A Two-Stage Hybrid Metaheuristic for a Low-Carbon Vehicle Routing Problem in Hazardous Chemicals Road Transportation

Abstract

:1. Introduction

2. Literature Review

2.1. Low–Carbon Vehicle Routing Problem

2.2. Multi-Trip Vehicle Routing Problem (MTVRP)

- Low-carbon economy advances the transportation of hazardous chemicals in the road transportation industry.

- Multi-trip, heterogeneous vehicles, prioritized customers, and incompatible cargoes are considered.

- An innovative two-phase heuristics algorithm is devised which balances the load rate and minimizes the transportation cost.

- The proposed solution approach is applied to a large-scale real case study.

3. Problem Description and Formulation

3.1. Problem Description and Characteristics

- The vehicles are heterogeneous;

- Some of customers have priority over others;

- More than one kind of cargo is transported and some cargoes are not permitted to be loaded into the same vehicle;

- Each vehicle starts and ends at the depot;

- Each vehicle cannot exceed the capacity limit;

- Each customer is visited only once;

- Each vehicle can continue to serve customers again after returning to the depot within the transport planning period.

3.2. Formulation

3.2.1. Cost Analysis

- (a)

- Fixed cost

- (b)

- Travel cost

- (c)

- Carbon emission cost

3.2.2. Establishment of the Model

4. Solution Method

4.1. I-GRASP

- For not-yet-visited customers, insert deliveries by each location on all the trips on all the routes (including the empty trip routes) respecting capacity, customer priority, and cargo attributes, then evaluate the cost change induced by the insertion operation.

- Rank the insertion by non-decreasing cost and choose randomly one from the first K most profitable ones.

- Continue the above steps till all customers have been visited.

| Algorithm 1 I-GRASP |

| Input: Solution size M. Customer data. |

| Output: the first M* feasible solution S. |

| Pool |

| For count1 to M do |

| Unvisited customer set |

| Initial Solution IS |

| While Unvisited customer set do |

| If IS does not include an empty route or empty trip for each route then |

| Add an empty route in IS or empty trip in these routes without an empty trip |

| End |

| Insert not visited customers into each location of each trip on all routes (satisfy all constraints in the model) |

| Calculate cost changes for all insertions, then sort them and store in Candidate List |

| Select a candidate insertion randomly from first K candidates and implement it |

| Unvisited customer set Unvisited customer set |

| End while |

| End for |

| Sort all initial feasible solutions by non-decreasing cost, then |

| Add first M* ones into S |

| Return S |

4.2. Hybrid Genetic Algorithm

4.2.1. Algorithm Overview

| Algorithm 2 HGA |

| Input: initial population M* and other parameters; |

| Output: the best solution found BestSol; |

| while stop criteria not reached do |

| Apply crossover operator to generate offspring individual |

| Apply mutation operator to generate offspring individuals |

| Apply local search strategy to generate improved neighborhood solution |

| Apply split-feasibility procedure to make new solution feasible |

| for each new individual generated at each step above do |

| if then |

| else |

| if then |

| else |

| with probability p defined in Section 4.2.5 |

| end for |

| end while |

| Return BestSol |

4.2.2. Genetic Operators

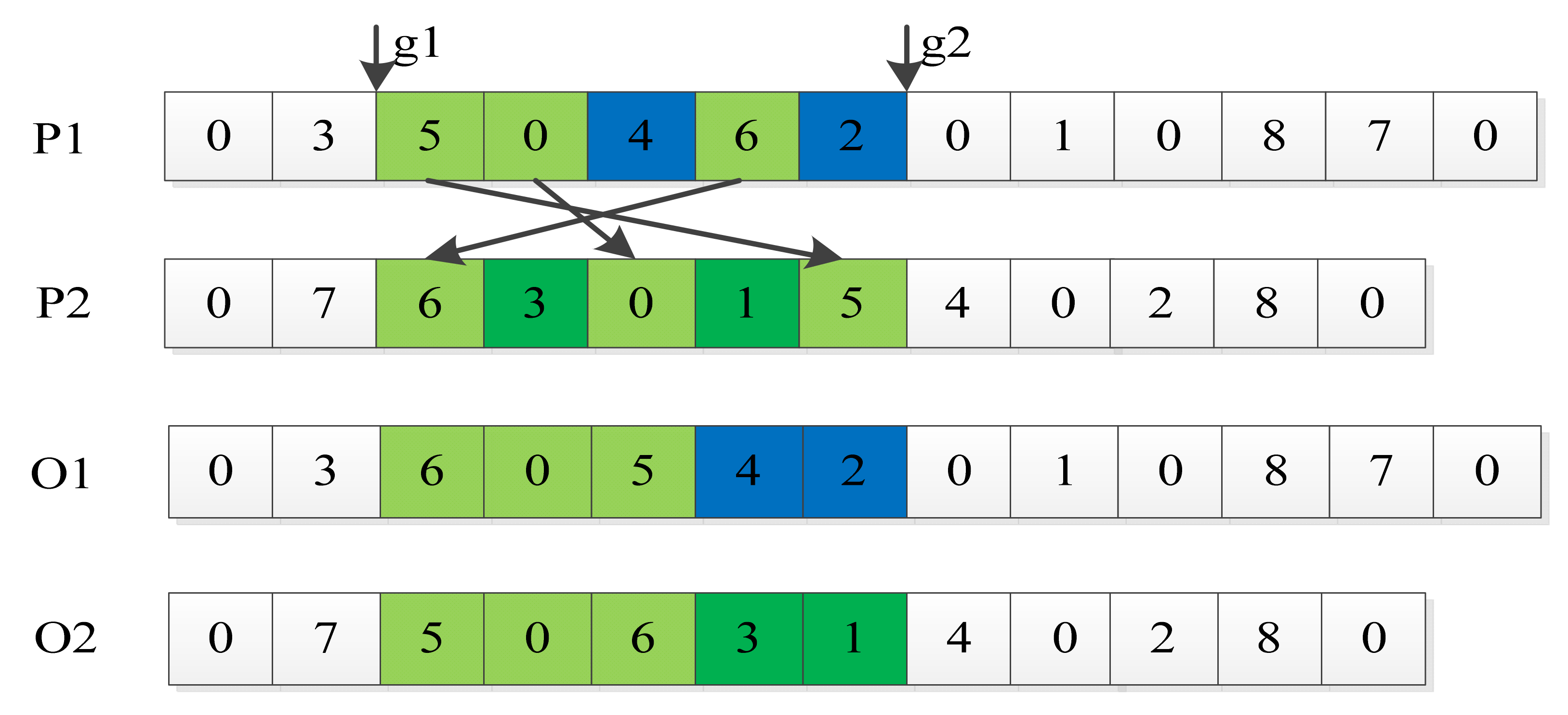

- Step 1:

- select randomly two individuals (P1 and P2) with crossover probability ;

- Step 2:

- select randomly two crossover genes (g1 and g2) ranging from 0 to , and is the number of customers with less customers between the two individuals;

- Step 3:

- add the same genes into set S0 (5, 0, and 6) sequentially between g1 and g2 for individual P1, and add the same genes into set S1 (6, 0, and 5) sequentially between g1 and g2 for individual P2;

- Step 4:

- for individual P1, add the genes into set S2 (4 and 2) which is different with P2 between g1 and g2, and for individual P2, add the genes into set S3 (3 and 1) which is different with P1 between g1 and g2;

- Step 5:

- reinsert S0 and S3 into P2 sequentially between g1 and g2, and then get an offspring individual O2; and reinsert S1 and S2 into P1 between g1 and g2, and then get an offspring individual O1.

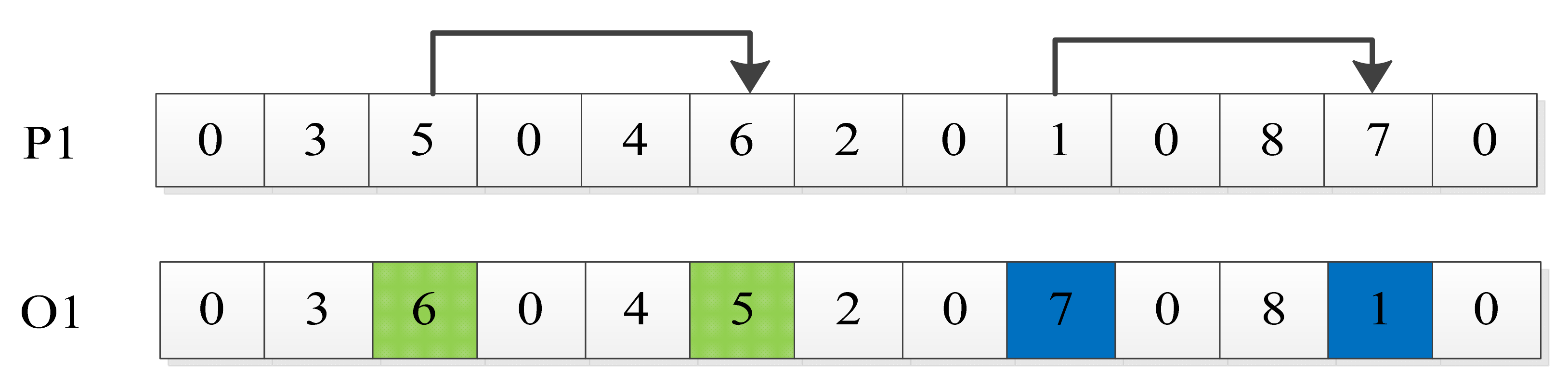

- Step 1:

- select an individual randomly with mutation probability ;

- Step 2:

- select a gene (such as g1 = 6) randomly on the individual and revise it into another gene (such as g2 = 5) randomly;

- Step 3:

- check if there is the same gene as g2 on other locations, if yes, then revise the gene into g1 = 6; and

- Step 4:

- repeat step 2–step 3 m times;

4.2.3. Local Search Strategy

- Intra-route swap: for any route, select randomly two customers and exchange them;

- Intra-route relocate: for any route, remove randomly a customer and reinsert it into another location on the same route;

- Intra-route 2-opt: for any route, select randomly two lists of sequential customers and reverse these customers between them, and exchange the two lists of sequential customers;

- Inter-route swap: select randomly one customer from two routes respectively, and exchange them;

- Intra-route relocate: remove randomly a customer on a route and reinsert it into another route;

- Inter-route 2-opt: select sequential customers on a route randomly; do the same for another route and exchange them.

4.2.4. Split-Feasibility Procedure (SFP)

- Step 1:

- check if the chromosome is feasible, if yes, turn to step 4, or turn to step 2;

- Step 2:

- regard the genes of this chromosome as an unvisited customer set S, a random-selection and greedy-insertion heuristic is designed to generate new feasible chromosomes as follows:

- Step 2.1:

- select one of the remaining customers from S randomly, reinsert it into a new chromosome;

- Step 2.2:

- evaluate the cost change induced by the above insertion operation at each point of the chromosome;

- Step 2.3:

- rank the insertion operations by nondecreasing cost and keep the most profitable one.

- Step 2.4:

- repeat Steps 2.1–2.3 until all customers are reinserted into the chromosomes.

- Step 3:

- generate G new chromosomes, and select the lowest cost one as the output.

- Step 4:

- Output the obtained chromosome.

4.2.5. Simulated Annealing (SA)

5. Case Study and Analysis

5.1. Data

5.2. Results

5.2.1. Simulation Examples

5.2.2. Impact of Prioritized Customers and Incompatible Cargoes

5.3. Performance Analysis of Algorithm

5.3.1. Stability Analysis

5.3.2. Efficiency Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Piecyk, M.I.; McKinnon, A.C. Forecasting the carbon footprint of road freight transport in 2020. Int. J. Prod. Econ. 2010, 128, 31–42. [Google Scholar] [CrossRef]

- Fahimnia, B.; Reisi, M.; Paksoy, T.; Özceylan, E. The implications of carbon pricing in Australia: An industrial logistics planning case study. Transp. Res. Part. D Transp. Environ. 2013, 18, 78–85. [Google Scholar] [CrossRef]

- Dekker, R.; Bloemhof, J.; Mallidis, I. Operations Research for green logistics An overview of aspects, issues, contributions and challenges. Eur. J. Oper. Res. 2012, 219, 671–679. [Google Scholar] [CrossRef] [Green Version]

- He, Y.; Wang, X.; Zhou, F.; Lin, Y. Dynamic vehicle routing problem considering simultaneous dual services in the last mile delivery. Kybernetes 2019, 49, 1267–1284. [Google Scholar] [CrossRef]

- He, Y.; Zhou, F.; Qi, M.; Wang, X. Joint distribution: Service paradigm, key technologies and its application in the context of Chinese express industry. Int. J. Logist. Res. Appl. 2020, 23, 211–227. [Google Scholar] [CrossRef]

- Kima, B.I.; Park, J. A school bus scheduling problem. Eur. J. Oper. Res. 2012, 218, 577–585. [Google Scholar] [CrossRef]

- Schrage, L. Formulation and structure of more complex/realistic routing and scheduling problems. Networks 1981, 11, 229–232. [Google Scholar] [CrossRef]

- Benjamin, A.; Beasley, J. Metaheuristics for the waste collection vehicle routing problem with time windows, driver rest period and multiple disposal facilities. Comput. Oper. Res. 2010, 37, 2270–2280. [Google Scholar] [CrossRef] [Green Version]

- Dantzig, G.B.; Ramser, J.H. The Truck Dispatching Problem. Manag. Sci. 1959, 6, 80–91. [Google Scholar] [CrossRef]

- Braekers, K.; Ramaekers, K.; Van Nieuwenhuyse, I. The vehicle routing problem: State of the art classification and re-view. Comput. Ind. Eng. 2016, 99, 300–313. [Google Scholar] [CrossRef]

- Ramanathan, U.; Bentley, Y.; Pang, G. The role of collaboration in the UK green supply chains: An exploratory study of the perspectives of suppliers, logistics and retailers. J. Clean. Prod. 2014, 70, 231–241. [Google Scholar] [CrossRef] [Green Version]

- Zhou, F.; He, Y.; Zhou, L. Last Mile Delivery with Stochastic Travel Times Considering Dual Services. IEEE Access 2019, 7, 159013–159021. [Google Scholar] [CrossRef]

- Tang, S.; Wang, W.; Yan, H.; Hao, G. Low carbon logistics: Reducing shipment frequency to cut carbon emissions. Int. J. Prod. Econ. 2015, 164, 339–350. [Google Scholar] [CrossRef]

- Yang, J.; Guo, J.; Ma, S. Low-carbon city logistics distribution network design with resource deployment. J. Clean. Prod. 2016, 119, 223–228. [Google Scholar] [CrossRef]

- Wang, J.; Lim, M.K.; Tseng, M.-L.; Yang, Y. Promoting low carbon agenda in the urban logistics network distribution system. J. Clean. Prod. 2019, 211, 146–160. [Google Scholar] [CrossRef]

- Xiao, Y.; Konak, A.J.J. A genetic algorithm with exact dynamic programming for the green vehicle routing & scheduling problem. J. Clean. Prod. 2017, 167, 1450–1463. [Google Scholar]

- Soysal, M.; Çimen, M.; Demir, E. On the mathematical modeling of green one-to-one pickup and delivery problem with road segmentation. J. Clean. Prod. 2018, 174, 1664–1678. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Soleimani, H.; Zohal, M. An improved ant colony optimization algorithm for the multi-depot green vehicle routing problem with multiple objectives. J. Clean. Prod. 2019, 227, 1161–1172. [Google Scholar] [CrossRef]

- Erdoğan, S.; Miller-Hooks, E. A Green Vehicle Routing Problem. Transp. Res. Part E-Logist. Transp. Rev. 2012, 48, 100–114. [Google Scholar] [CrossRef]

- He, Y.; Wang, X.; Lin, Y.; Zhou, F.; Zhou, L. Sustainable decision making for joint distribution center location choice. Transp. Res. Part. D Transp. Environ. 2017, 55, 202–216. [Google Scholar] [CrossRef]

- Lin, C.; Choy, K.; Ho, G.; Chung, S.; Lam, H. Survey of Green Vehicle Routing Problem: Past and future trends. Expert Syst. Appl. 2014, 41, 1118–1138. [Google Scholar] [CrossRef]

- Brandão, J.; Mercer, A. A tabu search algorithm for the multi-trip vehicle routing and scheduling problem. Eur. J. Oper. Res. 1997, 100, 180–191. [Google Scholar] [CrossRef]

- Nguyen, P.K.; Crainic, T.G.; Toulouse, M. A tabu search for Time-dependent Multi-zone Multi-trip Vehicle Routing Problem with Time Windows. Eur. J. Oper. Res. 2013, 231, 43–56. [Google Scholar] [CrossRef]

- Tang, J.; Yü, Y.; Li, J. An exact algorithm for the multi-trip vehicle routing and scheduling problem of pickup and delivery of customers to the airport. Transp. Res. Part. E Logist. Transp. Rev. 2015, 73, 114–132. [Google Scholar] [CrossRef]

- Hernandez, F.; Feillet, D.; Giroudeau, R.; Naud, O. A new exact algorithm to solve the multi-trip vehicle routing problem with time windows and limited duration. 4OR 2013, 12, 235–259. [Google Scholar] [CrossRef] [Green Version]

- Cattaruzza, D.; Absi, N.; Feillet, D.; Vigo, D. An iterated local search for the multi-commodity multi-trip vehicle routing problem with time windows. Comput. Oper. Res. 2014, 51, 257–267. [Google Scholar] [CrossRef]

- Cattaruzza, D.; Absi, N.; Feillet, D. The Multi-Trip Vehicle Routing Problem with Time Windows and Release Dates. Transp. Sci. 2016, 50, 676–693. [Google Scholar] [CrossRef] [Green Version]

- Bettinelli, A.; Cacchiani, V.; Crainic, T.G.; Vigo, D. A Branch-and-Cut-and-Price algorithm for the Multi-trip Separate Pickup and Delivery Problem with Time Windows at Customers and Facilities. Eur. J. Oper. Res. 2019, 279, 824–839. [Google Scholar] [CrossRef]

- He, P.; Li, J. The two-echelon multi-trip vehicle routing problem with dynamic satellites for crop harvesting and transportation. Appl. Soft Comput. 2019, 77, 387–398. [Google Scholar] [CrossRef]

- Zhang, L.-Y.; Tseng, M.-L.; Wang, C.-H.; Xiao, C.; Fei, T. Low-carbon cold chain logistics using ribonucleic acid-ant colony optimization algorithm. J. Clean. Prod. 2019, 233, 169–180. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Y.; Fei, T.; Ren, H. The Research on Low Carbon Logistics Routing Optimization Based on DNA-Ant Colony Algorithm. Discret. Dyn. Nat. Soc. 2014, 2014, 1–13. [Google Scholar] [CrossRef]

- Subramanian, A.; Penna, P.H.V.; Uchoa, E.; Ochi, L.S. A hybrid algorithm for the Heterogeneous Fleet Vehicle Routing Problem. Eur. J. Oper. Res. 2012, 221, 285–295. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, J. Study of logistics network optimization model considering carbon emissions. Management 2017, 8, 1102–1108. [Google Scholar] [CrossRef]

| ID | X | Y | Priority | Demand | Types | ID | X | Y | Priority | Demand | Types |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 118.64611 | 31.94249 | 0 | 0 | 0 | 24 | 118.84352 | 31.86329 | 0 | 33 | A |

| 1 | 118.72178 | 32.20923 | 1 | 3 | A | 25 | 118.98820 | 32.10691 | 0 | 20 | A |

| 2 | 119.37719 | 32.17857 | 0 | 10 | B | 26 | 118.96864 | 31.37930 | 0 | 32 | C |

| 3 | 119.02719 | 32.14194 | 0 | 32 | A | 27 | 118.96865 | 32.37930 | 0 | 2 | A |

| 4 | 118.37410 | 32.34485 | 1 | 16 | A | 28 | 118.83423 | 32.26079 | 0 | 30 | A |

| 5 | 118.35853 | 32.33745 | 0 | 10 | A | 29 | 118.39192 | 32.35888 | 0 | 64 | A |

| 6 | 119.83227 | 32.07926 | 0 | 1 | A | 30 | 118.61083 | 32.23142 | 0 | 19 | A |

| 7 | 119.40095 | 32.18148 | 0 | 54 | B | 31 | 118.56196 | 31.84031 | 0 | 45 | A |

| 8 | 119.72228 | 32.07920 | 0 | 54 | A | 32 | 118.56196 | 31.84031 | 0 | 32 | C |

| 9 | 118.98790 | 32.10089 | 0 | 32 | A | 33 | 118.70426 | 31.90448 | 1 | 15 | C |

| 10 | 118.59852 | 31.83661 | 1 | 10 | A | 34 | 118.76532 | 31.96886 | 0 | 2 | C |

| 11 | 118.63642 | 31.93083 | 0 | 12 | A | 35 | 118.76532 | 31.96886 | 0 | 3 | C |

| 12 | 118.78055 | 31.87620 | 0 | 16 | C | 36 | 118.38382 | 32.31247 | 0 | 45 | A |

| 13 | 118.85628 | 32.04281 | 0 | 8 | B | 37 | 118.65598 | 31.94535 | 0 | 32 | C |

| 14 | 118.85628 | 32.04281 | 0 | 4 | A | 38 | 118.65598 | 31.94535 | 0 | 16 | A |

| 15 | 119.18360 | 32.20393 | 0 | 5 | A | 39 | 118.56172 | 31.84080 | 0 | 15 | C |

| 16 | 118.54957 | 31.97212 | 0 | 10 | C | 40 | 118.56172 | 31.84080 | 0 | 25 | A |

| 17 | 118.54957 | 31.97212 | 0 | 10 | A | 41 | 118.68243 | 32.18886 | 0 | 4 | B |

| 18 | 118.68316 | 31.93047 | 0 | 20 | C | 42 | 119.59338 | 32.02327 | 0 | 15 | A |

| 19 | 118.60298 | 31.85022 | 1 | 22 | A | 43 | 118.48638 | 31.57159 | 0 | 32 | A |

| 20 | 118.61282 | 32.01586 | 0 | 16 | C | 44 | 118.56265 | 31.81674 | 0 | 32 | C |

| 21 | 119.37209 | 32.17886 | 0 | 18 | A | 45 | 118.56265 | 31.81674 | 0 | 16 | A |

| 22 | 119.70852 | 32.11134 | 0 | 20 | A | 46 | 118.56196 | 31.84031 | 0 | 4 | B |

| 23 | 118.55725 | 31.96583 | 1 | 10 | B | 47 | 118.39209 | 32.31064 | 0 | 16 | A |

| Algorithm | Approximate Optimal Value (yuan) | Average Value (yuan) | Standard Deviation |

|---|---|---|---|

| MM | 8550.61 | 8550.61 | 0.00 |

| GA | 5070.58 | 5336.54 | 236.45 |

| TSHM | 4199.21 | 4262.32 | 42.63 |

| LS | 4891.25 | 5019.92 | 110.39 |

| Solution Method | Scheduling Scheme |

|---|---|

| Manmade schedule | Schedule for vehicles with capacity 120 |

| Vehicle No.1 | |

| [4, 7] and [8] | |

| Vehicle No.2 | |

| [1, 29, 21, 22, 42], | |

| Schedule for vehicles with capacity 176 | |

| Vehicle No.1 | |

| [33, 12, 24, 35, 34, 20, 16, 11, 18, 38, 37] and [23, 17, 47, 36, 46, 40, 31, 45] | |

| Vehicle No.2 | |

| [19, 6, 26, 43, 44, 32, 39, 5] and [10, 30, 41, 28, 27, 15, 2, 9, 3, 25, 14, 13] | |

| GA | Schedule for vehicles with capacity 120 |

| Vehicle No.1 | |

| [20, 34, 35, 18, 38, 37] and [1, 30, 28, 13, 14] | |

| Vehicle No.2 | |

| [19, 45, 44, 40, 11] | |

| Schedule for vehicles with capacity 176 | |

| Vehicle No.1 | |

| [4, 29, 5, 36, 47, 17, 16] and [23, 41, 27, 22, 6, 8, 9, 46, 31] | |

| Vehicle No.2 | |

| [33, 12, 24, 26, 43, 32, 39] and [10, 42, 7, 2, 21, 15, 3, 25] | |

| TSHM | Schedule for vehicles with capacity 120 |

| Vehicle No.1 | |

| [37, 38] and [19, 31, 46, 40, 11] | |

| Vehicle No.2 | |

| [10, 39, 32, 16, 17, 20] | |

| Schedule for vehicles with capacity 176 | |

| Vehicle No.1 | |

| [23, 14, 13, 9, 25, 3, 15, 7, 2] and [4, 29, 5, 36, 47, 30, 41] | |

| Vehicle No.2 | |

| [33, 12, 24, 26, 43, 45, 44] and [1, 28, 27, 21, 22, 6, 8, 42, 35, 34, 18] |

| Without prioritized customers and incompatible cargoes | Scheduling scheme |

| Schedule for vehicles with capacity 120 | |

| No | |

| Schedule for vehicles with capacity 176 | |

| Vehicle No.1 | |

| [45, 44, 46, 31, 32, 40, 39] and [37, 38, 23, 16, 17] | |

| Vehicle No.2 | |

| [34, 21, 2, 7, 22, 6, 8, 42] and [18, 35, 14, 13, 9, 25, 3, 15, 27, 28, 1, 20] | |

| Vehicle No.3 | |

| [41, 30, 29, 4, 5, 36, 47] and [11, 19, 10, 43, 26, 24, 12, 33] |

| Instance | GA | TSHM | GAP (%) |

|---|---|---|---|

| R101_25_R | 2298.21 | 2256.29 | 1.82% |

| R101_100_R | 8965.31 | 7020.73 | 21.69% |

| C101_25_R | 1845.35 | 1801.38 | 2.38% |

| C101_100_R | 7968.58 | 6362.1 | 20.16% |

| RC101_25_R | 2754.25 | 2438.56 | 11.46% |

| RC101_100_R | 13234.74 | 9000.26 | 32.00% |

| Mean | 6177.74 | 4813.22 | 22.09% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, J.; He, Y. A Two-Stage Hybrid Metaheuristic for a Low-Carbon Vehicle Routing Problem in Hazardous Chemicals Road Transportation. Appl. Sci. 2021, 11, 4864. https://doi.org/10.3390/app11114864

Lyu J, He Y. A Two-Stage Hybrid Metaheuristic for a Low-Carbon Vehicle Routing Problem in Hazardous Chemicals Road Transportation. Applied Sciences. 2021; 11(11):4864. https://doi.org/10.3390/app11114864

Chicago/Turabian StyleLyu, Jieyin, and Yandong He. 2021. "A Two-Stage Hybrid Metaheuristic for a Low-Carbon Vehicle Routing Problem in Hazardous Chemicals Road Transportation" Applied Sciences 11, no. 11: 4864. https://doi.org/10.3390/app11114864

APA StyleLyu, J., & He, Y. (2021). A Two-Stage Hybrid Metaheuristic for a Low-Carbon Vehicle Routing Problem in Hazardous Chemicals Road Transportation. Applied Sciences, 11(11), 4864. https://doi.org/10.3390/app11114864