Out-of-Plane Experimental Study of Strengthening Slender Non-Structural Masonry Walls

Abstract

:1. Introduction

2. Experimental Program

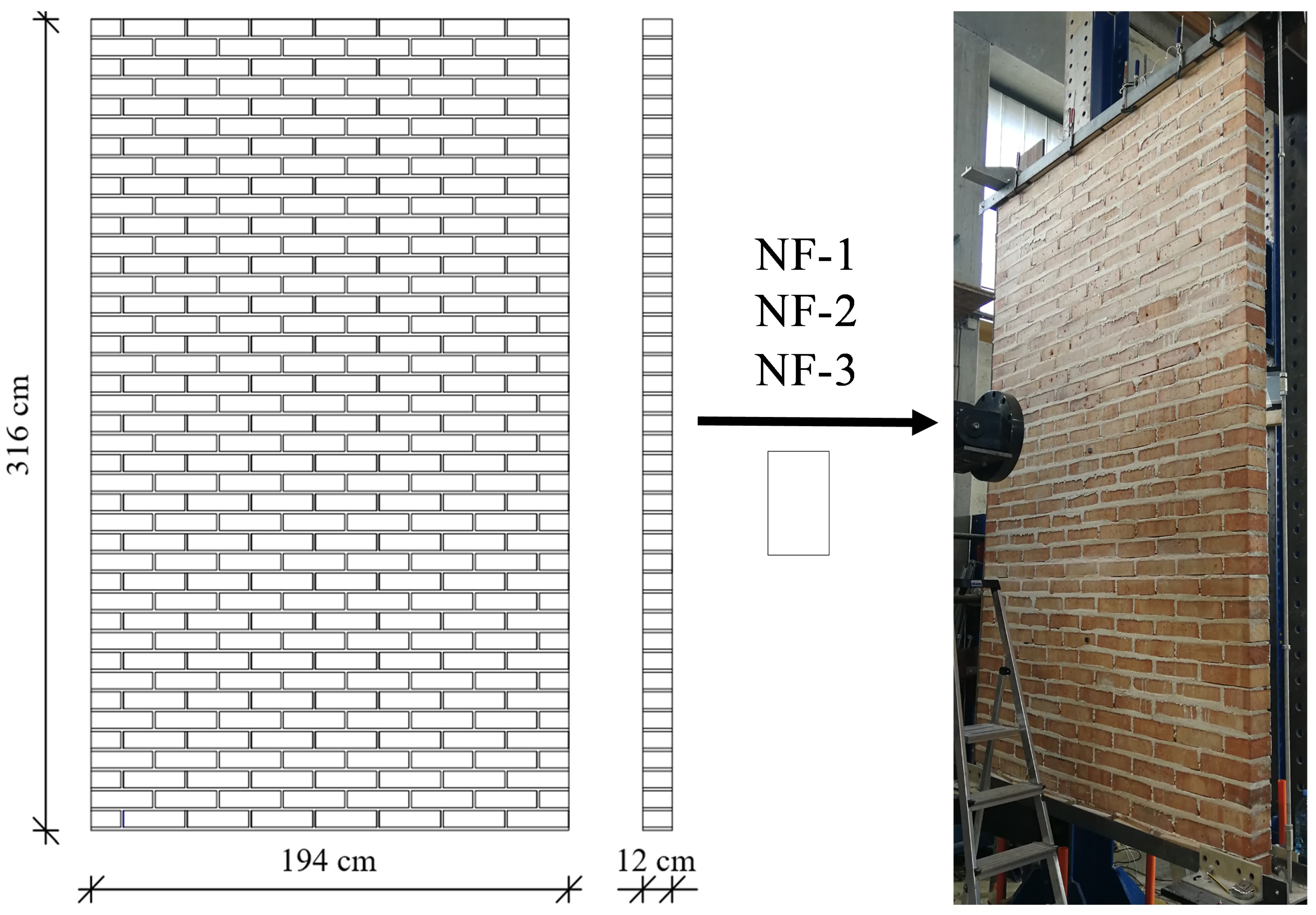

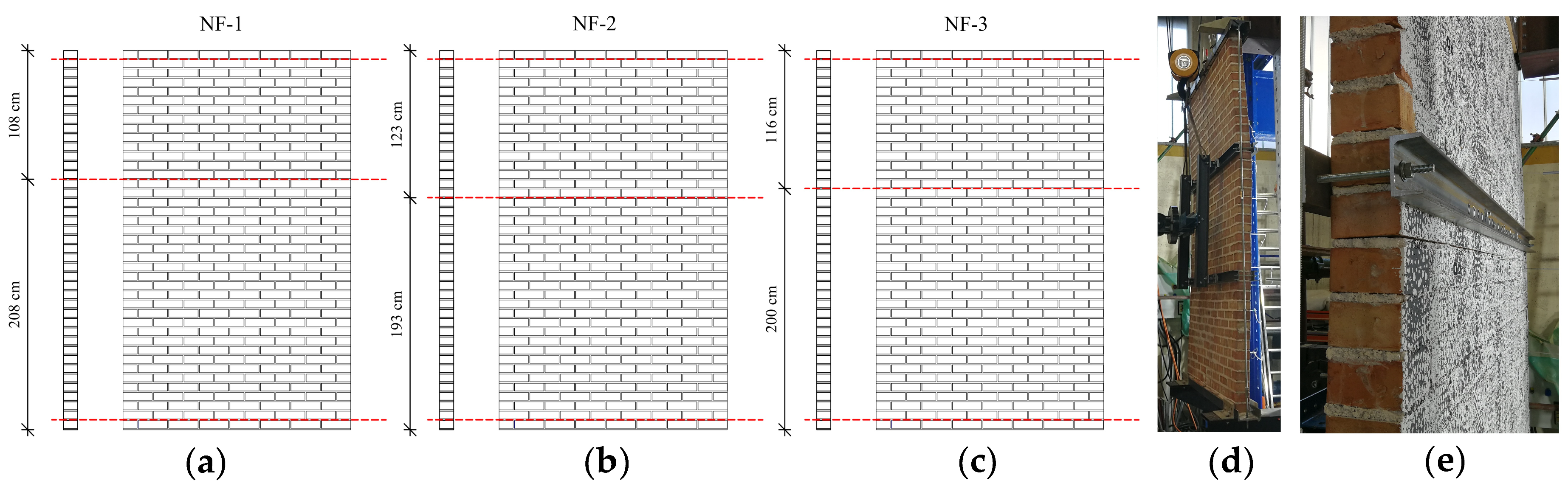

2.1. Non-Structural Wall Test Specimens

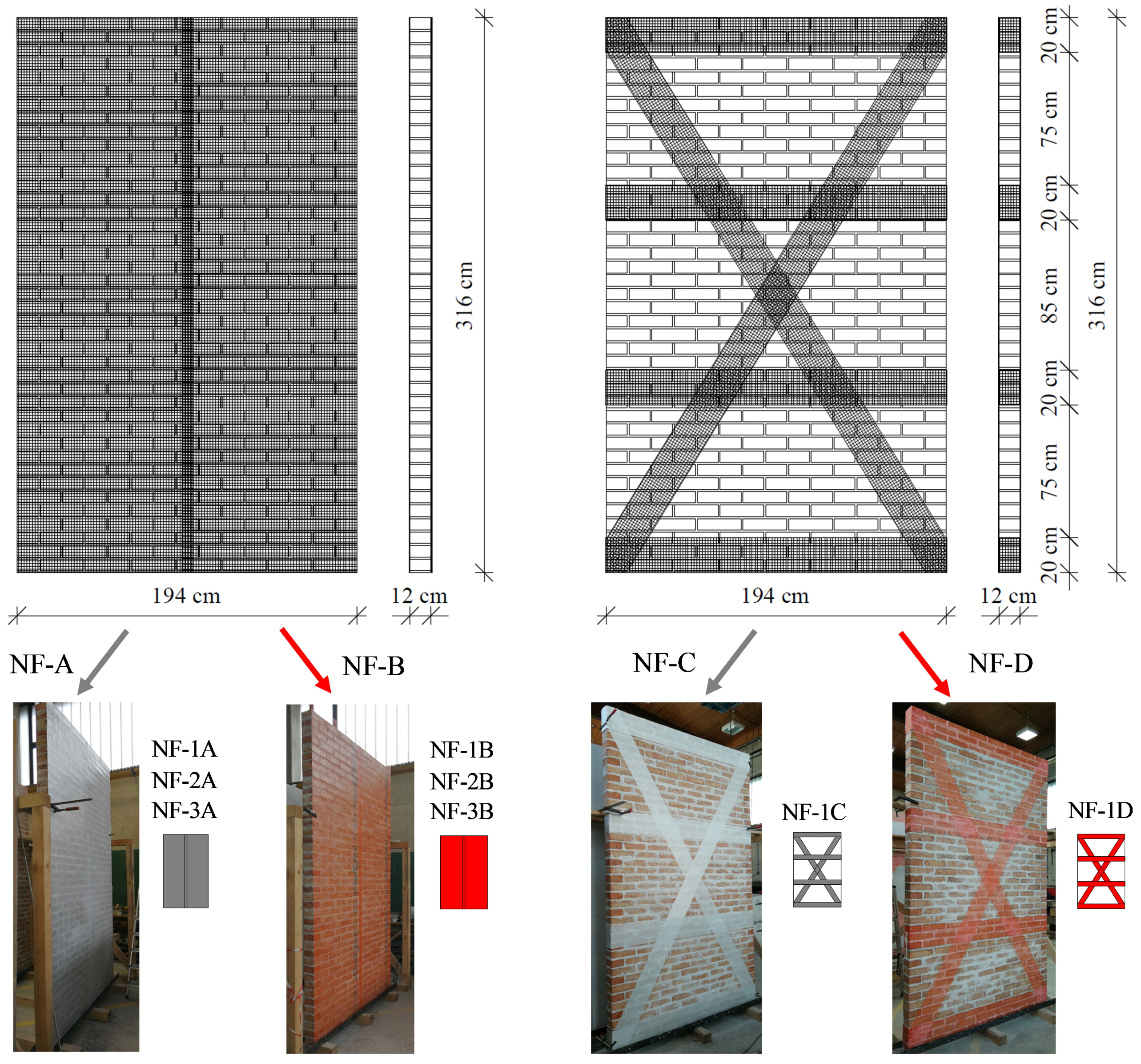

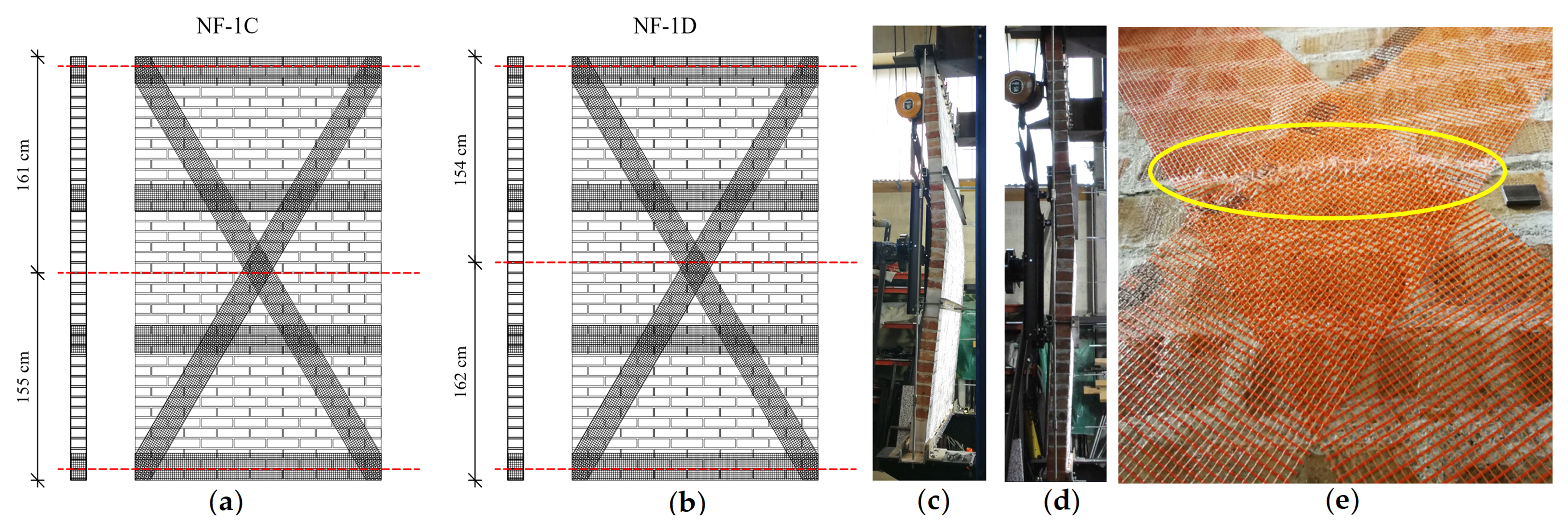

2.2. Strengthening Systems

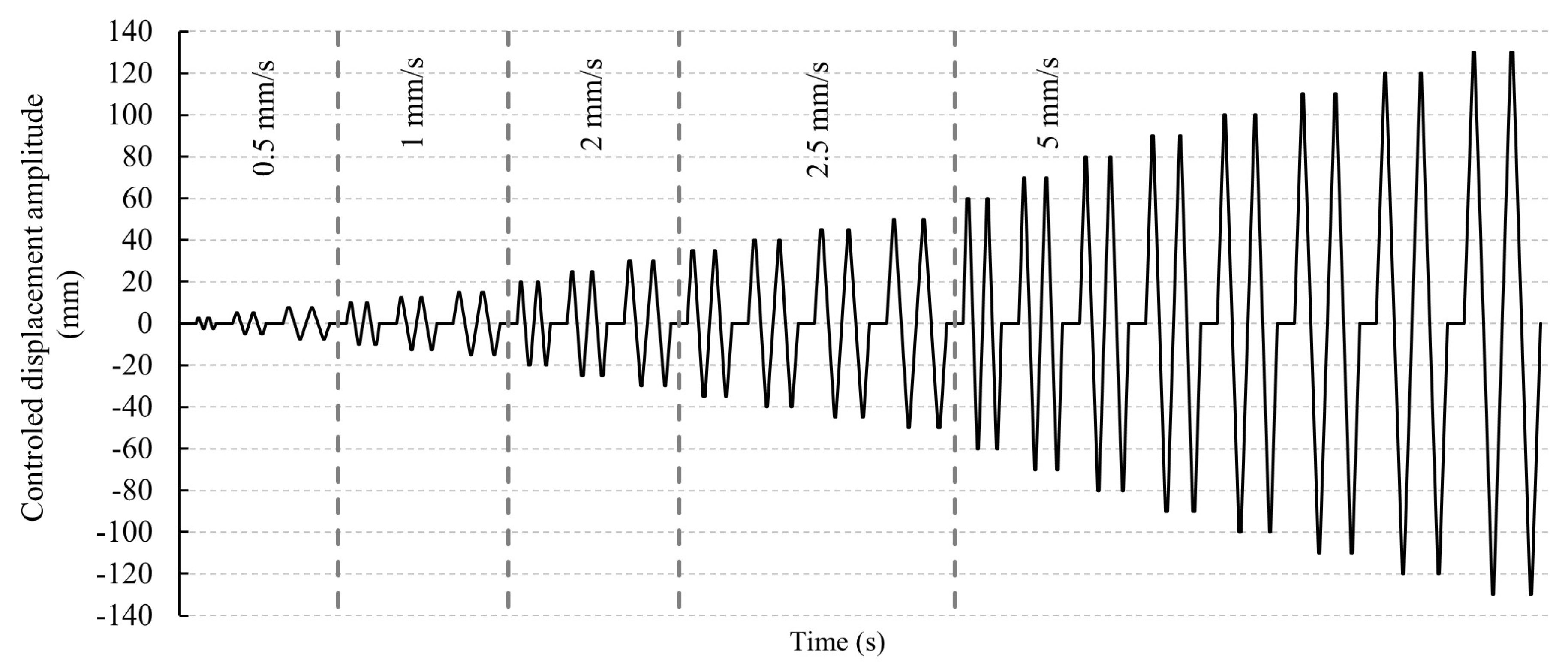

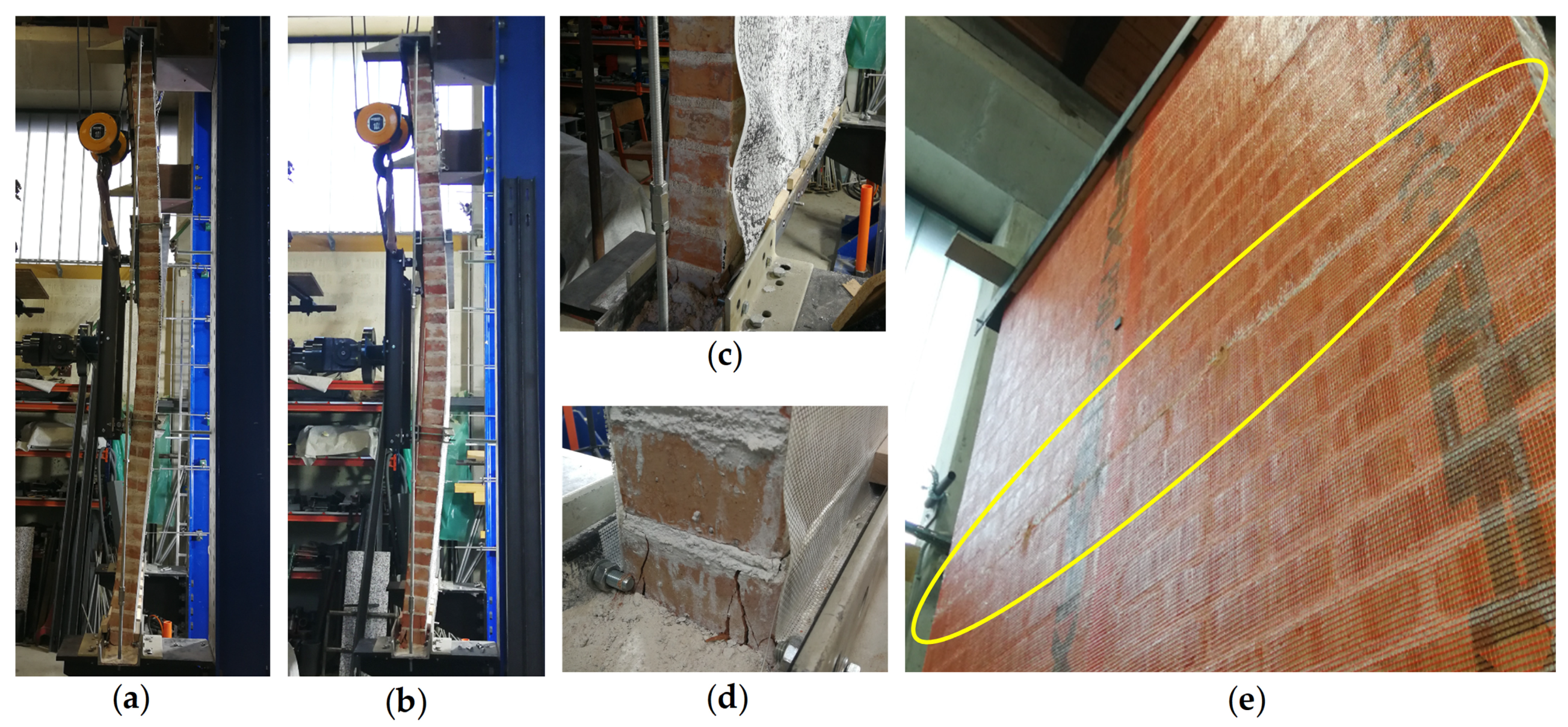

2.3. Test Setup and Loading Protocol

3. Experimental Results Analysis with Discussion

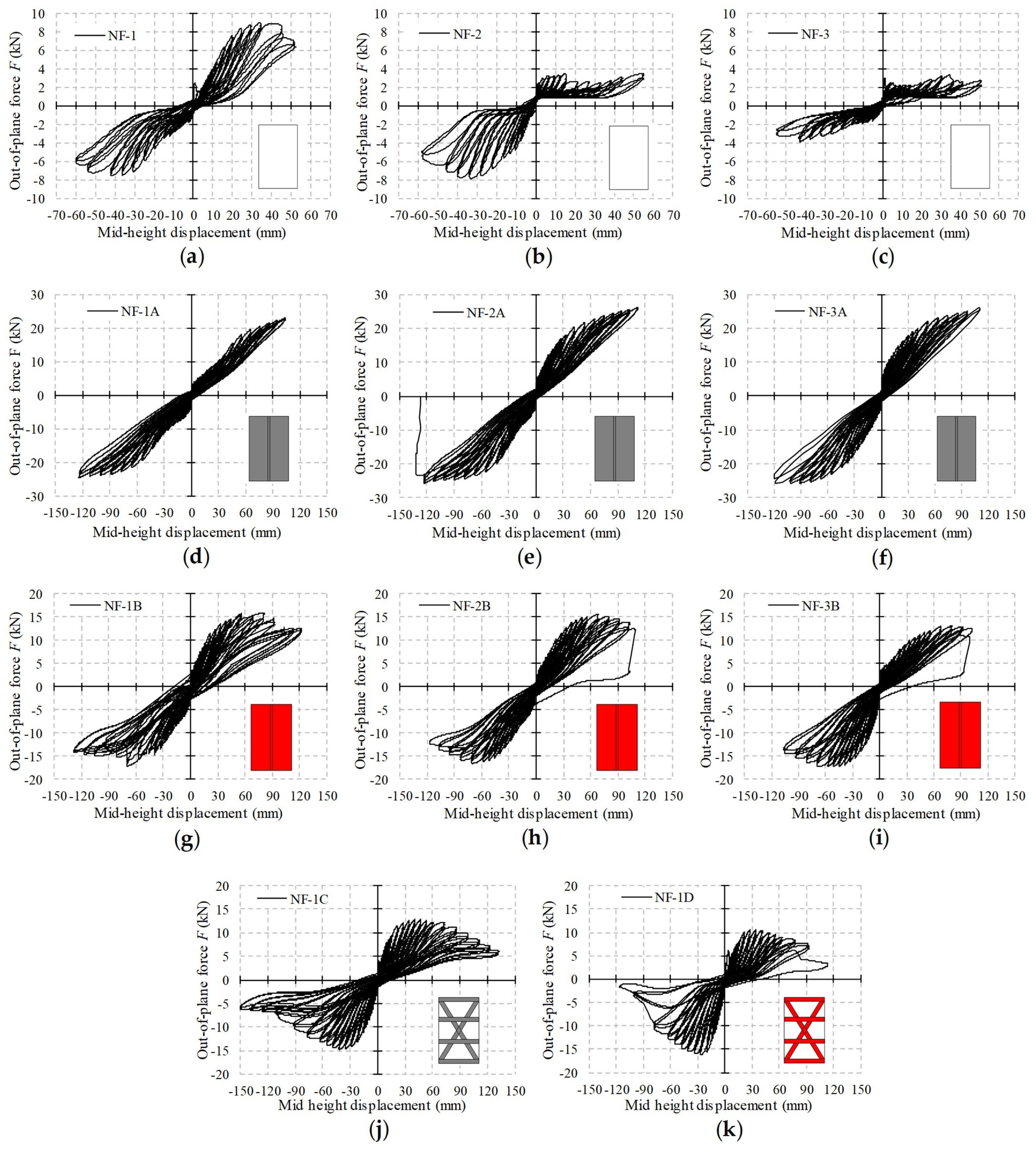

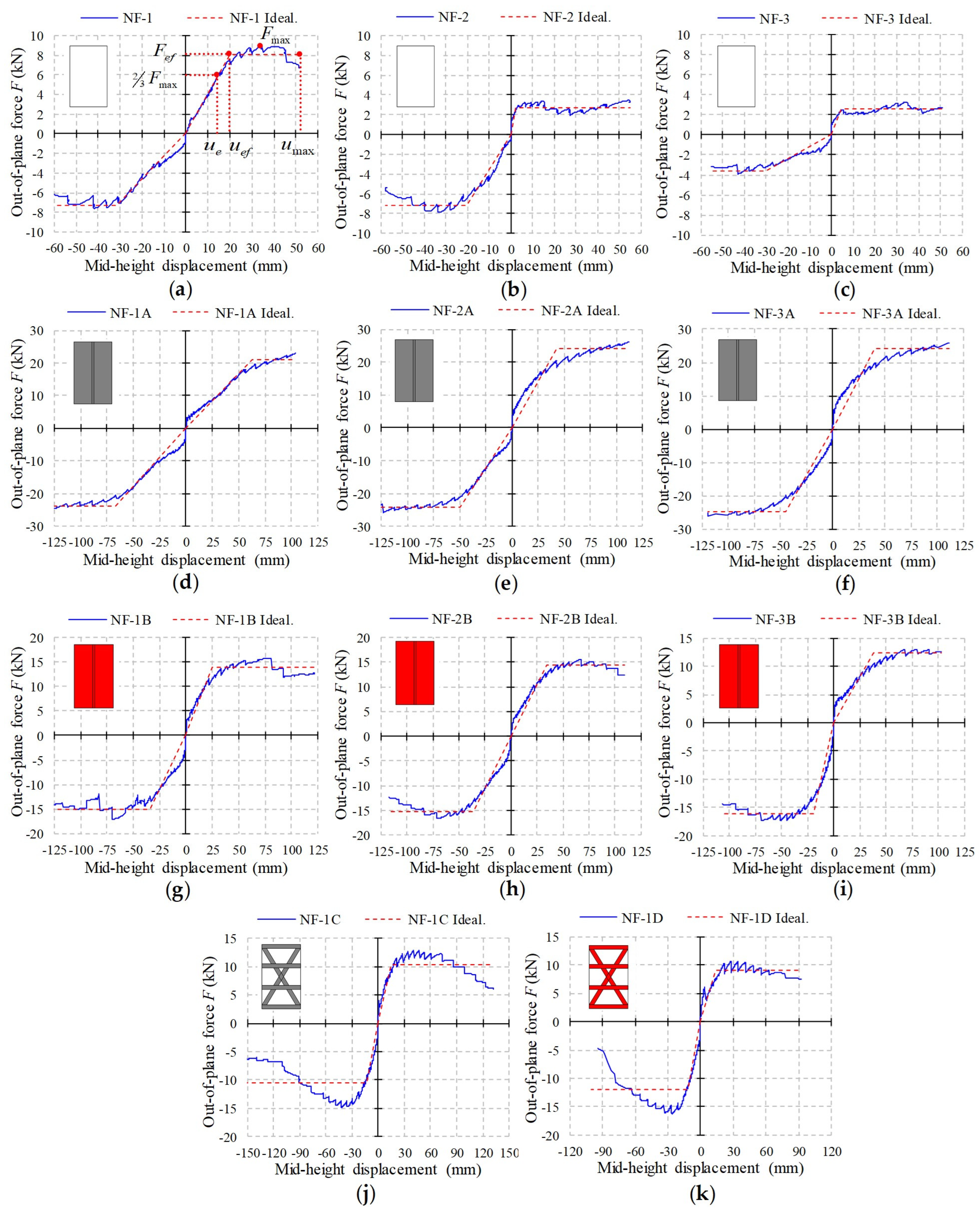

3.1. Out-of-Plane Force-Displacement Response and Failure Mechanisms

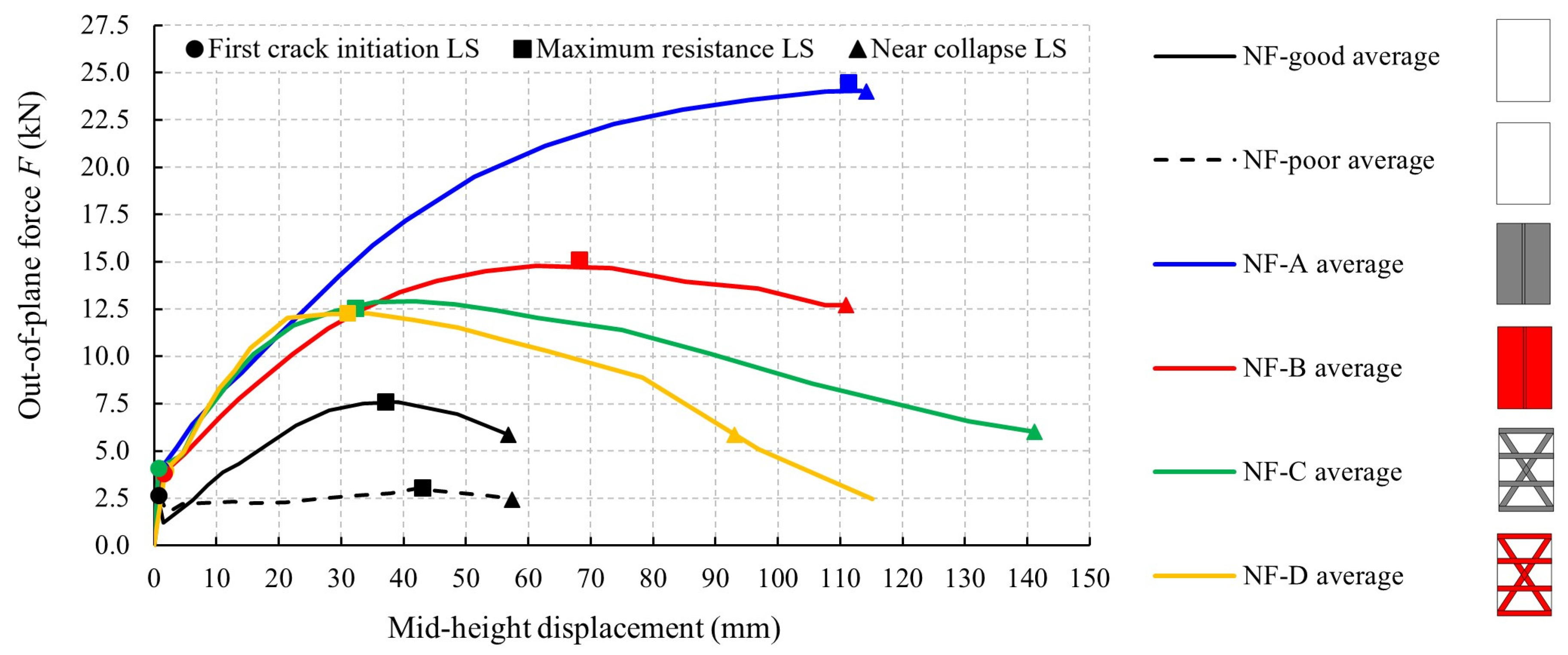

3.2. Response Envelope Curves and Limit States

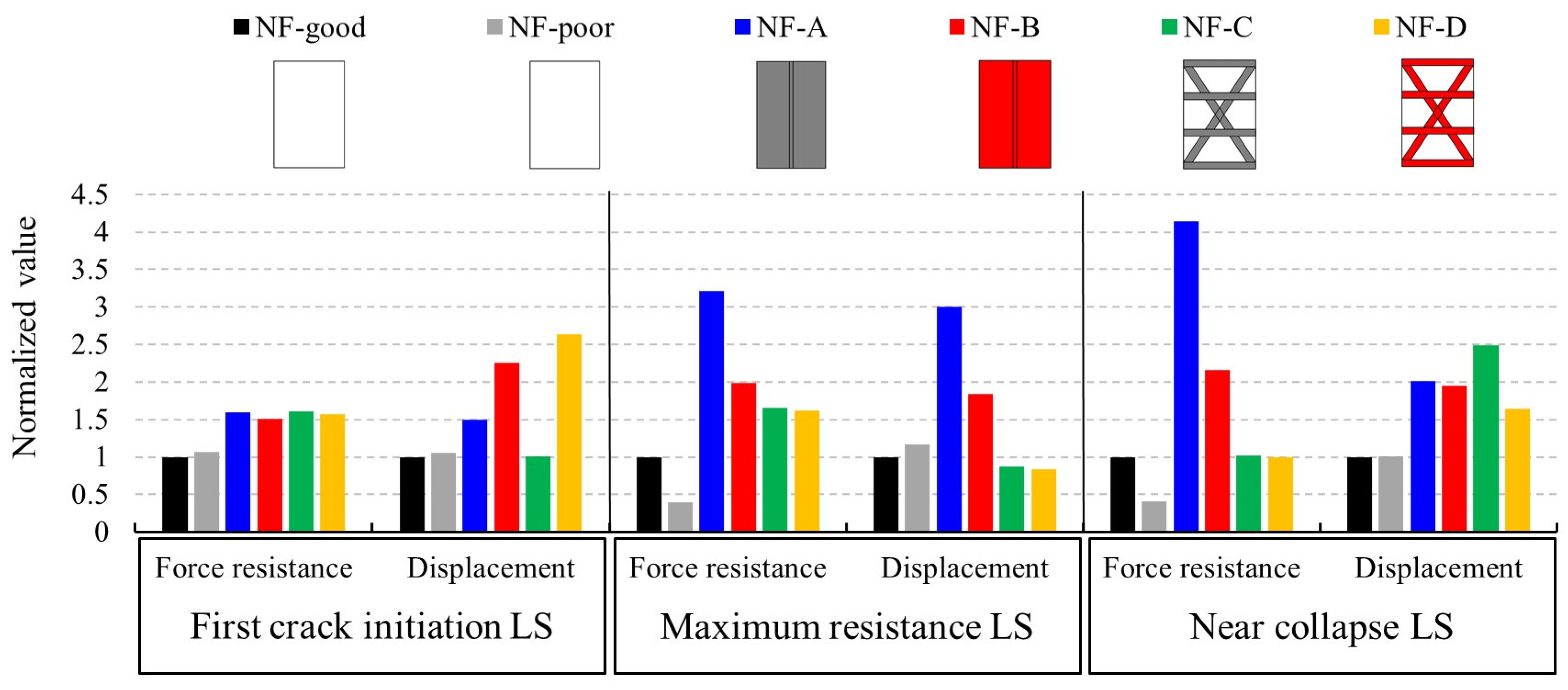

- First crack initiation LS: Reduction in stiffness is observed and a mechanism of plastic hinges in upper, mid-height, and bottom bed joint is formed.

- Maximum resistance LS: The specimen achieves the maximum out-of-plane resistance force Fmax at the corresponding mid-height out-of-plane displacement.

- Near collapse LS: The test specimen is severely damaged or in the next amplitude cycle; a collapse is likely to occur.

3.3. Stiffness Degradation

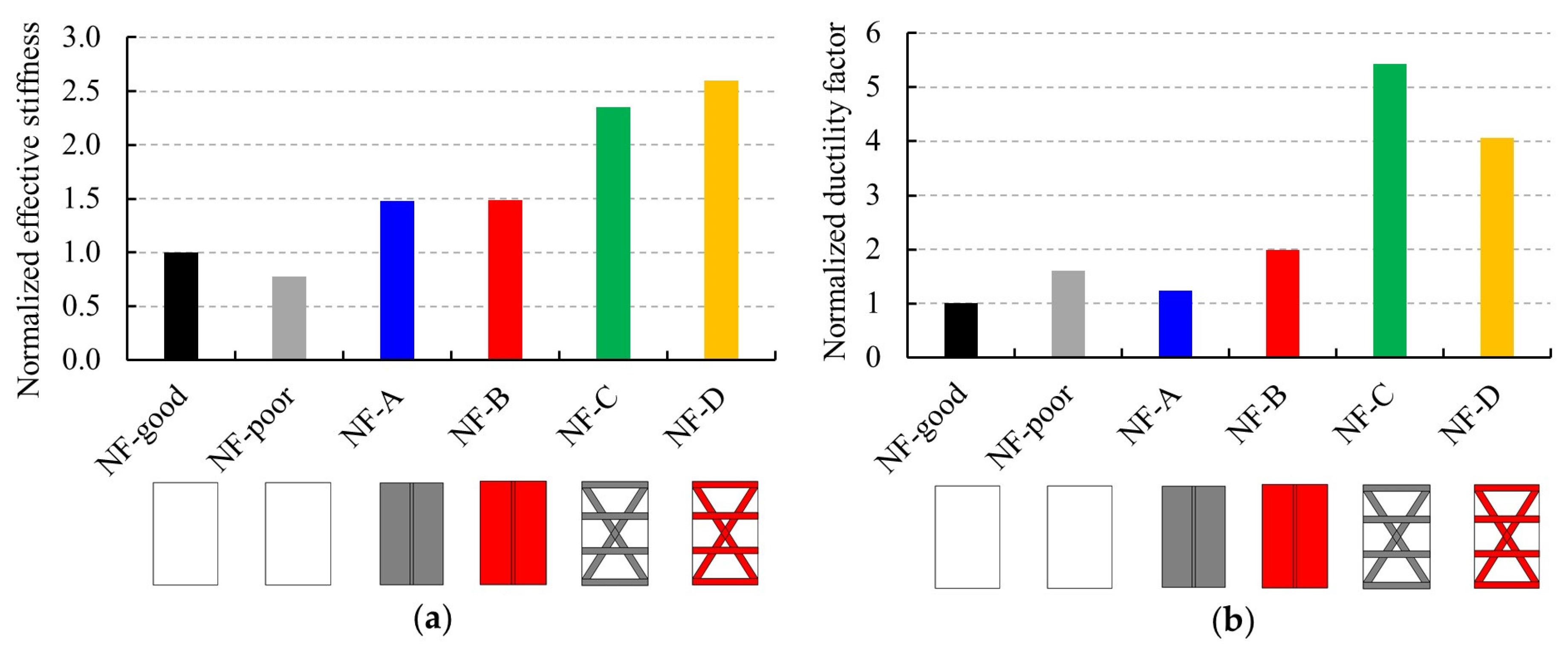

3.4. Ductility and Effective Stiffness

3.5. Eigenfrequencies and Damping

4. Final Remarks and Conclusions

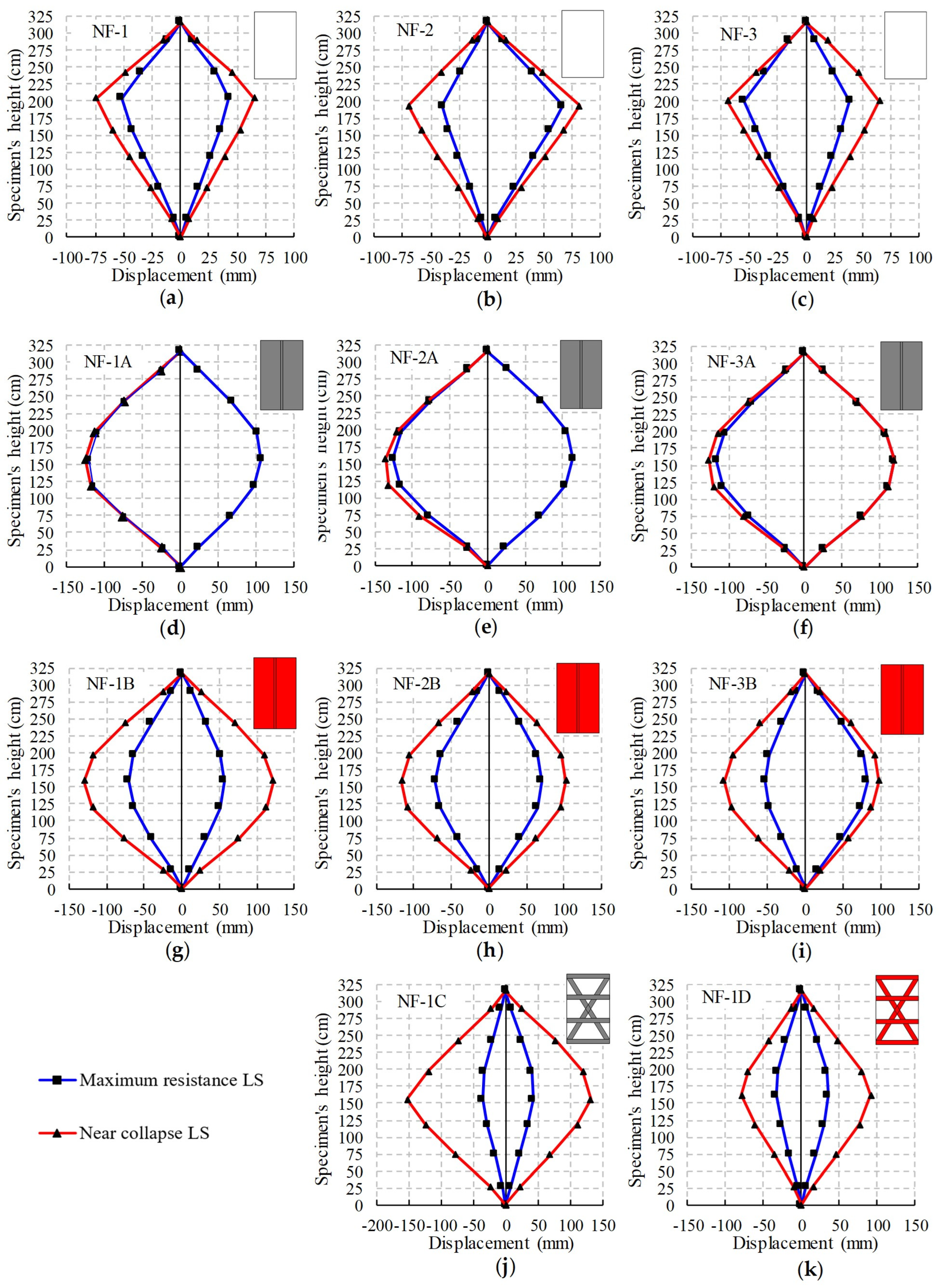

- The out-of-plane displacement deformed shape was more continuous when strengthening systems were applied compared to non-strengthened specimens. This is due to a more uniform response of strengthened masonry along the height of a wall. Non-strengthened specimens exposed the composite character of masonry where mortar joints are the plane of weakness. There, the failure was due to the formation of a plastic hinge in the bed joint at about 2/3 of the specimens’ height. The strengthened specimens, on the other hand, developed multiple bed joint cracks in the mid-height area with the constant bending moment.

- From the cyclic response of tested specimens, an asymmetrical out-of-plane behavior of non-strengthened specimens was obtained, in dependence on the quality of the workmanship, while the behavior of strengthened specimens was close to the symmetrical one.

- The quality of workmanship (the difference of results for NF-good and NF-poor) can be anticipated in the design practice by considering appropriate partial factors for materials as proposed in EN 1996-1-1 [64].

- The out-of-plane load-bearing resistance of non-structural walls, strengthened with systems A, B, C, and D, was increased by 221%, 98%, 65%, and 61%, respectively. Although twice lower, the low-cost system applied on the whole surface of the masonry significantly improved its resistance (A vs. B). For other dispositions of strengthening systems, this influence was negligible (C vs. D).

- The maximum mid-height out-of-plane horizontal displacement was increased with strengthening systems A, B, C, and D by 101%, 95%, 149%, and 64%, respectively.

- Strengthening systems A and D had the greatest impact on the global secant stiffness of the considered wall over the entire range of applied displacement amplitudes. The improvements of 171% and 168%, respectively, were observed. Comparison of hysteresis envelopes with the idealized one reveals that the methodology for idealization adopted from the in-plane shear tests could be used for the approximation of obtained results from cyclic out-of-plane testing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Filiatrault, A.; Sullivan, T. Performance-Based Seismic Design of Nonstructural Building Components: The next Frontier of Earthquake Engineering. Earthq. Eng. Eng. Vib. 2014, 13, 17–46. [Google Scholar] [CrossRef]

- Taghavi, S.; Miranda, E. Response Assessment of Nonstructural Building Elements; Stanford University: Stanford, CA, USA, 2003; p. 96. [Google Scholar]

- Braga, F.; Manfredi, V.; Masi, A.; Salvatori, A.; Vona, M. Performance of Non-Structural Elements in RC Buildings during the L’Aquila, 2009 Earthquake. Bull. Earthq. Eng. 2011, 9, 307–324. [Google Scholar] [CrossRef]

- Perrone, D.; Calvi, P.M.; Nascimbene, R.; Fischer, E.C.; Magliulo, G. Seismic Performance of Non-Structural Elements during the 2016 Central Italy Earthquake. Bull. Earthq. Eng. 2019, 17, 5655–5677. [Google Scholar] [CrossRef]

- Ian, R.; Selim, G.; Armando, M.; Giulia, S.; Ting, L.; Nikola, B.; Dimitrios, L.; Jorge, A.; Igor, T.; Katerina, Z.; et al. Joint Reconnaissance Report (JRR) in StEER-EERI: Petrinja, Croatia December 29, 2020, Mw 6.4 Earthquake, Report No. PRJ-2959; Natural Hazards Engineering Research Infrastructure: West Lafayette, IN, USA, 2021. [CrossRef]

- Lulić, L.; Ožić, K.; Kišiček, T.; Hafner, I.; Stepinac, M. Post-Earthquake Damage Assessment—Case Study of the Educational Building after the Zagreb Earthquake. Sustainability 2021, 13, 6353. [Google Scholar] [CrossRef]

- Stepinac, M.; Lourenço, P.B.; Atalić, J.; Kišiček, T.; Uroš, M.; Baniček, M.; Šavor Novak, M. Damage Classification of Residential Buildings in Historical Downtown after the ML5.5 Earthquake in Zagreb, Croatia in 2020. Int. J. Disaster Risk Reduct. 2021, 56, 102140. [Google Scholar] [CrossRef]

- Menon, A.; Magenes, G. Definition of Seismic Input for Out-of-Plane Response of Masonry Walls: I. Parametric Study. J. Earthq. Eng. 2011, 15, 165–194. [Google Scholar] [CrossRef]

- Akhoundi, F.; Vasconcelos, G.; Lourenco, P.; Silva, L.C. Out-of-Plane Response of Masonry Infilled RC Frames: Effect of Workmanship and Opening. In Proceedings of the 16th International Brick and Block Masonry Conference, Padova, Italy, 23 June 2016. [Google Scholar]

- Angel, R.; Abrams, D.P.; Shapiro, D.; Uzarski, J.; Webster, M. Behavior of Reinforced Concrete Frames with Masonry Infills; Department of Civil Engineering, University of Illinois at Urbana-Champaign: Champaign, IL, USA, 1994. [Google Scholar]

- Dizhur, D.; Walsh, K.; Giongo, I.; Derakhshan, H.; Ingham, J. Out-of-Plane Proof Testing of Masonry Infill Walls. Structures 2018, 15, 244–258. [Google Scholar] [CrossRef]

- Hashemi, A.; Mosalam, K.M. Shake-Table Experiment on Reinforced Concrete Structure Containing Masonry Infill Wall. Earthq. Eng. Struct. Dyn. 2006, 35, 1827–1852. [Google Scholar] [CrossRef]

- da Porto, F.; Guidi, G.; Dalla Benetta, M.; Verlato, N. Combined In-Plane/Out-of-Plane Experimental Behaviour of Reinforced and Strengthened Infill Masonry Walls. In Proceedings of the 12th Canadian Masonry Symposium, Vancouver, BC, Canada, 2–5 June 2013; p. 11. [Google Scholar]

- Di Domenico, M.; De Risi, M.T.; Ricci, P.; Verderame, G.M.; Manfredi, G. Empirical Prediction of the In-Plane/out-of-Plane Interaction Effects in Clay Brick Unreinforced Masonry Infill Walls. Eng. Struct. 2021, 227, 111438. [Google Scholar] [CrossRef]

- Flanagan, R.D.; Bennett, R.M. Bidirectional Behavior of Structural Clay Tile Infilled Frames. J. Struct. Eng. 1999, 125, 236–244. [Google Scholar] [CrossRef]

- Petrone, C.; Magliulo, G.; Manfredi, G. Shake Table Tests for the Seismic Assessment of Hollow Brick Internal Partitions. Eng. Struct. 2014, 72, 203–214. [Google Scholar] [CrossRef]

- Derakhshan, H.; Dizhur, D.; Griffith, M.C.; Ingham, J.M. In Situ Out-of-Plane Testing of As-Built and Retrofitted Unreinforced Masonry Walls. J. Struct. Eng. 2014, 140, 04014022. [Google Scholar] [CrossRef] [Green Version]

- Giaretton, M.; Dizhur, D.; da Porto, F.; Ingham, J.M. Construction Details and Observed Earthquake Performance of Unreinforced Clay Brick Masonry Cavity-Walls. Structures 2016, 6, 159–169. [Google Scholar] [CrossRef]

- Damiola, M.; Esposito, R.; Messali, F.; Rots, J.G. Quasi-Static Cyclic Two-Way out-of-Plane Bending Tests and Analytical Models Comparison for URM Walls. In Proceedings of the 10th International Masonry Conference, Milan, Italy, 9–11 July 2018. [Google Scholar]

- Doherty, K. An Investigation of the Weak Links in the Seismic Load Path of Unreinforced Masonry Buildings. Ph.D. Thesis, Adelaide University, Department of CIvil and Environmental Engineering, Adelaide, Australia, 2000. [Google Scholar]

- Drysdale, R.G.; Essawy, A.S. Out-of-Plane Bending of Concrete Block Walls. J. Struct. Eng. 1988, 114, 121–133. [Google Scholar] [CrossRef]

- Gattesco, N.; Boem, I. Out-of-Plane Behavior of Reinforced Masonry Walls: Experimental and Numerical Study. Compos. Part B Eng. 2017, 128, 39–52. [Google Scholar] [CrossRef] [Green Version]

- Graziotti, F.; Tomassetti, U.; Sharma, S.; Grottoli, L.; Magenes, G. Experimental Response of URM Single Leaf and Cavity Walls in Out-of-Plane Two-Way Bending Generated by Seismic Excitation. Constr. Build. Mater. 2019, 195, 650–670. [Google Scholar] [CrossRef]

- Griffith, M.C.; Vaculik, J.; Lam, N.T.K.; Wilson, J.; Lumantarna, E. Cyclic Testing of Unreinforced Masonry Walls in Two-Way Bending. Earthq. Eng. Struct. Dyn. 2007, 36, 801–821. [Google Scholar] [CrossRef]

- Mosallam, A.S. Out-of-Plane Flexural Behavior of Unreinforced Red Brick Walls Strengthened with FRP Composites. Compos. Part B Eng. 2007, 38, 559–574. [Google Scholar] [CrossRef]

- Valluzzi, M.R.; da Porto, F.; Garbin, E.; Panizza, M. Out-of-Plane Behaviour of Infill Masonry Panels Strengthened with Composite Materials. Mater. Struct. 2014, 47, 2131–2145. [Google Scholar] [CrossRef]

- Triantafillou, T.C. Strengthening of Masonry Structures Using Epoxy-Bonded FRP Laminates. J. Compos. Constr. 1998, 2, 96–104. [Google Scholar] [CrossRef]

- Anil, Ö.; Tatayoğlu, M.; Demirhan, M. Out-of-Plane Behavior of Unreinforced Masonry Brick Walls Strengthened with CFRP Strips. Constr. Build. Mater. 2012, 35, 614–624. [Google Scholar] [CrossRef]

- Tumialan, J.G.; Galati, N.; Nanni, A. Field Assessment of Unreinforced Masonry Walls Strengthened with Fiber Reinforced Polymer Laminates. J. Struct. Eng. 2003, 129, 1047–1056. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Al-Salloum, Y.A.; Al-Zaheri, Z.M.; Alsayed, S.H.; Abbas, H. Behavior and Design Aspects of FRP-Strengthened URM Walls under Out-of-Plane Loading. J. Compos. Constr. 2016, 20, 04016048. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Almusallam, T.H. Load Capacity of Concrete Masonry Block Walls Strengthened with Epoxy-Bonded GFRP Sheets. J. Compos. Mater. 2005, 39, 1719–1745. [Google Scholar] [CrossRef]

- Hamoush, S.; McGinley, M.; Mlakar, P.; Terro, M.J. Out-of-Plane Behavior of Surface-Reinforced Masonry Walls. Constr. Build. Mater. 2002, 16, 341–351. [Google Scholar] [CrossRef]

- Padalu, P.K.V.R.; Singh, Y.; Das, S. Out-of-Plane Flexural Behaviour of Masonry Wallettes Strengthened Using FRP Composites and Externally Bonded Grids: Comparative Study. Compos. Part B Eng. 2019, 176, 107302. [Google Scholar] [CrossRef]

- Al-Jaberi, Z.; Myers, J.; ElGawady, M. Flexural Capacity of Out-of-Plane Reinforced Masonry Walls Strengthened with Externally Bonded (EB) FRP. In Proceedings of the 7th International Conference on Advanced Composite Materials in Bridges and Structures, Vancouver, BC, Canada, 24–26 August 2016. [Google Scholar]

- Petersen, R.B.; Masia, M.J.; Seracino, R. Bond Behavior of Near-Surface Mounted FRP Strips Bonded to Modern Clay Brick Masonry Prisms: Influence of Strip Orientation and Compression Perpendicular to the Strip. J. Compos. Constr. 2009, 13, 169–178. [Google Scholar] [CrossRef]

- Ehsani, M.R.; Saadatmanesh, H.; Abdelghany, I.H.; Elkafrawy, W. Flexural Behavior of Masonry Walls Strengthened with Composite Fabrics. Spec. Publ. 1993, 138, 497–508. [Google Scholar]

- Ehsani, M.R.; Saadatmanesh, H. Seismic Retrofit of URM Walls with Fibre Composites. Mason. Soc. J. 1996, 14, 63–72. [Google Scholar]

- Galati, N.; Tumialan, G.; Nanni, A. Strengthening with FRP Bars of URM Walls Subject to Out-of-Plane Loads. Constr. Build. Mater. 2006, 20, 101–110. [Google Scholar] [CrossRef]

- Kuzik, M.D.; Elwi, A.E.; Cheng, J.J.R. Cyclic Flexure Tests of Masonry Walls Reinforced with Glass Fiber Reinforced Polymer Sheets. J. Compos. Constr. 2003, 7, 20–30. [Google Scholar] [CrossRef]

- Velazquez-Dimas, J.I.; Ehsani, M.R.; Saadatmanesh, H. Out-of-Plane Behavior of Brick Masonry Walls Strengthened with Fiber Composites. ACI Struct. J. 2000, 97, 377–387. [Google Scholar]

- Türkmen, Ö.S.; Wijte, S.N.M.; De Vries, B.T.; Ingham, J.M. Out-of-Plane Behavior of Clay Brick Masonry Walls Retrofitted with Flexible Deep Mounted CFRP Strips. Eng. Struct. 2021, 228, 111448. [Google Scholar] [CrossRef]

- De Santis, S.; De Canio, G.; de Felice, G.; Meriggi, P.; Roselli, I. Out-of-Plane Seismic Retrofitting of Masonry Walls with Textile Reinforced Mortar Composites. Bull. Earthq. Eng. 2019, 17, 6265–6300. [Google Scholar] [CrossRef]

- Harajli, M.; ElKhatib, H.; San-Jose, J.T. Static and Cyclic Out-of-Plane Response of Masonry Walls Strengthened Using Textile-Mortar System. J. Mater. Civ. Eng. 2010, 22, 1171–1180. [Google Scholar] [CrossRef]

- Papanicolaou, C.G.; Triantafillou, T.C.; Papathanasiou, M.; Karlos, K. Textile Reinforced Mortar (TRM) versus FRP as Strengthening Material of URM Walls: Out-of-Plane Cyclic Loading. Mater. Struct. 2008, 41, 143–157. [Google Scholar] [CrossRef]

- Furtado, A.; Rodrigues, H.; Arêde, A.; Varum, H. Impact of the Textile Mesh on the Efficiency of TRM Strengthening Solutions to Improve the Infill Walls Out-of-Plane Behaviour. Appl. Sci. 2020, 10, 8745. [Google Scholar] [CrossRef]

- Babaeidarabad, S.; Caso, F.D.; Nanni, A. Out-of-Plane Behavior of URM Walls Strengthened with Fabric-Reinforced Cementitious Matrix Composite. J. Compos. Constr. 2014, 18, 04013057. [Google Scholar] [CrossRef]

- Bellini, A.; Incerti, A.; Bovo, M.; Mazzotti, C. Effectiveness of FRCM Reinforcement Applied to Masonry Walls Subject to Axial Force and Out-Of-Plane Loads Evaluated by Experimental and Numerical Studies. Int. J. Archit. Herit. 2018, 12, 376–394. [Google Scholar] [CrossRef]

- Bernat-Maso, E.; Escrig, C.; Aranha, C.A.; Gil, L. Experimental Assessment of Textile Reinforced Sprayed Mortar Strengthening System for Brickwork Wallettes. Constr. Build. Mater. 2014, 50, 226–236. [Google Scholar] [CrossRef] [Green Version]

- D’Antino, T.; Carozzi, F.G.; Colombi, P.; Poggi, C. Out-of-Plane Maximum Resisting Bending Moment of Masonry Walls Strengthened with FRCM Composites. Compos. Struct. 2018, 202, 881–896. [Google Scholar] [CrossRef]

- D’Ambra, C.; Lignola, G.P.; Prota, A.; Fabbrocino, F.; Sacco, E. FRCM Strengthening of Clay Brick Walls for out of Plane Loads. Compos. Part B Eng. 2019, 174, 107050. [Google Scholar] [CrossRef]

- Donnini, J.; Maracchini, G.; Lenci, S.; Corinaldesi, V.; Quagliarini, E. TRM Reinforced Tuff and Fired Clay Brick Masonry: Experimental and Analytical Investigation on Their in-Plane and out-of-Plane Behavior. Constr. Build. Mater. 2021, 272, 121643. [Google Scholar] [CrossRef]

- Martins, A.; Vasconcelos, G.; Fangueiro, R.; Cunha, F. Experimental Assessment of an Innovative Strengthening Material for Brick Masonry Infills. Compos. Part B Eng. 2015, 80, 328–342. [Google Scholar] [CrossRef] [Green Version]

- Sagar, S.L.; Singhal, V.; Rai, D.C.; Gudur, P. Diagonal Shear and Out-of-Plane Flexural Strength of Fabric-Reinforced Cementitious Matrix–Strengthened Masonry Walletes. J. Compos. Constr. 2017, 21, 04017016. [Google Scholar] [CrossRef]

- Kadam, S.B.; Singh, Y.; Li, B. Out-of-Plane Behaviour of Unreinforced Masonry Strengthened Using Ferrocement Overlay. Mater. Struct. 2015, 48, 3187–3203. [Google Scholar] [CrossRef]

- Al-Jaberi, Z.; Myers, J.J.; ElGawady, M.A. Pseudo-Static Cyclic Loading Comparison of Reinforced Masonry Walls Strengthened with FRCM or NSM FRP. Constr. Build. Mater. 2018, 167, 482–495. [Google Scholar] [CrossRef]

- Kouris, L.A.S.; Triantafillou, T.C. State-of-the-Art on Strengthening of Masonry Structures with Textile Reinforced Mortar (TRM). Constr. Build. Mater. 2018, 188, 1221–1233. [Google Scholar] [CrossRef]

- Stempniewski, L.; Mowrtage, W.; Urban, M. Seismic Collapse Prevention of Non-Structural Infill Masonry Using Eq-Top: An Easy Earthquake Fibre Retrofitting System. Arab. J. Sci. Eng. 2014, 39, 1599–1605. [Google Scholar] [CrossRef]

- The European Committee for Standardization. EN 772-1. Methods of Test for Masonry Units, Part 1: Determination of Compressive Strength; CEN: Brussels, Belgium, 2015. [Google Scholar]

- The European Committee for Standardization. EN 1015-11. Methods of Test for Mortar for Masonry, Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; CEN: Brussels, Belgium, 2019. [Google Scholar]

- The European Committee for Standardization. EN 1052-5. Methods of Test for Masonry, Part 5: Determination of Bond Strength by the Bond Wrench Method; CEN: Brussels, Belgium, 2005. [Google Scholar]

- Griffith, M.C.; Kashyap, J.; Mohamed Ali, M.S. Flexural Displacement Response of NSM FRP Retrofitted Masonry Walls. Constr. Build. Mater. 2013, 49, 1032–1040. [Google Scholar] [CrossRef]

- Graziotti, F.; Tomassetti, U.; Penna, A.; Magenes, G. Out-of-Plane Shaking Table Tests on URM Single Leaf and Cavity Walls. Eng. Struct. 2016, 125, 455–470. [Google Scholar] [CrossRef]

- Derakhshan, H.; Griffith, M.C.; Ingham, J.M. Airbag Testing of Multi-Leaf Unreinforced Masonry Walls Subjected to One-Way Bending. Eng. Struct. 2013, 57, 512–522. [Google Scholar] [CrossRef] [Green Version]

- The European Committee for Standardization. EN 1996-1-1:2005+A1:2012. Eurocode 6: Design of Masonry Structures, Part 1-1: General Rules for Reinforced and Unreinforced Masonry Structures; CEN: Brussels, Belgium, 2013. [Google Scholar]

- Tomaževič, M. Earthquake-Resistant Design of Masonry Buildings; Series on Innovation in Structures and Construction; Imperial College Press: London, UK, 1999; Volume 1. [Google Scholar]

- Antolinc, D.; Rajčić, V.; Žarnić, R. Analysis of Hysteretic Response of Glass Infilled Wooden Frames. J. Civ. Eng. Manag. 2014, 20, 600–608. [Google Scholar] [CrossRef]

- Bosiljkov, V.Z.; Totoev, Y.Z.; Nichols, J.M. Shear Modulus and Stiffness of Brickwork Masonry: An Experimental Perspective. Struct. Eng. Mech. 2005, 20, 21–43. [Google Scholar] [CrossRef] [Green Version]

- PrEN 1998-3: Draft. Eurocode 8: Design of Structures for Earthquake Resistance—Part 3: Assessment and Retrofitting of Buildings and Bridges; CEN: Brussels, Belgium, 2019. [Google Scholar]

- Sorrentino, L.; D’Ayala, D.; de Felice, G.; Griffith, M.C.; Lagomarsino, S.; Magenes, G. Review of Out-of-Plane Seismic Assessment Techniques Applied To Existing Masonry Buildings. Int. J. Archit. Herit. 2017, 11, 2–21. [Google Scholar] [CrossRef]

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering, 3rd ed.; Prentice Hall College: Hoboken, NJ, USA, 2007. [Google Scholar]

- Priestley, M.J.N.; Seible, F.; Calvi, G.M. Seismic Design and Retrofit of Bridges; John Wiley & Sons, Inc.: New York, NY, USA.

| Specimen’s Label | Specimens’ Group Label | Strengthening System Label | Strengthening System Details | Symbol |

|---|---|---|---|---|

| NF-1 | NF | \ | As-built (without strengthening system) |  |

| NF-2 | ||||

| NF-3 | ||||

| NF-1A | NF-A | A | Glass fiber-reinforcing fabric (RF) applied to both sides of the specimen over the entire surface |  |

| NF-2A | ||||

| NF-3A | ||||

| NF-1B | NF-B | B | Glass fiber-rendering mesh (RM) applied to both sides of the specimen over the entire surface |  |

| NF-2B | ||||

| NF-3B | ||||

| NF-1C | NF-C | C | Glass fiber-reinforcing fabric (RF) diagonal strips combined with horizontal strips applied to the both sides of the specimen |  |

| NF-1D | NF-D | D | Glass fiber-rendering mesh (RM) diagonal strips combined with horizontal strips applied to the both sides of the specimen |  |

| Specimens’ Group | First Crack Initiation LS | Maximum Resistance LS | Near Collapse LS | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F | COV | u | COV | F | COV | u | COV | F | COV | u | COV | |

| (kN) | (%) | (mm) | (%) | (kN) | (%) | (mm) | (%) | (kN) | (%) | (mm) | (%) | |

| NF-good | 2.5 | \ | 0.7 | \ | 7.6 | 9.8 | 37.1 | 12.1 | 5.9 | 12.5 | 56.7 | 7.4 |

| NF-poor | 2.7 | \ | 0.7 | \ | 3.0 | 9.9 | 43.1 | 28.2 | 2.4 | 8.0 | 57.3 | 14.5 |

| NF-A | 4.1 | 19.0 | 1.0 | 28.6 | 24.5 | 4.6 | 111.3 | 8.8 | 24.3 | 4.4 | 114.1 | 8.2 |

| NF-B | 3.8 | 9.8 | 1.5 | 14.5 | 15.1 | 10.1 | 68.1 | 20.6 | 12.7 | 9.6 | 110.9 | 10.2 |

| NF-C | 4.1 | \ | 0.7 | \ | 12.6 | \ | 32.3 | \ | 6.0 | \ | 141.2 | \ |

| NF-D | 4.0 | \ | 1.8 | \ | 12.3 | \ | 31.1 | \ | 5.9 | \ | 93.1 | \ |

| Specimens’ Group | Fef (kN) | uef (mm) | uu (mm) | Kef (kN/mm) | μ (/) |

|---|---|---|---|---|---|

| NF-good | 7.49 | 23.8 | 44.1 | 0.31 | 1.8 |

| NF-poor | 2.95 | 12.2 | 36.16 | 0.24 | 3.0 |

| NF-A | 23.71 | 51.1 | 117.0 | 0.46 | 2.3 |

| NF-B | 14.48 | 31.1 | 114.2 | 0.47 | 3.7 |

| NF-C | 10.44 | 14.1 | 141.6 | 0.74 | 10.0 |

| NF-D | 10.51 | 12.9 | 96.7 | 0.82 | 7.5 |

| Before Testing | After Testing | |||||

|---|---|---|---|---|---|---|

| Specimen | f [Hz] | T [s] | ξ [%] | f [Hz] | T [s] | ξ [%] |

| NF-1 | 13.61 | 0.073 | 2.81 | 4.64 | 0.22 | 6.74 |

| NF-2 | 14.20 | 0.070 | 3.21 | 4.60 | 0.22 | 8.16 |

| NF-3 | 13.80 | 0.072 | 2.60 | 4.41 | 0.23 | 6.97 |

| Average | 13.87 | 0.072 | 2.87 | 4.55 | 0.22 | 7.29 |

| COV | 2.2% | 2.2% | 10.9% | 2.7% | 2.7% | 10.4% |

| NF-1A | 14.94 | 0.067 | 2.57 | 4.83 | 0.21 | 6.16 |

| NF-2A | 15.30 | 0.065 | 2.89 | 4.92 | 0.20 | 6.51 |

| NF-3A | 15.83 | 0.063 | 2.66 | 4.23 | 0.24 | 6.52 |

| Average | 15.36 | 0.065 | 2.71 | 4.66 | 0.22 | 6.40 |

| COV | 2.9% | 2.9% | 6.1% | 8.0% | 8.4% | 3.2% |

| NF-1B | 14.34 | 0.070 | 2.58 | 3.61 | 0.28 | 8.74 |

| NF-2B | 15.08 | 0.066 | 2.60 | 4.83 | 0.21 | 8.00 |

| NF-3B | 15.39 | 0.065 | 2.75 | 4.60 | 0.22 | 6.54 |

| Average | 14.94 | 0.067 | 2.64 | 4.35 | 0.23 | 7.76 |

| COV | 3.6% | 3.7% | 3.5% | 14.9% | 16.2% | 14.4% |

| NF-1C | 16.37 | 0.061 | 2.80 | 3.85 | 0.26 | 8.93 |

| NF-1D | 16.09 | 0.062 | 3.12 | 4.23 | 0.24 | 8.76 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klun, M.; Antolinc, D.; Bosiljkov, V. Out-of-Plane Experimental Study of Strengthening Slender Non-Structural Masonry Walls. Appl. Sci. 2021, 11, 9098. https://doi.org/10.3390/app11199098

Klun M, Antolinc D, Bosiljkov V. Out-of-Plane Experimental Study of Strengthening Slender Non-Structural Masonry Walls. Applied Sciences. 2021; 11(19):9098. https://doi.org/10.3390/app11199098

Chicago/Turabian StyleKlun, Martin, David Antolinc, and Vlatko Bosiljkov. 2021. "Out-of-Plane Experimental Study of Strengthening Slender Non-Structural Masonry Walls" Applied Sciences 11, no. 19: 9098. https://doi.org/10.3390/app11199098

APA StyleKlun, M., Antolinc, D., & Bosiljkov, V. (2021). Out-of-Plane Experimental Study of Strengthening Slender Non-Structural Masonry Walls. Applied Sciences, 11(19), 9098. https://doi.org/10.3390/app11199098