Comparison of Testing Method Effects on Cracking Resistance of Asphalt Concrete Mixtures

Abstract

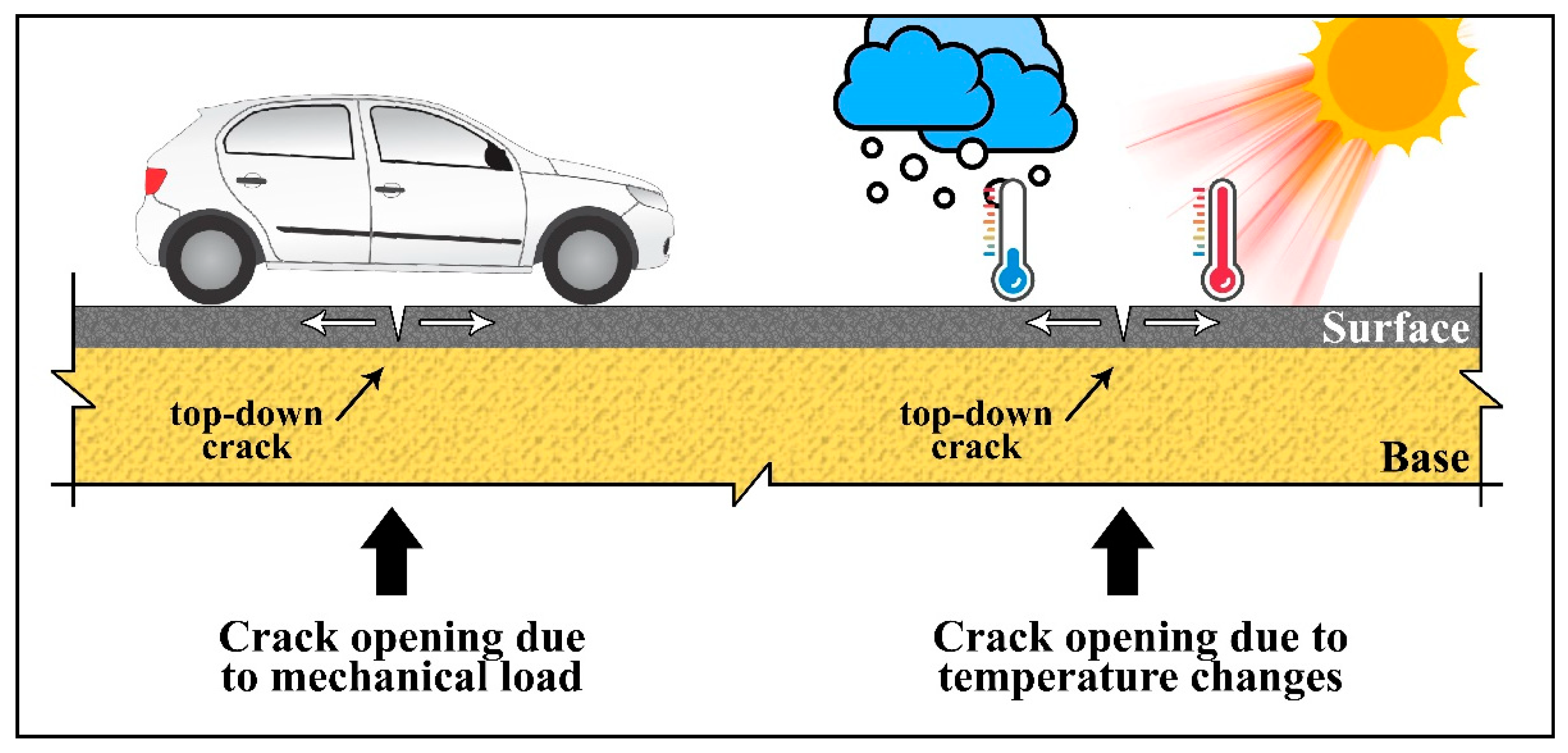

:1. Introduction

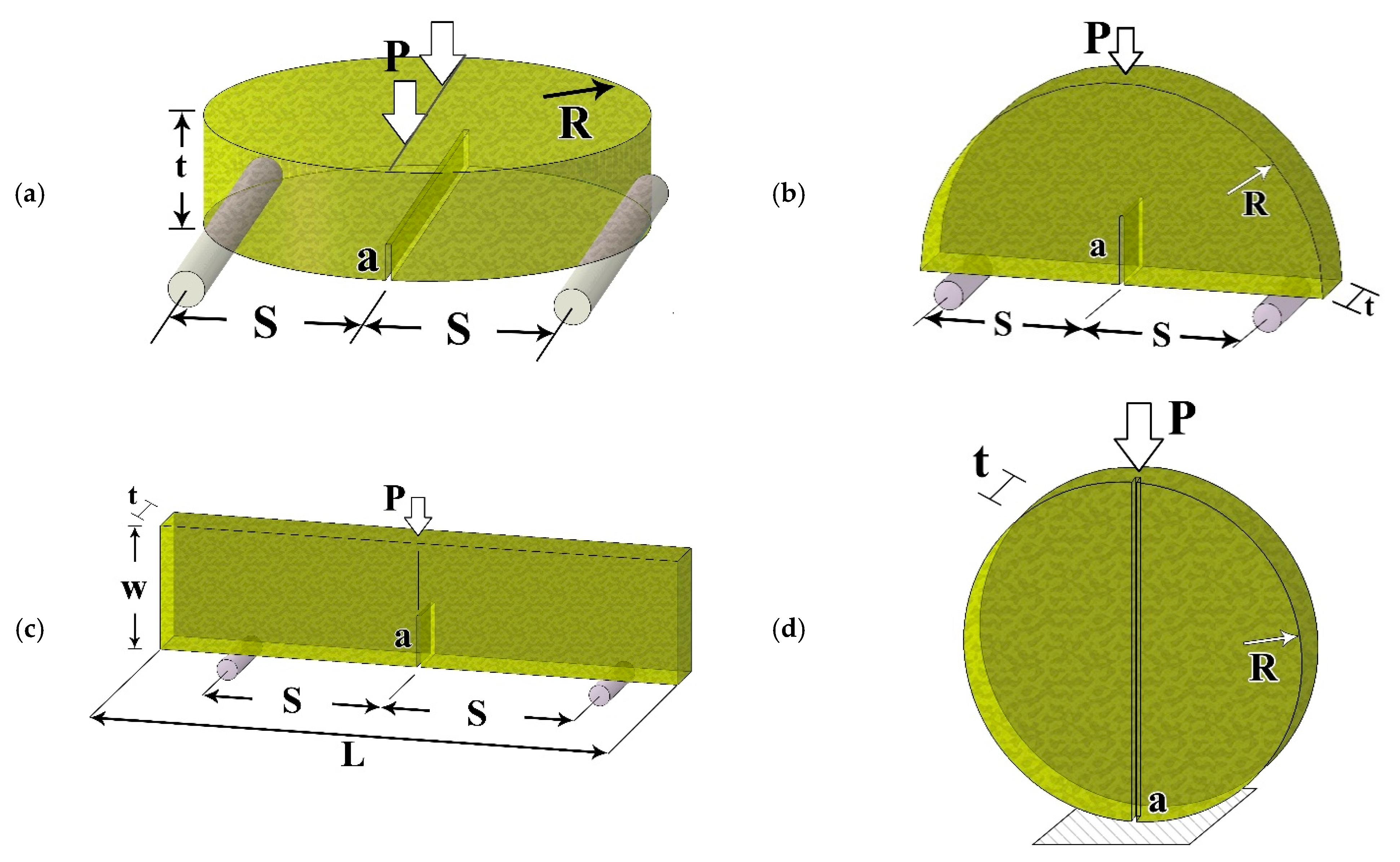

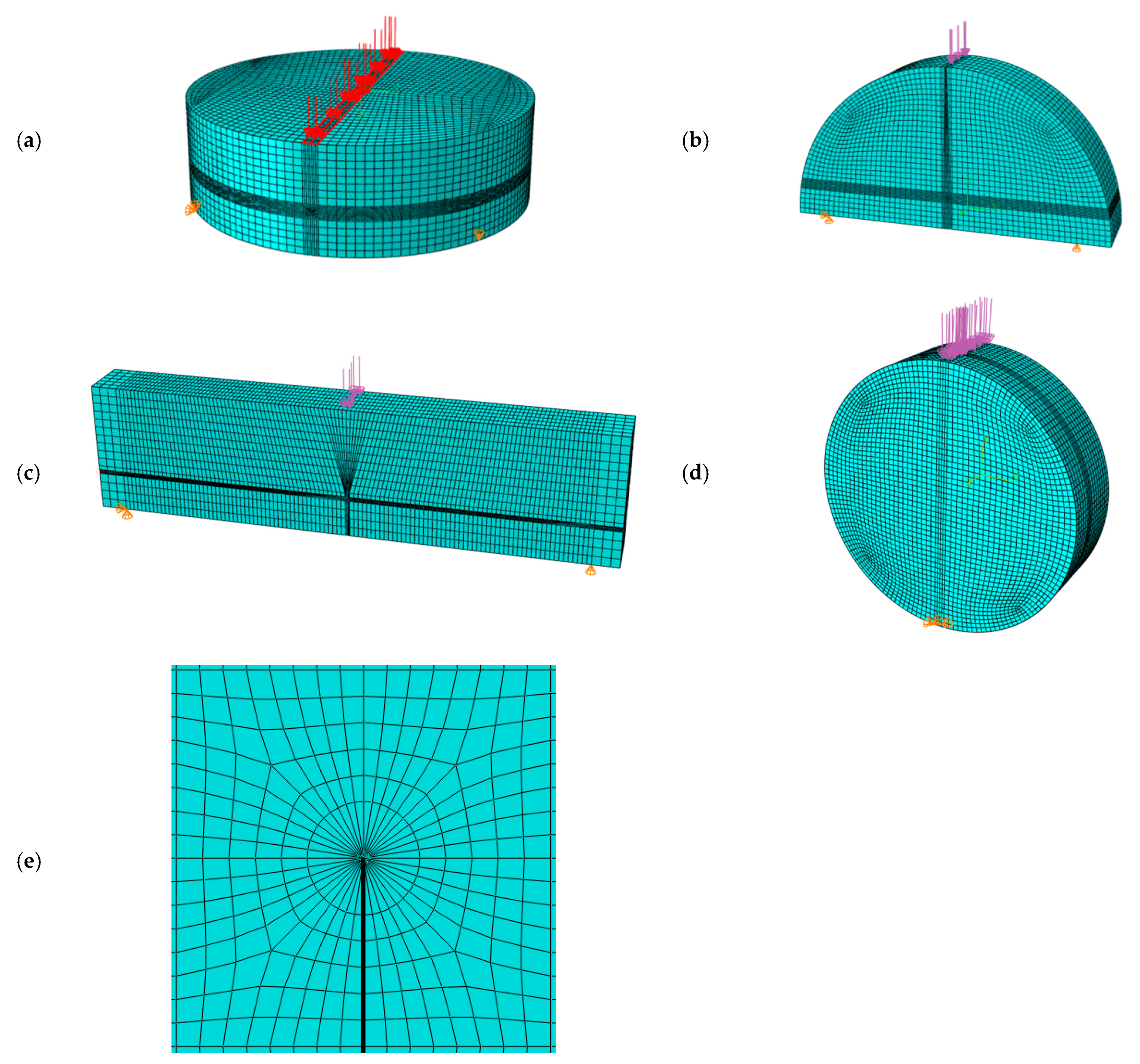

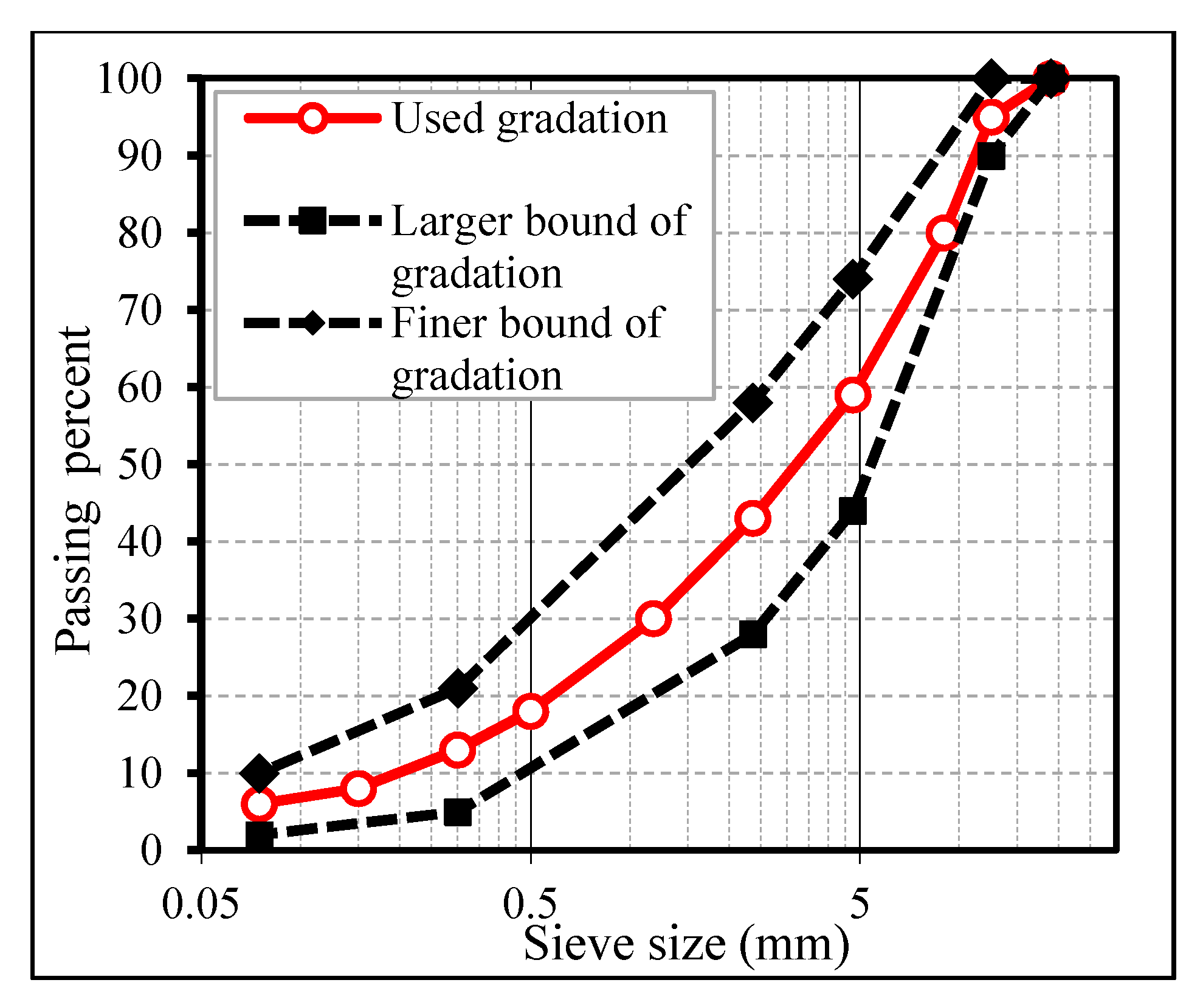

2. Fracture Toughness Test Specimens

3. Asphalt Mix Design

4. Results and Discussion

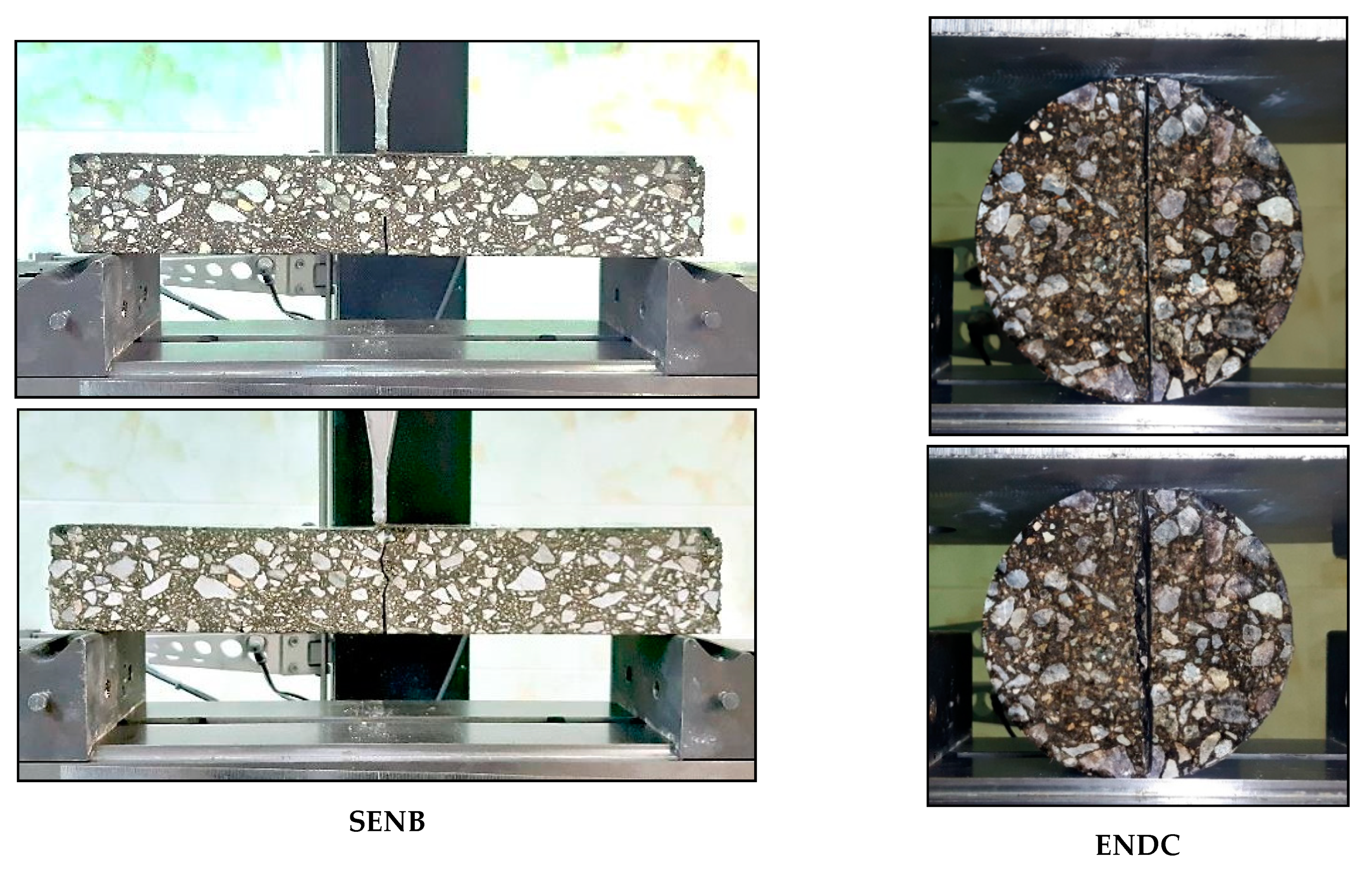

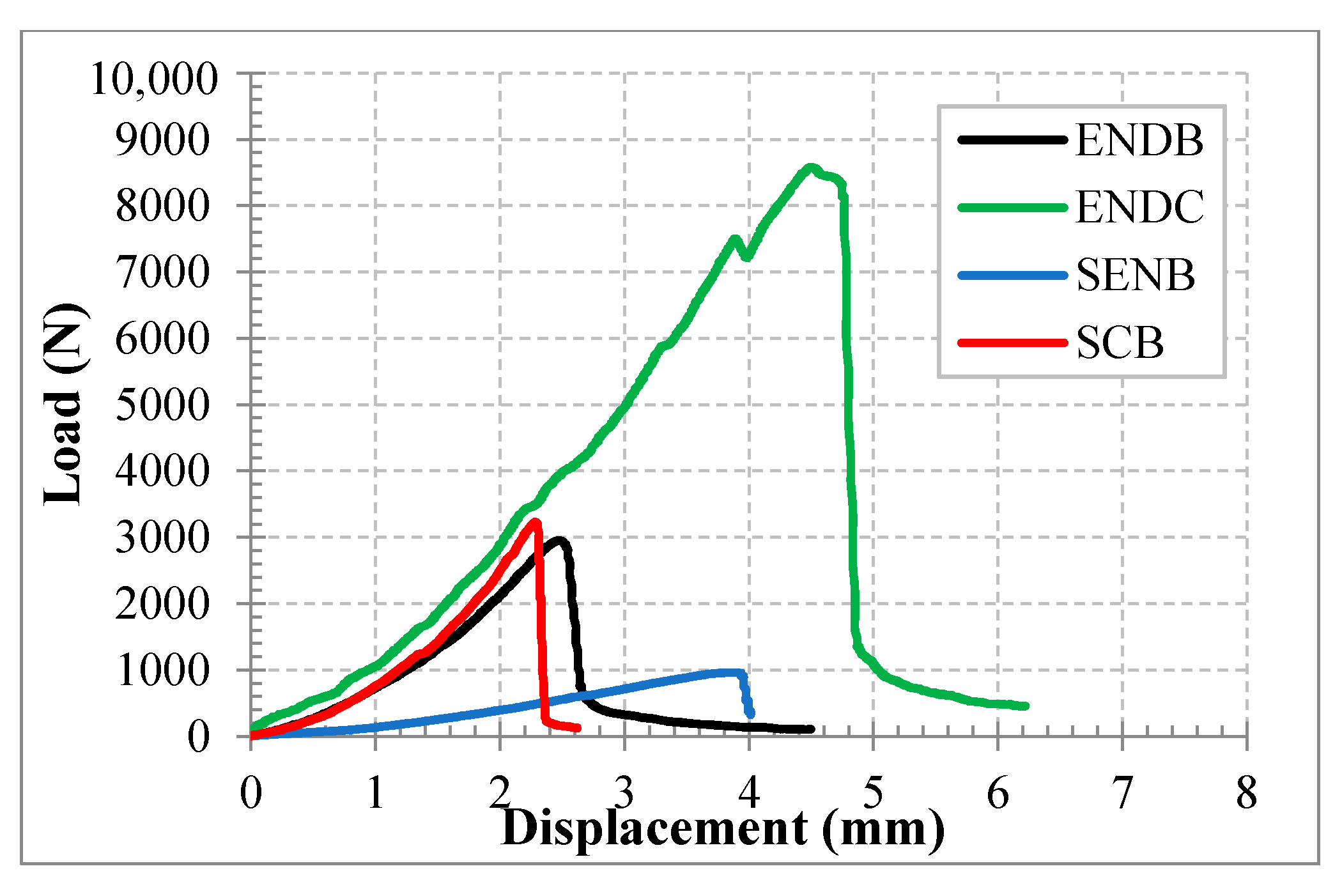

4.1. Fracture Pattern and Load-Displacement Curves

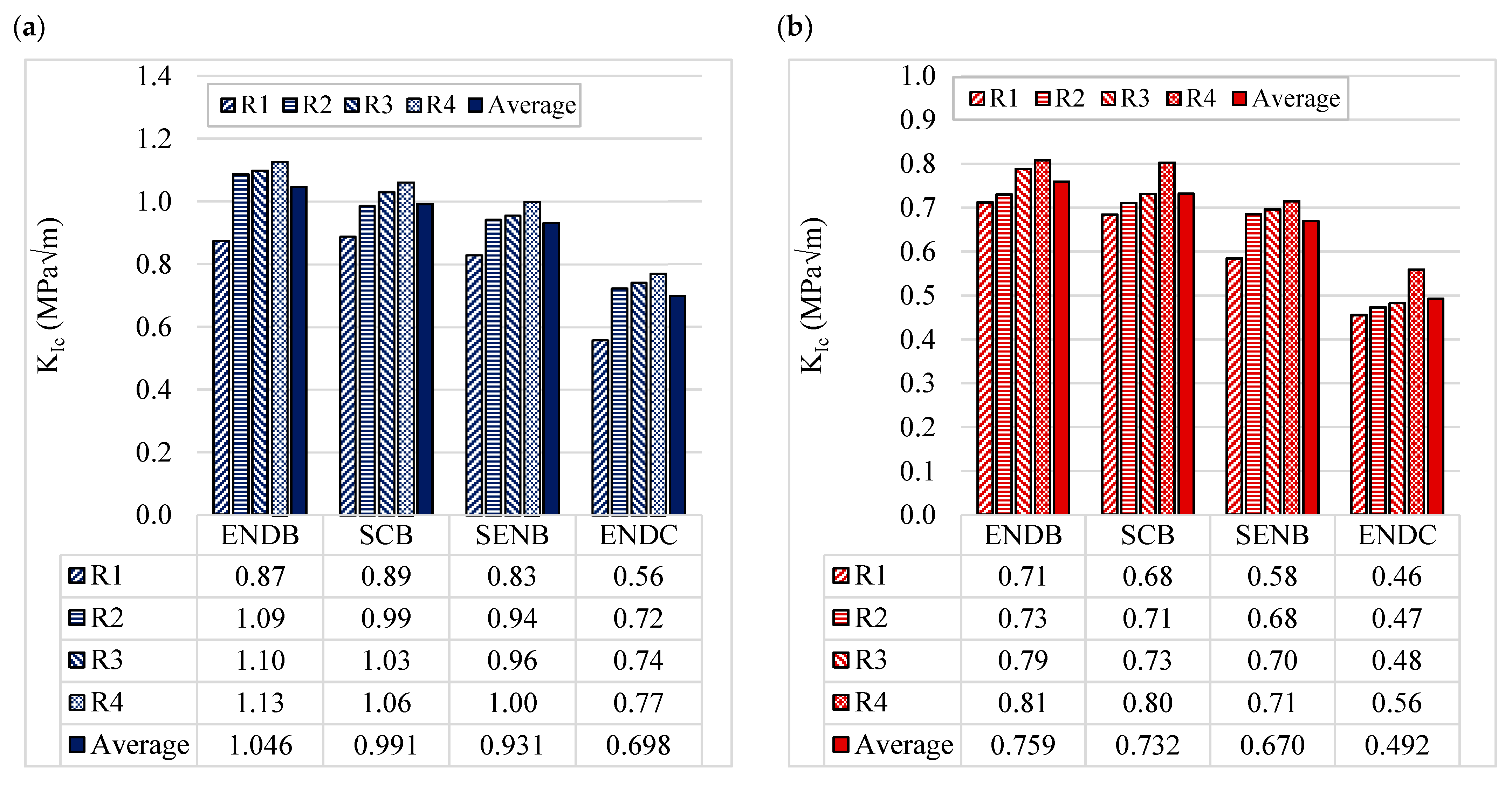

4.2. Fracture Resistance Values of Tested Samples

5. Conclusions

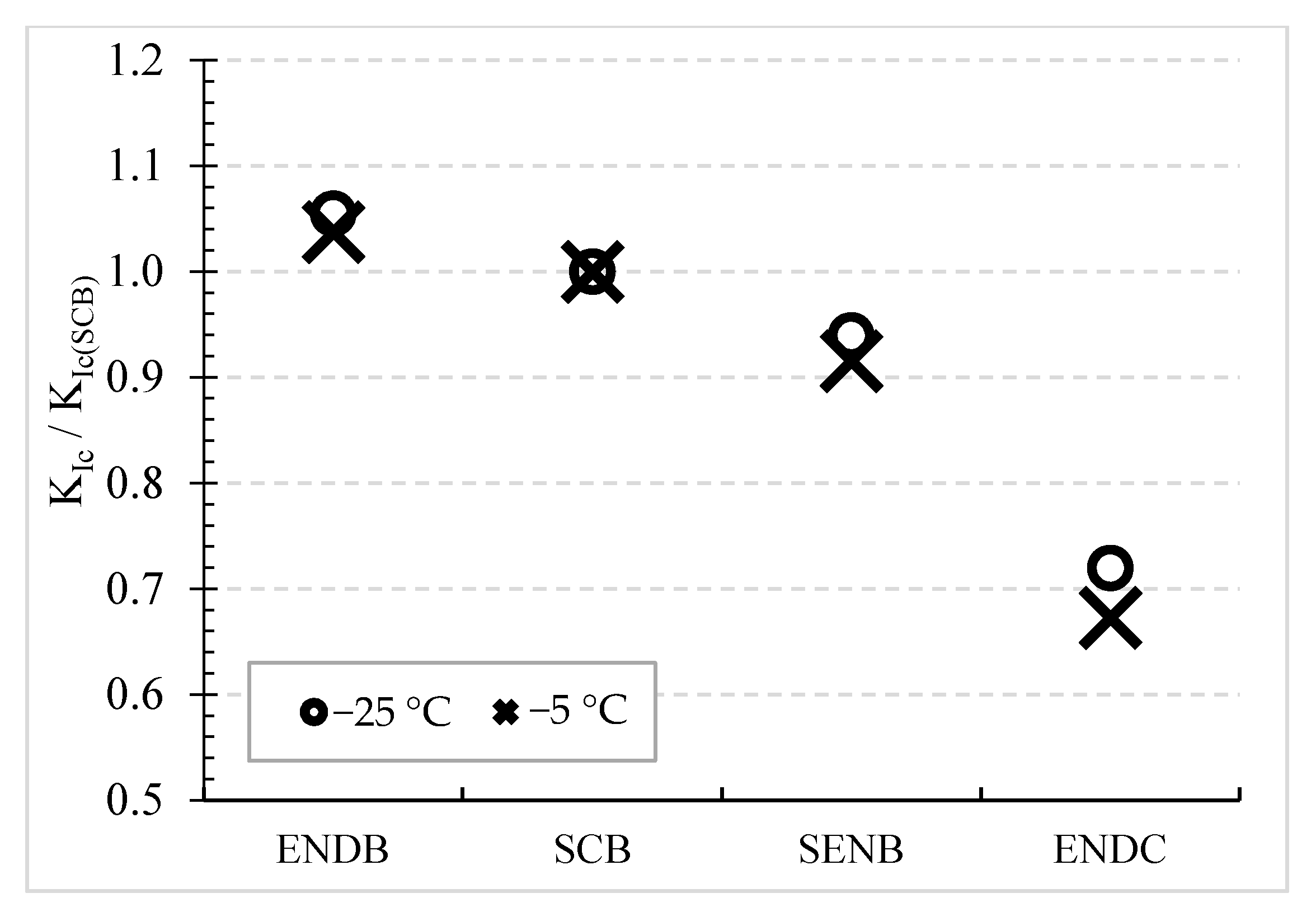

- The average fracture toughness value obtained using the ENDB, SCB, SENB and ENDC specimens at −25 °C were obtained equal to 1.05, 0.99, 0.93 and 0.7 MPa√m, respectively. Similarly, for −5 °C, the corresponding values of the average KIc for the same mixture were 0.76, 0.73, 0.67 and 0.49 MPa√m, respectively. These results demonstrate the effect of testing methods and temperature on the low temperature fracture resistance of asphalt mixtures.

- Results obtained from the bending type samples (ENDB, SCB and SENB specimens) were in a narrow bound and with slight differences. However, the KIc value obtained from the ENDC (loaded in diametral compression) was noticeably less than (about 25%) the results of other testing methods. It can be concluded that the type of the applied loading (i.e., bending or compression) has more significant effect than the shape of sample (disc or beam) on KIc value of asphalt mixtures.

- Fracture toughness results were increased by decreasing the test temperature from −5 °C to −25 °C by about 40 percent. However, the fracture toughness ratio (KIc (@−25 °C)/KIc (@−5 °C)) was nearly constant for the whole HMA tested samples under mode I with different shapes and loading conditions.

- The results of the ENDB specimen were very close to the fracture toughness obtained from the SCB specimen that is a recommended testing method by the ASTM. Therefore, among the investigated test samples the ENDB testing method can also be recommended for conducting low temperature fracture toughness test on asphalt mixtures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wagoner, M.P.; Buttlar, W.G.; Paulino, G.H.; Blankenship, P. Investigation of the Fracture Resistance of Hot-Mix Asphalt Concrete Using a Disk-Shaped Compact Tension Test. Transp. Res. Rec. 2005, 1929, 183–192. [Google Scholar] [CrossRef]

- Li, X.; Braham, A.F.; Marasteanu, M.O.; Buttlar, W.G.; Williams, R.C. Effect of Factors Affecting Fracture Energy of Asphalt Concrete at Low Temperature. Road Mater. Pavement Des. 2008, 9, 397–416. [Google Scholar] [CrossRef]

- Wagoner, M.P.; Buttlar, W.G.; Paulino, G.H. Disk-shaped compact tension test for asphalt concrete fracture. Exp. Mech. 2005, 45, 270–277. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Behbahani, H.; Fazaeli, H.; Rezaifar, M.H. Study of characteristic specification on mixed mode fracture toughness of asphalt mixtures. Constr. Build. Mater. 2014, 54, 623–635. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, Z.M.; Liu, H.J. On the I–II mixed mode fracture of granite using four-point bend specimen. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1193–1203. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Fazaeli, H.; Aghajani, S.; Moghadas Nejad, F. Effect of temperature and air void on mixed mode fracture toughness of modified asphalt mixtures. Constr. Build. Mater. 2015, 95, 545–555. [Google Scholar] [CrossRef]

- Mirsayar, M.; Shi, X.; Zollinger, D. Evaluation of Interfacial Bond Strength Between Portland Cement Concrete and Asphalt Concrete Layers Using Bimaterial Semicircular Bend Test Specimen. Eng. Solid Mech. 2017, 5, 293–306. [Google Scholar] [CrossRef]

- Xu, W.; Wei, X.; Wei, J.; Chen, Z. Experimental Evaluation of the Influence of Aggregate Strength on the Flexural Cracking Behavior of Epoxy Asphalt Mixtures. Materials 2020, 13, 1876. [Google Scholar] [CrossRef]

- Braham, A.; Buttlar, W.; Ni, F. Laboratory Mixed-Mode Cracking of Asphalt Concrete Using the Single-Edge Notch Beam. Road Mater. Pavement Des. 2010, 11, 947–968. [Google Scholar] [CrossRef]

- Kim, H.; Wagoner, M.P.; Buttlar, W.G. Micromechanical fracture modeling of asphalt concrete using a single-edge notched beam test. Mater. Struct. 2008, 42, 677. [Google Scholar] [CrossRef]

- Wang, J.; Zeng, W.; Qin, Y.; Huang, S.; Xu, J. Laboratory Evaluation of Rejuvenating Agent on Reclaimed SBS Modified Asphalt Pavement. Appl. Sci. 2017, 7, 743. [Google Scholar] [CrossRef] [Green Version]

- Marasteanu, M.O.; Dai, S.; Labuz, J.F.; Li, X. Determining the Low-Temperature Fracture Toughness of Asphalt Mixtures. Transp. Res. Rec. 2002, 1789, 191–199. [Google Scholar] [CrossRef] [Green Version]

- Stewart, C.M.; Oputa, C.W.; Garcia, E. Effect of specimen thickness on the fracture resistance of hot mix asphalt in the disk-shaped compact tension (DCT) configuration. Constr. Build. Mater. 2018, 160, 487–496. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, C.; Li, L.; You, Z.; Diab, A. Characterization of Low Temperature Crack Resistance of Crumb Rubber Modified Asphalt Mixtures Using Semi-Circular Bending Tests. J. Test. Eval. 2016, 44, 847–855. [Google Scholar] [CrossRef]

- Pérez-Jiménez, F.; Botella, R.; Moon, K.-H.; Marasteanu, M. Effect of load application rate and temperature on the fracture energy of asphalt mixtures. Fénix and semi-circular bending tests. Constr. Build. Mater. 2013, 48, 1067–1071. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Behbahani, H.; Fazaeli, H.; Rezairfar, M.H. Experimental study on mode i fracture toughness of different asphalt mixtures. Sci. Iran. 2015, 22, 120–130. [Google Scholar]

- Li, X.-J.; Marasteanu, M.O. Using Semi Circular Bending Test to Evaluate Low Temperature Fracture Resistance for Asphalt Concrete. Exp. Mech. 2010, 50, 867–876. [Google Scholar] [CrossRef]

- Ameri, M.; Mansourian, A.; Pirmohammad, S.; Aliha, M.R.M.; Ayatollahi, M.R. Mixed mode fracture resistance of asphalt concrete mixtures. Eng. Fract. Mech. 2012, 93, 153–167. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Fattahi Amirdehi, H.R. Fracture toughness prediction using Weibull statistical method for asphalt mixtures containing different air void contents. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 55–68. [Google Scholar] [CrossRef]

- Ameri, M.; Nowbakht, S.; Molayem, M.; Aliha, M.R.M. Investigation of fatigue and fracture properties of asphalt mixtures modified with carbon nanotubes. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 896–906. [Google Scholar] [CrossRef]

- Mubaraki, M.; Osman, S.A.; Sallam, H.E.M. Effect of RAP content on flexural behavior and fracture toughness of flexible pavement. Lat. Am. J. Solids Struct. 2019, 16. [Google Scholar] [CrossRef]

- Mubaraki, M.; Sallam, H.E.M. Reliability study on fracture and fatigue behavior of pavement materials using SCB specimen. Int. J. Pavement Eng. 2020, 21, 1563–1575. [Google Scholar] [CrossRef]

- Fakhri, M.; Haghighat Kharrazi, E.; Aliha, M.R.M.; Berto, F. The effect of loading rate on fracture energy of asphalt mixture at intermediate temperatures and under different loading modes. Frat. Integrita Strutt. 2018, 12, 113–132. [Google Scholar]

- Fakhri, M.; Haghighat Kharrazi, E.; Aliha, M.R.M. Mixed mode tensile—In plane shear fracture energy determination for hot mix asphalt mixtures under intermediate temperature conditions. Eng. Fract. Mech. 2018, 192, 98–113. [Google Scholar] [CrossRef]

- Fakhri, M.; Amoosoltani, E.; Aliha, M.R.M. Crack behavior analysis of roller compacted concrete mixtures containing reclaimed asphalt pavement and crumb rubber. Eng. Fract. Mech. 2017, 180, 43–59. [Google Scholar] [CrossRef]

- Fakhri, M.; Ali Siyadati, S.; Aliha, M.R.M. Impact of freeze–thaw cycles on low temperature mixed mode I/II cracking properties of water saturated hot mix asphalt: An experimental study. Constr. Build. Mater. 2020, 261, 119939. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Ziari, H.; Mojaradi, B.; Sarbijan, M.J. Heterogeneity effects on mixed-mode I/II stress intensity factors and fracture path of laboratory asphalt mixtures in the shape of SCB specimen. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 586–604. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Ziari, H.; Mojaradi, B.; Sarbijan, M.J. Modes I and II stress intensity factors of semi-circular bend specimen computed for two-phase aggregate/mastic asphalt mixtures. Theor. Appl. Fract. Mech. 2020, 106, 102437. [Google Scholar] [CrossRef]

- Najjar, S.; Mohammadzadeh Moghaddam, A.; Sahaf, A.; Rasaei Yazdani, M.; Delarami, A. Evaluation of the mixed mode (I/II) fracture toughness of cement emulsified asphalt mortar (CRTS-II) using mixture design of experiments. Constr. Build. Mater. 2019, 225, 812–828. [Google Scholar] [CrossRef]

- Mubaraki, M.; Elhady, A.; Sallam, H. Mixed mode fracture toughness of recycled tire rubber-filled concrete for airfield rigid pavements. Int. J. Pavement Res. Technol. 2013, 6, 8–14. [Google Scholar]

- He, J.; Liu, L.; Yang, H.; Aliha, M.R.M.; Karimi, H.R. Contribution of Interface Fracture Mechanism on Fracture Propagation Trajectory of Heterogeneous Asphalt Composites. Appl. Sci. 2021, 11, 3013. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Sarbijan, M.J.; Bahmani, A. Fracture toughness determination of modified HMA mixtures with two novel disc shape configurations. Constr. Build. Mater. 2017, 155, 789–799. [Google Scholar] [CrossRef]

- Bahmani, A.; Farahmand, F.; Ataei, F.; Aliha, M.R.M. Mixed mode I/III fracture parameters for edge-notched diametrically compressed disc specimen. Mater. Des. Process. Commun. 2019, 1, e86. [Google Scholar] [CrossRef] [Green Version]

- Aliha, M.R.M.; Bahmani, A.; Akhondi, S. Determination of mode III fracture toughness for different materials using a new designed test configuration. Mater. Des. 2015, 86, 863–871. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Bahmani, A.; Akhondi, S. A novel test specimen for investigating the mixed mode I+III fracture toughness of hot mix asphalt composites—Experimental and theoretical study. Int. J. Solids Struct. 2016, 90, 167–177. [Google Scholar] [CrossRef]

- Pirmohammad, S.; Bayat, A. Fracture resistance of HMA mixtures under mixed mode I/III loading at different subzero temperatures. Int. J. Solids Struct. 2017, 120, 268–277. [Google Scholar] [CrossRef]

- Eghbali, M.R.; Fallah Tafti, M.; Aliha, M.R.M.; Motamedi, H. The effect of ENDB specimen geometry on mode I fracture toughness and fracture energy of HMA and SMA mixtures at low temperatures. Eng. Fract. Mech. 2019, 216, 106496. [Google Scholar] [CrossRef]

- Motamedi, H.; Fazaeli, H.; Aliha, M.R.M.; Reza Amiri, H. Evaluation of temperature and loading rate effect on fracture toughness of fiber reinforced asphalt mixture using edge notched disc bend (ENDB) specimen. Constr. Build. Mater. 2020, 234, 117365. [Google Scholar] [CrossRef]

- Mansourian, A.; Hashemi, S.; Aliha, M.R.M. Evaluation of pure and mixed modes (I/III) fracture toughness of Portland cement concrete mixtures containing reclaimed asphalt pavement. Constr. Build. Mater. 2018, 178, 10–18. [Google Scholar] [CrossRef]

- Haghighat Pour, P.J.; Aliha, M.R.M.; Keymanesh, M.R. Evaluating mode I fracture resistance in asphalt mixtures using edge notched disc bend ENDB specimen with different geometrical and environmental conditions. Eng. Fract. Mech. 2018, 190, 245–258. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Jafari Haghighat Pour, P. Fracture resistance study for hot mix asphalt mixture under out of plane sliding mode. Eng. Fract. Mech. 2020, 238, 107230. [Google Scholar] [CrossRef]

- Najjar, S.; Mohammadzadeh Moghaddam, A.; Sahaf, A.; Aliha, M.R.M. Low temperature fracture resistance of cement emulsified asphalt mortar under mixed mode I/III loading. Theor. Appl. Fract. Mech. 2020, 110, 102800. [Google Scholar] [CrossRef]

- Kaloush, K.; Biligiri, K.; Zeiada, W.; Rodezno, M.; Reed, J. Evaluation of Fiber-Reinforced Asphalt Mixtures Using Advanced Material Characterization Tests. J. Test. Eval. 2010, 38, 400–411. [Google Scholar]

- Zhang, Z.; Roque, R.; Birgisson, B. Evaluation of Laboratory-Measured Crack Growth Rate for Asphalt Mixtures. Transp. Res. Rec. 2001, 1767, 67–75. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Sistaninia, M.; Smith, D.J.; Pavier, M.J.; Ayatollahi, M.R. Geometry effects and statistical analysis of mode I fracture in guiting limestone. Int. J. Rock Mech. Min. Sci. 2012, 51, 128–135. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Mahdavi, E.; Ayatollahi, M.R. The Influence of Specimen Type on Tensile Fracture Toughness of Rock Materials. Pure Appl. Geophys. 2017, 174, 1237–1253. [Google Scholar] [CrossRef]

- Chao, Y.J.; Liu, S.; Broviak, B.J. Brittle fracture: Variation of fracture toughness with constraint and crack curving under mode I conditions. Exp. Mech. 2001, 41, 232–241. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Bahmani, A.; Akhondi, S. Mixed mode fracture toughness testing of PMMA with different three-point bend type specimens. Eur. J. Mech. A/Solids 2016, 58, 148–162. [Google Scholar] [CrossRef]

- Pirmohammad, S.; Ayatollahi, M.R. Fracture resistance of asphalt concrete under different loading modes and temperature conditions. Constr. Build. Mater. 2014, 53, 235–242. [Google Scholar] [CrossRef]

- Song, W.; Huang, B.; Shu, X. Influence of warm-mix asphalt technology and rejuvenator on performance of asphalt mixtures containing 50% reclaimed asphalt pavement. J. Clean. Prod. 2018, 192, 191–198. [Google Scholar] [CrossRef]

- Wei, M.-D.; Dai, F.; Xu, N.-W.; Liu, Y.; Zhao, T. A novel chevron notched short rod bend method for measuring the mode I fracture toughness of rocks. Eng. Fract. Mech. 2018, 190, 1–15. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Razmi, A.; Mansourian, A. The influence of natural and synthetic fibers on low temperature mixed mode I+II fracture behavior of warm mix asphalt (WMA) materials. Eng. Fract. Mech. 2017, 182, 322–336. [Google Scholar] [CrossRef]

- Guo, Q.; Chen, Z.; Liu, P.; Li, Y.; Hu, J.; Gao, Y.; Li, X. Influence of basalt fiber on mode I and II fracture properties of asphalt mixture at medium and low temperatures. Theor. Appl. Fract. Mech. 2021, 112, 102884. [Google Scholar] [CrossRef]

- Somé, S.C.; Feeser, A.; Pavoine, A. Numerical and experimental investigation of mode I cracking of asphalt concrete using semi-circular bending test. Constr. Build. Mater. 2018, 169, 34–46. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Standard Test Method for Evaluation of Asphalt Mixture Cracking Resistance using the Semi-Circular Bend Test (SCB) at Intermediate Temperatures; D8044-16; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- American Society for Testing and Materials. Standard Test Method for Determining Fracture Energy of Asphalt Mixtures Using the Disk-Shaped Compact Tension Geometry; D7313-20; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Recho, N. Fracture Mechanics and Crack Growth; ISTE; Wiley: Clermont Ferrand, France, 2012; ISBN 9781118563281. [Google Scholar]

- Aliha, M.R.M.; Bahmani, A.; Akhondi, S. Numerical analysis of a new mixed mode I/III fracture test specimen. Eng. Fract. Mech. 2015, 134, 95–110. [Google Scholar] [CrossRef]

- Bahmani, A.; Aliha, M.R.M.; Jebalbarezi Sarbijan, M.; Mousavi, S.S. An extended edge-notched disc bend (ENDB) specimen for mixed-mode I+II fracture assessments. Int. J. Solids Struct. 2020, 193–194, 239–250. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Aliha, M.R.M.; Saghafi, H. An improved semi-circular bend specimen for investigating mixed mode brittle fracture. Eng. Fract. Mech. 2011, 78, 110–123. [Google Scholar] [CrossRef]

- Wagoner, M.P.; Buttlar, W.G.; Paulino, G.H. Development of a Single-Edge Notched Beam Test for Asphalt Concrete Mixtures. J. Test. Eval. 2005, 33, 452–460. [Google Scholar]

- Fuan, S.; Ke, M.; Kanghe, L.; Kun, L.; Aliha, M.R.M. Influence of specimen geometry on mode I fracture toughness of asphalt concrete. Constr. Build. Mater. 2021, 276, 122181. [Google Scholar] [CrossRef]

- Bahmani, A.; Farahmand, F.; Janbaz, M.R.; Darbandi, A.H.; Ghesmati-Kucheki, H.; Aliha, M.R.M. On the comparison of two mixed-mode I + III fracture test specimens. Eng. Fract. Mech. 2021, 241, 107434. [Google Scholar] [CrossRef]

- Bahmani, A.; Nemati, S. Fracture resistance of railway ballast rock under tensile and tear loads. Eng. Solid Mech. 2021, 9, 271–280. [Google Scholar] [CrossRef]

- Islam, M.R.; Kalevela, S.A.; Nesselhauf, S.K. Sensitivity of the Flow Number to Mix Factors of Hot-Mix Asphalt. Infrastructures 2019, 4, 34. [Google Scholar] [CrossRef] [Green Version]

- Shahryari, N.; Keymanesh, M.R.; Aliha, M.R.M. Specimen type effect on measured low-temperature fracture toughness of asphalt concrete. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 551–567. [Google Scholar] [CrossRef]

- Molenaar, J.M.M. Resistance to crack-growth and fracture of asphalt mixture. In Proceedings of the 6th International Rilem Symposium, Zurich, Switzerland, 14–16 April 2003; pp. 618–625. [Google Scholar]

- Mirsayar, M.M. On the low temperature mixed mode fracture analysis of asphalt binder—Theories and experiments. Eng. Fract. Mech. 2017, 186, 181–194. [Google Scholar] [CrossRef]

| Test | Value | Test Method |

|---|---|---|

| Specific gravity | 2.42 g/cm3 | ASTM C-127 |

| L.A. Abrasion | 23 (%) | AASHTO T-96 |

| Absorption (coarse aggregate) | 1.5 (%) | AASHTO T-85 |

| Absorption (fine aggregate) | 1 (%) | AASHTO T-84 |

| Percent fracture (one face) | 98 (%) | ASTM D5821 |

| Percent fracture (two face) | 91 (%) | ASTM D5821 |

| Optimal Bitumen (%) | Marshall Resistance (kN) | Air Voids (%) | Flow (mm) | Unit Weight (Kg/m3) | VMA * (%) | VFA ** (%) |

|---|---|---|---|---|---|---|

| 5.8 | 12.2 | 4.7 | 2.9 | 2200 | 14.6 | 67.8 |

| Specimen | Temperature (°C) | Fracture Load (N) | ||||

|---|---|---|---|---|---|---|

| Repeat 1 | Repeat 2 | Repeat 3 | Repeat 4 | Average | ||

| ENDB | −25 | 2401 | 2982 | 3014 | 3091 | 2872 |

| −5 | 1955 | 2005 | 2165 | 2218 | 2086 | |

| SCB | −25 | 2926 | 3249 | 3395 | 3493 | 3266 |

| −5 | 2252 | 2340 | 2409 | 2643 | 2411 | |

| SENB | −25 | 868 | 986 | 999 | 1044 | 974 |

| −5 | 611 | 716 | 728 | 747 | 701 | |

| ENDC | −25 | 6632 | 8595 | 8814 | 9158 | 8300 |

| −5 | 5415 | 5617 | 5739 | 6638 | 5852 | |

| Specimen | Dimentions | Test Condition | Mode I Geometry Factor |

|---|---|---|---|

| ENDB | R = 50 mm t = 30 mm | S/R = 0.9 a/t =0.4 | YI = 1.25 |

| SCB | R = 50 mm t = 30 mm | S/R = 0.66 a/R = 0.33 | YI = 4.0 |

| SENB | L = 400 mm W = 50 mm t = 50 mm | S/L = 0.9 a/w = 0.5 | YI = 0.79 |

| ENDC | R = 50 mm t = 30 mm | β = 0° | YI = 0.65 |

| Researcher | Temperature (°C) | Specimen | Asphalt Type | Fracture Toughness (MPa√m) |

|---|---|---|---|---|

| Aliha et al. [4] | −15 | SCB | HMA | 0.8 |

| Marasteanu et al. [12] | −18 | SENB | HMA | 0.52 and 0.61 |

| Aliha et al. [32] | −15 | ENDB | HMA | 0.67 |

| −15 | ENDC | HMA | 0.54 | |

| Pirmohammad and Bayat [36] | −5 | ENDB | HMA | 0.67 |

| −20 | ENDB | HMA | 0.78 | |

| Eghbali et al. [37] | −15 | ENDB | HMA | 0.86 |

| Fuan et al. [62] | −15 | ENDB | HMA | 0.95 |

| −15 | SCB | HMA | 0.75 | |

| −25 | ENDB | HMA | 1.05 | |

| −25 | SCB | HMA | 0.83 | |

| Shahryari et al. [66] | −20 | ENDC | HMA | 0.65 |

| −20 | ENDB | HMA | 0.75 | |

| Molenaar [67] | 0 | SCB | Dense Graded Asphalt | 0.88 |

| −10 | SCB | 0.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Karimi, H.R.; Aliha, M.R.M. Comparison of Testing Method Effects on Cracking Resistance of Asphalt Concrete Mixtures. Appl. Sci. 2021, 11, 5094. https://doi.org/10.3390/app11115094

Yang D, Karimi HR, Aliha MRM. Comparison of Testing Method Effects on Cracking Resistance of Asphalt Concrete Mixtures. Applied Sciences. 2021; 11(11):5094. https://doi.org/10.3390/app11115094

Chicago/Turabian StyleYang, Dayong, Hamid Reza Karimi, and Mohammad Reza Mohammad Aliha. 2021. "Comparison of Testing Method Effects on Cracking Resistance of Asphalt Concrete Mixtures" Applied Sciences 11, no. 11: 5094. https://doi.org/10.3390/app11115094

APA StyleYang, D., Karimi, H. R., & Aliha, M. R. M. (2021). Comparison of Testing Method Effects on Cracking Resistance of Asphalt Concrete Mixtures. Applied Sciences, 11(11), 5094. https://doi.org/10.3390/app11115094