A Dynamic Model for the Study and Simulation of the Pantograph–Rigid Catenary Interaction with an Overlapping Span

Abstract

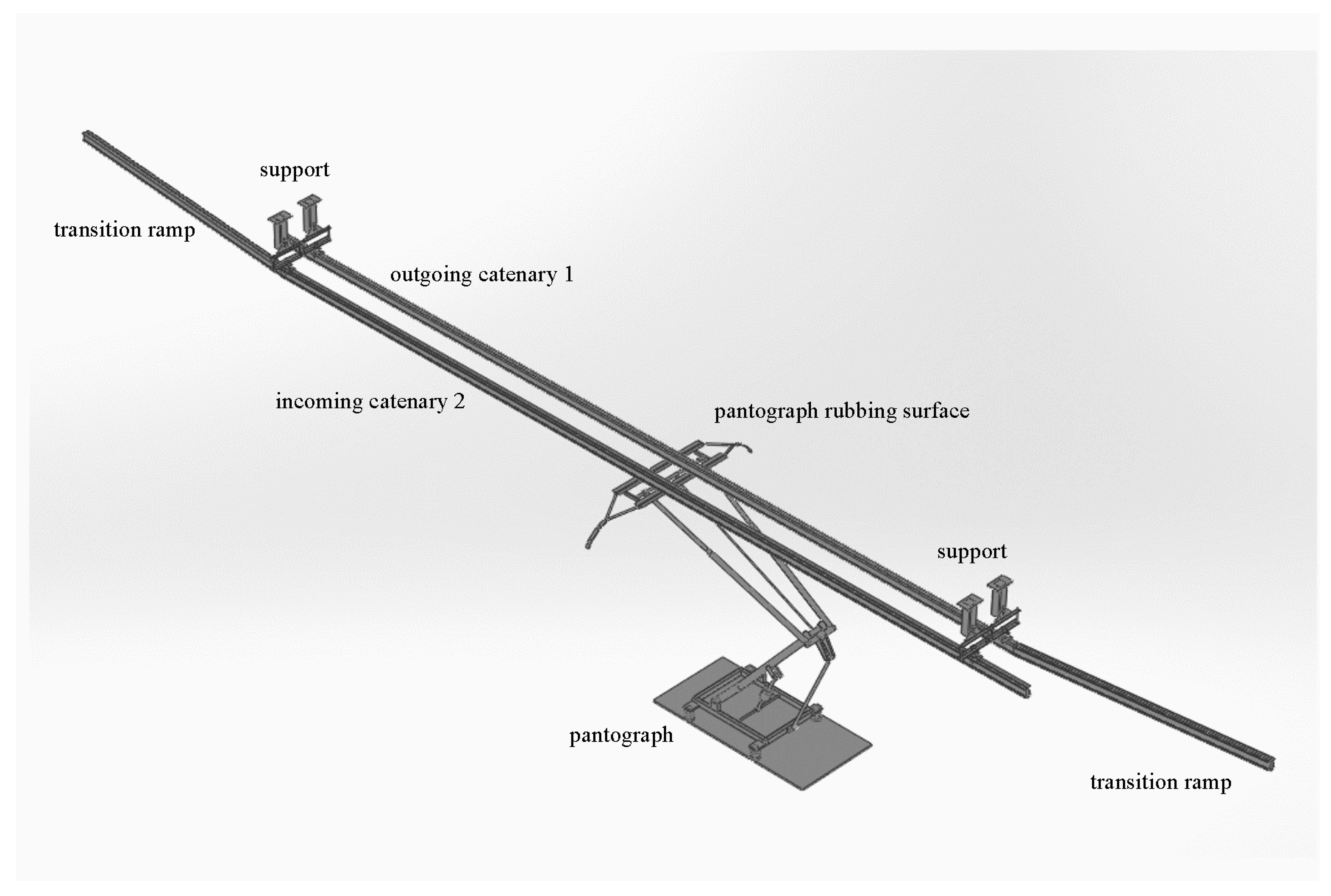

:1. Introduction

2. Materials and Methods

2.1. Dynamic Equations of the Catenary Pantograph System

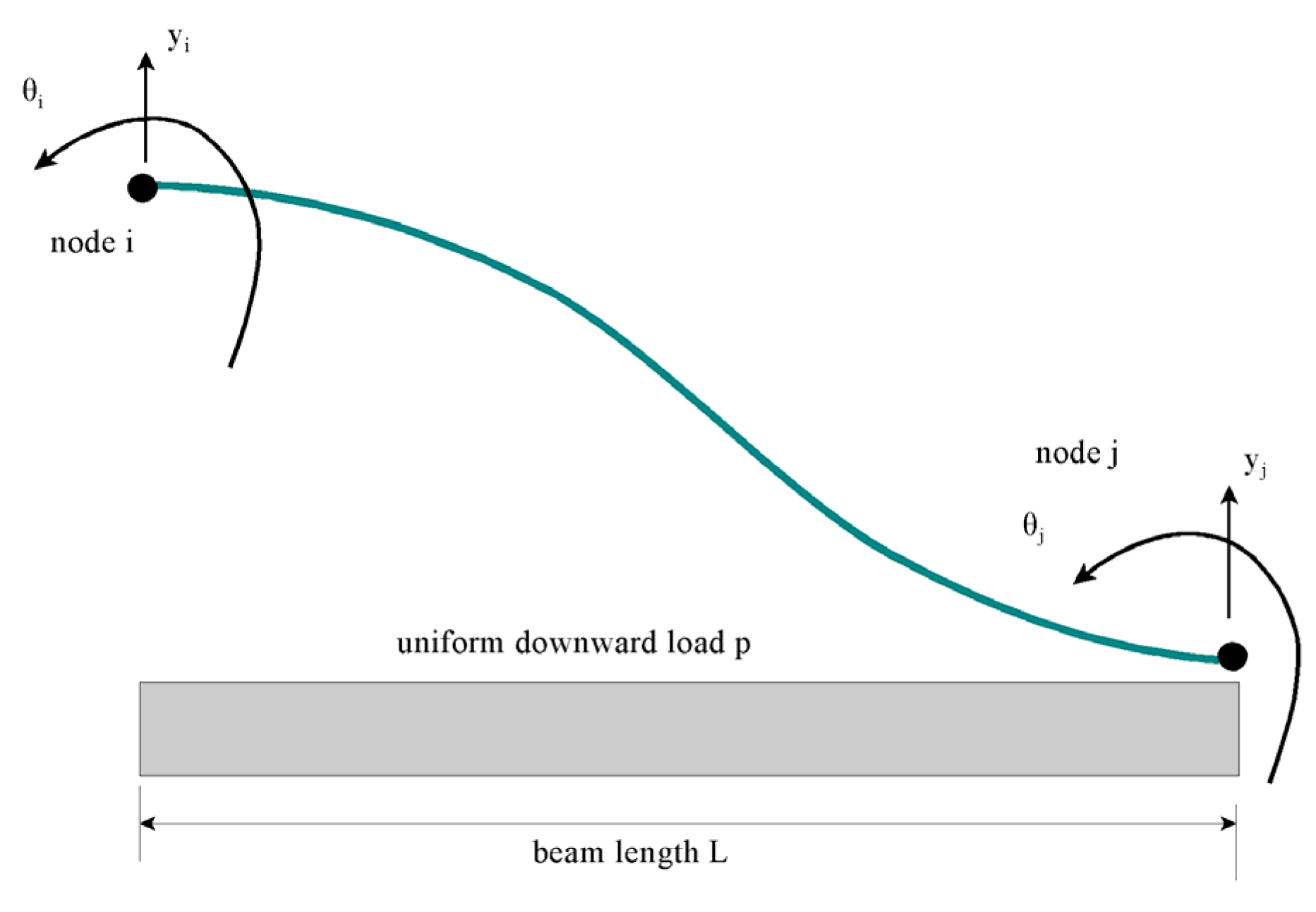

2.2. Beam Model for Rigid Catenary

2.3. Properties of the Rigid Catenary Section and the Supports

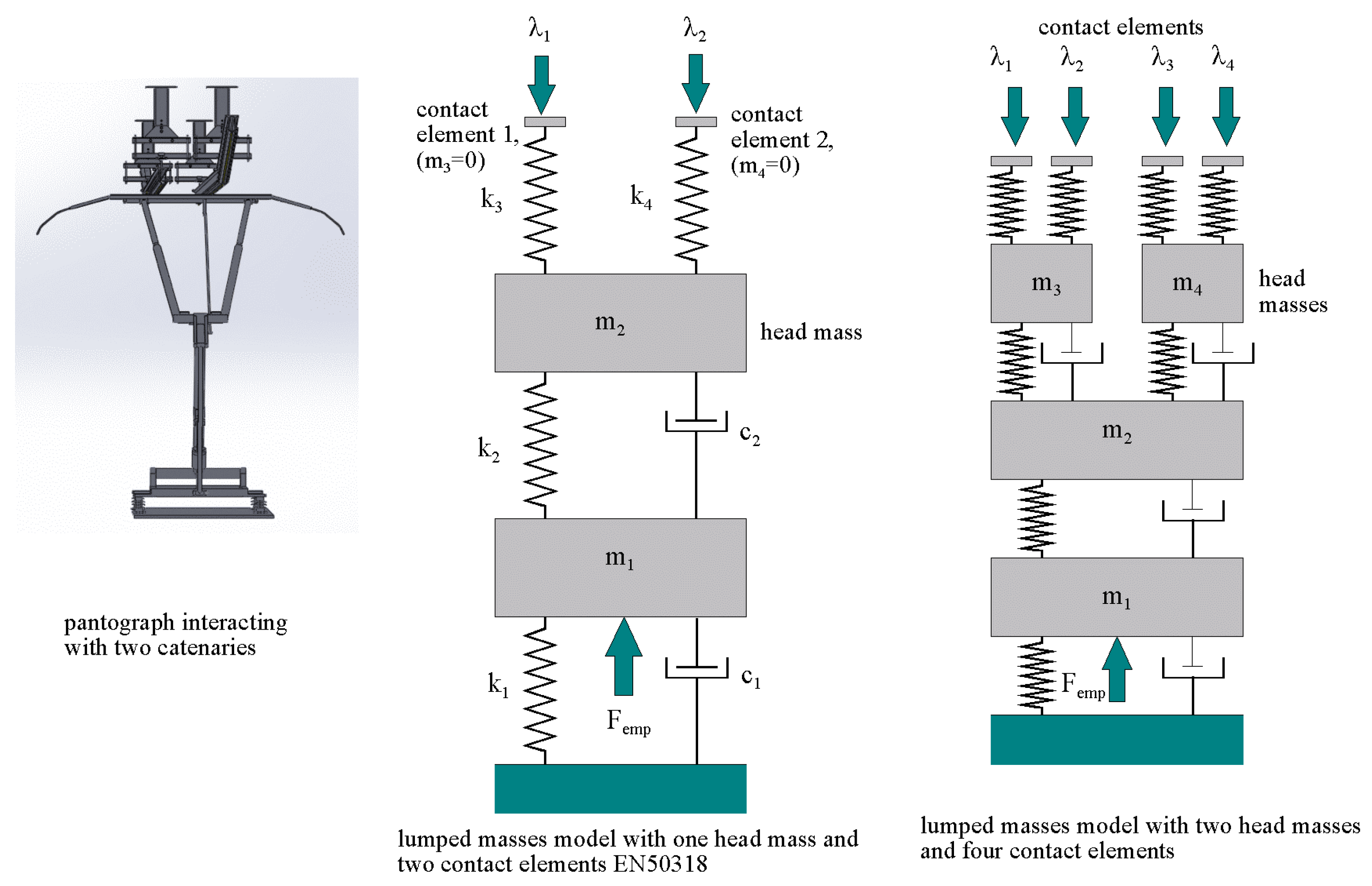

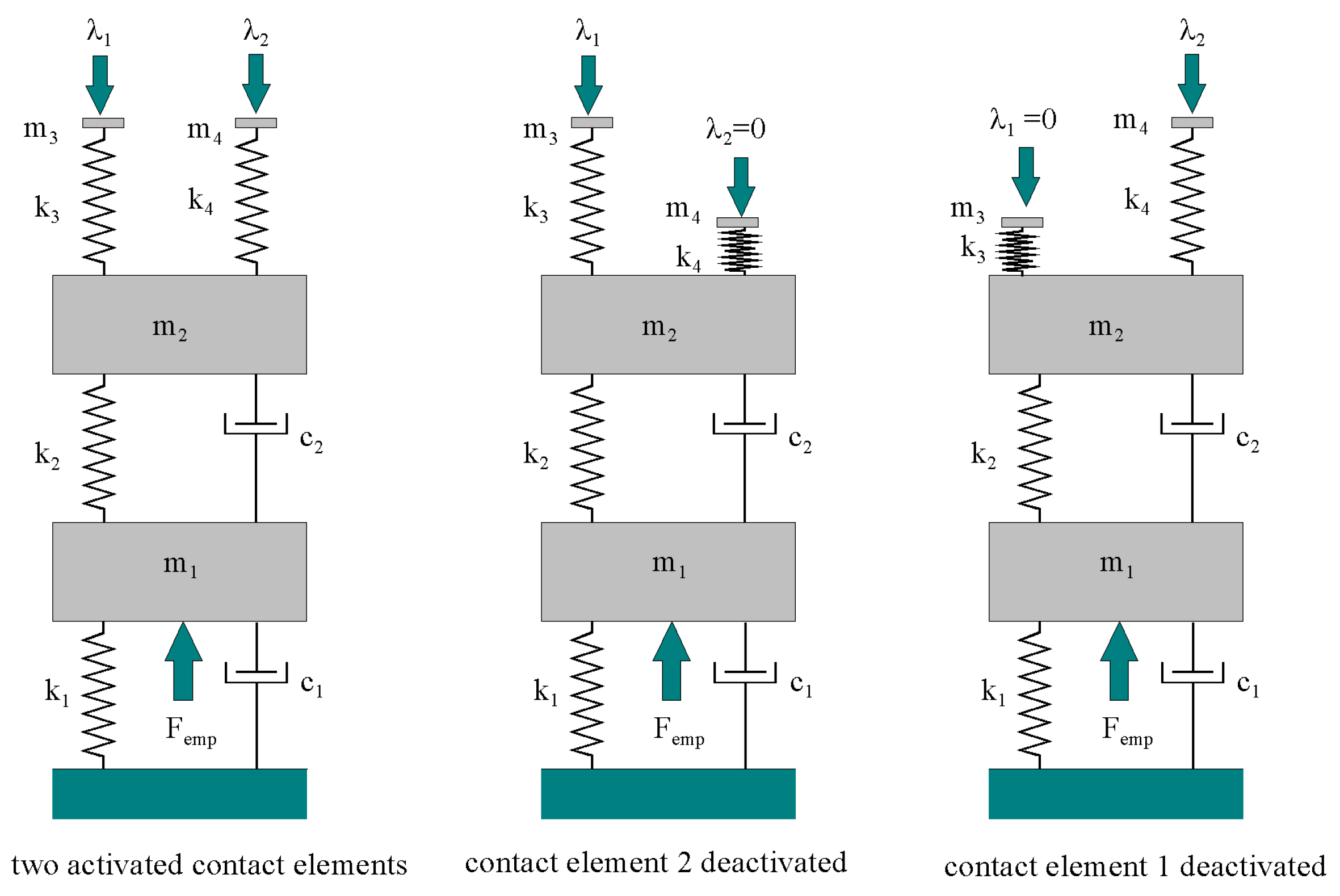

2.4. Pantograph Model

2.5. Contact Pantograph/Catenary Model

2.6. Formulation of Restriction Conditions

- The pantograph circulates through catenary 1 without reaching the common transition zone of the two catenaries, defined from the overlapping spans. In this case, interaction only exists with catenary 1 through contact element 1, and contact element 1 is activated and contact element 2 is deactivated.

- The pantograph circulates through catenary 2, having exceeded the common transition zone. In this case, there will only be interaction with catenary 2 through contact element 2; thus, contact element 2 is activated and contact element 1 is deactivated.

- The pantograph circulates in the common transition zone between the two catenaries. In this case, the pantograph interacts with the two catenaries, and the two contact elements are activated.

2.7. Integration of Dynamic Equations

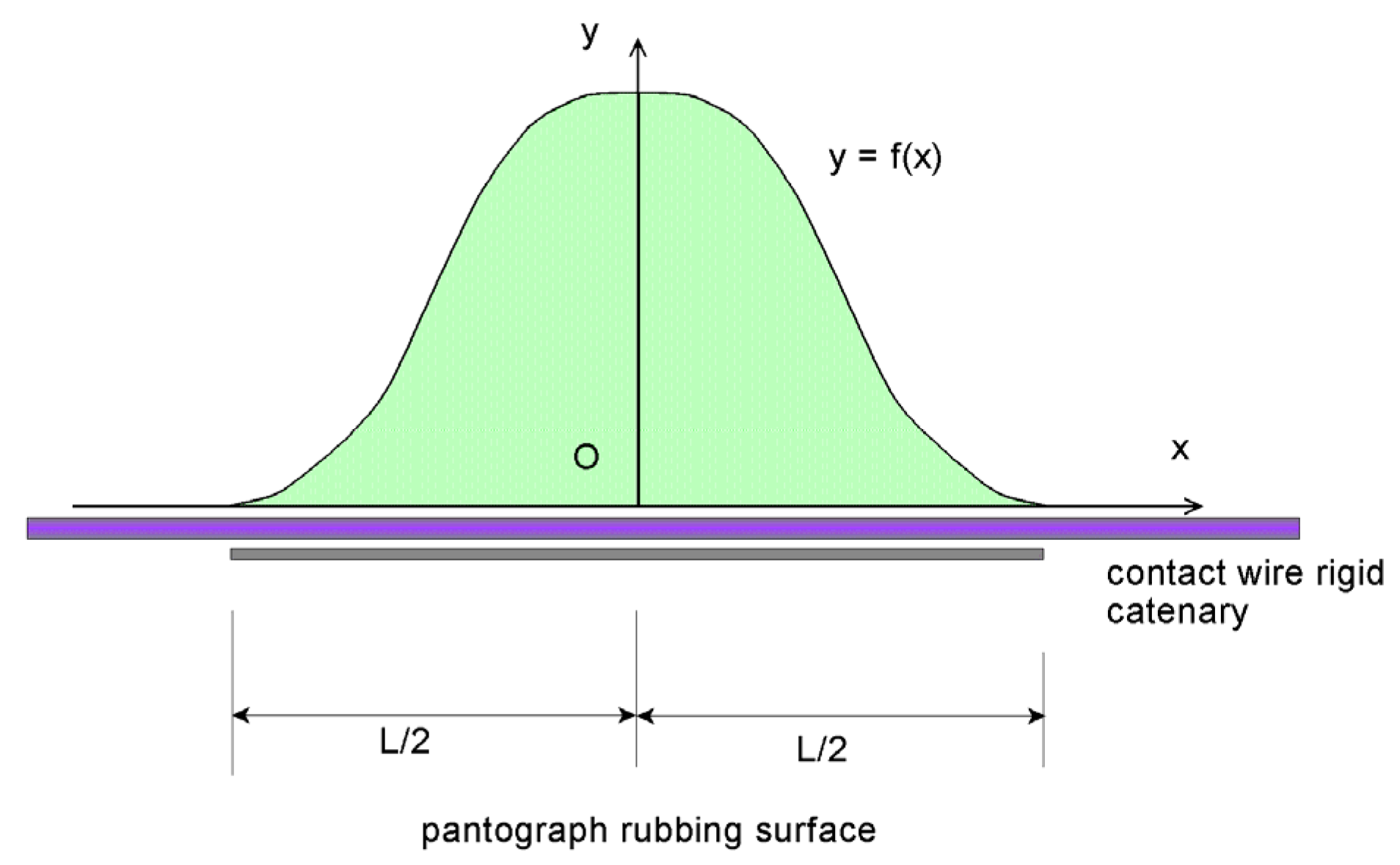

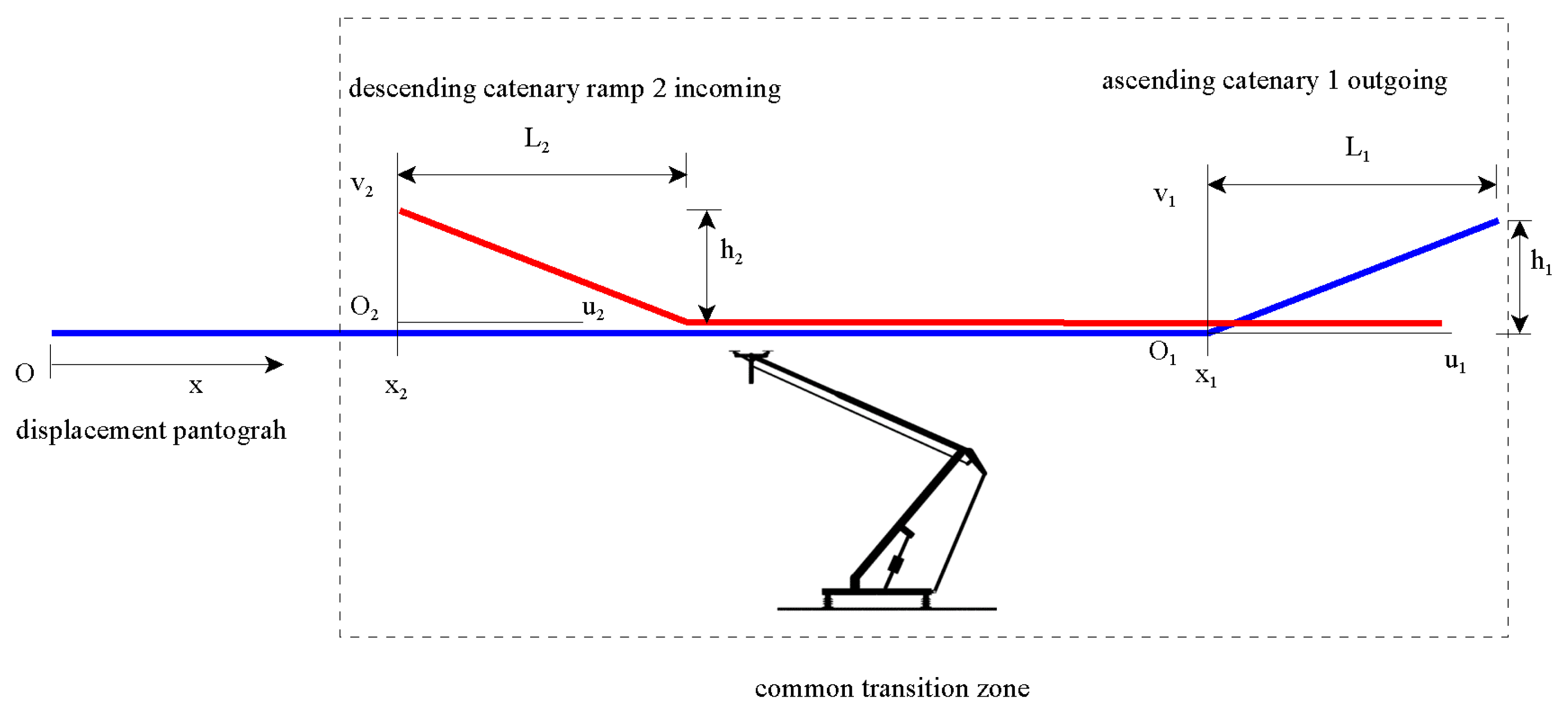

2.8. Functions for Correcting the Contact Position Due to the Effect of Overlapping Span

2.9. Algorithm for the Integration of Dynamic Equation

- Input data for catenary and pantograph. Regarding the catenary: the number of spans of the cantons, lengths of spans, moments of inertia of the elements of the Furrer beam section (body of the beam and the contact wire), characteristics of the materials, the geometry of the sections, characteristics of the flanges, etc. The characteristics of the equivalent section of the beam are then determined according to Equations (5) and (6). For pantographs, the following are entered: number and type of pantographs, masses, spring stiffnesses, dampers, etc.

- The setting of the different terms of the dynamic equation at the initial instant: the stiffness matrix, damping matrix, mass matrix, and external load vector, according to Equations (2)–(4) and (7). The matrix of restriction conditions at the initial position of the pantograph(s) is also established according to Equations (8)–(15).

- The initial value of the integration variables is set to t0 = 0: coordinates of the nodes q0 and their derivatives, and the initial contact force λ0 according to Equations (23) and (24).

- The integration cycle begins at the time of the differential Equation (18) in tn+1. The cycle varies for different time values with n = 0,1,2…, adding in each cycle the value of Δt to tn:

- Calculation of the coordinates corresponding to the positions of the catenary nodes and the pantograph masses qn+1, according to Equation (20).

- Calculation of the position of the contact elements of the pantograph(s): (y3)n+1 and (y4)n+1 according to Equation (10). If the contact element is deactivated, its position coincides with that of the pantograph head mass; in this case, Equation (14) or (15) shall be used.

- Calculation of the pantograph–catenary contact forces (λ1)n+1 and (λ2)n+1, according to Equations (21) and (22).

- Setting the restriction conditions matrix ϕn+1, using Equations (8)–(15), according to the advance of the pantograph(s) along the line.

- For the calculation of the forces, the positions of the contact elements, and the restriction conditions, the three cases of activation of the contact element are accounted for, according to the position of the pantograph along the line, as explained in Section 2.6.

- The remainder of the terms of the dynamic Equation (18) is also set in tn+1: Cn+1, Kn+1, and Rn+1, and, in particular, the pantograph stiffness matrix must be modified if there is a take-off or a coupling according to Equation (22).

- Calculation of the velocity vector in the coordinates for the next integration cycle in tn+1/2 by the mid-pass correction of the velocity vector, using Equation (19).

3. Results

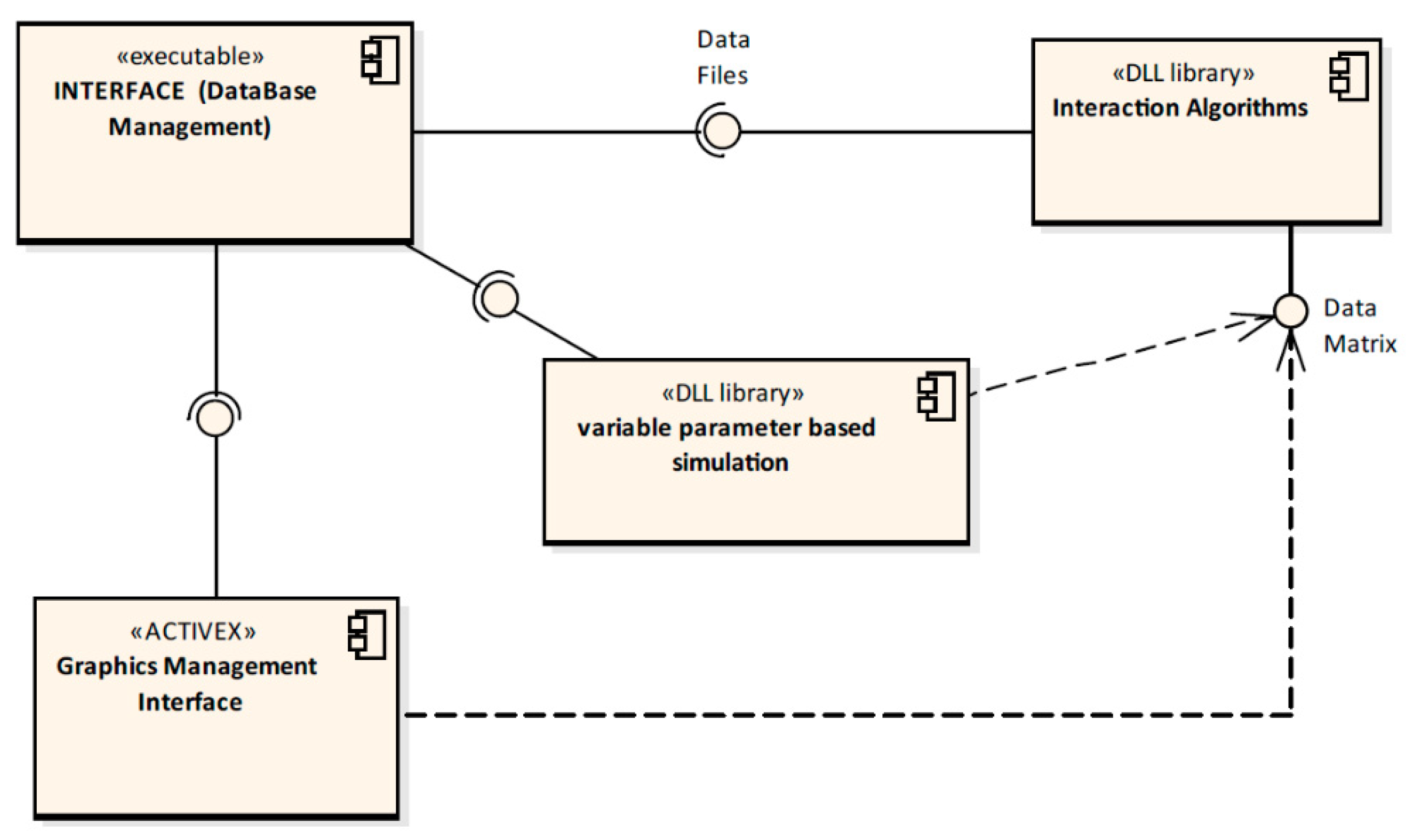

3.1. Computational Aspects

- Interface: The interface allows all of the data associated with the assembly to be entered. The set of parameters is stored in a database so that they can be retrieved, modified, or copied to obtain different calculations or perform simulations. The interface is structured in blocks according to the kind of data that they contain:

- General parameters: Generic data values are introduced regarding integration, speed, and data common to the whole catenary.

- Values for the catenary damping frequency: The critical damping percentage is established for two reference frequencies.

- Section data: Geometry of the overlapping span.

- Cross-section properties: Mechanical properties of the profile, wire, and flanges.

- Pantographs: Data of the pantograph to be used in the interaction. Up to four pantographs can be used. The pantographs are coded in such a way that they can be used in different calculations without the need to re-introduce all of their characteristics.

- Canton spans: Number of spans in each canton and for each span, length and height of the support above the nominal value, and distance from the flange to the left support.

- Interaction Algorithms: The dynamic library containing the algorithms for calculating the pantograph–catenary interaction. As a result, among other values, a table is generated indicating at each instant, according to the defined integration time step, and for each pantograph, the vertical position of two catenary points preset in the calculation, the height of the contact point, and the effort in each canton and plate.

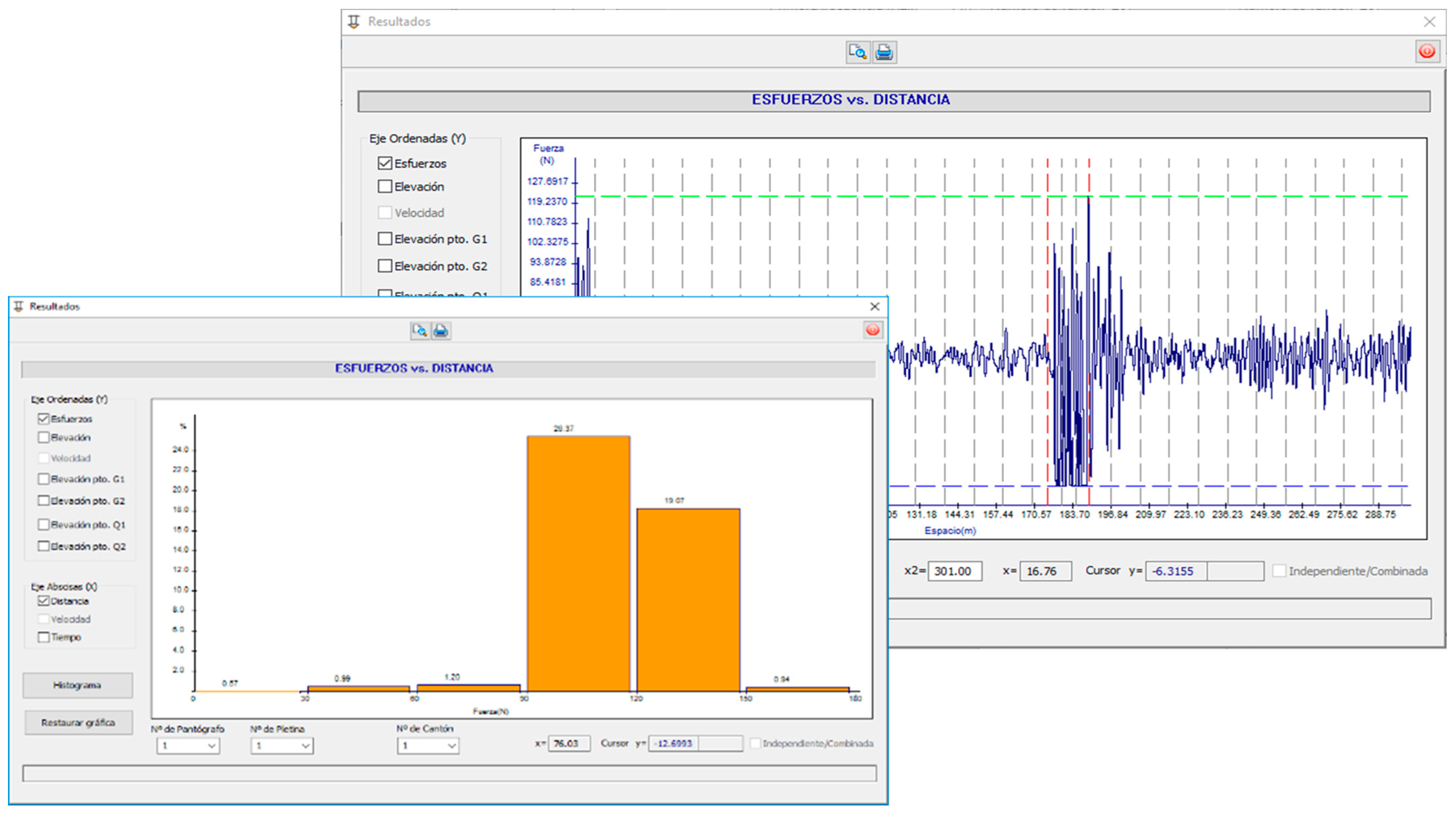

- Graph management: As a result, an interactive graphical interface is displayed in which different graphs can be obtained by independently selecting the abscissa (distance, time) and ordinate (efforts, elevation) axes, and allowing different graphs to overlap, in addition to the magnification of the area of the graphs marked by the user, as shown in Figure 9.

- Simulation: This allows for repeated execution of the calculation by modifying, at an established interval and increment, parameters such as the length of the overlapping span, the height of the slope, and the distance from the beginning of the slope to the end of the slope. The application repeatedly executes the algorithm by varying these data, thus allowing for a table with the maximum, minimum, deviation, number of take-offs, total distance of take-offs, and total time of take-offs in each independent canton or considering the sum of the efforts in the common zone of the two cantons.

3.2. Simulation Results

- Two cantons of 20 spans of 10 m length in the normal spans.

- Height above the track: 5 m.

- Maximum common area length: 12 m.

- Aluminum profiles and flanges corresponding to a Furrer beam per the values in Section 4.

- A pantograph of a simple plate and two stages defined according to EN50318 whose data are in Table 1 of Section 2.4.

- As in standard EN50318 for the flexible catenary, no damping is assumed for the catenary.

- The interface for the remainder of the values defining the catenary.

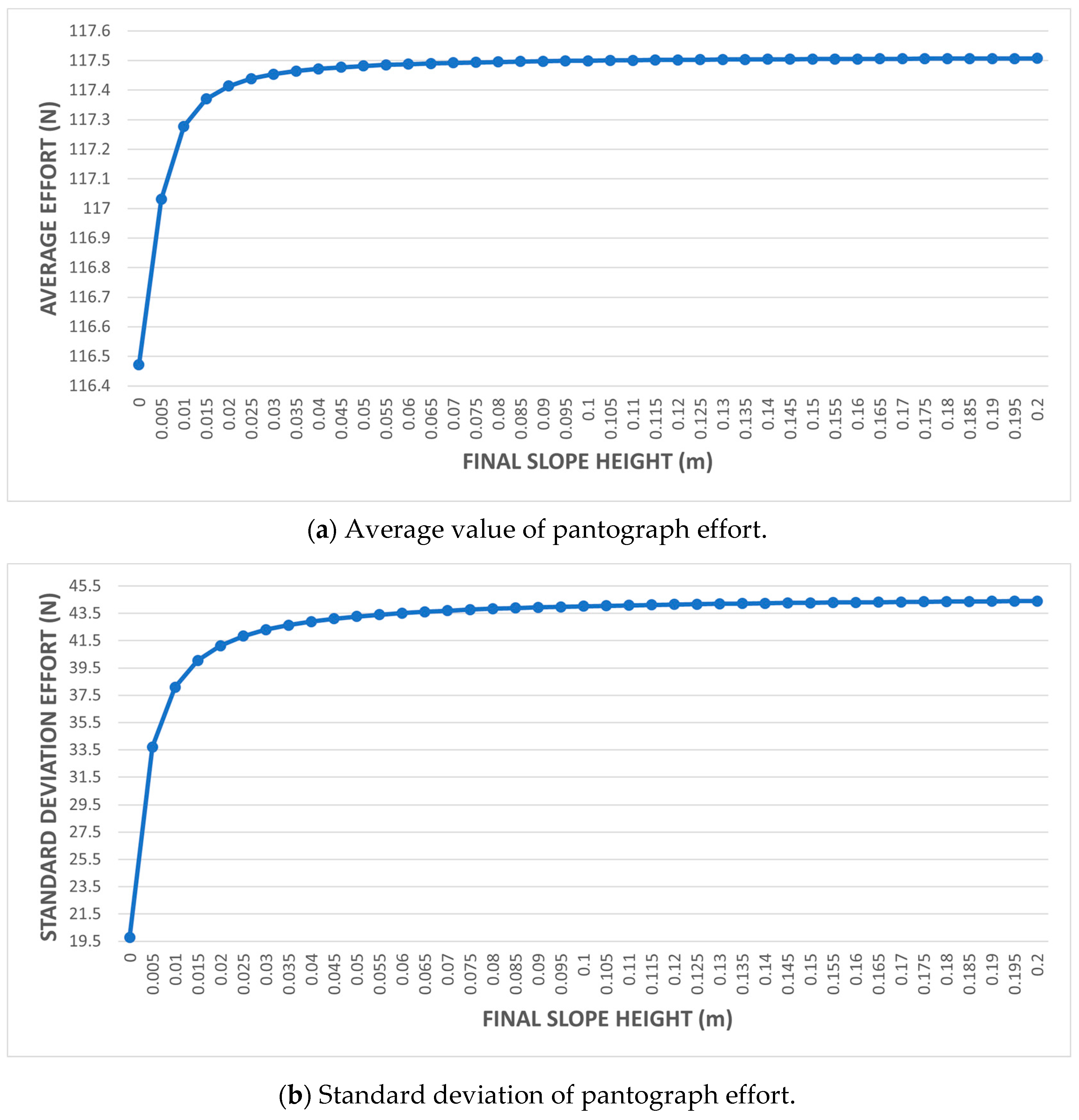

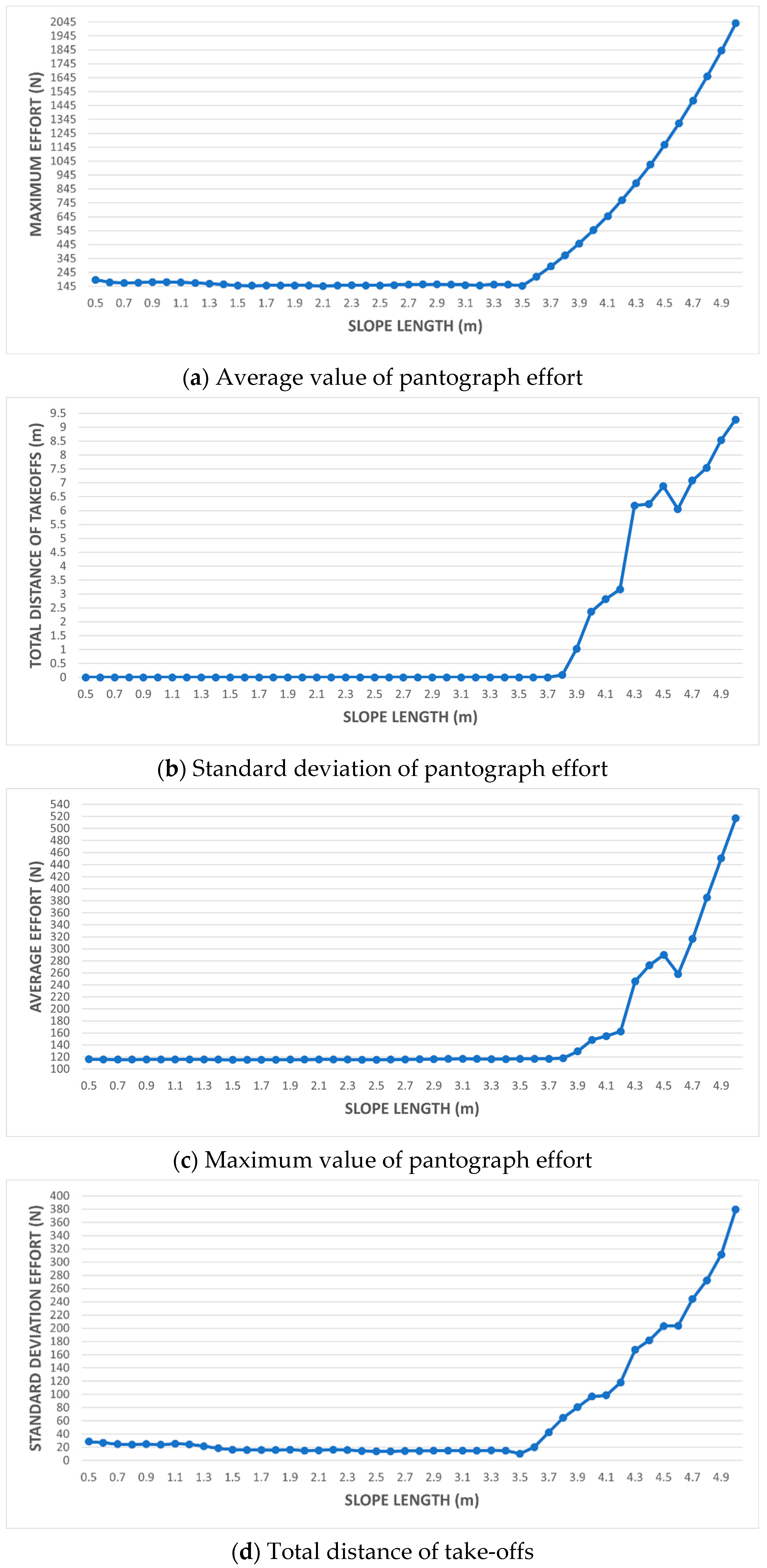

- An overlapping span of 1 m, slope length 1 m, and variation in the height of the slope at its end.

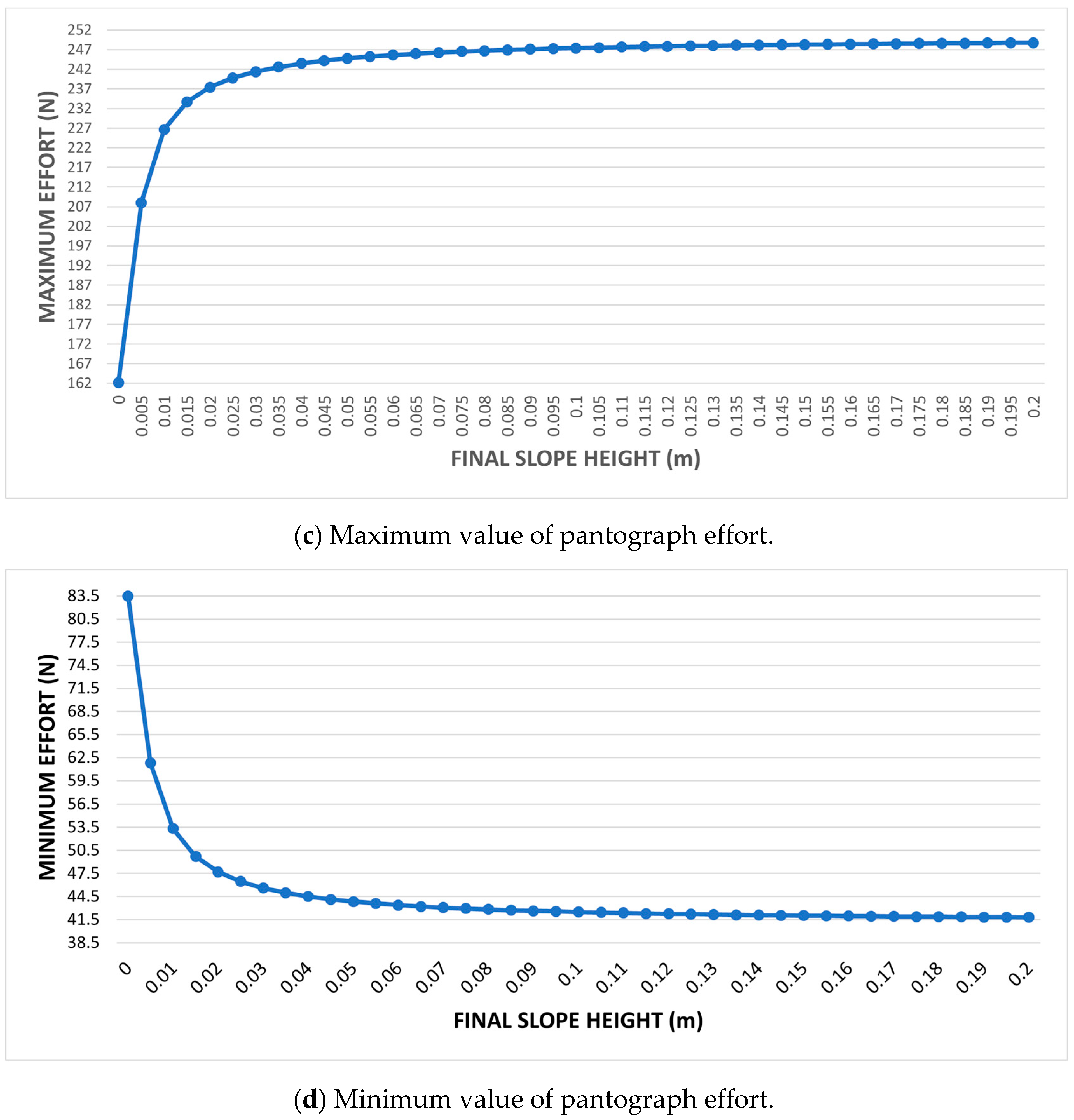

- An overlapping span of 1 m, variation in slope length in the range of 0.5 to 1 m with 0.05 m increments, and 0.1 m slope elevation.

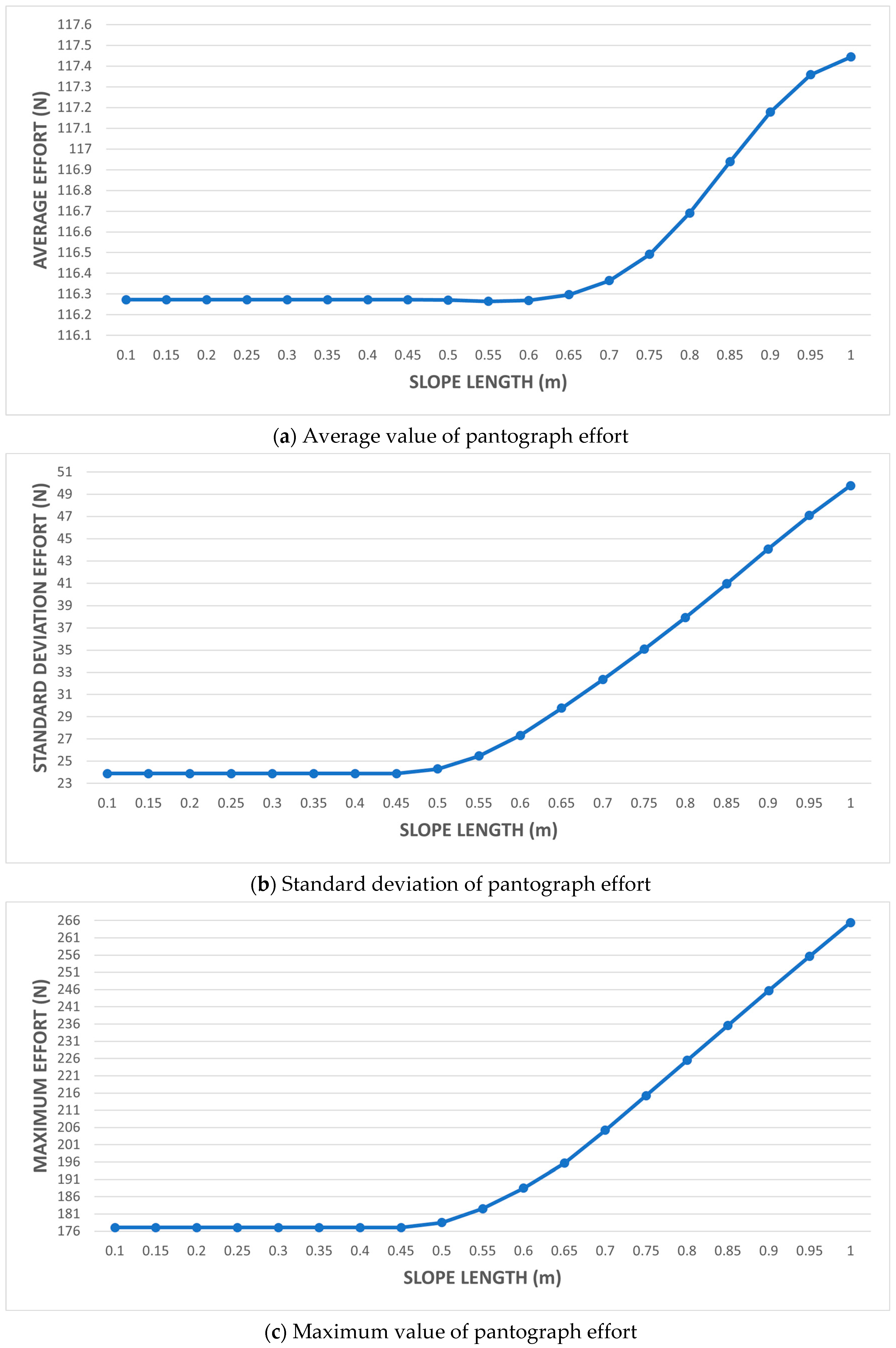

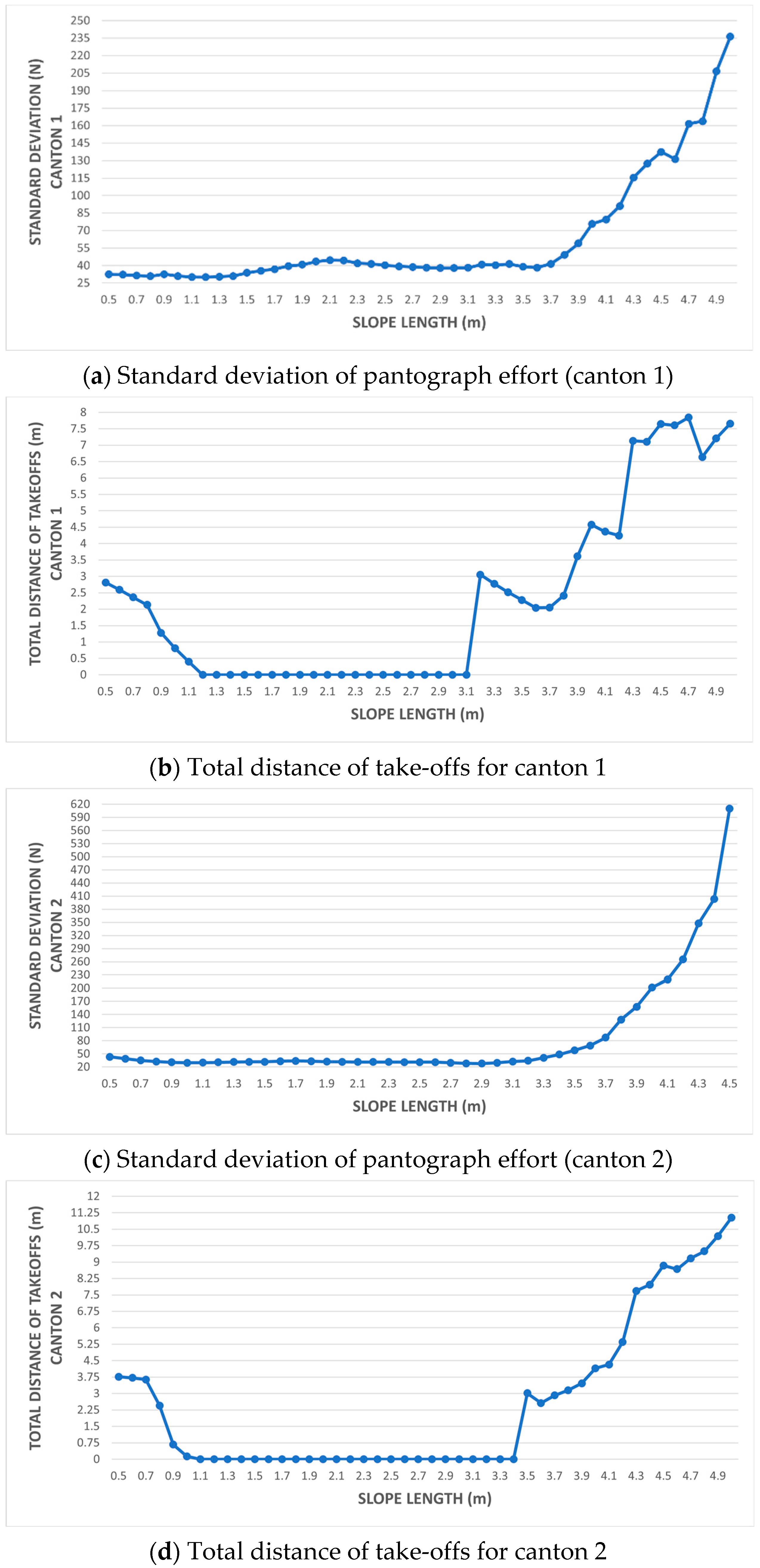

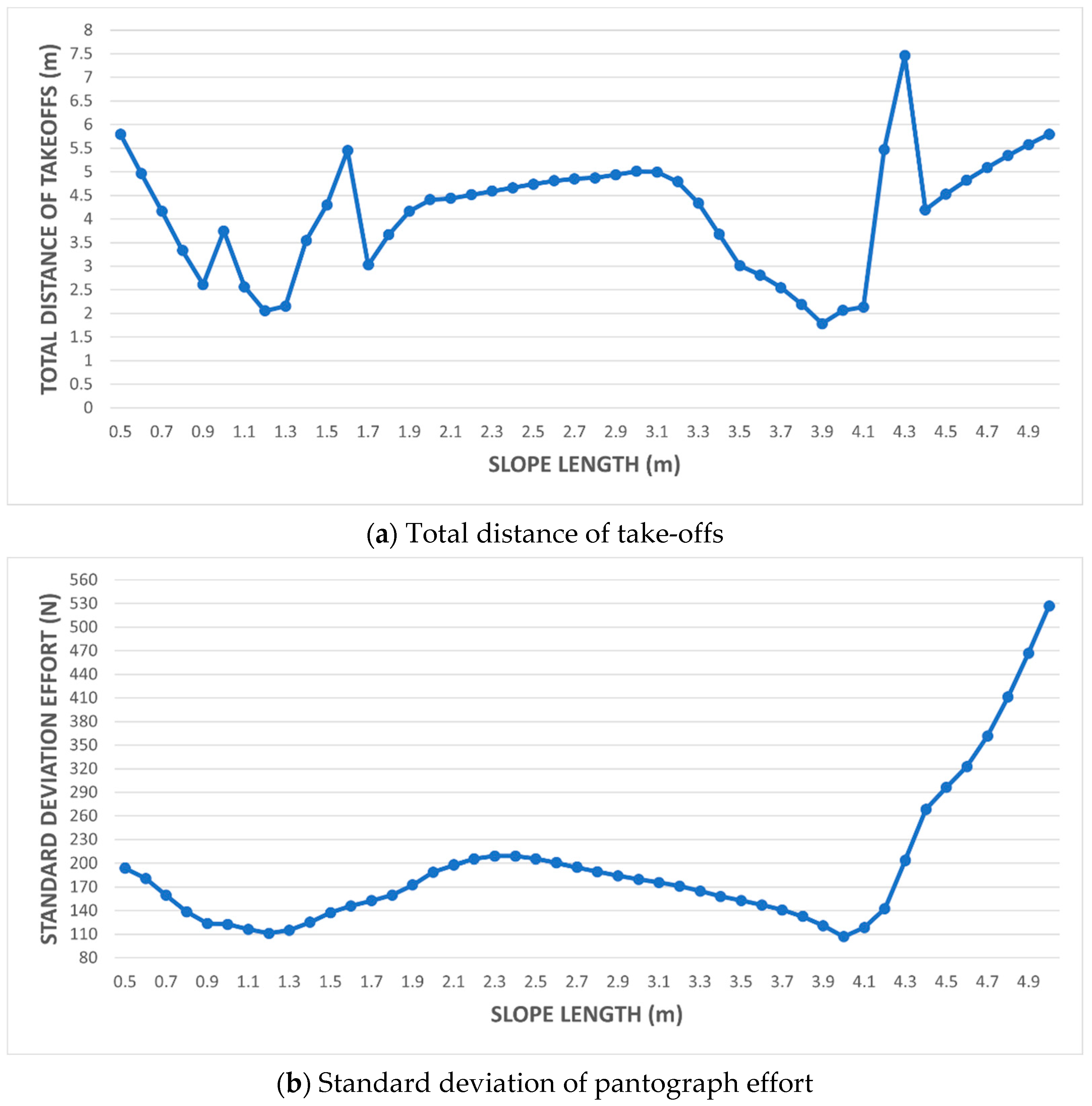

- Variation of the length of the overlapping span in the range of 0.5 to 5 m and height 0 of the slope. Normal spans are 10 m long.

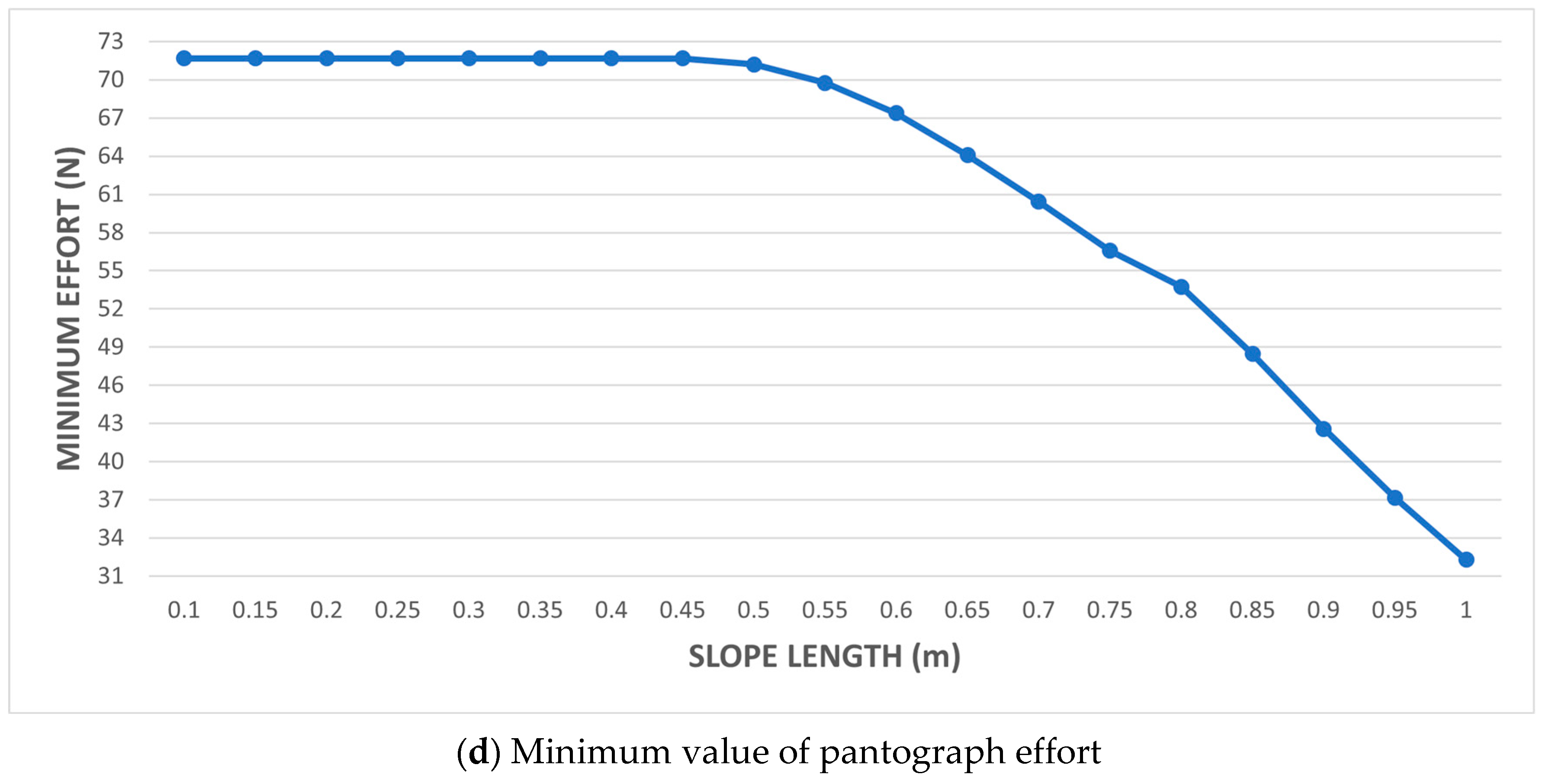

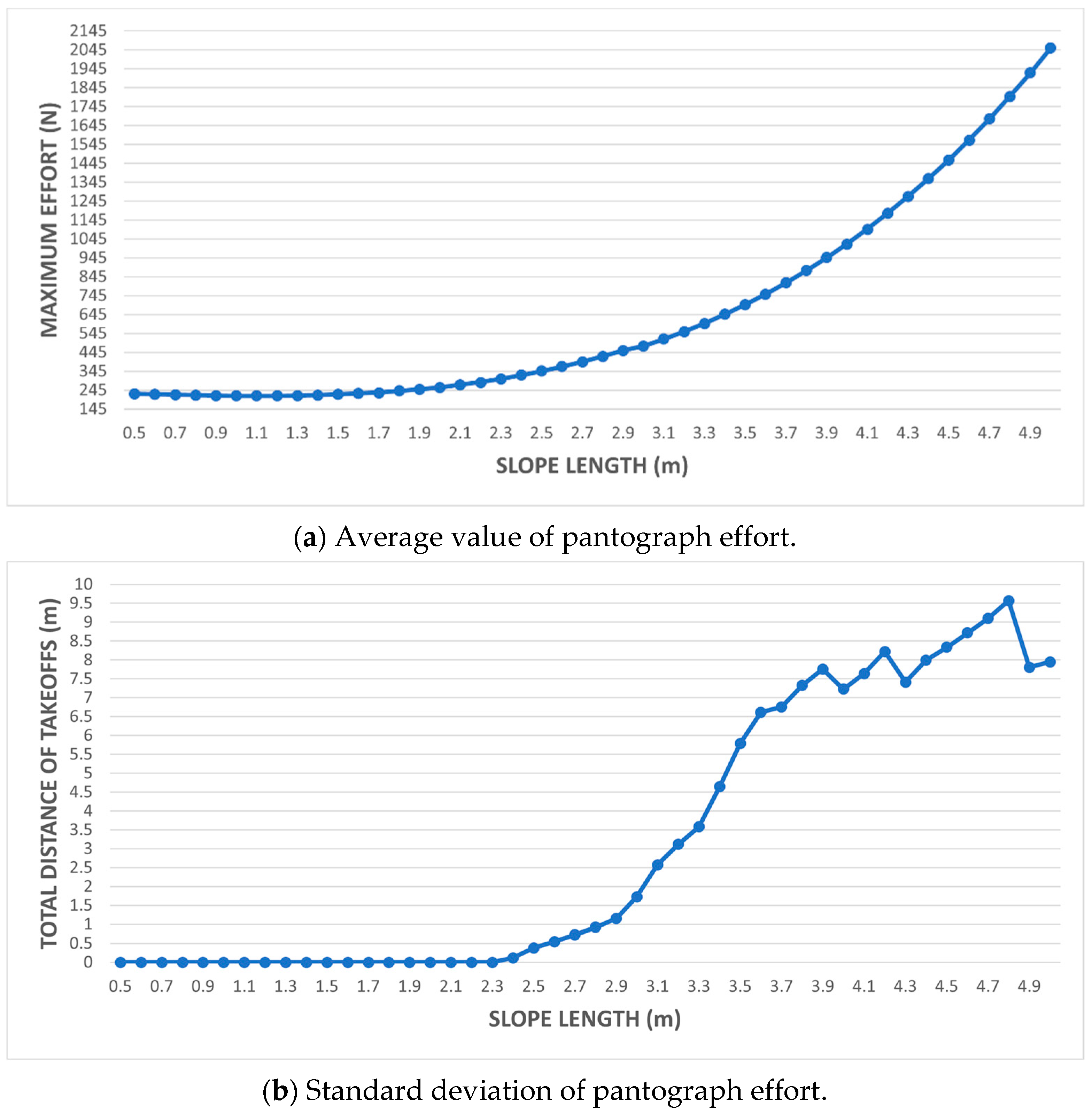

- Variation of the length of the overlapping span in the interval from 0.5 to 5 m and slope height 0. Normal spans are 5 m long.

3.2.1. Simulation 1

3.2.2. Simulation 2

3.2.3. Simulation 3

3.2.4. Simulation 4

4. Discussion

- Study of the behavior for different configurations in the geometry of the sectioning span.

- Development of the model in three dimensions.

- Study of the behavior and simulation in the transition between elastic and rigid catenary.

- Optimization of the algorithm, taking into account the data structures underlying the problem, in addition to the parallelization of the calculations, to obtain results in significantly shorter times.

- Development of RICATI following the paradigm of Software-as-a-Service. This model of the application in the cloud would allow access by more companies, from any point at which there is connectivity, and at a lower cost. In addition, this solution would allow different tests to be carried out simultaneously by requesting resources from the provider of the cloud service, and significantly more quickly, to find better solutions.

Author Contributions

Funding

Conflicts of Interest

References

- Morillas, A.A.; Benet, J.; Arias, E.; Cebrian, D.; Rojo, T.; Cuartero, F. A High Performance Tool for the Simulation of the Dynamic Pantograph–Catenary Interaction. Math. Comput. Simul. 2008, 79, 652–667. [Google Scholar] [CrossRef]

- Ambrósio, J.; Pombo, J.; Rauter, F.; Pereira, M. A Memory Based Communication in the Co-simulation of Multibody and Finite Element Codes for Pantograph-Catenary Interaction Simulation. In Multibody Dynamics; Springer: Dordrecht, The Netherlands, 2008; pp. 231–252. [Google Scholar] [CrossRef]

- Balestrino, A.O.; Landi, B.A.; Sani, L. PANDA a Friendly CAD Tool for Pantograph Design and Testing. In Proceedings of the VI International Conference COMPRAIL-VI, Lisbon, Portugal, 2–4 June 1998; pp. 817–826. [Google Scholar]

- Benet, J.; Cuartero, N.; Cuartero, F.; Rojo, T.; Tendero, P.; Arias, E. An Advanced 3D-Model for the Study and Simulation of the Pantograph Catenary System. Transp. Res. Part C Emerg. Technol. 2013, 36, 138–156. [Google Scholar] [CrossRef]

- Collina, A.; Bruni, S. Numerical Simulation of Pantograph-Overhead Equipment Interaction. Veh. Syst. Dyn. 2002, 38, 261–291. [Google Scholar] [CrossRef]

- Arias, E.; Morillas, A.A.; Montesinos, J.; Rojo, T.; Cuartero, F.; Benet, J. A Mathematical Model of the Static Pantograph/Catenary Interaction. Int. J. Comput. Math. 2009, 86, 333–340. [Google Scholar] [CrossRef]

- Drugge, L.; Larsson, T.; Stensson, A. Modelling and Simulation of Catenary-Pantograph Interaction. Veh. Syst. Dyn. 1999, 33, 490–501. [Google Scholar] [CrossRef]

- Kim, N.-I.; Thai, S.; Lee, J. Nonlinear Elasto-Plastic Analysis of Slack and Taut Cable Structures. Eng. Comput. 2016, 32, 615–627. [Google Scholar] [CrossRef]

- López, A.C.; Carnicero, A.; Torres, V. Computation of the Initial Equilibrium of Railway Overheads Based on the Catenary Equation. Eng. Struct. 2006, 28, 1387–1394. [Google Scholar] [CrossRef]

- Norton, R.L. Design of Machinery: An Introduction to the Synthesis and Analysis of Mechanisms and Machines, 3rd ed.; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Rauter, F.G.; Pombo, J.; Ambrósio, J.; Chalansonnet, J.; Bobillot, A.; Pereira, M.S. Contact Model for The Pantograph-Catenary Interaction. J. Syst. Des. Dyn. 2007, 1, 447–457. [Google Scholar] [CrossRef] [Green Version]

- Seo, J.-H.; Sugiyama, H.; Shabana, A.A. Three-Dimensional Large Deformation Analysis of the Multibody Pantograph/Catenary Systems. Nonlinear Dyn. 2005, 42, 199–215. [Google Scholar] [CrossRef]

- Simeon, B.; Arnold, M. Coupling DAEs and PDEs for Simulating the Interaction of Pantograph and Catenary. Math. Comput. Model. Dyn. Syst. 2000, 6, 129–144. [Google Scholar] [CrossRef]

- Teichelmann, G.; Schaub, M.; Simeon, B. Modelling and Simulation of Railway Cable Systems. ZAMM 2005, 85, 864–877. [Google Scholar] [CrossRef]

- Zhang, W.; Mei, G.; Wu, X.; Shen, Z. Hybrid Simulation of Dynamics for the Pantograph-Catenary System. Veh. Syst. Dyn. 2002, 38, 393–414. [Google Scholar] [CrossRef]

- Arnold, M.; Simeon, B. Pantograph and Catenary Dynamics: A Benchmark Problem and its Numerical Solution. Appl. Numer. Math. 2000, 34, 345–362. [Google Scholar] [CrossRef]

- Cho, Y.H.; Lee, K.; Park, Y.; Kang, B.; Kim, K.-N. Influence of Contact Wire Presag on the Dynamics of Pantograph–Railway Catenary. Int. J. Mech. Sci. 2010, 52, 1471–1490. [Google Scholar] [CrossRef]

- Beer, F.P.; Johnston, E.R.; Eisenberg, E.R. Vector Mechanics for Engineers, 8th ed.; McGraw Hill: New York, NY, USA, 2007. [Google Scholar]

- Bautista, A.; Montesinos, J.; Pintado, P. Dynamic Interaction between Pantograph and Rigid Overhead Lines using a Coupled FEM—Multibody Procedure. Mech. Mach. Theory 2016, 97, 100–111. [Google Scholar] [CrossRef]

- Paulin, J. Metodología y Criterios de Diseño Aplicados a la Optimización de un Sistema de Catenaria Rígida Para Explotación Ferroviaria. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2007. [Google Scholar]

- Vera, C.; Suarez, B.; Paulin, J.; Rodríguez, P. Simulation Model for the Study of Overhead Rail Current Collector Systems Dynamics, Focused on the Design of a New Conductor Rail. Veh. Syst. Dyn. 2006, 44, 595–614. [Google Scholar] [CrossRef] [Green Version]

- Bathe, K.J. Finite Element Procedures, 2nd ed.; Ed Prentice Hall: Hoboken, NJ, USA, 2014. [Google Scholar]

- Cook, D.C.; Malkus, D.S.; Plesha, M.E. Concepts and Applications of Finite Element Analysis, 3rd ed.; John Wiley and Sons: Hoboken, NJ, USA, 1989. [Google Scholar]

- Ortiz, L. Resistencia de Materiales, 3rd ed.; McGraw Hill Education: New York, NY, USA, 2007; ISBN 978-8448156336. [Google Scholar]

- EN 50318-2018. Railway Applications-Current Collection Systems-Validation of Simulation of the Dynamic Interaction between Pantographs and Overhead Contact Line. Available online: https://shop.bsigroup.com/ProductDetail?pid=0000000000303441702018 (accessed on 10 July 2021).

- Datta, B.N. Numerical Linear Algebra and Applications; Siam: Philadelphia, PA, USA, 2010. [Google Scholar]

- Saad, Y. SPARSKIT: A Basic Tool Kit for Sparse Matrix Computations-Version 2. 1994. Available online: http://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.41.3853 (accessed on 10 July 2021).

- BLAS (Basic Linear Algebra Subprograms). Available online: http://www.netlib.org/blas/ (accessed on 10 July 2021).

- Blackford, L.S.; Petitet, A.; Pozo, R.; Remington, A.K.; Whaley, R.C.; Demmel, J.; Dongarra, J.; Duff, I.S.; Hammarling, S.; Henry, G.M.; et al. An Updated Set of Basic Linear Algebra Subprograms (BLAS). ACM Trans. Math. Softw. 2002, 28, 135–151. [Google Scholar] [CrossRef] [Green Version]

- Zhai, W.; Wang, K.; Cai, C. Fundamentals of Vehicle–Track Coupled Dynamics. Veh. Syst. Dyn. 2009, 47, 1349–1376. [Google Scholar] [CrossRef]

- Zhang, Z.C.; Lin, J.H.; Zhang, Y.H.; Howson, W.P.; Williams, F.W. Non-Stationary Random Vibration Analysis of Three-Dimensional Train–Bridge Systems. Veh. Syst. Dyn. 2010, 48, 457–480. [Google Scholar] [CrossRef]

- Song, Y.; Liu, Z.; Rxnnquist, A.; Navik, P.; Liu, Z. Contact Wire Irregularity Stochastics and Effect on High-Speed Railway Pantograph-Catenary Interactions. IEEE Trans. Instrum. Meas. 2020, 69, 8196–8206. [Google Scholar] [CrossRef]

| Effective Mass (kg) | Rigidity (N/m) | Cushioning (Ns/m) | |

|---|---|---|---|

| Contact element | - | k3 = k4 = kcont = 50,000 | - |

| Head collector | m2 = 7.2 | k2 = 4200 | c2 = 10 |

| Base element | m1 = 15 | k1 = 50 | c1 = 90 |

| Thrust force applied to the base: Femp = 120 N | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benet, J.; Cuartero, F.; Rojo, T.; Tendero, P.; Arias, E. A Dynamic Model for the Study and Simulation of the Pantograph–Rigid Catenary Interaction with an Overlapping Span. Appl. Sci. 2021, 11, 7445. https://doi.org/10.3390/app11167445

Benet J, Cuartero F, Rojo T, Tendero P, Arias E. A Dynamic Model for the Study and Simulation of the Pantograph–Rigid Catenary Interaction with an Overlapping Span. Applied Sciences. 2021; 11(16):7445. https://doi.org/10.3390/app11167445

Chicago/Turabian StyleBenet, Jesús, Fernando Cuartero, Tomás Rojo, Pedro Tendero, and Enrique Arias. 2021. "A Dynamic Model for the Study and Simulation of the Pantograph–Rigid Catenary Interaction with an Overlapping Span" Applied Sciences 11, no. 16: 7445. https://doi.org/10.3390/app11167445

APA StyleBenet, J., Cuartero, F., Rojo, T., Tendero, P., & Arias, E. (2021). A Dynamic Model for the Study and Simulation of the Pantograph–Rigid Catenary Interaction with an Overlapping Span. Applied Sciences, 11(16), 7445. https://doi.org/10.3390/app11167445