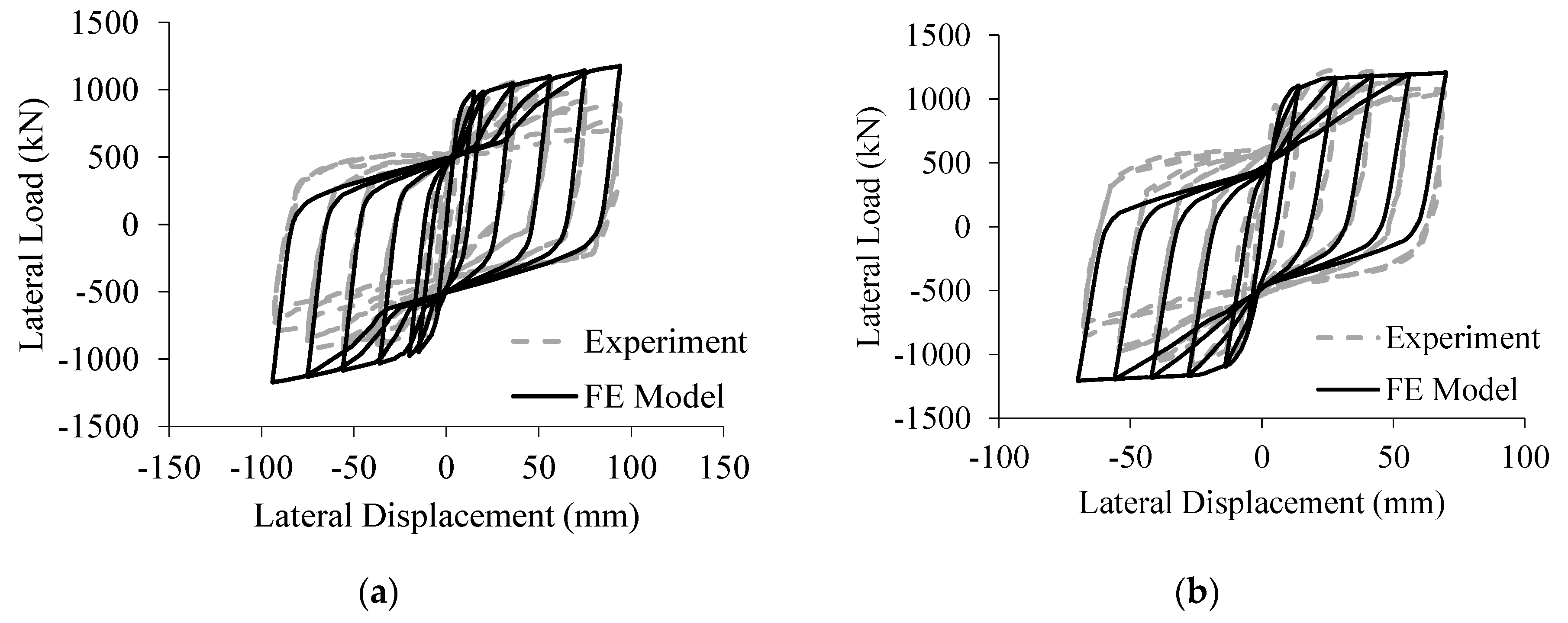

2.3. Validation of Numerical Modeling

3. Parametric Modeling of GSPCW Walls

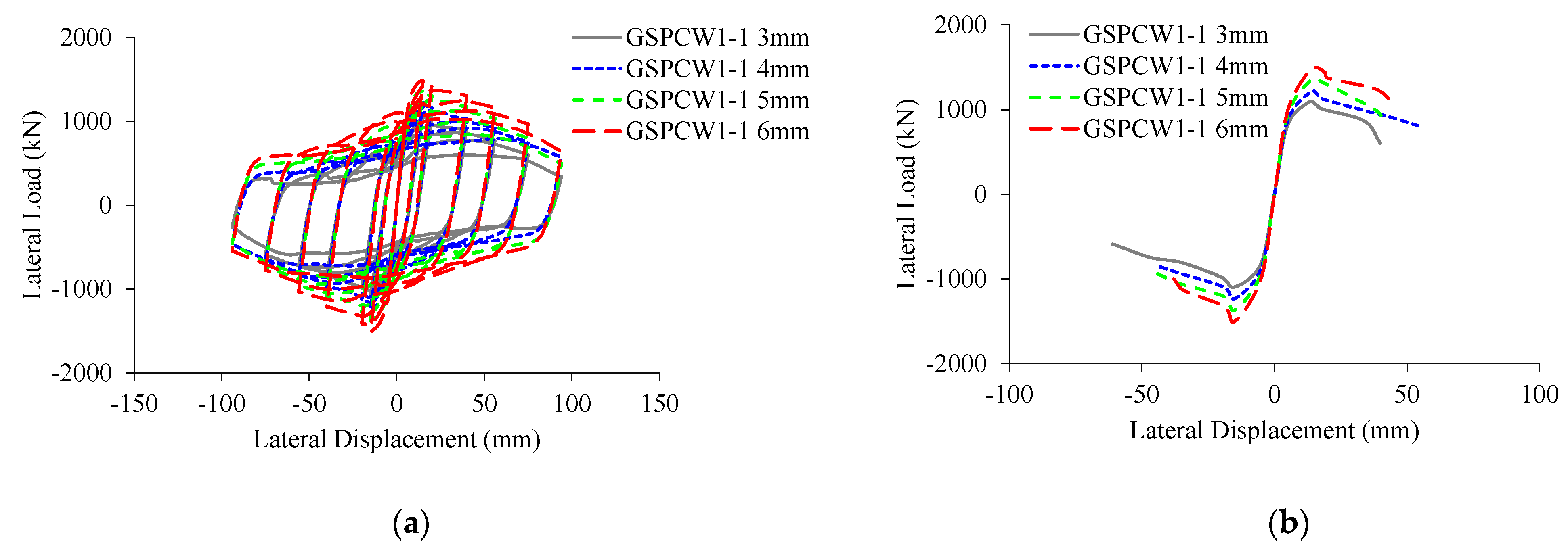

3.1. Steel Ratio

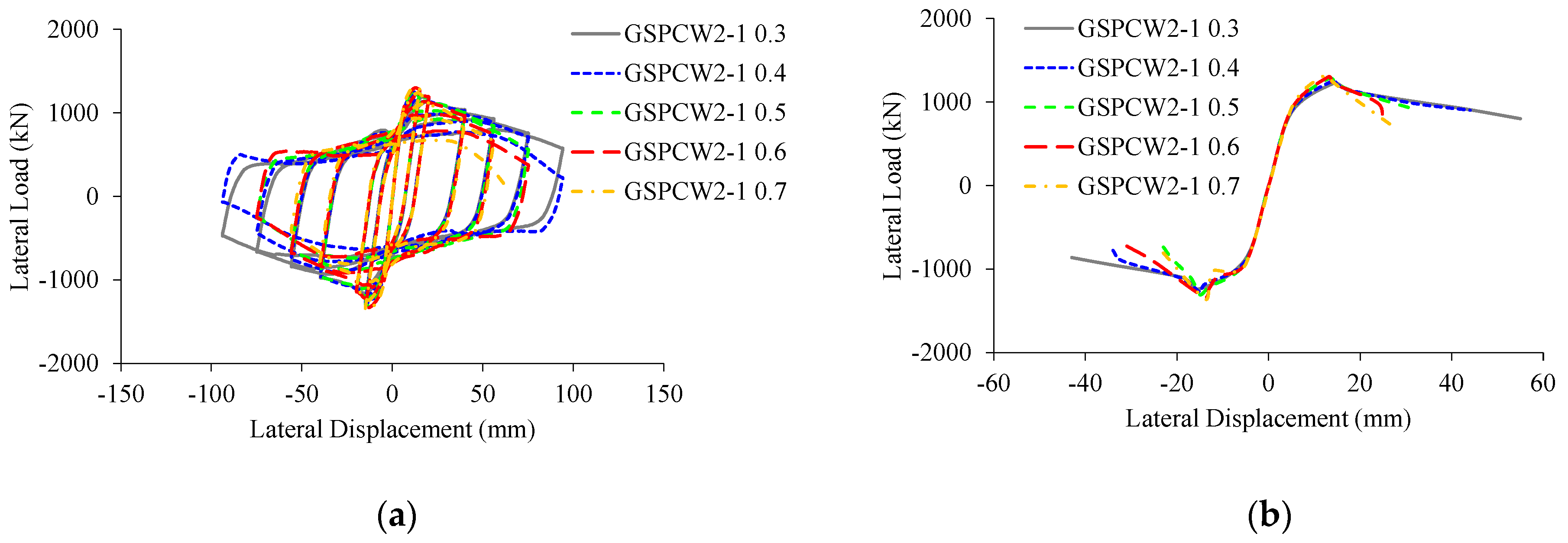

3.2. Axial Load Ratio

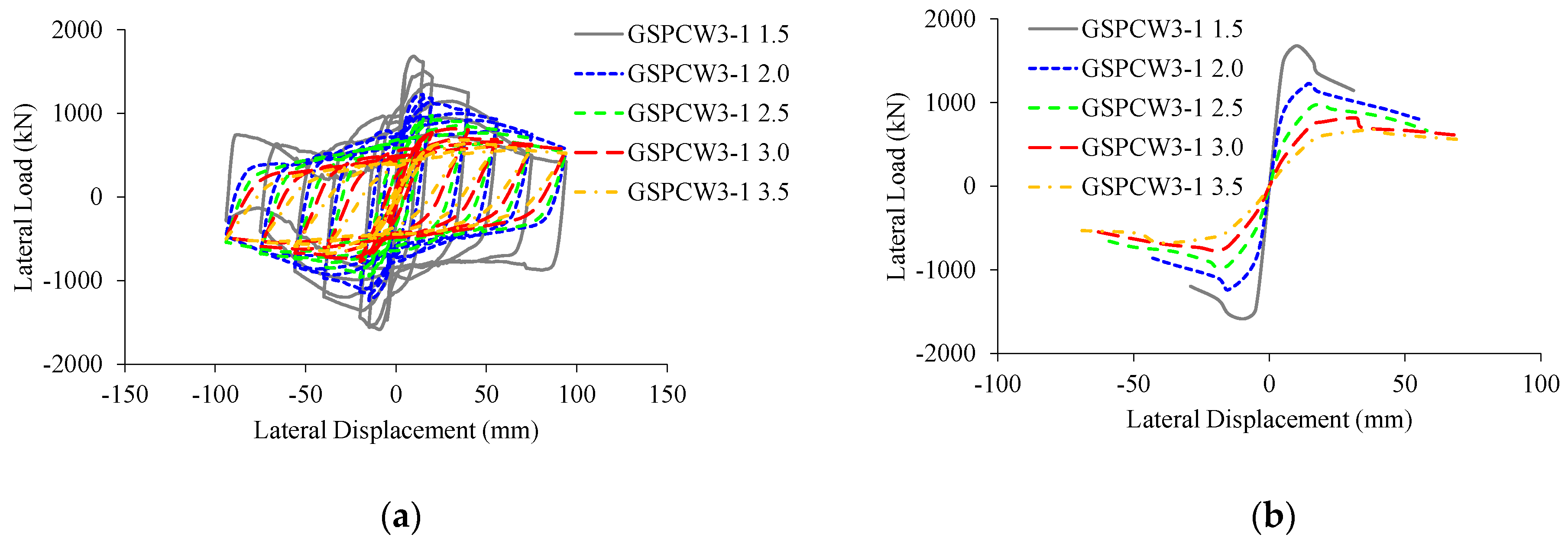

3.3. Height-to-Width Ratio

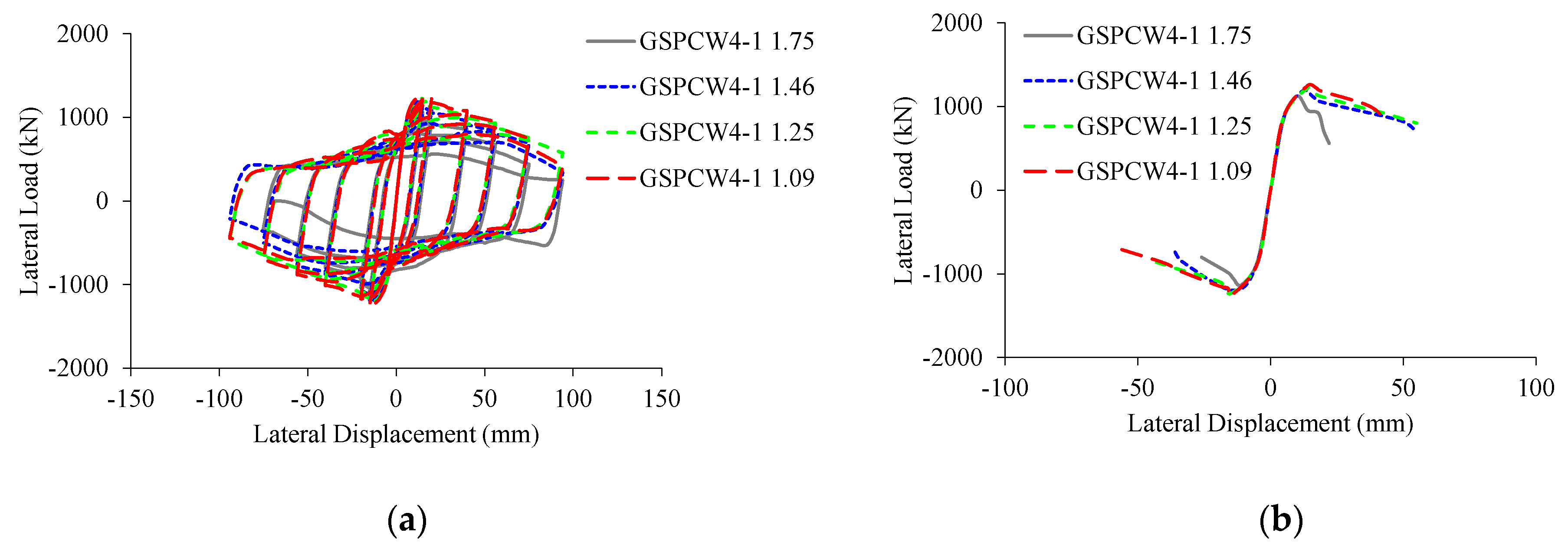

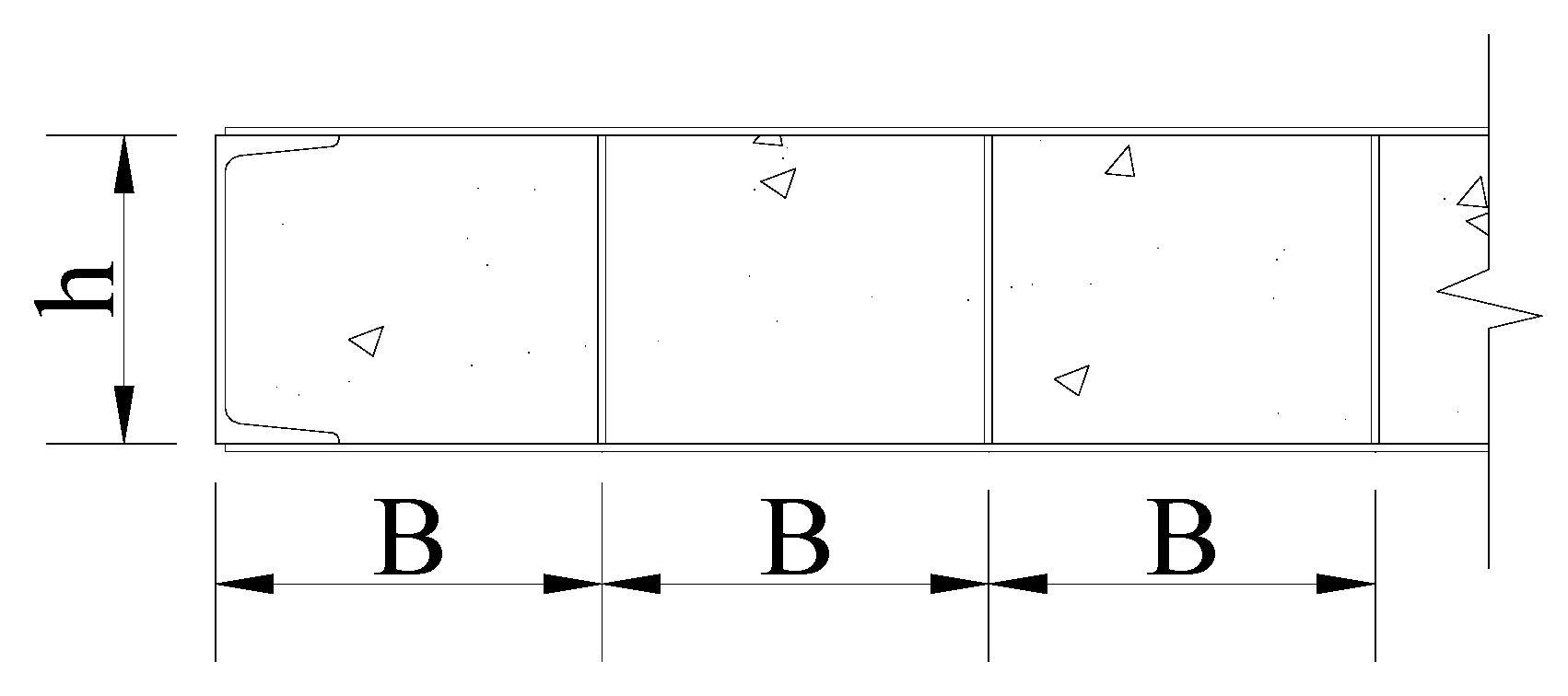

3.4. Aspect Ratio of Grille-Type Steel Plate

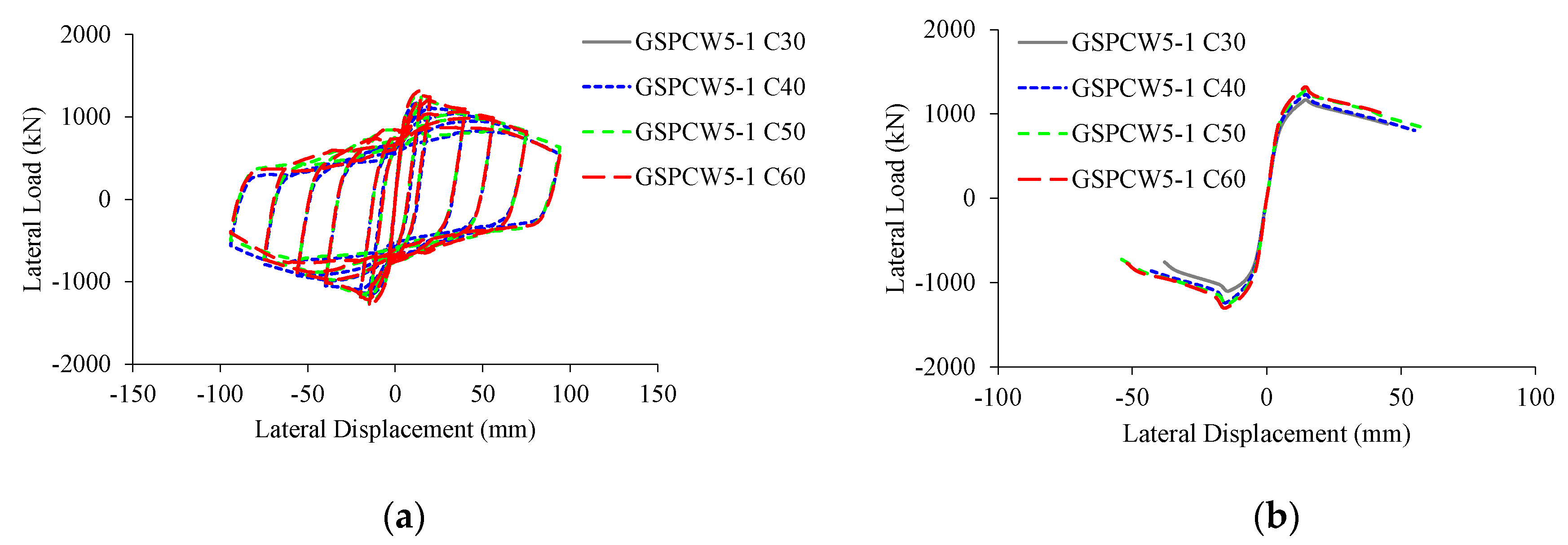

3.5. Concrete Compressive Strength

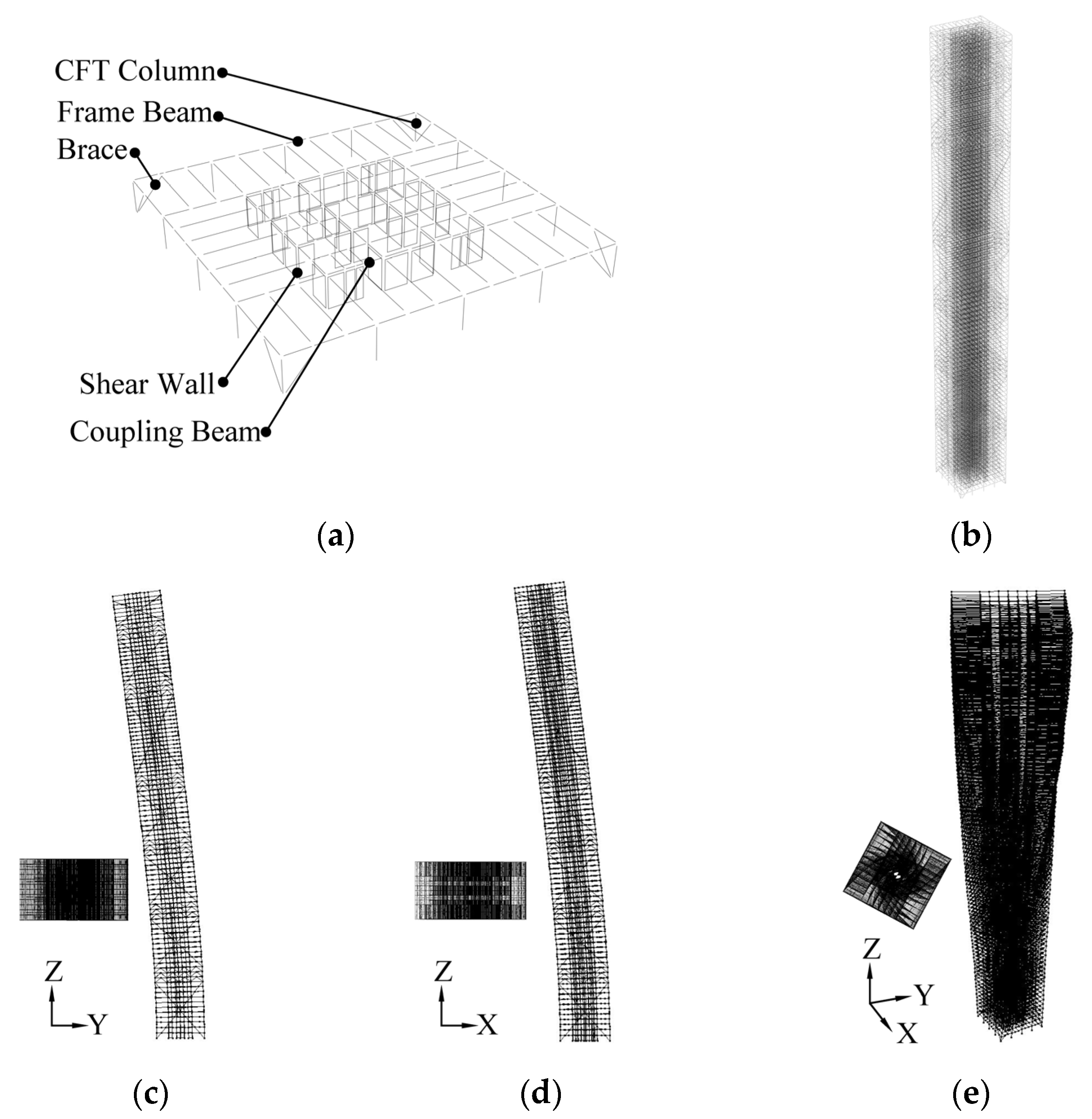

4. Selection and Modeling of a Case-Study Super-High-Rise Building

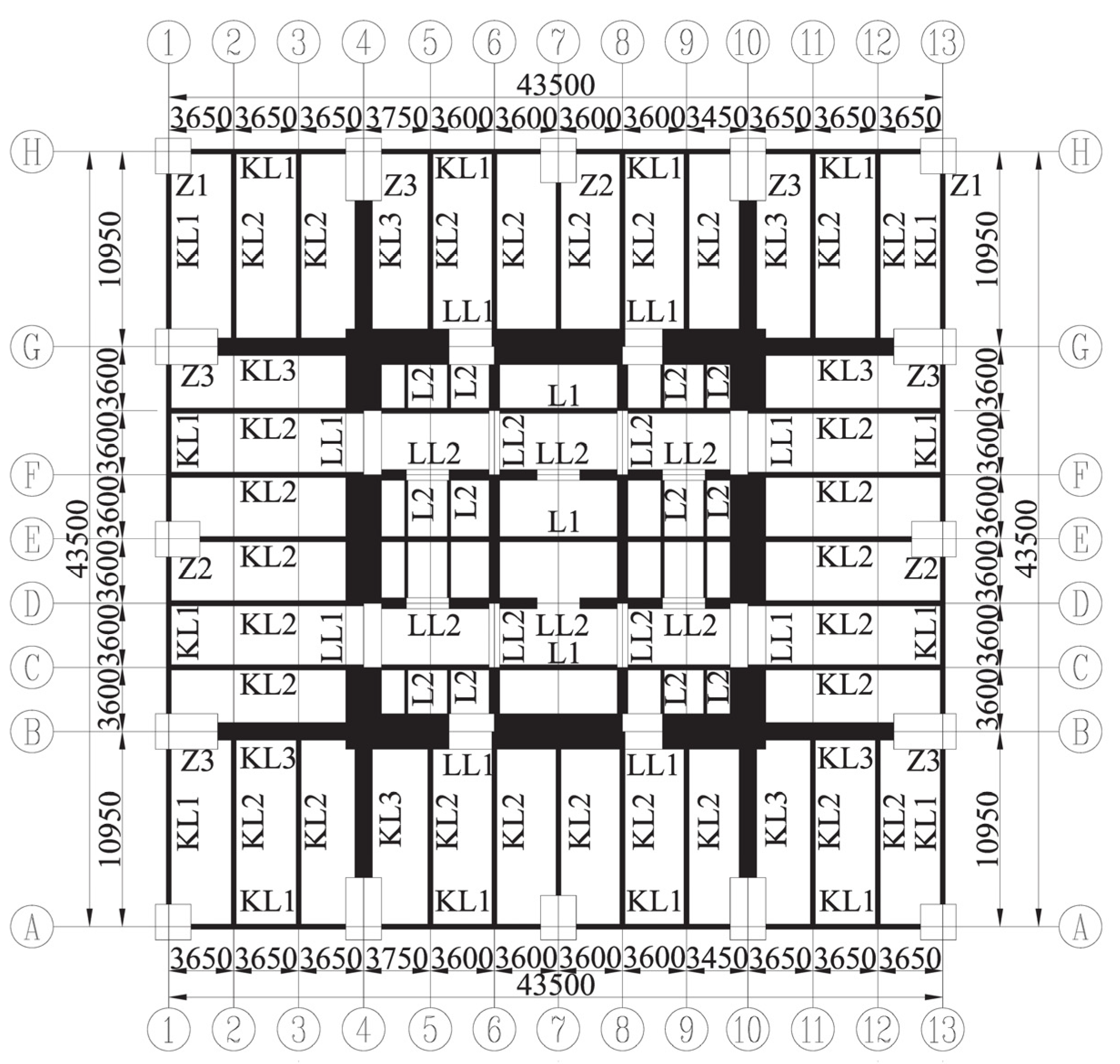

4.1. Case-Study Building

4.2. Modeling of the Case-Study Building

4.3. Validation of Modeling in PERFORM-3D

5. Seismic Performance Assessment through Nonlinear Time History Analysis

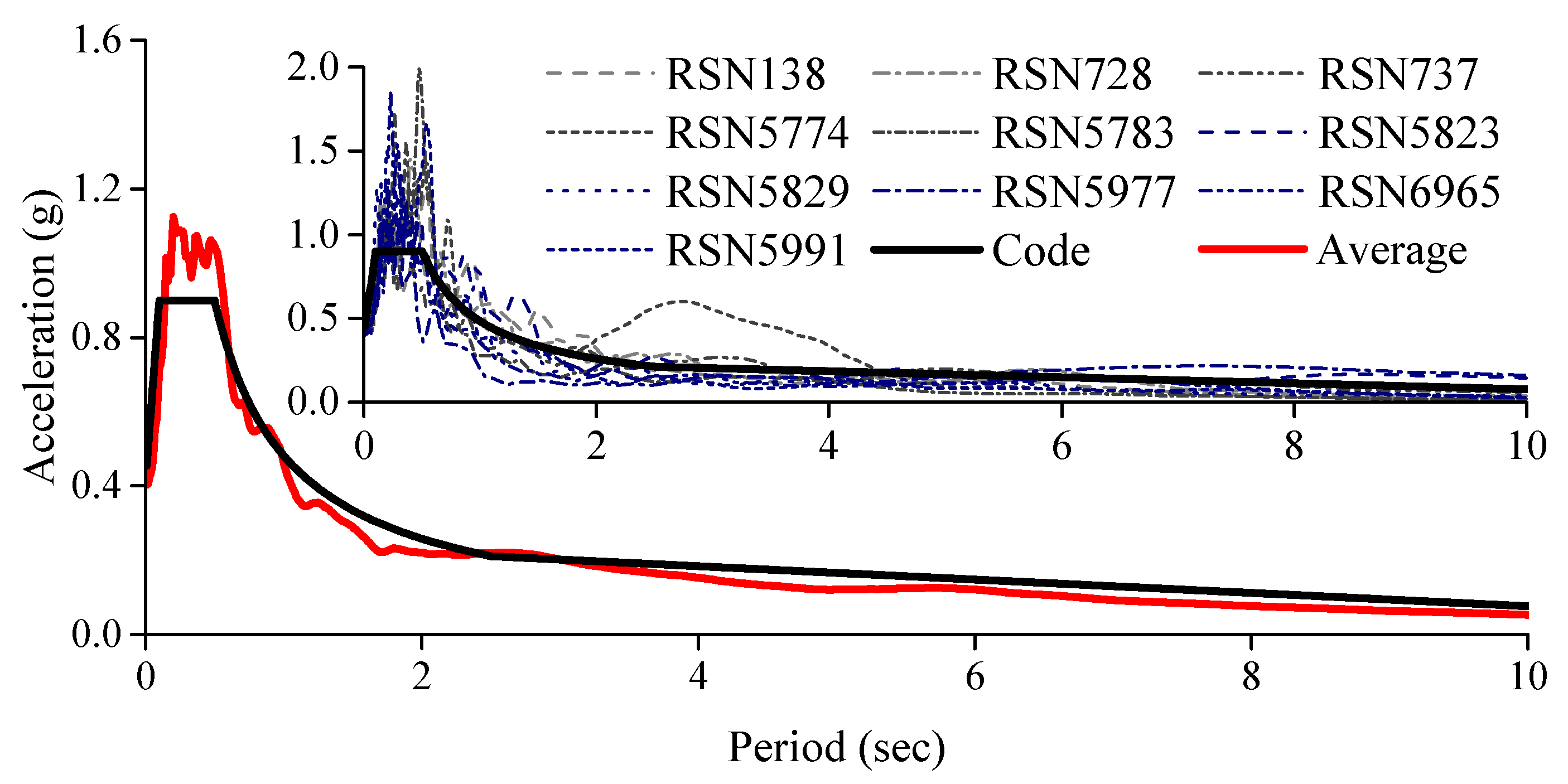

5.1. Ground Motions

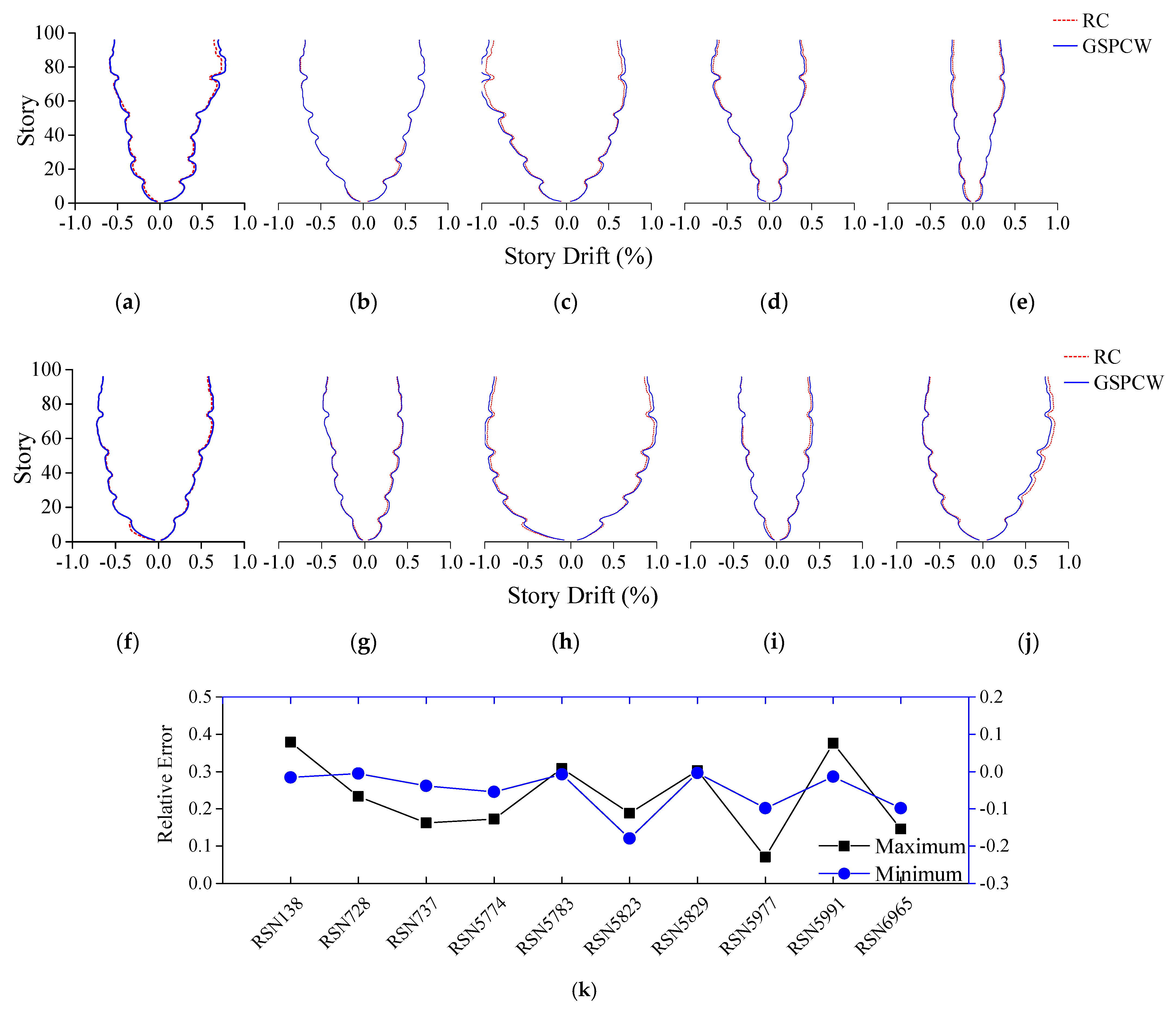

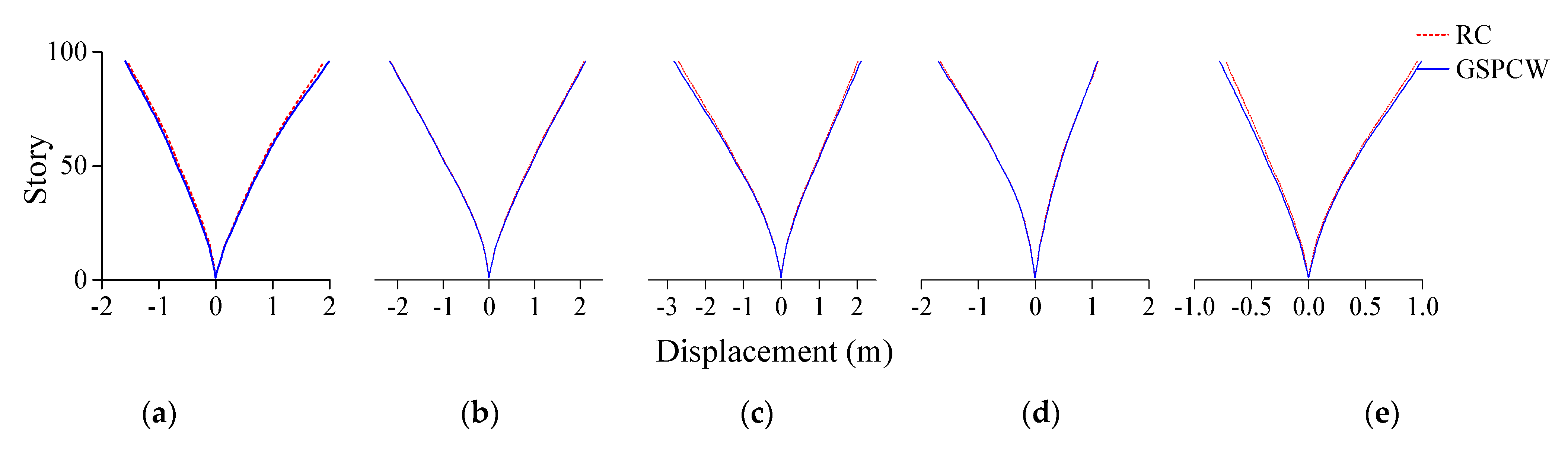

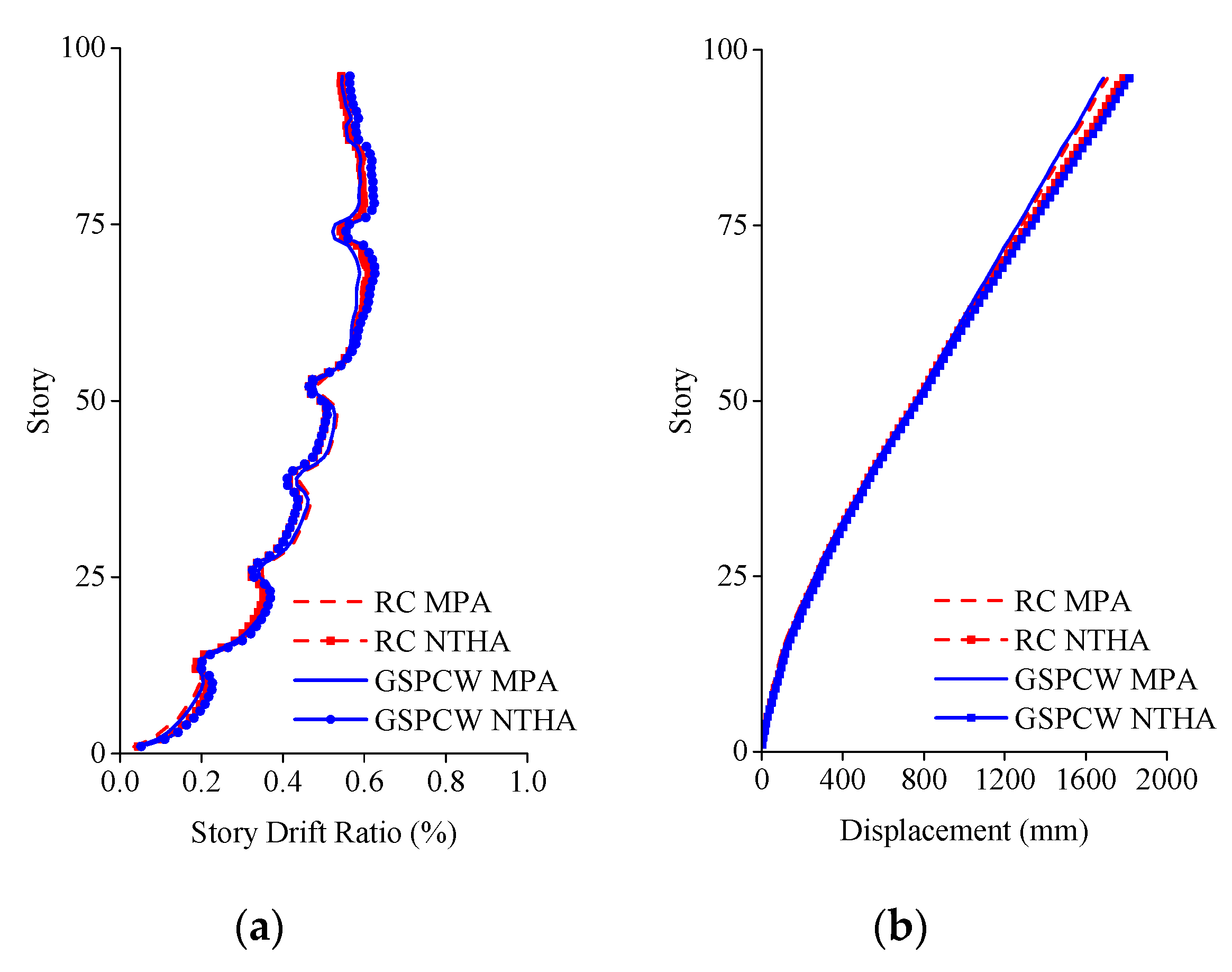

5.2. Story Drifts and Peak Displacements

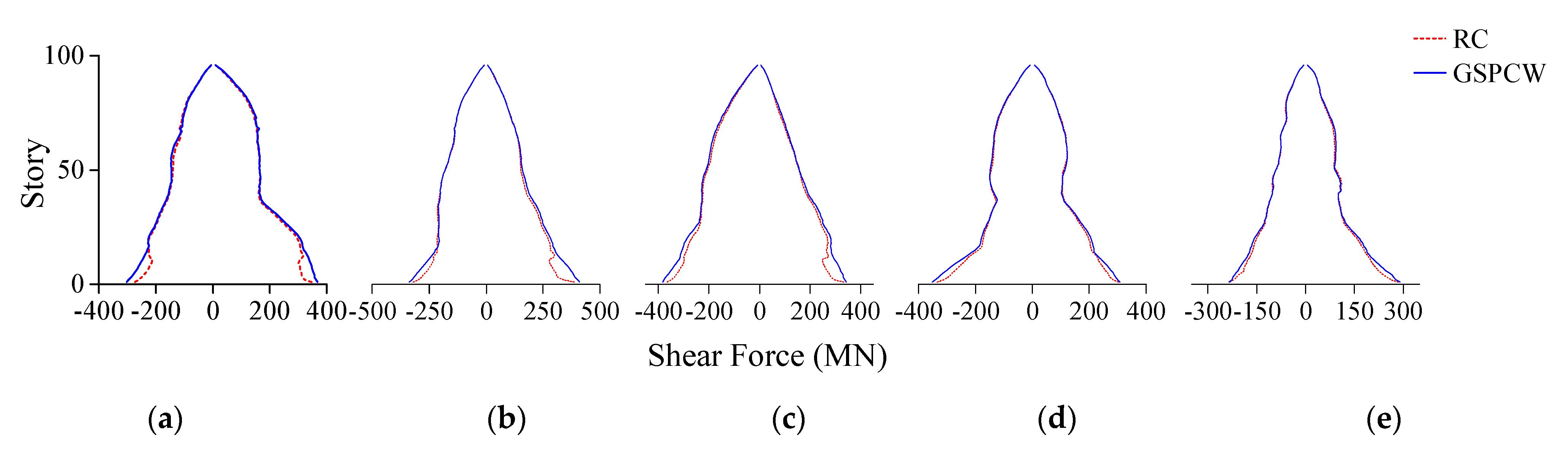

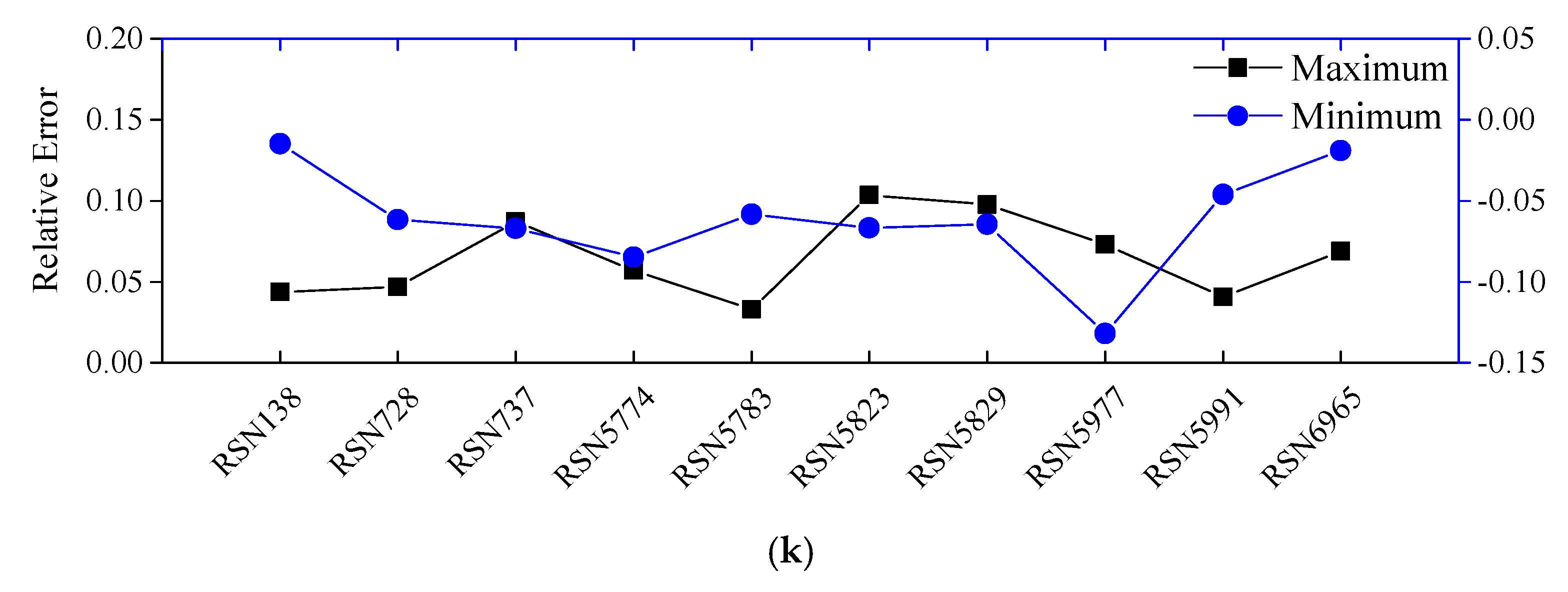

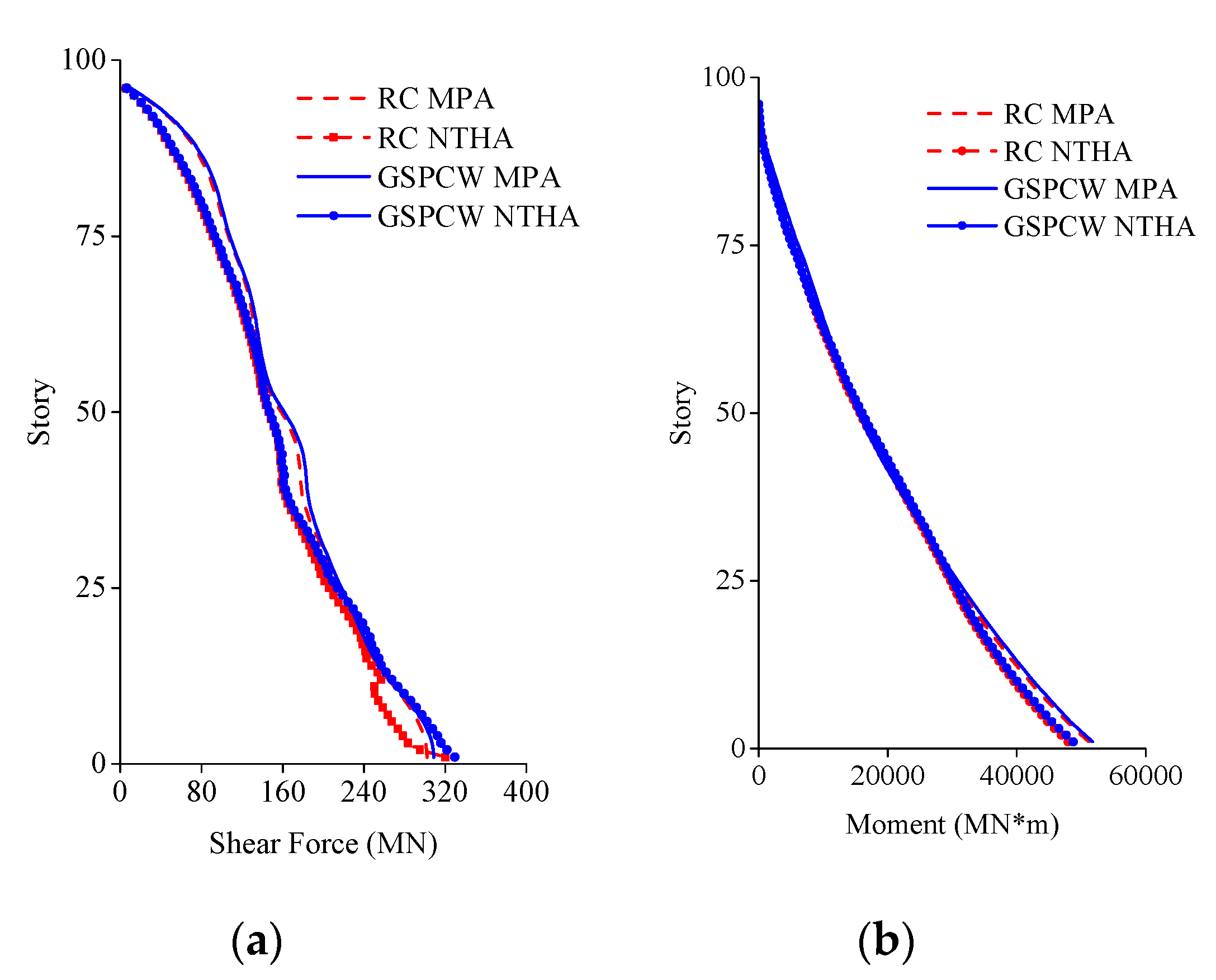

5.3. Story Shear Forces and Overturning Moments

6. Seismic Performance Assessment through Modal Pushover Analysis

6.1. Story Drifts and Peak Displacements

6.2. Story Shear Forces and Overturning Moments

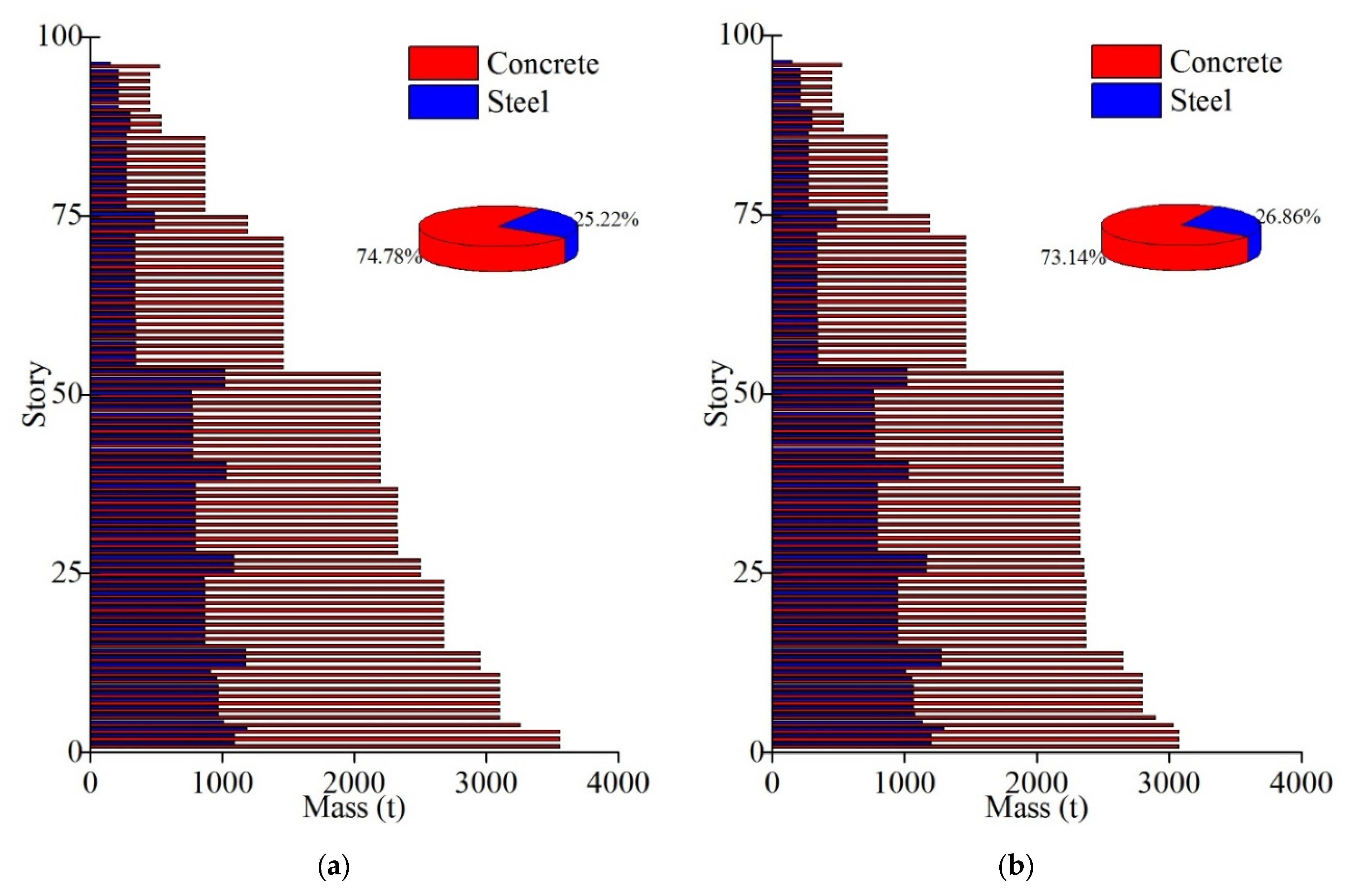

7. Economic Assessment

8. Conclusions

- Parametric analysis results show that the steel ratio has a critical effect on the load capacity and stiffness of GSPCW walls, since steel plate is the only source of steel in GSPCW walls, and no additional reinforcement (e.g., reinforcing bars) is used. The height-to-width ratio has a critical influence on the failure mode of GSPCW walls. The axial load ratio has some influence on the ductility of GSPCW walls, i.e., the ductility decreases as the axial load ratio increases, which is especially evident when the axial load ratio is greater than 0.5. Based on the current study, it is suggested that the axial load ratio be kept below 0.5 in practice in order to maintain good ductility. The aspect ratio of the grille determines the constraining effect from the steel plate on the filled concrete, which should be considered during the design process. Concrete compressive strength has little to no effect on the seismic performance of GSPCW.

- After replacing the ordinary reinforced concrete shear walls with GSPCW walls with wall thickness reduced by 30%, the GSPCW building was still able to control the overall deformation of the structures to a good extent, and the average deformation response from the analyses met the code requirements.

- In this study, the MPA procedure using five modes was verified to be accurate enough to provide similar results to those obtained using the NTHA procedure for nonlinear analysis. However, the time required for MPA analysis is much less than that required for NTHA.

- Based on a simple statistical analysis of the current case study, the amount of concrete consumed for the whole structure was decreased by 1.64% using the GSPCW model, while the steel consumption increased by 1.64%, which shows a marginal overall increase in steel consumption using GSPCW walls. Economic analysis shows the cost of materials for GSPCW models was only increased by about 2.2% per unit area. However, due to the reduction in the thickness of GSPCW walls, the available architecture area of GSPCW buildings is increased by almost 3% compared to the original area. Therefore, the economy of GSPCW walls can still be considered reasonable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Nie, J.G.; Tao, M.X.; Fan, J.S.; Pu, F.M.; Hu, H.S.; Ma, X.W.; Li, S.Y.; Liu, F.J. Research advances of composite shear walls with double steel plates and filled concrete. J. Build. Struct. 2011, 41, 52–60. (In Chinese) [Google Scholar]

- Wang, W.; Wang, Y.; Lu, Z. Experimental study on seismic behavior of steel plate reinforced concrete composite shear wall. Eng. Struct. 2018, 160, 281–292. [Google Scholar] [CrossRef]

- Ozaki, M.; Akita, S.; Osuga, H.; Nakayama, T.; Adachi, N. Study on steel plate reinforced concrete panels subjected to cyclic in-plane shear. Nucl. Eng. Des. 2004, 228, 225–244. [Google Scholar] [CrossRef]

- Emori, K. Compressive and shear strength of concrete filled steel box wall. Int. J. Steel Struct. 2002, 2, 29–40. [Google Scholar]

- Link, R.A.; Elwi, A.E. Composite concrete-steel plate walls: Analysis and behavior. J. Struct. Eng. 1995, 121, 260–271. [Google Scholar] [CrossRef]

- Xu, W.P.; Xu, T. Seismic performance test of grille type double steel plate concrete composite shear wall. J. Archit. Civ. Eng. 2018, 35, 111–118. (In Chinese) [Google Scholar]

- Guo, X. Study on Seismic Behavior of Grid-Type Steel Tube-Concrete Composite Shear Walls. Master’s Thesis, Southeast University, Nanjing, China, 2016. (In Chinese). [Google Scholar]

- Xu, T. Experimental Study on Grille-Type Steel Plate Concrete Composite Shear Wall under Low Cyclic Loading. Master’s Thesis, Southeast University, Nanjing, China, 2017. (In Chinese). [Google Scholar]

- Ye, S. Study on Seismic Performance of Concrete Filled Steel Tube Frame-Grille Type Steel Plate Shear Wall Structure. Master’s Thesis, Southeast University, Nanjing, China, 2018. (In Chinese). [Google Scholar]

- Zhang, X.L.; Liu, Y.; Wang, T.; Xu, W.P. Anti-seismic test study on the grid-tube-type double steel plate and infilled concrete composite shear wall. IOP Conf. Ser. Earth Environ. Sci. 2021, 719, 022004. [Google Scholar] [CrossRef]

- DIANA. User’s Manual—DIANA Documentation Release 10.3; Version 10.3; DIANA FEA BV.: Delft, The Netherlands, 2019. [Google Scholar]

- Mander, J.B.; Prestley, M.J.; Park, R. Theoretical stress-strain model for confined concrete. Am. Soc. Civ. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef] [Green Version]

- Cai, J.; Sun, G. Constitutive relationship of concrete core confined by square steel tube. J. South China Univ. Technol. 2008, 36, 105–109. [Google Scholar]

- CEB-FIP Model 1990. In Model Code for Concrete Structures (1990): Chapter 2: Material Properties; International Federation for Structural Concrete: Lausanne, Switzerland, 1991.

- GB 50010-2010. In Code for Design of Concrete Structures; China Architecture & Building Press: Beijing, China, 2015. (In Chinese)

- GB 50017-2017. In Standard for Design of Steel Structures; China Architecture & Building Press: Beijing, China, 2017. (In Chinese)

- GB 50011-2010. In Code for Seismic Design of Buildings; China Architecture & Building Press: Beijing, China, 2016. (In Chinese)

- PERFORM-3D. In User Guide PERFORM-3DTM Nonlinear Analysis and Performance Assessment for 3D Structures; Version 7; Computers and Structures, Inc.: Berkeley, CA, USA, 2018.

- JGJ 138-2016. In Code for Design of Composite Structures; China Architecture & Building Press: Beijing, China, 2016. (In Chinese)

- JGJ 3-2010. In Technical Specification for Concrete Structures of Tall Building; China Architecture & Building Press: Beijing, China, 2010. (In Chinese)

- GB 50009-2012. In Load Code for the Design of Building Structures; China Architecture & Building Press: Beijing, China, 2012. (In Chinese)

- PERFORM-3D. In Components and Elements for PERFORM-3DTM; Version 7; Computers and Structures, Inc.: Berkeley, CA, USA, 2018.

- Zhang, C.Q. Study on the Key Issues of Seismic Performance of Super High-Rise Structures with New Type Energy Dissipation Outrigger Truss. Ph.D. Thesis, Tongji University, Shanghai, China, 2014. (In Chinese). [Google Scholar]

- FEMA 273. In NEHRP Guidelines for the Seismic Rehabilitation of Buildings; Federal Emergency Management Agency: Washington, DC, USA, 1997.

- FEMA 356. In Prestandard and Commentary for the Seismic Rehabilitation of Building; Federal Emergency Management Agency: Washington, DC, USA, 2000.

- Elwood, K.J.; Matamoros, A.B.; Wallace, J.W.; Lehman, D.E.; Heintz, J.A.; Mitchell, A.D.; Moore, M.A.; Valley, M.T.; Lowes, L.N.; Comartin, C.D.; et al. Update to ASCE/SEI 41 concrete provision. Earthq. Spectra 2007, 23, 493–523. [Google Scholar] [CrossRef] [Green Version]

| Wall ID | Wall Dimension W × T * (mm × mm) | Steel Plate Thickness (mm) | Steel Channel (mm × mm × mm) | Axial Load Ratio | Concrete Strength (MPa) | Steel Plate Strength (MPa) |

|---|---|---|---|---|---|---|

| GSPCW-1 | 1400 × 160 | 4 | [16 (160 × 64 × 5) | 0.1 | 26.6 | 263.2 |

| GSPCW-2 | 1400 × 160 | 4 | [16 (160 × 64 × 5) | 0.4 | 26.6 | 263.2 |

| Wall ID | Loading Direction | Fy (kN) | Dy (mm) | Fp (kN) | Dp (mm) | Du (mm) | |

|---|---|---|---|---|---|---|---|

| GSPCW-1 | Test | positive | 803.47 | 10.94 | 1079.54 | 52.90 | 92.60 |

| negative | 840.59 | 13.10 | 930.00 | 55.40 | 91.90 | ||

| Model | positive | 898.69 | 7.75 | 1078.70 | 20.00 | 75.57 | |

| negative | 890.34 | 7.52 | 1060.00 | 20.00 | 91.00 | ||

| GSPCW-2 | Test | positive | 931.24 | 4.81 | 1223.11 | 26.64 | 66.80 |

| negative | 885.27 | 7.55 | 1070.00 | 26.40 | 60.04 | ||

| Model | positive | 1019.34 | 7.92 | 1190.00 | 13.00 | 40.07 | |

| negative | 1002.53 | 7.90 | 1180.00 | 14.00 | 35.73 |

| Wall ID | Wall Dimension W × T * (mm × mm) | Height (mm) | Height-to-Width Ratio | Concrete Grade | Aspect Ratio of Grille Steel Plate | Axial Load Ratio | Steel Plate Thickness | Steel Ratio |

|---|---|---|---|---|---|---|---|---|

| GSPCW1-1 | 1400 × 160 | 2800 | 2.0 | C40 | 1.25 | 0.3 | 3 | 7.2% |

| GSPCW1-2 | 1400 × 160 | 2800 | 2.0 | C40 | 1.25 | 0.3 | 4 | 8.9% |

| GSPCW1-3 | 1400 × 160 | 2800 | 2.0 | C40 | 1.25 | 0.3 | 5 | 10.5% |

| GSPCW1-4 | 1400 × 160 | 2800 | 2.0 | C40 | 1.25 | 0.3 | 6 | 12.1% |

| GSPCW2-1 | same as GSPCW1-2 | |||||||

| GSPCW2-2 | 1400 × 160 | 2800 | 2.0 | C40 | 1.25 | 0.4 | 4 | 8.9% |

| GSPCW2-3 | 1400 × 160 | 2800 | 2.0 | C40 | 1.25 | 0.5 | 4 | 8.9% |

| GSPCW2-4 | 1400 × 160 | 2800 | 2.0 | C40 | 1.25 | 0.6 | 4 | 8.9% |

| GSPCW2-5 | 1400 × 160 | 2800 | 2.0 | C40 | 1.25 | 0.7 | 4 | 8.9% |

| GSPCW3-1 | 1400 × 160 | 2100 | 1.5 | C40 | 1.25 | 0.3 | 4 | 8.9% |

| GSPCW3-2 | same as GSPCW1-2 | |||||||

| GSPCW3-3 | 1400 × 160 | 3500 | 2.5 | C40 | 1.25 | 0.3 | 4 | 8.9% |

| GSPCW3-4 | 1400 × 160 | 4200 | 3.0 | C40 | 1.25 | 0.3 | 4 | 8.9% |

| GSPCW3-5 | 1400 × 160 | 4900 | 3.5 | C40 | 1.25 | 0.3 | 4 | 8.9% |

| GSPCW4-1 | 1400 × 160 | 2800 | 2.0 | C40 | 1.75 | 0.3 | 4 | 8.3% |

| GSPCW4-2 | 1400 × 160 | 2800 | 2.0 | C40 | 1.46 | 0.3 | 4 | 8.6% |

| GSPCW4-3 | same as GSPCW1-2 | |||||||

| GSPCW4-4 | 1400 × 160 | 2800 | 2.0 | C40 | 1.09 | 0.3 | 4 | 9.1% |

| GSPCW5-1 | 1400 × 160 | 2800 | 2.0 | C30 | 1.25 | 0.3 | 4 | 8.9% |

| GSPCW5-2 | same as GSPCW1-2 | |||||||

| GSPCW5-3 | 1400 × 160 | 2800 | 2.0 | C50 | 1.25 | 0.3 | 4 | 8.9% |

| GSPCW5-4 | 1400 × 160 | 2800 | 2.0 | C60 | 1.25 | 0.3 | 4 | 8.9% |

| Story | KL1 | KL2 | KL3 | LL1 | LL2 | L1 | L2 |

|---|---|---|---|---|---|---|---|

| 1~4 | 1000 × 300 × 28 × 40 | 900 × 300 × 25 × 40 | 1000 × 1200 | 2000 × 2000 + 1200 × 1200 × 50 × 50 | 800 × 1000 | 300 × 700 | 200 × 350 |

| 5~11 | 1800 × 2000 + 1200 × 1200 × 50 × 50 | ||||||

| 12~14 | 600 × 800 | ||||||

| 15~24 | 1560 × 1000 + 800 × 800 × 45 × 45 | ||||||

| 25~27 | 1320 × 1000 + 800 × 800 × 45 × 45 | ||||||

| 28~37 | 1080 × 1000 + 800 × 400 × 50 × 55 | ||||||

| 38~53 | 1080 × 1000 | 400 × 800 | |||||

| 54~72 | 800 × 1000 | 800 × 1000 | |||||

| 73~75 | 650 × 300 × 14 × 30 | 600 × 800 | |||||

| 76~86 | 900 × 300 × 25 × 40 | 300 × 600 | |||||

| 87~95 | 700 × 300 × 16 × 30 | 650 × 300 × 14 × 30 | 300 × 600 | ||||

| 96 | 300 × 700 | ||||||

| Story | Z1 | Z2 | Z3 | Inner Wall | Exterior Wall | Truss | Brace |

|---|---|---|---|---|---|---|---|

| 1~4 | 2000 × 2000 × 70 × 70 | 2000 × 3500 × 70 × 70 | 2000 × 3500 × 70 × 80 | 800 | 2000 (1350) | - | 800 × 800 × 55 × 55 |

| 5~11 | 1800 (1350) | ||||||

| 12~14 | 600 | 700 × 700 × 50 × 50 | - | ||||

| 15~24 | 1560 (1100) | - | 1000 × 1000 × 60 × 60 | ||||

| 25~27 | 1320 (1100) | 700 × 700 × 50 × 50 | - | ||||

| 28~37 | 1080 (-) | - | 1000 × 1000 × 60 × 60 | ||||

| 38~40 | 400 | 700 × 700 × 50 × 50 | - | ||||

| 41~50 | - | 1000 × 1000 × 60 × 60 | |||||

| 51~53 | 700 × 700 × 50 × 50 | - | |||||

| 54~72 | 1500 × 1500 | 1500 × 2000 | 1500 × 3000 | 800 (-) | - | 1000 × 1000 × 60 × 60 | |

| 73~75 | 1200 × 1200 | 1200 × 1600 | 1200 × 2000 | 600 (-) | 700 × 700 × 50 × 50 500 × 500 × 30 × 30 | - | |

| 76~86 | 1000 × 1000 | 1000 × 1200 | 1000 × 1800 | 300 | 600 (-) | - | 700 × 700 × 50 × 50 |

| 87~89 | 500 × 500 | 500 × 800 | 650 × 1000 | 300 (-) | 500 × 500 × 30 × 30 | - | |

| 90~95 | - | 700 × 700 × 50 × 50 | |||||

| 96 | - | ||||||

| No. | Direction | RC Model | GSPCW Model | Error of Periods | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Periods (s) | Angle (deg) | Effective Modal Mass | Periods (s) | Angle (deg) | Effective Modal Mass | |||||

| EX | EY | EX | EY | |||||||

| 1 | Y | 6.047 | 89.90 | 0.00% | 56.85% | 6.117 | 89.84 | 0.00% | 57.64% | 1.15% |

| 2 | X | 5.967 | 179.90 | 56.53% | 0.00% | 6.039 | 179.80 | 57.32% | 0.00% | 1.20% |

| 3 | T | 2.253 | 90.00 | 0.00% | 0.00% | 2.370 | 49.37 | 0.00% | 0.00% | 5.19% |

| 4 | Y | 1.678 | 89.98 | 0.00% | 19.87% | 1.717 | 89.97 | 0.00% | 20.55% | 2.33% |

| 5 | X | 1.612 | 180.00 | 20.33% | 0.00% | 1.652 | 180.00 | 20.98% | 0.00% | 2.48% |

| 6 | T | 0.883 | 89.27 | 0.00% | 0.01% | 0.919 | 86.83 | 0.00% | 0.00% | 4.02% |

| 7 | Y | 0.875 | 90.01 | 0.00% | 7.30% | 0.895 | 90.01 | 0.00% | 7.35% | 2.30% |

| 8 | X | 0.811 | 0.01 | 7.47% | 0.00% | 0.831 | 0.01 | 7.52% | 0.00% | 2.56% |

| 9 | Y | 0.592 | 90.00 | 0.00% | 3.98% | 0.606 | 90.01 | 0.00% | 3.88% | 2.20% |

| 10 | T | 0.542 | 83.24 | 0.00% | 0.00% | 0.563 | 85.11 | 0.00% | 0.00% | 3.84% |

| No. | Station | Event | Arias Intensity (m/s) | Year | Duration (s) |

|---|---|---|---|---|---|

| RSN138 | Boshrooyeh | Tabas Iran | 0.3 | 1978 | 35 |

| RSN728 | Westmorland Fire Station | Superstition Hills-02 | 1.2 | 1987 | 60 |

| RSN737 | Agnews State Hospital | Loma Prieta | 0.5 | 1989 | 60 |

| RSN5774 | Nakashinden Town | Iwate Japan | 1.0 | 2008 | 60 |

| RSN5783 | Semine Kurihara City | Iwate Japan | 0.8 | 2008 | 120 |

| RSN5823 | Chihuahua | El Mayor-Cucapah Mexico | 2.3 | 2010 | 130 |

| RSN5829 | RIITO | El Mayor-Cucapah Mexico | 4.7 | 2010 | 130 |

| RSN5977 | Chihuahua | El Mayor-Cucapah Mexico | 0.0 | 2010 | 105 |

| RSN5991 | El Centro Array #10 | El Mayor-Cucapah Mexico | 3.6 | 2010 | 275 |

| RSN6965 | SBRC | Darfield_ New Zealand | 0.7 | 2010 | 64 |

| RC Model | GSPCW Model | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Total Area (m2) | Mass of Concrete (t) | Mass of Steel (t) | Price (JPY/m2) | Available Area (m2) | Mass of Concrete (t) | Mass of Steel (t) | Price (JPY/m2) | Available Area (m2) | |

| Total | 181,660.8 | 182,892.7 | 61,696.3 | 5182.9 | 45,754.7 | 174,796.8 | 64,181.8 | 5298.1 | 47,038.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Wu, H.; Yu, Q.; Li, Y.; Li, J.; Li, L. Seismic Performance of Grille-Type Steel Plate Concrete Composite Walls with Application in a Super-High-Rise Building. Appl. Sci. 2021, 11, 7580. https://doi.org/10.3390/app11167580

Liu Y, Wu H, Yu Q, Li Y, Li J, Li L. Seismic Performance of Grille-Type Steel Plate Concrete Composite Walls with Application in a Super-High-Rise Building. Applied Sciences. 2021; 11(16):7580. https://doi.org/10.3390/app11167580

Chicago/Turabian StyleLiu, Yang, Hao Wu, Qiao Yu, Yun Li, Jianan Li, and Lingzhi Li. 2021. "Seismic Performance of Grille-Type Steel Plate Concrete Composite Walls with Application in a Super-High-Rise Building" Applied Sciences 11, no. 16: 7580. https://doi.org/10.3390/app11167580

APA StyleLiu, Y., Wu, H., Yu, Q., Li, Y., Li, J., & Li, L. (2021). Seismic Performance of Grille-Type Steel Plate Concrete Composite Walls with Application in a Super-High-Rise Building. Applied Sciences, 11(16), 7580. https://doi.org/10.3390/app11167580