Drying Stress and Strain of Wood: A Review

Abstract

:1. Introduction

2. Wood Drying Stress

2.1. Wood Drying Defects and Drying Stress

2.2. The Generation and Development Mechanism of Wood Drying Stress

2.3. Advances of the Wood Drying Stress Model

3. Composition of Drying Strain

3.1. Free Shrinkage Strain

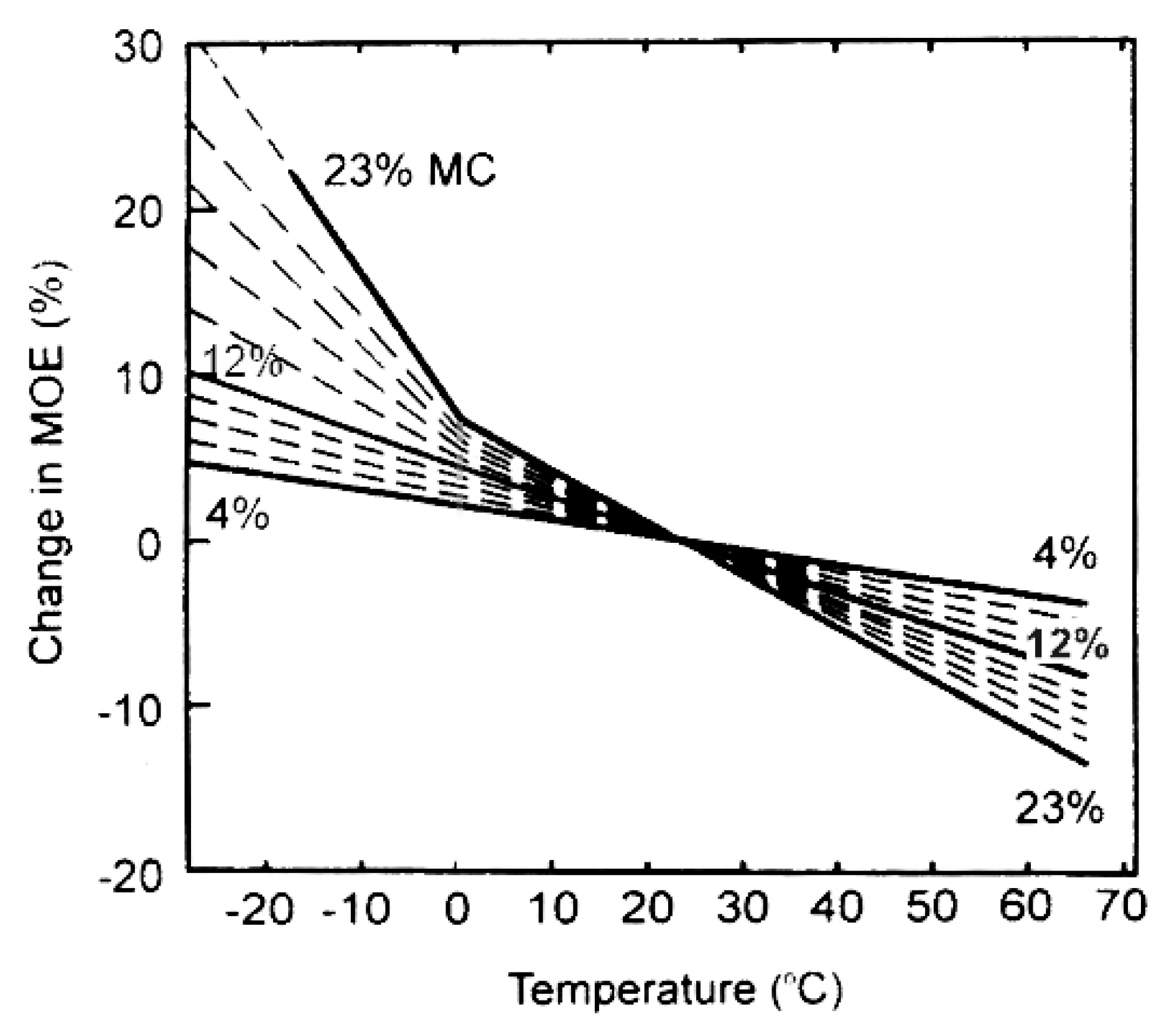

3.2. Elastic Strain

3.3. Viscoelastic Creep Strain

3.4. Mechano-Sorptive Creep Strain

4. Testing Methods of Wood Drying Stress and Strain

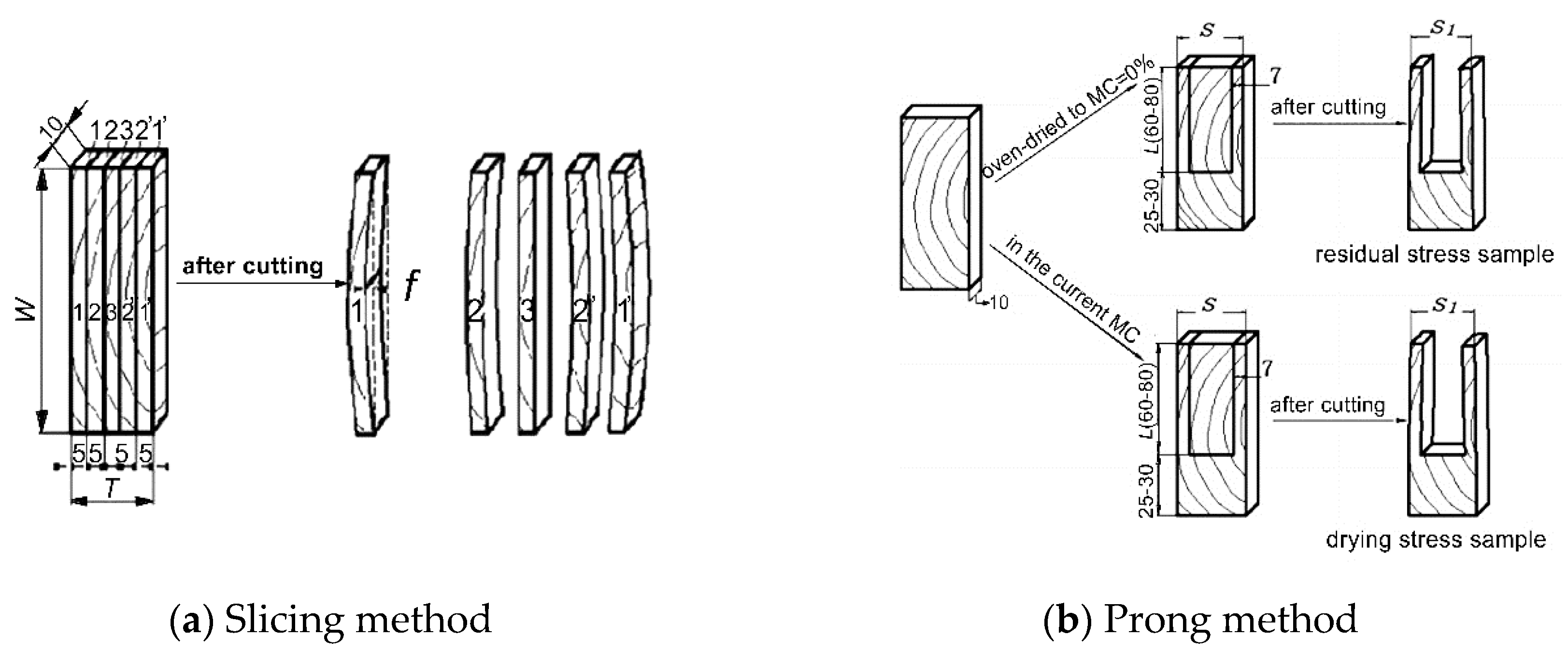

4.1. Commonly Used Testing Methods

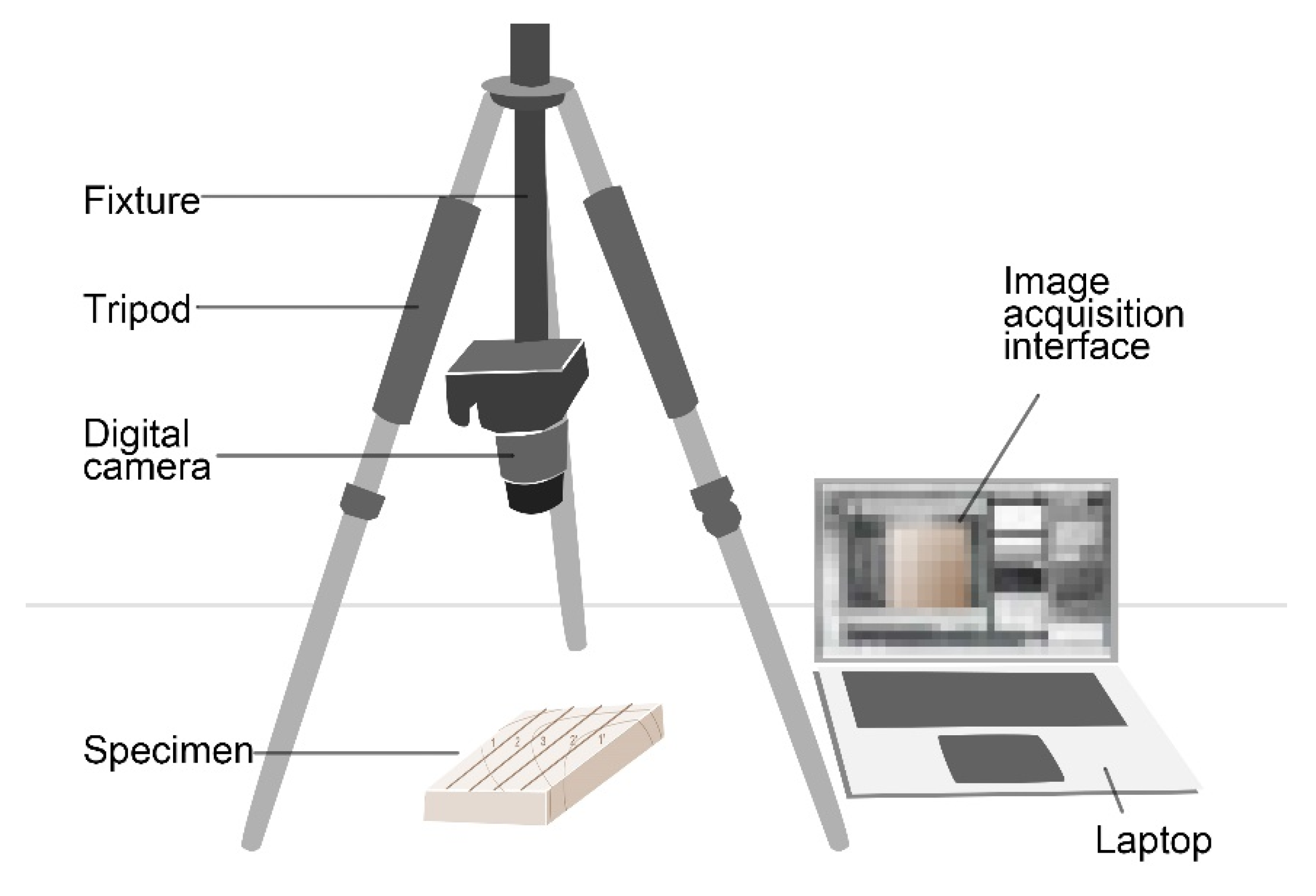

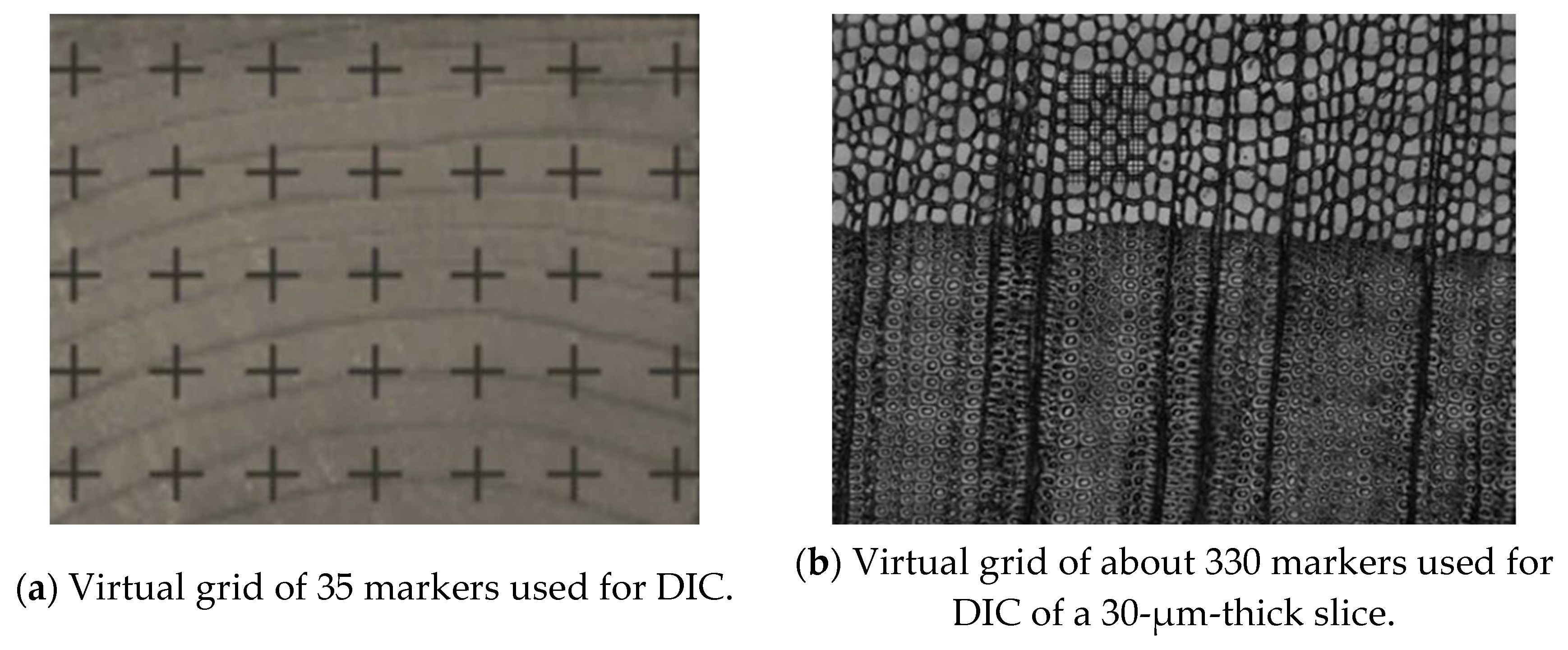

4.2. Modern Testing Methods

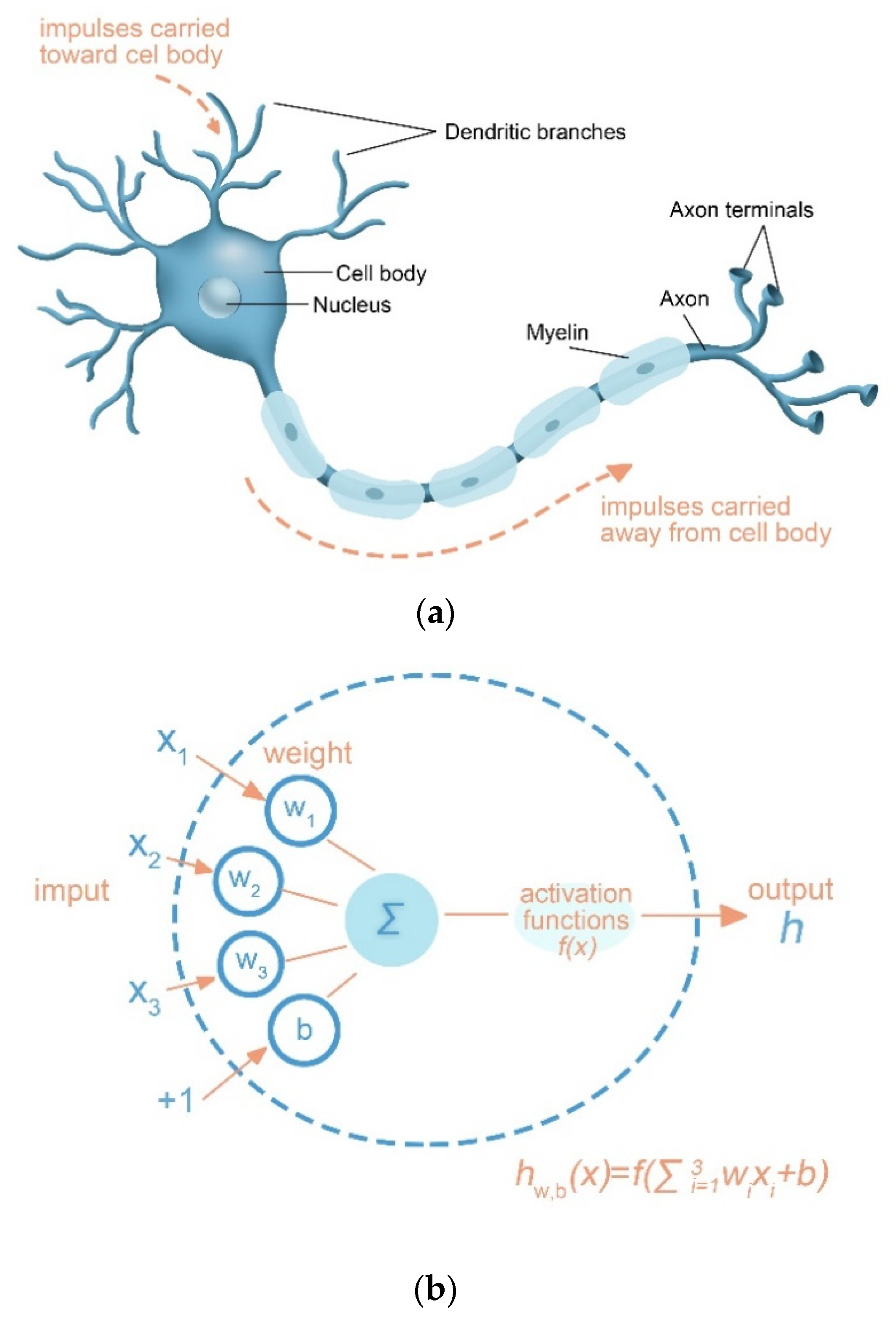

5. Artificial Neural Network and Its Application in the Field of Wood Drying

5.1. Artificial Neural Network (ANN)

5.2. Back Propagation (BP) Neural Network Structure and Algorithm

5.2.1. BP Neural Network Structure

5.2.2. BP Neural Network Algorithm

5.3. Application of ANNs in the Field of Wood Drying

6. Conclusions and Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Liu, X.Y.; Lv, M.Q.; Liu, M.; Lv, J.F. Repeated humidity cycling’s effect on physical properties of three kinds of wood-based panels. Bioresources 2019, 14, 9444–9453. Available online: https://ojs.cnr.ncsu.edu/index.php/BioRes/article/view/BioRes_14_4_9444_Liu_Humidity_Cycling_Wood_Panels/7219 (accessed on 12 December 2020).

- Liu, X.Y.; Tu, X.W.; Liu, M. Effects of light thermal treatments on the color, hygroscopity and dimensional stability of wood. Wood Res. 2021, 66, 95–104. Available online: http://www.woodresearch.sk/wr/202101/09.pdf (accessed on 7 May 2021). [CrossRef]

- Wan, Y.; Hou, S.J.; Guo, M.Y.; Fu, Y.C. Surface Properties of Spray-Assisted Layer-By-Layer ElectroStatic Self-Assembly Treated Wooden Take-Off Board. Appl. Sci. 2021, 11, 836. Available online: https://www.mdpi.com/2076-3417/11/2/836 (accessed on 7 May 2021). [CrossRef]

- Liu, Y.; Hu, J. Investigation of polystyrene-based microspheres from different copolymers and their structural color coatings on wood surface. Coatings 2021, 11, 14. Available online: https://www.mdpi.com/2079-6412/11/1/14 (accessed on 2 May 2021). [CrossRef]

- Zhao, Z.; Sakai, S.; Wu, D.; Chen, Z.; Zhu, N.; Huang, C.; Sun, S.; Zhang, M.; Umemura, K.; Yong, Q. Further exploration of sucrose–citric acid adhesive: Investigation of optimal hot-pressing conditions for plywood and curing behavior. Polymers 2019, 11, 1996. Available online: https://www.mdpi.com/2073-4360/11/11/1875 (accessed on 12 December 2020).

- Xiong, X.Q.; Ma, Q.R.; Yuan, Y.Y.; Wu, Z.H.; Zhang, M. Current situation and key manufacturing considerations of green furniture in China: A review. J. Clean. Prod. 2020, 267, 121957. [Google Scholar] [CrossRef]

- Lu, X.R.; Teng, Q.C.; Li, Z.R.; Zhang, X.L.; Wang, X.M.; Komatsu, K.H.; Que, Z.L. Study on shear property of spruce glulam and steel plate connected with inclined screw. J. For. Eng. 2020, 5, 48–53. Available online: https://qzl.njfu.edu.cn/kindeditor/attached/file/20200514/20200514215442524252.pdf (accessed on 20 December 2020).

- Gao, X.; Zhou, F.; Fu, Z.Y.; Zhou, Y.D. Analysis of rosin in pine wood by time domain nuclear magnetic resonance. J. For. Eng. 2019, 4, 42–47. [Google Scholar] [CrossRef]

- Telkki, V.V.; Yliniemi, M.; Jokisaari, J. Moisture in softwoods: Fiber saturation point, hydroxyl site content, and the amount of micropores as determined from NMR relaxation time distributions. Holzforschung 2013, 67, 291–300. [Google Scholar] [CrossRef]

- Ma, E.N.; Wang, W.; Li, X.; Yang, T.T. The States of Water in Wood during Drying Process Studied by Low-Field Nuclear Magnetic Resonance (LFNMR). Sci. Silvae Sin. 2017, 53, 111–117. Available online: http://www.linyekexue.net/CN/abstract/abstract7626.shtml (accessed on 15 April 2021). (In Chinese).

- Rostom, L.; Caré, S.; Courtier-Murias, D. Analysis of water content in wood material through 1D and 2D 1H NMR relaxometry: Application to the determination of the dry mass of wood. Magn. Reson. Chem. 2021, 59, 614–627. Available online: https://analyticalsciencejournals.onlinelibrary.wiley.com/doi/abs/10.1002/mrc.5125 (accessed on 15 April 2021). [CrossRef]

- Avramidis, S.; Wu, H. Artificial neural network and mathematical modeling comparative analysis of nonisothermal diffusion of moisture in wood. Holz Roh Werkstoff 2007, 65, 89–93. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, X.L.; Hu, Z.K.; Yu, Y.B.; Yang, Y.T.; Xu, C.Y. Wood defect recognition based on optimized convolution neural network algorithm. J. For. Eng. 2019, 4, 115–120. [Google Scholar] [CrossRef]

- Broda, M. Natural Compounds for Wood Protection against Fungi—A Review. Molecules 2020, 25, 3538. Available online: https://www.mdpi.com/1420-3049/25/15/3538 (accessed on 2 February 2020). [CrossRef] [PubMed]

- Broda, M.; Dąbek, I.; Dutkiewicz, A.; Dutkiewicz, M.; Popescu, C.-M.; Mazela, B.; Maciejewski, H. Organosilicons of different molecular size and chemical structure as consolidants for waterlogged archaeological wood—A new reversible and retreatable method. Sci. Rep. 2020, 10, 2188. [Google Scholar] [CrossRef] [Green Version]

- Broda, M.; Mazela, B.; Dutkiewicz, A. Organosilicon compounds with various active groups as consolidants for the preservation of waterlogged archaeological wood. J. Cult. Herit. 2019, 35, 123–128. Available online: https://www.sciencedirect.com/science/article/pii/S1296207418302462 (accessed on 2 February 2020). [CrossRef]

- Lisuzzo, L.; Hueckel, T.; Cavallaro, G.; Sacanna, S.; Lazzara, G. Pickering Emulsions Based on Wax and Halloysite Nanotubes: An Ecofriendly Protocol for the Treatment of Archeological Woods. ACS Appl. Mater. Interfaces 2021, 13, 1651–1661. [Google Scholar] [CrossRef]

- Yang, L.; Han, T.Q.; Fu, Y.D. Effect of Heat Treatment and Wax Impregnation on Dimensional Stability of Pterocarpus Macrocarpus wood. Wood Res. 2020, 65, 963–974. Available online: http://www.woodresearch.sk/wr/202006/10.pdf (accessed on 12 December 2020). [CrossRef]

- Tiemann, H.D. Effect of Moisture on the Strength and Stiffness of Wood; J Frankl Associates, Inc.: New York, NY, USA, 1906; Volume 162, pp. 465–466. Available online: https://www.sciencedirect.com/science/article/pii/S0016003206902658 (accessed on 12 December 2020).

- Stamm, A.J. Review of nine methods for determining the fiber saturation points of wood and wood products. Wood Sci. 1971, 4, 114–128. [Google Scholar]

- Hoffmeyer, P.; Engelund, E.T.; Thygesen, L.G. Equilibrium moisture content (EMC) in Norway spruce during the first and second desorptions. Holzforschung 2011, 65, 875–882. [Google Scholar] [CrossRef]

- Engelund, E.T.; Thygesen, L.G.; Svensson, S.; Hill, C.A.S. A critical discussion of the physics of wood–water interactions. Wood Sci. Technol. 2013, 47, 141–161. [Google Scholar] [CrossRef] [Green Version]

- Brischke, C.; Alfredsen, G. Wood-water relationships and their role for wood susceptibility to fungal decay. Appl. Microbiol. Biotechnol. 2020, 104, 3781–3795. Available online: https://www.ncbi.nlm.nih.gov/pubmed/32144473 (accessed on 2 February 2020). [CrossRef]

- Pang, S. Mathematical Modeling of Kiln Drying of Softwood Timber: Model Development, Validation, and Practical Application. Dry. Technol. 2007, 25, 421–431. [Google Scholar] [CrossRef]

- Simpson, W.T. Dry kiln operator’s manual. In Agriculture Handbook; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1991; Available online: https://www.woodweb.com/knowledge_base/Dry_kiln_operators_manual.html?fb_locale=fr_FR (accessed on 12 December 2020).

- Skaar, C.; Simpson, W.T.; Honeycutt, R.M. Use of acoustic emissions to identify high levels of stress during oak lumber drying. For. Prod. J. 1980, 30, 21–22. [Google Scholar] [CrossRef]

- Stöhr, H.P. Shrinkage differential as a measure for drying stress determination. Wood Sci. Technol. 1988, 22, 121–128. [Google Scholar] [CrossRef]

- Ashworth, J.G. The Mathematical Simulation of Drying of Softwood Timber. Ph.D. Thesis, University of Canterburg, Christchurch, New Zealand, 1977. [Google Scholar]

- Morgan, K.; Thomas, H.R.; Lewis, R.W. Numerical modeling of stress reversal in timber drying. Wood Sci. 1982, 15, 139–149. [Google Scholar]

- Avramidis, S.; Liadis, L. Predicting wood thermal conductivity using artificial neural networks. Wood Fiber Sci. 2005, 37, 682–690. Available online: https://www.mendeley.com/catalogue/366618fd-0598-3982-b4e0-966d4a94d0b6/ (accessed on 11 October 2020).

- Fernández, F.; Esteban, L.G.; Palacios, P.D.; Casasús, A. Use of artificial neural networks in timber engineering: Calculating modulus of elasticity using non-destructive testing. In Proceedings of the 11th World Conference on Timber Engineering, Riva del Garda, Italy, 20–24 June 2010; pp. 66–72. [Google Scholar]

- Desch, H.E.; Dinwoodie, J.M. Timber: Structure, Properties, Conversion and Use, 7th ed.; Macmillan Press: London, UK, 1996; 306p. [Google Scholar]

- Haque, N. Delamination in timber induced by drying. In Delamination in Wood, Wood Products and Wood-Based Composites; Bucur, V., Ed.; Springer: Cham, Switzerland, 2007; p. 212. [Google Scholar]

- Gao, J.M.; Wang, X.M. Wood Drying, 2nd ed.; Science Press: Peking, China, 2018; pp. 104–133. [Google Scholar]

- Campbell, G.S. The value of pre-steaming for drying some collapse-susceptible Eucalypts. For. Prod. J. 1961, 11, 343–347. [Google Scholar]

- Chen, P.Y. The effect of steaming time and temperature on the longitudinal permeability of black walnut. Wood Fiber 1975, 7, 222–225. [Google Scholar]

- Simpson, W.T. Effect of pre-steaming on moisture gradient of northern red oak during drying. Wood Sci. 1976, 8, 272–276. [Google Scholar]

- Alexiou, P.N.; Marchant, J.F.; Groves, K.W. Effect of pre-steaming on moisture gradients, dryinag stresses and sets, and face checking in regrowth Eucalyptus pilularis Sm. Wood Sci. Technol. 1990, 24, 201–209. [Google Scholar] [CrossRef]

- Alexiou, P.N.; Wilkins, A.P.; Hartley, J. Effect of pre-steaming on drying rate, wood anatomy and shrinkage of regrowth Eucalyptus pilularis Sm. Wood Sci. Technol. 1990, 24, 103–110. [Google Scholar] [CrossRef]

- Lee, N.H.; Li, C.; Zhao, X.F.; Park, M.J. Effect of pretreatment with high temperature and low humidity on drying time and prevention of checking during radio-frequency/vacuum drying of Japanese cedar pillar. J. Wood Sci. 2010, 56, 19–24. [Google Scholar] [CrossRef]

- Ratnasingam, J.; Grohmann, R.; Scholz, F. Effects of pre-steaming on the drying quality of Rubberwood. Eur. J. Wood Wood Prod. 2014, 72, 135–137. [Google Scholar] [CrossRef]

- Harris, G.; Torgovnikov, G.; Vinden, P.; Brodie, G.; Shaginov, A. Microwave Pretreatment of Backsawn Messmate Boards to Improve Drying Quality: Part 1. Dry. Technol. 2008, 26, 579–584. [Google Scholar] [CrossRef]

- Weng, X.; Zhou, Y.; Fu, Z.; Gao, X.; Zhou, F.; Jiang, J. Effects of microwave pretreatment on drying of 50 mm-thickness Chinese fir lumber. J. Wood Sci. 2021, 67, 1–9. [Google Scholar] [CrossRef]

- Zhan, J.F.; Avramidis, S. Impact of conventional drying and thermal post-treatment on the residual stresses and shape deformations of larch lumber. Dry. Technol. 2017, 35, 15–24. [Google Scholar] [CrossRef]

- Hou, J.F.; Zhou, Y.D. The research status and application prospects of wood hot-press drying. World For. Res. 2017, 30, 41–45. (In Chinese) [Google Scholar]

- Scherer, G.W. Stress and strain during supercritical drying. J. Sol Gel Sci. Technol. 2019, 90, 8–19. [Google Scholar] [CrossRef]

- Wang, H.H.; Youngs, R.L. Drying Stress and Check Development in the Wood of two Oaks. IAWA J. 1996, 17, 15–30. [Google Scholar] [CrossRef]

- Chen, G.; Keey, R.B.; Walker, J.C.F. The drying stress and check development on high-temperature kiln seasoning of sapwoodPinus radiata boards: I. Moisture movement and strain model. Holz Roh Werkstoff 1997, 55, 59–64. [Google Scholar] [CrossRef]

- Chen, G.; Keey, R.B.; Walker, J.C.F. The drying stress and check development on high-temperature kiln seasoning of sapwoodPinus radiata boards: II. Stress development. Holz Roh Werkstoff 1997, 55, 169–173. [Google Scholar] [CrossRef]

- Fu, Z.; Zhao, J.; Huan, S.; Sun, X.; Cai, Y. The variation of tangential rheological properties caused by shrinkage anisotropy and moisture content gradient in white birch disks. Holzforschung 2015, 69, 573–579. Available online: https://www.researchgate.net/publication/282551406 (accessed on 11 October 2020). [CrossRef]

- Liu, J.X. Research of Wood Drying Shrinkage Development Process and Drying Contraction Stress. Master’s Thesis, Inner Mongolia Agricultural University, IMAR, China, 2017. [Google Scholar]

- Song, T.Y.; Fu, Z.F.; Cai, Y.C. The effect of high-frequency-convection combined heating and drying on wood temperature gradient and drying quality. J. Nor. For. Univ. 2018, 46, 74–79. (In Chinese) [Google Scholar]

- Salinas, C.; Chavez, C.; Ananias, R.A.; Elustondo, D. Unidimensional Simulation of Drying Stress in Radiata Pine Wood. Dry. Technol. 2015, 33, 996–1005. [Google Scholar] [CrossRef]

- Salinas, C.H.; Chávez, C.A.; Pérez-Peña, N.; Vargas, H.; Ananías, R.A. Two-dimensional simulation of mechanical stresses during isothermal drying of Eucalyptus nitens wood. Wood Sci. Technol. 2020, 54, 187–201. [Google Scholar] [CrossRef]

- Truscott, S.L.; Turner, I.W. A heterogeneous three-dimensional computational model for wood drying. Appl. Math. Model. 2005, 29, 381–410. Available online: https://www.sciencedirect.com/science/article/pii/S0307904x04001040 (accessed on 20 October 2020). [CrossRef]

- Shi, X.L.; Xiu, S.C.; Su, H.L. Residual stress model of pre-stressed dry grinding considering coupling of thermal, stress, and phase transformation. Adv. Manuf. 2019, 7, 401–410. [Google Scholar] [CrossRef]

- Perré, P.; Huber, F. Measurement of free shrinkage at the tissue level using an optical microscope with an immersion objective: Results obtained for Douglas fir (Pseudotsuga menziesii) and spruce (Picea abies). Ann. For. Sci. 2007, 64, 255–265. [Google Scholar] [CrossRef] [Green Version]

- Perré, P.; Almeida, G.; Ayouz, M.; Frank, X. New modelling approaches to predict wood properties from its cellular structure: Image-based representation and meshless methods. Ann. For. Sci. 2016, 73, 147–162. [Google Scholar] [CrossRef] [Green Version]

- Almeida, G.; Assor, C.; Perré, P. The Dynamic of Shrinkage/Moisture Content Behavior Determined During Drying of Microsamples for Different Kinds of Wood. Dry. Technol. 2008, 26, 1118–1124. [Google Scholar] [CrossRef]

- Kobayashi, I. Application of surface strain reasoning for wood drying. In Proceedings of the 7th International IUFRO Wood Drying Conference, Tsukuba, Japan, 9–13 July 2001; pp. 336–341. [Google Scholar]

- Tu, D.Y. Research on Drying Stress Model and Strain Continuous Measurement of Masson Pine Board. Ph.D. Thesis, Nanjing Forestry University, Nanjing, China, 2005. [Google Scholar]

- Kang, W.; Lee, N.H. Relationship between radial variations in shrinkage and drying defects of tree disks. J. Wood Sci. 2004, 50, 209–216. [Google Scholar] [CrossRef]

- Li, C.Y.; Lee, N.H. Effect of compressive load on shrinkage of larch blocks during radio-frequency vacuum heating. Wood Fiber Sci. 2004, 36, 9–16. [Google Scholar]

- Bodig, J.; Jayne, B.A. Mechanics of Wood and Wood Composites; Krieger Publishing: Malabar, FL, USA, 1982. [Google Scholar]

- Green, D.W.; Evans, J.W. The immediate effect of temperature on the modulus of elasticity of green and dry lumber. Wood Fiber Sci. 2008, 40, 374–383. [Google Scholar]

- Gao, S.; Wang, X.P. The influence of temperature and moisture state on the flexural elastic modulus of American Korean pine. J. For. Eng. 2014, 28, 38–42. (In Chinese) [Google Scholar]

- Sun, L.W.; Bian, Y.L.; Zhou, A.P.; Zhu, Y. Study on short-term creep property of bamboo scrimber. J. For. Eng. 2020, 5, 69–75. [Google Scholar] [CrossRef]

- Hanhijärvi, A.; Hunt, D. Experimental indication of interaction between viscoelastic and mechano-sorptive creep. Wood Sci. Technol. 1998, 32, 57–70. [Google Scholar] [CrossRef]

- Han, Y.; Yang, S.Y.; Park, J.H.; Chang, Y.S.; Eom, C.D.; Yeo, H. Separation of drying strains and the calculation of drying stresses considering the viscoelasticity of red pine wood during drying. Dry. Technol. 2017, 35, 1858–1866. [Google Scholar] [CrossRef]

- Ranta-Maunus, A. The viscoelasticity of wood at varying moisture content. Wood Sci. Technol. 1975, 9, 189–205. [Google Scholar] [CrossRef]

- Haque, M.N.; Langrish, T.A.G.; Keep, L.B.; Keey, R.B. Model fitting for visco-elastic creep of Pinus radiata during kiln drying. Wood Sci. Technol. 2000, 34, 447–457. [Google Scholar] [CrossRef]

- Hering, S.; Niemz, P. Moisture-dependent, viscoelastic creep of European beech wood in longitudinal direction. Eur. J. Wood Wood Prod. 2012, 70, 667–670. [Google Scholar] [CrossRef]

- Armstrong, L.D.; Kingston, R.S. Effect of Moisture Changes on Creep in Wood. Nature 1960, 185, 862–863. [Google Scholar] [CrossRef]

- Hunt, D.G. Dimensional changes and creep of spruce, and consequent model requirements. Wood Sci. Technol. 1997, 31, 3–16. [Google Scholar] [CrossRef]

- Wu, Q.L.; Milota, M.R. Rheological behavior of Douglas-fir perpendicular to the grain at elevated temperatures. Wood Fiber Sci. 1995, 27, 285–295. [Google Scholar]

- Pérez-Peña, N.; Cloutier, A.; Segovia, F.; Salinas-Lira, C.; Sepúlveda-Villarroel, V.; Salvo-Sepúlveda, L.; Elustondo, D.M.; Ananías, R.A. Hygromechanical strains during the drying of Eucalyptus nitens boards. Maderas Cienc. Tecnol. 2016, 18, 235–244. Available online: http://www.scielo.cl/scielo.php?script=sci_arttext&pid=S0718-221x2016000200001&nrm=iso (accessed on 25 October 2020). [CrossRef] [Green Version]

- Pérez-Peña, N.; Segovia, F.; Salinas, C.; Ananias, R. Perpendicular Mechano-Sorptive Strains during Moisture Desorption from Eucalyptus nitens Specimens. BioResources 2016, 11, 8277–8284. [Google Scholar] [CrossRef] [Green Version]

- Mårtensson, A. Mechano-sorptive effects in wooden material. Wood Sci. Technol. 1994, 28, 437–449. [Google Scholar] [CrossRef]

- Li, D.G.; Gu, L.B. Study on rheological behavior of surface layer of poplar during high-temperature drying. Sci. Silvae Sin. 1999, 35, 85–91. Available online: http://www.linyekexue.net/article/1999/1001-7488/19990114.shtml (accessed on 12 December 2020). (In Chinese).

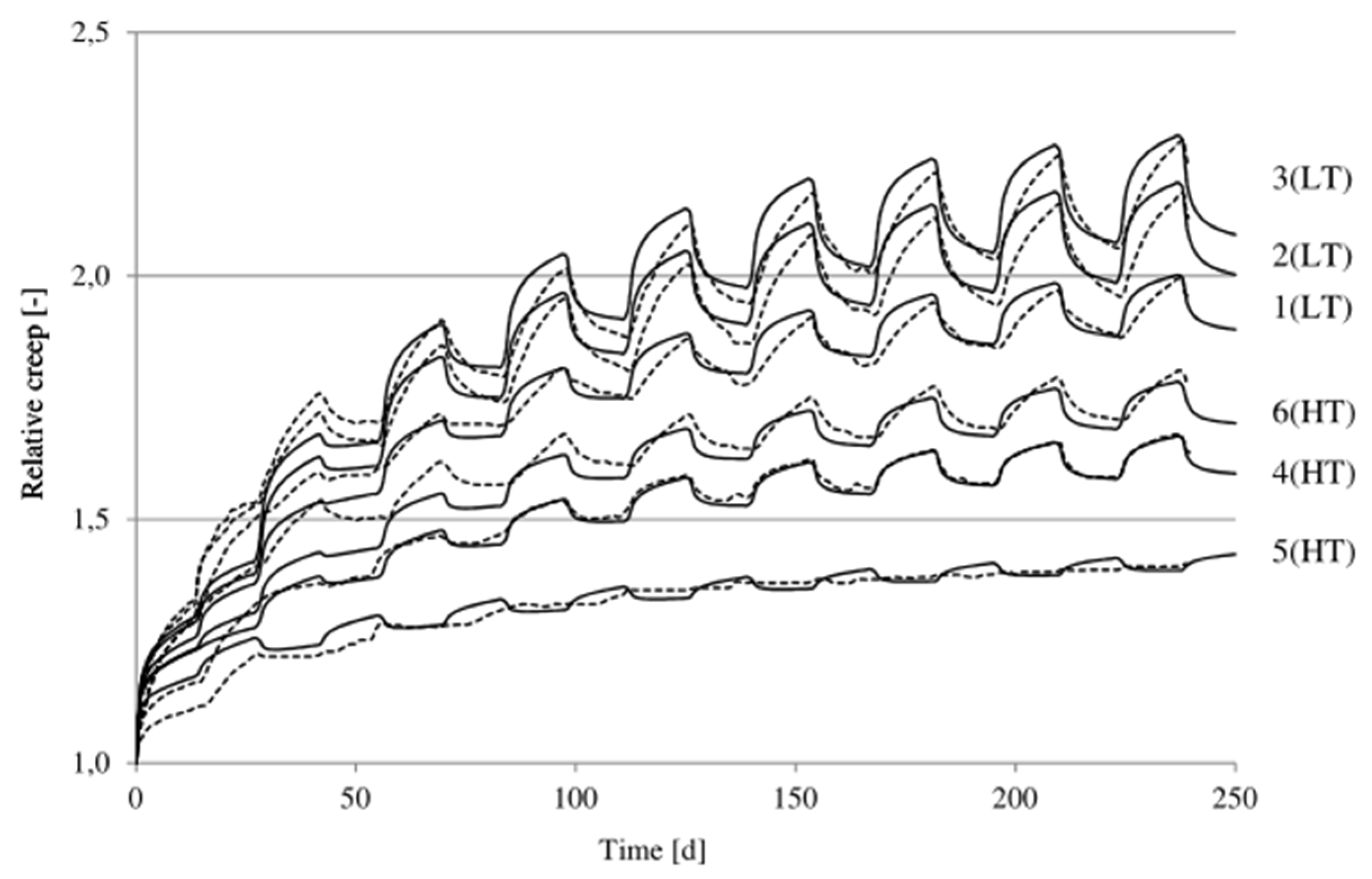

- Bengtsson, C.; Kliger, R. Bending Creep of High-Temperature Dried Spruce Timber. Holzforschung 2003, 57, 95–100. [Google Scholar] [CrossRef]

- Honfi, D.; Mårtensson, A.; Thelandersson, S.; Kliger, R. Modelling of bending creep of low- and high-temperature-dried spruce timber. Wood Sci. Technol. 2013, 48, 1–14. [Google Scholar] [CrossRef]

- Erickson, R.W.; Seavey, R.T. Energy Quantication and mechano-sorptive behavior in the kiln drying of 2.5 cm thick Red Oak lumber. Dry. Technol. 1992, 10, 1183–1206. [Google Scholar] [CrossRef]

- Pang, S. Modelling of stress developent during drying and relief during steaming in pinus radiata lumber. Dry. Technol. 2000, 18, 1677–1696. [Google Scholar] [CrossRef]

- Zhan, J.F.; Avramidis, S. Mechanosorptive Creep of Hemlock under Conventional Drying: I. The Determination of Free Shrinkage Strain. Dry. Technol. 2011, 29, 789–796. [Google Scholar] [CrossRef]

- Zhan, J.F.; Avramidis, S. Mechanosorptive Creep of Hemlock Under Conventional Drying: II. Description of Actual Creep Behavior in Drying Lumber. Dry. Technol. 2011, 29, 1140–1149. [Google Scholar] [CrossRef]

- Mcmillen, J.M. Drying stress in wood drying. For. Prod. J. 1955, 5, 230. [Google Scholar]

- Nishio, S. KAP Method Drying Stress Estimation; Wood Industry: Tokyo, Japan, 1972; p. 27. [Google Scholar]

- Chang, J.M. Research on non-contact testing methods of wood drying stress. In Proceedings of the 6th National Wood Drying Symposium, Beijing, China, 27–31 August 1997. [Google Scholar]

- Chang, J.M.; Hu, S.T.; Run, Y.Z. Research on Non-contact Testing Method of Wood Drying Stress. For. Prod. Ind. 1998, 5, 21–24. (In Chinese) [Google Scholar]

- An, L.; Gao, J.M.; Hu, C.K. Non-contact non-destructive testing method for wood drying stress. For. Environ. Sci. 2007, 23, 63–66. (In Chinese) [Google Scholar]

- Zhou, F.; Fu, Z.; Zhou, Y.; Zhao, J.; Gao, X.; Jiang, J. Moisture transfer and stress development during high-temperature drying of Chinese fir. Dry. Technol. 2020, 38, 545–554. [Google Scholar] [CrossRef]

- Nasir, V.; Nourian, S.; Avramidis, S.; Cool, J. Stress wave evaluation for predicting the properties of thermally modified wood using neuro-fuzzy and neural network modeling. Holzforschung 2019, 73, 827–838. [Google Scholar] [CrossRef]

- Cheng, W.L.; Liu, Y.X.; Shi Gang, M.L. Tensile stress relaxation of wood under high temperature and high pressure steam conditions. J. Beijing For. Univ. 2007, 29, 84–89. (In Chinese) [Google Scholar]

- Muszyński, L.; Lagana, R.; Shaler, S.M. An optical method for characterization of basic hygro-mechanical properties of solid wood in tension. In Proceedings of the 8th International IUFRO Wood Drying Conference, Brasov, Romania, 24–29 August 2003; pp. 77–82. [Google Scholar]

- Rice, R.W.; Youngs, R.L. The mechanism and development of creep during drying of red oak. Holz Roh Werkstoff 1990, 48, 73–79. [Google Scholar] [CrossRef]

- Han, Y.; Park, Y.; Park, J.H.; Yang, S.Y.; Eom, C.D.; Yeo, H. The shrinkage properties of red pine wood assessed by image analysis and near-infrared spectroscopy. Dry. Technol. 2016, 34, 1613–1620. [Google Scholar] [CrossRef]

- Fu, Z.Y.; Zhao, J.Y.; Cai, Y.C. Measurement and analysis of strain caused by anisotropy of trunk shrinkage. Eng. Sci. 2014, 16, 25–29. (In Chinese) [Google Scholar]

- Tsuchikawa, S.; Hayashi, K.; Tsutsumi, S. Nondestructive Measurement of the Subsurface Structure of Biological Material Having Cellular Structure by Using Near-Infrared Spectroscopy. Appl. Spectrosc. 1996, 50, 1117–1124. [Google Scholar] [CrossRef]

- Yang, S.Y.; Han, Y.; Chang, Y.S.; Kim, K.M.; Choi, I.G.; Yeo, H. Moisture Content Prediction Below and Above Fiber Saturation Point by Partial Least Squares Regression Analysis on Near Infrared Absorption Spectra of Korean Pine. Wood Fiber Sci. 2013, 45, 415–422. [Google Scholar]

- Watanabe, K.; Kobayashi, I.; Saito, S.; Kuroda, N.; Noshiro, S. Nondestructive evaluation of drying stress level on wood surface using near-infrared spectroscopy. Wood Sci. Technol. 2013, 47, 299–315. [Google Scholar] [CrossRef]

- Hagan, M.T.; Demuth, H.B.; Beale, M.H.; De Jesús, O. Neural Network Design, 2nd ed.; Hagan, M.T., Ed.; University of Kansas: Lawrence, KS, USA, 2002; pp. 23–54. Available online: http://hagan.okstate.edu/nnd.html (accessed on 12 December 2020).

- Avramidis, S.; Iliadis, L.; Mansfield, S.D. Wood dielectric loss factor prediction with artificial neural networks. Wood Sci. Technol. 2006, 40, 563. [Google Scholar] [CrossRef]

- Mansfield, S.D.; Iliadis, L.; Avramidis, S. Neural network prediction of bending strength and stiffness in western hemlock (Tsuga heterophylla Raf.). Holzforschung 2007, 61, 707–716. [Google Scholar] [CrossRef]

- Iliadis, L.; Mansfield, S.D.; Avramidis, S.; El-Kassaby, Y.A. Predicting Douglas-fir wood density by artificial neural networks (ANN) based on progeny testing information. Holzforschung 2013, 67, 771–777. [Google Scholar] [CrossRef]

- Fernández, F.G.; de Palacios, P.; Esteban, L.G.; Garcia-Iruela, A.; Rodrigo, B.G.; Menasalvas, E. Prediction of MOR and MOE of structural plywood board using an artificial neural network and comparison with a multivariate regression model. Compos. Part B 2012, 43, 3528–3533. Available online: https://www.sciencedirect.com/science/article/pii/S1359836811005233 (accessed on 30 November 2020). [CrossRef]

- Tiryaki, S.; Aydın, A. An artificial neural network model for predicting compression strength of heat treated woods and comparison with a multiple linear regression model. Constr. Build. Mater. 2014, 62, 102–108. [Google Scholar] [CrossRef]

- Tiryaki, S.; Aras, U.; Kalaycıoğlu, H.; Erişir, E.; Aydın, A. Predictive Models for Modulus of Rupture and Modulus of Elasticity of Particleboard Manufactured in Different Pressing Conditions. High Temp. Mater. Process. 2017, 36, 623–634. [Google Scholar] [CrossRef]

- Van Nguyen, T.H.; Nguyen, T.T.; Ji, X.; Lanh Do, K.T.; Guo, M. Using Artificial Neural Networks (ANN) for Modeling Predicting Hardness Change of Wood during Heat Treatment. IOP Conf. Ser. Mater. Sci. Eng. 2018, 394, 032044. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Van Nguyen, T.H.; Ji, X.; Yuan, B.; Trinh, H.M.; Do, K.T.L.; Guo, M. Prediction of the color change of heat-treated wood during artificial weathering by artificial neural network. Eur. J. Wood Wood Prod. 2019, 77, 1107–1116. [Google Scholar] [CrossRef]

- Schmid, M. Discussion of: “Artificial neural network and mathematical modeling comparative analysis of nonisothermaldiffusion of moisture in wood” by Stavros Avramidis and Hongwei Wu. Holz Roh Werkstoff 2008, 66, 71–73. [Google Scholar] [CrossRef]

- Ceylan, İ. Determination of Drying Characteristics of Timber by Using Artificial Neural Networks and Mathematical Models. Dry. Technol. 2008, 26, 1469–1476. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Liu, Y.X.; Cao, J.; Sun, L.P. Modeling of temperature-humidity for wood drying based on time-delay neural network. J. For. Res. 2006, 17, 141–144. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Sun, L.P.; Cao, J. Neural Network Prediction Model of Wood Moisture Content for Drying Process. Sci. Silvae Sin. 2008, 44, 94–98. [Google Scholar] [CrossRef]

- Watanabe, K.; Kobayashi, I.; Matsushita, Y.; Saito, S.; Kuroda, N.; Noshiro, S. Application of Near-Infrared Spectroscopy for Evaluation of Drying Stress on Lumber Surface: A Comparison of Artificial Neural Networks and Partial Least Squares Regression. Dry. Technol. 2014, 32, 590–596. [Google Scholar] [CrossRef]

- Bedelean, B.; Lazarescu, C.; Avramidis, S. Predicting RF heating rate during pasteurization of green softwoods using artificial neural networks and Monte Carlo method. Wood Res. 2015, 60, 83–94. Available online: http://www.centrumdp.sk/wr/201501/08.pdf (accessed on 5 December 2020).

- Ma, X.Y.; Wang, X.F.; Duan, W.Y. Research on BP Neural Network Model of Larch Wood Drying. For. Eng. 2015, 31, 63–65. (In Chinese) [Google Scholar]

- Chai, H.; Chen, X.; Cai, Y.; Zhao, J. Artificial Neural Network Modeling for Predicting Wood Moisture Content in High Frequency Vacuum Drying Process. Forests 2019, 10, 16. [Google Scholar] [CrossRef] [Green Version]

- Fu, Z.Y.; Cai, Y.C.; Gao, X.; Zhou, F.; Jiang, J.H.; Zhou, Y.D. Simulation and prediction of wood drying strain based on artificial neural network model. Sci. Silvae Sin. 2020, 56, 76–82. Available online: http://www.linyekexue.net/article/2020/1001-7488/20200608.shtml (accessed on 20 December 2020).

| Sample | Final MC (%) | Drying Uniformity (%) | MC Deviation in the Thickness (%) | Residual Stress Index (%) |

|---|---|---|---|---|

| Pre-treated quarter-sawn | 8.55 | ±0.54 | 1.34 ± 0.46 | 1.29 ± 0.44 |

| Control quarter-sawn | 9.23 | ±0.87 | 2.58 ± 1.17 | 2.26 ± 0.85 |

| Sig. | — | * | * | |

| Pre-treated flat-sawn | 8.02 | ±0.43 | 1.03 ± 0.27 | 1.28 ± 0.82 |

| Control flat-sawn | 9.01 | ±0.62 | 1.51 ± 0.38 | 2.49 ± 0.88 |

| Sig. | * | * | * |

| Drying Condition (°C) | Maximum (%) | Time to Reach the Maximum (h) |

|---|---|---|

| 85 1 | 3.65 | 5 |

| 105 | 4.96 | 5 |

| 115 | 3.14 | 3 |

| 125 | 4.23 | 1.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Q.; Liu, H.-H. Drying Stress and Strain of Wood: A Review. Appl. Sci. 2021, 11, 5023. https://doi.org/10.3390/app11115023

Yin Q, Liu H-H. Drying Stress and Strain of Wood: A Review. Applied Sciences. 2021; 11(11):5023. https://doi.org/10.3390/app11115023

Chicago/Turabian StyleYin, Qin, and Hong-Hai Liu. 2021. "Drying Stress and Strain of Wood: A Review" Applied Sciences 11, no. 11: 5023. https://doi.org/10.3390/app11115023

APA StyleYin, Q., & Liu, H.-H. (2021). Drying Stress and Strain of Wood: A Review. Applied Sciences, 11(11), 5023. https://doi.org/10.3390/app11115023