Development of a New Pasta Product by the Incorporation of Chestnut Flour and Bee Pollen

Abstract

:1. Introduction

2. Materials and Methods

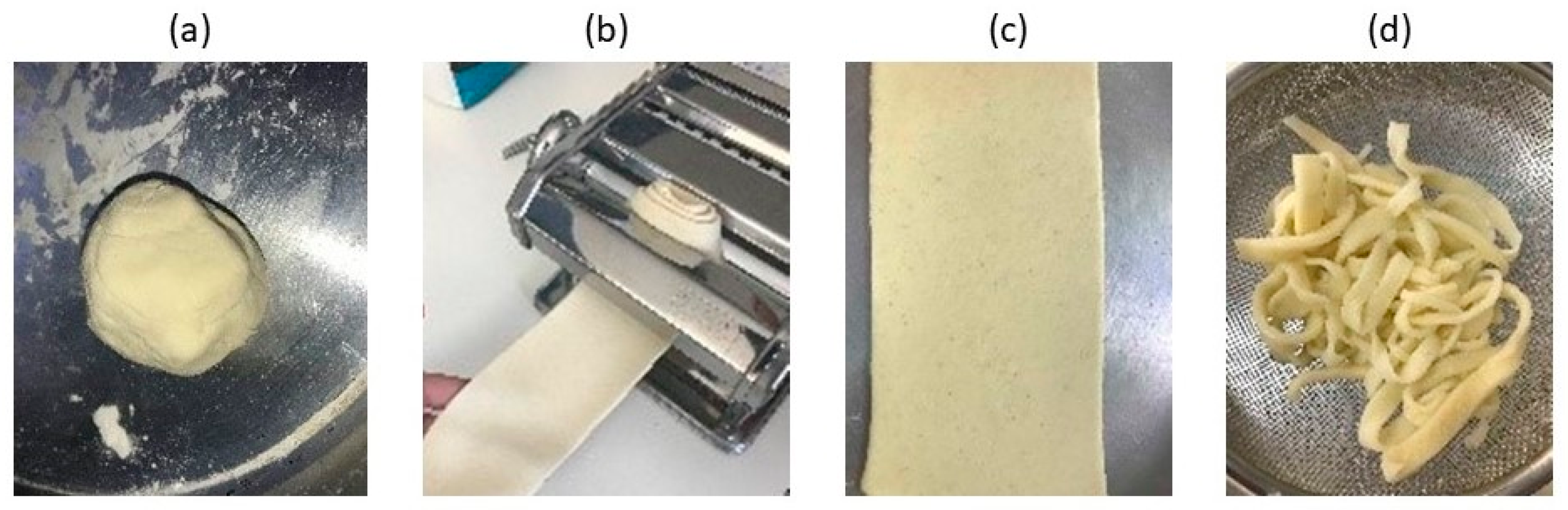

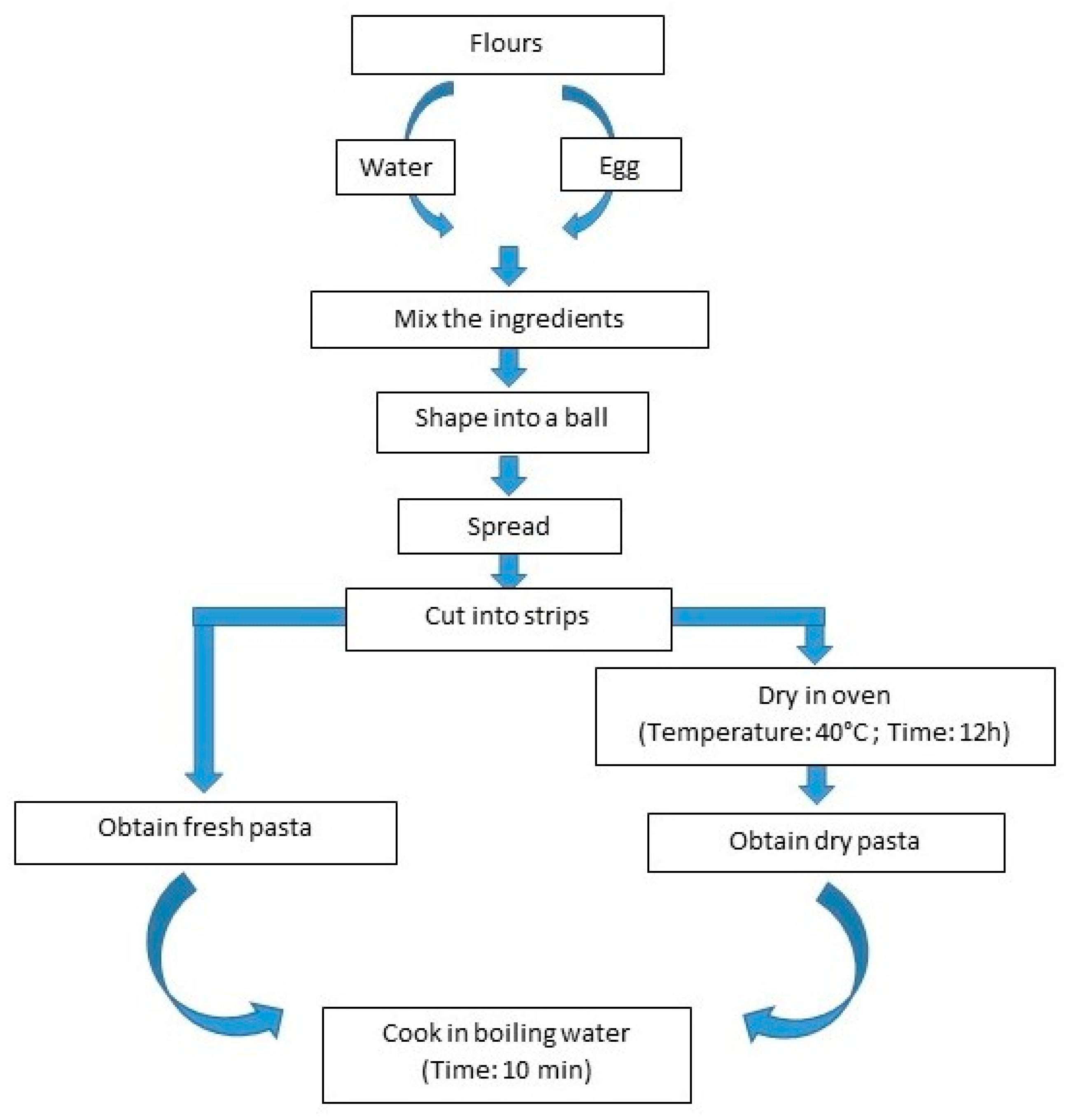

2.1. Pasta Formulation and Preparation

- Wheat flour T55: flour obtained from wheat at extra fine grinding grade, Brand: Espiga;

- Wheat flour T65: flour obtained from wheat at fine grinding grade, Brand: Espiga;

- Wheat semolina: rough flour obtained from durum wheat, containing gluten, Brand: Espiga;

- Chestnut flour: obtained from grinding dried chestnuts, provided by the bread company Fábrica do Pão;

- Pollen powder: multiflora granulated bee pollen, Brand: Naturitas;

- Egg—chicken fresh eggs size L (large), Brand: Matinados;

- Water: tap water with quality for human consumption.

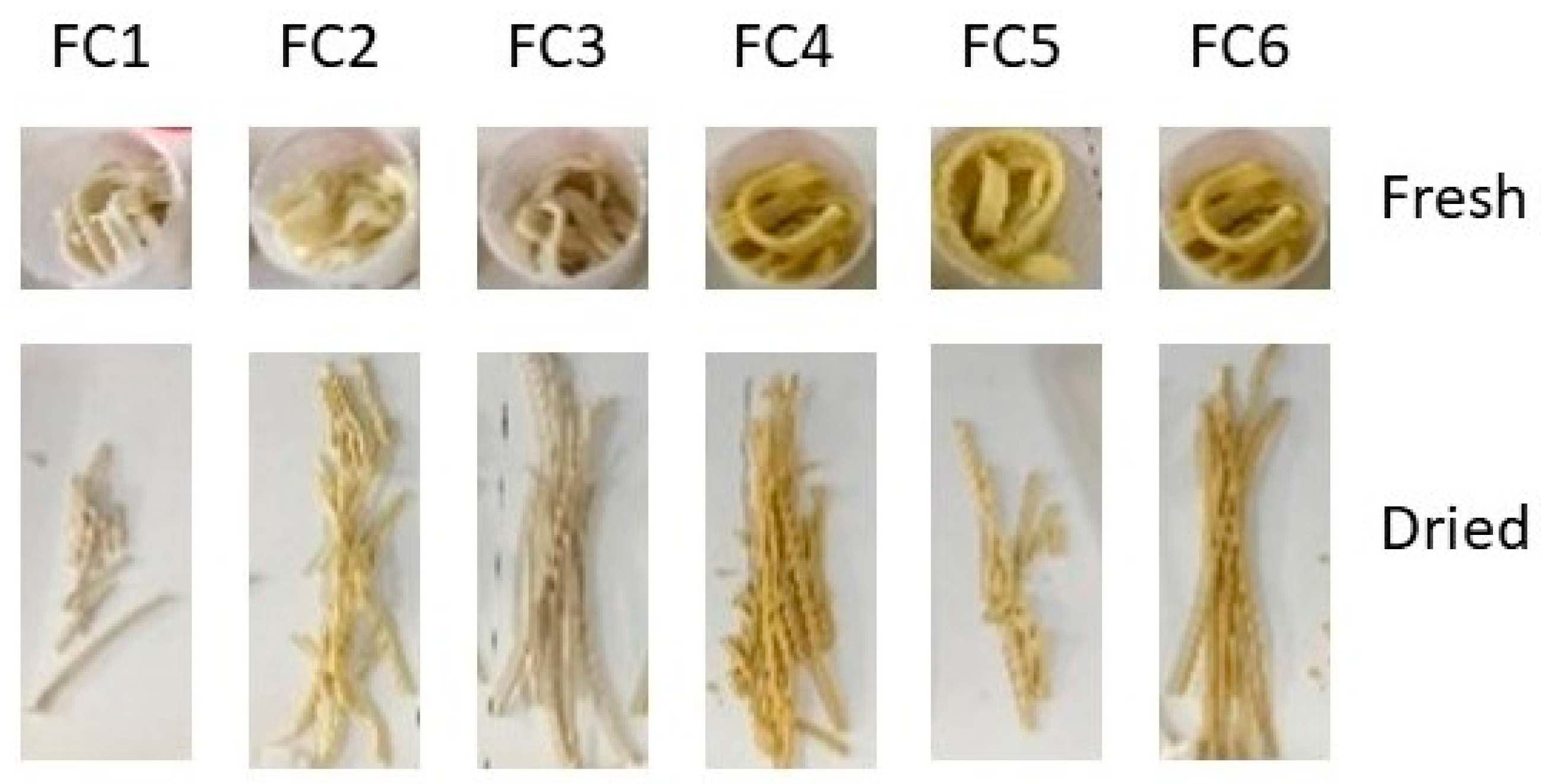

2.1.1. Preliminary Essays

- FC1—50 g water + 100 g wheat flour T 55

- FC2—50 g water + 100 g wheat flour T 65

- FC3—50 g water + 100 g wheat semolina

- FC4—50 g egg + 100 g wheat flour T 55

- FC5—50 g egg + 100 g wheat flour T 65

- FC6—50 g egg + 100 g wheat semolina

2.1.2. Formulations Incorporating Chestnut and Pollen

2.2. Physical Properties

2.2.1. Color

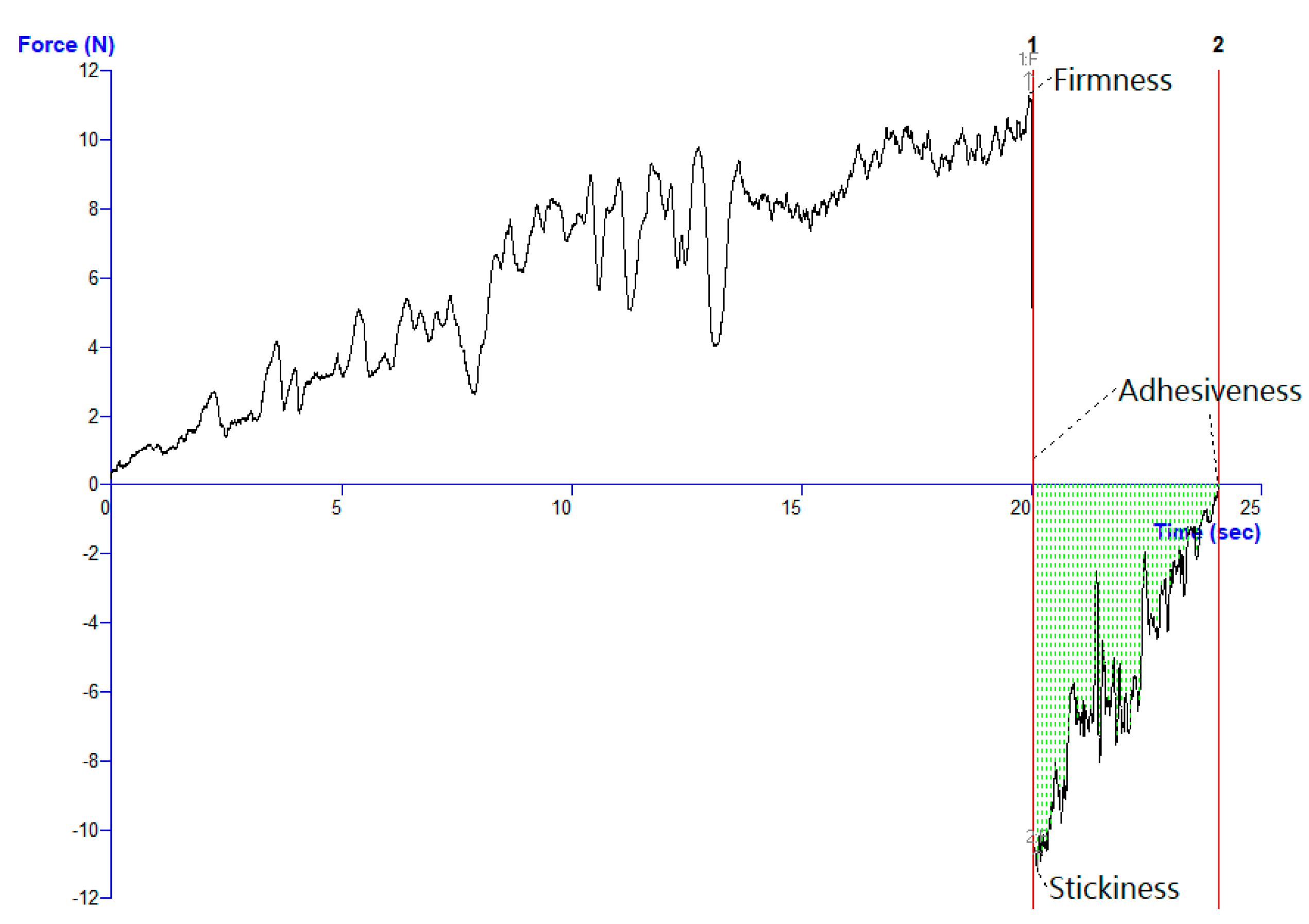

2.2.2. Texture

2.3. Chemical Analyses

2.4. Statistical Analyses

3. Results and Discussion

3.1. Optimization of Pasta Formulation

3.2. Chemical Composition

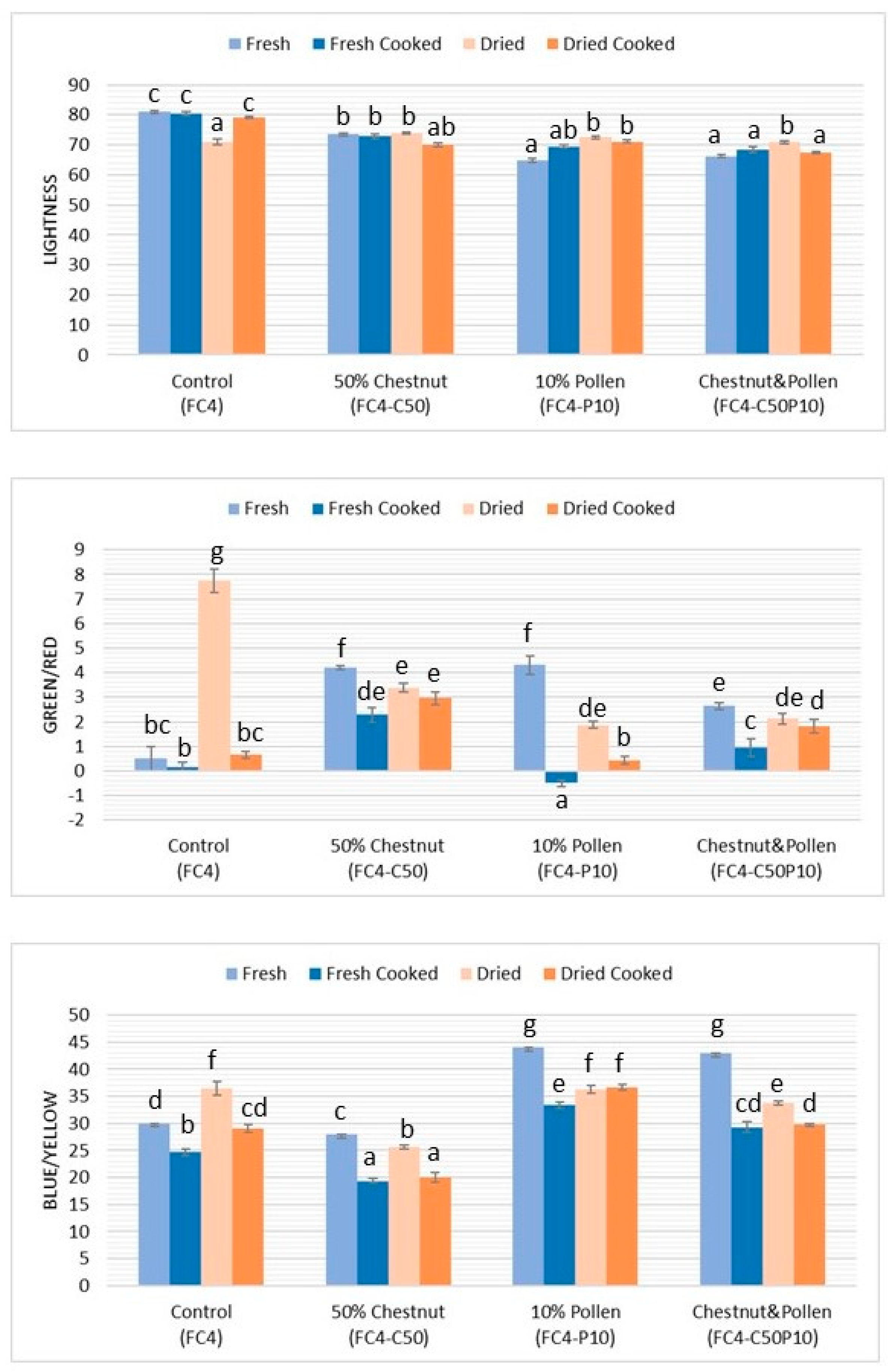

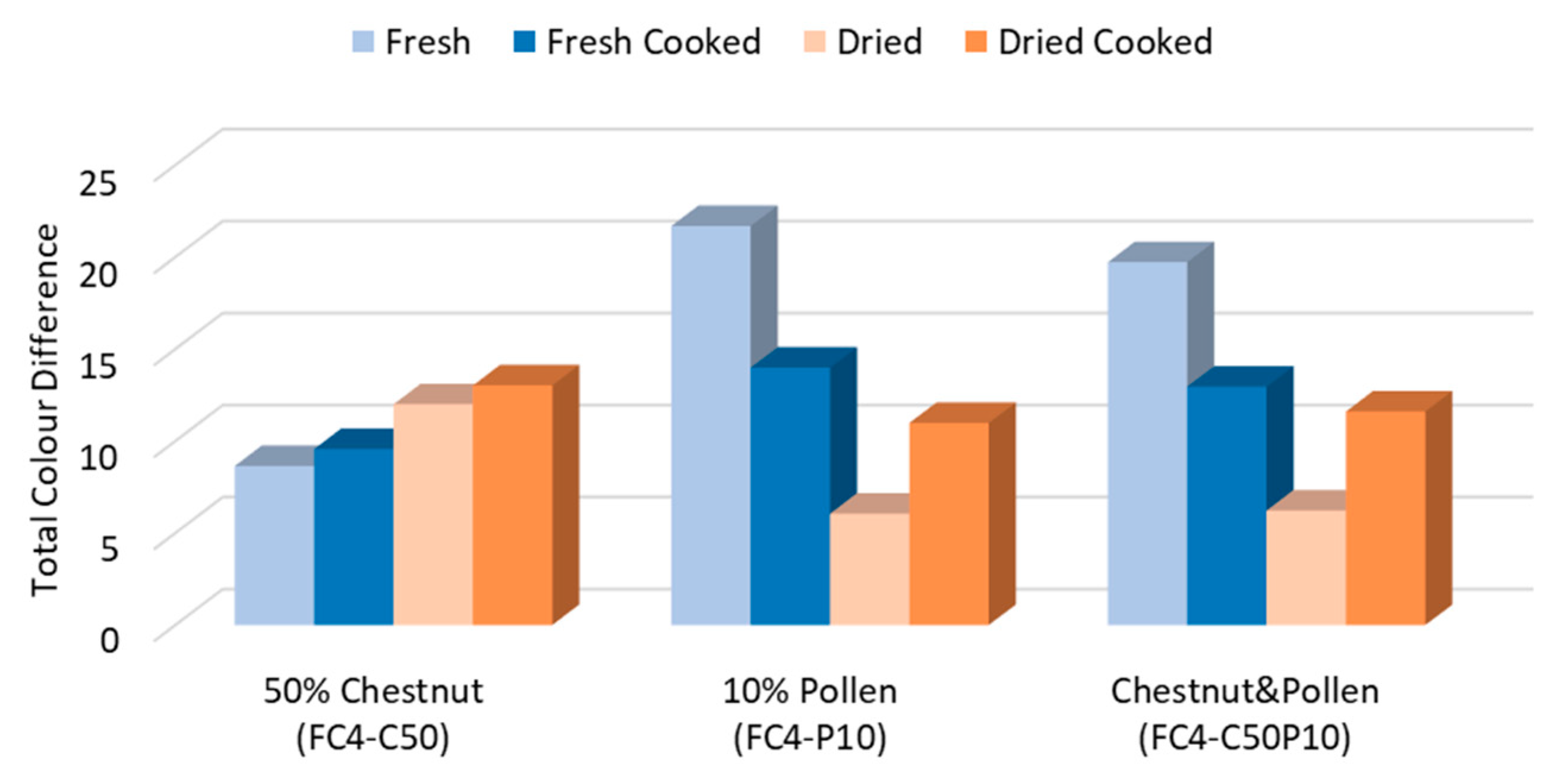

3.3. Color

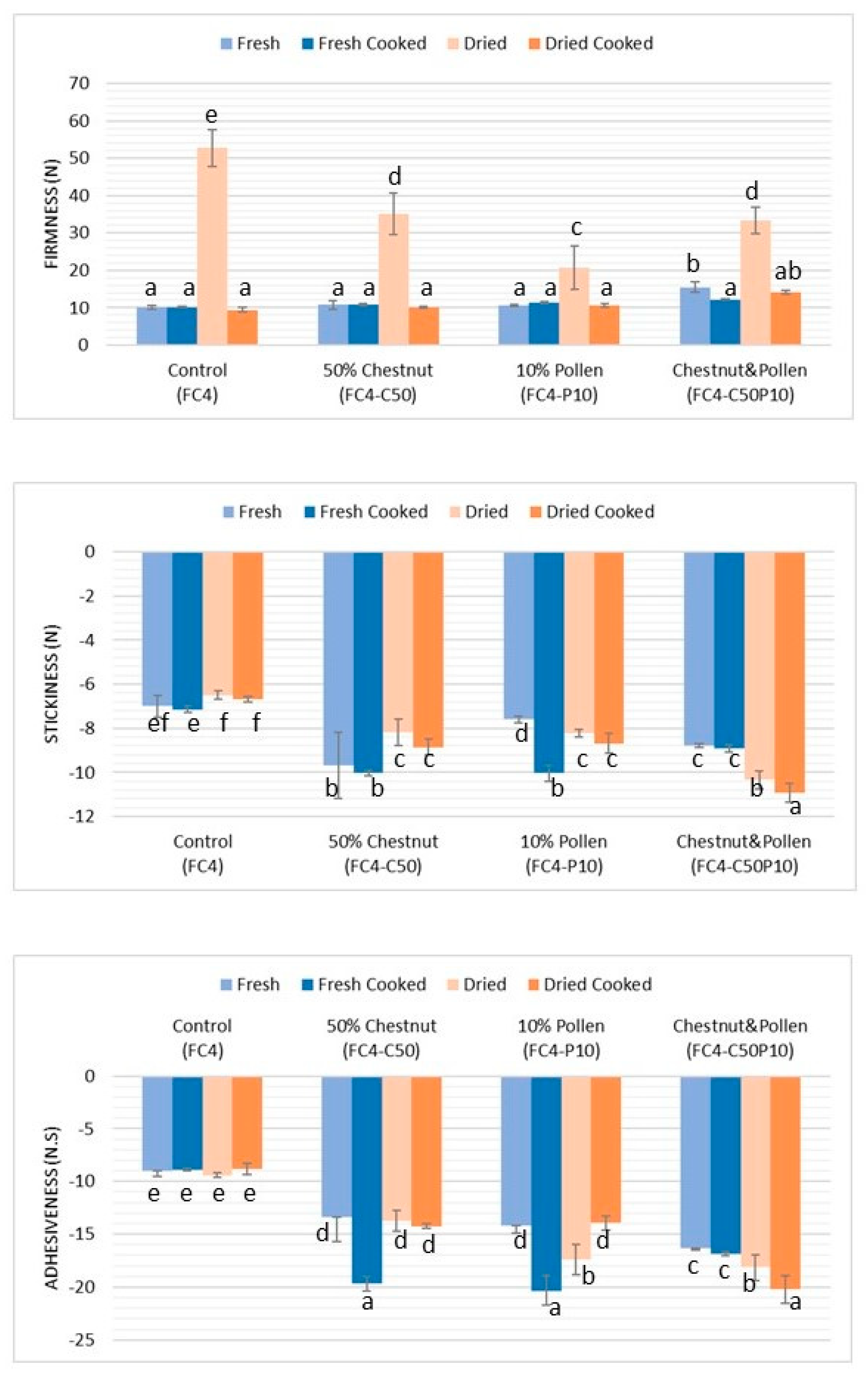

3.4. Texture

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Coello, K.E.; Peñas, E.; Martinez-Villaluenga, C.; Elena Cartea, M.; Velasco, P.; Frias, J. Pasta Products Enriched with Moringa Sprout Powder as Nutritive Dense Foods with Bioactive Potential. Food Chem. 2021, 360, 130032. [Google Scholar] [CrossRef] [PubMed]

- Brochard, M. Placement Report-Development of Innovative Pasta Formulations; Polytechnic Institute of Viseu: Viseu, Portugal, 2019. [Google Scholar]

- Arcangelis, E.; Cuomo, F.; Trivisonno, M.C.; Marconi, E.; Messia, M.C. Gelatinization and Pasta Making Conditions for Buckwheat Gluten-Free Pasta. J. Cereal Sci. 2020, 95, 103073. [Google Scholar] [CrossRef]

- Singh, S.; Singh, N. Relationship of Polymeric Proteins and Empirical Dough Rheology with Dynamic Rheology of Dough and Gluten from Different Wheat Varieties. Food Hydrocoll. 2013, 33, 342–348. [Google Scholar] [CrossRef]

- Bondt, Y.; Hermans, W.; Moldenaers, P.; Courtin, C.M. Selective Modification of Wheat Bran Affects Its Impact on Gluten-Starch Dough Rheology, Microstructure and Bread Volume. Food Hydrocoll. 2020, 106348. [Google Scholar] [CrossRef]

- Donmez, D.; Pinho, L.; Patel, B.; Desam, P.; Campanella, O. Characterization of Starch–Water Interactions and Their Effects on Two Key Functional Properties: Starch Gelatinization and Retrogradation. Curr. Opin. Food Sci. 2021. [Google Scholar] [CrossRef]

- Thomas, J.M.; Dourish, C.T.; Higgs, S. Effects of Awareness That Food Intake Is Being Measured by a Universal Eating Monitor on the Consumption of a Pasta Lunch and a Cookie Snack in Healthy Female Volunteers. Appetite 2015, 92, 247–251. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martini, D.; Brusamolino, A.; Del Bo’, C.; Laureati, M.; Porrini, M.; Riso, P. Effect of Fiber and Protein-Enriched Pasta Formulations on Satiety-Related Sensations and Afternoon Snacking in Italian Healthy Female Subjects. Physiol. Behav. 2018, 185, 61–69. [Google Scholar] [CrossRef]

- Papanikolaou, Y. Pasta Foods Are Associated with Improved Nutrient Intakes, Increased Whole Grain and Vegetable Consumption and Nutrient Adequacy in US Adults. J. Acad. Nutr. Diet. 2019, 119, A147. [Google Scholar] [CrossRef]

- Peña, E.; Manthey, F.A.; Patel, B.K.; Campanella, O.H. Rheological Properties of Pasta Dough during Pasta Extrusion: Effect of Moisture and Dough Formulation. J. Cereal Sci. 2014, 60, 346–351. [Google Scholar] [CrossRef]

- Ciccoritti, R.; Taddei, F.; Nicoletti, I.; Gazza, L.; Corradini, D.; D’Egidio, M.G.; Martini, D. Use of Bran Fractions and Debranned Kernels for the Development of Pasta with High Nutritional and Healthy Potential. Food Chem. 2017, 225, 77–86. [Google Scholar] [CrossRef] [PubMed]

- Ungureanu-Iuga, M.; Dimian, M.; Mironeasa, S. Development and Quality Evaluation of Gluten-Free Pasta with Grape Peels and Whey Powders. LWT 2020, 130, 109714. [Google Scholar] [CrossRef]

- Sharma, R.; Dar, B.N.; Sharma, S.; Singh, B. In Vitro Digestibility, Cooking Quality, Bio-Functional Composition, and Sensory Properties of Pasta Incorporated with Potato and Pigeonpea Flour. Int. J. Gastron. Food Sci. 2021, 23, 100300. [Google Scholar] [CrossRef]

- Kowalczewski, P.Ł.; Pauter, P.; Smarzyński, K.; Różańska, M.B.; Jeżowski, P.; Dwiecki, K.; Mildner-Szkudlarz, S. Thermal Processing of Pasta Enriched with Black Locust Flowers Affect Quality, Phenolics, and Antioxidant Activity. J. Food Process. Preserv. 2019, 43, e14106. [Google Scholar] [CrossRef]

- Bustos, M.C.; Vignola, M.B.; Paesani, C.; León, A.E. Berry Fruits-Enriched Pasta: Effect of Processing and in Vitro Digestion on Phenolics and Its Antioxidant Activity, Bioaccessibility and Potential Bioavailability. Int. J. Food Sci. Technol. 2020, 55, 2104–2112. [Google Scholar] [CrossRef]

- Armellini, R.; Peinado, I.; Pittia, P.; Scampicchio, M.; Heredia, A.; Andres, A. Effect of Saffron (Crocus sativus L.) Enrichment on Antioxidant and Sensorial Properties of Wheat Flour Pasta. Food Chem. 2018, 254, 55–63. [Google Scholar] [CrossRef] [Green Version]

- Wood, J.A. Texture, Processing and Organoleptic Properties of Chickpea-Fortified Spaghetti with Insights to the Underlying Mechanisms of Traditional Durum Pasta Quality. J. Cereal Sci. 2009, 49, 128–133. [Google Scholar] [CrossRef]

- Sęczyk, Ł.; Świeca, M.; Gawlik-Dziki, U. Effect of Carob (Ceratonia siliqua L.) Flour on the Antioxidant Potential, Nutritional Quality, and Sensory Characteristics of Fortified Durum Wheat Pasta. Food Chem. 2016, 194, 637–642. [Google Scholar] [CrossRef]

- Spinelli, S.; Padalino, L.; Costa, C.; Del Nobile, M.A.; Conte, A. Food By-Products to Fortified Pasta: A New Approach for Optimization. J. Clean. Prod. 2019, 215, 985–991. [Google Scholar] [CrossRef]

- Romero, H.M.; Zhang, Y. Physicochemical Properties and Rheological Behavior of Flours and Starches from Four Bean Varieties for Gluten-Free Pasta Formulation. J. Agric. Food Res. 2019, 1, 100001. [Google Scholar] [CrossRef]

- El-Sohaimy, S.A.; Brennan, M.; Darwish, A.M.G.; Brennan, C. Physicochemical, Texture and Sensorial Evaluation of Pasta Enriched with Chickpea Flour and Protein Isolate. Ann. Agric. Sci. 2020, 65, 28–34. [Google Scholar] [CrossRef]

- INSA Tabela da Composição de Alimentos. Available online: http://www2.insa.pt/sites/INSA/Portugues/AreasCientificas/AlimentNutricao/AplicacoesOnline/TabelaAlimentos/Paginas/TabelaAlimentos.aspx (accessed on 2 June 2021).

- Mir, S.A.; Bosco, S.J.D.; Shah, M.A. Technological and Nutritional Properties of Gluten-Free Snacks Based on Brown Rice and Chestnut Flour. J. Saudi Soc. Agric. Sci. 2019, 18, 89–94. [Google Scholar] [CrossRef]

- Littardi, P.; Paciulli, M.; Carini, E.; Rinaldi, M.; Rodolfi, M.; Chiavaro, E. Quality Evaluation of Chestnut Flour Addition on Fresh Pasta. LWT 2020, 126, 109303. [Google Scholar] [CrossRef]

- Elli, L.; Branchi, F.; Tomba, C.; Villalta, D.; Norsa, L.; Ferretti, F.; Roncoroni, L.; Bardella, M.T. Diagnosis of Gluten Related Disorders: Celiac Disease, Wheat Allergy and Non-Celiac Gluten Sensitivity. World J. Gastroenterol. 2015, 21, 7110–7119. [Google Scholar] [CrossRef] [PubMed]

- Durazzo, A.; Turfani, V.; Azzini, E.; Maiani, G.; Carcea, M. Phenols, Lignans and Antioxidant Properties of Legume and Sweet Chestnut Flours. Food Chem. 2013, 140, 666–671. [Google Scholar] [CrossRef] [PubMed]

- Paciulli, M.; Mert, I.D.; Rinaldi, M.; Pugliese, A.; Chiavaro, E. Chapter 19-Chestnut and Breads: Nutritional, Functional, and Technological Qualities. In Flour and Breads and Their Fortification in Health and Disease Prevention, 2nd ed.; Preedy, V.R., Watson, R.R., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 237–247. ISBN 978-0-12-814639-2. [Google Scholar]

- Romano, A.; Aponte, M. Chestnut as Source of Novel Ingredients for Celiac People. In Encyclopedia of Food Security and Sustainability; Ferranti, P., Berry, E.M., Anderson, J.R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 364–368. ISBN 978-0-12-812688-2. [Google Scholar]

- Sirini, N.; Roldán, A.; Lucas-González, R.; Fernández-López, J.; Viuda-Martos, M.; Pérez-Álvarez, J.A.; Frizzo, L.S.; Rosmini, M.R. Effect of Chestnut Flour and Probiotic Microorganism on the Functionality of Dry-Cured Meat Sausages. LWT 2020, 134, 110197. [Google Scholar] [CrossRef]

- Cheng, Y.; Quan, W.; He, Y.; Qu, T.; Wang, Z.; Zeng, M.; Qin, F.; Chen, J.; He, Z. Effects of Postharvest Irradiation and Superfine Grinding Wall Disruption Treatment on the Bioactive Compounds, Endogenous Enzyme Activities, and Antioxidant Properties of Pine (Pinus Yunnanensis) Pollen during Accelerated Storage. LWT 2021, 144, 111249. [Google Scholar] [CrossRef]

- Bayram, N.E.; Gercek, Y.C.; Çelik, S.; Mayda, N.; Kostić, A.Ž.; Dramićanin, A.M.; Özkök, A. Phenolic and Free Amino Acid Profiles of Bee Bread and Bee Pollen with the Same Botanical Origin–Similarities and Differences. Arab. J. Chem. 2021, 14, 103004. [Google Scholar] [CrossRef]

- Guiné, R. Bee Pollen: Chemical Composition and Potential Beneficial Effects on Health. Curr. Nutr. Food Sci. 2015, 11, 301–308. [Google Scholar] [CrossRef]

- Komosinska-Vassev, K.; Olczyk, P.; Kaźmierczak, J.; Mencner, L.; Olczyk, K. Bee Pollen: Chemical Composition and Therapeutic Application. Evid. Based Complement. Altern. Med. 2015, 2015. [Google Scholar] [CrossRef] [Green Version]

- Anjos, O.; Fernandes, R.; Cardoso, S.M.; Delgado, T.; Farinha, N.; Paula, V.; Estevinho, L.M.; Carpes, S.T. Bee Pollen as a Natural Antioxidant Source to Prevent Lipid Oxidation in Black Pudding. LWT 2019, 111, 869–875. [Google Scholar] [CrossRef] [Green Version]

- Denisow, B.; Denisow-Pietrzyk, M. Biological and Therapeutic Properties of Bee Pollen: A Review. J. Sci. Food Agric. 2016, 96, 4303–4309. [Google Scholar] [CrossRef]

- Mirhosseini, H.; Abdul Rashid, N.F.; Tabatabaee Amid, B.; Cheong, K.W.; Kazemi, M.; Zulkurnain, M. Effect of Partial Replacement of Corn Flour with Durian Seed Flour and Pumpkin Flour on Cooking Yield, Texture Properties, and Sensory Attributes of Gluten Free Pasta. LWT Food Sci. Technol. 2015, 63, 184–190. [Google Scholar] [CrossRef]

- Oduro-Obeng, H.; Fu, B.X.; Beta, T. Influence of Cooking Duration on Carotenoids, Physical Properties and in Vitro Antioxidant Capacity of Pasta Prepared from Three Canadian Durum Wheat Cultivars. Food Chem. 2021, 363, 130016. [Google Scholar] [CrossRef]

- Simões de Borba, V.; Silveira, C.O.; Alves, J.B.; Grupelli, V.M.; Badiale-Furlong, E. Experimental Design Applied in the Semolina Pasta Cooking to Increase the Resistant Starch Formation. LWT 2021, 138, 110708. [Google Scholar] [CrossRef]

- Xie, L.; Nishijima, N.; Oda, Y.; Handa, A.; Majumder, K.; Xu, C.; Zhang, Y. Utilization of Egg White Solids to Improve the Texture and Cooking Quality of Cooked and Frozen Pasta. LWT 2020, 122, 109031. [Google Scholar] [CrossRef]

- Bonfatti, V.; Carnier, P. Prediction of Dry-Cured Ham Weight Loss and Prospects of Use in a Pig Breeding Program. Animal 2020, 14, 1128–1138. [Google Scholar] [CrossRef]

- Xie, Y.-K.; Li, X.-Y.; Zhang, Y.; Zheng, Z.-A.; Huang, L.-Q.; Liu, D.-H.; Xiao, H.-W.; Liu, Y.-H. Effects of High-Humidity Hot Air Impingement Steaming on Gastrodia Elata: Steaming Degree, Weight Loss, Texture, Drying Kinetics, Microstructure and Active Components. Food Bioprod. Process. 2021, 127, 255–265. [Google Scholar] [CrossRef]

- Dall’Olio, S.; Aboagye, G.; Nanni Costa, L.; Gallo, M.; Fontanesi, L. Effects of 17 Performance, Carcass and Raw Ham Quality Parameters on Ham Weight Loss at First Salting in Heavy Pigs, a Meat Quality Indicator for the Production of High Quality Dry-Cured Hams. Meat Sci. 2020, 162, 108012. [Google Scholar] [CrossRef]

- Guiné, R.; Matos, S.; Gonçalves, C.; da Costa, D.V.T.; Mendes, M.; Gonçalves, F. Modeling the Influence of Production and Storage Conditions on the Blueberry Quality. Agric. Eng. Int. 2018, 20, 226–238. [Google Scholar]

- Guiné, R.P.F.; Barroca, M.J. Mass Transfer Properties for the Drying of Pears. In Transactions on Engineering Technologies; Springer: Singopare, 2014; pp. 271–280. [Google Scholar]

- Cruz, A.C.; Guiné, R.P.F.; Gonçalves, J.C. Drying Kinetics and Product Quality for Convective Drying of Apples (Cvs. Golden Delicious and Granny Smith). Int. J. Fruit Sci. 2015, 15, 54–78. [Google Scholar] [CrossRef]

- Barroca, M.J.; Guiné, R.P.F.; Calado, A.R.P.; Correia, P.M.R.; Mendes, M. Artificial Neural Network Modelling of the Chemical Composition of Carrots Submitted to Different Pre-Drying Treatments. Food Meas. 2017, 11, 1815–1826. [Google Scholar] [CrossRef]

- Guiné, R.P.F.; Almeida, C.F.F.; Correia, P.M.R.; Mendes, M. Modelling the Influence of Origin, Packing and Storage on Water Activity, Colour and Texture of Almonds, Hazelnuts and Walnuts Using Artificial Neural Networks. Food Bioprocess Technol. 2015, 8, 1113–1125. [Google Scholar] [CrossRef] [Green Version]

- Guiné, R.P.F.; Almeida, C.F.F.; Correia, P.M.R. Influence of Packaging and Storage on Some Properties of Hazelnuts. Food Meas. 2014, 9, 11–19. [Google Scholar] [CrossRef]

- Guiné, R.P.F.; Almeida, C.F.F.; Correia, P.M.R. Effect of Packaging and Conservation Conditions on Some Physical-Chemical Properties of Almonds. J. Hyg. Eng. Des. 2014, 8, 82–87. [Google Scholar]

- Guiné, R.P.F.; Sério, S.I.A.; Correia, P.M.R.; Barroca, M.J. Effect of Pre-Treatment on Some Physical-Chemical Properties of Dried Carrots. J. Hyg. Eng. Des. 2014, 6, 187–191. [Google Scholar]

- Guiné, R.P.F.; Henriques, F.; Barroca, M.J. Influence of Drying Treatments on the Physical and Chemical Properties of Cucumber. Food Meas. 2014, 8, 195–206. [Google Scholar] [CrossRef]

- Guiné, R.P.F.; De Lemos, E.T. Development of New Dairy Products with Functional Ingredients. J. Culin. Sci. Technol. 2020, 18, 159–176. [Google Scholar] [CrossRef]

- Guiné, R.P.F.; Gonçalves, F.J.A.; Oliveira, S.F.; Correia, P.M.R. Evaluation of Phenolic Compounds, Antioxidant Activity and Bioaccessibility in Physalis Peruviana L. Int. J. Fruit Sci. 2020, 20, S470–S490. [Google Scholar] [CrossRef]

- Kosović, I.; Jukić, M.; Jozinović, A.; Ačkar, Đ.; Komlenić, D.K. Influence of Chestnut Flour Addition on Quality Characteristics of Pasta Made on Extruder and Minipress. Czech J. Food Sci. 2016, 34, 166–172. [Google Scholar] [CrossRef] [Green Version]

- Aravind, N.; Sissons, M.; Egan, N.; Fellows, C.M.; Blazek, J.; Gilbert, E.P. Effect of β-Glucan on Technological, Sensory, and Structural Properties of Durum Wheat Pasta. Cereal Chem. 2012, 89, 84–93. [Google Scholar] [CrossRef]

- Garcia-Valle, D.E.; Bello-Pérez, L.A.; Agama-Acevedo, E.; Alvarez-Ramirez, J. Effects of Mixing, Sheeting, and Cooking on the Starch, Protein, and Water Structures of Durum Wheat Semolina and Chickpea Flour Pasta. Food Chem. 2021, 360, 129993. [Google Scholar] [CrossRef] [PubMed]

- Tyl, C.; Marti, A.; Ismail, B.P. Changes in Protein Structural Characteristics upon Processing of Gluten-Free Millet Pasta. Food Chem. 2020, 327, 127052. [Google Scholar] [CrossRef] [PubMed]

- Tomás, A.; Falcão, S.I.; Russo-Almeida, P.; Vilas-Boas, M. Potentialities of Beebread as a Food Supplement and Source of Nutraceuticals: Botanical Origin, Nutritional Composition and Antioxidant Activity. J. Apic. Res. 2017, 56, 219–230. [Google Scholar] [CrossRef]

- Larrosa, V.; Lorenzo, G.; Zaritzky, N.; Califano, A. Dynamic Rheological Analysis of Gluten-Free Pasta as Affected by Composition and Cooking Time. J. Food Eng. 2015, 160, 11–18. [Google Scholar] [CrossRef]

- Surasani, V.K.R.; Singh, A.; Gupta, A.; Sharma, S. Functionality and Cooking Characteristics of Pasta Supplemented with Protein Isolate from Pangas Processing Waste. LWT 2019, 111, 443–448. [Google Scholar] [CrossRef]

- Miranda, K.F. Estudo da Concentração de Licopeno por Ultrafiltração a Partir de Suco de Melancia (Citrullus Vulgaris Schard); Unicamp: Campinas, Brazil, 2005. [Google Scholar]

- Carini, E.; Vittadini, E.; Curti, E.; Antoniazzi, F.; Viazzani, P. Effect of Different Mixers on Physicochemical Properties and Water Status of Extruded and Laminated Fresh Pasta. Food Chem. 2010, 122, 462–469. [Google Scholar] [CrossRef]

- Collar, C.; Armero, E. Kinetics of in Vitro Starch Hydrolysis and Relevant Starch Nutritional Fractions in Heat-Moisture Treated Blended Wheat-Based Bread Matrices: Impact of Treatment of Non-Wheat Flours. Eur. Food Res. Technol. 2018, 244, 1977–1984. [Google Scholar] [CrossRef] [Green Version]

- Dall’Asta, C.; Cirlini, M.; Morini, E.; Rinaldi, M.; Ganino, T.; Chiavaro, E. Effect of Chestnut Flour Supplementation on Physico-Chemical Properties and Volatiles in Bread Making. LWT Food Sci. Technol. 2013, 53, 233–239. [Google Scholar] [CrossRef]

- Al-Kahtani, S.N.; Taha, E.-K.; Khan, K.A.; Ansari, M.J.; Farag, S.A.; Shawer, D.M.B.; Elnabawy, E.-S.M. Effect of Harvest Season on the Nutritional Value of Bee Pollen Protein. PLoS ONE 2020, 15, e0241393. [Google Scholar] [CrossRef]

- Liolios, V.; Tananaki, C.; Papaioannou, A.; Kanelis, D.; Rodopoulou, M.-A.; Argena, N. Mineral Content in Monofloral Bee Pollen: Investigation of the Effect of the Botanical and Geographical Origin. J. Food Meas. Charact. 2019, 13, 1674–1682. [Google Scholar] [CrossRef]

- Zhu, F. Properties and Food Uses of Chestnut Flour and Starch. Food Bioprocess Technol. 2017, 10, 1173–1191. [Google Scholar] [CrossRef]

- Castiglioni, S.; Astolfi, P.; Conti, C.; Monaci, E.; Stefano, M.; Carloni, P. Morphological, Physicochemical and FTIR Spectroscopic Properties of Bee Pollen Loads from Different Botanical Origin. Molecules 2019, 24, 3974. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Teterycz, D.; Sobota, A.; Kozłowicz, K.; Zarzycki, P. Substitution of Semolina Durum with Common Wheat Flour in Egg and Eggless Pasta. Acta Sci. Pol. Technol. Aliment. 2019, 18, 439–451. [Google Scholar] [CrossRef] [PubMed]

- Cocci, E.; Sacchetti, G.; Vallicelli, M.; Angioloni, A.; Dalla Rosa, M. Spaghetti Cooking by Microwave Oven: Cooking Kinetics and Product Quality. J. Food Eng. 2008, 85, 537–546. [Google Scholar] [CrossRef]

| With Water | With Egg | |||||

|---|---|---|---|---|---|---|

| FC1 | FC2 | FC3 | FC4 | FC5 | FC6 | |

| FRESH 1 | ||||||

| Color | − | ++ | − | +++ | ++ | +++ |

| Easy to manipulate without breaking | − | ++ | ++ | +++ | − | +++ |

| Sticky | + | ++ | ++ | − | − | − |

| Taste | + | ++ | ++ | +++ | − | +++ |

| Texture in mouth | − | + | + | +++ | − | − |

| Texture in hand | + | + | − | +++ | − | + |

| DRIED 1 | ||||||

| Color | − | + | − | ++ | − | ++ |

| Easy to manipulate without breaking | − − | + | ++ | ++ | + | ++ |

| Sticky | ++ | + | − | − | − | − |

| Taste | − | ++ | ++ | ++ | − | − − |

| Texture in mouth | − | ++ | ++ | ++ | − | − − |

| Texture in hand | − | + | ++ | ++ | − | ++ |

| % of Chestnut Flour 1 | ||||||

|---|---|---|---|---|---|---|

| 0% | 25% | 30% | 40% | 50% | 55% | |

| Formulations with Water | ||||||

| FC2 | FC2-C25 | FC2-C30 | FC2-C40 | FC2-C50 | FC2-C55 | |

| Chestnut flour (g) | 0 | 18.76 | 22.50 | 30.00 | 37.50 | 41.25 |

| Wheat flour T65 (g) | 75.00 | 56.25 | 52.50 | 44.99 | 37.50 | 33.75 |

| Water (g) | 37.49 | 37.50 | 37.50 | 37.50 | 37.50 | 37.50 |

| Pasta obtained (g) | 87.73 | 89.97 | 89.25 | 80.44 | 82.29 | 86.77 |

| Formulations with Egg | ||||||

| FC4 | FC4-C25 | FC4-C30 | FC4-C40 | FC4-C50 | FC4-C55 | |

| Chestnut flour (g) | 0 | 18.76 | 22.51 | 30.03 | 37.51 | 45.03 |

| Wheat flour T55 (g) | 75.01 | 56.24 | 52.49 | 45.01 | 37.49 | 30.00 |

| Egg (g) | 37.51 | 37.51 | 37.49 | 37.47 | 37.51 | 37.50 |

| Pasta obtained (g) | 108.6 | 107.2 | 105.0 | 99.87 | 94.77 | 95.06 |

| % of Pollen Powder 1 | |||||

|---|---|---|---|---|---|

| 0% | 5% | 10% | 15% | 20% | |

| Formulations with Water | |||||

| FC2 | FC2-P5 | FC2-P10 | FC2-P15 | FC2-P20 | |

| Pollen powder (g) | 0 | 6.00 | 7.50 | 11.25 | 15.02 |

| Wheat semolina (g) | 75.00 | 69.00 | 67.50 | 63.75 | 60.01 |

| Water (g) | 37.49 | 37.50 | 37.60 | 37.54 | 37.51 |

| Pasta obtained (g) | 87.73 | 99.53 | 78.45 | 84.73 | 72.08 |

| Formulations with Egg | |||||

| FC4 | FC4-P5 | FC4-P10 | FC4-P15 | FC4-P20 | |

| Pollen powder (g) | 0 | 5.99 | 7.50 | 11.25 | 15.00 |

| Wheat flour T55 (g) | 75.01 | 68.99 | 67.51 | 63.75 | 60.01 |

| Egg (g) | 37.51 | 37.05 | 37.48 | 37.22 | 37.49 |

| Pasta obtained (g) | 108.6 | 86.99 | 83.19 | 74.08 | 85.65 |

| FC4-C50P10 | % in Relation to the Mass of Solids | % in Relation to the Total Mass | |

|---|---|---|---|

| Chestnut flour (g) | 37.5 | 50.0 | 33.3 |

| Pollen powder (g) | 7.5 | 10.0 | 6.7 |

| Wheat flour T55 (g) | 30.0 | 40.0 | 26.7 |

| Egg (g) | 37.5 | — | 33.3 |

| Total (g) | 75 a/112.5 b | 100 | 100 |

| Pasta obtained (g) | 79.20 |

| Formulation with Water | FC2 | FC2-C25 | FC2-C30 | FC2-C40 | FC2-C50 | FC2-C55 |

| % of Chestnut Flour 1 | 0% | 25% | 30% | 40% | 50% | 55% |

| FRESH | ||||||

| Mass of fresh pasta (g) | 31.61 | 37.65 | 36.51 | 38.59 | 35.88 | 37.26 |

| Mass of cooked pasta (g) | 63.43 | 81.71 | 83.60 | 67.58 | 64.11 | 65.00 |

| Cooking time (min:s) | 10:00 | 6:55 | 6:40 | 5:30 | 5:15 | 5:00 |

| Cooking yield (%) | 201 | 217 | 229 | 175 | 179 | 174 |

| DRIED | ||||||

| Mass of fresh pasta (g) | 56.12 | 52.32 | 52.74 | 41.85 | 46.41 | 49.51 |

| Mass of dried pasta (g) | 32.19 | 33.29 | 35.59 | 28.04 | 31.22 | 32.89 |

| Drying loss (%) | 57 | 64 | 67 | 67 | 67 | 66 |

| Mass of cooked pasta (g) | 76.19 | 71.06 | 83.35 | 58.98 | 69.19 | 81.01 |

| Cooking time (min:s) | 11:58 | 7:17 | 6:46 | 6:30 | 7:44 | 9:00 |

| Coking yield (%) | 237 | 213 | 234 | 210 | 222 | 246 |

| Formulation with Egg | FC4 | FC4-C25 | FC4-C30 | FC4-C40 | FC4-C50 | FC4-C55 |

| % of Chestnut Flour 1 | 0% | 25% | 30% | 40% | 50% | 55% |

| FRESH | ||||||

| Mass of fresh pasta (g) | 32.98 | 37.31 | 35.40 | 38.09 | 39.02 | 38.04 |

| Mass of cooked pasta (g) | 60.00 | 66.72 | 61.96 | 65.11 | 62.45 | 66.25 |

| Cooking time (min:s) | 11:42 | 9:00 | 8:31 | 8:05 | 8:00 | 8:00 |

| Cooking yield (%) | 182 | 179 | 175 | 171 | 160 | 174 |

| DRIED | ||||||

| Mass of fresh pasta (g) | 55.42 | 53.69 | 53.54 | 46.71 | 55.75 | 57.02 |

| Mass of dried pasta (g) | 38.68 | 36.21 | 37.87 | 30.88 | 25.49 | 28.95 |

| Drying loss (%) | 70 | 67 | 71 | 66 | 46 | 51 |

| Mass of cooked pasta (g) | 93.41 | 88.38 | 83.33 | 81.58 | 82.18 | 72.47 |

| Cooking time (min:s) | 17:25 | 16:12 | 15:00 | 14:00 | 14:00 | 18:00 |

| Coking yield (%) | 241 | 244 | 220 | 264 | 322 | 250 |

| Formulation with Water | FC2 | FC2-P5 | FC2-P10 | FC2-P15 | FC2-P20 |

| % of Pollen Powder 1 | 0% | 5% | 10% | 15% | 20% |

| FRESH | |||||

| Mass of fresh pasta (g) | 31.61 | 37.54 | 34.30 | 36.55 | 37.91 |

| Mass of cooked pasta (g) | 63.43 | 81.80 | 76.39 | 65.47 | 68.97 |

| Cooking time (min:s) | 10:00 | 8:00 | 8:25 | 6:50 | 6:53 |

| Cooking yield (%) | 201 | 218 | 223 | 179 | 182 |

| DRIED | |||||

| Mass of fresh pasta (g) | 56.12 | 61.99 | 44.15 | 48.18 | 34.17 |

| Mass of dried pasta (g) | 32.19 | 36.37 | 28.64 | 28.92 | 25.94 |

| Drying loss (%) | 57 | 59 | 65 | 60 | 76 |

| Mass of cooked pasta (g) | 76.19 | 101.2 | 57.63 | 59.92 | 56.38 |

| Cooking time (min:s) | 11:58 | 8:46 | 11:57 | 9:40 | 9:32 |

| Cooking yield (%) | 237 | 278 | 201 | 207 | 217 |

| Formulation with Egg | FC4 | FC4-P5 | FC4-P10 | FC4-P15 | FC4-P20 |

| % of Pollen Powder 1 | 0% | 5% | 10% | 15% | 20% |

| FRESH | |||||

| Mass of fresh pasta (g) | 32.98 | 39.93 | 37.64 | 37.34 | 37.79 |

| Mass of cooked pasta (g) | 60.00 | 69.44 | 78.92 | 73.00 | 68.48 |

| Cooking time (min:s) | 11:42 | 12:30 | 6:35 | 8:56 | 10:07 |

| Cooking yield (%) | 182 | 174 | 210 | 196 | 181 |

| DRIED | |||||

| Mass of fresh pasta (g) | 56.12 | 47.06 | 45.55 | 36.74 | 47.86 |

| Mass of dried pasta (g) | 32.19 | 31.41 | 35.16 | 28.88 | 37.75 |

| Drying loss (%) | 57 | 67 | 77 | 79 | 79 |

| Mass of cooked pasta (g) | 76.19 | 62.70 | 70.76 | 61.95 | 77.23 |

| Cooking time (min:s) | 11:58 | 8:46 | 11:57 | 9:40 | 9:32 |

| Coking yield (%) | 237 | 200 | 201 | 215 | 205 |

| Egg Formulation with 50% Chestnut Flour and 10% Pollen Powder (FC4-C50P10) | ||

|---|---|---|

| FRESH | DRIED | |

| Mass of fresh pasta (g) | 34.20 | 45.00 |

| Mass of dried pasta (g) | — | 31.70 |

| Drying loss (%) | — | 70 |

| Mass of cooked pasta (g) | 70.85 | 76.84 |

| Cooking time (min:s) | 9:00 | 12:00 |

| Cooking yield (%) | 207 | 242 |

| Property (Units) (1) | FC4 (2) | FC4-C50 (3) | FC4-P10 (4) | FC4-C50P10 (5) |

|---|---|---|---|---|

| Water activity (dimensionless) | 0.924 ± 0.002 b | 0.935 ± 0.003 c | 0.944 ± 0.004 d | 0.903 ± 0.001 a |

| Moisture (g/100 g sample) | 32.43 ± 2.15 a | 30.46 ± 0.52 a | 32.23 ± 4.15 a | 31.39 ± 0.295 a |

| Protein (g/100 g dm) | 10.10 ± 0.47 a | 12.96 ± 0.22 b | 16.57 ± 0.15 d | 14.67 ± 0.13 c |

| Fiber (g/100 g dm) | 0.53 ± 0.86 a | 1.63 ± 0.33 b | 1.77 ± 1.01 b | 1.53 ± 0.21 b |

| Fat (g/100 g dm) | 6.65 ± 0.42 b | 7.60 ± 1.01 c | 5.70 ± 2.04 a | 8.04 ± 0.96 d |

| Ash (g/100 g dm) | 0.57 ± 0.02 a | 1.57 ± 0.07 c | 1.14 ± 0.03 b | 1.67 ± 0.03 c |

| Carbohydrates (g/100 g dm) (6) | 82.15 | 76.24 | 74.82 | 74.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brochard, M.; Correia, P.; Barroca, M.J.; Guiné, R.P.F. Development of a New Pasta Product by the Incorporation of Chestnut Flour and Bee Pollen. Appl. Sci. 2021, 11, 6617. https://doi.org/10.3390/app11146617

Brochard M, Correia P, Barroca MJ, Guiné RPF. Development of a New Pasta Product by the Incorporation of Chestnut Flour and Bee Pollen. Applied Sciences. 2021; 11(14):6617. https://doi.org/10.3390/app11146617

Chicago/Turabian StyleBrochard, Maëlys, Paula Correia, Maria João Barroca, and Raquel P. F. Guiné. 2021. "Development of a New Pasta Product by the Incorporation of Chestnut Flour and Bee Pollen" Applied Sciences 11, no. 14: 6617. https://doi.org/10.3390/app11146617

APA StyleBrochard, M., Correia, P., Barroca, M. J., & Guiné, R. P. F. (2021). Development of a New Pasta Product by the Incorporation of Chestnut Flour and Bee Pollen. Applied Sciences, 11(14), 6617. https://doi.org/10.3390/app11146617