1. Introduction

The radial basis function neural network (RBFNN) is one of artificial neural network (ANN) methods employing a hidden layer of radial units and an output layer of linear units, and characterized by relatively fast training, generalization and compact type of network [

1]. RBFNN has been widely used in surface and/or image constructions that typically consist of bulky size of data in the order of thousands or even millions of points. It also has been known to be suitable for highly nonlinear function approximate problems. The RBFNN has been recognized as useful method in various fields such as pattern recognition, automatic control, signal processing, approximate optimization and so on [

2,

3,

4,

5]. Meta-models are generally applied to approximate multi-objective optimization, reliability analysis, reliability-based design optimization, etc., not only in order to improve the efficiencies of numerical calculation and convergence, but also to facilitate the analysis of design sensitivity. The RBFNN has been usefully applied as the meta-model in design approximation. A sequential approximate robust design optimization with the RBFNN was proposed to find a robust optimal solution with a small number of function evaluations, not identifying a set of Pareto-optimal solution using multi-objective evolutionary algorithms [

6]. To further reduce the computational expense of metamodel-based design optimization, a novel sequential RBF-based optimization method using virtual sample generation was proposed employing the virtual sample generation mechanism to improve the optimization efficiency [

7]. However, the role of learning parameters in the RBFNN meta-model was hardly investigated in the design approximation and its application to the optimization or the reliability analysis. The reason for that the role of learning parameters in the RBFNN meta-model was not investigated closely in design approximation is that the review of parameters affecting the accuracy of the meta-model was overlooked due to the extensive numerical calculation process of optimization or reliability analysis. In

Section 2.1, the author reviewed several references in which the RBFNN meta-model was utilized for the design optimizations and the reliability analyses, and it was found that the role of learning parameters in the RBFNN meta-model was hardly investigated in the design approximation. In general, the values of parameters in RBFNN meta-model have been applied empirically or adjusted through simple estimation of the accuracy of RBFNN meta-model or comparison with the results of other meta-models.

This study aims to identify the effect of various learning parameters such as the spline smoothing parameter (SSP), the number of training data, and the number of hidden layers on the performances of RBFNN meta-model regarding the design approximation of rotor blade. In particular, it is important to minimize the scattered noisy data to approximate a design space to prevent local minimum in gradient based optimization or reliability analysis using the RBFNN meta-model. Since the noisy data must be smoothed out in order for the RBFNN to be applied as the meta-model to an actual structural design problem, the SSP must be properly determined. In case of applying the RBFNN to approximate the design space, how to determine the learning parameters such as the SSP, training data, and hidden layers is important in the structural design application to enhance the performances of the meta-model. An actual rotor blade design problem was considered to investigate the characteristics of RBFNN approximation with respect to the range of SSP, the number of training data, and the number of hidden layers. In the rotor blade design approximation with the RBFNN, design sensitivity characteristics such as main effects were also evaluated including the performance analysis according to the variation of learning parameters. The present study briefly reviewed the RBFNN and its smoothing parameter theories, and then carried out the rotor blade design approximation using the RBFNN. The rotor blade design approximation included fitting of meta-models, the design sensitivity analysis, the performance analyses. The overall performances of RBFNN meta-model were evaluated using two standard accuracy measures—root mean square error and maximum error. From the design approximation results of rotor blades, it was found that the number of training data had larger influence on the RBFNN meta-model accuracy than the SSP while the number of hidden layers had little effect on the performances of RBFNN meta-model. Such study results help to suggest a reference index that can reasonably apply the learning parameter value in case of adopting the RBFNN to the design approximation. This paper is comprised of the following:

Section 2 addresses literature survey related to the RBFNN and its theoretical backgrounds;

Section 3 addresses the results and discusses the characteristics of the rotor blade design approximation with the RBFNN;

Section 4 presents the concluding remarks of this study.

3. Rotor Blade Design Approximation with RBFNN

In the rotor blade design, it is important to minimize the distance between aerodynamic and shear centers in order to reduce both the flutter instability and the restrictions on the flight envelope. Also, the weight of rotor blade should be improved while the structural stiffness properties are almost maintained at the level of the baseline design. The design optimization problem of rotor blade can be formulated as follows:

where

is the aerodynamic center, and

is the shear center. The properties GJ, EI

22 and EI

33 are torsional, flap-wise bending, and chord-wise bending stiffnesses, respectively. The notation

m is mass per unit length. The subscript

base denotes the value representing the baseline model. An application of optimization methods to the structural design problems of rotor blade often requires a large amount of numerical costs. An alternative for reducing the numerical cost in the process of design optimization is to employ the meta-model by establishing the accurate levels of approximate objective and constraint functions over the exploratory design space. Using rationally constructed meta-models, near-optimal approximate solutions can be obtained in addition to the estimation of design behaviors, that is, the sensitivity-like information.

The practical design problem of rotor blade was chosen to investigate the characteristics of the RBFNN approximation with respect to the learning parameters such as the range of spline smoothing parameter, the number of training data, and the number of hidden layers. The RBFNN based meta-models were generated for the rotor blade design problem. The architecture of RBFNN consisted of one to three layers in the hidden layers to evaluate the effect of the number of hidden layers on the performance of RBFNN. The number of neurons in that layer was defined as the mean of the neurons in the input and output layers referring to the related research book [

28]. Each neural network in the RBFNN was trained by back-propagation algorithm which is one of the most reliable algorithms having such characteristics as the simplicity of implementation and the ability to quickly generate networks that have the capability to generalize [

28]. Error analyses were carried out to evaluate the variation of performance according to the variation learning parameters. In order to complete the RBFNN meta-modeling for the rotor blade design problem, the calculation time was 8.3 h using a server equipped with six core Intel Xeon CPUs and 128 GB RAM.

In order to investigate the characteristics of the RBFNN approximation with respect to the learning parameters for the practical design problem with a number of performance functions, the design problem of composite rotor blade was explored [

32]. The composite rotor blade was designed to use for the tilt rotor aircraft combines the advantages of vertical takeoff and landing capabilities. The design performance functions of rotor blade were calculated a rotor blade cross-sectional modeling and analysis program, which is Variational Asymptotic Beam Section (VABS) [

33] developing for analyzing the composite blade structure using an equivalent beam model. In the VABS program, the cross-sectional stiffness matrix is calculated from a two-dimensional finite element discretization. In this study, the VABS was used for obtaining both training and testing data for use in RBFNN based meta-modeling. Regarding to the cross-section of rotor blade with specific geometry information, a NURBS curve was generated for a given number of points, and the non-uniform rational B-spline (NURBS) was transformed into the cross-section of rotor blades with specific geometry data. Such information was adopted to calculate the design performance functions of rotor blade by VABS. The structure design configuration and the design variables of the rotor blade were shown in

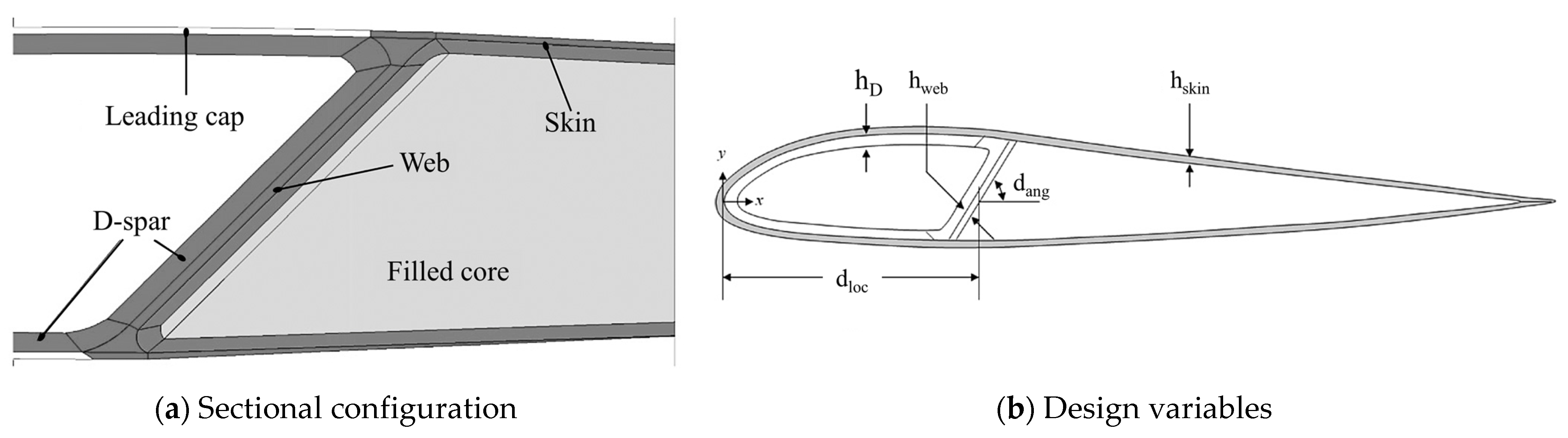

Figure 6.

As shown in

Figure 6, the design variables were thicknesses of D-spar (h

D), skin (h

skin), and web (h

web), as well as the web location (d

loc) and the web connection orientation (d

ang). Both initial values and design range for the design variables were represented in

Table 3.

In the calculation of design performances, the chord length was considered 20.2 in., and the aerodynamic center was at the quarter chord. In the structure design problem of composite rotor blade, the distance between aerodynamic and shear centers should be minimized to avoid flutter instability of the rotor blade, and to avert the restrictions on the flight envelope. As design performance functions, the structural mass of rotor blade should be minimized while some important internal structural stiffness properties such as torsional (GJ), flap-wise bending (EI22) and chord-wise bending stiffnesses (EI33) were almost maintained at the level of the initial design, i.e., within ±5% variations.

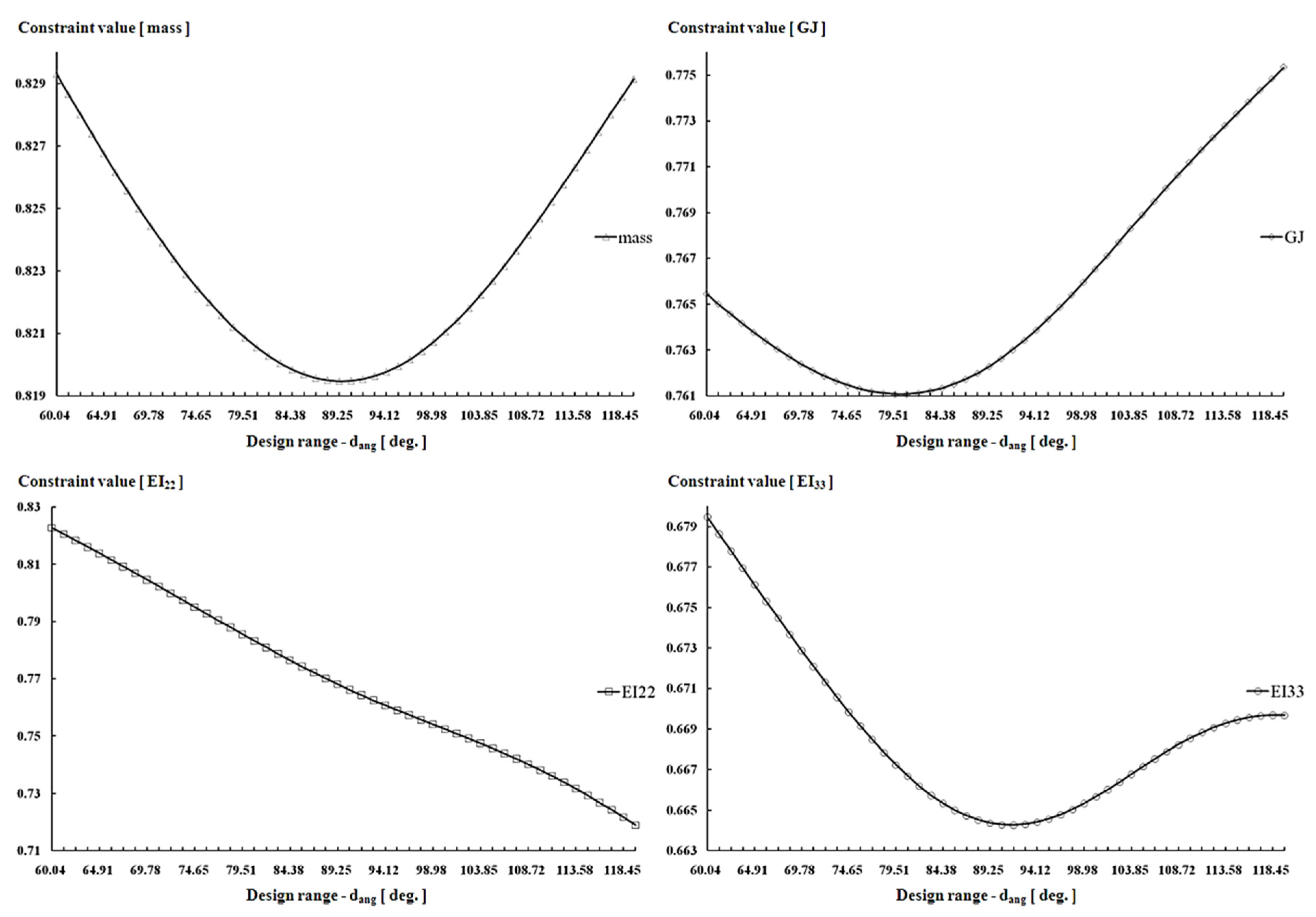

In the present study, the RBFNN-based approximation was carried out for the design performance functions. With 500 training data and 90 testing data, the RBFNN based meta-models were fitted for each design performance function. The fitted RBFNN meta-models of rotor blade design are shown in

Figure 7,

Figure 8,

Figure 9,

Figure 10 and

Figure 11.

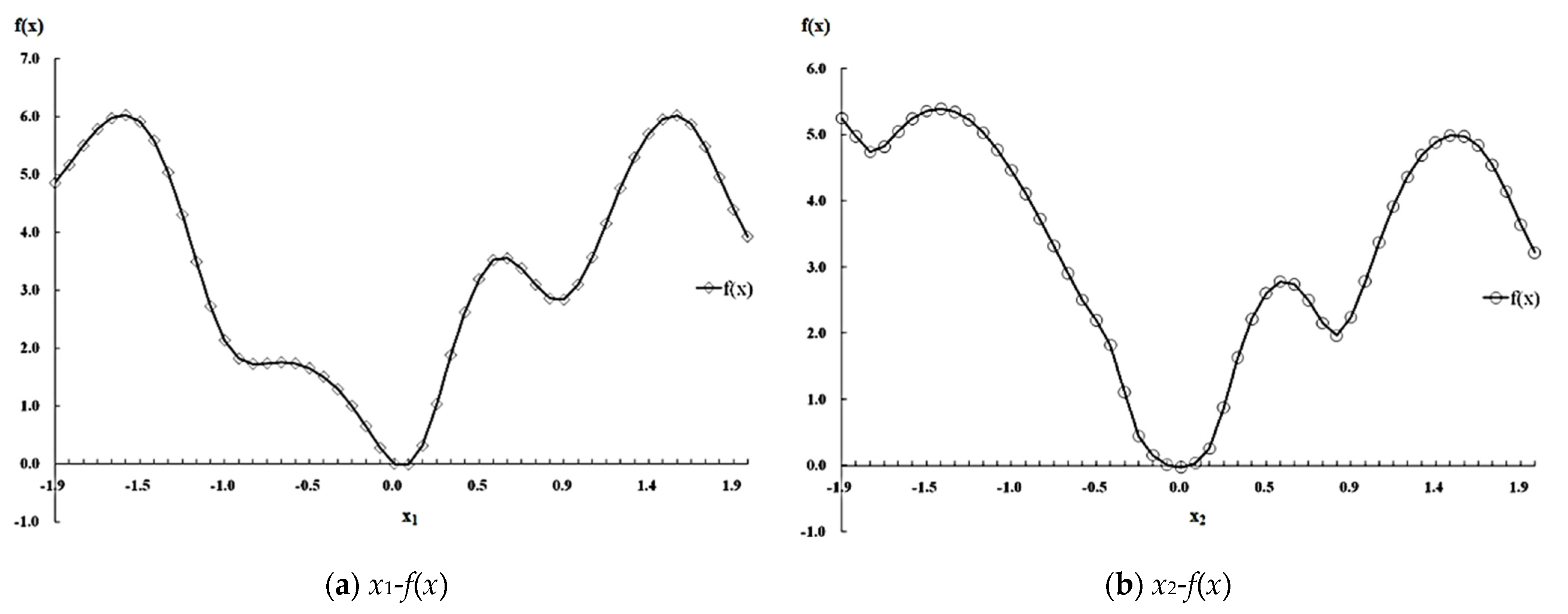

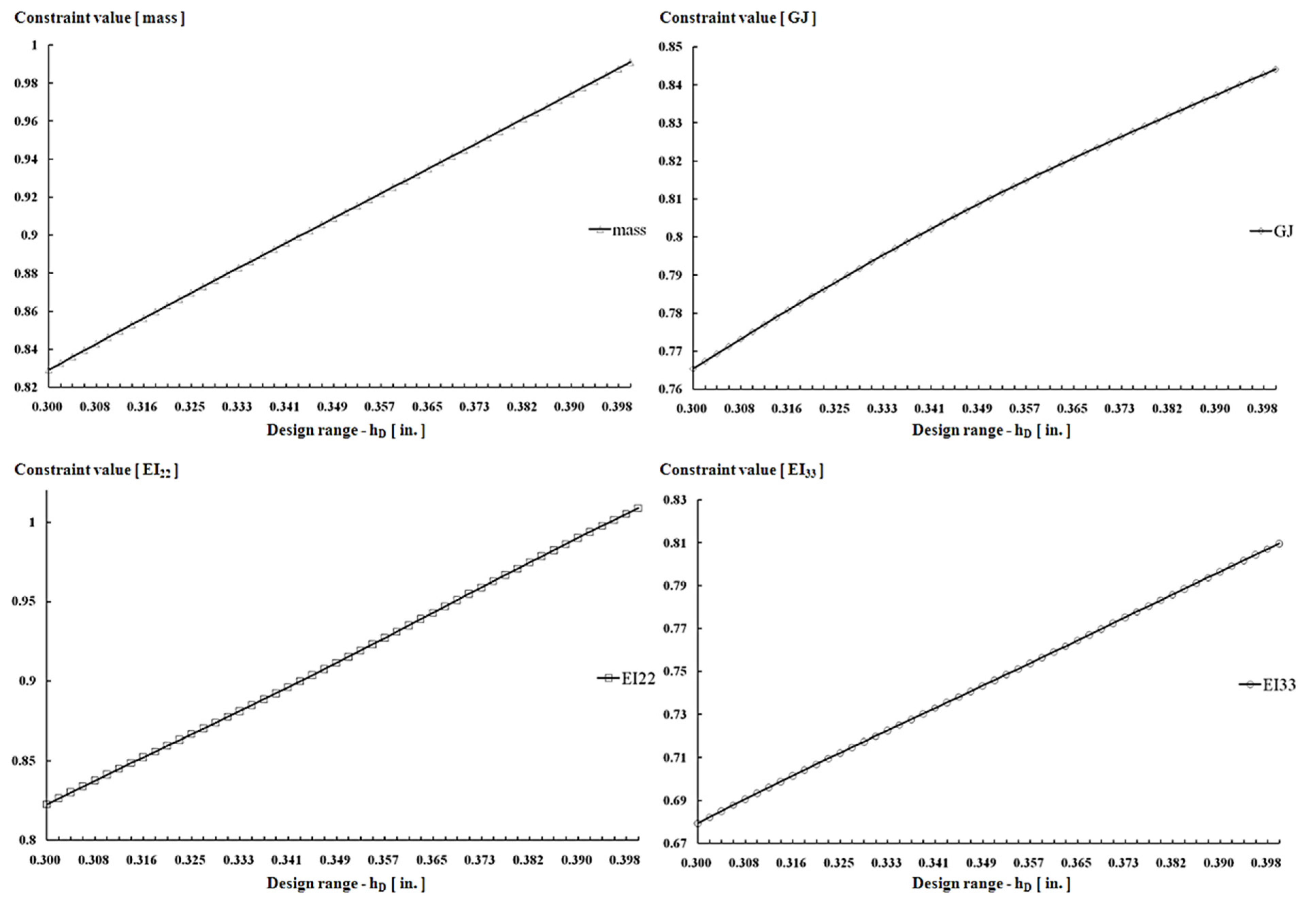

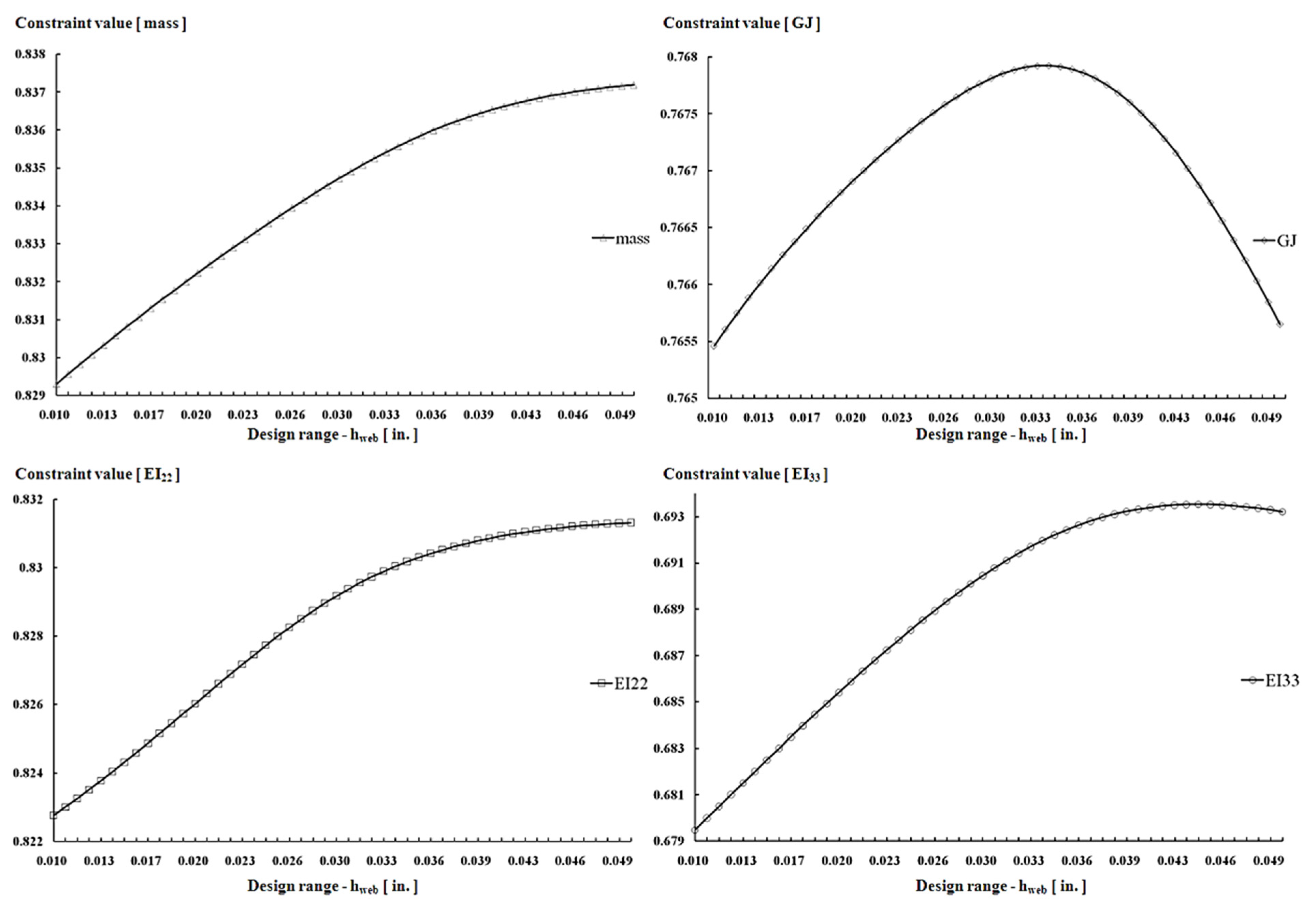

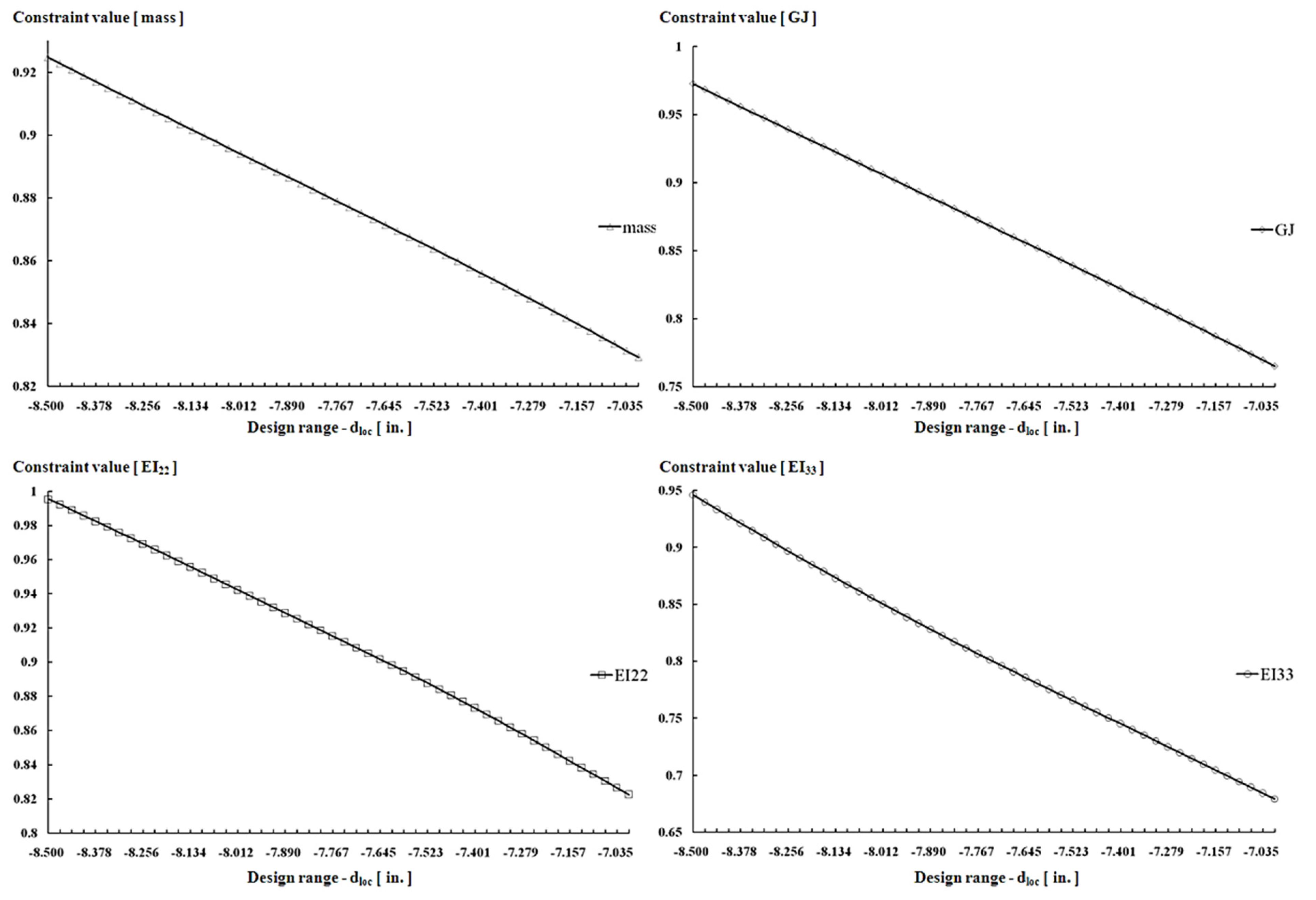

From the meta-modeling results, remarkable multi-modal variations were found in the relations between two design variables (h

web and d

ang) and the design performance functions. In other design variables such as the thicknesses of D-spar (h

D), the skin (h

skin) and the web location, their meta-modeling results represented almost linear characteristics. Statistical analyses were also performed to evaluate the main effects of design variables on the responses of design performance functions. The results of statistical analyses were shown in

Figure 12.

The main effects of hD and dloc among the design performance functions were higher than other design variables. The most sensitive design variable on the mass and the EI22 was the hD, and the main effect values on the mass and the EI22 were 47% and 44%, respectively. The most sensitive design variable on the GJ and the EI33 was the dloc, and the main effect values on the GJ and the EI33 were −52% and −48%, respectively. The statistical results also showed that dloc and dang had negative effects on all the design performance functions while other design variables had positive effects. From the main effect results, it was found that the design performances of rotor blade were increased as the hD value was increased and the dloc value was decreased.

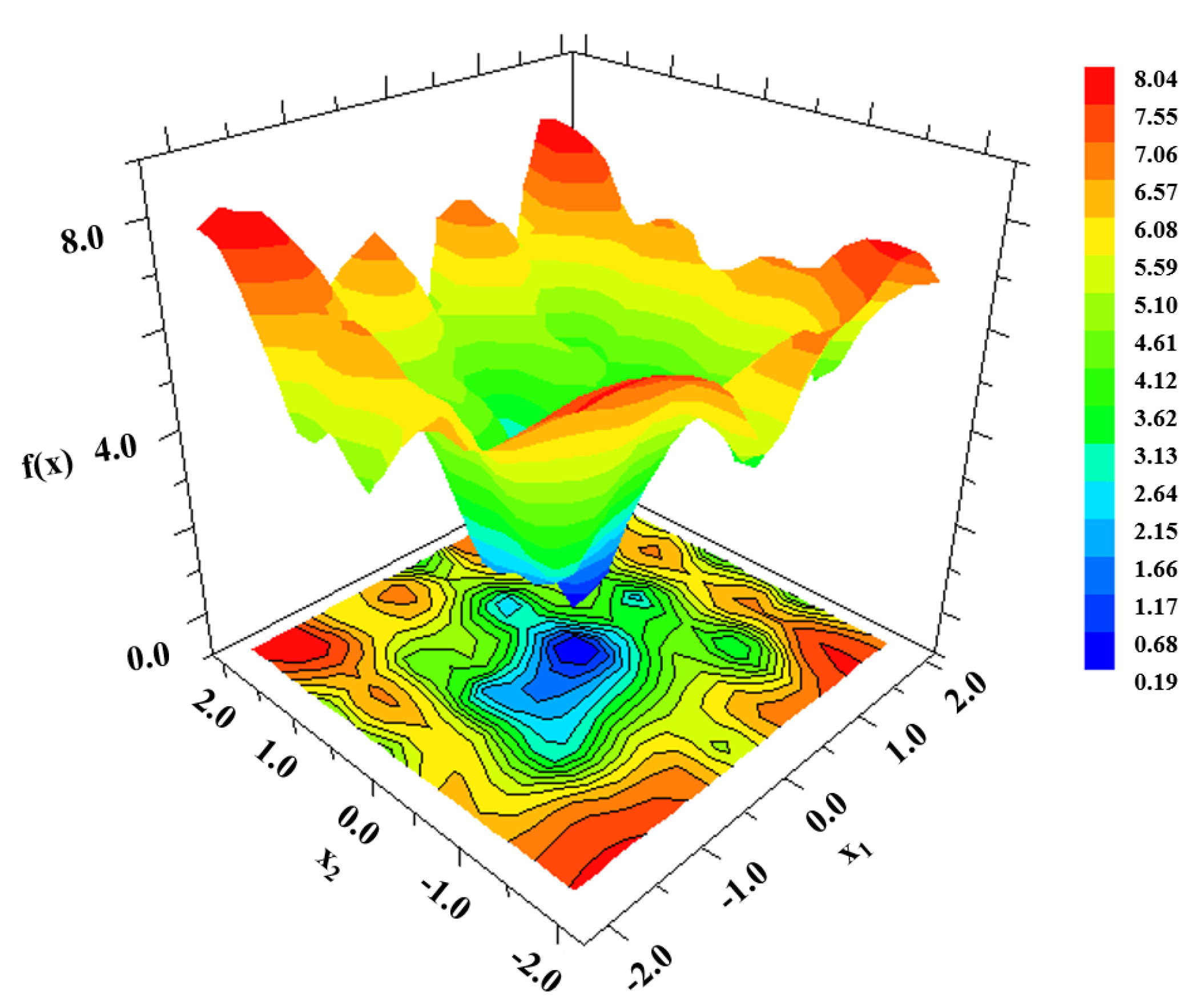

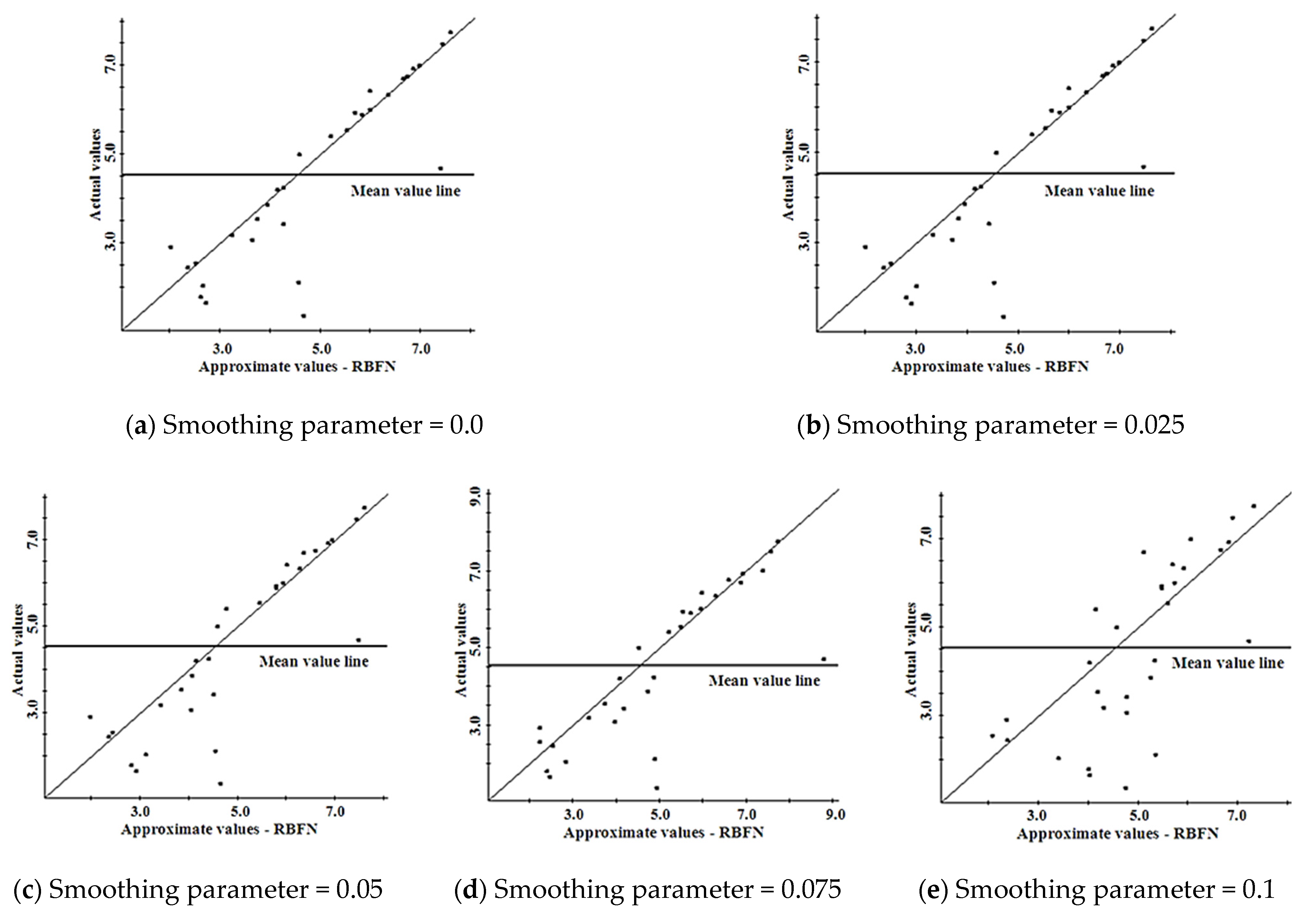

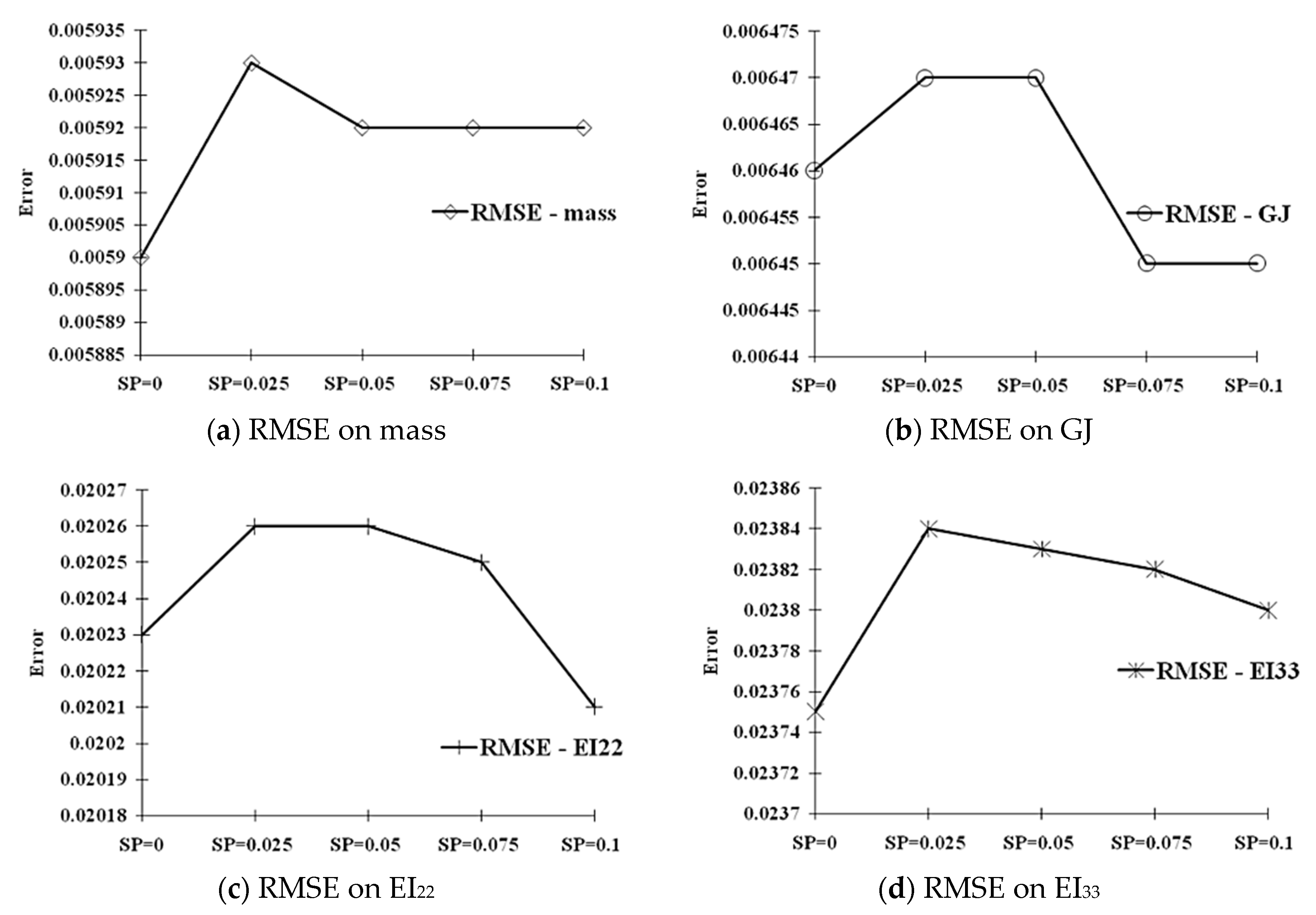

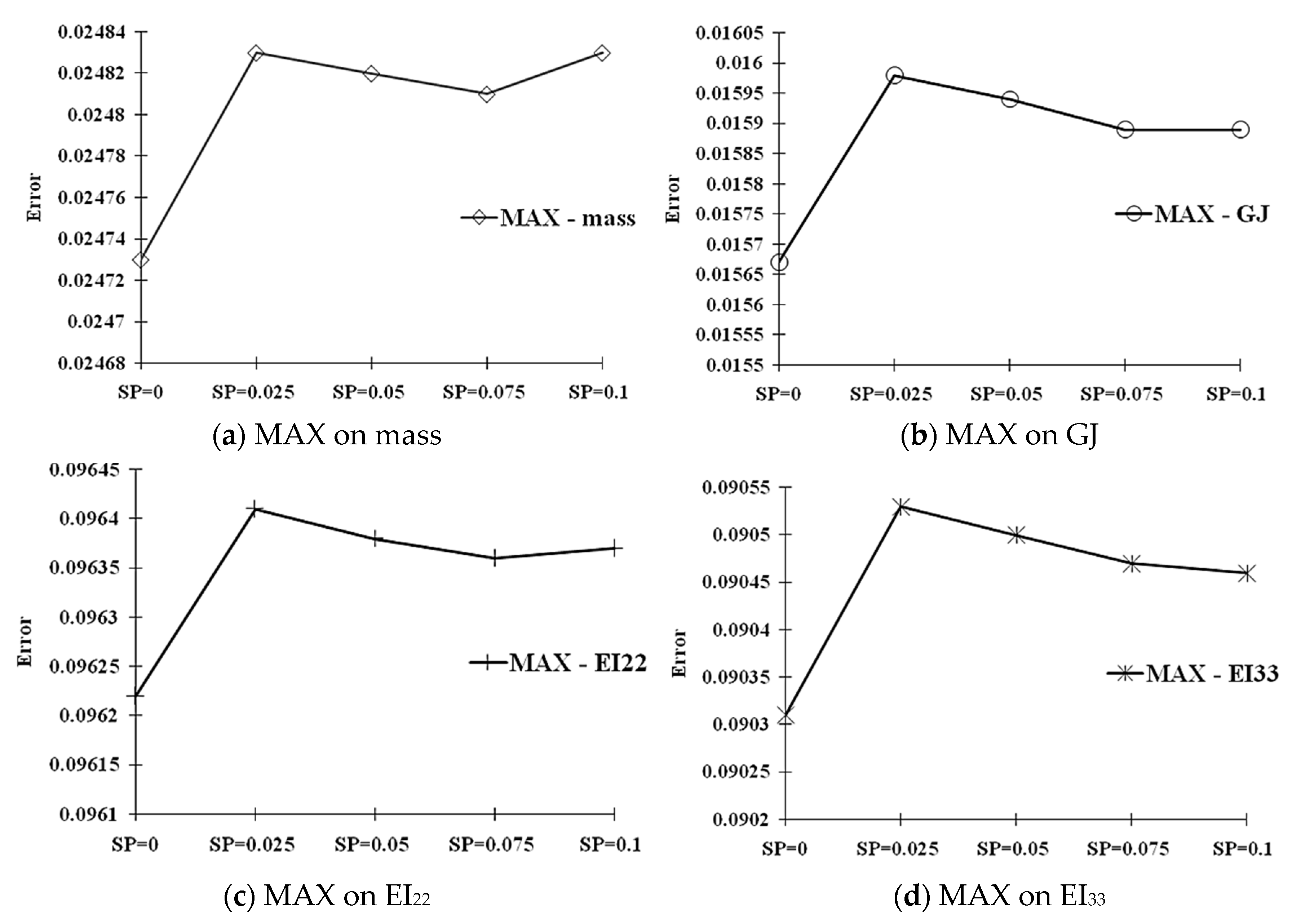

The error analyses were carried out to evaluate the variation of performance according to the variation of learning parameters such as the SSP value, the number of training data, and the number of hidden layers. The SSP values were varied from zero to 0.1 with 0.025 step size, and the accuracy measures such as RMSE and MAX were analyzed. Their results were represented in

Table 4 and

Figure 13 and

Figure 14.

As shown in

Table 4 and

Figure 13, the RMSEs of Mass, GJ, EI

22, and EI

33 were distributed in the range of 0.00590 to 0.00593, 0.00645 to 0.00647, 0.02021 to 0.02026, and 0.02375 to 0.02384, respectively, according to the variation of SSP. The MAXs of Mass, GJ, EI

22, and EI

33 were distributed in the range of 0.02473 to 0.02483, 0.01567 to 0.01589, 0.09622 to 0.09637, and 0.09031 to 0.09046, respectively, as represented in

Table 4 and

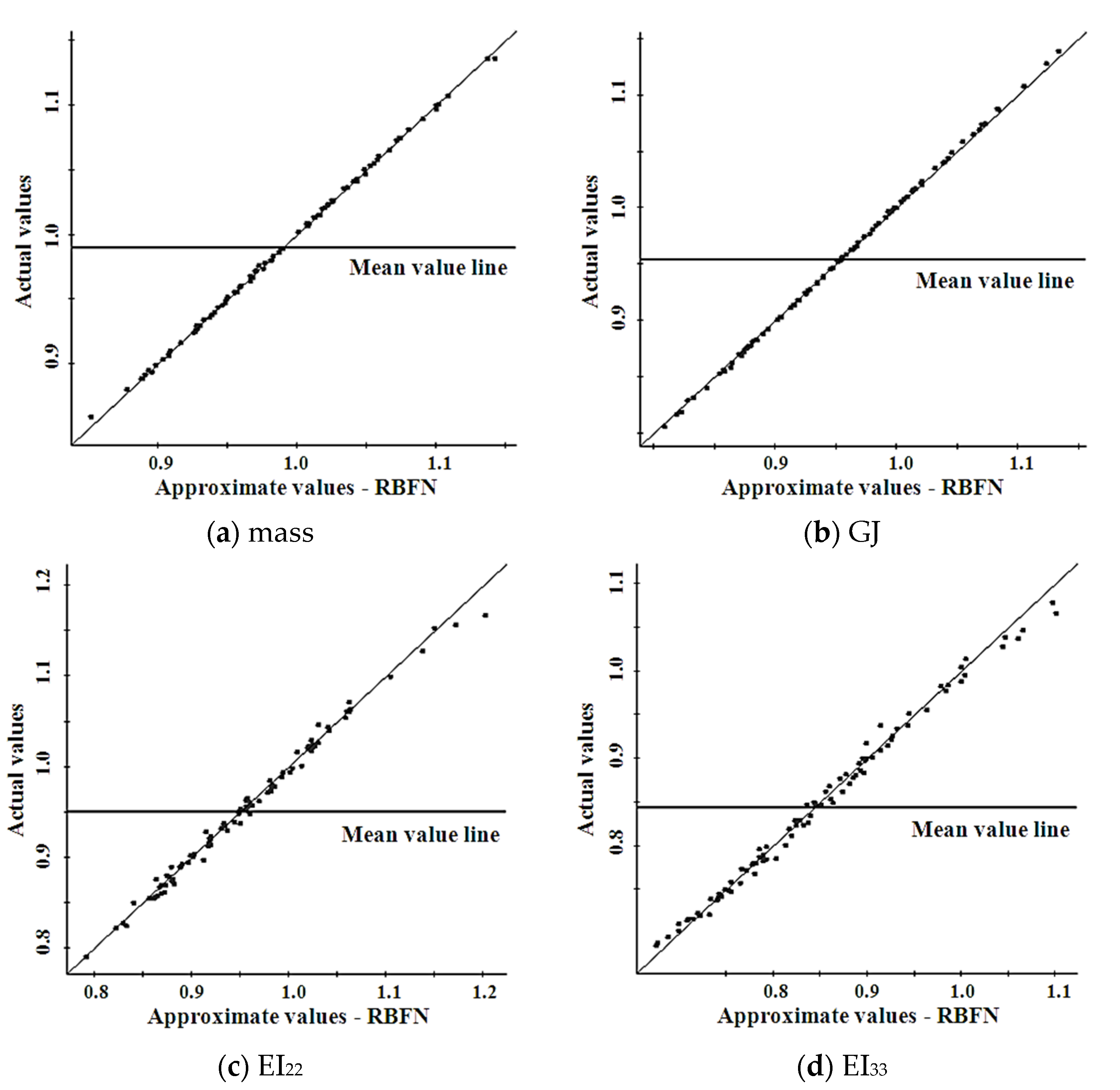

Figure 14. From the results of error analyses, it was clear that the variation of accuracy occurred in the slight magnitude because the rotor blade design problem had relatively a low multi-modal variation as represented in the meta-modeling results and the statistical analysis. Although the influence of SSP was not significant in the RBFNN approximation of the actual rotor blade design problem, it could be seen that the accuracy of the approximation was increased based on RMSE as the SSP was applied in the range of 0.075 to 0.1. The results of error scattering were also evaluated according to the SSP values. The results of error scattering analyses were shown in

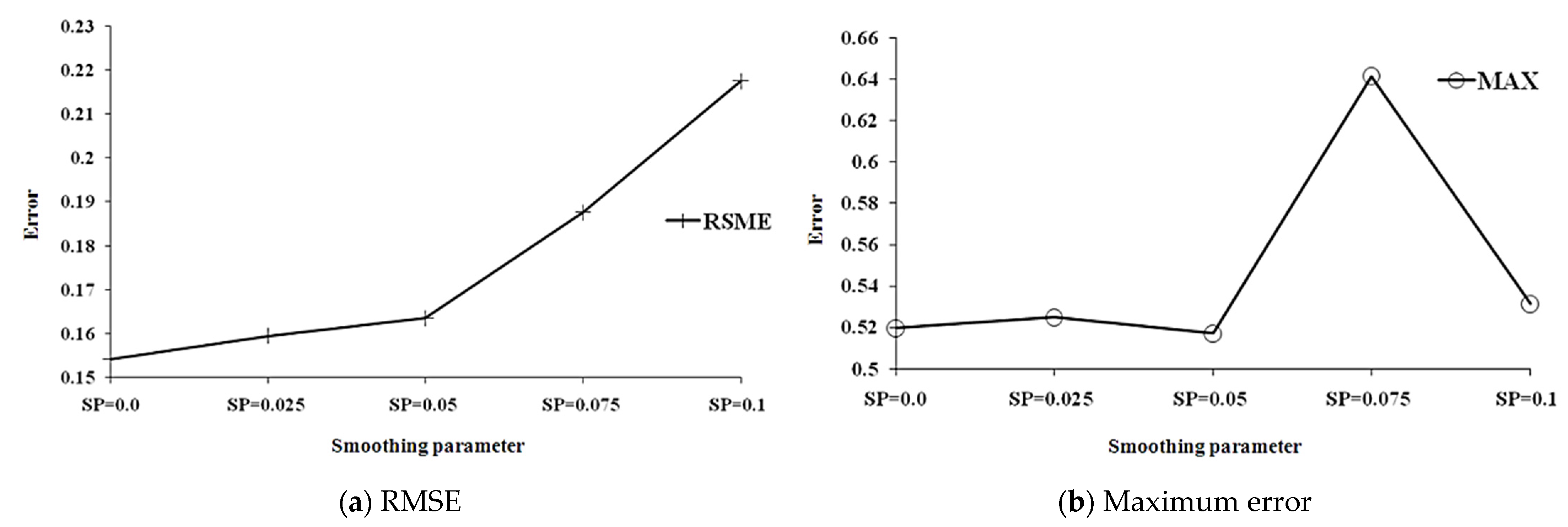

Figure 15.

Figure 15 showed only for the zero SSP, and it was sufficient to represent the characteristics of error scattering because the variation of accuracy is tiny in the rotor blade design problem.

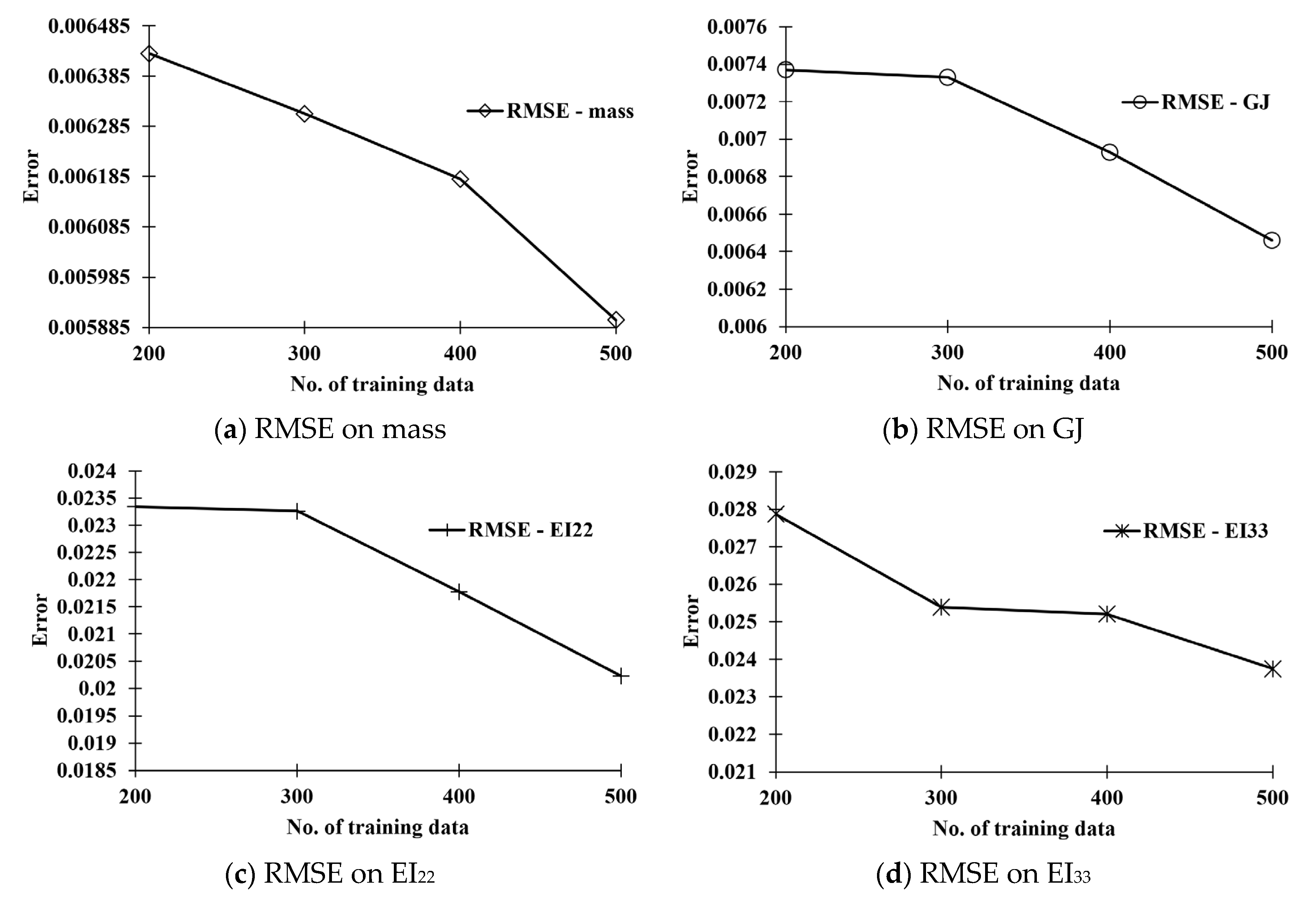

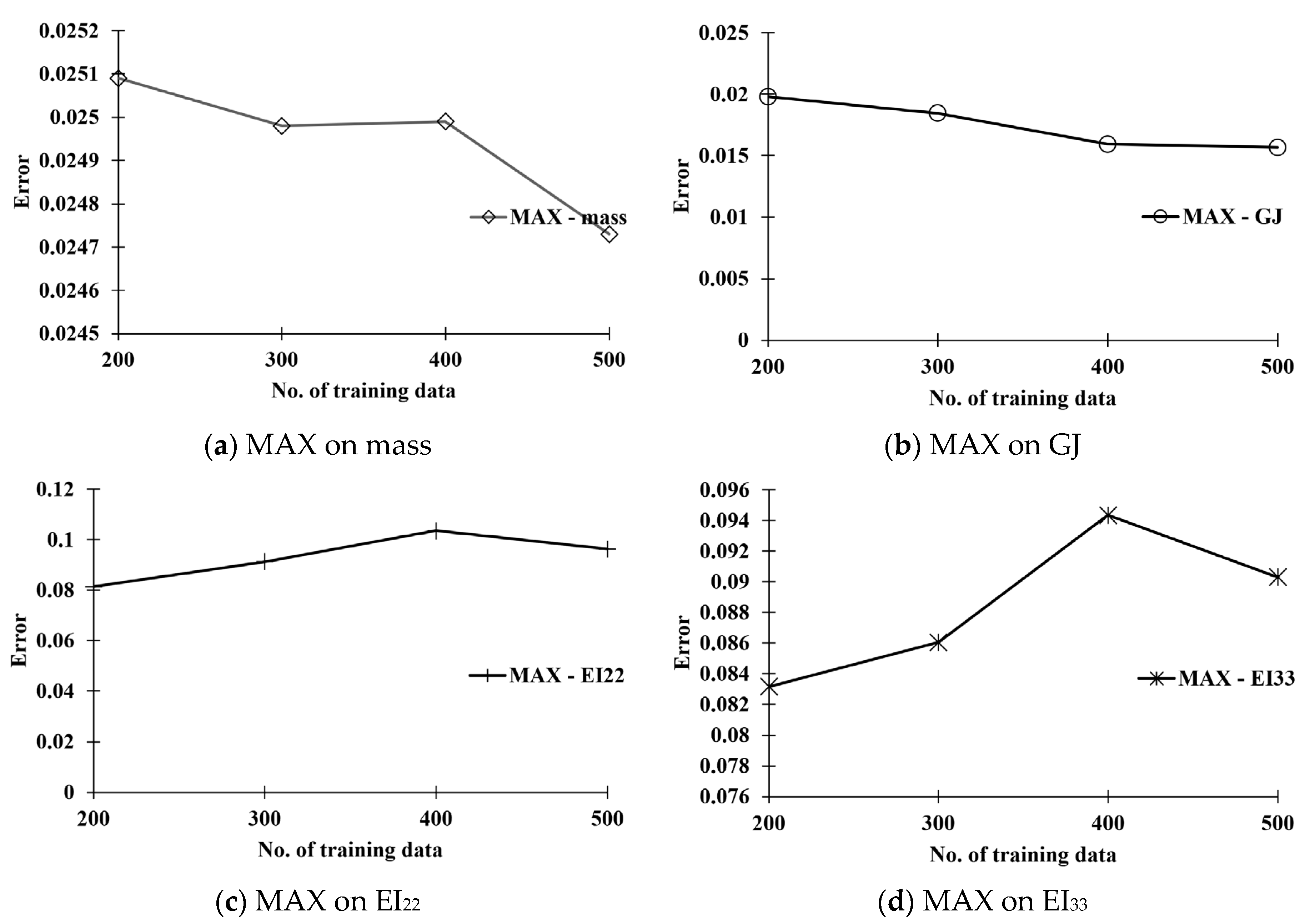

In the context of the error analyses of rotor blade design problem, the performance characteristics according to the variation of the number of training data were secondly evaluated. The initial number of 500 training data was varied up to 200 training data with 100 data step size. The results of RMSE and MAX were shown in

Table 5 and

Figure 16 and

Figure 17.

The results of

Table 5 and

Figure 16 represented that the RMSEs of Mass, GJ, EI

22 and EI

33 were distributed in the range of 0.00590 to 0.00643, 0.00646 to 0.00737, 0.02023 to 0.02334, and 0.02375 to 0.02787, respectively, according to the variation of training data. It was found that the influence of the number of training data on the accuracy of the meta-model in the rotor blade design was higher than that of the SSP. RMSEs for all the design performance functions were enhanced as the number of training data was increased. The MAXs of Mass, GJ, EI

22 and EI

33 were distributed in the range of 0.02473 to 0.02509, 0.01567 to 0.01977, 0.08138 to 0.09622, and 0.08316 to 0.09031, respectively, as represented in

Table 4. Among the MAX results, however, EI

22 and EI

33 were deteriorated as the number of training data was increased, as shown in

Figure 17. Such result was because some larger deviation data was included in the set of training data.

From

Table 5 and

Figure 17, it was found that the number of training data had larger influence on the RBFNN meta-model accuracy than the SSP in the approximation of rotor blade design problem. From the results of the rotor design approximation, it was able to conclude that the decrement of less than 100 times of number of design variables for the number of training data showed the inferior accuracy due to insufficient learning data for the RBFNN meta-model.

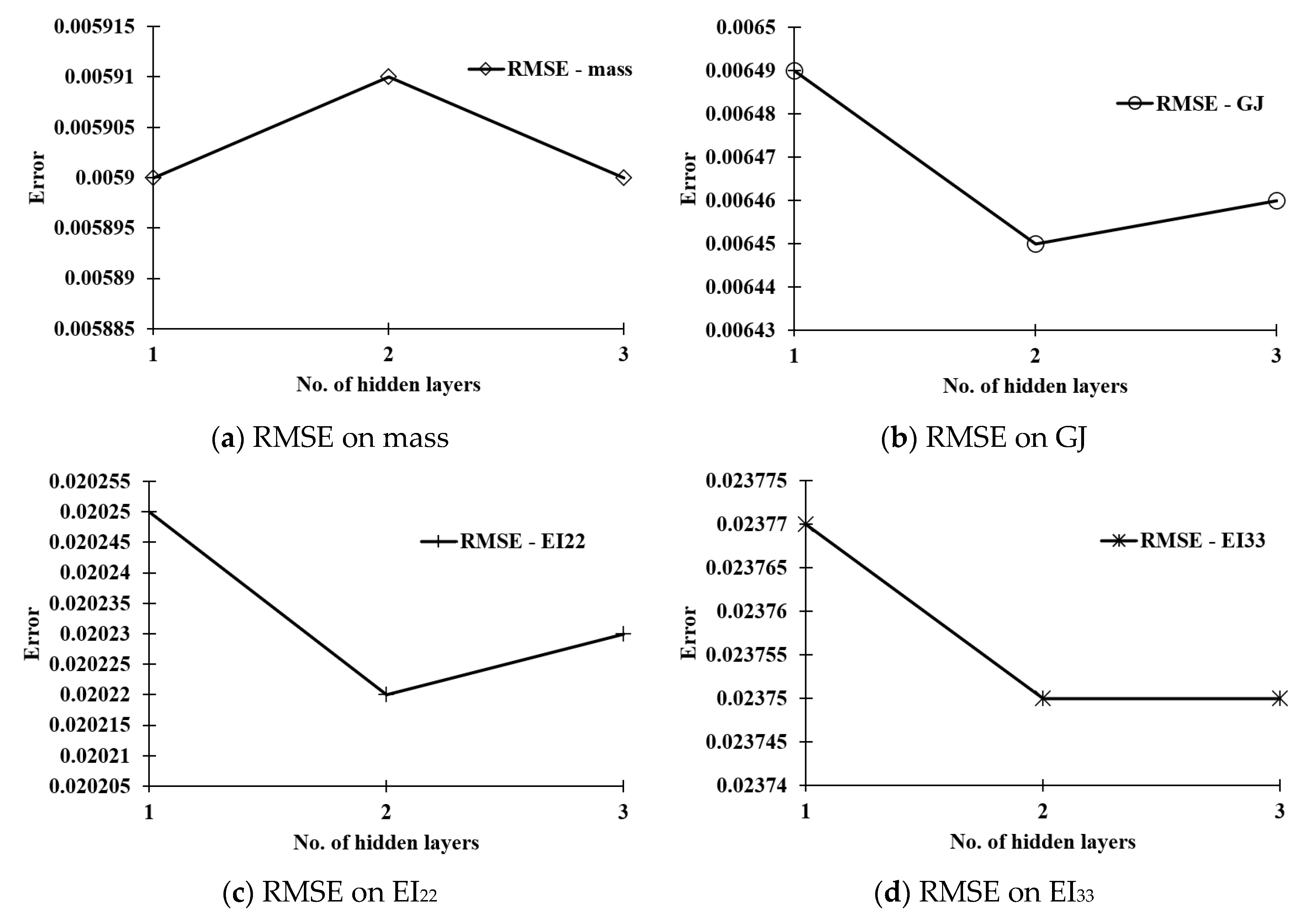

Among the learning parameters, the number of hidden layers were finally considered to evaluate the performance effects on the rotor blade design approximation. The error analyses were carried out applying one layer, two layers, and three layers to the RBFNN, respectively. In such those cases, 0.0 and 500 were applied in common for the SSP value and the number of training data. The results of RMSE and MAX were represented in

Table 6 and

Figure 18 and

Figure 19.

The results of

Table 6 and

Figure 18 represented that the RMSEs of Mass, GJ, EI

22, and EI

33 were distributed in the range of 0.00590 to 0.00591, 0.00645 to 0.00649, 0.02023 to 0.02025, and 0.02375 to 0.02377, respectively, according to the variation of hidden layer. The MAXs of Mass, GJ, EI

22, and EI

33 were distributed in the range of 0.02473 to 0.02491, 0.01567 to 0.01597, 0.09622 to 0.09627, and 0.09031 to 0.09041, respectively, as represented in

Table 6 and

Figure 19. It was found that the influence of the number of hidden layers on the accuracy of the meta-model in the rotor blade design was scarcely detected comparing with the SSP and the number of training data. Although the effect of the number of hidden layers on the accuracy of the meta-model was insignificant, the RMSEs for all the design performance functions tended to slightly improve as the number of hidden layers was increased. The MAX results were also similar to the RSME results in case of the variation of the number of hidden layers.

4. Closing Remarks

This study identified the effect of various learning parameters such as the range of SSP, the number of training data, and the number of hidden layers on performances of RBFNN meta-model with respect to the design approximation. The rotor blade design problems were considered to review the characteristics of RBFNN approximation according to the variation of the learning parameters.

The RBFNN based meta-models were generated for the rotor blade design as the actual design problem. In the actual design problem of rotor blade with a number of performance functions, both the error analysis and the statistical analysis were performed. In the error analysis, two accuracy measures (RMSE and MAX) were used to evaluate the performance of RBFNN. With 500 training data and 90 testing data, RBFNN based meta-models of the rotor blade were fitted for each design performance function. From the statistical analysis results of the rotor design problem, it was found that the design performances of rotor blade were increased as the D-spar thickness was increased and the web location was decreased. In the results of the statistical analysis, it was also confirmed that the most sensitive design variable on both the mass and the flap-wise bending stiffness was the D-spar thickness while the most sensitive design variable on the torsional and chord-wise bending stiffnesses was the web location.

In regard of the learning parameters variation, first the SSP values were varied from zero to 0.1 with 0.025 step size, secondly the initial number of 500 training data was varied up to 200 training data with 100 data step size, and finally the RBFNN architecture was composed of one layer, two layers, and three layers respectively. From the results of the error analysis on the rotor design problem, it was found that the number of training data had larger influence on the RBFNN meta-model accuracy than the SSP variation while the number of hidden layers had little effect on the performances of RBFNN meta-model. Although the influence of SSP was not significant in the RBFNN approximation of the actual rotor blade design problem, it could be seen that the accuracy of the approximation was increased based on RMSE as the SSP was applied in the range of 0.075 to 0.1. From the results of the number of training data in the rotor blade design approximation, it was able to conclude that the decrement of less than 100 times of number of design variables for the number of training data showed the inferior accuracy due to insufficient learning data for the RBFNN meta-model. It was also found that RMSEs for all the design performance functions were enhanced as the number of training data was increased in the rotor blade design approximation. Regarding to the number of hidden layers, it was found that the influence of the number of hidden layers on the accuracy of the meta-model in the rotor blade design was scarcely detected comparing with the SSP and the number of training data. Although the effect of the number of hidden layers on the accuracy of the meta-model was insignificant, the RMSEs for all the design performance functions tended to slightly improve as the number of hidden layers was increased. This study results can help to suggest a reference index that can reasonably apply the learning parameter value in case of adopting the RBFNN to the design approximation.

Even though the RBFNN meta-model was utilized for the design optimizations and the reliability analyses, the role of learning parameters in the RBFNN meta-model was hardly investigated in the design approximation. In most previous studies, the values of parameters in RBFNN meta-model have been applied empirically or adjusted through simple estimation of the accuracy of RBFNN meta-model or comparison with the results of other meta-models. From this study results, the role of the important learning parameters such as the SSP, the number of training data, and the number of hidden layers was identified quantitatively using the rotor blade design problem. It was also clearly confirmed that the number of training data had larger influence on the RBFNN meta-model accuracy than the SSP variation while the number of hidden layers had little effect on the accuracy of RBFNN meta-model in the rotor blade design.

Author will carry out the application of RBFNN meta-model to some deep multi-modal practical design and multidisciplinary design problems in further study.