Compressive and Diagonal Tension Strengths of Masonry Prisms Strengthened with Amorphous Steel Fiber-Reinforced Mortar Overlay

Abstract

1. Introduction

2. Experimental Program

2.1. Test Setup and Instrumentation

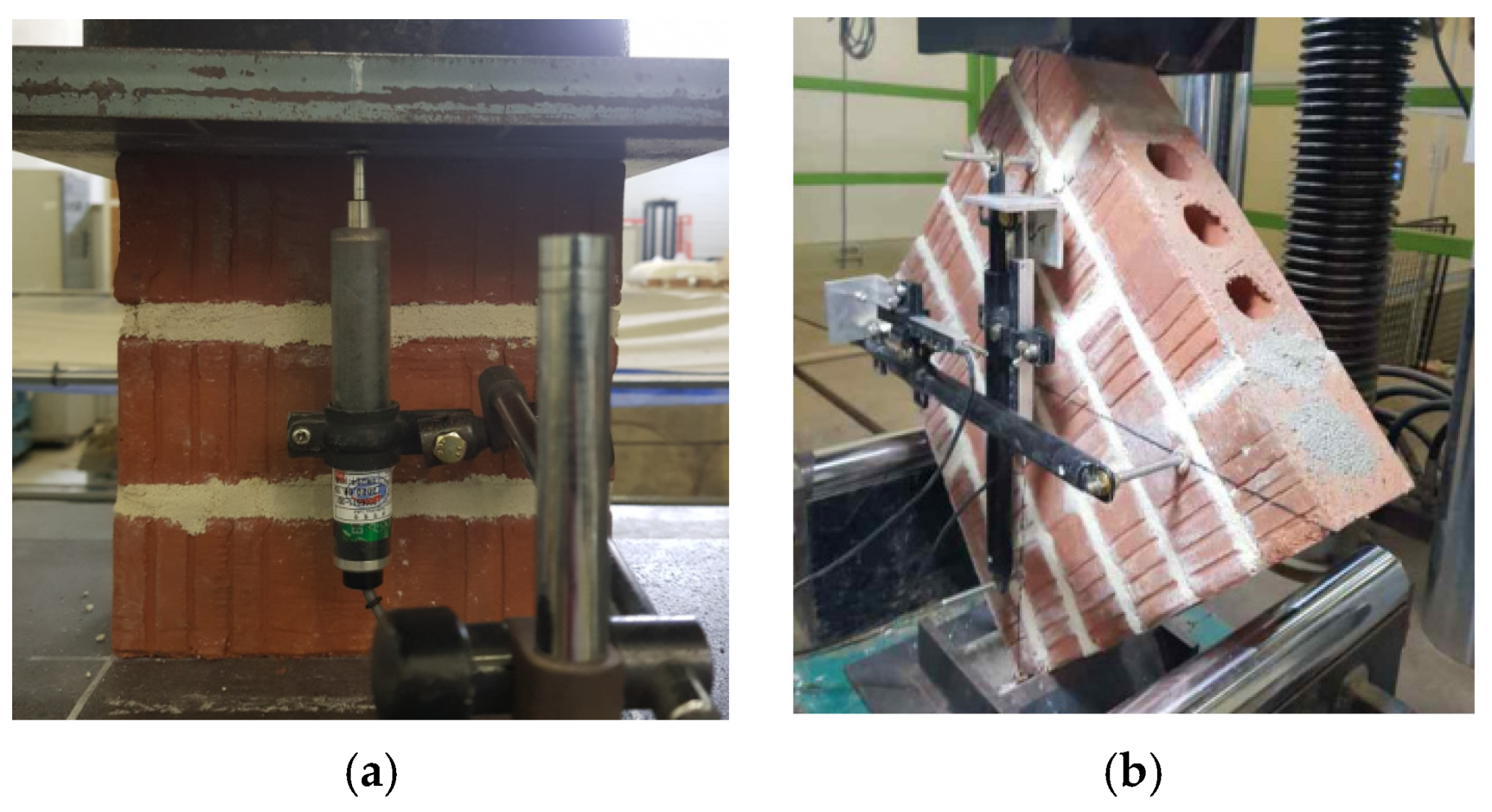

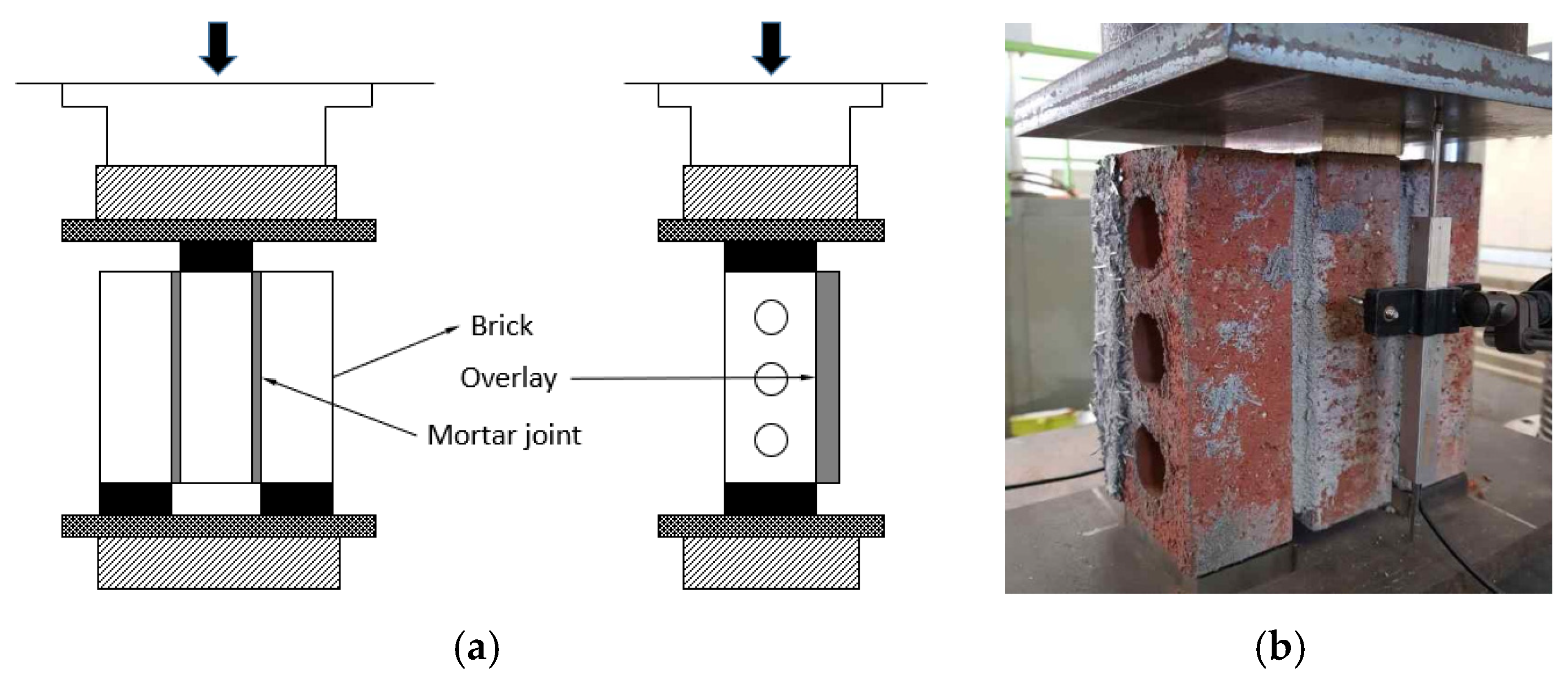

2.1.1. Test for Compressive and Diagonal Tension Strength

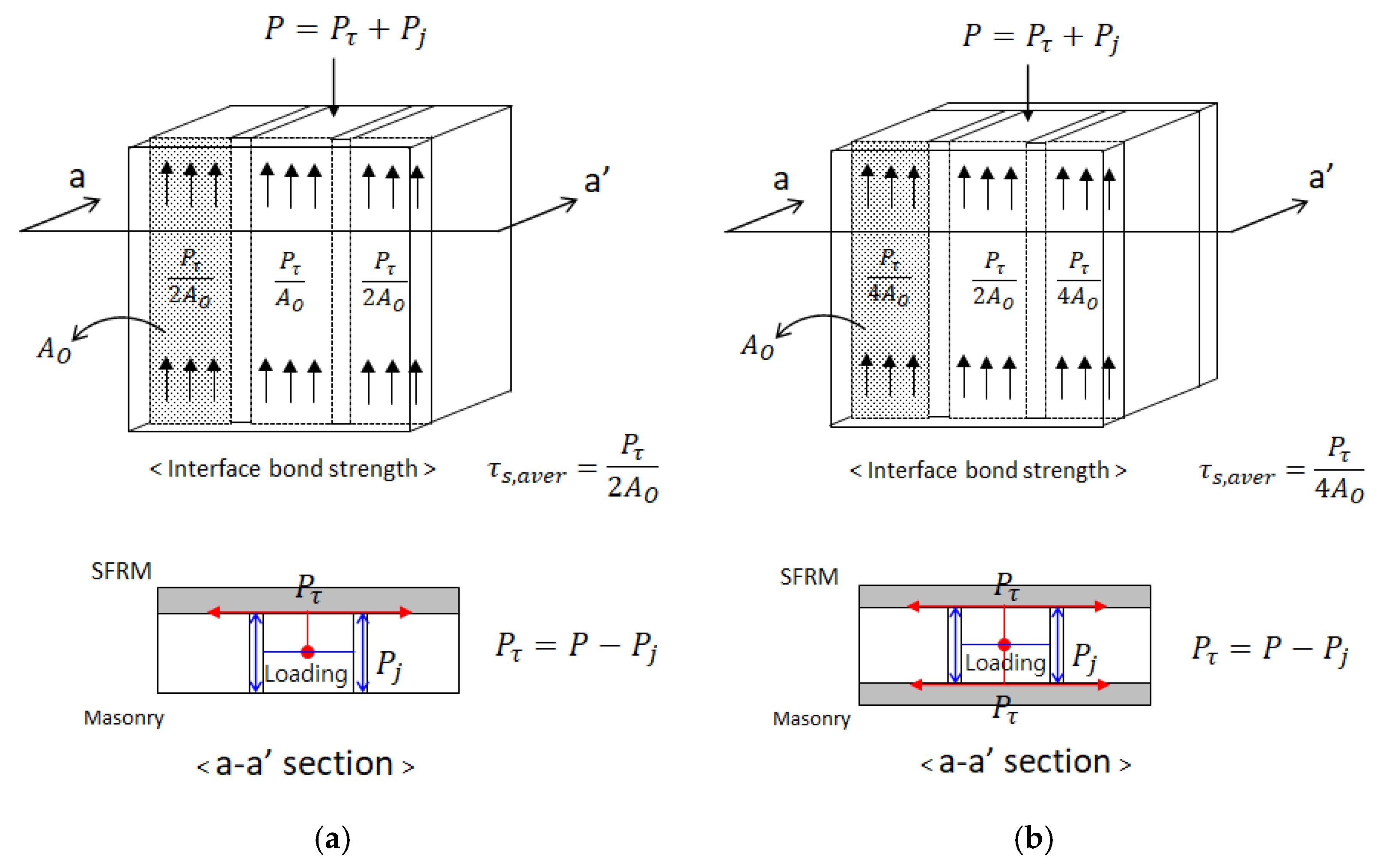

2.1.2. Test for Bond Strength

2.2. Test Variables and Characteristics of Specimens

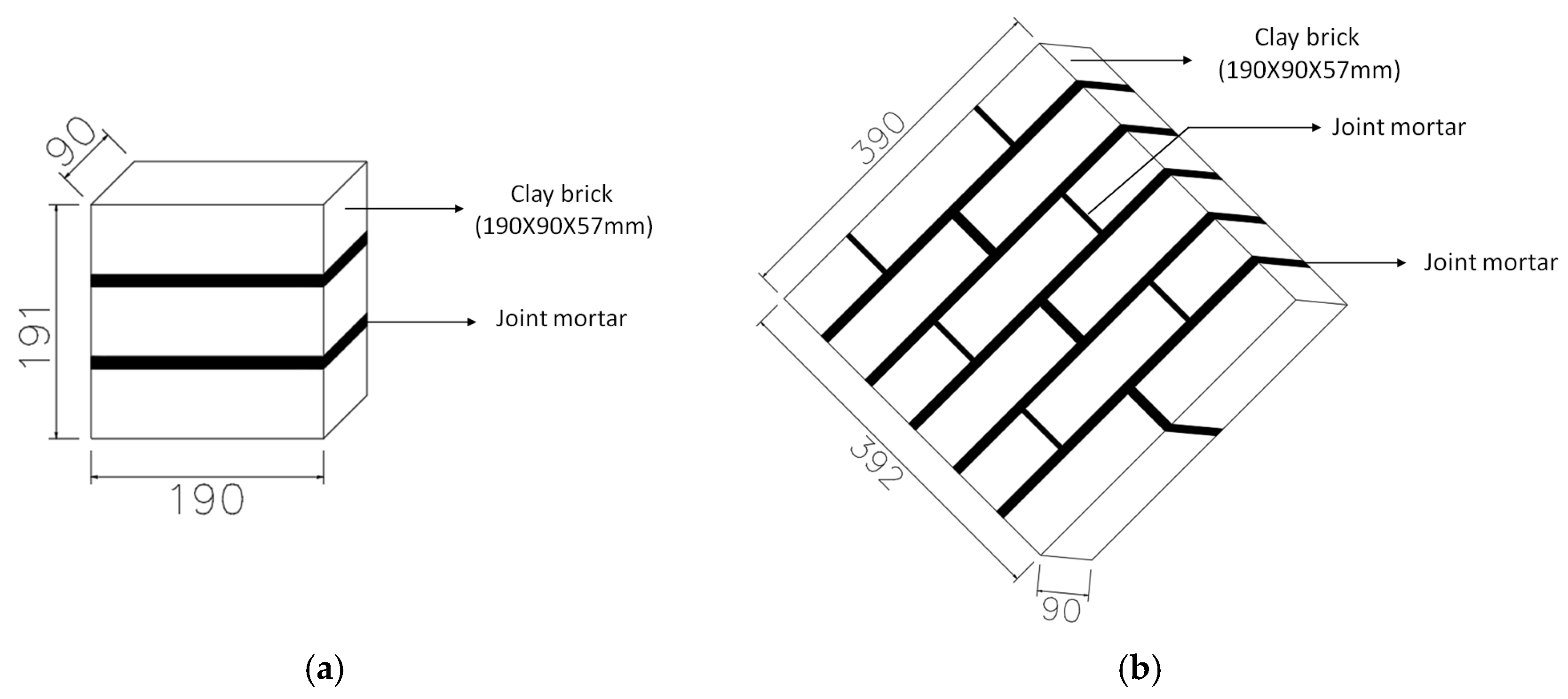

2.2.1. Test for Compressive and Diagonal Tension Strengths

2.2.2. Test for Bond Strength

2.3. Preparation of Specimens

2.3.1. Mixing Ratio of ASFRM

2.3.2. Masonry Prisms

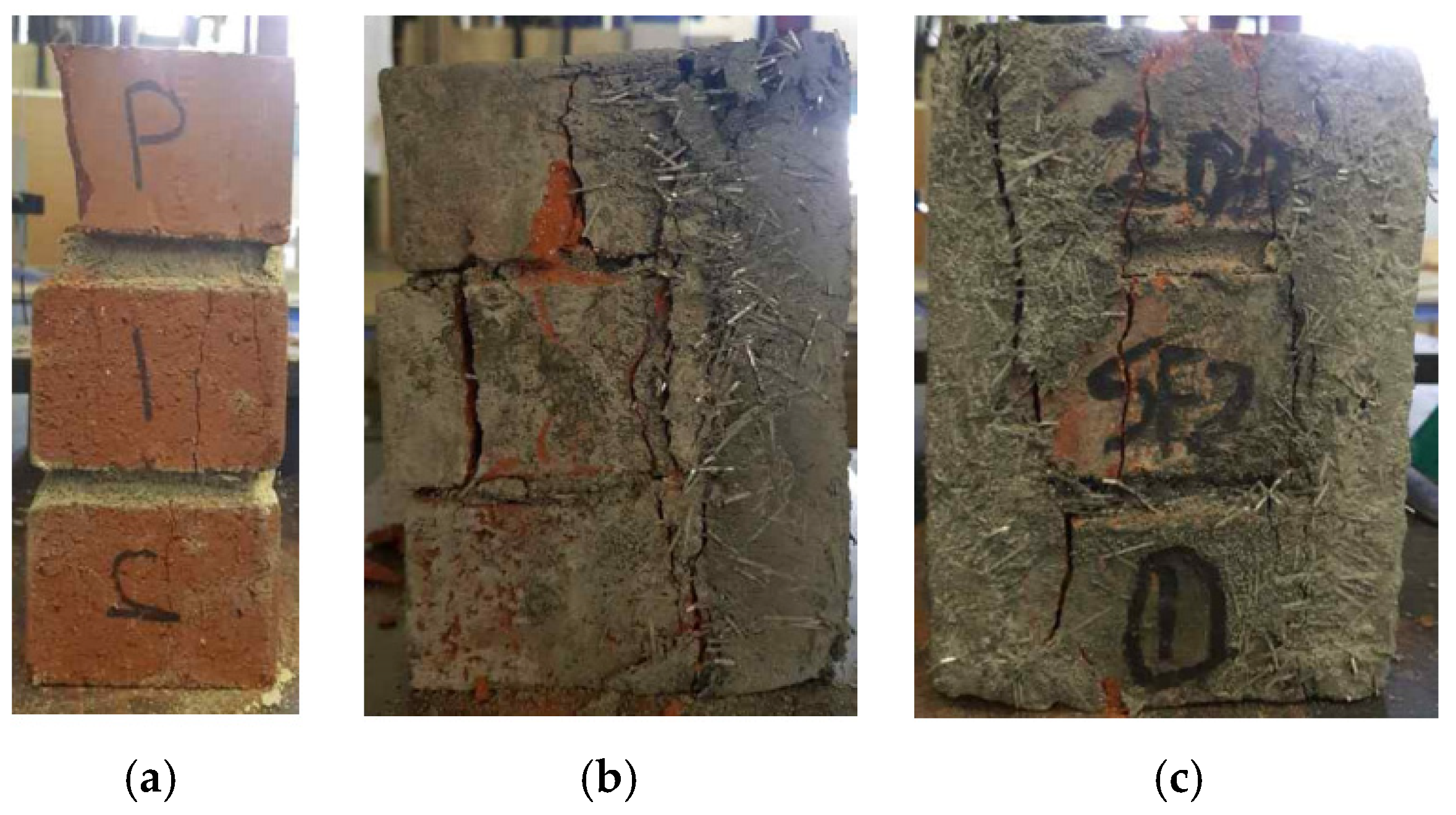

2.3.3. Strengthened Masonry Prisms

3. Test Results

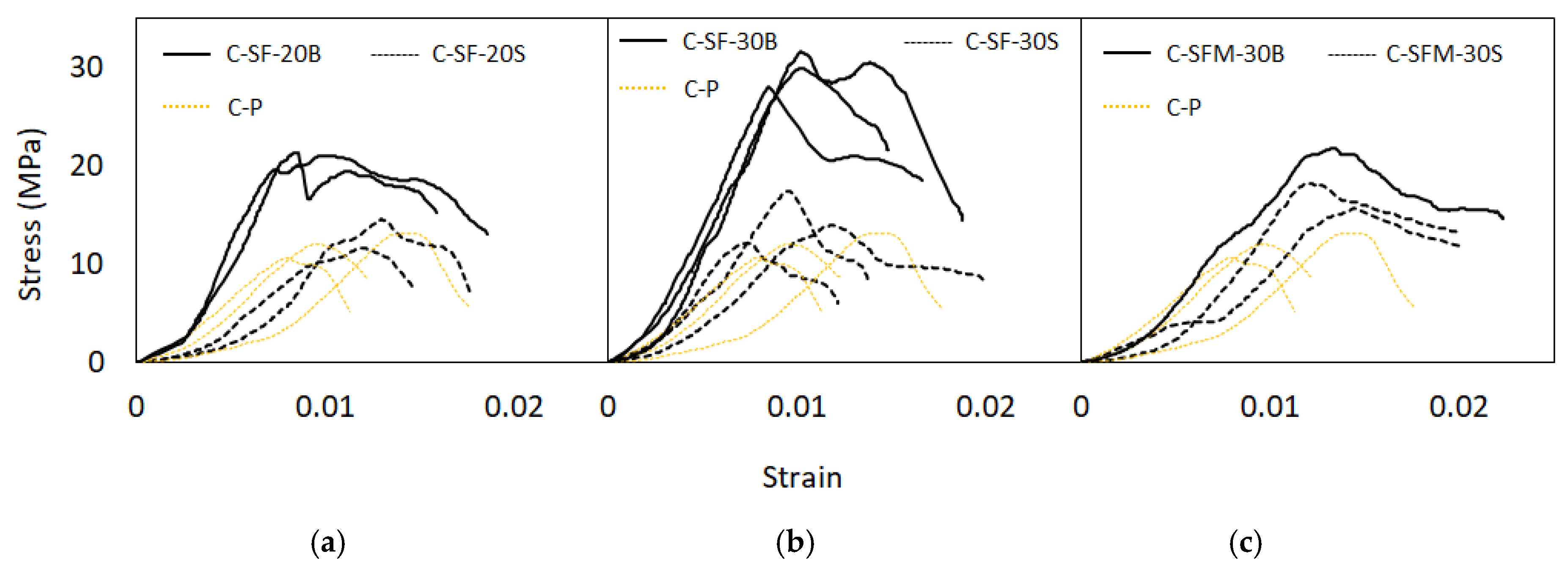

3.1. Test for Compressive Strength

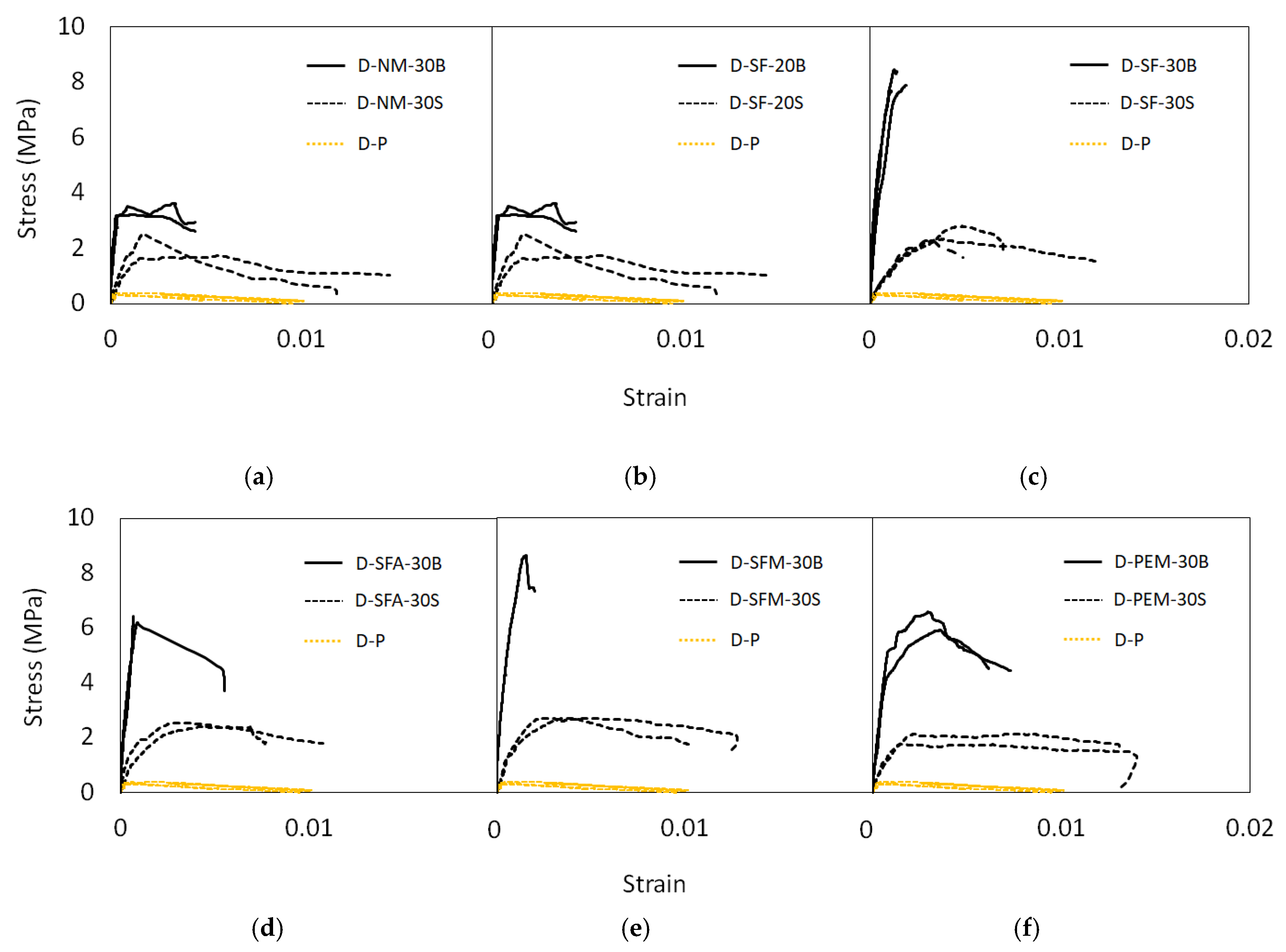

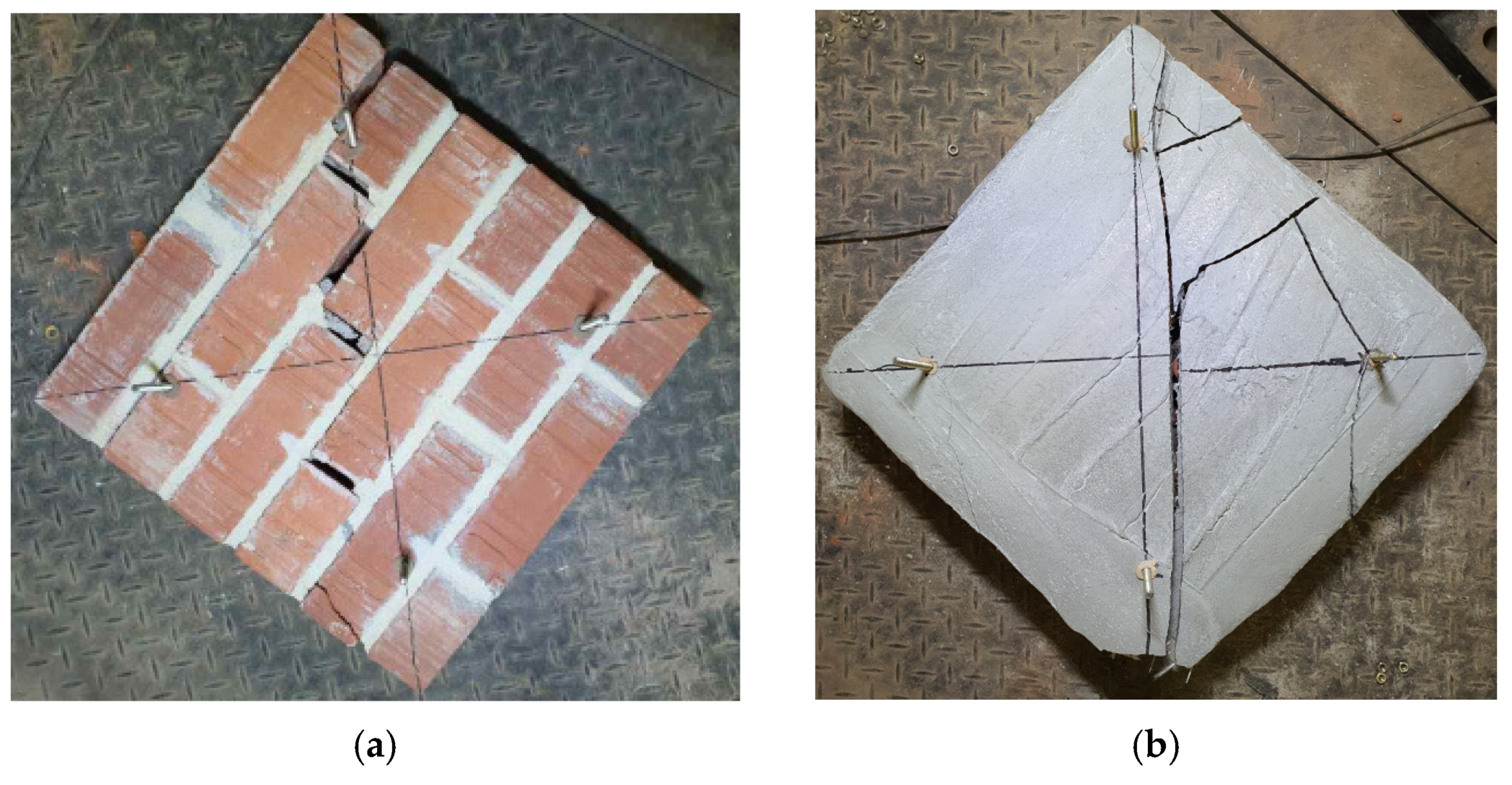

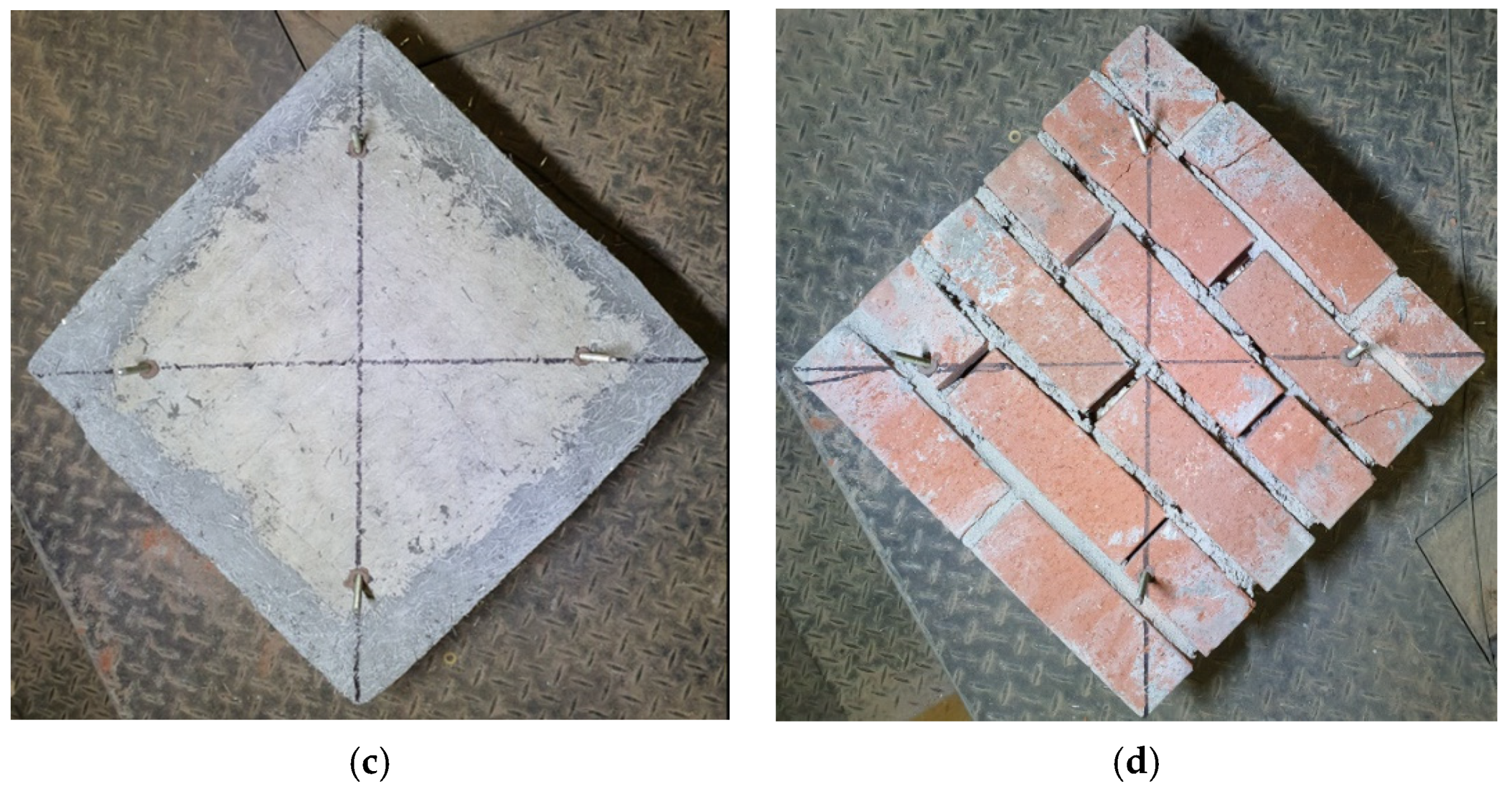

3.2. Test for Diagonal Tension Strength

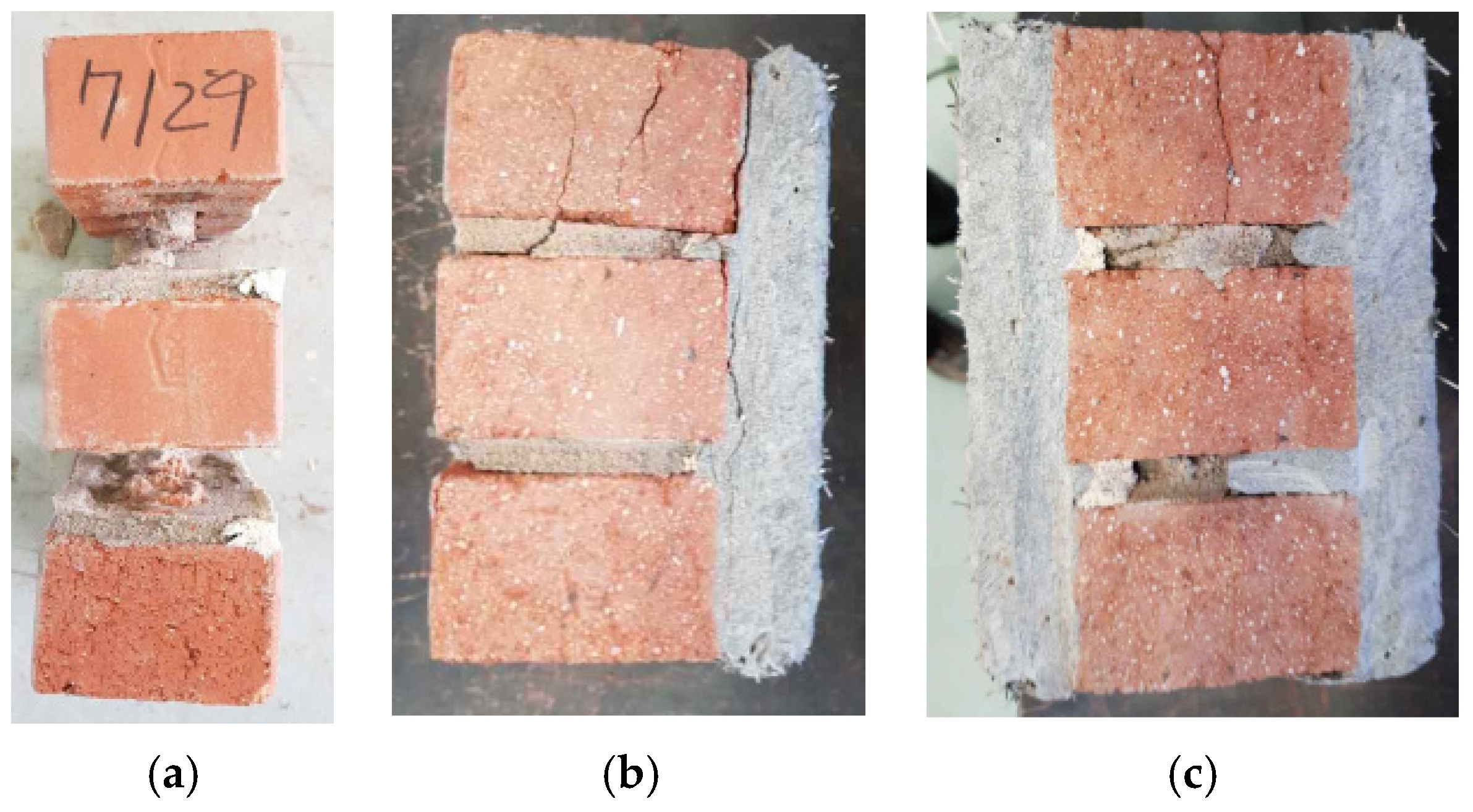

3.3. Test for Bond Strength

4. Design Equations for Strengthening with ASFRM Overlay

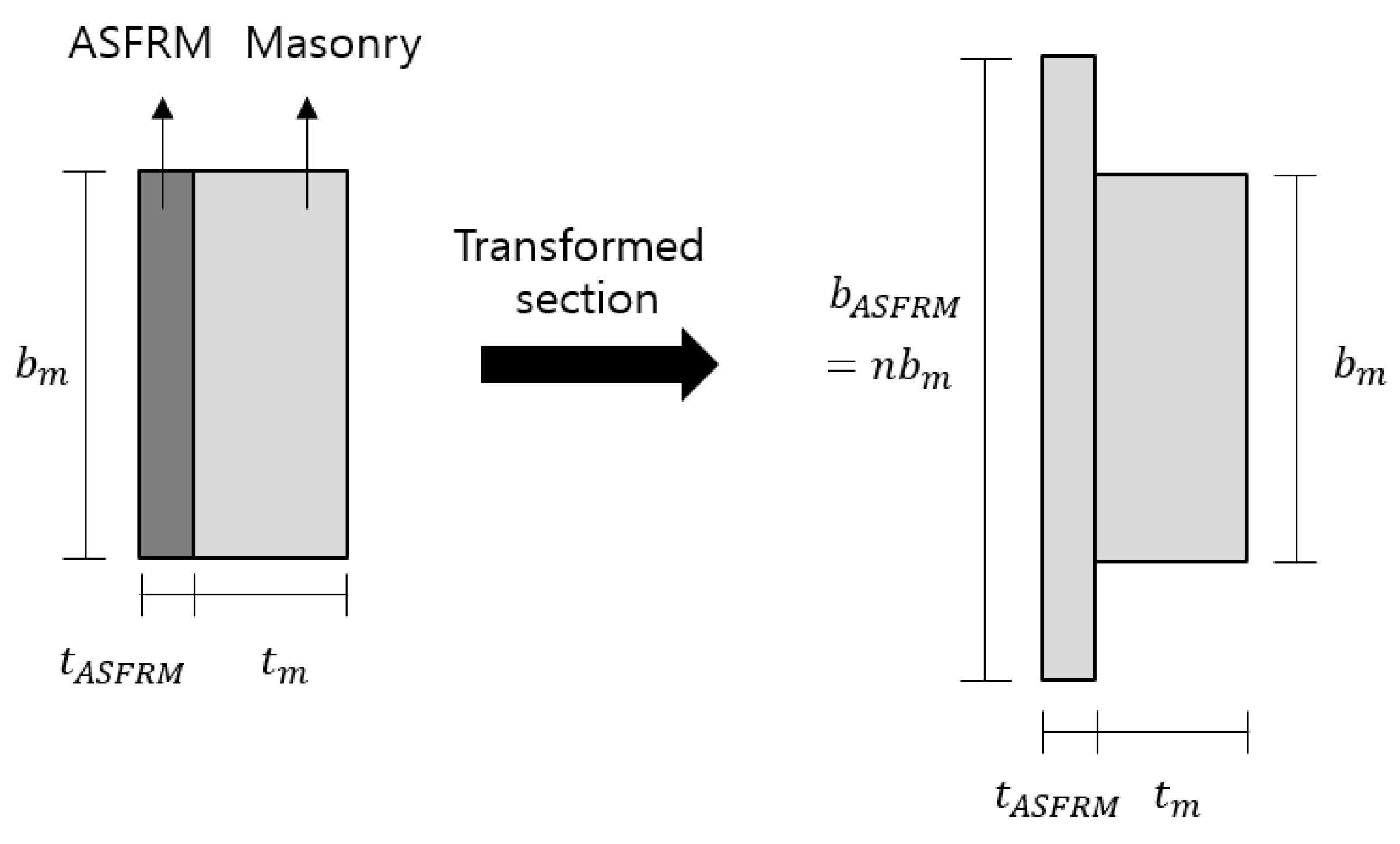

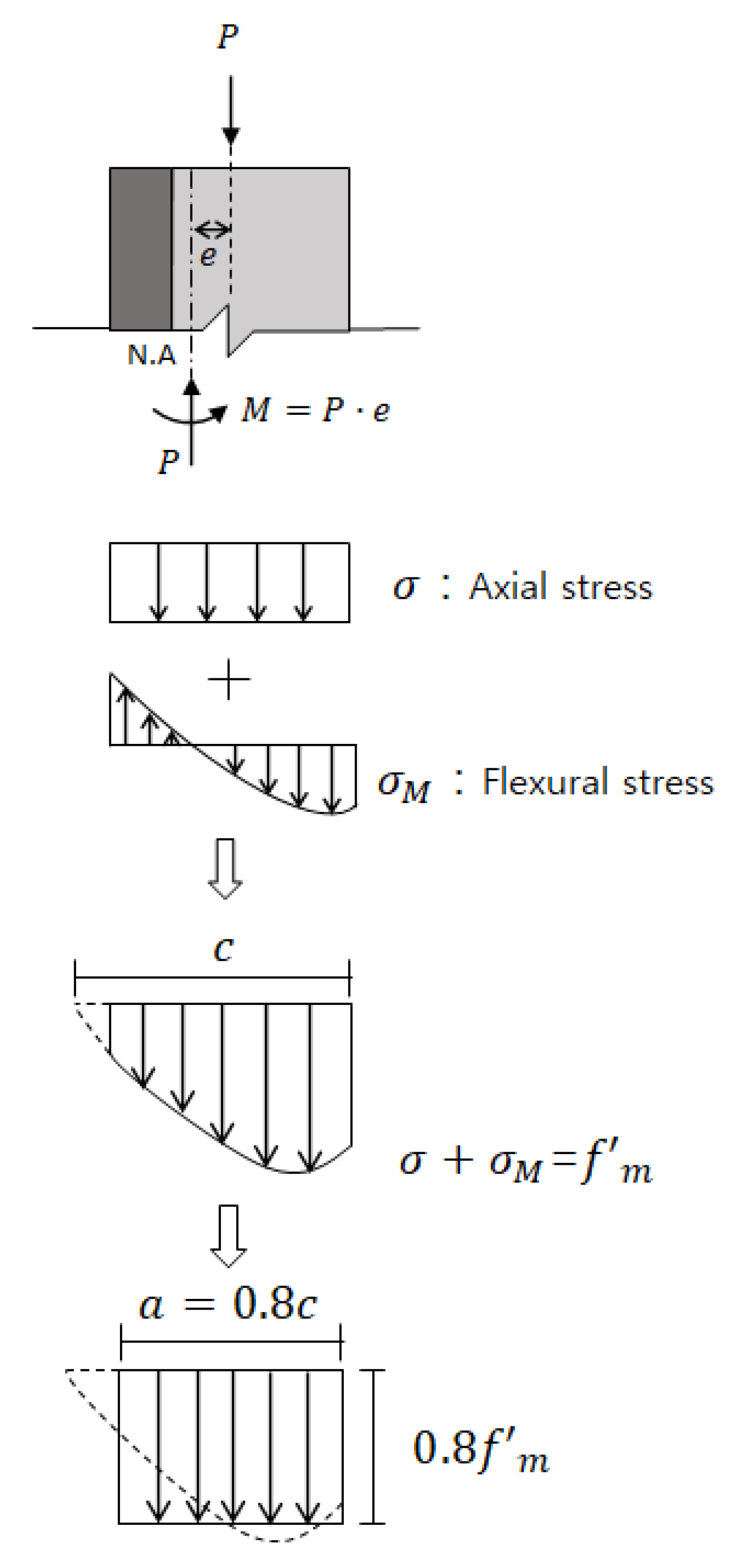

4.1. Design Equations for Compressive Strength

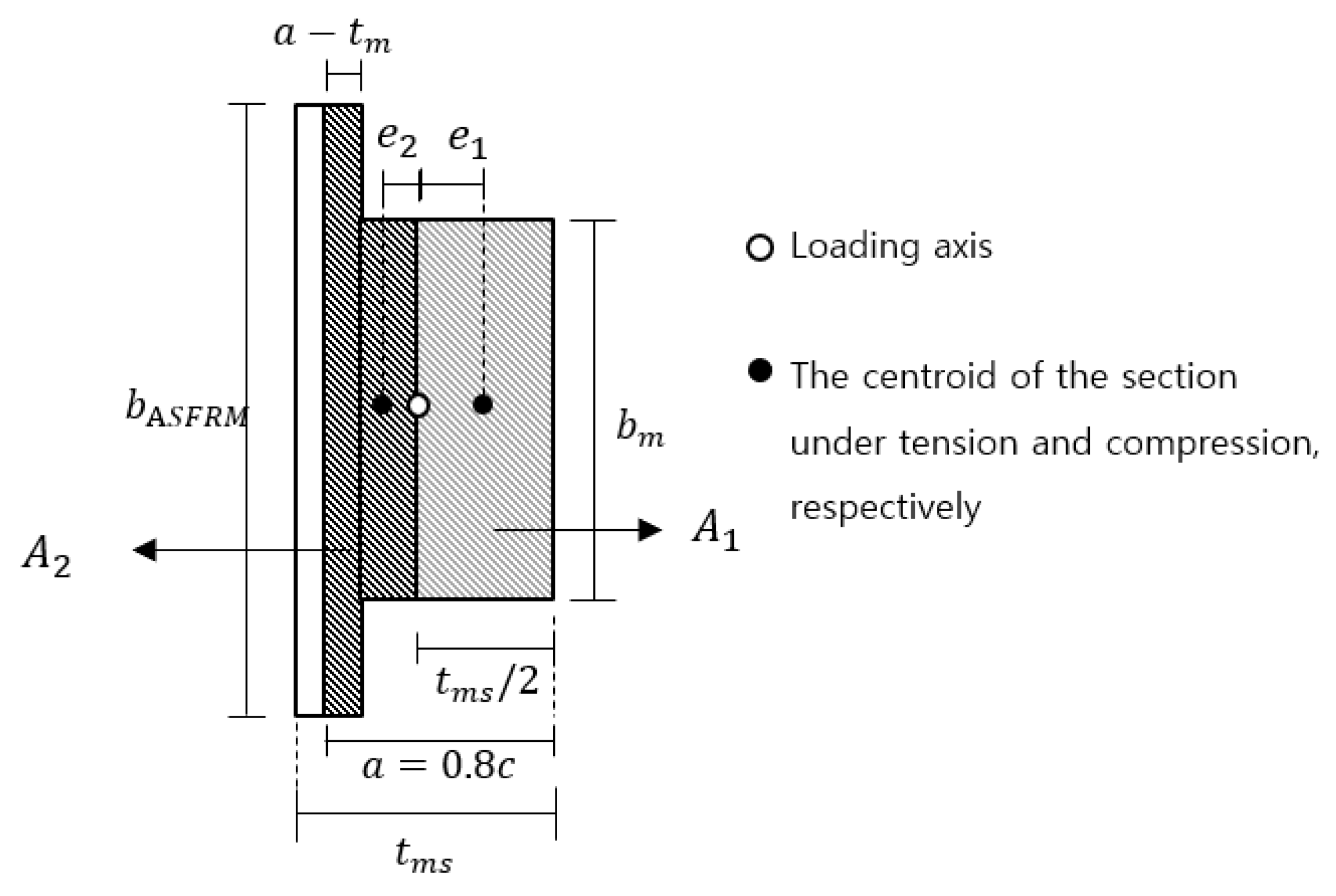

4.1.1. Strengthening on One Side

4.1.2. Strengthening on Both Sides

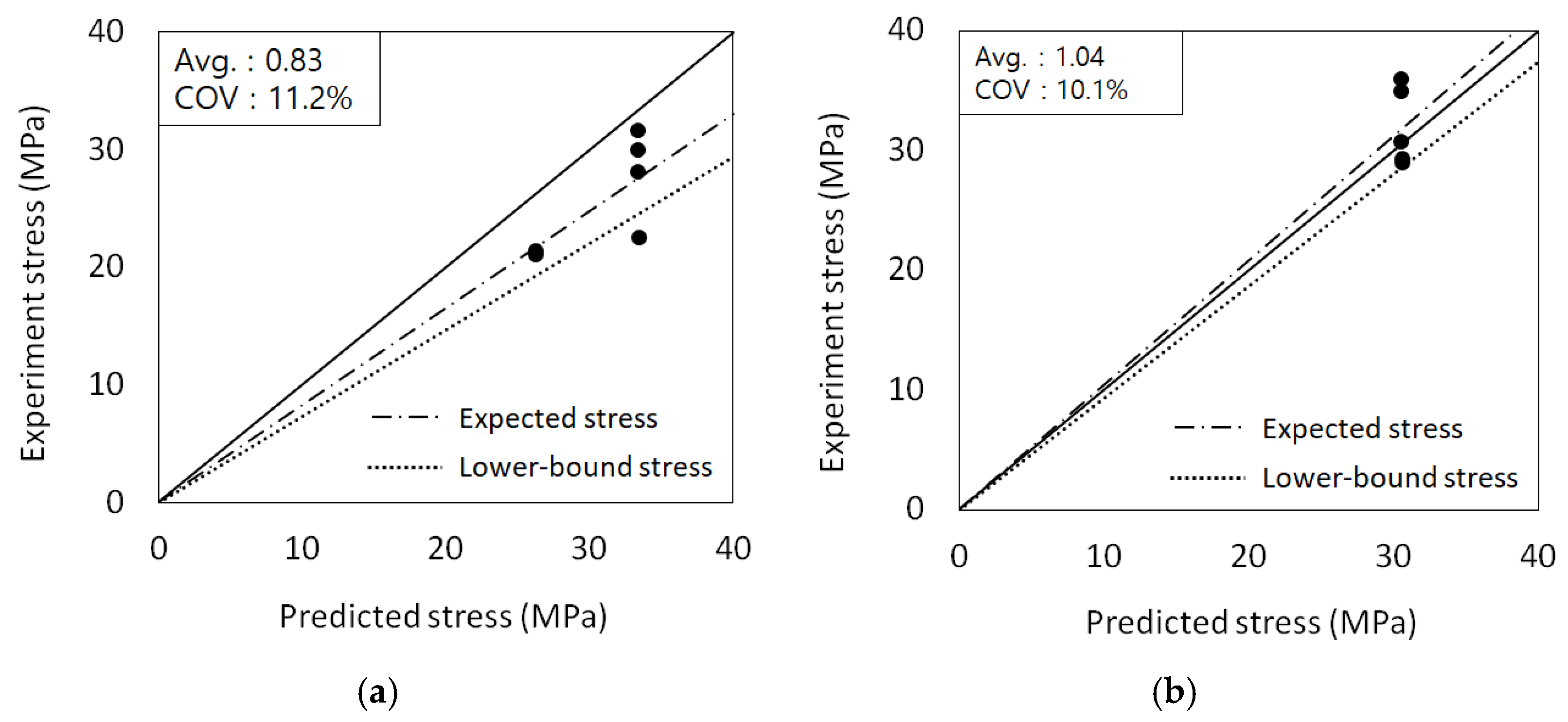

4.2. Design Equations for Diagonal Tension Strength

4.3. Applicability to Seismic Retrofit Design

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Notation

| Cross-sectional area for the ASFRM overlay | |

| Cross-sectional area of the masonry layer in a strengthened prism | |

| Interface area between the adjacent masonry units | |

| Area located on the left-hand side of the loading axis in a masonry prism under compression | |

| Area located on the right-hand side of the loading axis in a masonry prism under compression | |

| Equivalent stress block depth | |

| Width of the masonry layer | |

| Elastic modulus of ASFRM | |

| Elastic modulus of a bare prism | |

| Distance from the loading axis to the centroids of | |

| Distance from the loading axis to the centroids of | |

| Elastic modulus ratio | |

| Number of strengthened sides on the masonry prism | |

| Total load in the compression test | |

| Compressive resistance by the ASFRM overlay in the strengthened prism | |

| Load shared by the overlay-to-masonry interface | |

| Compressive resistance by the masonry layer in the strengthened prism | |

| Total compressive resistance of the strengthened masonry prism | |

| Load shared by the overlay-to-masonry interface | |

| Expected strength | |

| Nominal strength predicted by the proposed design equation | |

| Lower bound strength | |

| Diagonal tension strength of the ASFRM | |

| Expected diagonal tension strength for the strengthened masonry prism | |

| Upper bound to the diagonal tension strength | |

| Upper bound to the diagonal tension strength for the specimen strengthened on a single side | |

| Upper bound to the diagonal tension strength for the specimen strengthened on both sides | |

| Diagonal tension strength for the bare masonry prism obtained from tests | |

| Standard deviation of the test strength-over-nominal strength ratio for individual specimen | |

| Thickness of the masonry layer | |

| Thickness of the strengthened masonry prism | |

| Standard deviation of the test strength-over-nominal strength ratio for individual specimen | |

| Fraction of the compressive resistance by the masonry layer over the total resistance | |

| Ultimate strain of the masonry layer | |

| Normal stress in the section of the masonry prism | |

| Compressive strength for the strengthened masonry prism | |

| Flexural stress in a section of the masonry prism | |

| Compressive strength for the bare masonry prism | |

| Average bond strength between the ASFRM and masonry layer | |

| Bond strength at the overlay-to-masonry interface for strengthening on both sides | |

| Bond strength at the overlay-to-masonry interface for strengthening on a single side | |

| Peak bond stress |

References

- FEMA P-774. Unreinforced Masonry Buildings and Earthquakes; FEMA: Washington, DC, USA, 2009.

- Doğangün, A.; Ural, A.; Livaoğlu, R. Seismic performance of masonry buildings during recent earthqukes in Turkey. In Proceedings of the 14th World Conference on Earthquake Engineering (14WCEE), Beijing, China, 12–17 October 2008; pp. 1–8. [Google Scholar]

- D’Altri, A.M.; Sarhosis, V.; Milani, G.; Rots, J.; Cattari, S.; Lagomarsino, S.; Sacco, E.; Tralli, A.; Castellazzi, G.; Miranda, S. Modeling strategies for the computational analysis of unreinforced masonry structures: Review and classification. Arch. Comput. Methods Eng. 2020, 27, 1153–1185. [Google Scholar] [CrossRef]

- Korumaz, M.; Betti, M.; Conti, A.; Tucci, G.; Bartoli, G.; Bonora, V.; Korumaz, A.G.; Fiorini, L. An integrated Terrestrial Laser Scanner (TLS), Deviation Analysis (DA) and Finite Element (FE) approach for health assessment of historical structures. A minaret case study. Eng. Struct. 2017, 153, 224–238. [Google Scholar] [CrossRef]

- Funari, M.F.; Spadea, S.; Lonetti, P.; Fabbrocino, F.; Luciano, R. Visual programming for structural assessment of out-of-plane mechanisms in historic masonry structures. J. Build. Eng. 2020, 31, 101425. [Google Scholar] [CrossRef]

- Yang, K.H.; Mun, J.H.; Hwang, S.H. Cyclic shear behavior of masonry walls strengthened with prestressed steel bars and glass fiber grids. Compos. Struct. 2020, 238, 1–12. [Google Scholar] [CrossRef]

- Ismail, N.; Petersen, R.B.; Masia, M.J.; Ingham, J.M. Diagonal shear behavior of unreinforced masonry wallettes strengthened using twisted steel bars. Constr. Build. Mater. 2011, 25, 4386–4393. [Google Scholar] [CrossRef]

- Silva, B.; Benetta, M.D.; da Porto, F.; Modena, C. Experimental assessment of in-plane behaviour of three-leaf stone masonry walls. Constr. Build. Mater. 2014, 53, 149–161. [Google Scholar] [CrossRef]

- Taghdi, M.; Bruneau, M.; Saatcioglu, M. Seismic retrofitting of low-rise masonry and concrete walls using steel strips. ASCE J. Struct. Eng. 2000, 126, 1017–1025. [Google Scholar] [CrossRef]

- Darbhanzi, A.; Marefat, M.S.; Khanmohammadi, M. Investigation of in-plane seismic retrofit of unreinforced masonry walls by means of vertical steel ties. Constr. Build. Mater. 2014, 52, 122–129. [Google Scholar] [CrossRef]

- Ghiassi, B.; Marcari, G.; Oliveira, D.V.; Lourenço, P.B. Numerical analysis of bond behavior between masonry bricks and composite materials. Eng. Struct. 2012, 43, 210–220. [Google Scholar] [CrossRef]

- Bae, B.I.; Yun, H.J.; Choi, C.S.; Choi, H.K. Evaluation of shear strength of unreinforced masonry walls retrofitted by fiber reinforced polymer sheet. J. Korea Concr. Inst. 2012, 24, 305–313. [Google Scholar] [CrossRef][Green Version]

- Choi, H.K.; Bae, B.I.; Choi, C.S. Lateral resistance of unreinforced masonry walls strengthened with engineering cementitious composite. Int. J. Civil. Eng. Korea 2016, 14, 411–424. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Mezzi, M.; Caporale, A. Experimental investigation on polymeric net-RCM reinforced masonry panels. Compos. Struct. 2013, 105, 207–215. [Google Scholar] [CrossRef]

- Almeida, J.A.P.P.; Pereira, E.N.B.; Barros, J.A.O. Assessment of overlay masonry strengthening system under in-plane monotonic and cyclic loading using the diagonal tensile test. Constr. Build. Mater. 2015, 94, 851–865. [Google Scholar] [CrossRef]

- Mustafaraj, E.; Yardim, Y. In-plane shear strengthening of unreinforced masonry walls using GFRP jacketing. Period. Polytech. Civ. Eng. 2018, 62, 330–336. [Google Scholar] [CrossRef]

- Benedetti, A. In plane behaviour of masonry walls reinforced with mortar coatings and fibre meshes. Int. J. Archit. Herit. 2019, 13, 1029–1041. [Google Scholar] [CrossRef]

- Kreivakais, T. Experimental study on carbon fiber textile reinforced mortar system as a means for confinement of masonry columns. Constr. Build. Mater. 2019, 208, 723–733. [Google Scholar] [CrossRef]

- Ombres, L.; Verre, S. Analysis of the Behavior of FRCM Confined Clay Brick Masonry Columns. Fibers 2020, 8, 11. [Google Scholar] [CrossRef]

- Yu, J.-H.; Park, J.-H. Investigation of Steel Fiber-Reinforced Mortar Overlay for Strengthening Masonry Walls by Prism Tests. Appl. Sci. 2020, 10, 6395. [Google Scholar] [CrossRef]

- Yu, J.H.; Myeong, S.J.; Park, J.H. Enhancement of compressive and shear strength for concrete masonry prisms with steel fiber-reinforced mortar overlay. J. Earthq. Eng. Soc. Korea 2021, 25, 21–32. [Google Scholar] [CrossRef]

- Yu, J.H. Retrofit Effects of Steel Fiber-Reinforced Mortar Plastered on Unreinforced Masonry Walls. Master’s Degree, Incheon National University, Incheon, Korean, 2021. [Google Scholar]

- ASTM C1314. Standard Test Method for Compressive Strength of Masonry Prisms; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM E519/E519M. Standard Test Method for Diagonal Tension (Shear) in Masonry Assemblages; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Lee, S.K.; Ju, Y.K.; Lee, S.S.; Song, H.Y. A study on the dynamic and durability properties of high-ductile mortar using reinforced fiber. J. Reg. Assoc. Archit. Inst. Korea 2008, 1, 931–936. [Google Scholar]

- Korea Construction Standards 41 16 01. Plaster Work; Ministry of Land, Infrastructure and Transport: Seoul, Korea, 2018.

- ASCE 41-17. Seismic Evaluation and Retrofit of Existing Buildings; ASCE: Reston, VA, USA, 2017. [Google Scholar]

- TMS 402. Building Code Requirements for Masonry Structures; The Masonry Society: Longmont, CO, USA, 2012. [Google Scholar]

| Type of Test | FRM Overlay | Fibers | Glass Fiber Mesh | Shear Connector | Overlay Thickness | Specimen Name 1 | Number of Specimens |

|---|---|---|---|---|---|---|---|

| Compressive | - | - | - | - | - | C-P | 3 |

| One side | ASF | - | - | 20 | C-SF-20S | 2 | |

| - | - | 30 | C-SF-30S | 3 | |||

| O | - | 30 | C-SFM-30S | 2 | |||

| Two sides | ASF | - | - | 20 | C-SF-20B | 2 | |

| - | - | 30 | C-SF-30B | 3 | |||

| O | - | 30 | C-SFM-30B | 1 | |||

| Diagonal tension | - | - | - | - | - | D-P | 3 |

| One side | - | O | - | 30 | D-NM-30S | 2 | |

| ASF | - | - | 20 | D-SF-20S | 2 | ||

| - | - | 30 | D-SF-30S | 3 | |||

| - | O | 30 | D-SFA-30S | 2 | |||

| O | - | 30 | D-SFM-30S | 2 | |||

| PE | O | - | 30 | D-PEM-30S | 2 | ||

| Two sides | - | O | - | 30 | D-NM-30B | 2 | |

| ASF | - | - | 20 | D-SF-20B | 2 | ||

| - | - | 30 | D-SF-30B | 3 | |||

| - | O | 30 | D-SFA-30B | 2 | |||

| O | - | 30 | D-SFM-30B | 2 | |||

| PE | O | - | 30 | D-PEM-30B | 2 |

| Type of the Brick | Number of Specimens | ||

|---|---|---|---|

| B-P (Plain) | B-SF-30S (One-Side Overlay) | B-SF-30B (Two-Side Overlay) | |

| Clay brick | 3 | 3 | 3 |

| Fiber | Cement: Sand 1 | W/C (%) 2 | Fiber Volume Fraction (%) 3 | Strength (MPa) | Modulus of Elasticity (MPa) | |

|---|---|---|---|---|---|---|

| Compressive | Tensile | |||||

| ASF | 1:1 | 35 | 2.0 | 63 | 7.7 | 9260 |

| PE | 1:1 | 38 | 2.0 | 49 | 3.8 | 7843 |

| Specimens | Average | Rate of Increase (%) | |||

|---|---|---|---|---|---|

| Peak Load (kN) | Compressive Strength (MPa) | (MPa) | Compressive Strength | ||

| C-P | 204 | 11.9 | 1780 | - | - |

| C-SF-20S | 227 | 13.3 | 1980 | 11.8 | 11.2 |

| C-SF-30S | 248 | 14.5 | 2250 | 21.8 | 26.4 |

| C-SFM-30S | 290 | 16.9 | 2040 | 42 | 14.6 |

| C-SF-20B | 364 | 21.3 | 3950 | 79 | 121.9 |

| C-SF-30B | 511 | 29.8 | 3790 | 150 | 112.9 |

| C-SFM-30B | 385 | 22.5 | 2600 | 89.1 | 46.1 |

| Specimens | Average | Rate of Increase (%) | |||

|---|---|---|---|---|---|

| Peak Load (kN) | Diagonal Tension Strength (MPa) | (MPa) | Diagonal Tension Strength | ||

| D-P | 11.9 | 0.29 | 1410 | - | - |

| D-NM-30S | 87.2 | 2.11 | 2210 | 628 | 56.7 |

| D-SF-20S | 96.7 | 2.34 | 3690 | 707 | 162 |

| D-SF-30S | 102 | 2.47 | 1920 | 752 | 36.2 |

| D-SFA-30S | 102 | 2.46 | 2840 | 748 | 101 |

| D-SFM-30S | 111 | 2.7 | 2340 | 831 | 66 |

| D-PEM-30S | 80.2 | 1.94 | 1870 | 569 | 32.6 |

| D-NM-30B | 141 | 3.41 | 10,000 | 1080 | 609 |

| D-SF-20B | 212 | 5.13 | 6940 | 1670 | 392 |

| D-SF-30B | 330 | 8.0 | 14,100 | 2660 | 900 |

| D-SFA-30B | 260 | 6.3 | 10,800 | 2070 | 666 |

| D-SFM-30B | 265 | 6.41 | 8260 | 2110 | 486 |

| D-PEM-30B | 257 | 6.23 | 6230 | 2050 | 342 |

| Type of Bricks | Specimen | Maximum Load (kN) | ||

|---|---|---|---|---|

| B-P (Plain) | B-SF-30S (One-Side Overlay) | B-SF-30B (Two-Side Overlay) | ||

| Clay brick | 1 | 15.3 | 33.5 | 55 |

| 2 | 17.3 | 27.3 | 52.8 | |

| 3 | 20.1 | 38.6 | 59.7 | |

| Average | 17.6 | 33.1 | 55.8 | |

| Type of Bricks | B-SF-30S (One-Side Overlay) | B-SF-30B (Two-Side Overlay) | ||

|---|---|---|---|---|

| Interface Bond Load (kN) | (MPa) | Interface Bond Load (kN) | (MPa) | |

| Red clay | 15.6 | 0.716 | 38.3 | 0.884 |

| Concrete [22] | 11.7 | 0.540 | 53.0 | 1.22 |

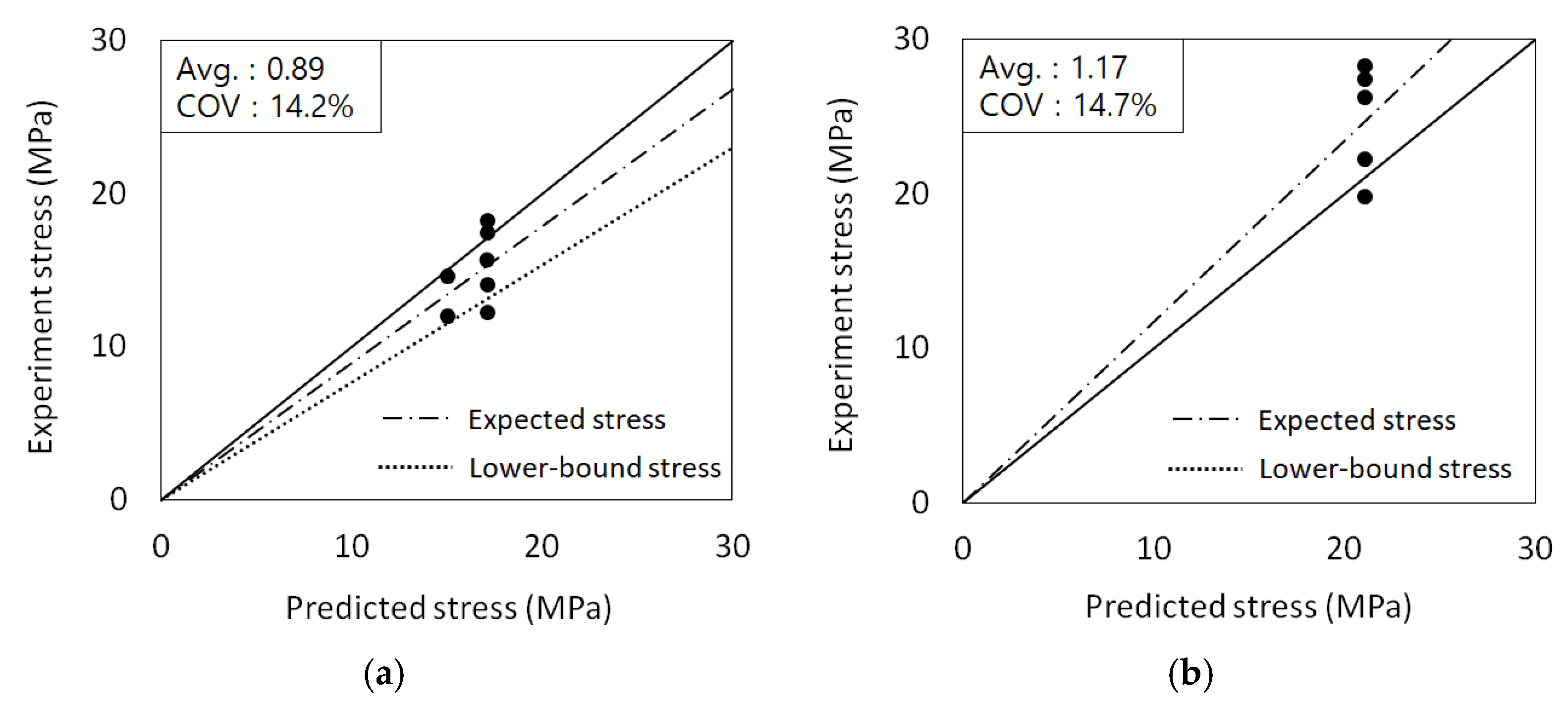

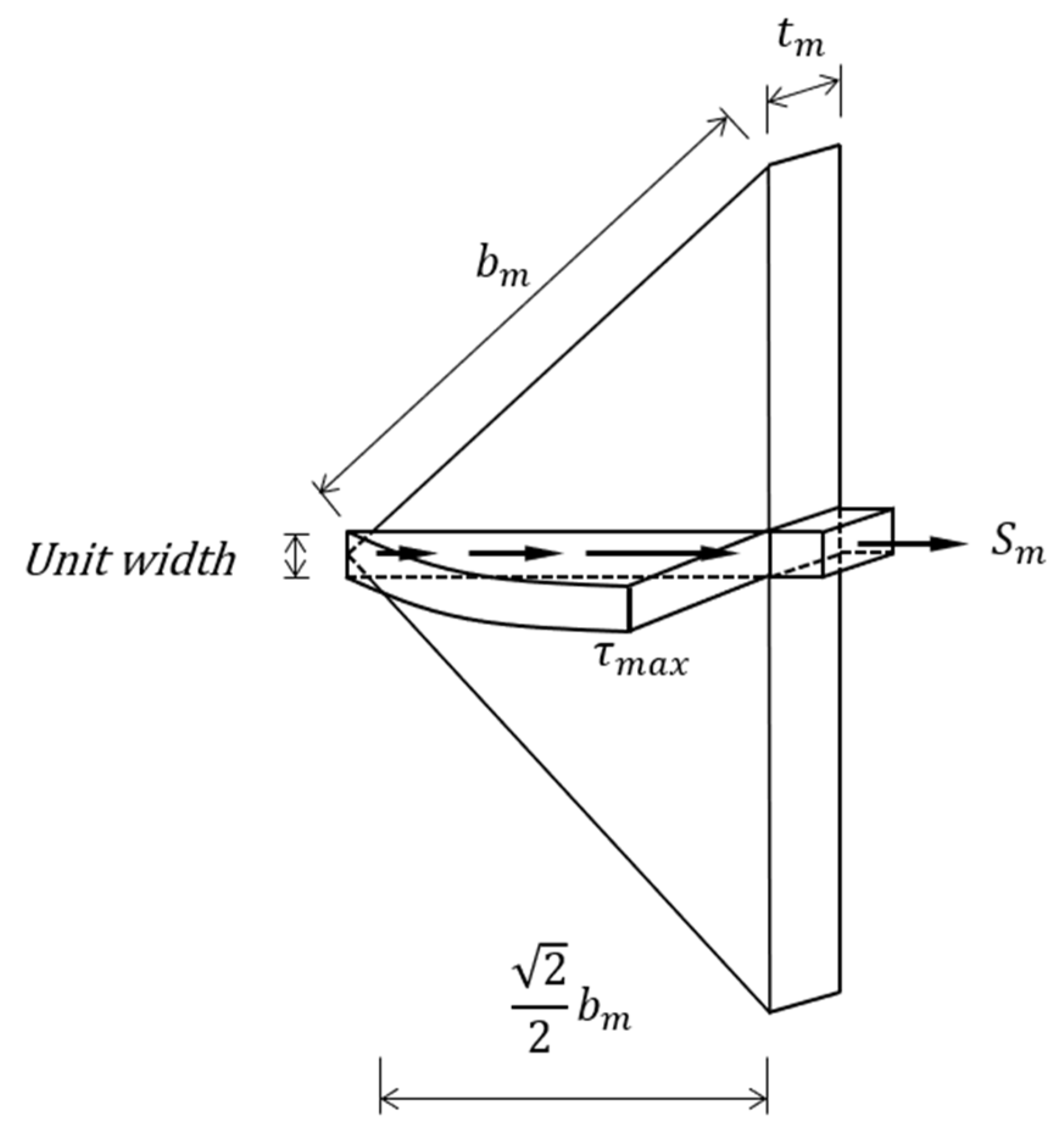

| Type of Test | Nominal Strength | Expected Strength | Lower-Bound Strength | |

|---|---|---|---|---|

| Compressive | One side | Equation (12) | 0.89 | 0.77 |

| Two sides | Equation (13) | 0.83 | 0.73 | |

| Diagonal tension 1 | Equation (14) | 1.15 | 0.92 | |

| Type of Test | Nominal Strength | Expected Strength | Lower-Bound Strength | |

|---|---|---|---|---|

| Compressive | One side | Equation (12) | 1.17 | 1.0 |

| Two sides | Equation (13) | 1.04 | 0.94 | |

| Diagonal tension 1 | Equation (14) | 1.12 | 0.86 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.-H.; Park, J.-H. Compressive and Diagonal Tension Strengths of Masonry Prisms Strengthened with Amorphous Steel Fiber-Reinforced Mortar Overlay. Appl. Sci. 2021, 11, 5974. https://doi.org/10.3390/app11135974

Yu J-H, Park J-H. Compressive and Diagonal Tension Strengths of Masonry Prisms Strengthened with Amorphous Steel Fiber-Reinforced Mortar Overlay. Applied Sciences. 2021; 11(13):5974. https://doi.org/10.3390/app11135974

Chicago/Turabian StyleYu, Ji-Hoon, and Ji-Hun Park. 2021. "Compressive and Diagonal Tension Strengths of Masonry Prisms Strengthened with Amorphous Steel Fiber-Reinforced Mortar Overlay" Applied Sciences 11, no. 13: 5974. https://doi.org/10.3390/app11135974

APA StyleYu, J.-H., & Park, J.-H. (2021). Compressive and Diagonal Tension Strengths of Masonry Prisms Strengthened with Amorphous Steel Fiber-Reinforced Mortar Overlay. Applied Sciences, 11(13), 5974. https://doi.org/10.3390/app11135974