Numerical Simulation on Dynamic Behavior of Slab–Column Connections Subjected to Blast Loads

Abstract

:1. Introduction

2. Literature Review

3. Numerical Analysis

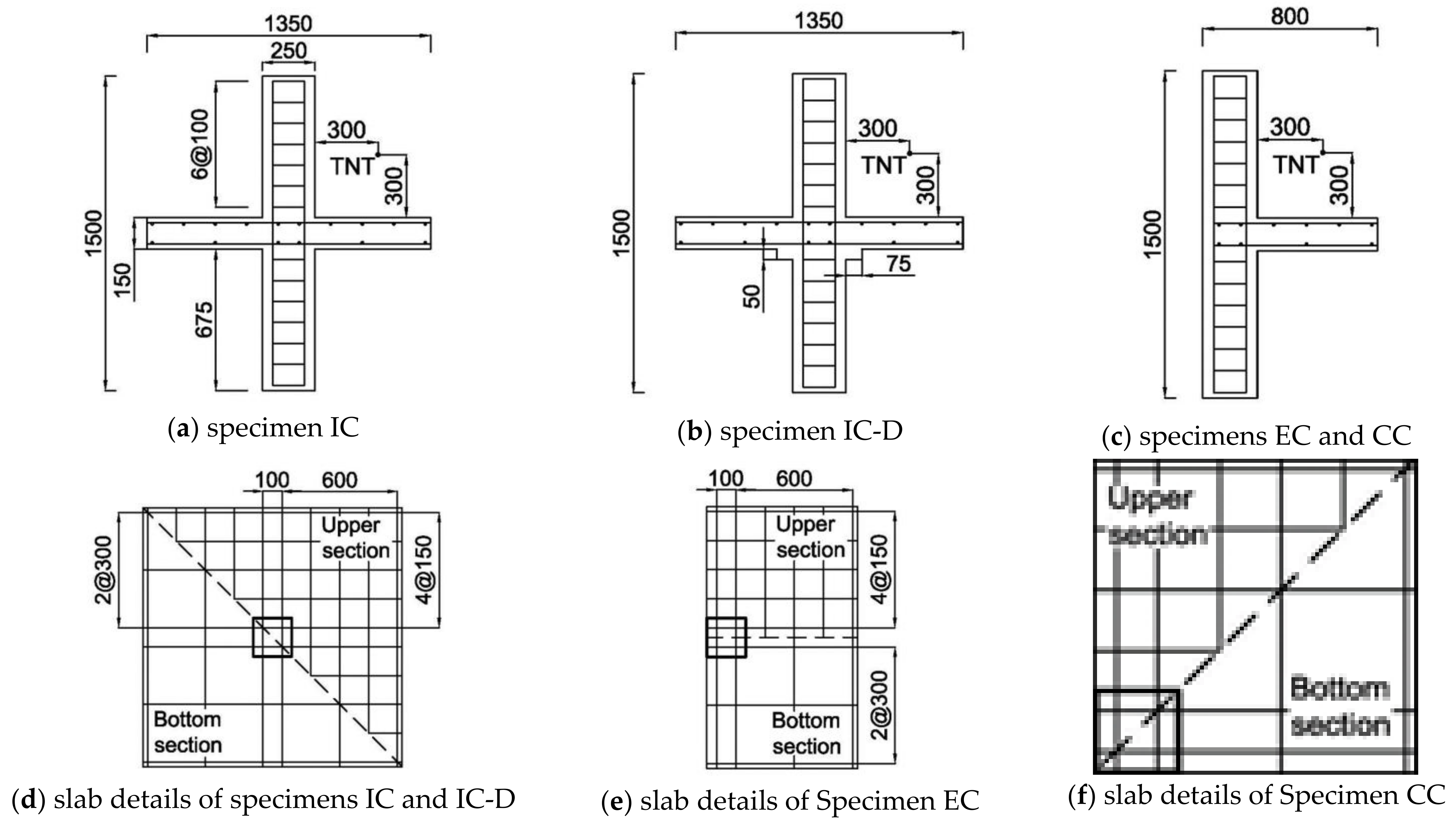

3.1. Details of Specimens

3.2. Modeling of Specimens

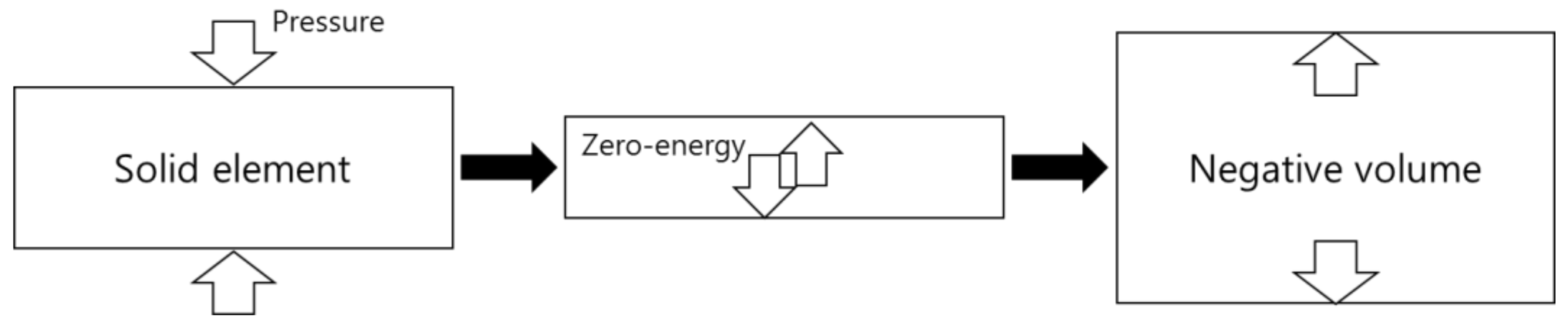

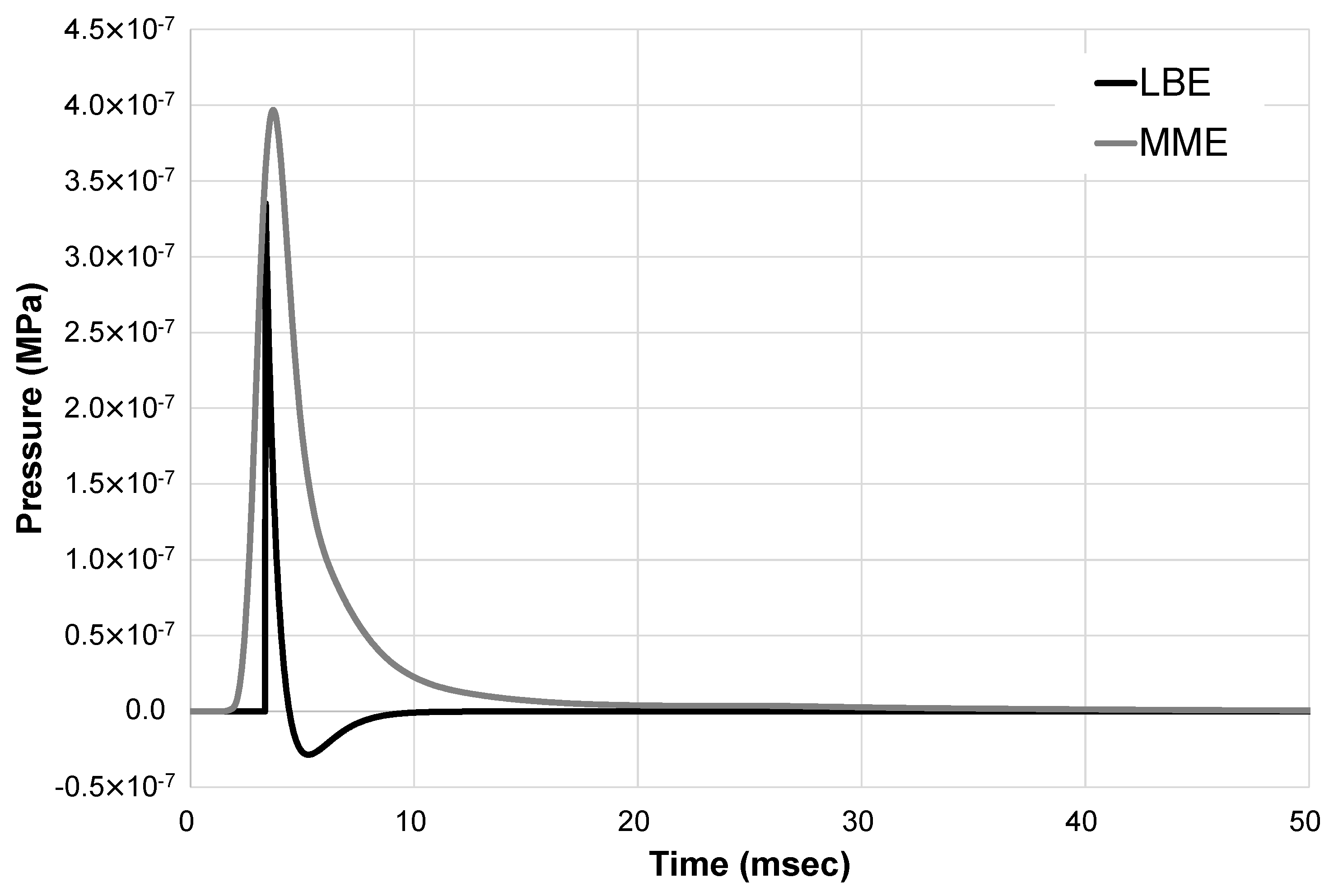

3.3. Modeling of Blast Loads

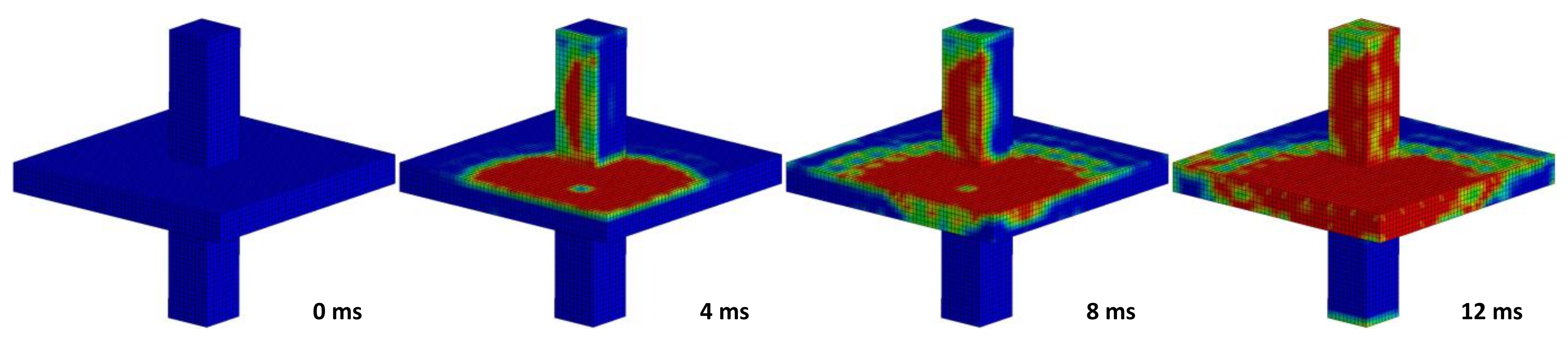

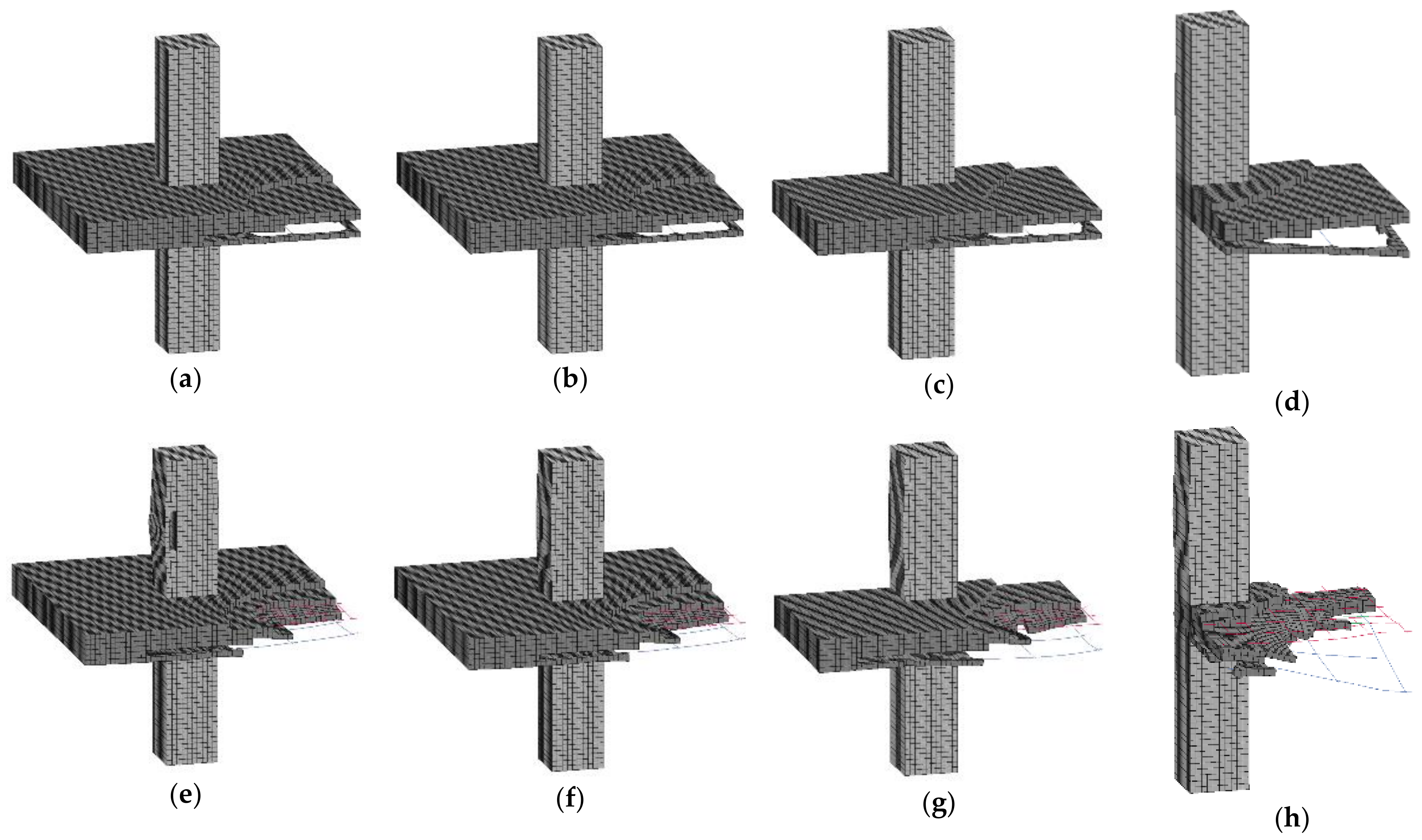

4. Analysis Results

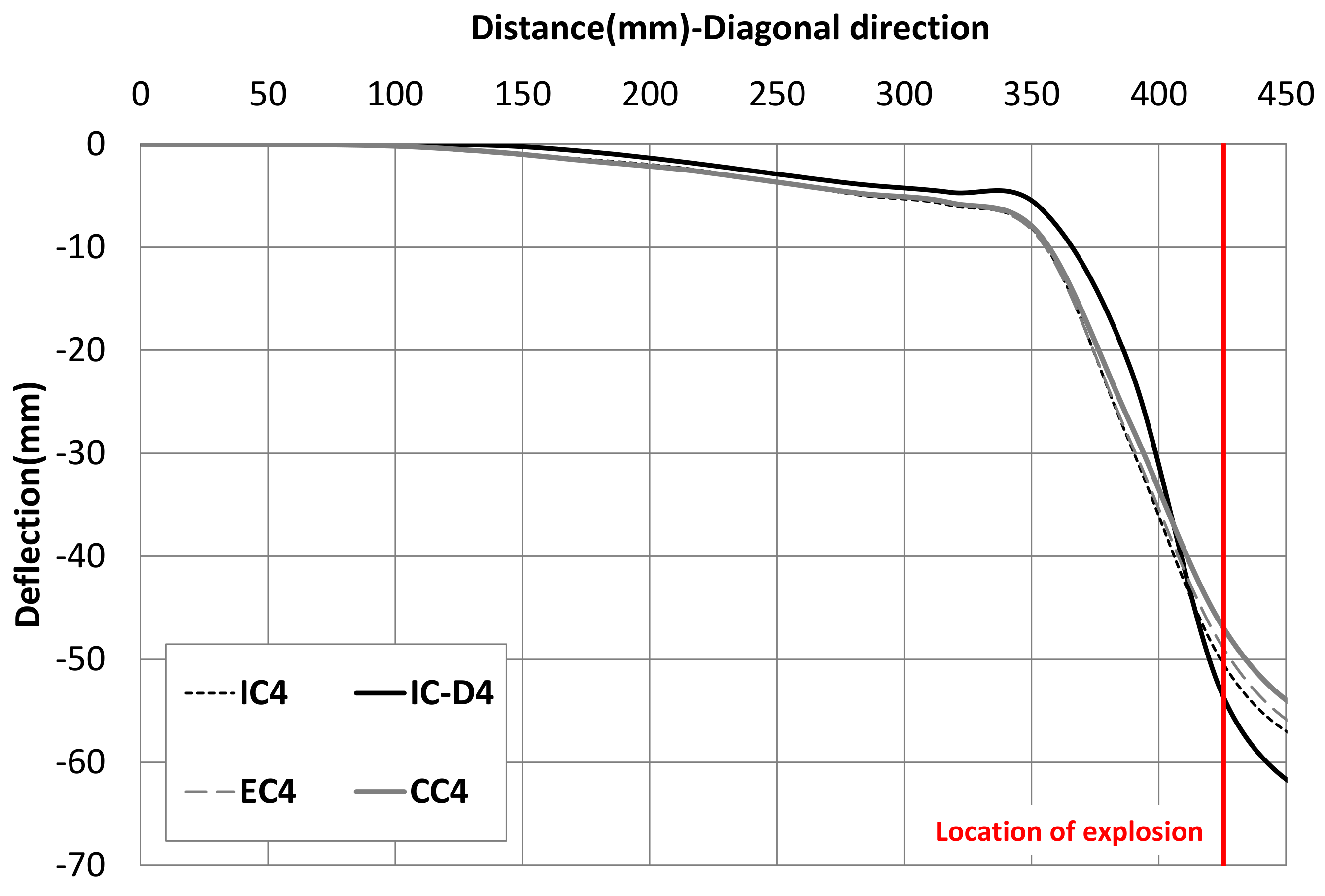

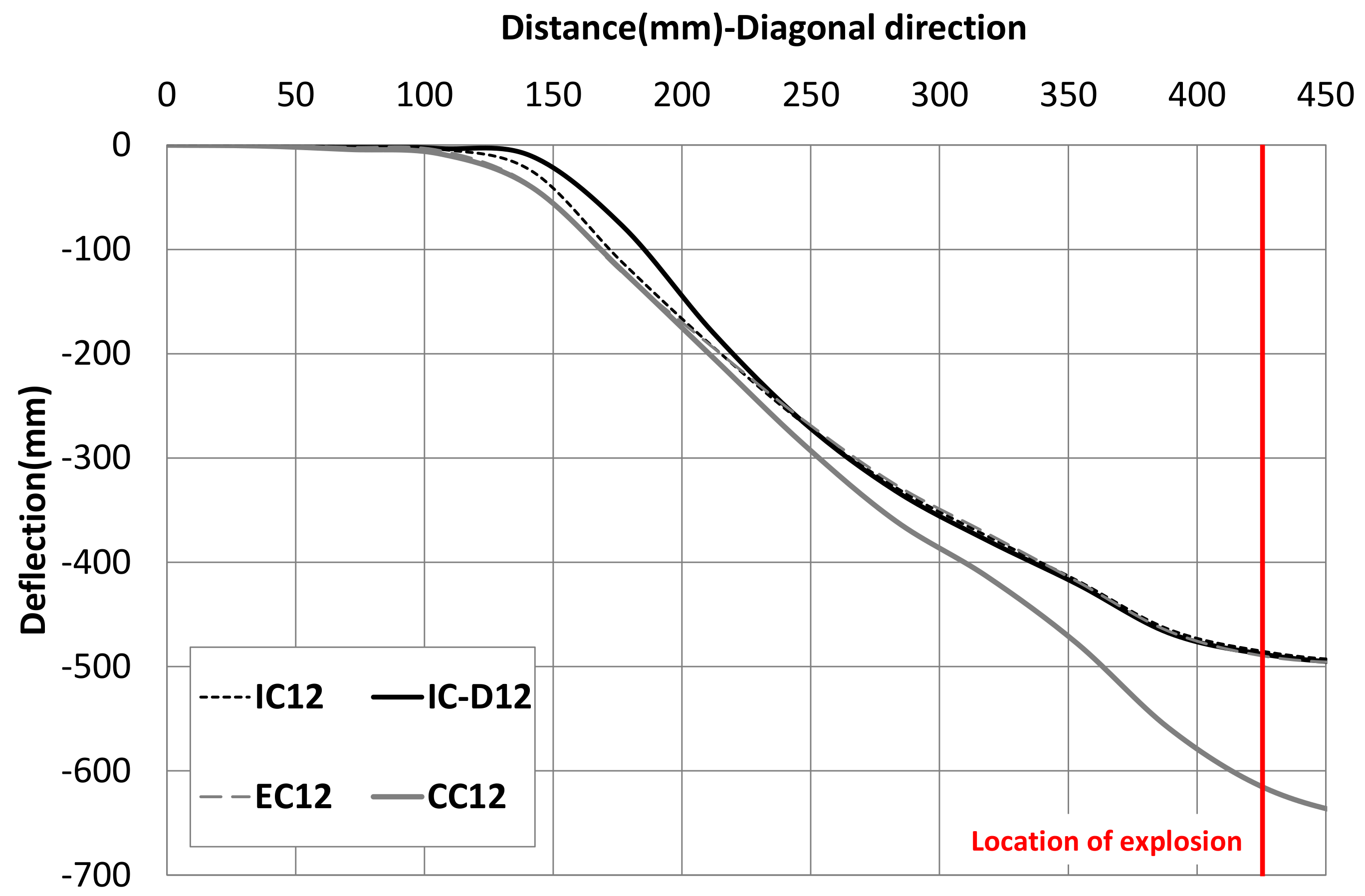

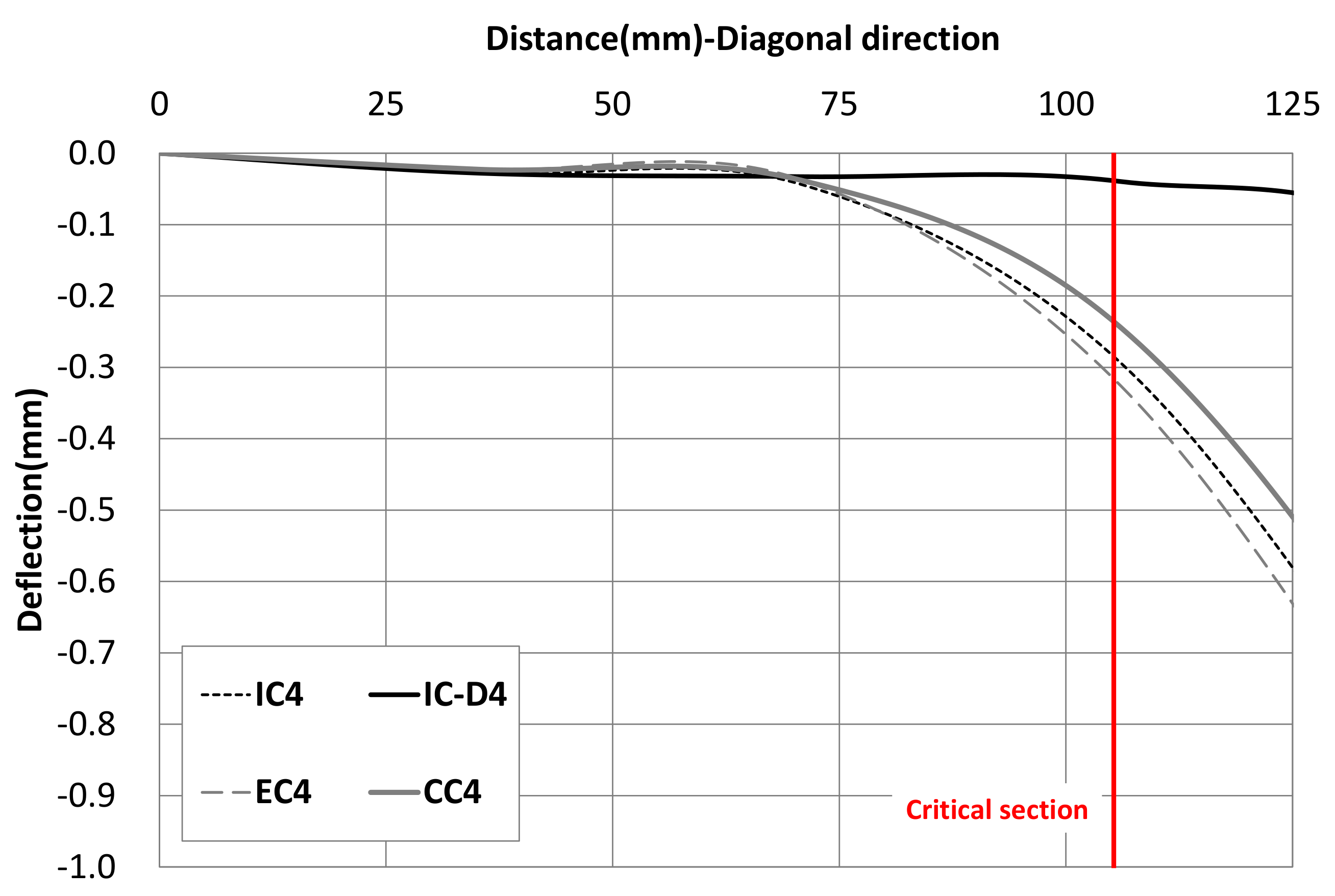

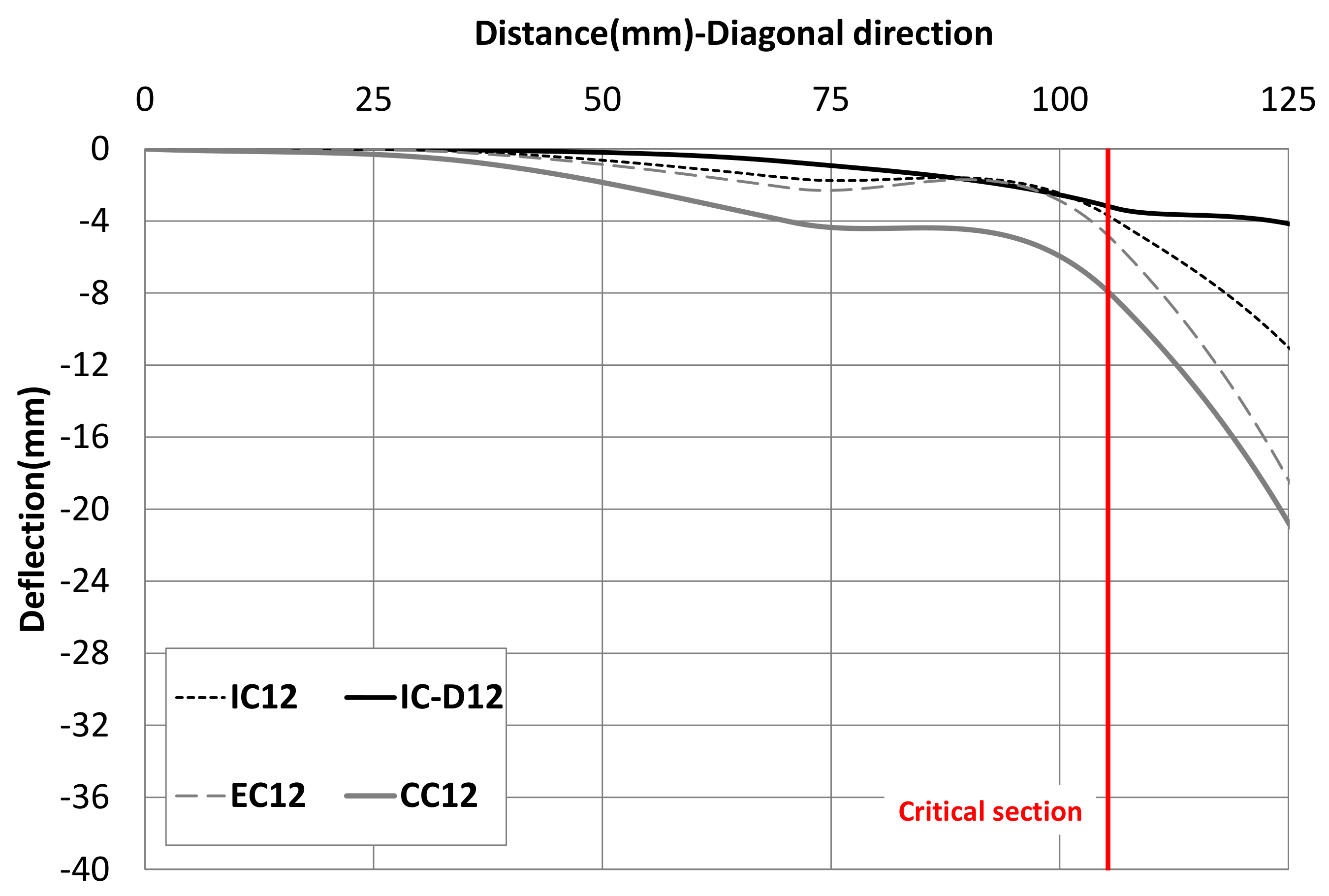

4.1. Slab Deflection

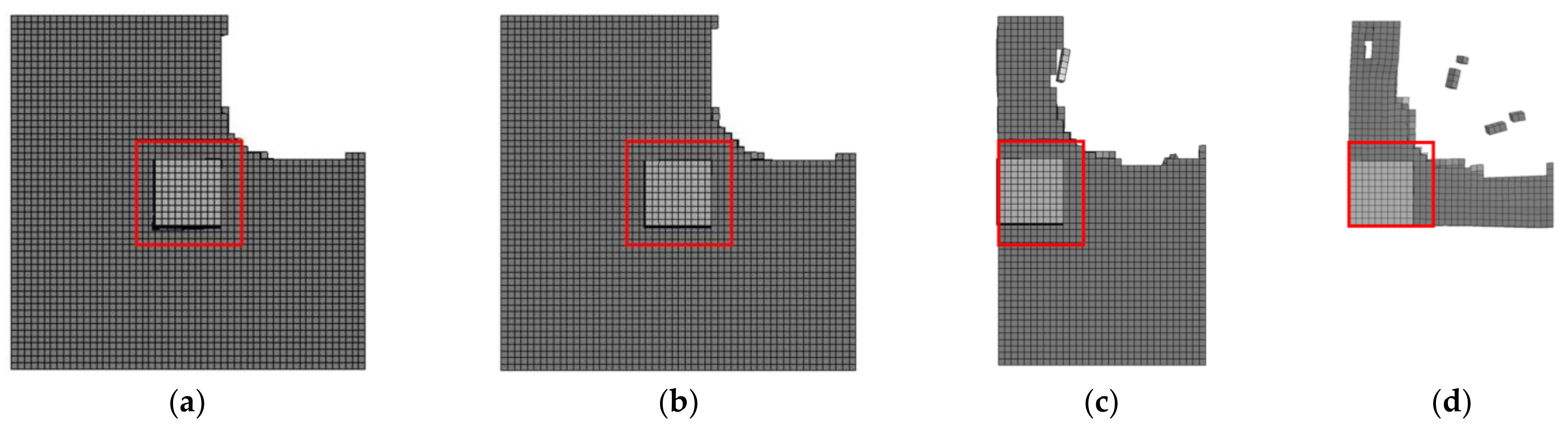

4.2. Critical Section in Slab

4.3. Steel Stresses in Slab

4.4. Column Behavior

5. Conclusions

- (1)

- Analysis results showed that the slab-interior column had a better performance than the slab-edge column and slab-corner column in terms of slab failure at critical section and column deformation. The confinement effect seems to be considered in the design of blast-resistant structures. However, the effect of the position of the column on the behavior of the slab such as slab deflection and support rotation under explosive load was not apparent. Further research is needed with the location of the explosive load and the dimensions of columns and slabs as variables.

- (2)

- The drop panel was observed to contribute to the improvement of the blast-resistance performance. For 4 kg and 12 kg of TNT, the drop panel reduced the maximum deflection of the slab at the critical section by approximately 86% and 17%, and the column deformation by approximately 2.9% and 4.8%, respectively.

- (3)

- Although significant concrete fracture occurred in the slab, the maximum stress of the reinforcing bar did not reach the tensile strength. This phenomenon occurs because the concrete is momentarily destroyed by the explosive energy and the energy is not sufficiently transmitted to the reinforcing bars. Further research is needed to ensure that the blast energy can be sufficiently transmitted to the rebar through the concrete.

- (4)

- For most design criteria, the support rotation has been considered as a major criterion for blast-resistant capacities. It is a very simple and good evaluation factor representing the critical behavior of the joint. However, in this study, considerable failure occurred in the slab member even though the support rotations at the critical section were satisfied with the criteria. Therefore, for a more accurate evaluation of blast resistance performance, various evaluation factors such as ductility ratio, reinforcing stress, and concrete fracture area can be considered along with the support rotation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brun, M.; Batti, A.; Limam, A.; Gravouil, A. Explicit/implicit multi-time step co-computations for blast analyses on a reinforced concrete frame structure. Finite Elem. Anal. Des. 2012, 52, 41–59. [Google Scholar] [CrossRef]

- Hajek, R.; Fladr, J.; Pachman, J.; Stoller, J.; Foglar, M. An experimental evaluation of the blast resistance of heterogeneous concrete-based composite bridge decks. Eng. Struct. 2018, 179, 204–210. [Google Scholar] [CrossRef]

- Kumar, V.; Kartik, K.; Iqbal, M. Experimental and numerical investigation of reinforced concrete slabs under blast loading. Eng. Struct. 2020, 206, 110125. [Google Scholar] [CrossRef]

- Abdulsamee, M.H.; Yazan, B.A.T.; Amin, H.A.; George, Z.V. The effect of shape memory alloys on the ductility of exterior reinforced concrete beam-column joints using the damage plasticity model. Eng. Struct. 2019, 200, 109676. [Google Scholar]

- Cumhur, C.; Ahmet, M.T.; Atakan, M.; Turgay, C.; Guven, K. Experimental behavior and failure of beam-column joints with plain bars, low-strength concrete and different anchorage details. Eng. Fail. Anal. 2020, 109, 104247. [Google Scholar]

- Yim, H.C.; Krauthammer, T. Load-impulse characterization for steel connections in monolithic reinforced concrete structures. Int. J. Impact Eng. 2009, 36, 737–745. [Google Scholar] [CrossRef]

- Andrew, R.; Nicola, B.; Giuseppe, C.; Stefano, D.M.; Gianluca, I.; Sonia, M.; Elio, S.; Sara, S.; Gabriel, T. Full scale experimental tests and numerical model validation of reinforced concrete slab subjected to direct contact explosion. Int. J. Impact Eng. 2019, 132, 103309. [Google Scholar]

- Azer, M.; Stijn, M.; Bachir, B.; David, L.; John, V. Blast response of retrofitted reinforced concrete hollow core slabs under a close distance explosion. Eng. Struct. 2019, 191, 447–459. [Google Scholar]

- Bianchini, A.C.; Woods, R.E.; Kesler, C.E. Effect of floor concrete strength on column strength. ACI J. Proc. 1960, 56, 1149–1170. [Google Scholar]

- McHarg, P.J.; Cook, W.D.; Mitchell, D.; Yoon, Y.S. Benefits of concentrated slab reinforcement and steel fibers on performance of slab-column connections. ACI Struct. J. 2000, 97, 225–234. [Google Scholar]

- Lee, J.-H.; Yoon, Y.-S.; Cook, W.D.; Mitchell, D. Benefits of Using Puddled HSC with Fibers in Slabs to Transmit HSC Column Loads. J. Struct. Eng. 2007, 133, 1843–1847. [Google Scholar] [CrossRef]

- Morrison, D.G.; Hirasawa, I.; Sozen, M.A. Lateral-load tests of R/C slab-column connections. J. Struct. Eng. 1983, 109, 2698–2714. [Google Scholar] [CrossRef]

- Marzouk, H.; Osman, M.; Hussein, A. Cyclic Loading of High-Strength Lightweight Concrete Slabs. ACI Struct. J. 2001, 98, 207–214. [Google Scholar]

- Tian, Y.; Jirsa, J.O.; Bayrak, O.; Widianto; Argudo, J.F. Behavior of Slab-Column Connections of Existing Flat-Plate Structures. ACI Struct. J. 2008, 105, 561. [Google Scholar] [CrossRef]

- Drakatos, I.-S.; Muttoni, A.; Beyer, K. Internal slab-column connections under monotonic and cyclic imposed rotations. Eng. Struct. 2016, 123, 501–516. [Google Scholar] [CrossRef] [Green Version]

- Isufi, B.; Rossi, M.; Ramos, A.P. Influence of flexural reinforcement on the seismic performance of flat slab–column connections. Eng. Struct. 2021, 242, 112583. [Google Scholar] [CrossRef]

- Emam, M.; Marzouk, H.; Hilal, M.S. Seismic response of slab-column connections constructed with high-strength concrete. ACI Struct. J. 1997, 94, 197–205. [Google Scholar]

- Marzouk, H.; Emam, M.; Hilal, M.S. Effect of high-strength concrete slab on the behavior of slab-column connections. ACI Struct. J. 1998, 95, 227–237. [Google Scholar]

- Inácio, M.; Isufi, B.; Lapi, M.; Ramos, A.P. Rational use of high-strength concrete in flat slab-column connections under seismic loading. ACI Struct. J. 2020, 117, 297–310. [Google Scholar] [CrossRef]

- Smadi, M.; Yasin, I.B. Behavior of high-strength fibrous concrete slab–column connections under gravity and lateral loads. Constr. Build. Mater. 2008, 22, 1863–1873. [Google Scholar] [CrossRef]

- Scotta, R.; Giorgi, P. Comparative cyclic tests of exterior flat slab–column connections in normal concrete and fiber-reinforced lightweight aggregate concrete. Mater. Struct. 2015, 49, 4049–4067. [Google Scholar] [CrossRef]

- Buitrago, M.; Bertolesi, E.; Sagaseta, J.; Calderón, P.A.; Adam, J.M. Robustness of RC building structures with infill masonry walls: Tests on a purpose-built structure. Eng. Struct. 2020, 226, 111384. [Google Scholar] [CrossRef]

- Adam, J.M.; Buitrago, M.; Bertolesi, E.; Sagaseta, J.; Moragues, J.J. Dynamic performance of a real-scale reinforced concrete building test under a corner-column failure scenario. Eng. Struct. 2020, 210, 110414. [Google Scholar] [CrossRef]

- Mousapoor, E.; Ghiasi, V.; Madandoust, R. Macro modeling of slab-column connections in progressive collapse with post-punching effect. In Structures; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Yankelevsky, D.; Karinski, Y.; Feldgun, V. Dynamic punching shear failure of a RC flat slab-column connection under a collapsing slab impact. Int. J. Impact Eng. 2019, 135, 103401. [Google Scholar] [CrossRef]

- Adam, J.M.; Parisi, F.; Sagaseta, J.; Lu, X. Research and practice on progressive collapse and robustness of building structures in the 21st century. Eng. Struct. 2018, 173, 122–149. [Google Scholar] [CrossRef]

- Setiawan, A.; Vollum, R.L.; Macorini, L. Numerical and analytical investigation of internal slab-column connections subject to cyclic loading. Eng. Struct. 2019, 184, 535–554. [Google Scholar] [CrossRef]

- Silva, F.P.; Lu, B. Improving the blast resistance capacity of RC slabs with innovative composite materials. Compos. Part B Eng. 2007, 38, 523–534. [Google Scholar] [CrossRef]

- Schenker, A.; Anteby, I.; Gal, E.; Kivity, Y.; Nizri, E.; Sadot, O.; Michaelis, R.; Levintant, O.; Ben-Dor, G. Full-scale field tests of concrete slabs subjected to blast loads. Int. J. Impact Eng. 2008, 35, 184–198. [Google Scholar] [CrossRef]

- Wu, C.; Oehlers, D.; Rebentrost, M.; Leach, J.; Whittaker, A. Blast testing of ultra-high performance fibre and FRP-retrofitted concrete slabs. Eng. Struct. 2009, 31, 2060–2069. [Google Scholar] [CrossRef]

- Alonso, M.G.; Cendon, A.D.; Galvez, F.; Erice, B.; Galvez, S.V. Blast response analysis of reinforced concrete slabs: Experimental procedure and numerical simulation. J. Appl. Mech. 2011, 78, 1–12. [Google Scholar]

- Wang, W.; Zhang, D.; Lu, F.; Wang, S.-C.; Tang, F. Experimental study and numerical simulation of the damage mode of a square reinforced concrete slab under close-in explosion. Eng. Fail. Anal. 2012, 27, 41–51. [Google Scholar] [CrossRef]

- Thiagarajan, G.; Kadambi, V.A.; Robert, S.; Johnson, F.C. Experimental and finite element analysis of doubly reinforced concrete slabs subjected to blast loads. Int. J. Impact Eng. 2015, 75, 162–173. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.; Hao, H. Investigation of ultra-high performance concrete slab and normal strength concrete slab under contact explosion. Eng. Struct. 2015, 102, 395–408. [Google Scholar] [CrossRef]

- Castedo, R.; Segarra, P.; Alanon, A.; Lopez, M.L.; Santos, P.A.; Sanchidrian, A.J. Air blast resistance of full-scale slabs with different compositions: Numerical modeling and field validation. Int. J. Impact Eng. 2015, 86, 145–156. [Google Scholar] [CrossRef]

- Yao, S.; Zhang, D.; Chen, X.; Lu, F.; Wang, W. Experimental and numerical study on the dynamic response of RC slabs under blast loading. Eng. Fail. Anal. 2016, 66, 120–129. [Google Scholar] [CrossRef]

- Zhou, Q.X.; Kuznetsov, A.V.; Hao, H.; Waschl, J. Numerical prediction of concrete slab response to blast loading. Int. J. Impact Eng. 2008, 35, 1186–1200. [Google Scholar] [CrossRef]

- Shahriari, A.; Birzhandi, M.S.; Zafarani, M.M. Seismic behavior, blast response and progressive collapse of RC structures equipped with viscoelastic dampers. Soil Dyn. Earthq. Eng. 2021, 143, 106643. [Google Scholar] [CrossRef]

- Krauthammer, T. Blast-resistant structural concrete and steel connections. Int. J. Impact Eng. 1999, 22, 887–910. [Google Scholar] [CrossRef]

- Lim, K.M.; Yoon, Y.S.; Lee, J.H. Numerical analysis on dynamic behavior of slab-column connections subjected to blast loads. In Proceedings of the 7th Civil Engineering Conference in the Asian Region (CECAR 7), Waikiki, HI, USA, 30 August–2 September 2016. [Google Scholar]

- ASCE/SEI (American Society of Civil Engineers/Structural Engineering Institute). ASCE/SEI 59-11: Blast Protection of Building; ASCE: Reston, VA, USA, 2011. [Google Scholar]

- Pereira, J.M.; Dias, A.; Lourenco, P.B. Dynamic properties of clay brick at different stain rates. In Proceedings of the 12th Canadian Masonry Symposium, Vancouver, BC, Canada, 2–5 June 2013. [Google Scholar]

- Department of Defense. UFC 3-340-02: Structures to Resist the Effects of Accidental Explosions; Department of Defense: Arlington, VA, USA, 2008.

- ACI (American Concrete Institute) Committee 318. ACI318-11: Building Code Requirements for Structural Concrete & Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2011. [Google Scholar]

- ACI-ASCE (American Concrete Institute-American Society of Civil Engineers) Committee 352. ACI352.1R-11: Guide for Design of Slab-Column Connections in Monolithic Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2012. [Google Scholar]

- Gamble, W.L.; Klinar, J.D. Tests of High?Strength Concrete Columns with Intervening Floor Slabs. J. Struct. Eng. 1991, 117, 1462–1476. [Google Scholar] [CrossRef]

- Brannon, R.M.; Leelavanichkul, S. Survey of Four Damage Models for Concrete; SAND2009-5544; Sandia National Laboratories: Albuquerque, NM, USA, 2009. [Google Scholar]

- Crawford, J.E.; Wu, Y.; Choi, H.J.; Magallanes, J.M.; Lan, S. Use and Validation of the Release III K&C Concrete Material Model in LS-DYNA; Karagozian & Case Technical Report TR-11-36.5; Karagozian & Case, Inc.: Glendale, CA, USA, 2012. [Google Scholar]

- LSTC (Livermore Software Technology Corporation). LS-DYNA Keyword User’s Manual Volume II Material Models; Livermore Software Technology Corporation: Livermore, CA, USA, 2013. [Google Scholar]

- Ling, L. Local Damages and Blast Resistance of RC Slabs Subjected to Contact Detonation. Master’s Thesis, Korea University, Seoul, Korea, 2013. [Google Scholar]

- Gonzalez, H.A.; Zapatero, J. Influence of minimum element size to determine crack closure stress by the finite element method. Eng. Fract. Mech. 2005, 72, 337–355. [Google Scholar] [CrossRef]

- Krauthammer, T.; Otani, R. Mesh, gravity and load effects on finite element simulations of blast loaded reinforced concrete structures. Comput. Struct. 1997, 63, 1113–1120. [Google Scholar] [CrossRef]

- Foglar, M.; Kovar, M. Conclusions from experimental testing of blast resistance of FRC and RC bridge decks. Int. J. Impact Eng. 2013, 59, 18–28. [Google Scholar] [CrossRef]

- Shi, Y.; Stewart, M.G. Damage and risk assessment for reinforced concrete wall pannels subjected to explosive blast loading. Int. J. Impact Eng. 2015, 85, 5–19. [Google Scholar] [CrossRef]

- Guang, Z.; Hong, N.; Jinbao, C.; Chuanzhi, C.; Heow, P.L. Dynamic analysis of lunar lander during soft landing using explicit finite element method. Acta Astronaut. 2018, 148, 69–81. [Google Scholar]

- Kang, J.J.; Oh, S.I. Hourglass control in rigid-plastic finite element analysis. Korean Soc. Mech. Eng. 1996, 20, 1290–1300. [Google Scholar]

- Kim, K.S.; Cho, J.U.; Choi, D.S. An analysis of plastic stress in square bar impacting plat. Trans. Korean Soc. Automot. Eng. 2004, 12, 198–204. [Google Scholar]

- LSTC (Livermore Software Technology Corporation). LS-DYNA Keyword User’s Manual Volume I; Livermore Software Technology Corporation: Livermore, CA, USA, 2013. [Google Scholar]

- Bae, D.-M.; Zakki, A. Comparisons of Multi Material ALE and Single Material ALE in LS-DYNA for Estimation of Acceleration Response of Free-fall Lifeboat. J. Soc. Nav. Arch. Korea 2011, 48, 552–559. [Google Scholar] [CrossRef] [Green Version]

- Jang, I.H. Sloshing Response Analysis of LNG Carrier Tank Using Fluid Structure Interaction Analysis Technique of LS-DYNA3D. Master’s Thesis, Korea Maritime and Ocean University, Busan, Korea, 2007. [Google Scholar]

- Zahra, S.T.; Jeffery, S.V. A comparison between three different blast methods in LS-DYNA: LBE, MM-ALE, Coupling of LBE and MM-ALE. In Proceedings of the 12th International LS-DYNA User Conference, Dearborn, MI, USA, 3–5 June 2012. [Google Scholar]

- Huh, Y.C.; Chung, T.Y.; Kim, K.C.; Jung, H.J.; Choi, H.H. A study on the modeling techniques of air blast load using LS-DYNA. In Proceedings of the Korean Society for Noise and Vibration Engineering Conference, Daegu, Korea, 26–27 April 2012; pp. 375–376. [Google Scholar]

- Yandzio, E.; Gough, M. Protection of Buildings against Explosions; The Steel Construction Institute: Ascot, UK, 1999. [Google Scholar]

- Krauthammer, T. Modern Protective Structures; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Lim, K.-M.; Shin, H.; Kim, D.-J.; Yoon, Y.-S.; Lee, J.-H. Numerical Assessment of Reinforcing Details in Beam-Column Joints on Blast Resistance. Int. J. Concr. Struct. Mater. 2016, 10, 87–96. [Google Scholar] [CrossRef] [Green Version]

| Variables | Number of Elements | Analysis Time | Duration of Analysis | ||

|---|---|---|---|---|---|

| Structures | Air | TNT | |||

| LBE | 800 | - | - | 129 s | 100 ms |

| MME | 800 | 56075 | 125 | 11,075 s | |

| Explosion Method | Material Type | Loaded Weight |

|---|---|---|

| Small briefcase | Military commercial bomb such as TNT | 2~4 kg |

| Large briefcase | 4~12 kg | |

| Suitcase | 12~22 kg | |

| Bicycle | 30 kg |

| Specimen | Description | Charged Weight of TNT |

|---|---|---|

| IC4 | Slab-interior—column connection | 4 kg |

| IC12 | 12 kg | |

| IC-D4 | Slab-interior—column connection reinforcing with drop panel | 4 kg |

| IC-D12 | 12 kg | |

| EC4 | Slab-edge—column connection | 4 kg |

| EC12 | 12 kg | |

| CC4 | Slab-corner—column connection | 4 kg |

| CC12 | 12 kg |

| Specimen | Deflection (mm) | Support Rotation (°) |

|---|---|---|

| IC4 | 0.294 | 0.159 |

| IC-D4 | 0.040 | 0.021 |

| EC4 | 0.326 | 0.176 |

| CC4 | 0.244 | 0.132 |

| IC12 | 3.941 | 1.277 |

| IC-D12 | 3.284 | 1.064 |

| EC12 | 5.190 | 1.682 |

| CC12 | 8.297 | 2.687 |

| Specimen | Peak Stress (MPa) | |

|---|---|---|

| Top Reinforcing Bar | Bottom Reinforcing Bar | |

| IC4 | 32.40 | 157.04 |

| IC-D4 | 33.93 | 164.08 |

| EC4 | 29.52 | 162.08 |

| CC4 | 31.17 | 137.43 |

| IC12 | 122.62 | 298.52 |

| IC-D12 | 128.38 | 279.72 |

| EC12 | 176.12 | 312.99 |

| CC12 | 440.92 | 440.48 |

| Specimen | Column Deformation (mm) | |

|---|---|---|

| TNT 4 kg | TNT 12 kg | |

| IC | 0.034 | 0.104 |

| IC-D | 0.033 | 0.099 |

| EC | 0.035 | 0.171 |

| CC | 0.038 | 12.91 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, K.M.; Han, T.H.; Lee, J.H. Numerical Simulation on Dynamic Behavior of Slab–Column Connections Subjected to Blast Loads. Appl. Sci. 2021, 11, 7573. https://doi.org/10.3390/app11167573

Lim KM, Han TH, Lee JH. Numerical Simulation on Dynamic Behavior of Slab–Column Connections Subjected to Blast Loads. Applied Sciences. 2021; 11(16):7573. https://doi.org/10.3390/app11167573

Chicago/Turabian StyleLim, Kwang Mo, Taek Hee Han, and Joo Ha Lee. 2021. "Numerical Simulation on Dynamic Behavior of Slab–Column Connections Subjected to Blast Loads" Applied Sciences 11, no. 16: 7573. https://doi.org/10.3390/app11167573

APA StyleLim, K. M., Han, T. H., & Lee, J. H. (2021). Numerical Simulation on Dynamic Behavior of Slab–Column Connections Subjected to Blast Loads. Applied Sciences, 11(16), 7573. https://doi.org/10.3390/app11167573