Motion Planning for Mobile Robot with Modified BIT* and MPC

Abstract

1. Introduction

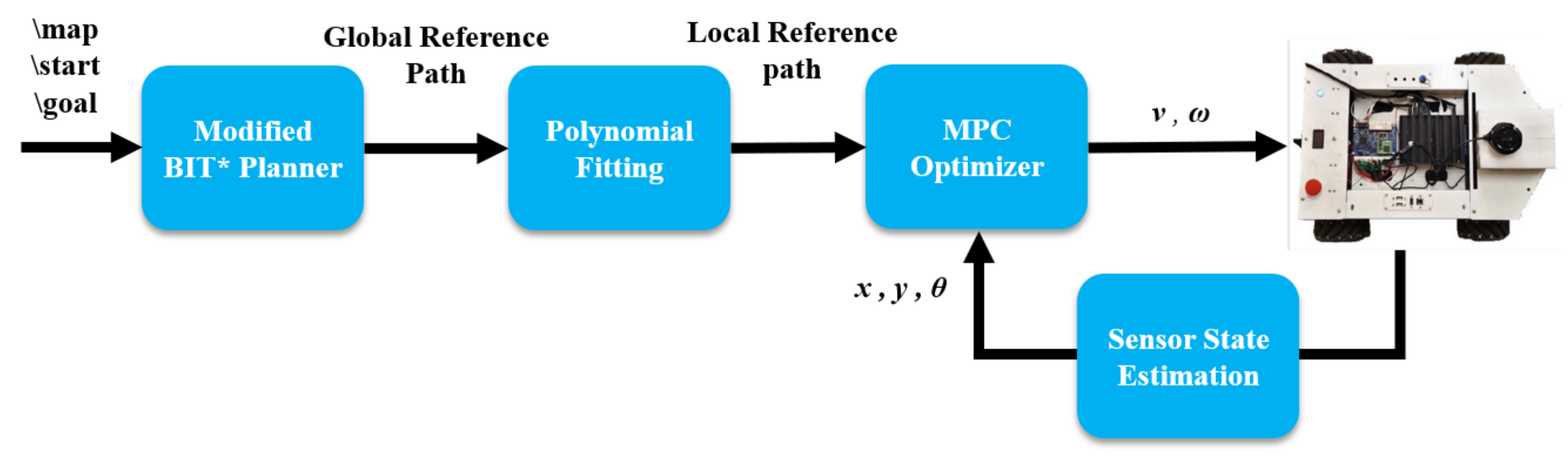

- During connecting the path points, the initial path may be tortuous so it always leads to unnecessary path cost. We adopt a simple stretch method to modify the connecting process and reduce the initial path cost. More importantly, the initial path cost determines the elliptical region in which samples in next iteration will improve the path. The modified BIT* with the stretch method can further reduce the size of elliptical region to accelerate the converging rate.

- After obtaining the global reference path with above method, we use the cubic polynomial curve to fit the reference path points in the robot coordinate system to obtain a local reference path which is smoother for a mobile robot to track.

- Then a nonlinear MPC method is adopted for trajectory tracking and speed generation considering obstacles near the robot.

2. Modified BIT* Planner

2.1. Sampling Strategy of Informed RRT*

| Algorithm 1:InformedSample(). |

|

2.2. Stretch Method

| Algorithm 2:Stretch(P). |

|

2.3. Modified BIT*

| Algorithm 3:Modified BIT*. |

|

3. MPC Method

3.1. Kinematic Model

3.2. Implementation of MPC

4. Simulation

4.1. Simulation Setting

4.2. Modified BIT* Planner

- Few obstacles with narrow channel: Figure 8 shows the environment with fewer obstacles and a narrow channel. The coordinates of the start point and the goal point are (0 m, 0 m) and (0 m, 5.5 m) respectively. The green solid line is the path generated by the global planner. From the map, we can see that there are two obstacle between start and goal, and the optimal path for mobile robot is to across the narrow channel between the obstacle. For sampling-based planning algorithm that uses a random sampling method like RRT*, the sampling points are rarely located in the narrow channel. So it is difficult to find an good path when iterations are not enough. In Figure 8a, instead of passing through a narrow channel, the path found by RRT* after 3000 iterations bypasses the obstacles above to the goal. In addition, this path has unnecessary twists and turns, which is not suitable for mobile robots. Figure 8b shows the solution of BIT*. Compared with RRT*, BIT* successfully found a path through the narrow channel and it uses 1600 iterations. However, in our multiple tests, BIT* does not always find a solution as shown in Figure 8b and sometimes BIT* can only find a path around obstacles with 1600 iterations. The path from start to goal in Figure 8c shows the better performance of our proposed method. Benefit from the stretch method, the modified BIT* can find a shorter and smoother path through the narrow channel with less iterations.

- Multiple obstacles: In practical applications, mobile robots may need to plan a collision-free path in environment with multiple obstacles. Based on this requirement, we design an environment shown in Figure 9, Figure 10 and Figure 11 with intensive obstacles to test the performance of the three planners. The coordinates of the start point and the goal point are (0 m, 0 m) and (−3 m, −2 m) respectively. Firstly, by observing the map, we can know that there are two kinds of good paths from the start to goal. One is to across the top left of goal, the other is through the top of the goal. So we show three different solutions for each planner to see that which kind of solutions these planners tend to select.

4.3. Whole Framework

- Few obstacles with narrow channel: Figure 12a shows the map and the reference path generated by modified BIT* planner. The reference path and actual path of mobile robot are illustrated in Figure 12b. The coordinates of the start point and the goal point are (1 m, 1 m) and (0 m, 5.5 m) respectively. Actually, the actual path does not track the reference path perfectly. Because the repulsive function is added into the objective function of MPC method, the actual path deviates from the reference path in the place close to the obstacle, so that the robot will not be too close to the obstacle to avoid possible collision. Moreover, the ratio of parameters , and is also an important factor, and the robot may tend to stay away from the obstacles rather than track the reference trajectory in this situation. So we can adjust the ratio of , and to make the robot behave differently. Figure 12c,d show the variation of linear velocity and angular velocity with time respectively. During 6s to 8s, the robot approaches the obstacle, and according to the design of the objective function, the robot will decelerate appropriately. At the same time, the angular velocity will be adjusted according to the position of the obstacle, resulting in fluctuation. Most of the time, the robot will move at the desired speed (0.3 m/s).

- Multiple obstacles: Figure 13a shows an environment with many obstacles and the reference path. Mobile robot need to react to these obstacles in time when it moves along the reference path. In Figure 13b, the blue solid line represents the reference path, and the red dotted line represents the actual path of the robot. The coordinates of the start point and the goal point are (0.7 m, 0.45 m) and (−3 m, −1.95 m) respectively. Similar to the previous case, the actual path does not exactly coincide with the reference path. There is slight deviation in the three sections near the obstacle to ensure safety. In Figure 13c, due to its proximity to the obstacle, the robot slows down during 1 s–2.5 s, 6 s–7.5 s and 13 s–15 s, which shows that the robot can decelerate in time when approaching multiple obstacles. As the robot approaches the obstacle and decelerates, the angular velocity of the robot will fluctuate, so as to adjust the direction of movement and keep away from the obstacle, which can be seen in Figure 13d.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khatib, O. Real-time obstacle avoidance for manipulators and mobile robots. In Proceedings of the 1985 IEEE International Conference on Robotics and Automation, St. Louis, MO, USA, 25–28 March 1985; Volume 2, pp. 500–505. [Google Scholar]

- Dijkstra, E.W. A Note on Two Probles in Connexion with Graphs. Numer. Math. 1959, 1, 269–271. [Google Scholar] [CrossRef]

- Hart, P.E.; Nilsson, N.J.; Raphael, B. A Formal Basis for the Heuristic Determination of Minimum Cost Paths. IEEE Trans. Syst. Sci. Cybern. 1968, 4, 100–107. [Google Scholar] [CrossRef]

- Kavraki, L.E.; Svestka, P.; Latombe, J.; Overmars, M.H. Probabilistic roadmaps for path planning in high-dimensional configuration spaces. IEEE Trans. Robot. Autom. 1996, 12, 566–580. [Google Scholar] [CrossRef]

- LaValle, S.M.; Kuffner, J.J. Randomized kinodynamic planning. In Proceedings of the 1999 IEEE International Conference on Robotics and Automation (Cat. No.99CH36288C), Detroit, MI, USA, 10–15 May 1999; Volume 1, pp. 473–479. [Google Scholar]

- Urmson, C.; Simmons, R. Approaches for heuristically biasing RRT growth. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003) (Cat. No.03CH37453), Las Vegas, NV, USA, 27–31 October 2003; Volume 2, pp. 1178–1183. [Google Scholar]

- Kuffner, J.J.; LaValle, S.M. RRT-connect: An efficient approach to single-query path planning. In Proceedings of the 2000 ICRA. Millennium Conference, IEEE International Conference on Robotics and Automation, Symposia Proceedings (Cat. No.00CH37065), San Francisco, CA, USA, 24–28 April 2000; Volume 2, pp. 995–1001. [Google Scholar]

- Karaman, S.; Frazzoli, E. Sampling-Based Algorithms for Optimal Motion Planning. Int. J. Robot. Res. 2011, 30, 846–894. [Google Scholar] [CrossRef]

- Karaman, S.; Frazzoli, E. Optimal kinodynamic motion planning using incremental sampling-based methods. In Proceedings of the 49th IEEE Conference on Decision and Control (CDC), Atlanta, GA, USA, 15–17 December 2010; pp. 7681–7687. [Google Scholar]

- Hasan, O. RRT*-Smart: Rapid convergence implementation of RRT* towards optimal solution. In Proceedings of the International Conference on Mechatronics & Automation, Chengdu, China, 5–8 August 2012. [Google Scholar]

- Dillmann, R. RRT*-Connect: Faster, Asymptotically Optimal Motion Planning. In Proceedings of the 2015 IEEE International Conference on Robotics and Biomimetics (ROBIO 2015), Zhuhai, China, 6–9 December 2015. [Google Scholar]

- Persson, S.M.; Sharf, I. Sampling-Based A * Algorithm for Robot Path-Planning. Int. J. Robot. Res. 2014, 33, 1683–1708. [Google Scholar] [CrossRef]

- Pavone, M. Fast Marching Tree: A Fast Marching Sampling-Based Method for Optimal Motion Planning in Many Dimensions. Int. J. Robot. Res. 2015, 34, 883–921. [Google Scholar]

- Gammell, J.D.; Srinivasa, S.S.; Barfoot, T.D. Informed RRT*: Optimal sampling-based path planning focused via direct sampling of an admissible ellipsoidal heuristic. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014; pp. 2997–3004. [Google Scholar]

- Gammell, J.D.; Srinivasa, S.S.; Barfoot, T.D. Batch Informed Trees (BIT*): Sampling-based optimal planning via the heuristically guided search of implicit random geometric graphs. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 3067–3074. [Google Scholar]

- Huynh, H.N.; Verlinden, O.; Vande Wouwer, A. Comparative Application of Model Predictive Control Strategies to a Wheeled Mobile Robot. J. Intell. Robot. Syst. 2017, 87, 81–95. [Google Scholar] [CrossRef]

- Li, W.; Yang, C.; Jiang, Y.; Liu, X.; Su, C.Y. Motion Planning for Omnidirectional Wheeled Mobile Robot by Potential Field Method. J. Adv. Transp. 2017, 2017, 4961383. [Google Scholar] [CrossRef]

- Kong, H.; Yang, C.; Li, G.; Dai, S.L. A sEMG-Based Shared Control System with No-Target Obstacle Avoidance for Omnidirectional Mobile Robots. IEEE Access 2020, 8, 26030–26040. [Google Scholar] [CrossRef]

- Chen, W.; Wang, N.; Liu, X.; Yang, C. VFH* Based Local Path Planning for Mobile Robot. In Proceedings of the 2019 2nd China Symposium on Cognitive Computing and Hybrid Intelligence (CCHI), Xi’an, China, 21–22 September 2019; pp. 18–23. [Google Scholar]

- Teatro, T.A.V.; Eklund, J.M. Nonlinear model predictive control for omnidirectional robot motion planning and tracking. In Proceedings of the 26th IEEE Canadian Conference on Electrical and Computer Engineering (CCECE), Regina, SK, Canada, 5–8 May 2013; pp. 1–4. [Google Scholar]

- Liu, J.; Jayakumar, P.; Stein, J.L.; Ersal, T. Combined Speed and Steering Control in High-Speed Autonomous Ground Vehicles for Obstacle Avoidance Using Model Predictive Control. IEEE Trans. Veh. Technol. 2017, 66, 8746–8763. [Google Scholar] [CrossRef]

| Planner | Path Length (m) | Iterations | Computational Time (ms) |

|---|---|---|---|

| RRT* | 4.16 | 3000 | 106.3 |

| BIT* | 4.05 | 1600 | 90.6 |

| Modified BIT* | 3.92 | 800 | 64.2 |

| Prameters | Value | Parameters | Value | Parameters | Value |

|---|---|---|---|---|---|

| 0.1 (s) | diag{50, 20} | p | 10 | ||

| 20 | 40 | q | 0.05 | ||

| 2 | 30 | threshold | 0.8 (m) | ||

| 60 | 2 | 0.5 (m/s) | |||

| 50 | 0.3 (m/s) | 0.6 (rad/s) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, P.; Wang, N.; Dai, S.-L.; Zuo, L. Motion Planning for Mobile Robot with Modified BIT* and MPC. Appl. Sci. 2021, 11, 426. https://doi.org/10.3390/app11010426

Xu P, Wang N, Dai S-L, Zuo L. Motion Planning for Mobile Robot with Modified BIT* and MPC. Applied Sciences. 2021; 11(1):426. https://doi.org/10.3390/app11010426

Chicago/Turabian StyleXu, Puyong, Ning Wang, Shi-Lu Dai, and Lei Zuo. 2021. "Motion Planning for Mobile Robot with Modified BIT* and MPC" Applied Sciences 11, no. 1: 426. https://doi.org/10.3390/app11010426

APA StyleXu, P., Wang, N., Dai, S.-L., & Zuo, L. (2021). Motion Planning for Mobile Robot with Modified BIT* and MPC. Applied Sciences, 11(1), 426. https://doi.org/10.3390/app11010426